Preparation method of high-metal-content hydrogenation catalyst

A hydrogenation catalyst, high-metal technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, hydrogenation refining of aromatics, etc., can solve the problem of catalyst specific surface area decrease, catalyst activity decrease, blockage problems such as improving catalyst activity, reducing preparation cost, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

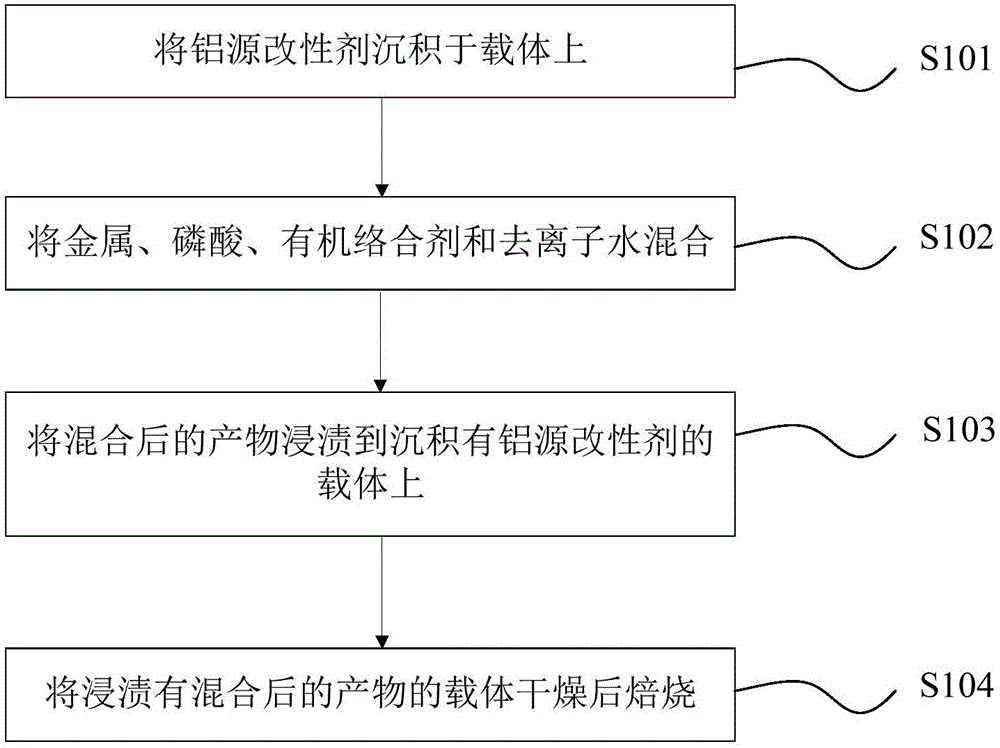

[0020] figure 1 It is a flow chart of the preparation method of the high metal content hydrogenation catalyst in the embodiment of the present invention, such as figure 1 Shown, the preparation method of the high metal content hydrogenation catalyst provided by the invention comprises the following steps:

[0021] S101: Depositing an aluminum source modifier on a carrier. Wherein, the aluminum source modifier is a composition of one or more of aluminum isopropoxide, aluminum chloride and aluminum nitrate; the carrier is a silica carrier, and the Si / Al atomic ratio is 5-25.

[0022] S102: mixing metal, phosphoric acid, organic complexing agent and deionized water. Among them, the metal includes a main component and an auxiliary component; the main component is Mo of the VIB group, and the auxiliary component is Ni of the VIII group; the atomic ratio of Ni / (Ni+Mo) is 0.23-0.30, and the P / Mo The mass ratio of Ni / organic complexing agent is 0.04-0.09, and the molar ratio of N...

