Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

147results about How to "Conducive to emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

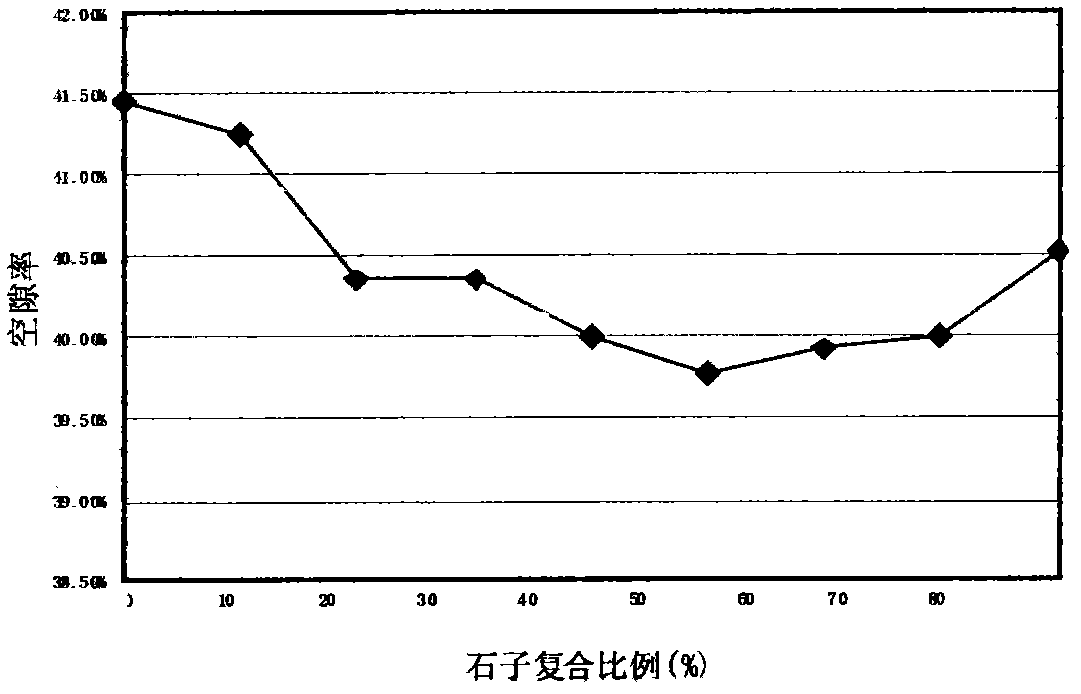

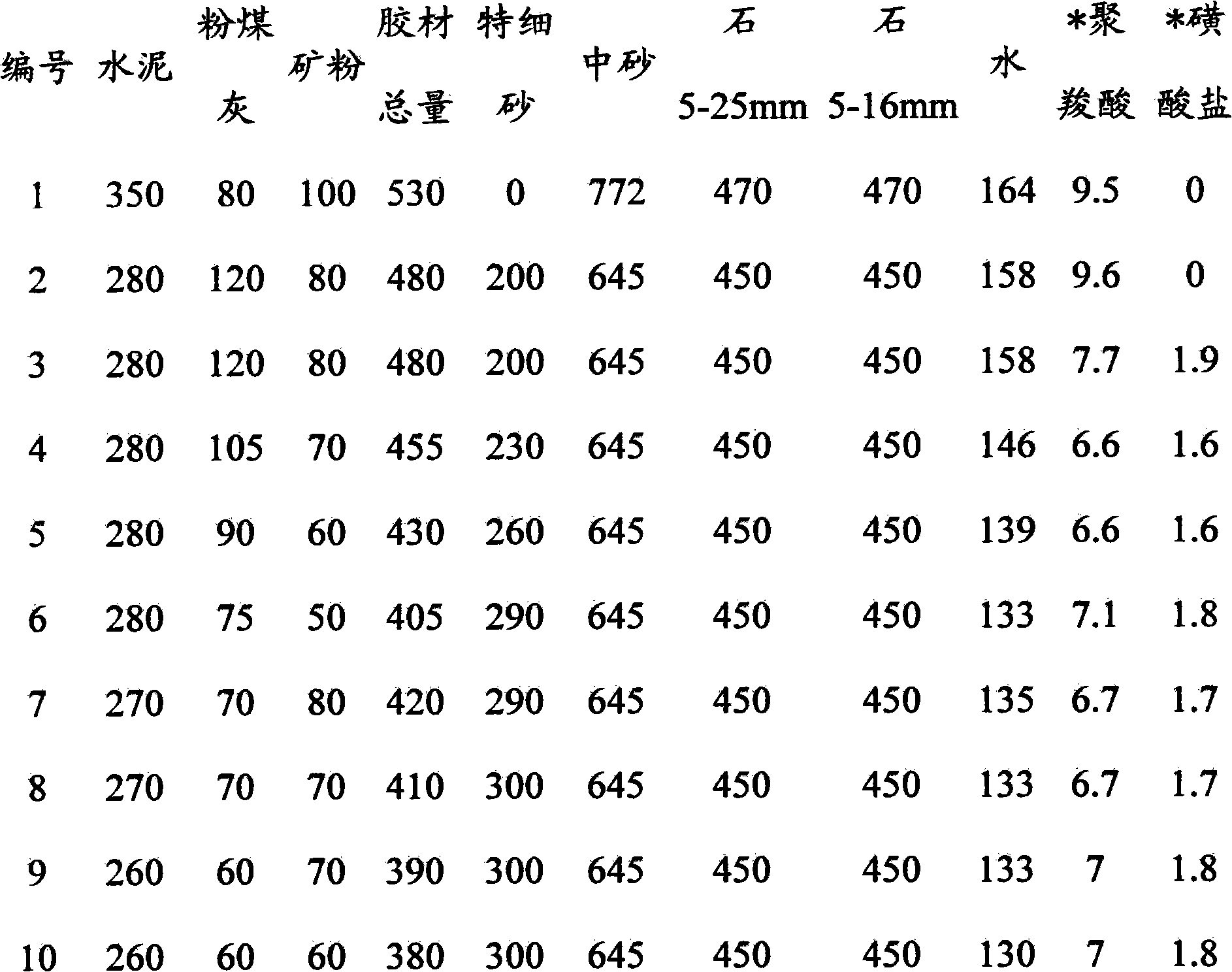

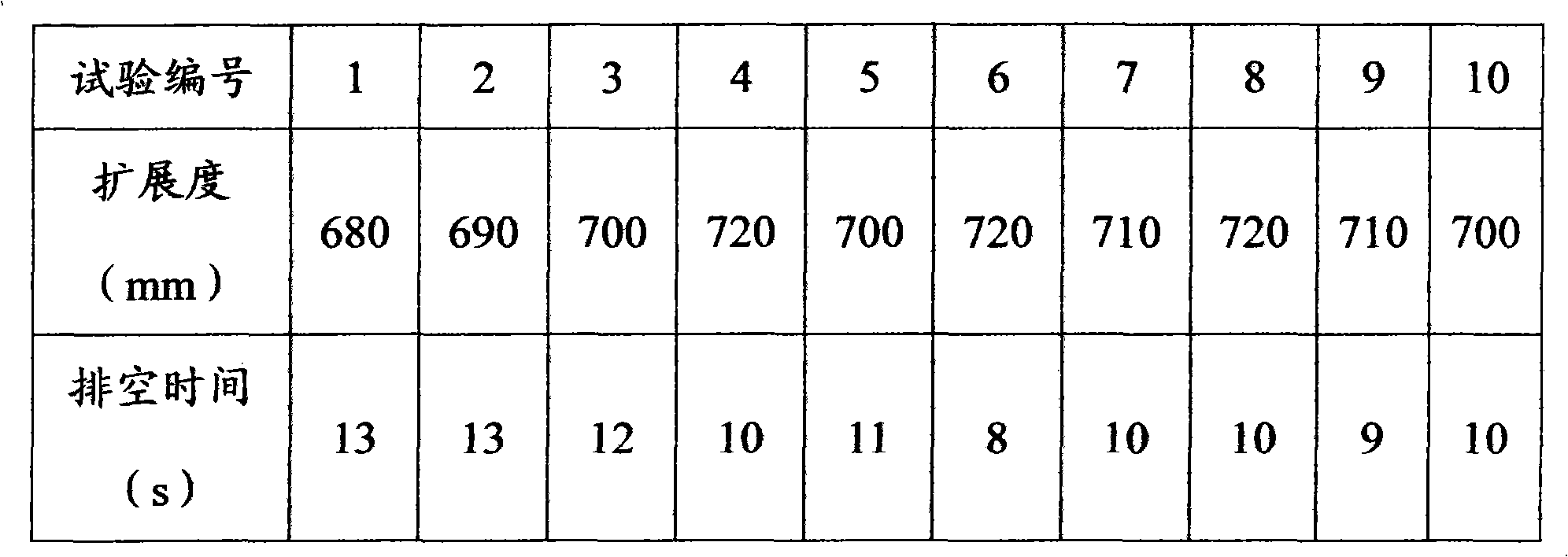

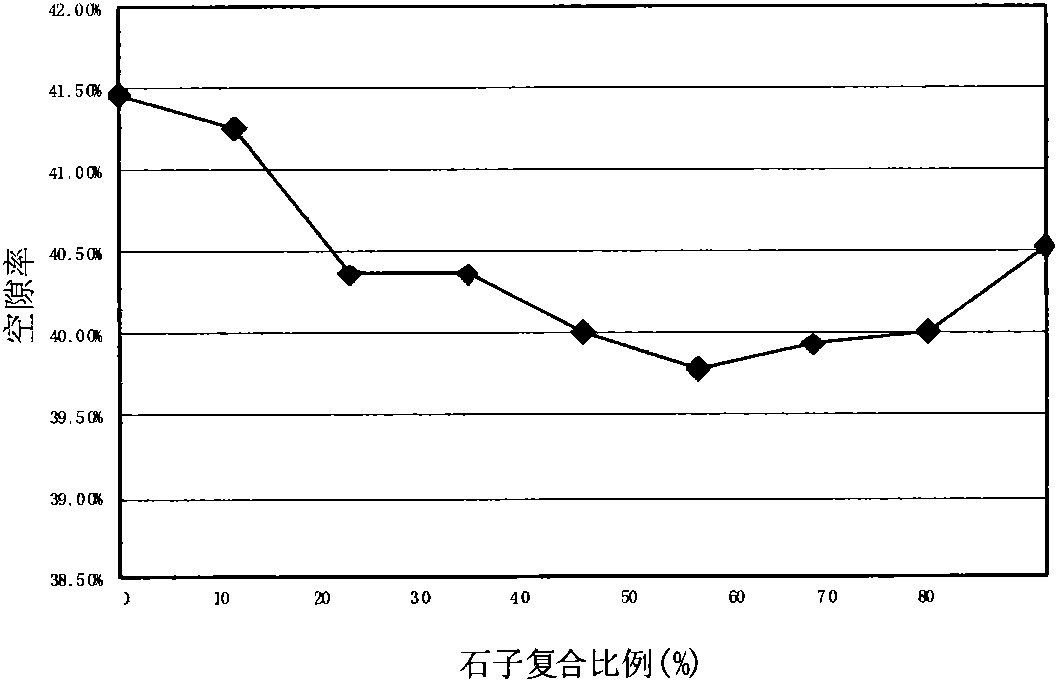

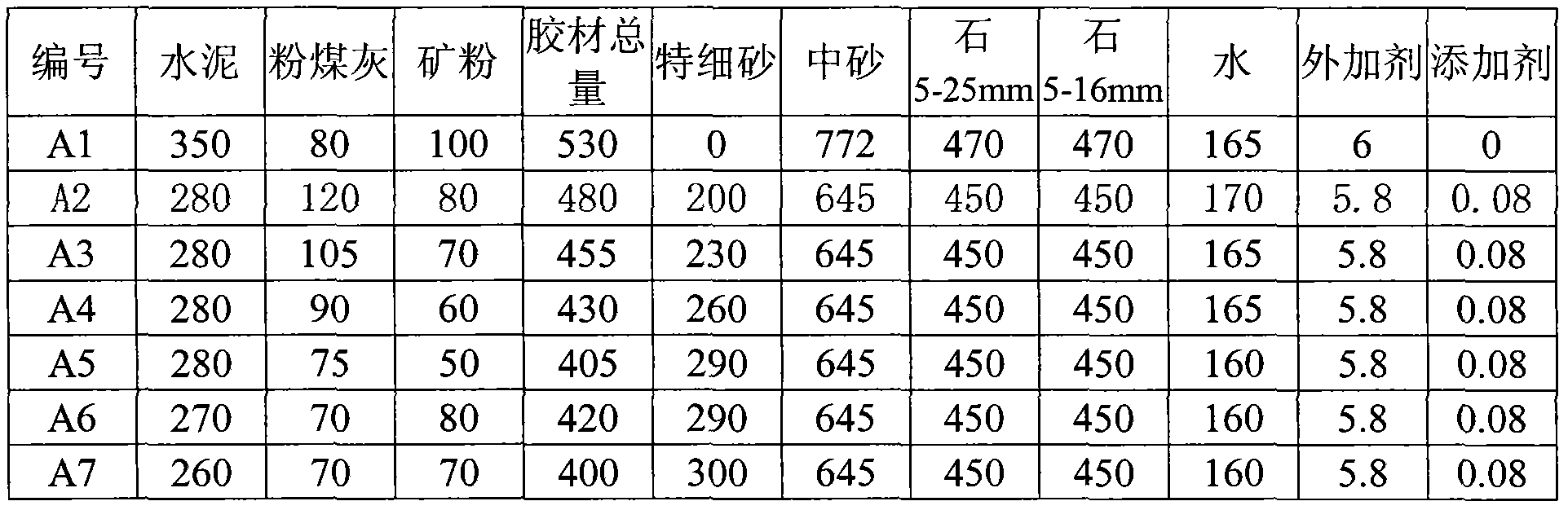

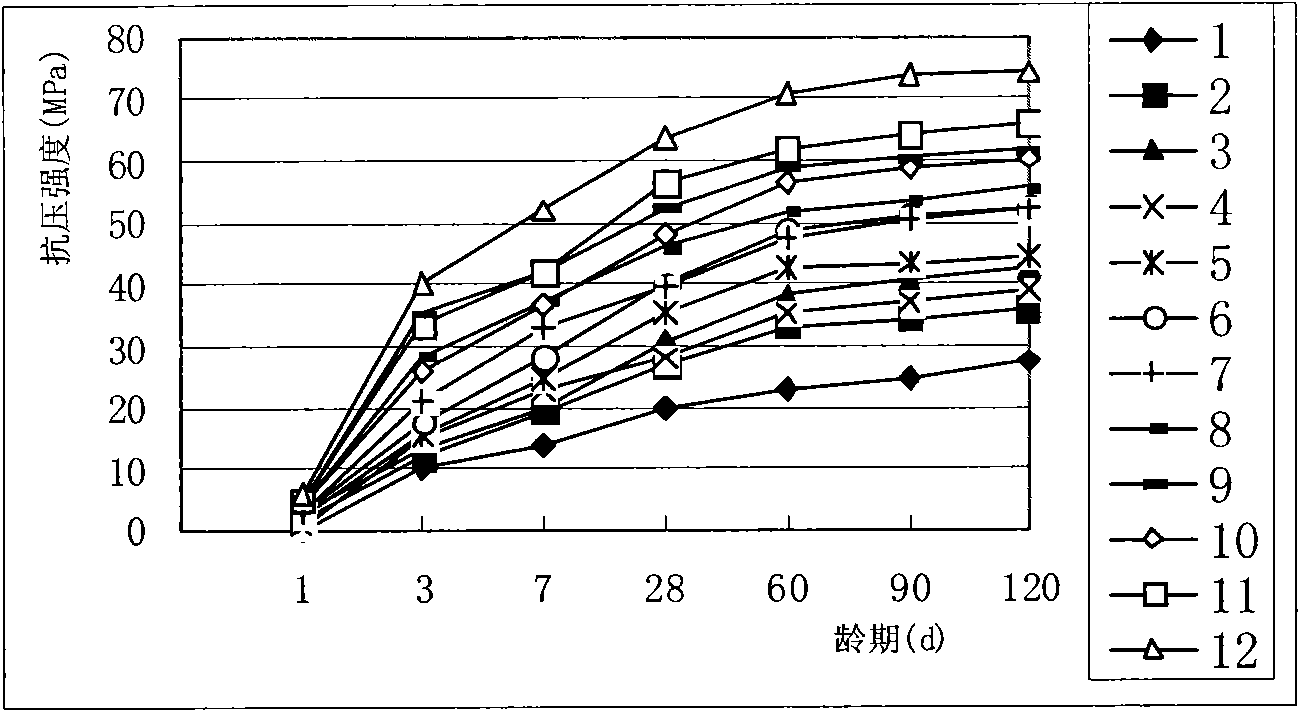

Self-compacting concrete

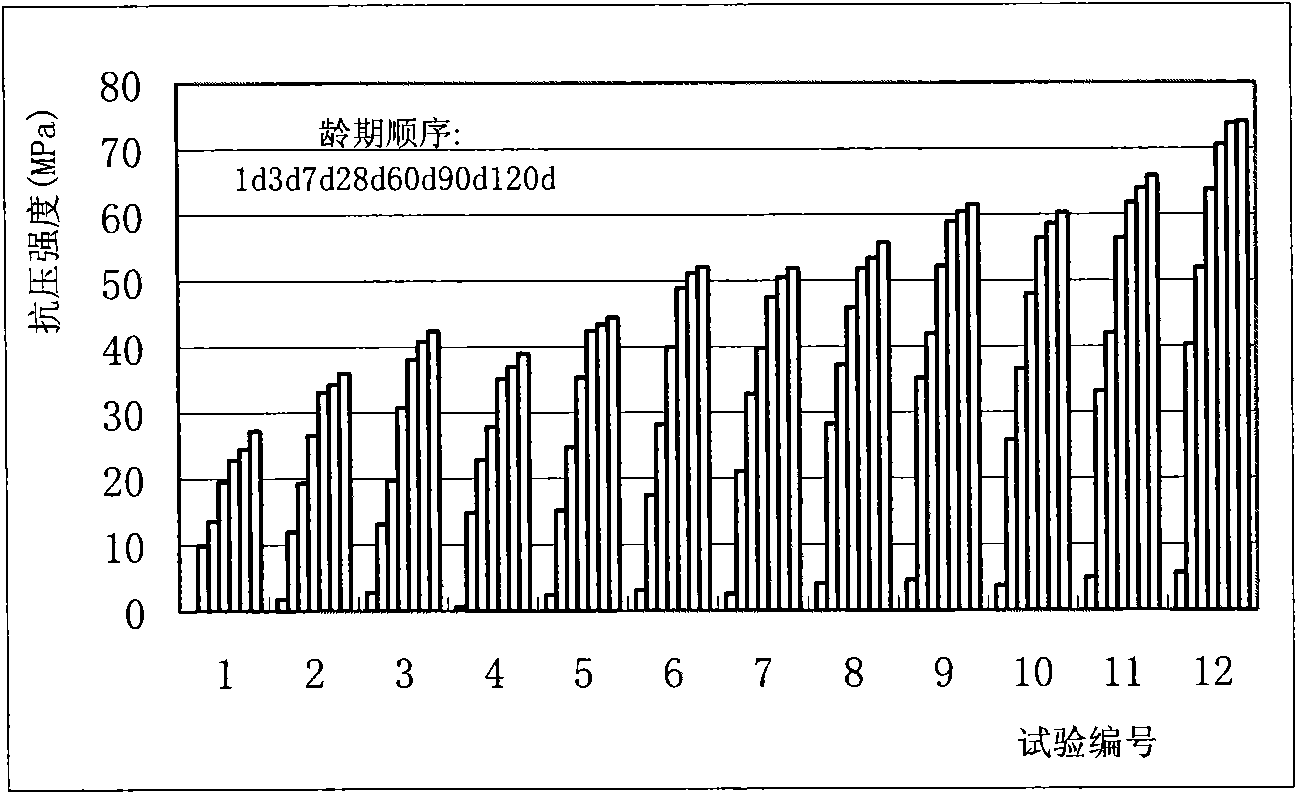

InactiveCN102060482AImprove volume stabilityIncreased durabilitySolid waste managementSuperplasticizerCoal

The invention relates to self-compacting concrete which is used for overcoming the contradiction between flowability and stability, early strength and delayed coagulation, contraction and expansion and the like of the self-compacting concrete in the prior art. In the invention, by means of combination of an aliphatic (hydroxyl) sulfonate superplasticizer and a polycarboxylic acid superplasticizer, selection and collocation of a cementing material and coarse and fine aggregates as well as specific mix design, the self-compacting concrete (more than C40) with low consumption of the cementing material is prepared from coal ash, mineral powder and tailings, wherein, a ketoaldehyde condensate is taken as the main component of the aliphatic (hydroxyl) sulfonate superplasticizer; and when the superplasticizer is added to cement paste, the mixed concrete has the advantages of good construction workability, less possibility of bleeding and segregation, no crystallization precipitate at low temperature and the like. Compared with the prior art, the self-compacting concrete prepared by the method provided by the invention has the advantages of lowering cement consumption by at least 70kg / m<3>, reducing consumption of the cementing material by at least 70kg / m<3>, comprehensively utilizing at least 470kg / m<3> of solid waste, and lowering concrete cost by at least **yuan / m<3>.

