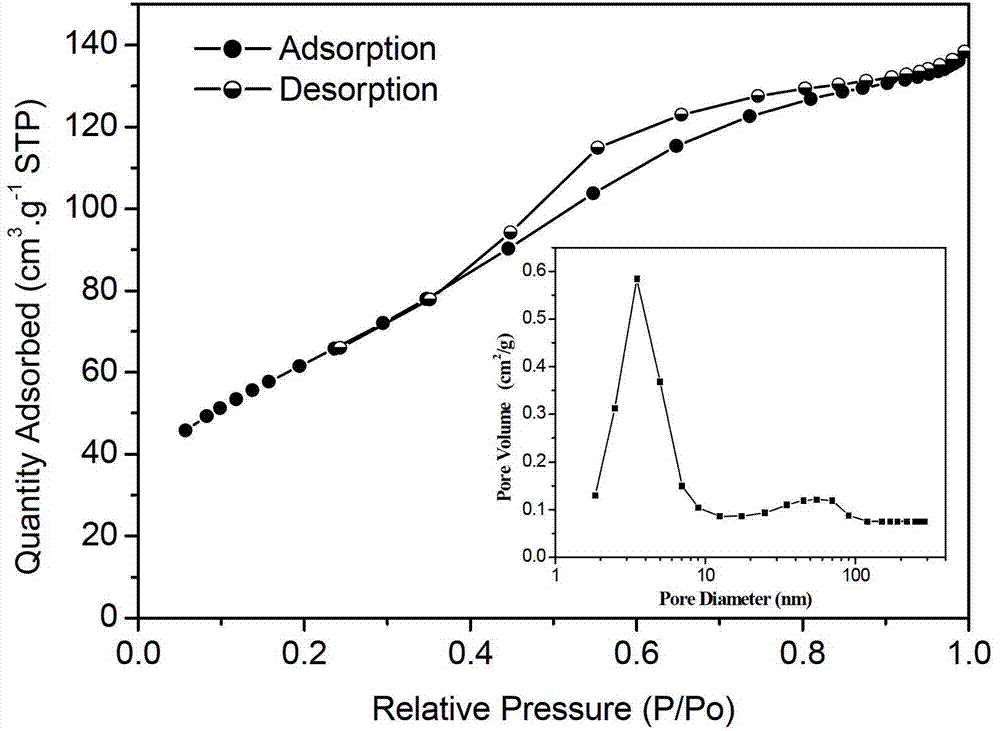

High-specific surface area mesoporous nickel oxide hydrogenation catalyst and preparation method thereof

A high specific surface area, hydrogenation catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst carrier, etc., can solve the problems of pore volume reduction, catalyst specific surface area reduction, etc., Achieve the effect of improving activity and stability and increasing diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] High specific surface area, mesoporous nickel oxide is based on the molar ratio of absolute ethanol, benzene, Ni, P123, tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentapentyl alcohol ester is 1 / 0.13 / 1.1 / 0.001 / 0.01 ratio, prepared by sol-gel method.

[0042] (1) Dissolve P123 (molecular weight: 5800) in a mixed solution of absolute ethanol and benzene at room temperature, and stir until completely dissolved;

[0043] (2) Add tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythyl alcohol ester into the solution of (1) under stirring condition, and stir until dissolved;

[0044] (3) the anhydrous NiCl 2 Add to (2) solution, stir for 0.5h, put the obtained sol in an open crucible, and age in a constant temperature water bath at 40°C for 24h;

[0045] (4) Put the aged gel into a muffle furnace and bake at 350°C for 4 hours to prepare mesoporous nickel oxide with high specific surface area. The nickel oxide used in the following examples all...

Embodiment 2

[0048] Take 4.0g of concentrated nitric acid, 2.7g of citric acid, 62g of nickel nitrate, and 70g of deionized water to prepare a solution, then add small-pore alumina dry powder (pore volume: 0.3-0.5ml / g, specific surface area: 230-360m 2 / g of aluminum hydroxide dry powder) 100g to make a sol. Take 14.5g of nickel oxide and 1.8g of powder and mix them thoroughly, then knead them with the prepared sol to form a plastic paste, extrude into a rod, dry at 110°C for 3 hours, and roast at 450°C for 3 hours to make catalyst R1. Its main physicochemical properties are listed in Table 1.

Embodiment 3

[0050] Take 4.0g of concentrated nitric acid, 2.7g of citric acid, 54.0g of nickel nitrate, and 70g of deionized water to form a solution, then add small-pore alumina dry powder (pore volume: 0.3-0.5ml / g, specific surface area: 230-360m 2 / g of aluminum hydroxide dry powder) 100g to make a sol. Take 24.0g of nickel oxide and 1.8g of powder and mix them thoroughly, then knead them with the prepared sol to form a plastic paste, extrude, dry at 110°C for 3 hours, and roast at 450°C for 3 hours to make catalyst R2. Its main physicochemical properties are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com