Embodiment 1

[0030] Weigh 50g of large pore volume SiO 2 Put it in a beaker, add 500ml of n-hexane, then weigh 11.3g of aluminum isopropoxide, Si / Al=15, dissolve it with a small amount of n-hexane under stirring and add it to the beaker; then add 1500ml of n-hexane, and continue stirring at room temperature 24 hours. Filter, wash with a large amount of n-hexane, dry at 120°C for 6h, and then heat up to 550°C at a rate of 2°C / min and calcined for 4h to obtain an aluminum source-modified silica carrier, which is designated as S-1.

[0031] Weigh 50g of large pore volume SiO 2 Put it in a beaker, add 500ml of absolute ethanol, then weigh 7.4g of anhydrous aluminum chloride, Si / Al=5, dissolve it with a small amount of absolute ethanol under stirring and add it to the beaker; then add 1500ml of absolute ethanol, Stirring was continued at room temperature for 24 hours. Filter, wash with a large amount of absolute ethanol, dry at 120°C for 6 hours, and then heat up to 550°C at a rate of 2°C / mi...

Embodiment 2

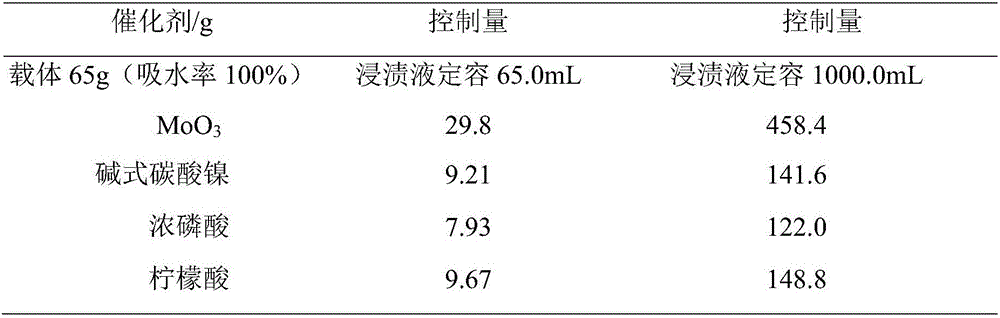

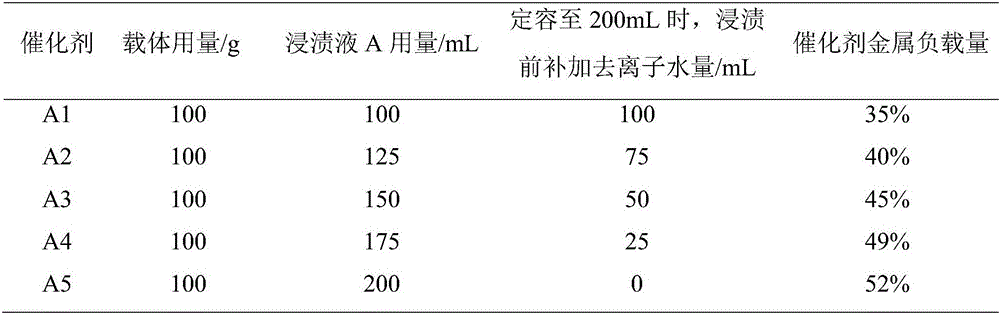

[0035] Measure the water absorption rate of carrier S-1 to 1.8ml / g, weigh 100g aluminum source modified silica carrier S-1, 91.7g molybdenum trioxide, 28.3g basic nickel carbonate, 24.4g concentrated phosphoric acid and 29.8g citric acid. Add molybdenum trioxide, basic nickel carbonate, concentrated phosphoric acid and 200mL deionized water into a 500ml glass beaker with a white label, place it on a magnetic heating stirrer, heat and stir, and boil for 1-3h. Evaporation can add some deionized water until it is clear and transparent. Stop heating and cool down. When the temperature drops to 60°C, add citric acid and continue stirring. After the citric acid is completely dissolved, the solution is clear and transparent. Dilute to 180mL. The catalyst was prepared by an equal volume impregnation method. After the impregnation was completed, put it into an evaporating dish, seal it with a parafilm and maintain it for 2 to 3 hours, dry it at 200°C for 12 hours, and roast it at 550°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com