Owner:北京中联新航建材有限公司 +1

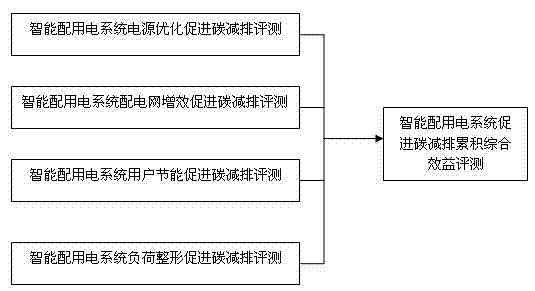

Carbon emission reduction evaluation and calculation method for intelligent power distribution and utilization system

ActiveCN103544541AConducive to emission reductionForecastingTechnology managementCouplingEngineering

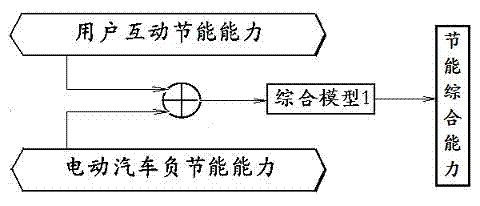

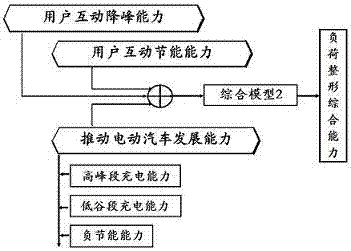

A carbon emission reduction evaluation and calculation method for an intelligent power distribution and utilization system includes the steps of making an evaluation technology route relating to the feature capacity of carbon emission reduction promotion (low-carbon capacity for short) and low-carbon benefit, creating an evaluation method for carbon emission reduction promotion by power supply optimization of the intelligent power distribution and utilization system, creating an evaluation method for carbon emission reduction promotion by power distribution network efficacy enhancement of the intelligent power distribution and utilization system, creating an evaluation method for carbon emission reduction promotion by energy saving of the intelligent power distribution and utilization system, creating an evaluation method for carbon emission reduction promotion by load shaping of the intelligent power distribution and utilization system, and creating an evaluation method for accumulated comprehensive benefits of carbon emission reduction promotion of the intelligent power distribution and utilization system. With the method, an intelligent power distribution and utilization system low-carbon benefit evaluation system is built and covers all related links and elements involving carbon emission reduction of the intelligent power distribution and utilization system, low-carbon benefit overlapping caused by electrical coupling and effect coupling is avoided, and thus, quantity of carbon emission reduction achieved by the intelligent power distribution and utilization system can be calculated accurately. The method is applicable to evaluation and calculation of carbon emission reduction of the intelligent power distribution and utilization system.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +1

Low cementitious material self-compacting concrete

ActiveCN102060481AIncrease plastic viscosityIncrease the slurry-solid ratioHigh strength concreteSelf-consolidating concrete

The invention discloses low cementitious material self-compacting concrete. Cement is a main raw material in a cementitious material of the self-compacting concrete; and if the cement consumption is high, overhigh concrete shrinkage is easily caused due to overhigh hydration heat of the cement, which is unfavorable for concrete crack control and concrete durability improvement, and problems such as disintegration, bleeding and the like easily occur. An additive XAMC is added into the concrete formula and can adsorb onto surfaces of particles to form a close adsorption layer so as to prevent the particles from flocculating and aggregating to realize the dispersion and stabilization function. Water-washing superfine sand which is rich in resources replaces partial mineral admixture, the low cementitious material self-compacting concrete can meet the basic requirement of high strength concrete by adding the XAMC under the condition of reducing cement consumption, and has obvious thickening and water retaining functions; concrete mixtures do not bleed or disintegrate, the homogenization and workability of the concrete are improved, and the concrete has important significance for saving energy and reducing emission.

