Cement-based modified composite material and preparation method thereof

A composite material and cement-based technology, applied in the field of concrete construction, can solve the problems of excessive heavy metal precipitation and performance degradation, and achieve the effects of improving the performance of molecular structure, reducing shrinkage and excellent performance indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The second aspect of the embodiment of the present application provides a method for preparing a cement-based modified composite material, comprising the following steps:

[0053] S01. Performing a first mixing treatment on Portland cement, slag, incineration fly ash, water-absorbing polymer and polycarboxylate superplasticizer to obtain a first mixture;

[0054] S02. performing a second mixing process on the first mixture and water to obtain a second mixture;

[0055] S03. The second mixture is subjected to a standing treatment, and then a third mixing treatment is performed to obtain a cement-based modified composite material.

[0056] The preparation method of the cement-based modified composite material provided in the second aspect of the present application, the preparation method provides the components of the cement-based modified composite material, mixes the solid components, and then adds water for mixing to obtain the cement-based modified composite material...

Embodiment 1

[0063] Cement-based modified composite material and preparation method thereof

[0064] Cement-based Modified Composite Materials

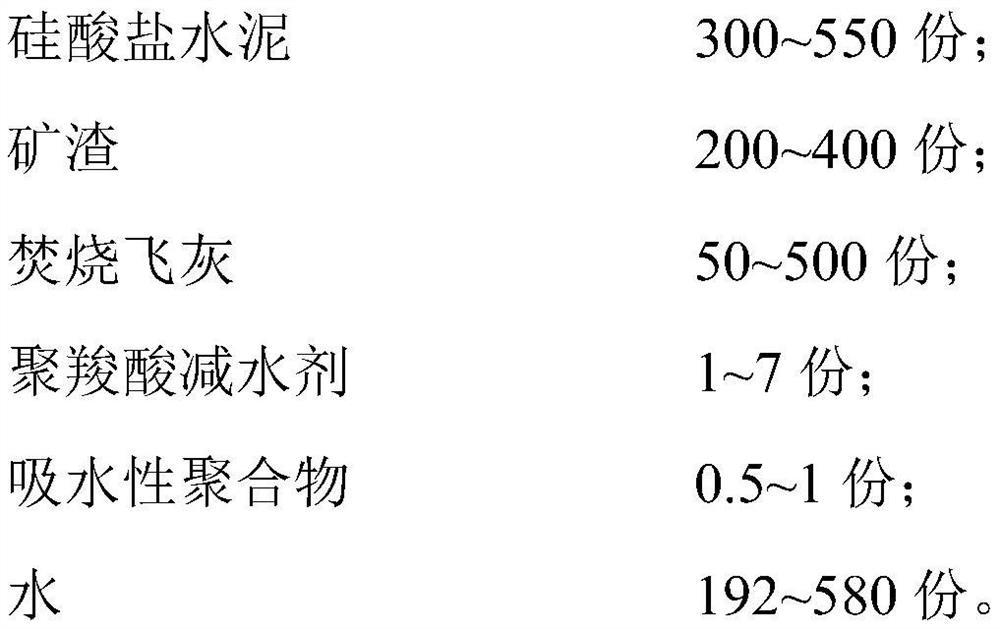

[0065] The cement-based modified composite material comprises the following components in the following parts by weight:

[0066]

[0067] Among them, the grade of Portland cement is selected from 42.5R;

[0068] The particle size of incineration fly ash is selected from 1 to 110 microns, taking the mass of incineration fly ash as 100%, the mass percentage of incineration fly ash with a particle size of 3 microns or less is 22 wt%, and the particle size is 3 to 32 microns The mass percentage of incineration fly ash is 58 wt%, the mass percentage of incineration fly ash with a particle size of 32 to 65 microns is 15 wt%, and the mass percentage of incineration fly ash with a particle size of 65 microns or more is 5wt%;

[0069] Polycarboxylate water reducer selected from SK-67;

[0070] The water-absorbing polymer is selected from crossli...

Embodiment 2

[0077] Cement-based modified composite material and preparation method thereof

[0078] Cement-based Modified Composite Materials

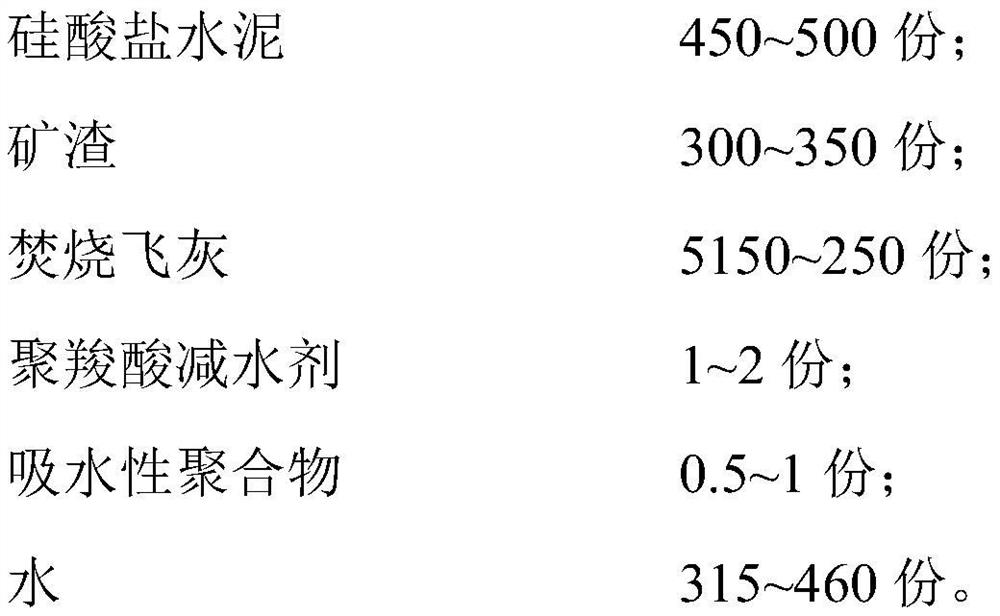

[0079] The cement-based modified composite material comprises the following components in the following parts by weight:

[0080]

[0081] Among them, the grade of Portland cement is selected from 42.5R;

[0082]The particle size of incineration fly ash is selected from 1 to 110 microns, taking the mass of incineration fly ash as 100%, the mass percentage of incineration fly ash with a particle size of 3 microns or less is 22 wt%, and the particle size is 3 to 32 microns The mass percentage of incineration fly ash is 58 wt%, the mass percentage of incineration fly ash with a particle size of 32 to 65 microns is 15 wt%, and the mass percentage of incineration fly ash with a particle size of 65 microns or more is 5wt%;

[0083] Polycarboxylate water reducer selected from SK-67;

[0084] The water-absorbing polymer is selected from crosslin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com