Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Low pore volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal organic framework material used for absorbing and separating CO2 and preparation method thereof

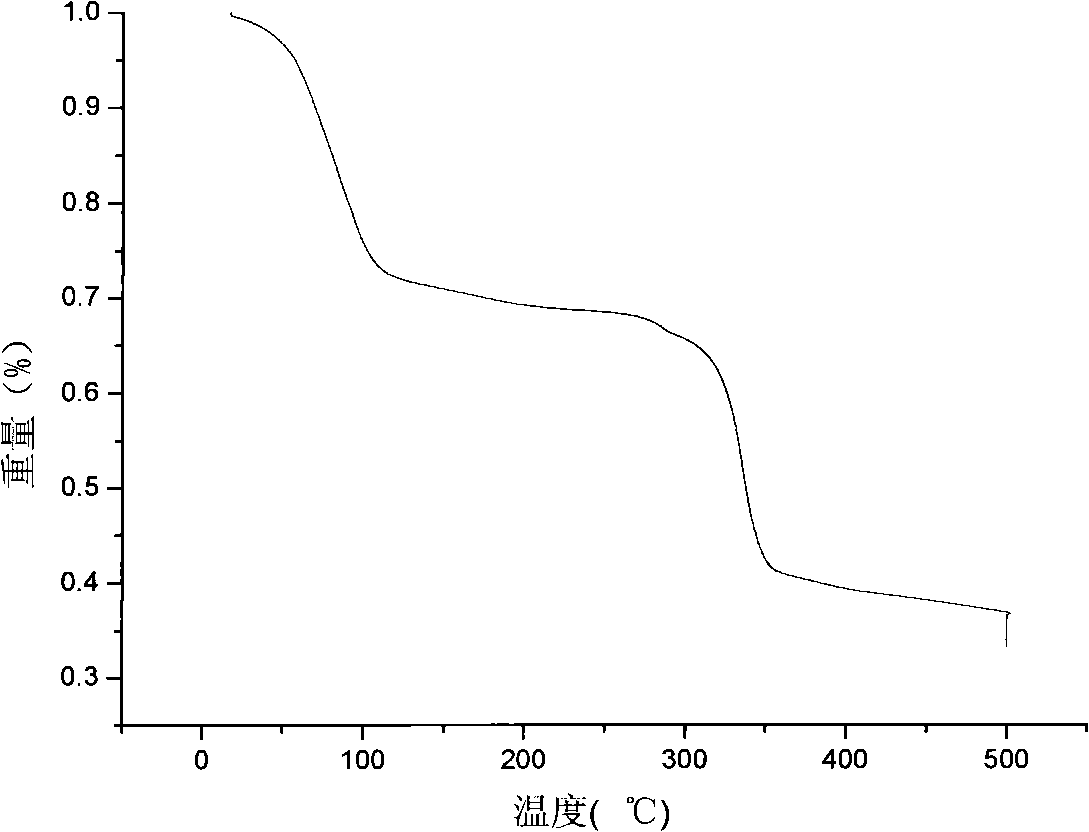

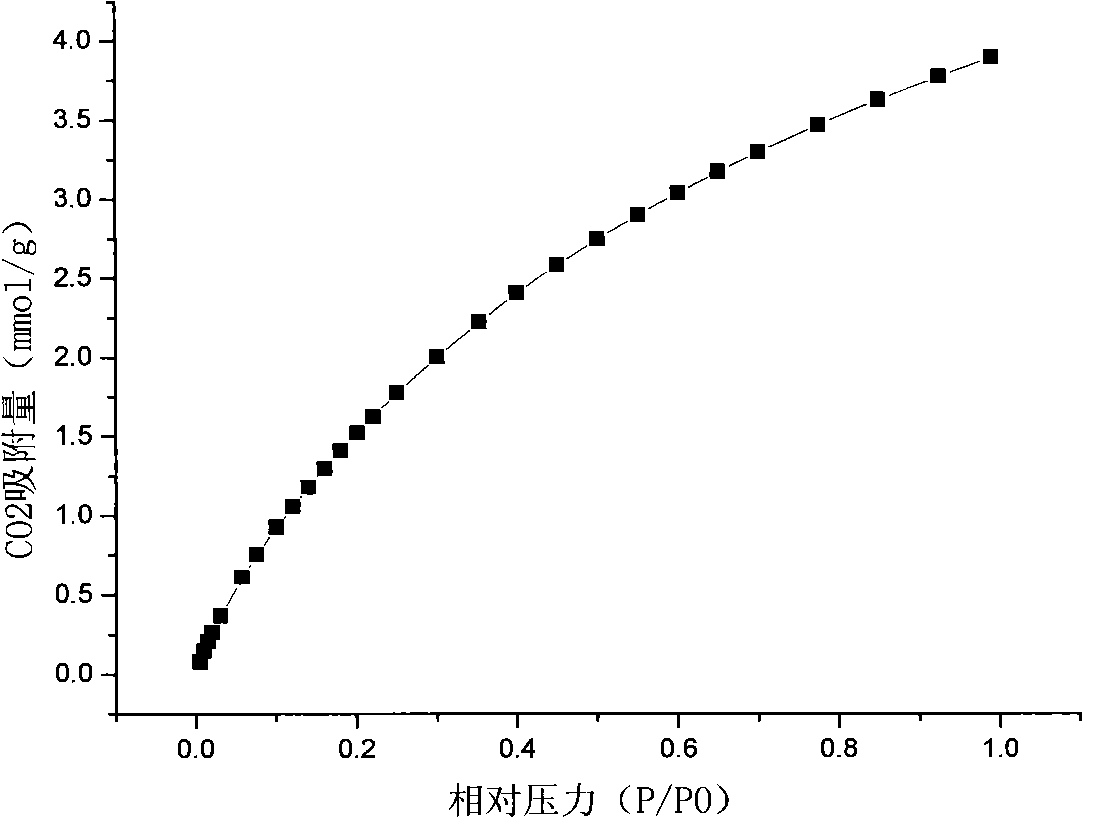

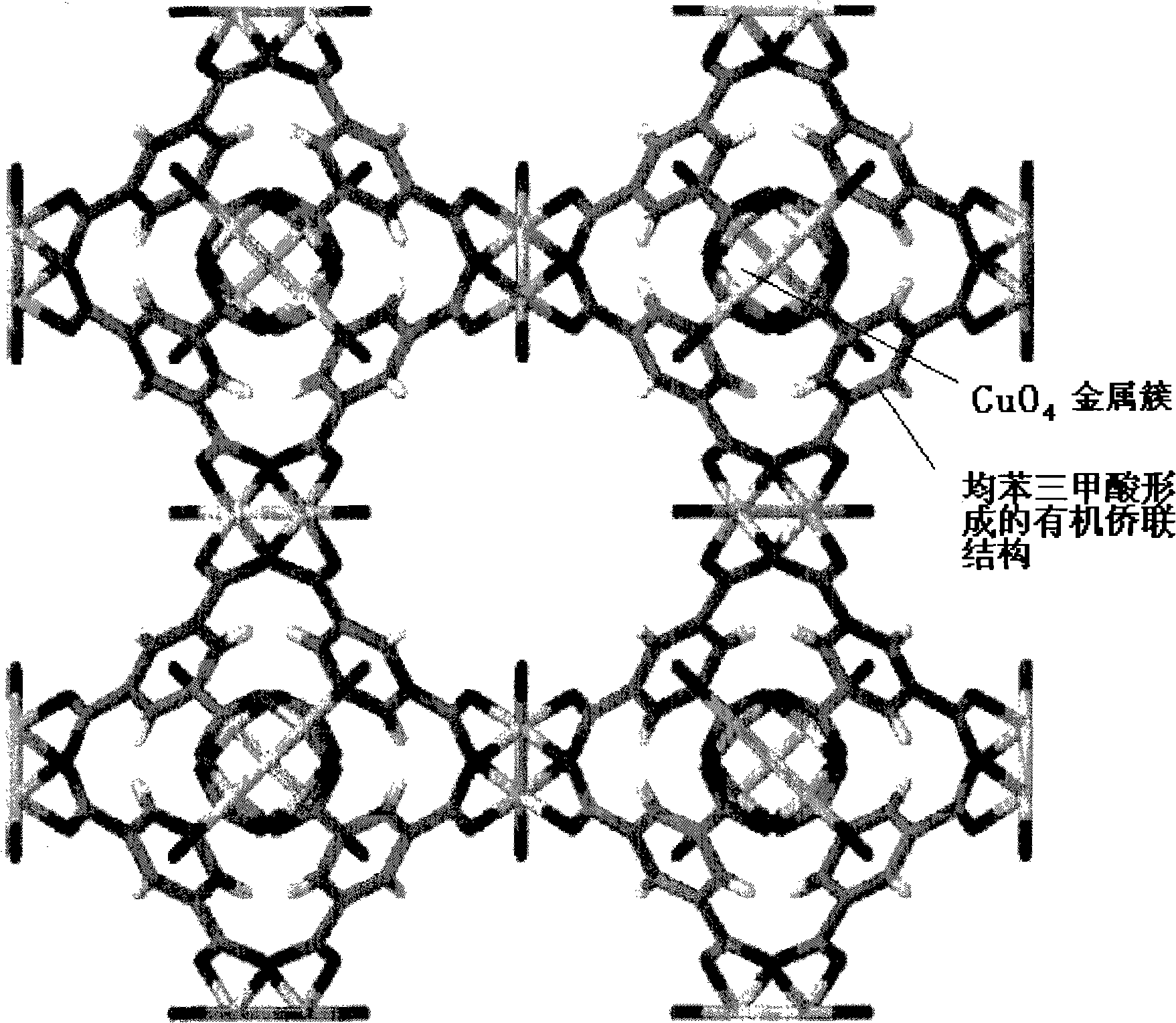

InactiveCN101816924ALarge specific surface areaImprove adsorption capacityProductsCarbon compoundsMetal-organic frameworkChemical measurement

The invention provides a metal organic framework material used for absorbing and separating CO2 and a preparation method thereof. The metal organic framework material is a rigid metal carboxyl compound cluster-like structure which is formed by transition metal ions and multidentate organic ligands through covalent bonds and intermolecular forces. An amine polymer is modified on the metal organic framework material; and the metal organic framework material used for absorbing and separating the CO2 has a specific surface area of 1,000 to 1,200 m<2> / g, and a pore volume of 0.4 to 0.6 cm<3> / g. The preparation method comprises the following steps of: respectively dissolving the nitrate, the chloride or the carbonate of copper or zinc and 1,3,5-trimesic acid together in a stoichiometric ratio in water or an organic solvent; mixing uniformly and sufficiently to react to obtain a BTC bridged complex crystal; and applying a product obtained by reacting an obtained BTC bridged complex crystal with the solution of polyethyleneimine to the metal organic framework material used for absorbing and separating the CO2. The material can realize selective absorption of a gas under a low pressure.