Owner:北京元泰达环保科技有限公司

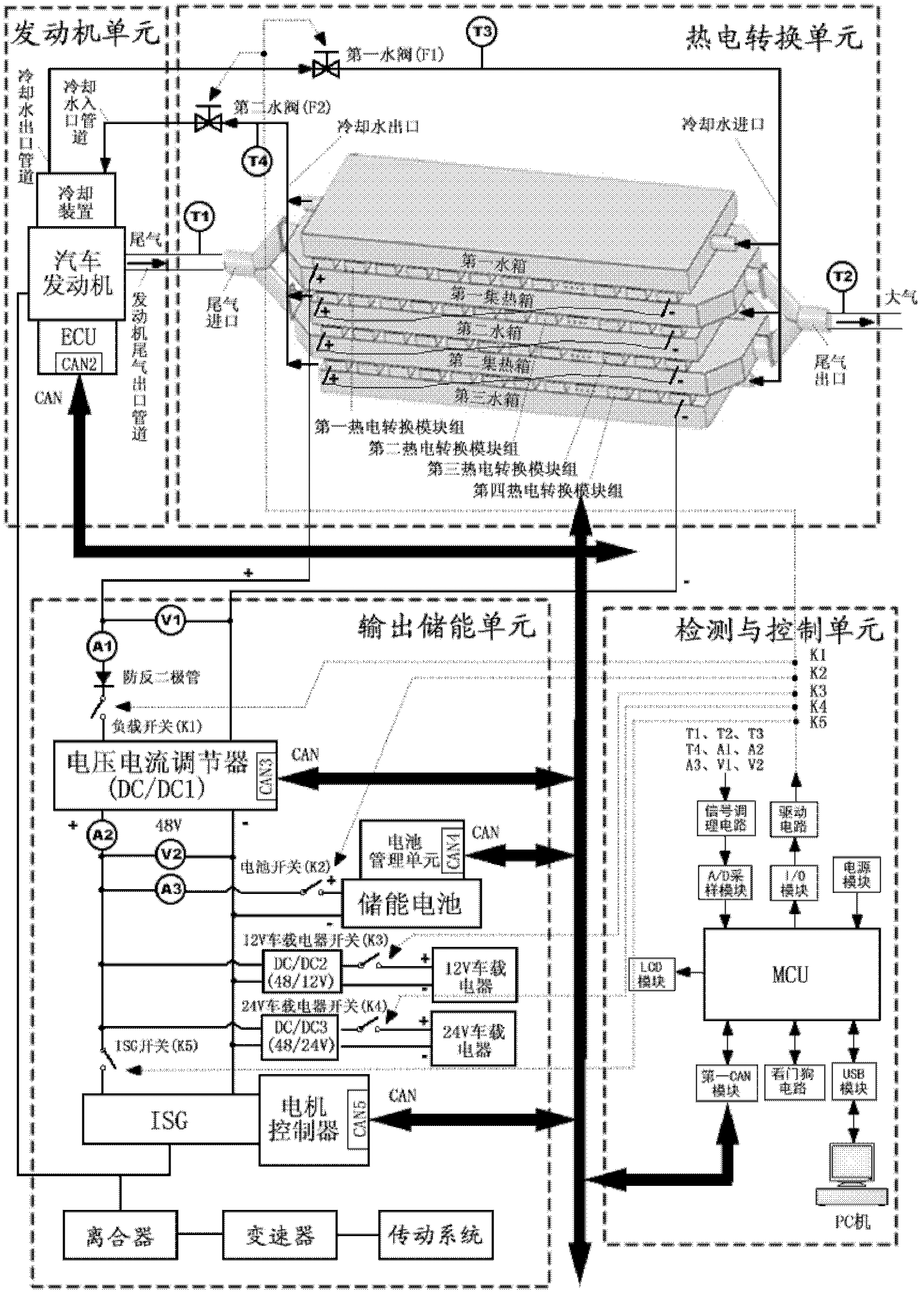

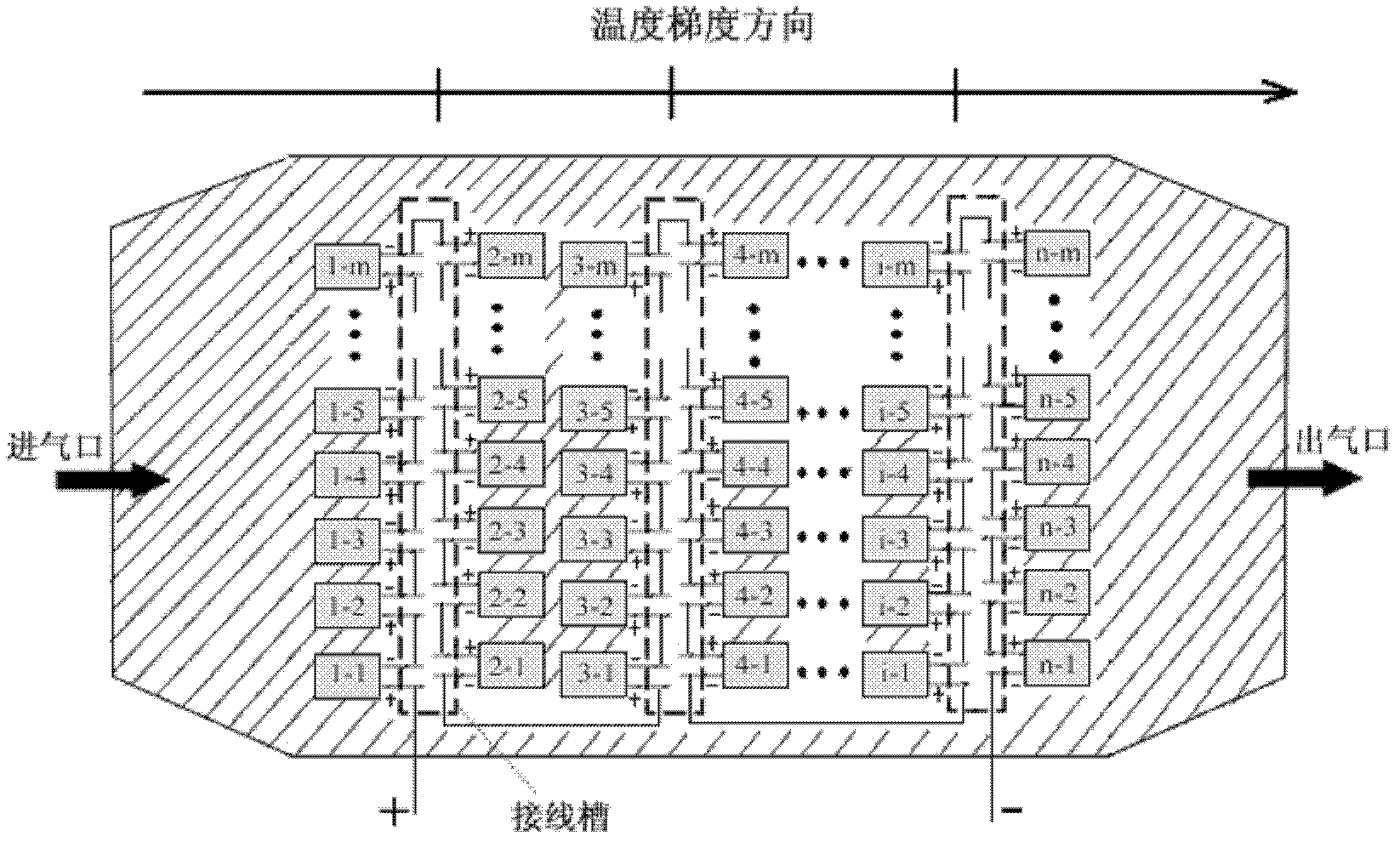

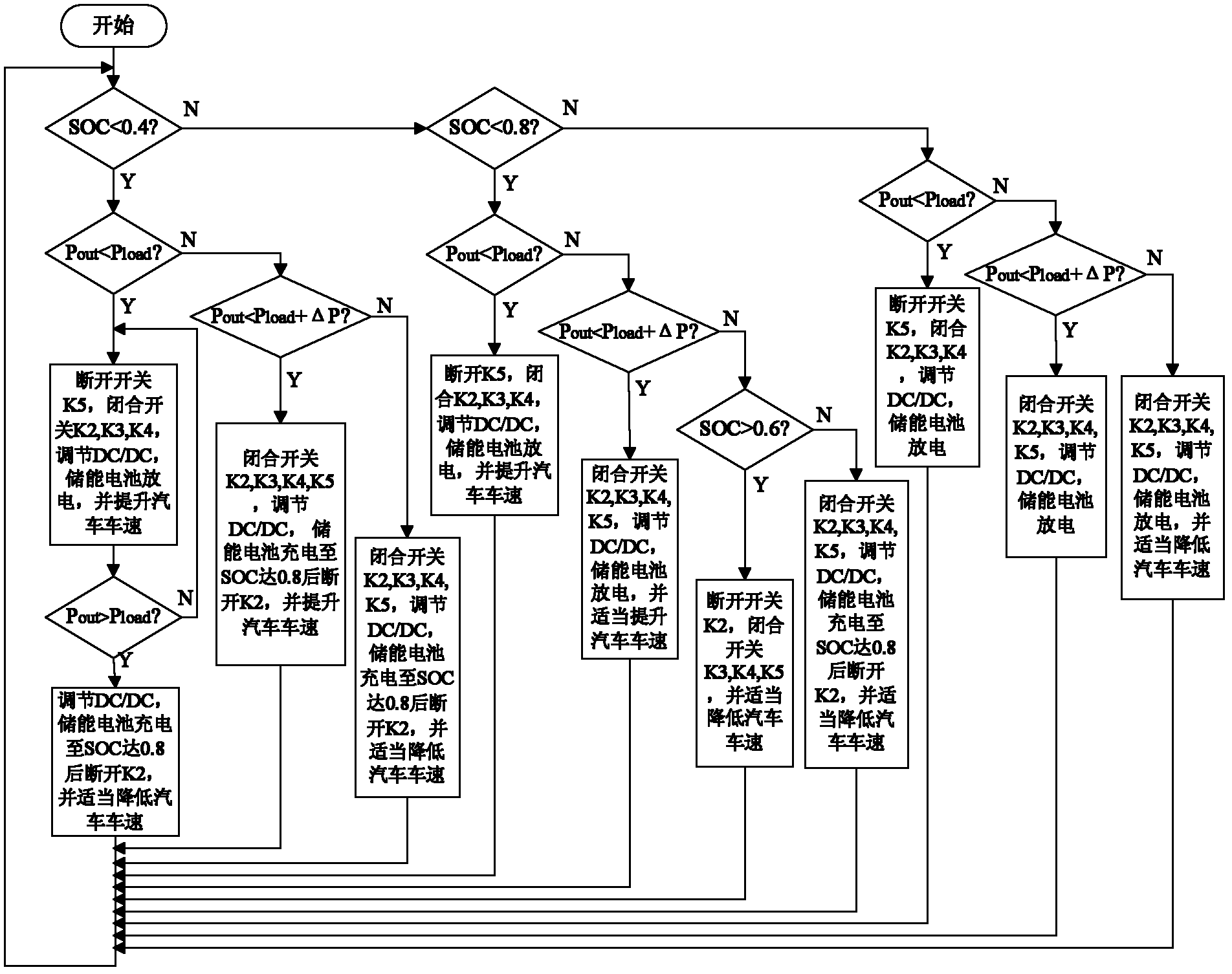

Vehicle exhaust waste heat thermoelectric conversion vehicle power supply system and control method

InactiveCN102281025AEmission reductionImprove work efficiencyBatteries circuit arrangementsElectric powerElectrical batteryAutomotive emissions

The invention relates to a thermoelectric conversion automotive power supply system using waste heat from automobile exhaust and a control method thereof, wherein the system is composed of an engine unit, a thermoelectric conversion unit, an output and electric energy storage unit and a detection and control unit. The system is characterized in that high temperature exhaust is discharged during the running of the engine and cooling water in a certain temperature range is provided; the heat brought by the high temperature exhaust is absorbed by hot terminals of a plurality of thermoelectric modules connected in series in the thermoelectric conversion unit, and cold terminals of the thermoelectric modules form temperature difference between the hot terminals and the cold terminals under thecooling effect of the cooling water of the automotive engine, so as to generate direct-current electric energy; the voltage and the current of the electric energy generated from the thermoelectric conversion unit are regulated by the output and electric energy storage unit, and the electric energy is used to supply on-vehicle appliances and ISG or charge the energy storage battery; the detection and control unit is used for detecting parameters, sending a control command and performing comprehensive energy management on the system. The system effectively recycles and utilizes the waste heat from the automobile exhaust, improves the economical efficiency of the fuel of the automotive engine, and is contributed to reducing the automobile exhaust emission.

Owner:WUHAN UNIV OF TECH

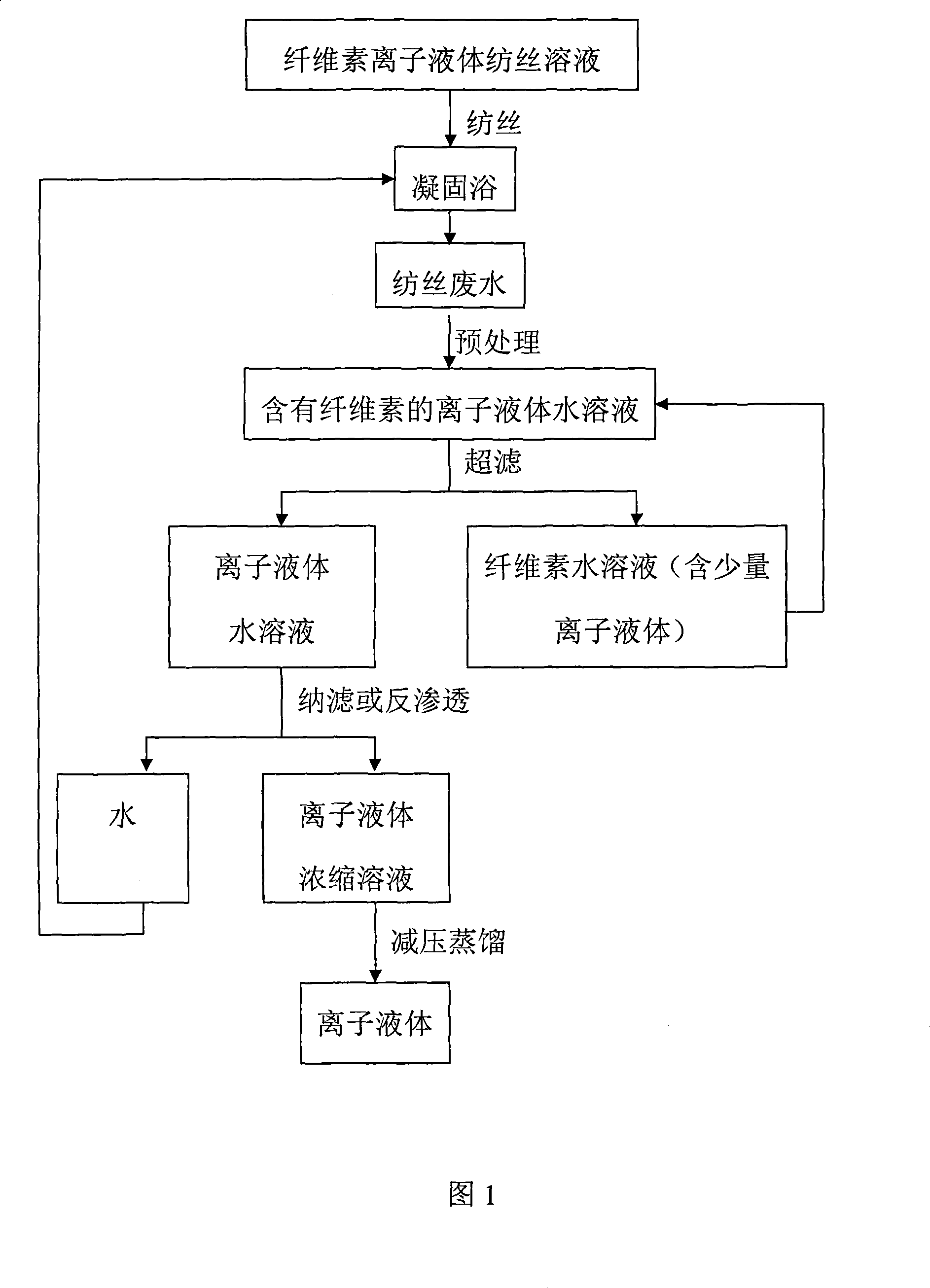

Method for recycling ion liquid from filature wastewater

InactiveCN101219840AReduce energy consumptionNo pollution in the processGeneral water supply conservationUltrafiltrationCelluloseReverse osmosis

The invention relates to a method for recycling the ionic liquid in spinning wastewater, which comprises the processes: first, the spinning wastewater is pretreated by precipitating, roughly filtering as well as finely filtering to obtain the pretreatment solution; then, the pretreatment solution is processed by ultrafiltration process to obtain the water solution of the ionic liquid with mass concentration of 0.01-5 percent and the separated cellulose and the cellulose in polyacrylonitrile or the polyacrylonitrile are further processed by ultrafiltration washing and concentration or drying and then the obtained solution is recycled; ultrafiltration membrane of molecular weight cutoff adopted by the ultrafiltration process is 6000-50000 and the operation pressure is 0.01-0.5MPa; the obtained ultrafiltration water solution is further processed by nanofiltration and the reverse osmosis to obtain concentration solution of the ionic liquid with mass concentration of 5-30 percent and removed water after concentration is recycled and reused; the desalinization ratio of the nanofiltration membrane is 50-98 percent and the operation pressure is 0.4-1.0MPa; the desalinization ratio of the reverse osmosis membrane is 98 percent and the operation pressure is 1.0-15MPa; at last, the concentration solution of the ionic solution is decompressed and distilled under 60-110 DEG C to obtain the ionic solution with purity of 95-99 percent.

