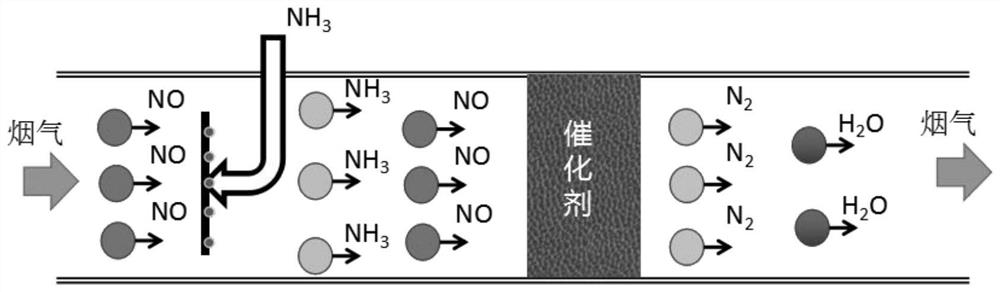

A kind of preparation method for scr denitrification catalyst under low temperature condition

A technology of denitrification catalyst and low temperature conditions, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of no correlation of catalytic activity, difficulty in industrial application, and low denitrification efficiency, and achieve the goal of overcoming low temperature The effect of low activity and instability, promotion of uniform loading, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) preparation of molecular sieve carrier: at first weigh 0.5mol 86g of titanium tetramethoxide (172) (titanium source) to be dissolved in dehydrated alcohol, stir with a magnetic stirrer to make it evenly mixed, and the aqueous solution of acetic acid is adjusted to pH 2, Then, 0.0263mol (10.08g) of yttrium nitrate hexahydrate (383.06) (precursor of rare earth metal) and 10g of porogen (polyoxyethylene leafamine) were added and stirred (reaction at 60°C for 8h) to form a sol, evaporated ethanol and dried at 500 After roasting for 12h, the molecular sieve carrier TiO2-Y2O3 was obtained, and the particle size of the molecular sieve carrier was 0.2 mm;

[0032] (2) Impregnation process of active components: impregnating molecular sieve carrier TiO2-Y2O3 with an aqueous solution of 1 mol / L vanadic acid (2h), and drying at room temperature to obtain a molecular sieve catalyst impregnated with vanadic acid;

[0033] (3) Roasting and oxidation process: the impregnated molecu...

Embodiment 2

[0035] (1) Preparation of molecular sieve carrier: firstly, 0.5mol 114g of tetraethoxytitanium (228) (titanium source) was weighed and dissolved in absolute ethanol, stirred with a magnetic stirrer to make it evenly mixed, and the aqueous solution of propionic acid was adjusted to pH is 2, then 0.01547mol (4.408g) of Sc(NO3)3·3H2O(285) (precursor of rare earth metal) and 10g of porogen (polyoxyethylene soybean amine) were added and stirred (reaction at 75°C for 5h) to form a sol, After evaporating ethanol, drying, calcining at 650°C for 10h to obtain molecular sieve carrier TiO2-Sc2O3, molecular sieve particle size is 0.6mm;

[0036] (2) Impregnation process of active components: The molecular sieve carrier TiO2-Sc2O3 is repeatedly impregnated with an aqueous solution of 1 mol / L FeVO4 (6h), and dried at room temperature to obtain a molecular sieve catalyst impregnated with FeVO4;

[0037] (3) Roasting and oxidation process: the impregnated molecular sieve catalyst was roasted ...

Embodiment 3

[0039] (1) Preparation of molecular sieve carrier: firstly, 0.5mol 170.2g of tetrapropoxide titanium (284.22) (titanium source) was weighed and dissolved in absolute ethanol, stirred with a magnetic stirrer to make it evenly mixed, and the aqueous solution of propionic acid was adjusted The pH was set to 2, then 0.0005mol (0.2165) of La(NO3)·6H2O(433) (precursor of rare earth metal) and 10g of porogen (polyoxyethylene tallowamine) were added and stirred (reaction at 90°C for 2h) to form a sol, which was evaporated After drying with ethanol, calcined at 800°C for 8h to obtain the molecular sieve carrier TiO2-La2O3, and the molecular sieve particle size is 1.0mm;

[0040] (4) Impregnation process of active components: the molecular sieve carrier TiO2-La2O3 (8h) was repeatedly impregnated with an aqueous solution of 1mol / L Mn(NO3)2, and dried at room temperature to obtain a molecular sieve catalyst impregnated with Mn(NO3)2;

[0041] (2) Roasting and oxidation process: the impreg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com