Owner:SOUTHEAST UNIV

Method for preparing hydrocracking catalyst

ActiveCN103191774AIncrease the apertureLow pore volumeMolecular sieve catalystsHydrocarbon oil crackingPolymer scienceFiltration

The invention discloses a method for preparing a hydrocracking catalyst. The method comprises the following steps of carrying out hydrothermal treatment on alumina dry gel powder, uniformly mixing the treated alumina dry gel powder and at least one acidic cracking material powder, dipping the mixture into a hydrogenation active ingredient-containing metal salt solution, carrying out filtration, drying and crushing, adding a peptizing agent or a binder into the crushed product, and carrying out molding, drying and calcination to obtain the hydrocracking catalyst. The hydrocracking catalyst has high hydrogenation active ingredient content, a large pore volume, a large aperture size and a large specific surface area, and is suitable for hydrocracking of a heavy vacuum distillate having a higher boiling point.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst and preparation method thereof

ActiveCN102463131AHigh active metal contentIncrease the apertureMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst and a preparation method thereof. The preparation method comprises the following steps: 1, dipping aluminum hydroxide xerogel powder used in a carrier in a solution containing a hydrogenation metal component; 2, drying the powder; and 3, fully rolling, molding and roasting the powder together with molecular sieve under the action of a peptizer or a binder to obtain the catalyst. The catalyst of the invention is obtained only through one-time high temperature roasting, so the preparation method is simple, and the preparation cost is obviously reduced. In addition, the hydrogenation center and the cracking center of the catalyst of the invention coordinate and cooperate with each other, so the catalyst has a high catalytic activity, and the catalyst which simultaneously has a large specific surface area and a large pore volume is suitable for processing catalytic process for the high productivity of naphtha by hydrocracking high-dry-point low-quality reduced pressure distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of sulfurization type hydro-cracking catalyst

ActiveCN103769198AIncreased degree of vulcanizationImprove hydrogenation performanceMolecular sieve catalystsHydrocarbon oil crackingNickel saltTungstate

The invention discloses a preparation method of a sulfurization type hydro-cracking catalyst. The preparation method comprises the following steps: selecting a hydro-cracking catalyst carrier component, wherein the carrier component at least comprises an acidic cracking component; adding water into the carrier component powder, pulping so as to obtain slurry (c), then adding sulfo-molybdate and / or sulfo-tungstate slurry (a) and a nickel salt and / or cobalt salt solution (b) into the slurry (c), evenly stirring, filtering, washing, drying in the protection of inert gas, adding an adhesive, kneading, forming, and finally drying and burning in the protection of inert gas so as to obtain the sulfurization type hydro-cracking catalyst. The preparation method makes the active metal be evenly distributed on the carrier so as to generate more II type Ni(Co)Mo(W)S active phases with a higher activity; thus the catalyst has a high sulfurization degree and a high utilization rate of active metal, so that the hydrogenation performance of the catalyst is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-specific surface area mesoporous nickel oxide hydrogenation catalyst and preparation method thereof

ActiveCN102824912ASmall specific surface areaLow pore volumeCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsInorganic saltsNickel salt

The invention discloses a high-specific surface area mesoporous nickel oxide hydrogenation catalyst and a preparation method of the high-specific surface area mesoporous nickel oxide hydrogenation catalyst. The preparation method of the catalyst comprises the following steps of: taking high-specific surface area mesoporous nickel oxide as a carrier and active metal, taking sol prepared by peptizing agent and metallic nickel inorganic salt as binder, kneading in a mixing way, forming by means of strip squeezing, drying and roasting, so that the catalyst can be prepared. The high-specific surface area mesoporous nickel oxide carrier used in the catalyst disclosed by the invention takes nickel salt as a nickel source, non-ionic surface active agent as structure-directing agent, and organic matter having the function of solubilization as auxiliary pore-forming agent, and is prepared by a sol-gel method. According to the catalyst disclosed by the invention, the problems that the nickel hydrogenation catalyst is prepared by taking nickel oxide and aluminum oxide as carriers, the specific surface area of the catalyst is reduced, and the pore volume is lowered when the nickel content is higher in the catalyst in the prior art can be solved; and the catalyst is high in hydrogenation activity, high in raw material adaptability, and good in running stability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Structurally Enhanced Cracking Catalysts

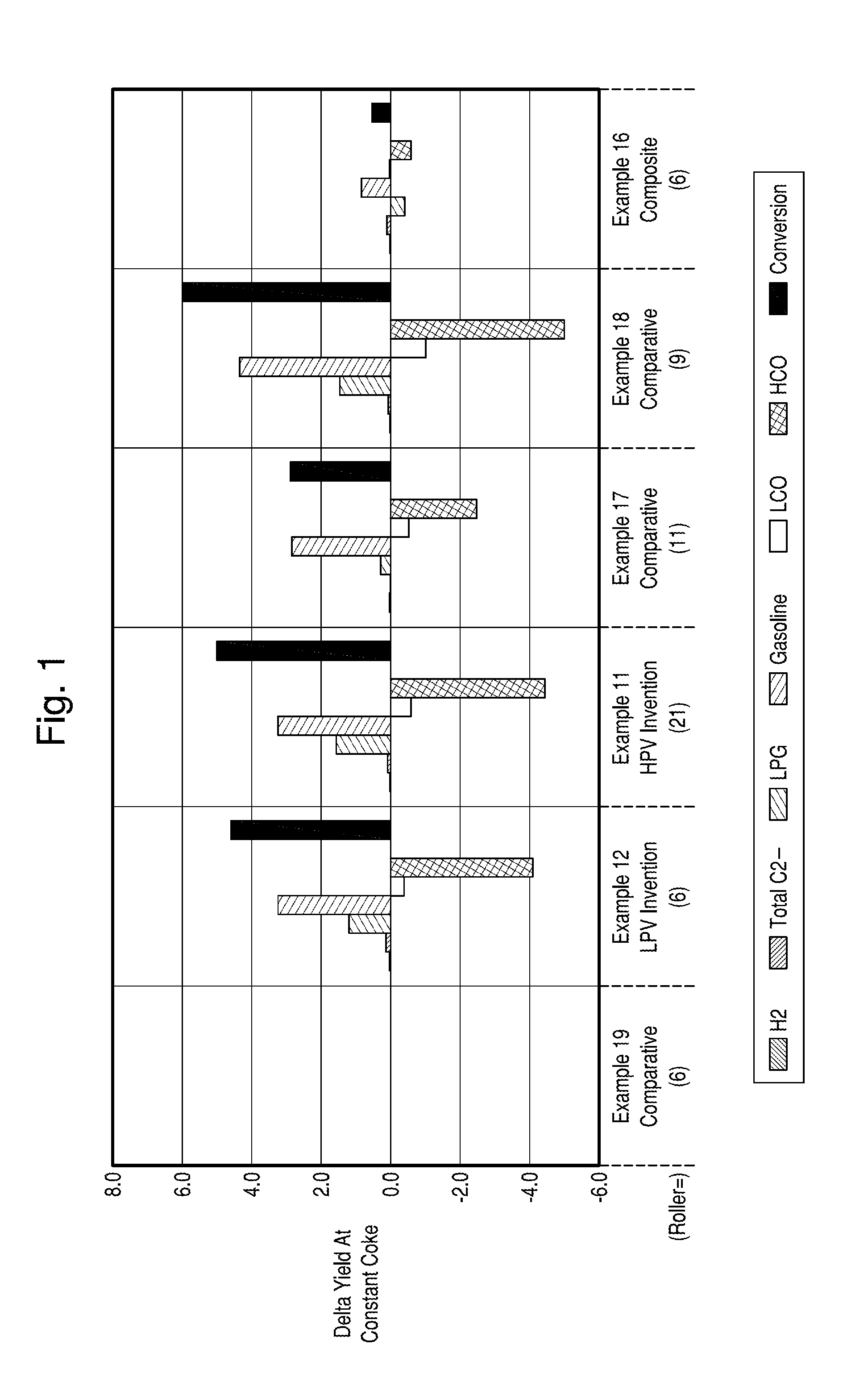

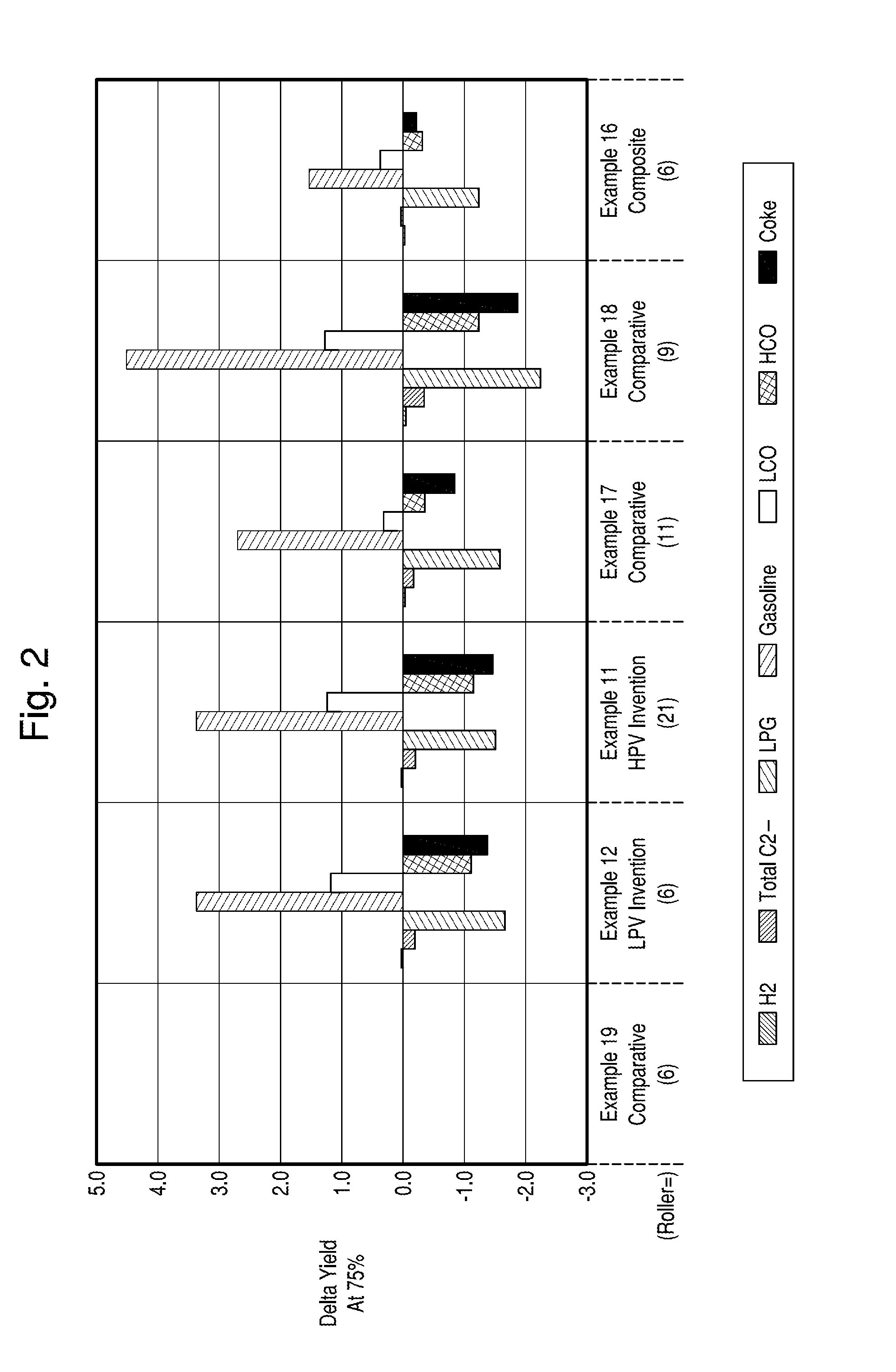

InactiveUS20110000821A1Reduced pore volumeIncrease coverageCatalytic crackingMolecular sieve catalystsOrganic chemistryPtru catalyst

Owner:BASF CORP

Prepn process of hydroprocessing catalyst

ActiveCN101088610AHigh pore volumeHigh surface areaMetal/metal-oxides/metal-hydroxide catalystsPlastic materialsActive component