Owner:TIANJIN POLYTECHNIC UNIV

Potato peeling, washing and shredding device

ActiveCN107485037AAchieve peeling effectEasy dischargeClimate change adaptationVegetable peelingPulp and paper industryHigh pressure

The invention discloses a potato peeling, washing and shredding device, and belongs to the field of food processing mechanisms. The potato peeling, washing and shredding device comprises a shredding mechanism, a peeling and washing mechanism, a material pushing mechanism and a transmission mechanism, wherein the peeling and washing mechanism comprises an inner cylinder, a roller and a rotating disc; the roller is located in the inner cylinder; a spiral piece is arranged on the roller; brushes are arranged on the inner wall of the inner cylinder and the outer wall of the roller; an inner shaft is fixedly connected to the lower end of the roller; the rotating disc is located at the lower end of the roller, and is fixed to the inner shaft; an annular sprinkling pipe is arranged at the upper end of the inner wall of the inner cylinder in the circumferential direction; high-pressure spray heads are uniformly distributed at the bottom of the annular sprinkling pipe; the shredding mechanism comprises an outer cylinder and a shredding cylinder which is fixedly arranged in the outer cylinder; the diameter of the upper end of the shredding cylinder is greater than that of the lower end of the shredding cylinder; an outer shaft is fixedly connected to the lower end of the shredding cylinder; the inner shaft and the outer shaft are connected with the transmission mechanism; and the inner shaft is embedded in the outer shaft. Through the adoption of the potato peeling, washing and shredding device disclosed by the invention, functions of peeling potatoes, washing the potatoes and shredding the potatoes can be realized; the processing procedures of the peeling of the potatoes and the shredding of the potatoes are simplified; and the working efficiency is greatly improved.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

New process for co-producing ultra-fine white carbon black and calcium carbonate

InactiveCN101898776AAddress effectivenessImprove qualityCalcium/strontium/barium carbonatesSilicaPhysical chemistryCarbide

The invention provides a method for co-producing white carbon black and calcium carbonate. Carbide slag or lime and quartz sand are used as main raw materials. The method comprises the following steps of: introducing sodium silicate solution into carbon dioxide to obtain a mixture of white carbon black and sodium carbonate or sodium bicarbonate, filtering the solution, adding lime or carbide slag into the solution, preparing caustic soda and ultra-fine calcium carbonate by causticizing reaction, adding the quartz sand into the filtered dilute alkali liquor, and reacting the mixture under a heating band pressure to obtain sodium silicate solution so as to realize circulation and co-production.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

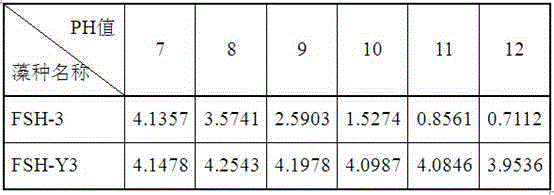

Parachlorella kessleri with tolerance to high pH and culture and applications of parachlorella kessleri

ActiveCN106467896AImprove solubilityEasy to fixUnicellular algaeMutant preparationSolubilityMicroorganism

The invention discloses parachlorella kessleri with the tolerance to a high pH and culture and applications of parachlorella kessleri. A parachlorella kessleri mutant strain FSH-Y3 with the tolerance to the high pH is obtained through the method adopting ultraviolet mutagenesis and acclimation screening utilizing step-by-step pH increase, the classification name is Parachlorella Kessleri, and the parachlorella kessleri strain FSH-Y3 is prepared in the China General Microbiological Culture Collection Center (CGMCC) on May 26, 2014, and is assigned with the accession number of CGMCC No.9238. The bred parachlorella kessleri FSH-Y3 can well absorb and utilize carbon dioxide at the high pH, and rapidly grow and reproduce, therefore, the problems that the existing parachlorella kessleri only can grow at the neutral pH, but the solubility of carbon dioxide is low, and the carbon dioxide fixing efficiency is low under the neutral pH condition are solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

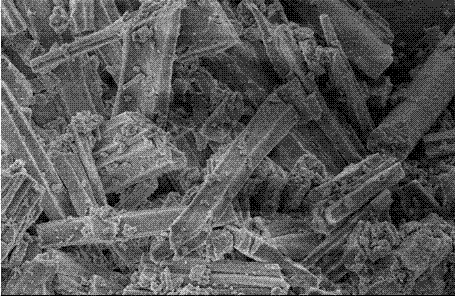

Preparation method of prismatic biological calcium carbonate

InactiveCN103571235AWide variety of sourcesImprove surface activityPigment treatment with organosilicon compoundsPigment physical treatmentPotassium hydroxideMechanical property

The invention discloses a preparation method of prismatic biological calcium carbonate. The preparation method comprises the following steps: washing shells to remove residues, soaking the shells in a sodium hydroxide solution, a potassium hydroxide solution or a sodium hypochlorite solution and washing the shells to remove stratum corneum; soaking the samples without the stratum corneum in a sodium hydroxide solution or a potassium hydroxide solution for 30-180 minutes, and washing the samples in a roller for separating prismatic layers of the shells from nacreous layers of the shells, thus obtaining the prismatic layers of the shells; mixing powder obtained by grinding the prismatic layers of the shells with water and a grinding aid and stirring the mixture at high speed to prepare pulp; grinding the prepared pulp and performing dehydration, washing and re-dehydration to obtain filter cakes; adding water to the washed filter cakes to prepare pulp and adding a surfactant in the stirring process; drying surface modified shell prismatic biological calcium carbonate and then breaking the dried surface modified shell prismatic biological calcium carbonate apart, thus obtaining the finished product. The shell prismatic biological calcium carbonate has natural oleophylic hydrophobicity and excellent mechanical property, has good compatibility with matrixes and is uniformly distributed in the matrixes.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

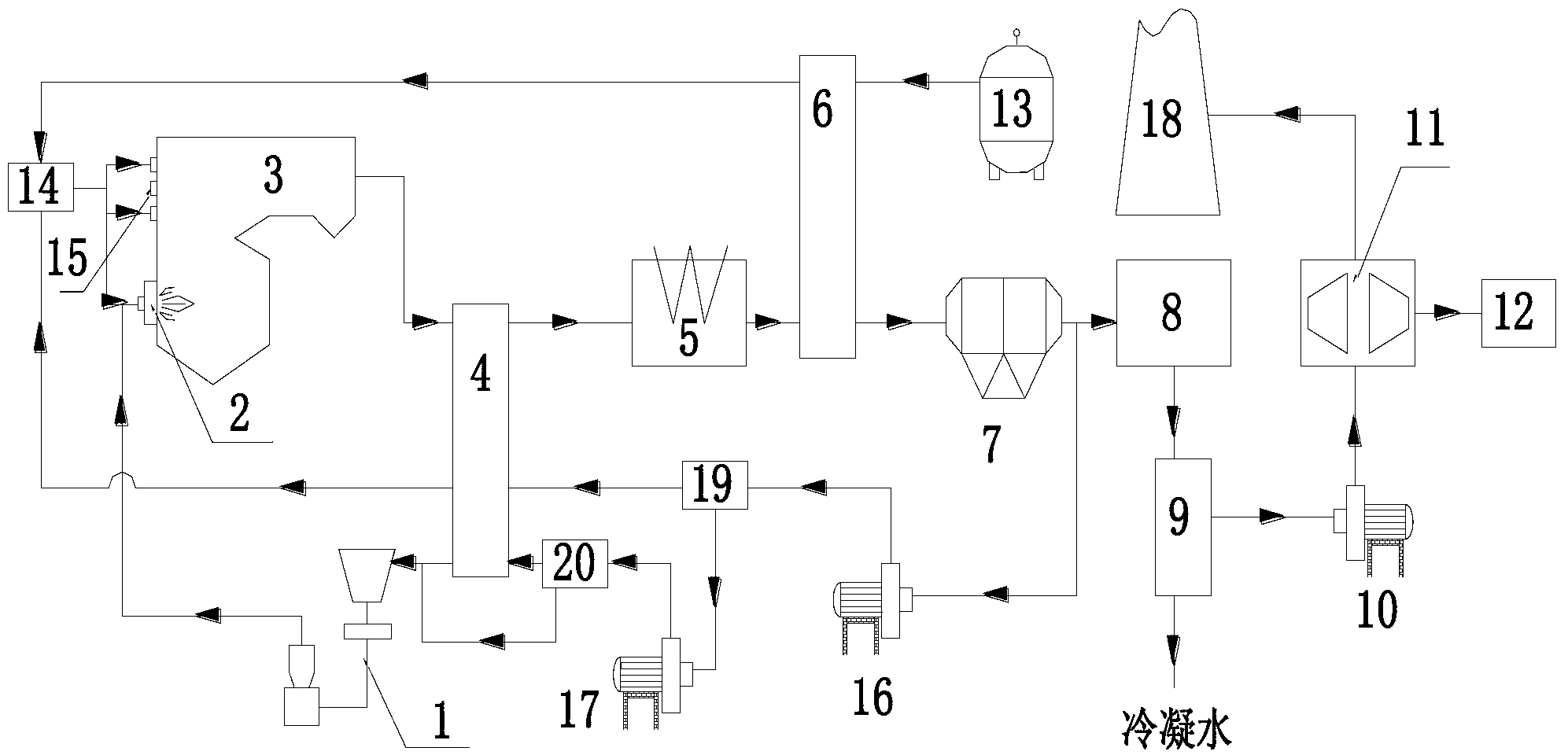

Superfine coal dust oxygen-enriched combustion technology and system

InactiveCN103234198AIncrease burnoutAlleviate the problem of slagging on the heating surfaceCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelTrappingFlue gas

The invention discloses a superfine coal dust oxygen-enriched combustion technology and system in the technical field of energy conservation and emission reduction. The technology comprises the following steps of: preparing superfine coal dust with an average particle size of less than 20 microns, and burning in an oxygen-enriched environment with overall concentration kept at 27-35% (v / v); extracting part of the hot flue gas in a flue at the rear part of a deduster; and circularly preparing superfine coal dust by taking the extracted flue gas and oxygen as combustion-supporting mediums again. According to the technology and system disclosed by the invention, the superfine coal dust is applied to the oxygen-enriched combustion technology, and the advantages of the two are effectively combined to realize an effect of using advantages and bypassing disadvantages; and the superfine coal dust oxygen-enriched combustion technology finishes efficient trapping of CO2 and is a new coal dust combustion technology with good combustion property and better pollutant discharge performance, and surely becomes an emerging technology for pollutant cooperative removal deserving vigorous promotion.

