Ordered mesoporous organosilica hollow sphere prepared by one-step method and preparation method thereof

A technology of organic silicon oxide and hollow spheres, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of limited loading of organic groups, hindering industrialization process, long production cycle, etc., and achieves simple and easy preparation process, Good prospects for industrial applications and the effect of increasing loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Octadecyltrimethylammonium bromide, water and ethanol are mixed to form solution A, and the mass ratio of cetyltrimethylammonium bromide, water and ethanol is: 1:180:60;

[0038] (2) Dissolve 1,2-bis(triethoxysilyl)ethane in ethanol to form solution B, the concentration of 1,2-bis(triethoxysilyl)ethane in ethanol is: 0.05g / ml;

[0039] (3) Mix solution A and solution B and stir for 1 min to obtain solution C;

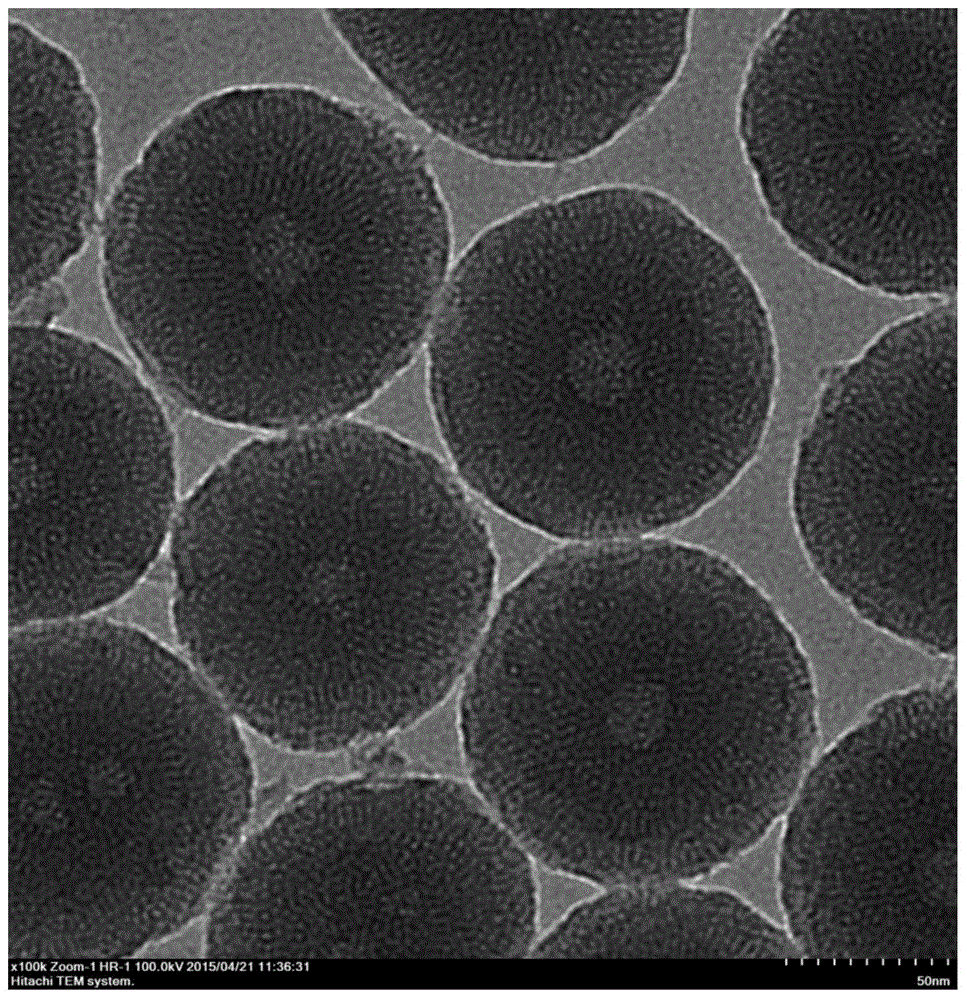

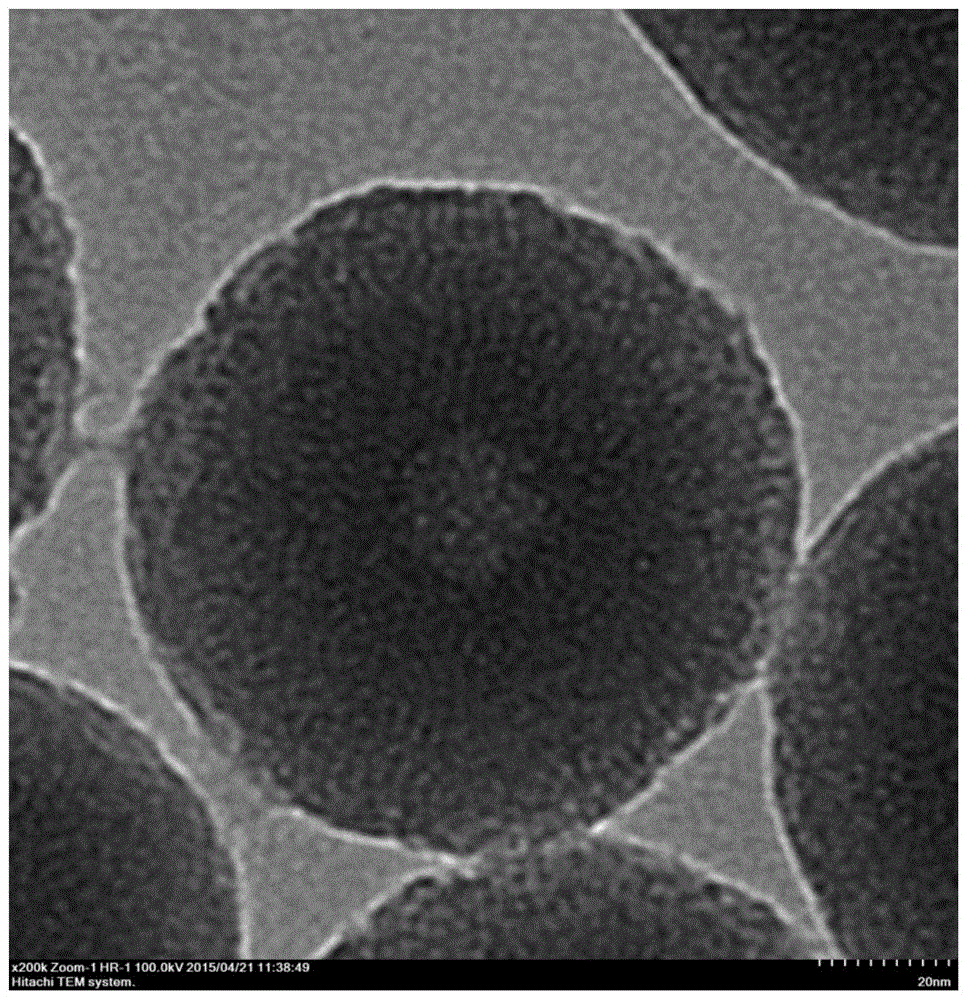

[0040] (4) Add ammonia water to solution C, stir or stand still for 0.25h at 25°C, and form positively charged ordered mesoporous organosilica hollow spheres in one step (such as figure 1 , figure 2 Shown), the concentration of ammoniacal liquor in solution C is 5mg / ml;

[0041] (5) After centrifugation, filtration, and water washing, the ordered mesoporous organosilica hollow spheres with positive charges on the surface are transferred to the surfactant extraction solution, and heated at 35°C for 6 hours to remove the cationic surfactant to obtain Orde...