The present invention relates to preparation process of hydrocarbon hydroprocessing catalyst, which has gamma-Al2O3 as carrier, VIB and VIII metal as the active component, and Ti, etc as the active assistant, with the assistant Ti being introduced in the pH swinging carbonization process for producing aluminum hydroxide. The process of preparing the catalyst is one complete mixing and kneading process including the steps of introducing Ti to aluminum hydroxide powder via adding Ti salt solution, adding Mo and / or W containing alkaline solution, mixing and kneading until the aluminum hydroxide powder is wetted completely by the alkaline solution, adding Co and / or Ni containing acid solution, mixing and kneading to obtain plastic material, extruding, drying, and roasting to obtain the catalyst. The catalyst has homogeneously distributed Ti component and obviously raised performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN103191772AIncrease the apertureLarge apertureMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a preparation method of a hydrocracking catalyst. The preparation method comprises the following steps of carrying out low-temperature hydro-thermal treatment on alumina dry gel powder in the ammonia-containing water vapor atmosphere, dipping the alumina dry gel powder subjected to hydro-thermal treatment into a solution containing a hydrogenation active metal ingredient, carrying out drying, and carrying out full grinding, molding, drying and calcination of the alumina dry gel powder with the hydrogenation active metal ingredient, and a molecular sieve in the presence of a peptizer or a binder to obtain the hydrocracking catalyst. The preparation method improves a catalyst pore structure. The hydrocracking catalyst obtained by the preparation method has a large specific surface area and a large pore volume, is conducive to optimized cooperation of a hydrogenation ingredient and a cracking ingredient, has high catalytic activity, and is suitable for hydrocracking yield-increasing of high-quality heavy naphtha from vacuum distillate having a high dry point and poor quality and for a catalytic process for improvement of tail oil product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for utilizing waste hydro-treatment catalyst

ActiveCN103769173APhysical properties (lower than surfaceLow pore volumeOrganic compound preparationCarbonyl compound preparationPartial oxidationAcrolein

The invention discloses a method for utilizing waste hydro-treatment catalyst. The method utilizes waste hydro-treatment catalysts which have been used in partial oxidation of propane to prepare acrolein and hydro-treatment, recycles the Mo, Co, Ni, and alumina carriers in waste hydro-treatment catalysts, also fully recycles Ni and V which are deposited on the waste hydro-treatment catalysts, thus solves the pollution problem caused by waste catalysts, saves the resources, increases the economic profit, and is easy to carry out in technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

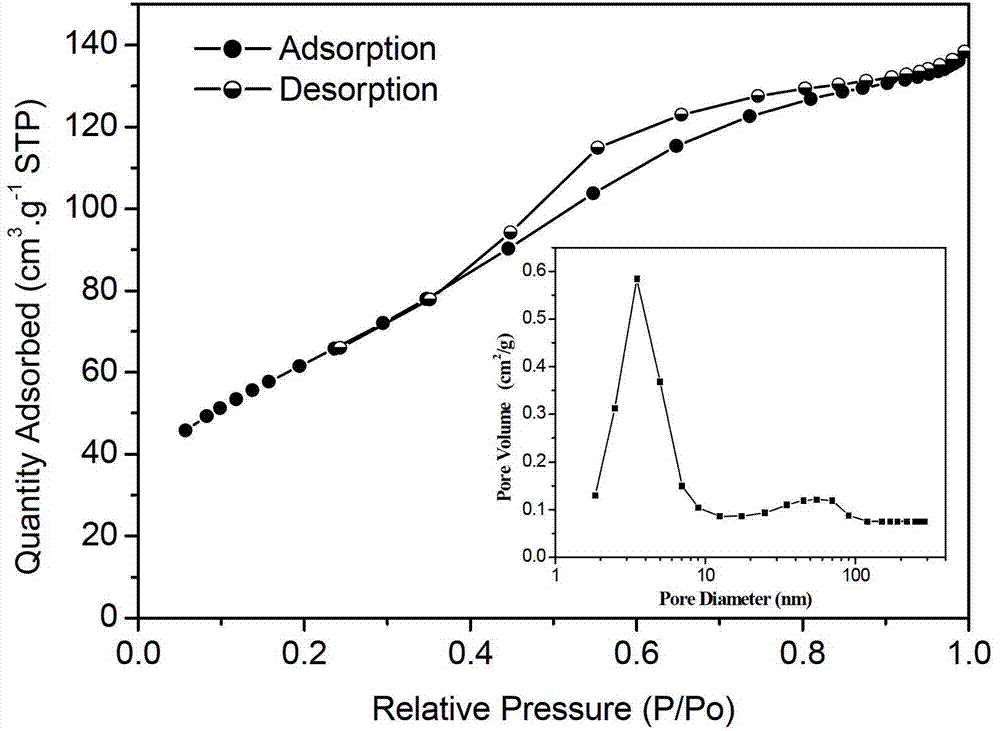

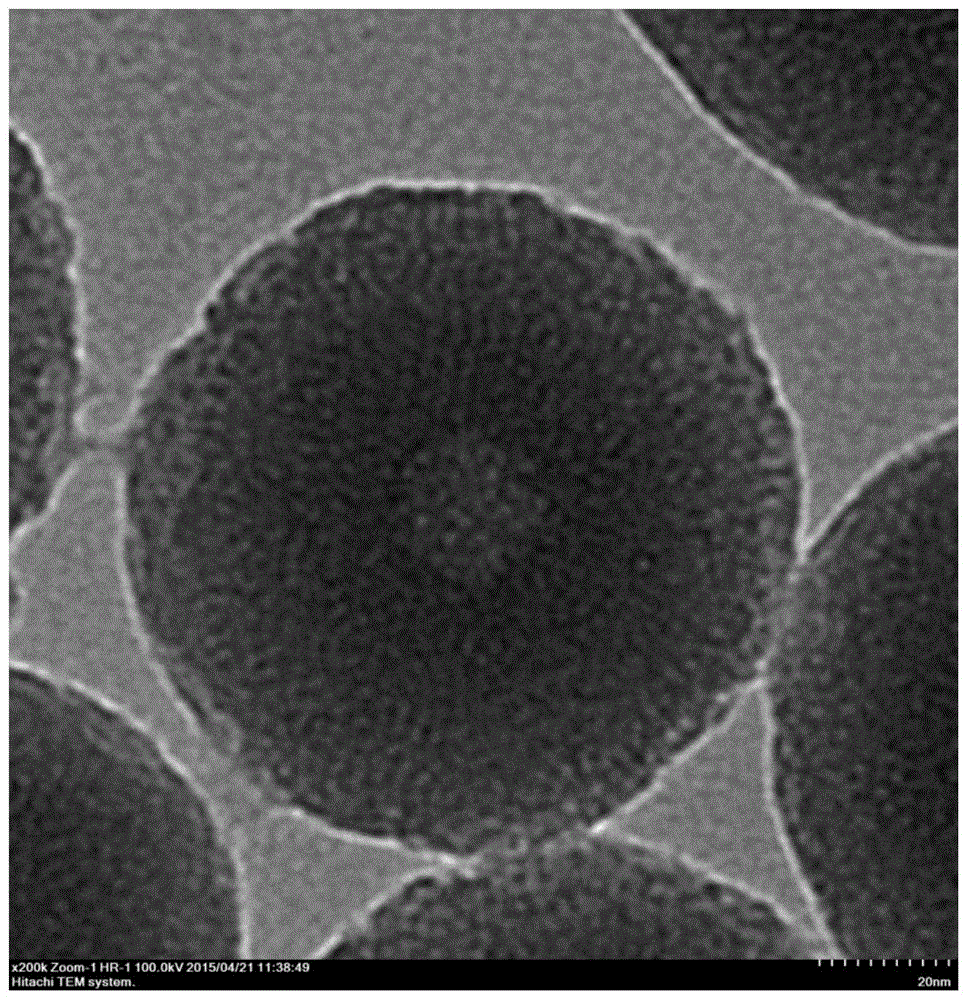

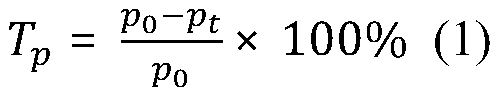

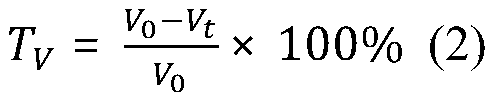

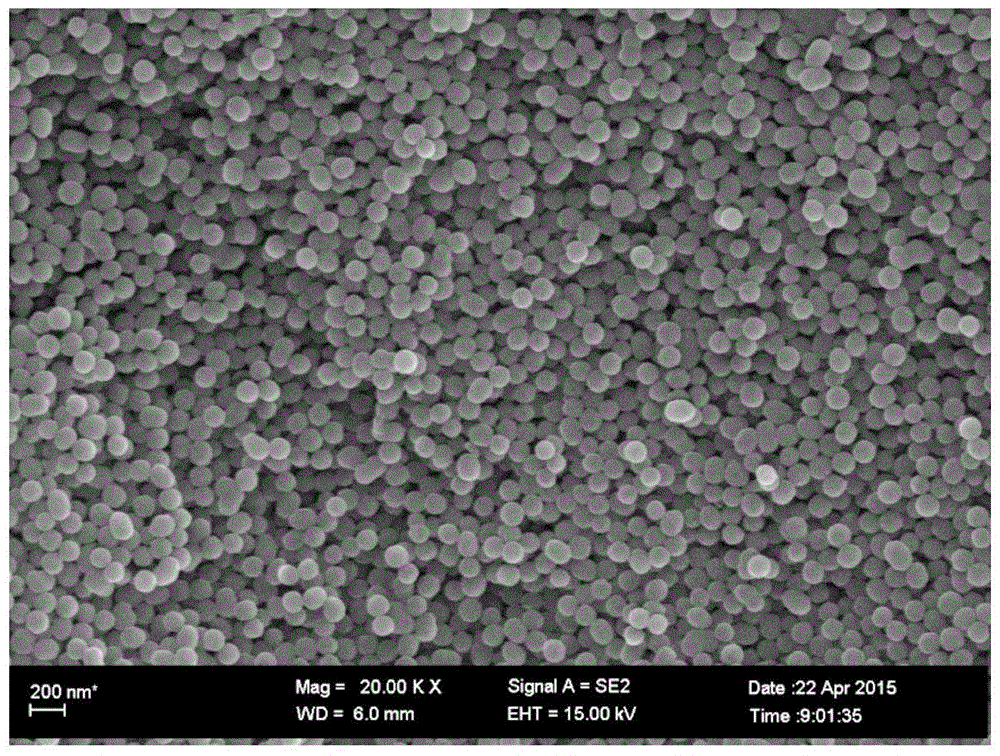

Ordered mesoporous organic silicon oxide hollow ball prepared through one-step method and preparation method of ordered mesoporous organic silicon oxide hollow ball

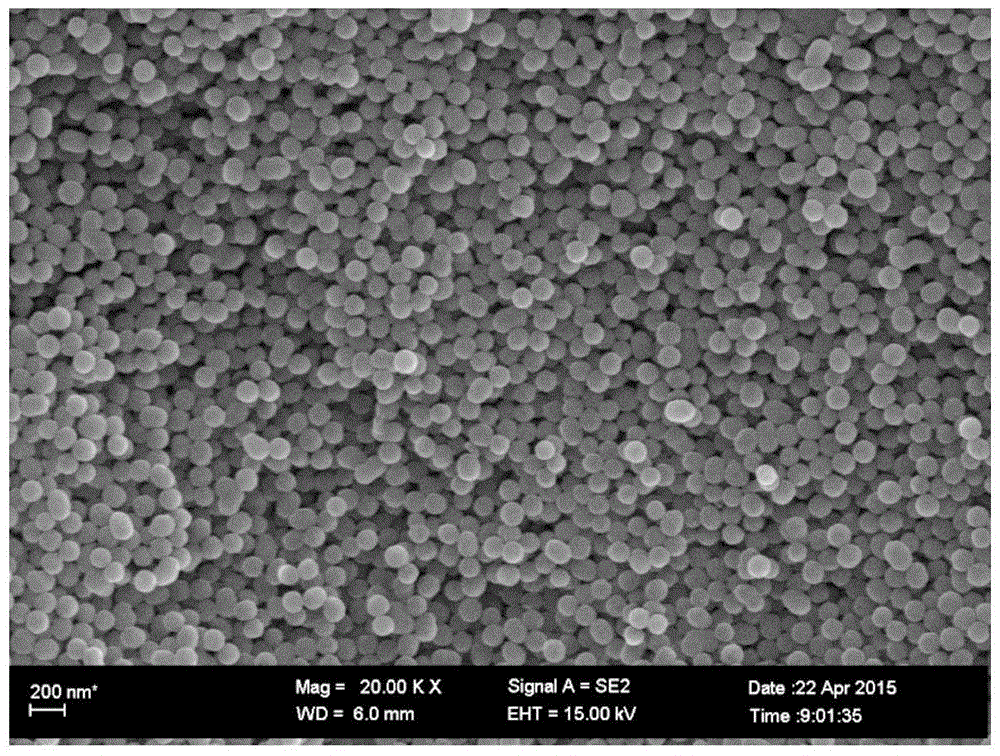

ActiveCN105036145AFast preparationSimple manufacturing processSilicaSpherical morphologySilicon oxide

The invention relates to an ordered mesoporous organic silicon oxide hollow ball prepared through a one-step method and a preparation method of the ordered mesoporous organic silicon oxide hollow ball. The prepared ordered mesoporous organic silicon oxide hollow ball has good spherical morphology. The ball grain size ranges from 50 nm to 100 nm. The ball grain size distribution is uniform. The ordered mesoporous organic silicon oxide hollow ball is high in monodispersity, strength and dispersibility. A spherical shell comprises ordered radial mesoporous ducts. The preparation method is simple and easy to implement and can be easily conducted in an industrial mode. The ordered mesoporous organic silicon oxide hollow ball can be prepared through one step without sacrificial template or postprocessing. The fastest preparation process lasts for only 0.25 h. By means of the structure, reaction molecules or medicine molecules can conveniently enter and leave the ordered mesoporous organic silicon oxide hollow ball, and the ordered mesoporous organic silicon oxide hollow ball has good application prospects in the fields of medicine slow release, release control, medical imaging, catalysis and the like.