Owner:SHANGHAI JIAO TONG UNIV

Mineral admixture concrete

The invention relates to a mineral admixture concrete. Mineral admixtures are used as concrete cementitous materials, common concrete and a complex of gypsum and sodium sulfate are added and used as activity excitants so as to coordinate the combined action of naphthalenesulfonate formaldehyde condensate and a crude anthracene sulfonate superplasticizer, and the high-efficiency concrete is prepared. Compared with the prior art, the excitants in the invention has the advantages that early excitation effect is good, mixing amount is less, the early or later strength and durance of the concrete can be greatly improved, the concrete dosage is reduced by 5-20% under the condition of maintaining the strength and workability of the concrete not to be changed, and the gypsum and sodium sylfate are both industrial byproducts with low costs. In the invention, concrete plaster is mixed in advance by using a secondary feeding method, residual materials are added in the mixed concrete plaster, and the strength of the concrete is improved while reducing the abrasion of coarse aggregates on equipment. The concrete has the advantages of good workability and less bleeding, is convenient for construction, and can be applied to large-volume concrete engineering, underground engineering, seaport engineering and the like.

Owner:北京元泰达环保科技有限公司

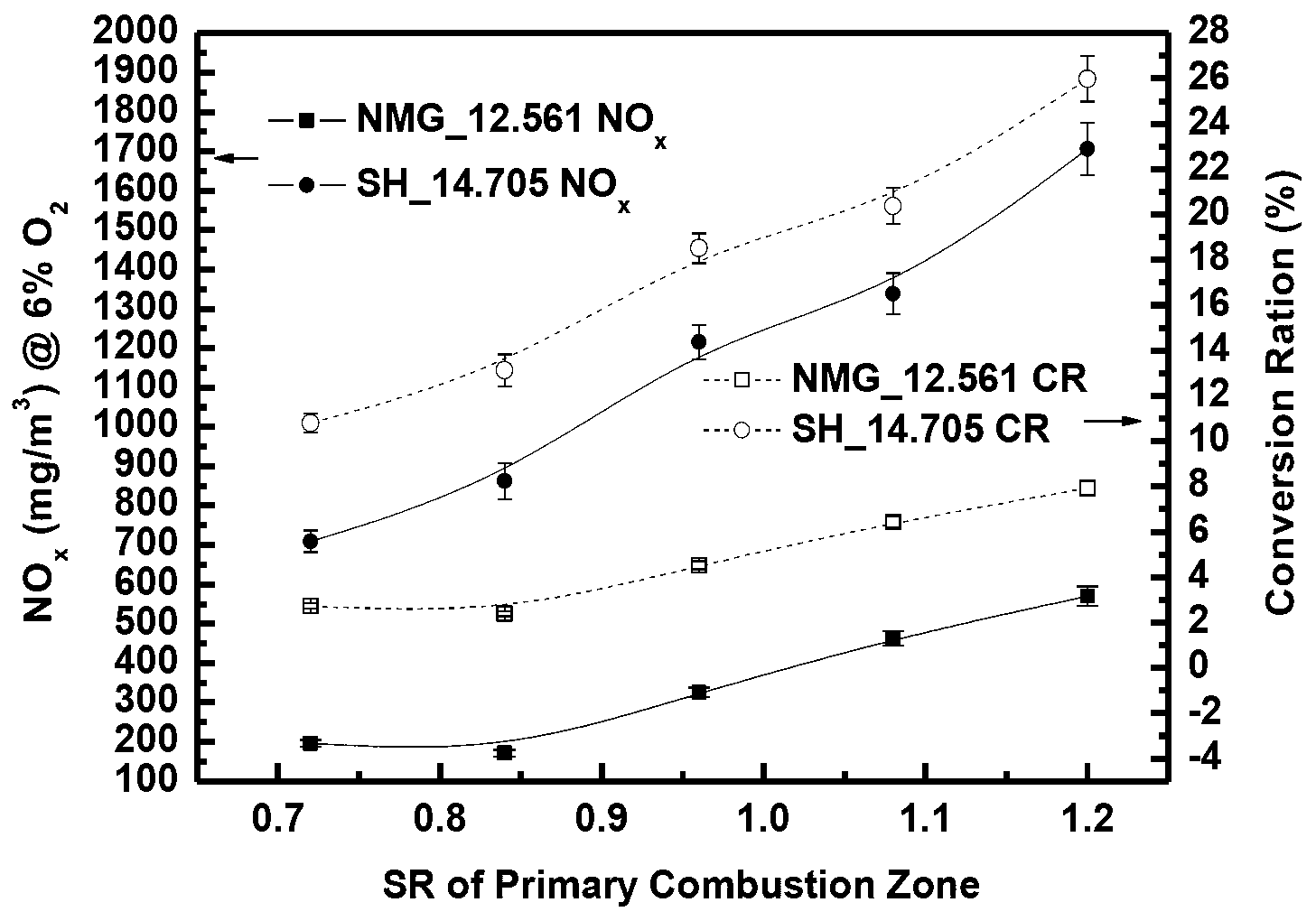

Method for reducing nitrogen oxide of powder coal boiler mixed burning gas fuel

InactiveCN101050853AGuaranteed combustion efficiencyEmission reductionCombustion using gaseous and pulverulent fuelBurnersOxygenMixed gas

A method for decreasing nitrogen oxide of mixed gas fuel used on pulverized-coal boiler includes dividing gas fuel to be two grades then leading them into pulverized-coal furnace tank, leading in primary gas fuel as combustion-assistant fuel at bottom of master burner at master combustion region to burn it by utilizing gradation air-combustion technique with low air overdose parameter, leading in secondary gas fuel at top of master combustion region to form reducing atmosphere of re-combustion region and leading in burn out air at top of re-combustion region.

