Nano SiO2 high-strength waterproof impermeable mortar and preparation method thereof

A waterproof, impermeable, nano-technology, applied in the field of building materials, can solve the problems of reducing the strength and toughness of concrete, cracking of the concrete structure, etc., and achieve the effect of improving the density, improving the integrity, and reducing the number of crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

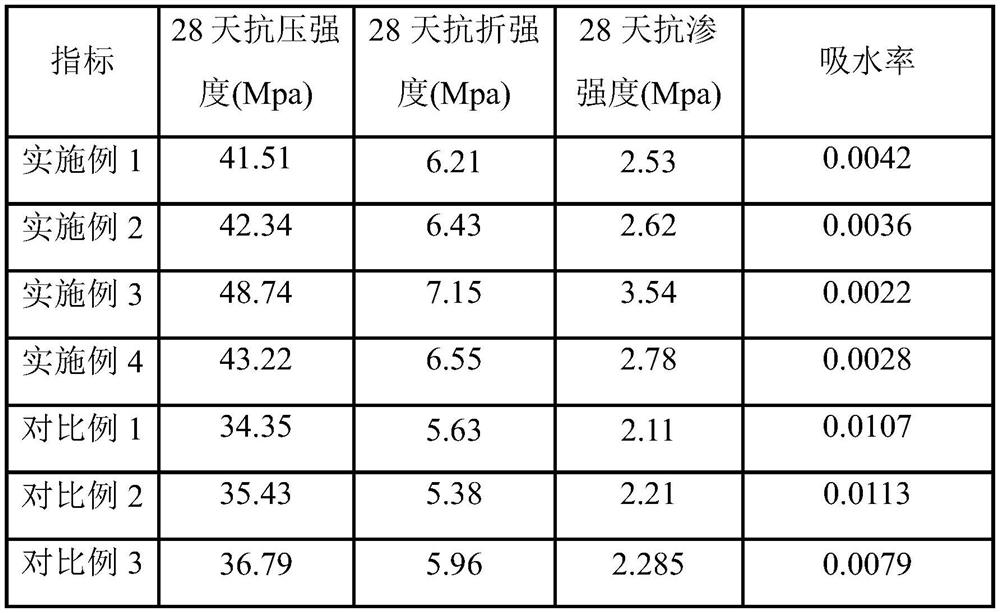

Examples

Embodiment 1

[0023] A kind of nano-SiO 2 High-strength waterproof and anti-seepage mortar, including the following raw materials in parts by weight: 60-100 parts of cement, 36-72 parts of water, 160-300 parts of sand, 6-15 parts of fly ash, 0.5-2 parts of nano-SiO 2 Dispersion liquid, 0.6-2.4 parts of polypropylene fiber, 0.2-0.8 parts of water reducing agent, 0.8-2 parts of polyvinyl alcohol, 1-4 parts of early strength agent.

[0024] It should be noted that the accelerator in the examples of the present application includes a mixture of magnesium chloride and triethanolamine, wherein the mass ratio of magnesium chloride and triethanolamine is 1:(3-5).

[0025] In each embodiment and comparative example in this application, nano-SiO 2 The solutions were purchased from Hangzhou Hengge Nano Technology Co., Ltd., where SiO 2 The mass content of SiO is 25-35%. 2 The average particle size is 8-30nm.

[0026] In the examples of this application, the cement is Portland cement with a strengt...

Embodiment 2

[0038] The nano-SiO of the embodiment of the present application 2 The preparation method of high-strength waterproof and anti-seepage mortar is the same as that of Example 1, except that the added 0.9 parts by weight of nano-SiO 2 solution.

Embodiment 3

[0040] The nano-SiO of the embodiment of the present application 2 The preparation method of high-strength waterproof and anti-seepage mortar is the same as that of Example 1, except that 1.2 parts by weight of nano-SiO 2 solution,

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com