Owner:TSINGHUA UNIV +1

Preparation method of hydrocarbon hydrotreatment catalyst

The invention relates to a preparation method for a catalyst to hydrotreat hydrocarbons, which comprises gama- Al2O3 as carrier, metal from VIB group and VIII group as active constituents, and Ti as active adjuvant. The prepraration method comprises: adding titanate solution to bring said Ti during the gelatinization for preparing aluminum hydroxide; adding basic solution contained Mo or W into the dried aluminum hydroxide powder, mixing till the powder wet fully by solution; adding acid solution contained Co or Ni, mixing till plastic, extruding to form, drying, baking, and obtaining the catalyst. This invention improves the catalyst property obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified activated carbon and method for regenerating active carbon by photocatalysis of gas-solid fluidized bed

ActiveCN102527336ARestore adsorption capacityReduce lossesOther chemical processesCombustible gas purificationThioureaSorbent

The invention discloses a modified activated carbon. The modified activated carbon is characterized in that a S-TiO2 photocatalyst is loaded on the active carbon. A method for preparing the modified activated carbon comprises the following steps of: adopting an inorganic salt or alcohol salt of titanium as a TiO2 precursor, adopting thiourea as a sulfur source, hydrolyzing sol for preparing inorganic hydrated metal oxide S-TiO2, adding the PEG and the activated carbon, stirring or ultrasonically mixing to be uniform, carrying out dipping treatment, drying and roasting the activated carbon after dipping treatment, and obtaining the modified activated carbon. The activated carbon can adopt a gas-solid fluidized bed photocatalytic method for regeneration. The modified activated carbon belongs to a suitable novel absorbent. The gas-solid fluidized bed photocatalytic method is simple, no secondary pollution is caused, the loss of the activated carbon is less, and the mechanical strength is not changed basically, so that the activated carbon and the regeneration technology thereof disclosed by the invention are environmentally-friendly.

Owner:NANJING NORMAL UNIVERSITY

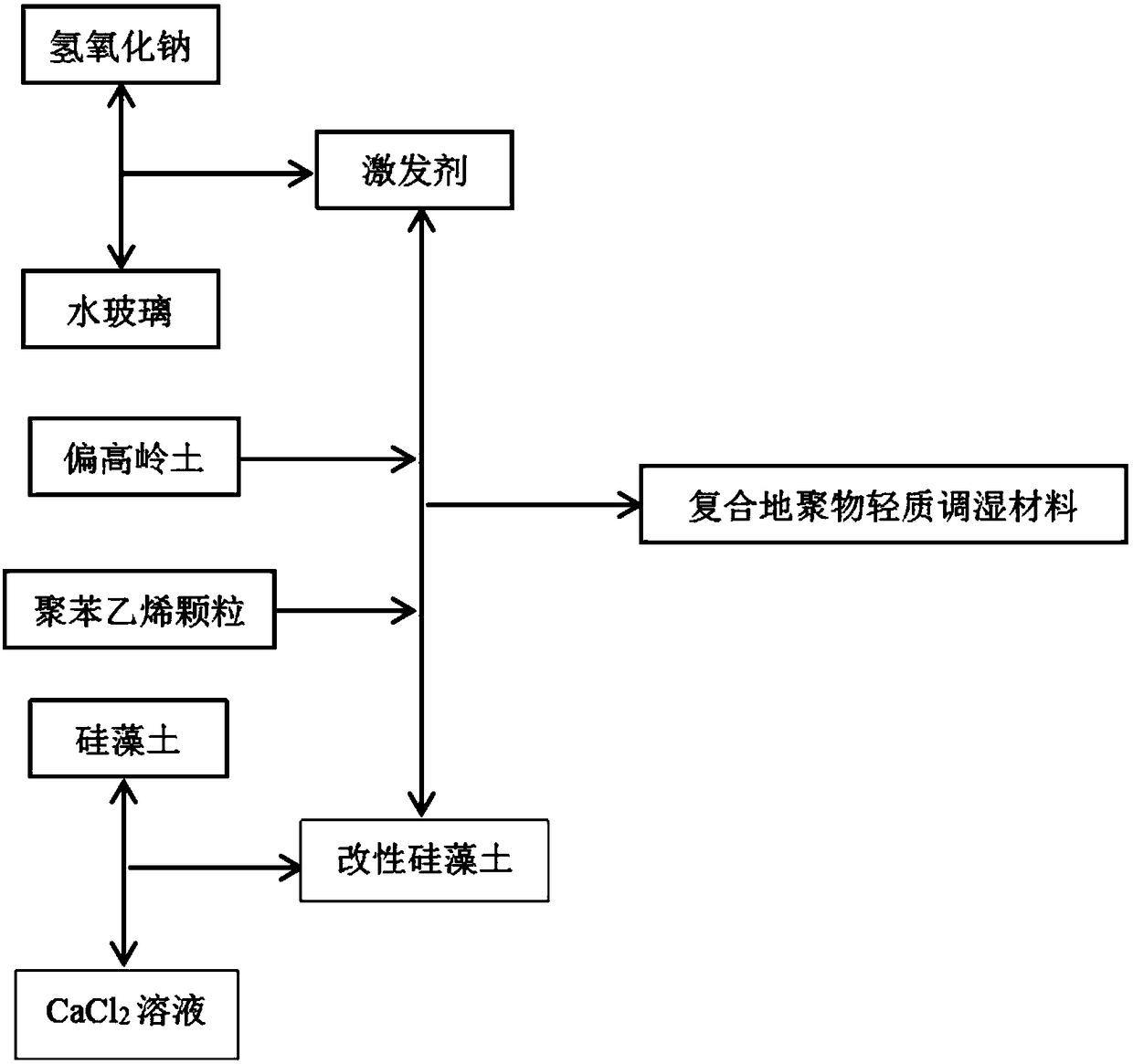

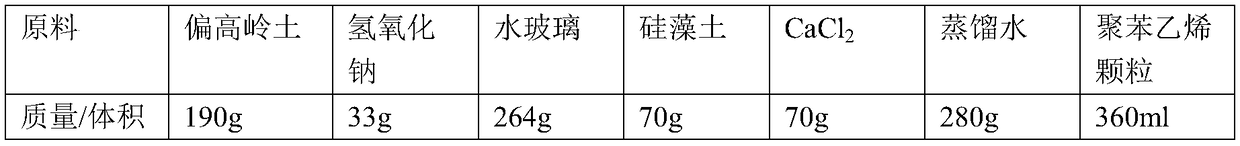

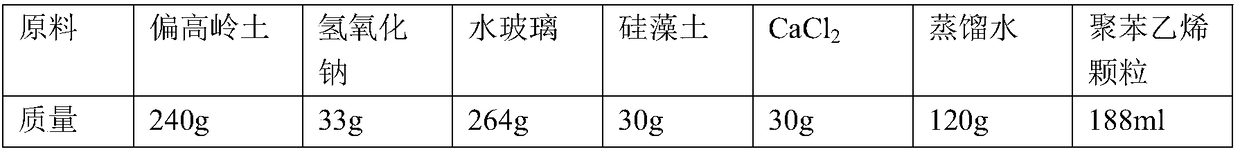

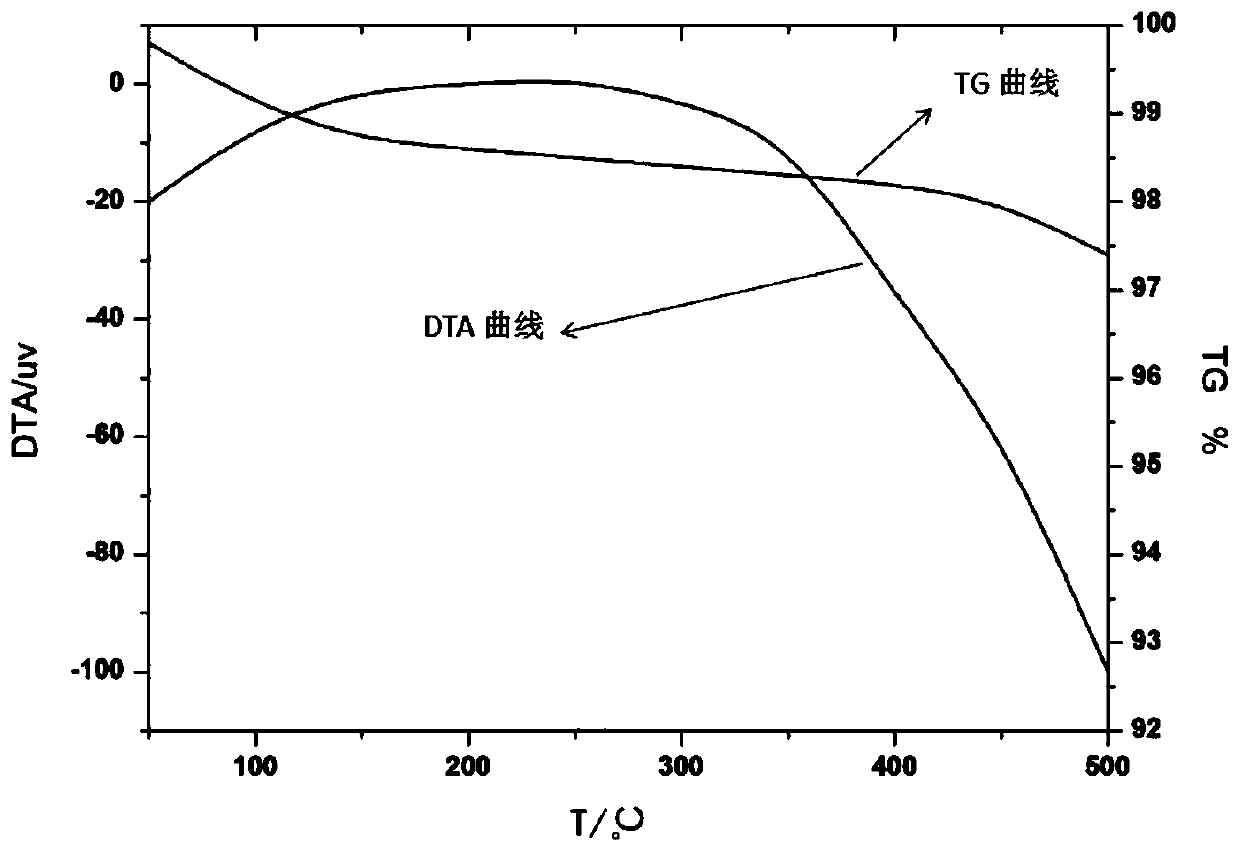

Composite geopolymer lightweight moisture-regulating material and preparation method thereof