Owner:HARBIN INST OF TECH

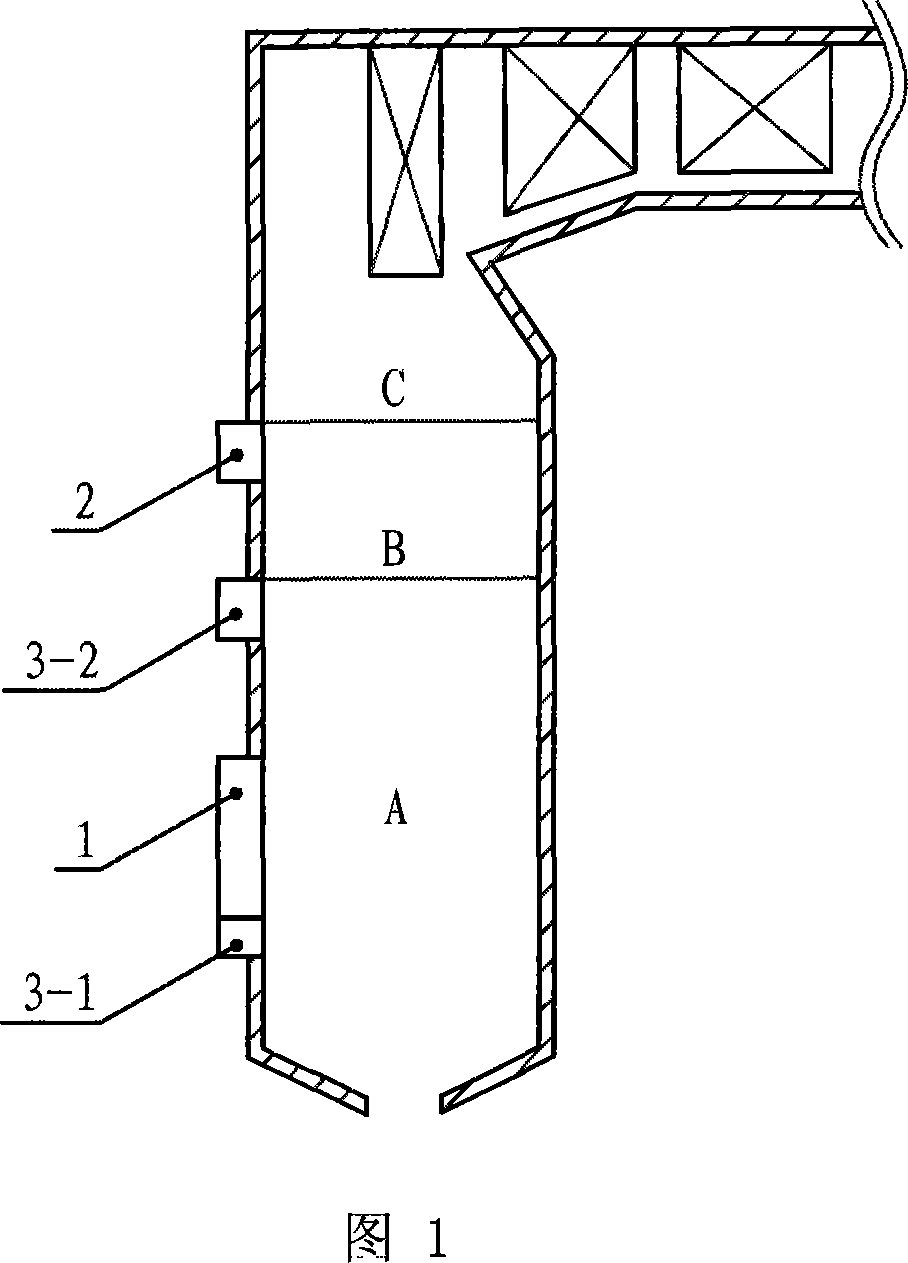

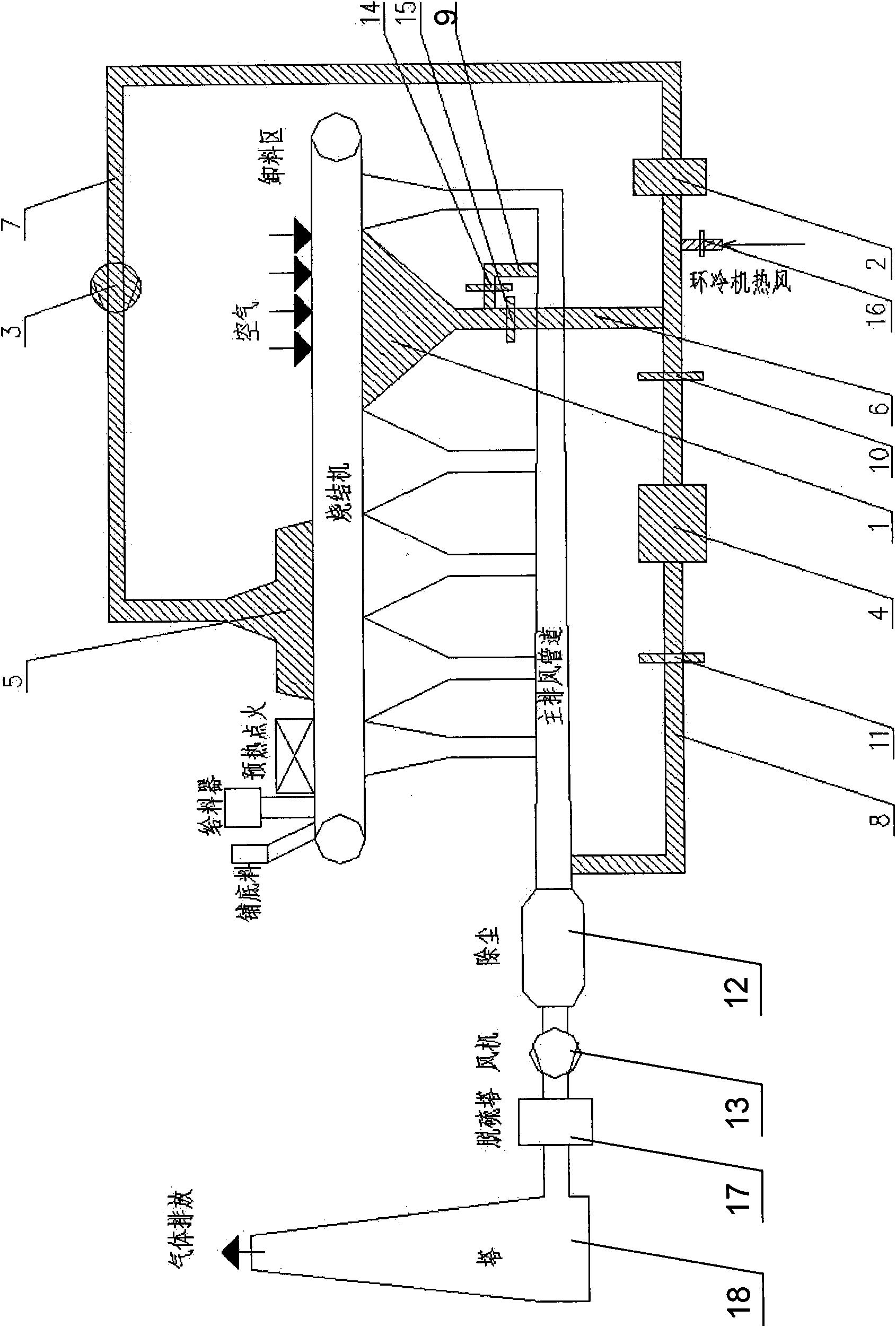

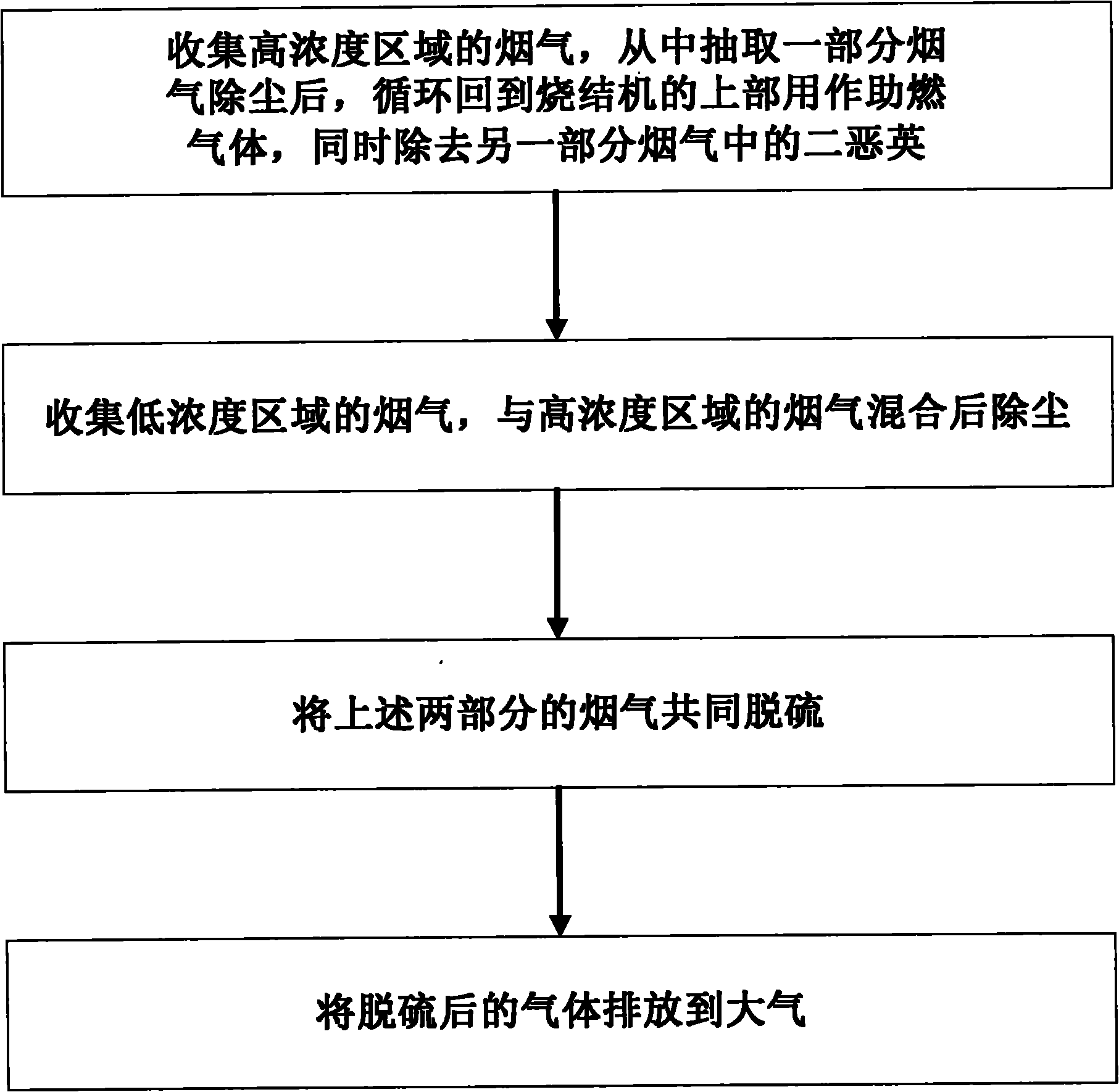

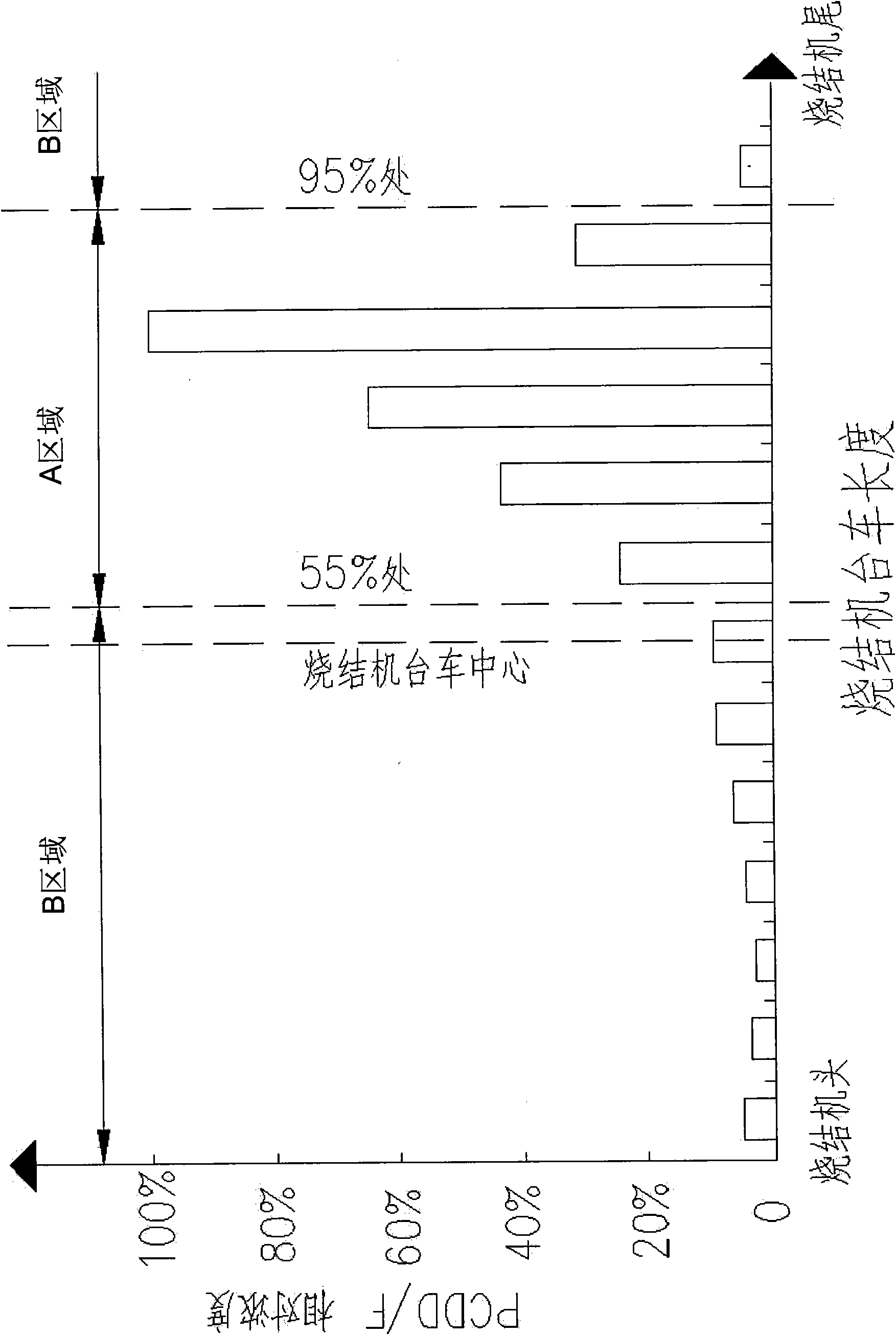

Low energy consumption sintering flue gas dioxin emission-reducing system and method thereof