Embodiment 2

[0044] (1) Mix octadecyltrimethylammonium bromide, water and ethanol to form solution A, the mass ratio of cetyltrimethylammonium bromide, water and ethanol is: 1:210:130;

[0045] (2) Dissolve 1,2-bis(trimethoxysilyl)ethane in ethanol to form solution B, the concentration of 1,2-bis(trimethoxysilyl)ethane in ethanol is: 0.01g / ml ;

[0046] (3) Mix solution A and solution B and stir for 1 min to form solution C;

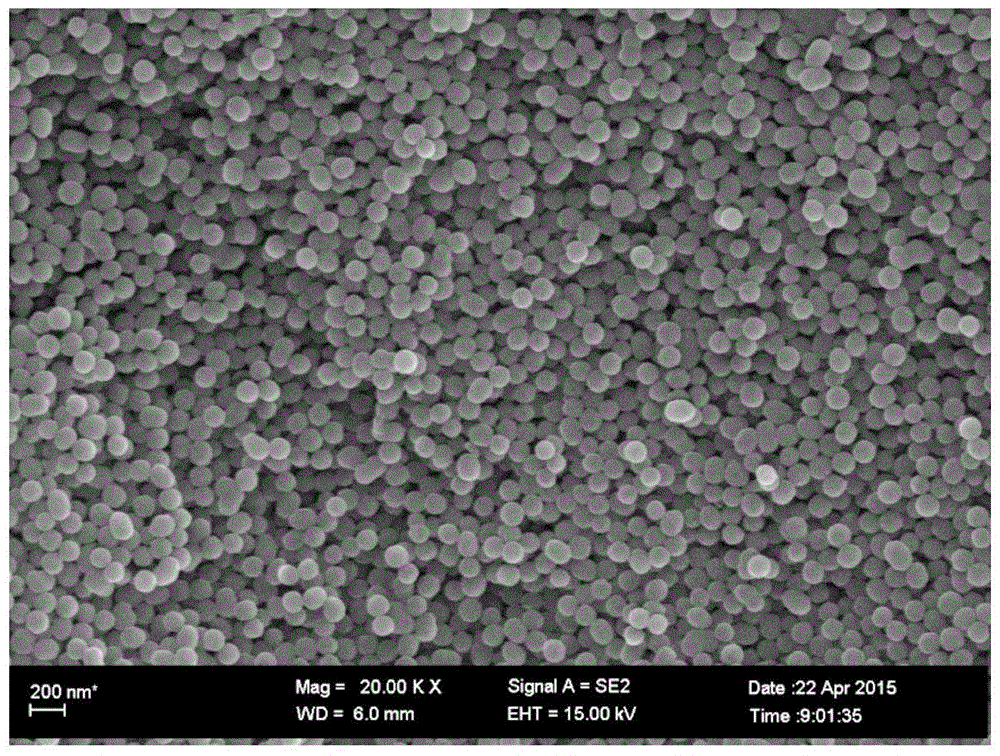

[0047] (4) Add ammonia water to solution C, stir or stand still for 0.25h at 25°C, and form positively charged ordered mesoporous organosilica hollow spheres in one step (such as image 3 Shown), the concentration of ammoniacal liquor in solution C is 11mg / ml;

[0048] (5) After centrifugation, filtration, and water washing, the ordered mesoporous organosilica hollow spheres with positive charges on the surface are transferred to the surfactant extraction solution, and heated at 32°C for 8 hours to remove the cationic surfactant to obtain Ordered mesoporous organo...

Embodiment 3

[0051] (1) Tetradecyltrimethylammonium bromide, water and tert-butanol are mixed to form solution A, and the mass ratio of tetradecyltrimethylammonium bromide, water and tert-butanol is: 1:110: 150;

[0052] (2) Dissolve 1,2-bis(triethoxysilyl)ethane in tert-butanol to form solution B, 1,2-bis(triethoxysilyl)ethane in tert-butanol alcohol The concentration is: 0.08g / ml;

[0053] (3) Mix solution A and solution B and stir for 2 minutes to form solution C;

[0054] (4) Add ammonia water to solution C, stir or stand still for 0.25h at 25°C, and form positively charged ordered mesoporous organosilica hollow spheres in one step (such as Figure 4 Shown), the concentration of ammoniacal liquor in solution C is 6mg / ml;

[0055] (5) After centrifugation, filtration, and water washing, the ordered mesoporous organosilica hollow spheres with positive charges on the surface are transferred to the surfactant extraction solution, and heated at 55°C for 3 hours to remove the cationic sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com