ActiveCN109250964AHigh strengthFast moisture absorption and desorption reactionCement productionPolymer scienceDesorption

The invention relates to a composite geopolymer lightweight moisture-regulating material and a preparation method thereof, and belongs to the technical field of composite materials. The moisture-regulating material is prepared from the following components: 100 parts by mass of a cementitious material, 105-115 parts by mass of an activator, and a light aggregate having the amount accounting for 2-5 times the volume of metakaolin, wherein the cementitious material is composed of 70-90 parts by mass of metakaolin and 10-30 parts by mass of modified diatomite, and the light aggregate is polystyrene particles. The preparation method comprises the steps: firstly, stirring solid powder evenly, adding the liquid activator, fully stirring in a concrete stirrer, then adding the polystyrene particles, stirring evenly, pouring into a mould smeared with demoulding oil in advance, placing the mould on a horizontal table top, allowing to stand, curing at room temperature for 1 d, then demoulding totake out a plate-shaped finished product. The prepared moisture-regulating material has the characteristics of high efficiency moisture absorption and desorption, light weight, heat preservation and high strength, no pollution in the preparation process, low energy consumption, no needing of pressure forming and simple process.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Preparation method of hydrocracking catalyst

ActiveCN103191775AEvenly dispersedGood dispersionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a preparation method of a hydrocracking catalyst. The preparation method comprises carrying out low-temperature hydro-thermal treatment on alumina dry gel powder, dipping the alumina dry gel powder into a hydrogenation active metal-containing solution, carrying out drying, and carrying out full grinding, molding, drying and calcination of the dipped material with a molecular sieve in the presence of a peptizing agent or a binder. The preparation method improves a catalyst pore structure. The hydrocracking catalyst has a large specific surface area and a large pore volume, is conducive to optimization cooperation of a hydrogenation ingredient and a cracking ingredient, has high catalytic activity, and is suitable for hydrocracking yield-increasing of high-quality heavy naphtha from vacuum distillate having a high dry point and poor quality and for improvement of tail oil product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

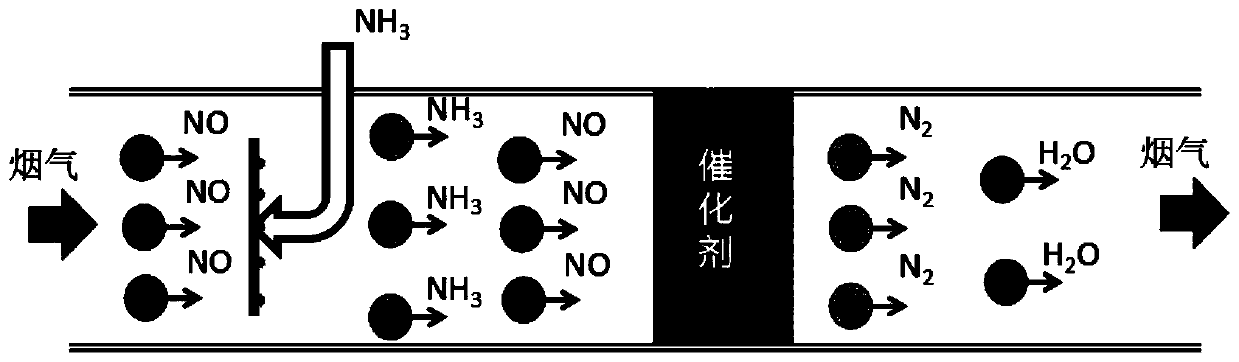

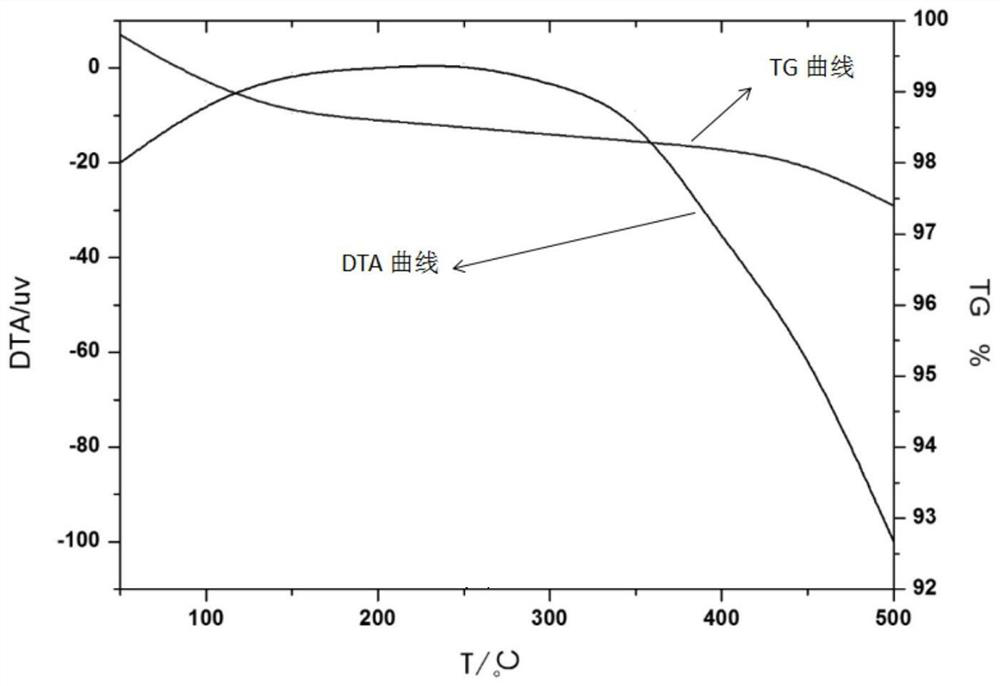

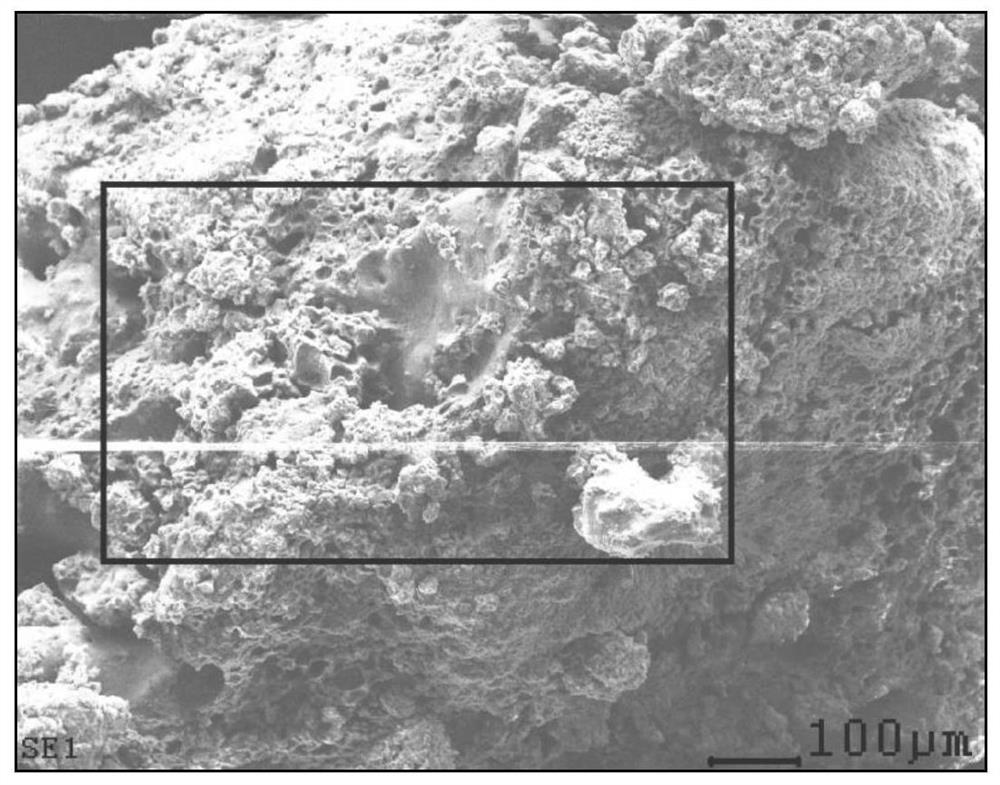

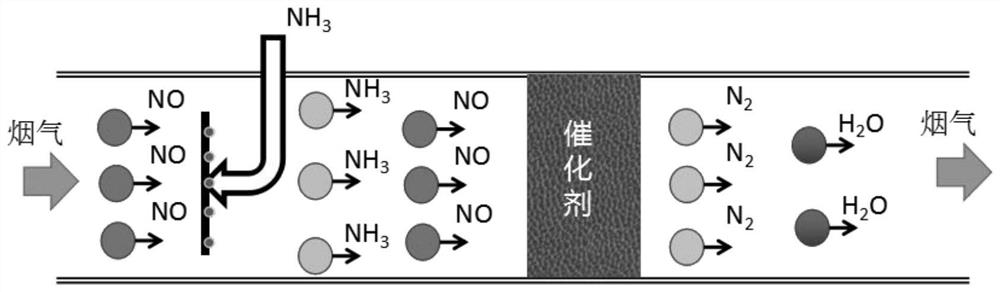

Method for preparing SCR denitration catalyst at low temperatures

ActiveCN110052264AReduce concentrationLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsOrganic acidMolecular sieve

The invention relates to a method for preparing an SCR denitration catalyst at low temperatures. The method includes dissolving a titanium source in absolute ethyl alcohol, regulating the pH value to2-6 by an organic acid solution, adding a rare earth metal precursor, mixing a pore-forming agent, stirring to react at 60-90 DEG C for 2-8 hours, drying after the ethyl alcohol evaporates, and roasting at 500-800 DEG C for 8-12 hours so as to obtain a molecular sieve carrier; impregnating the molecular sieve carrier by one or more of a precursor metal salt of a transition metal oxide, an acid solution or a complex for 2-8 hours, and drying at a room temperature so as to obtain an impregnated molecular sieve catalyst of the precursor metal salt, the acid solution or the complex; roasting the impregnated molecular sieve catalyst in a muffle furnace for 500-800 DEG C so as to obtain the SCR denitration catalyst. When used in catalytic cracking flue gas, the catalyst is low in SCR denitrationreaction temperature, good in activity, high in conversion rate and long in service life, thereby having promising application prospect.

Owner:CHINA PETROLEUM & CHEM CORP

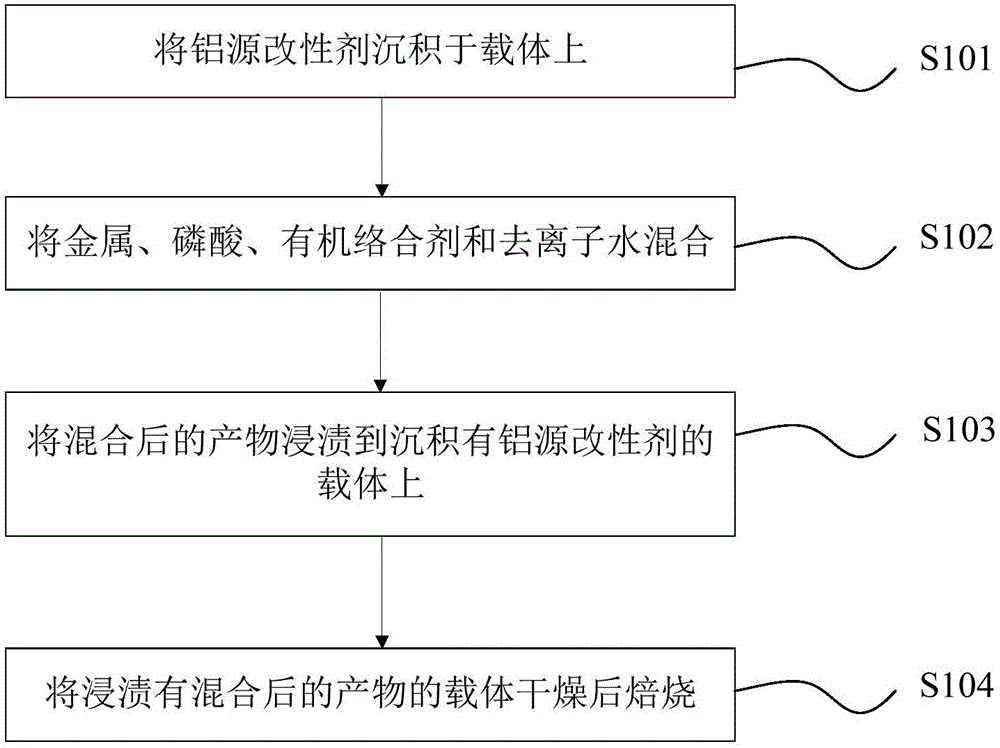

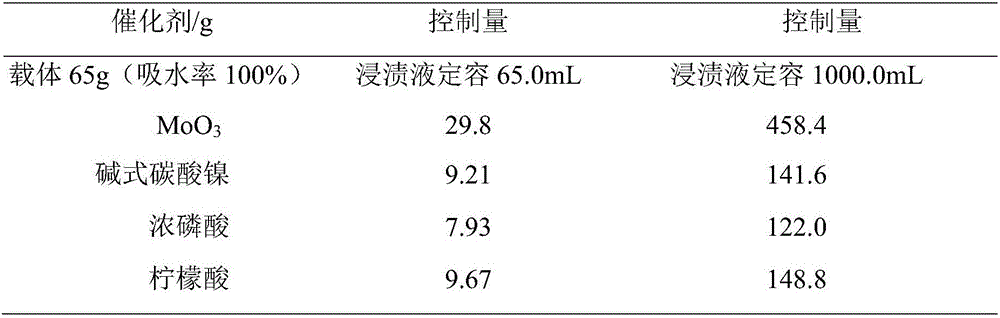

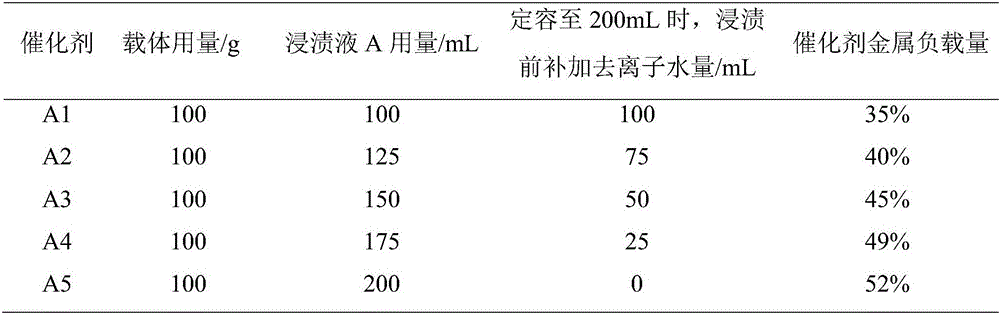

Preparation method of high-metal-content hydrogenation catalyst

ActiveCN106423183ALarge specific surface areaHigh activityMetal/metal-oxides/metal-hydroxide catalystsRefining by aromatic hydrocarbon hydrogenationCarrying capacityPhosphoric acid

The invention relates to a preparation method of a high-metal-content hydrogenation catalyst, comprising the steps of depositing an aluminum source modifier to a carrier; mixing a metal, phosphoric acid, an organic complexing agent and deionized water; impregnating the mixture to the carrier on which the aluminum source modifier is deposited; drying and calcining the carrier on which the mixture is impregnated; wherein the metal is made from a main component, Mo in VIB, and an aid component, Ni in VIII, the aluminum source modifier is one, or a composition of any, of aluminum isopropoxide, aluminum chloride and aluminum nitrate, the carrier on which the aluminum source modifier is deposited is 1.3-2.3 ml / g in pore volume and 400-700 m<2> / g in specific surface area, and pores 14-18 nm in diameter accounts for greater than 50%. The preparation method of the high-metal-content hydrogenation catalyst provided herein has significantly improved activity and good pore structure and large specific surface area since metal carrying capacity is increased; the preparation process of the catalyst is simplified, and the preparation cost of high-metal-content hydrogenation catalyst is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

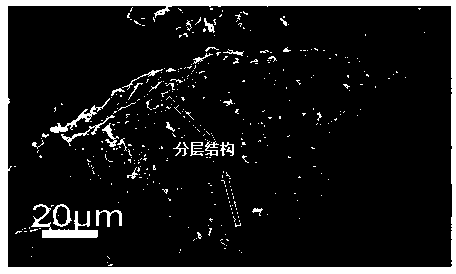

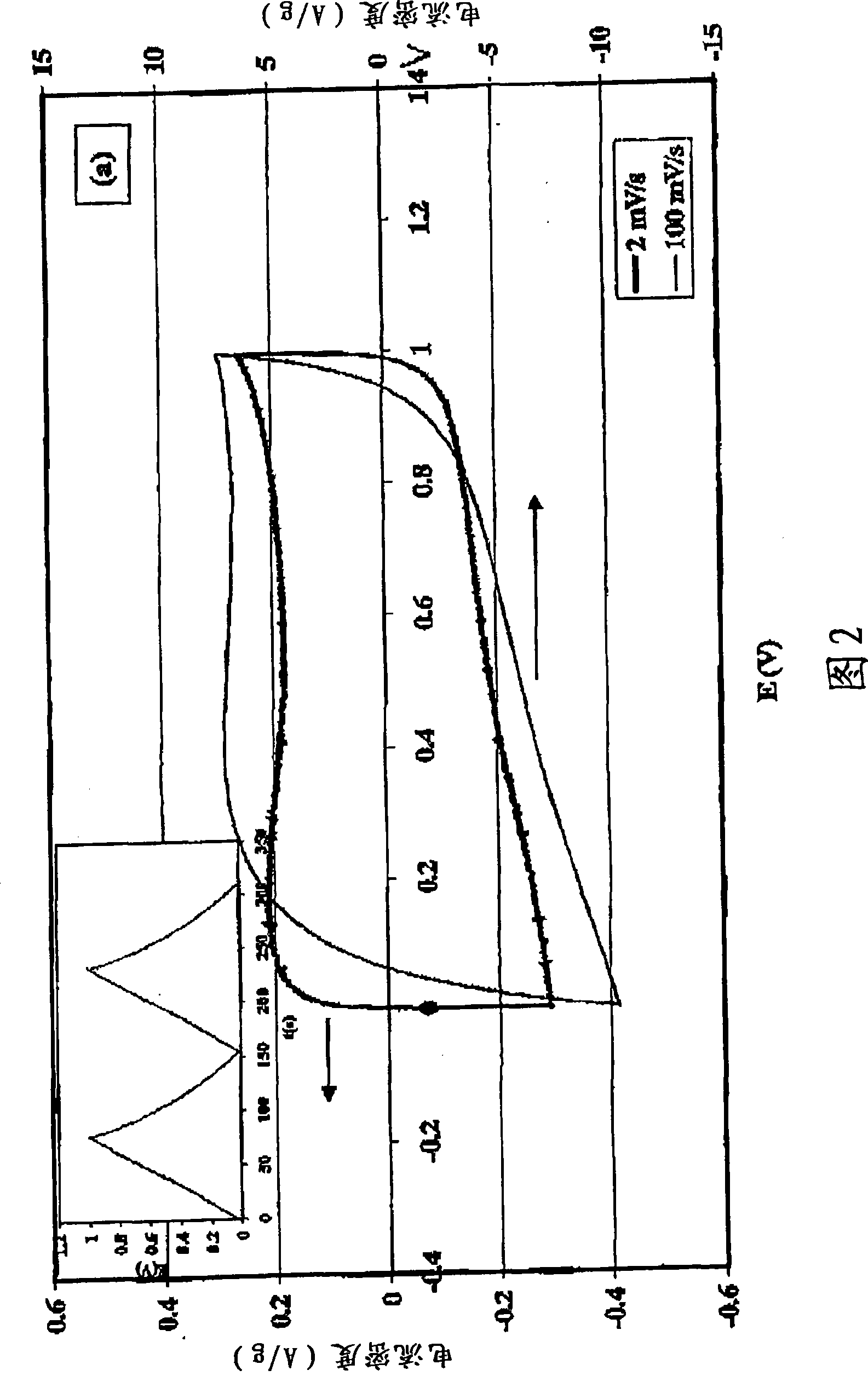

Preparation method of layered porous active carbon electrode material for supercapacitor

ActiveCN107680826AReduce manufacturing costEfficient resource utilizationHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceMetallurgy

A preparation method of a layered porous active carbon electrode material for a supercapacitor relates to the technical field of a supercapacitor electrode material. The layered porous active carbon electrode material for the supercapacitor is obtained by the steps of mixing casing after being carbonized with KOH and deionized water under an ultrasonic condition, performing drying to obtain a mixture, activating the mixture in a nitrogen atmosphere and finally performing grinding. The casing is rich in source, can be reproduced and is environmental-friendly, the active carbon material preparedby a simple processing technology has a layered structure, developed specific area and reasonable aperture distribution and has relatively good capacitance performance in the supercapacitor when usedas the electrode material. The preparation process is simple and easy to operate and has important significance to reduction of the production cost of high-surface active carbon for the supercapacitor.

Owner:YANGZHOU UNIV

Preparation method of catalyst for oxidative hydrogenation of propane

ActiveCN103769136APhysical properties (lower than surfaceLow pore volumeHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsOrganic acidResource utilization

The invention discloses a preparation method of a catalyst for oxidative hydrogenation of propane. The method comprises the following steps: grinding waste residual oil desulfurization catalysts into powder, adding a strong inorganic acid into the powder, filtering, adding an organic acid into the filtrate, then adding pseudo-boehmite, stirring the solution and heating at the same time until the solution is totally evaporated so as to obtain a solid substance, and then subjecting the solid substance to processes of drying, burning, and forming so as to obtain the catalyst for oxidative hydrogenation of propane. The preparation method fully utilizes the waste residual oil hydro-desulfurization catalysts, improves the resource utilization rate, and greatly reduces the cost; furthermore, the obtained catalyst has a large specific surface area, the active metal is highly dispersed on the catalyst surface, thus the utilization rate of active metal is improved, so the catalytic activity and selectivity of the catalyst are both improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

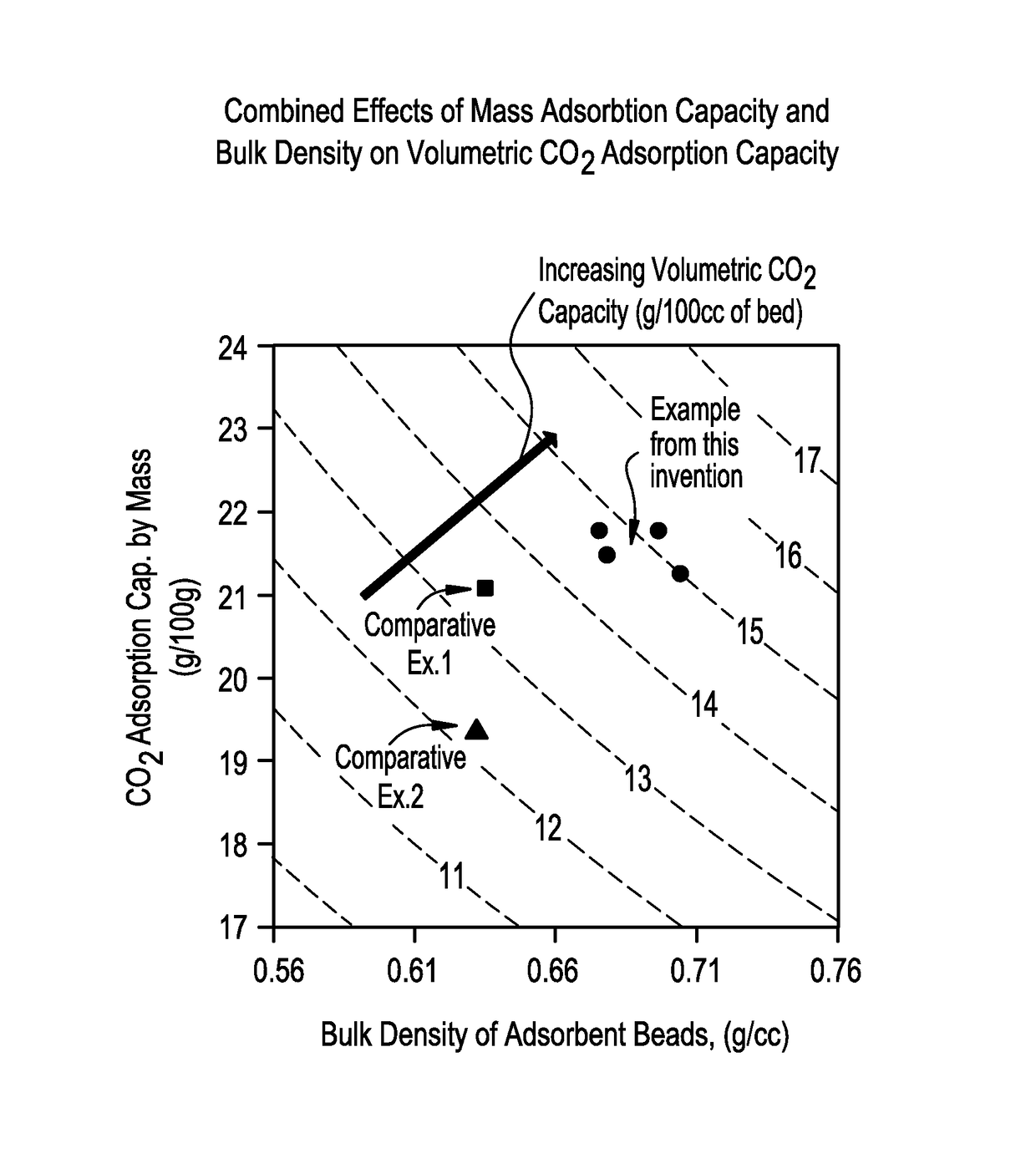

Zeolite particles for adsorption and/or desorption of gases and liquids

ActiveUS10137428B2Increase capacityHighly effectiveRespiratorsCarbon compoundsDesorptionSilicon dioxide

Owner:WR GRACE & CO CONN

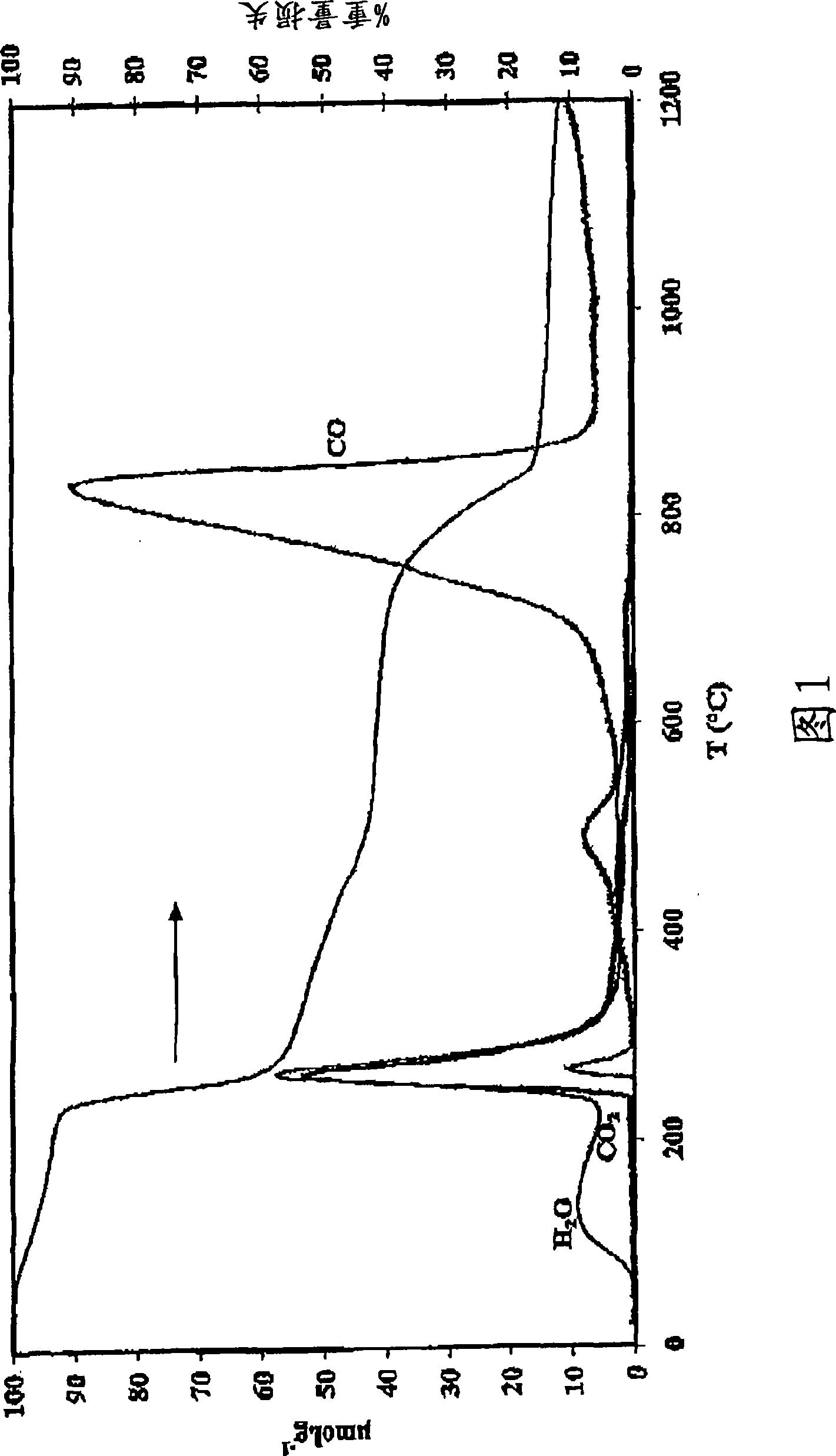

Carbonized biopolymers

InactiveCN101378987ALow pore volumeHigh densityHybrid capacitor electrodesCell electrodesBiopolymerCarbonization

A carbon material suitable for the preparation of electrodes for electrochemical capacitors is obtained by single-stage carbonization of biopolymers with a large content of heteroatoms. Neither addition of an activating agent during carbonization nor subsequent gas phase activation is necessary. Several biopolymers which are available by extraction from seaweed are suitable precursors. Alternatively, the seaweed containing such biopolymers is carbonized directly.

Owner:SGL CARBON SE +2

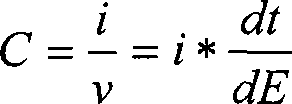

Porous silicon dioxide carrier and preparation method and application thereof

ActiveCN112520745AImprove catalytic performanceImprove conversion rateCatalyst carriersSilicaPtru catalystPhysical chemistry

The invention discloses a porous silicon dioxide carrier as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) impregnating silicon dioxidepowder with an acid solution of a saccharide compound, and dehydrating and carbonizing the impregnated material to obtain silicon dioxide with protected pore channels, namely a carbon-containing precursor; and (2) roasting the carbon-containing precursor obtained in the step (1) to obtain the porous silicon dioxide. The specific surface area of the porous silicon dioxide is not less than 200m<2> / g, and the pore volume is not less than 1.0 ml / g. When being used as an isobutylene oxyacetylation catalyst carrier, the porous silicon dioxide has better catalytic performance, and has the advantagesof high conversion rate and high stability.

Owner:北京水木滨华科技有限公司

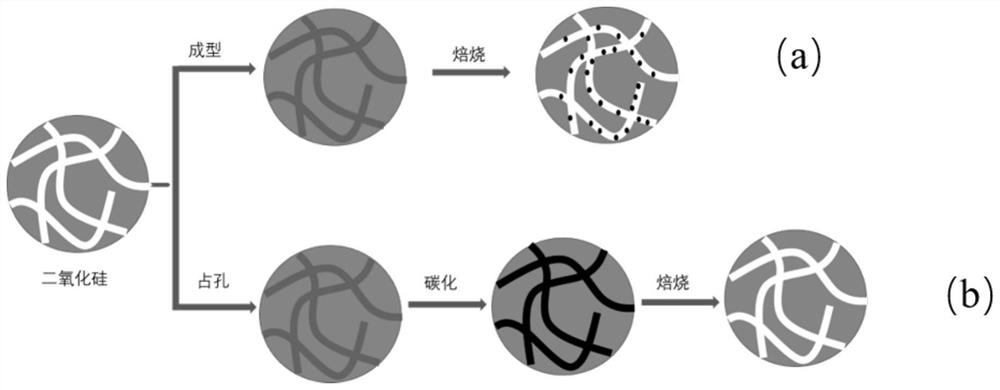

Method for preparing sintering-free high-stability mesoporous silica-aluminum material from silica fume and aluminum ash and product

The invention discloses a method for preparing a sintering-free high-stability mesoporous silica-aluminum material from silica fume and aluminum ash and a product. The method comprises the following steps: weighing silica fume and aluminum ash, mixing, and grinding at a high speed of 500-2500 rpm for 5-15 minutes to obtain activated silicon-doped aluminum ash; respectively weighing an ammonium bicarbonate water solution and activated silicon-doped aluminum ash, mixing, stirring at a rotating speed of 30-150 rpm, at the same time, carrying out low-temperature plasma irradiation for 1-2 hours toobtain silicon-doped aluminum slurry; and drying and cooling the silicon-doped aluminum slurry to obtain the sintering-free high-stability mesoporous silica-aluminum material. The maximum values of the pore diameter, the pore volume and the specific surface area of the prepared mesoporous silica-aluminum material is 13.3 nm, 0.65 cm<3> / g and 512 m<2> / g respectively, and the pore diameter change rate, the pore volume change rate and the specific surface area change rate of the mesoporous silica-aluminum material pretreated at 900 DEG C for 1 hour are all lower than 4%.

Owner:浙江慧科环保科技有限公司

Ordered mesoporous organosilica hollow sphere prepared by one-step method and preparation method thereof

ActiveCN105036145BFast preparationSimple manufacturing processSilicaSpherical morphologyMedical imaging

The invention relates to an ordered mesoporous organic silicon oxide hollow ball prepared through a one-step method and a preparation method of the ordered mesoporous organic silicon oxide hollow ball. The prepared ordered mesoporous organic silicon oxide hollow ball has good spherical morphology. The ball grain size ranges from 50 nm to 100 nm. The ball grain size distribution is uniform. The ordered mesoporous organic silicon oxide hollow ball is high in monodispersity, strength and dispersibility. A spherical shell comprises ordered radial mesoporous ducts. The preparation method is simple and easy to implement and can be easily conducted in an industrial mode. The ordered mesoporous organic silicon oxide hollow ball can be prepared through one step without sacrificial template or postprocessing. The fastest preparation process lasts for only 0.25 h. By means of the structure, reaction molecules or medicine molecules can conveniently enter and leave the ordered mesoporous organic silicon oxide hollow ball, and the ordered mesoporous organic silicon oxide hollow ball has good application prospects in the fields of medicine slow release, release control, medical imaging, catalysis and the like.

Owner:TSINGHUA UNIV +1

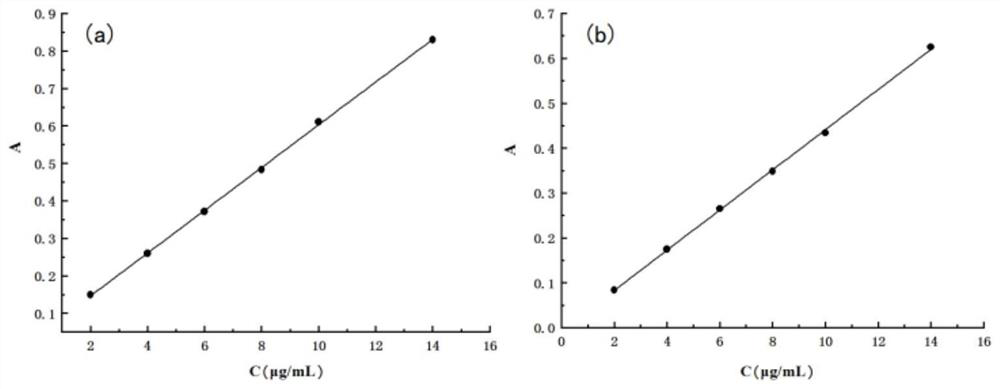

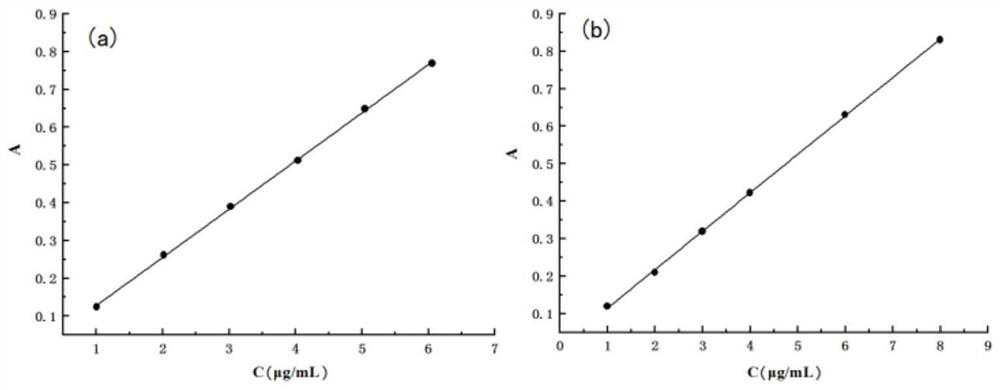

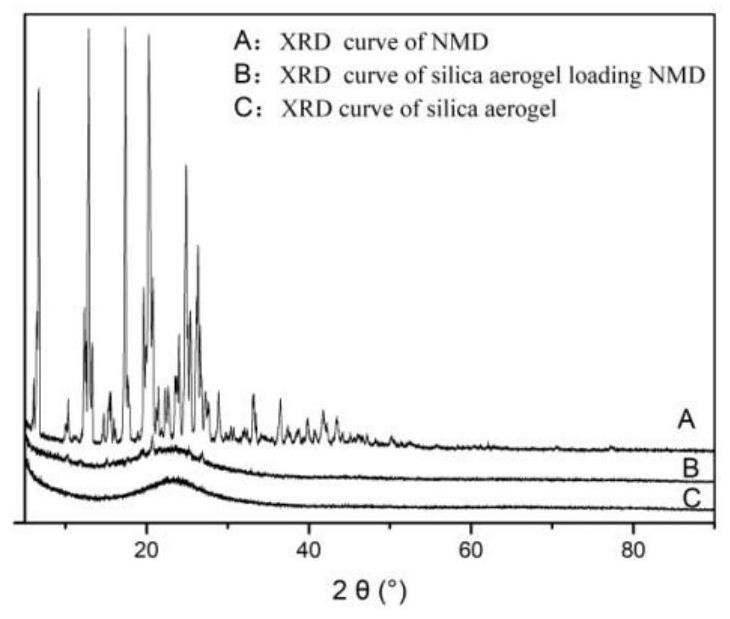

Construction and evaluation method of nano drug delivery system based on silica aerogel

PendingCN113304271ALarge specific surface areaHigh porosityHydroxy compound active ingredientsInorganic non-active ingredientsAlcoholNimodipine

The invention provides a construction and evaluation method of a nano drug loading system based on silica aerogel, and particularly relates to a method for preparing the drug silica aerogel nano drug loading system by taking two BCS II drugs (nimodipine and resveratrol) as indissolvable representative drugs, taking silica aerogel in the silica aerogel as a carrier and taking a centrifugal impregnation method as a drug loading method. The process for determining the optimal prescription comprises the following steps: dissolving medicine powder with absolute ethyl alcohol by adopting a centrifugal impregnation method, preparing a medicine ethanol solution with a certain concentration, weighing a proper amount of silica aerogel, adding the silica aerogel into an NMD ethanol solution, setting the medicine carrying temperature to be 25 DEG C, stirring at a medium speed for 24 hours, centrifuging for 5 minutes at the speed of 5000r / min, separating precipitates, and drying the precipitates under reduced pressure to obtain sample powder. Through test detection, the prepared silica aerogel nano drug loading system is obviously improved in the aspects of solubility and release rate of indissolvable drugs.

Owner:HARBIN UNIV OF COMMERCE

Hydrocracking catalyst and preparation method thereof

ActiveCN102463131BHigh active metal contentIncrease the apertureMolecular sieve catalystsMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst and a preparation method thereof. The preparation method comprises the following steps: 1, dipping aluminum hydroxide xerogel powder used in a carrier in a solution containing a hydrogenation metal component; 2, drying the powder; and 3, fully rolling, molding and roasting the powder together with molecular sieve under the action of a peptizer or a binder to obtain the catalyst. The catalyst of the invention is obtained only through one-time high temperature roasting, so the preparation method is simple, and the preparation cost is obviously reduced. In addition, the hydrogenation center and the cracking center of the catalyst of the invention coordinate and cooperate with each other, so the catalyst has a high catalytic activity, and the catalyst which simultaneously has a large specific surface area and a large pore volume is suitable for processing catalytic process for the high productivity of naphtha by hydrocracking high-dry-point low-quality reduced pressure distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method for scr denitrification catalyst under low temperature condition

ActiveCN110052264BLow costEasy to makeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMolecular sieveOrganic acid

The invention belongs to a preparation method for an SCR denitration catalyst under low temperature conditions. Dissolve titanium source in absolute ethanol, adjust pH to 2-6 with organic acid solution, add rare earth metal precursor and porogen, mix and stir, react at 60-90°C for 2-8h, evaporate ethanol and dry, 500- Roast at 800°C for 8-12 hours to obtain a molecular sieve carrier; impregnate the molecular sieve carrier with one or more of transition metal oxide precursor metal salts or acid solutions or complexes, impregnate for 2-8 hours, and dry at room temperature to obtain an impregnated precursor Molecular sieve catalysts of metal salts or acid solutions or complexes; the impregnated molecular sieve catalysts are roasted in a muffle furnace at 500-800°C to obtain SCR denitration catalysts. The catalyst of the invention is used for SCR denitrification reaction temperature in catalytic cracking flue gas, has low temperature, good activity, high conversion rate, long service life and good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP

Chemical component for hydrogen production by hydrolysis of sodium borohydride

InactiveCN109205555AHigh hydrogen storage densityIncrease reaction rateHydrogen productionHydrogen/synthetic gas productionHigh concentrationEnvironmental resistance

The invention relates to a chemical component for hydrogen production by hydrolysis of sodium borohydride. The chemical component provided by the invention is composed of borohydride, acid and water,wherein borohydride and acid are both solid powder. According to the invention, the borohydride is NaBH4 and the acid is H3BO3. The formula consists of: 10-17% of NaBH4, 50-70% of H3BO3, and the balance water. The chemical component has the advantages of high efficiency hydrogen production, safety, environmental protection, convenient use and the like. NaBH4 has high hydrogen storage density and can react with water to generate H2 at room temperature, however, along with the progress of the reaction, the pH of the solution gradually increases, the reaction decreases gradually, and the reactionefficiency is low. Adding of H3BO3 into the system can reduce the pH of the solution and increase the reaction efficiency. H2 is the only gas in the reaction product, thus ensuring the high concentration of H2, and the by-product can be recycled. NaBH4 and H3BO3 are inexpensive, and the hydrogen production cost is low.

Owner:NANJING UNIV OF TECH +1

Preparation method of catalyst for partial oxidization of isobutene to prepare methylacrolein

ActiveCN103769135APhysical properties (lower than surfaceLow pore volumeOrganic compound preparationCarbonyl compound preparationPartial oxidationAluminate

The invention discloses a preparation method of a catalyst for partial oxidation of isobutene to prepare methylacrolein. The preparation method comprises the following steps: grinding waste hydro-treatment catalysts into powder, dissolving the powder in a strong inorganic acid, filtering, then adding a precursor of Bi, adding an alkaline solution to adjust the pH value to a range of 7.0 to 10.0, then adding a strong alkaline solution to adjust the pH value to a range of 12.0 to 14.0, heating and stirring at the same time, filtering so as to obtain the precipitant, washing, drying, and burning the precipitant, and finally forming so as to obtain the catalyst. The preparation method recycles the active metals in waste hydro-treatment catalysts, and at the same time fully utilizes the Fe, Ni and V which are deposited on the waste catalysts to prepare the catalyst, which has the advantages of large specific surface area and high activity and is used to catalyze partial oxidation of isobutene to prepare methylacrolein; wherein the byproduct of the preparation method is meta-aluminate. The preparation method has the advantages of simpleness and easy operation, and is capable of fully utilizing the carriers and metals in waste hydro-treatment catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Co-impregnation solution and preparation method of catalyst obtained by hydrofining paraffin oil

InactiveCN106552655ADecrease in pore volumeHigh activityPhysical/chemical process catalystsHydrocarbon oils treatmentMetallic NickelAtmosphere

The invention discloses a co-impregnation solution and a preparation method of a catalyst obtained by hydrofining paraffin oil. The preparation method is characterized by comprising the following steps of preparing a catalyst carrier; preparing an aqueous solution of ammonium metatungstate, ammonium paramolybdate or ammonium tetramolybdate, nickel nitrate and orthophosphoric acid as the co-impregnation solution at the room temperature, wherein the co-impregnation solution comprises, by concentration, 16-30 g / 100ml of WO<3>, 11-16 g / 100ml of MoO<3>, 7-10 g / 100ml of NiO and 3.5-5.5 g / 100ml of P; impregnating the carrier obtained in step 1 one time with the obtained co-impregnation solution at the room temperature; firstly, drying the impregnated carrier at the room temperature, and then conducting heating and drying under water-vapor atmosphere, so that the catalyst is obtained, wherein calcinations is conducted while heating and drying are conducted. The catalyst prepared through the method is uniform in active component distribution, large in pore volume and specific surface area and high in desulfuration activity and denitrification activity.

Owner:新疆佳宇恒能源科技有限公司

Preparation method of hydrocarbon hydrotreatment catalyst

The invention relates to a preparation method for a catalyst to hydrotreat hydrocarbons, which comprises gama- Al2O3 as carrier, metal from VIB group and VIII group as active constituents, and Ti as active adjuvant. The prepraration method comprises: adding titanate solution to bring said Ti during the gelatinization for preparing aluminum hydroxide; adding basic solution contained Mo or W into the dried aluminum hydroxide powder, mixing till the powder wet fully by solution; adding acid solution contained Co or Ni, mixing till plastic, extruding to form, drying, baking, and obtaining the catalyst. This invention improves the catalyst property obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com