InactiveCN101822946AConducive to emission reductionEmission reductionDispersed particle separationHigh concentrationAtmospheric air

The invention relates to a low energy consumption sintering flue gas dioxin emission-reducing system and a method thereof. The system comprises a main flue exhaust pipeline, a main dust remover, an air blower, a dioxin desorption system, a closed gas hood, a high dioxin compound flue gas flue, a circulating air pipeline, a dioxin compound desorption flue, a bypass flue, a dust remover, the other air blower, a desulfurizing tower and a chimney. A low-concentration area exhaust box is connected with the main flue exhaust pipeline, passes through the main dust remover, the air blower and the desulfurizing tower in sequence to reach the chimney, and then the flue gas is exhausted to the air. The closed gas hood covers above a sintering machine board trolley; one end of the high dioxin compound flue gas flue is connected with a high-concentration area exhaust box; and the other end of the high dioxin compound flue gas flue is connected with the dioxin compound desorption flue and the main dust remover of the main flue exhaust pipeline. The method comprises the steps of collecting flue gas, removing dioxin in the flue gas, removing dust, desulfurizing, exhausting to the air and the like. The invention greatly reduces the flue gas to be purified and treated, reduces the construction investment and the operation cost, and is beneficial to reducing the emission of various pollutants in sintering flue gas.

Owner:BAOSTEEL ENG & TECH GRP

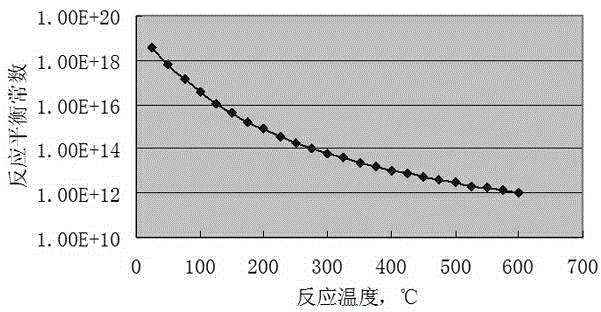

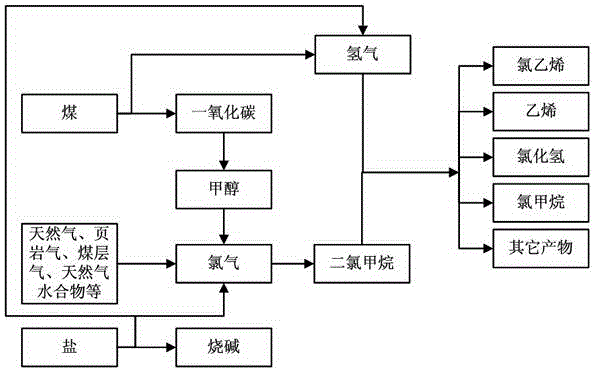

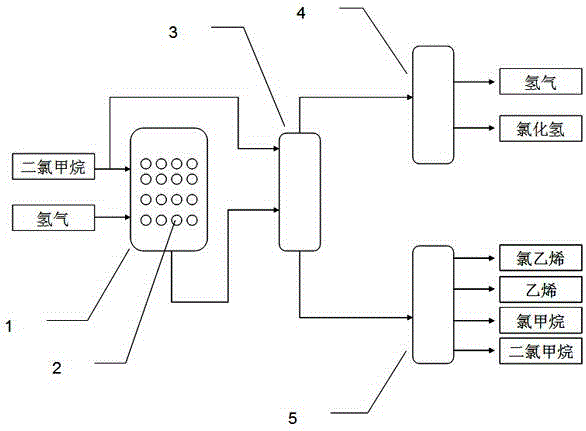

Method for preparing chloroethylene monomer from dichloromethane

ActiveCN104402668AReduce usageEasy to save energyHalogenated hydrocarbon preparationHydrogenReaction temperature

The invention discloses a method for preparing a chloroethylene monomer from dichloromethane. Under the condition of existence of a catalyst with hydrogenation activity, dichloromethane and hydrogen react to prepare the chloroethylene monomer; the reaction equation is 2CH2Cl2+H2=C2H3Cl+3HCl; the mole ratio of hydrogen to dichloromethane is (0.01-20) to 1; the reaction temperature of the reaction is 25-600 DEG C, and the reaction pressure is 0.001-10 atm. According to the method, raw materials are readily available and are low in cost, so that the production cost is low, and the reaction conversion rate is high; the chloroethylene monomer is high in selectivity; the method is a novel chloroethylene monomer synthesis technology and is suitable for being popularized and applied.

Owner:YIBIN TIANYUAN GRP CO LTD +1

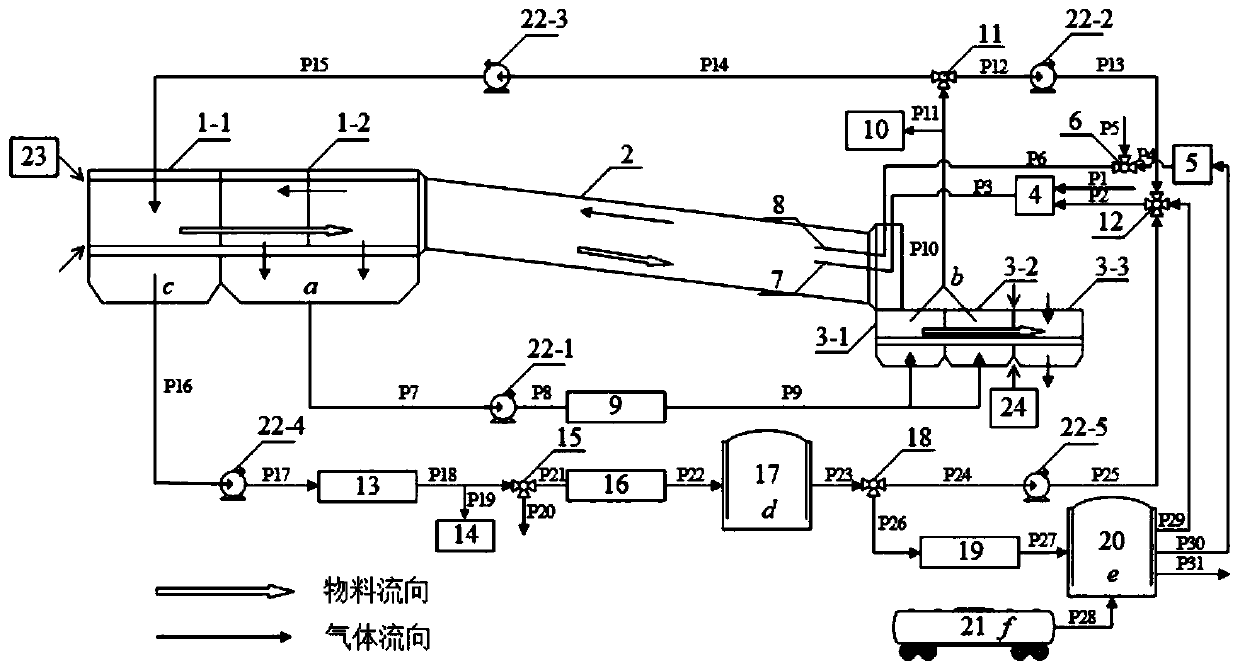

Pellet production technology and preparation system based on exhaust circulation O2-CO2 combustion supporting

ActiveCN109813129AReduce inputReduce generationCarbon compoundsRotary drum furnacesHigh concentrationNitrogen

The invention discloses a pellet production technology and preparation system based on exhaust circulation O2-CO2 combustion supporting, and belongs to the field of pellet environment-friendly efficient preparation production in the ferrous metallurgy process. The physical heat of exhaust in the production process is used for drying and preheating of pellets, and the exhaust containing high-concentration CO2 is directly mixed with or mixed with industrial pure oxygen after being purified to serve as combustion-supporting gas of fuel. According to the pellet production technology and preparation system, the waste heat of the exhaust is sufficiently utilized, and the heat utilization efficiency of the pellet preparation system is improved; approximate zero input of nitrogen of the pellet preparation system is achieved, and the generation amount of NOx in the production process is decreased from the source; and the exhaust containing the high-concentration CO2 can be used for preparing industrial grade / food grade CO2 with low cost, and a CO2 recycling and emission reduction approach is provided.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for producing ultra-low carbon steel by use of VD (vacuum degasser) device

InactiveCN108330253AIncreased decarburization rateMetallurgical effect to achieve deep decarburizationBrickDegasser

The invention discloses a method for producing ultra-low carbon steel by use of a VD (vacuum degasser) device and belongs to the technical field of refining of molten steel. In the molten steel refining treatment process of the VD device, carbon dioxide is taken as bottom blowing gas for bottom blowing of a steel ladle of the VD device, CO2 and C elements in the molten steel react in the high-vacuum state for forced decarbonization, forced decarbonization and natural forced decarbonization of the molten steel are combined, the decarbonization rate of the VD device is increased, and the metallurgical effect is realized. A steel ladle bottom blowing system is configured with two kinds of gas, namely, carbon dioxide and argon, carbon dioxide and argon can be switched for use, carbon dioxide is used in the vacuum state in the treatment cycle, and argon is adopted in the non-vacuum state in the treatment cycle. The method has the benefits as follows: forced decarbonization and natural forced decarbonization of the molten steel are combined, and ultra-low carbon steel production by the VD device is realized, removal of impurities in steel can be promoted, the desulfurization rate can beincreased, and production of high-purity steel by the VD device is realized; the temperature of the molten steel in the CO2 bottom blowing area is reduced, a bottom blowing brick is protected, and corrosion to the bottom blowing brick is reduced.

Owner:BEIJING SHOUGANG INT ENG TECH

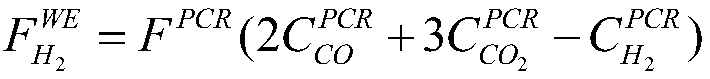

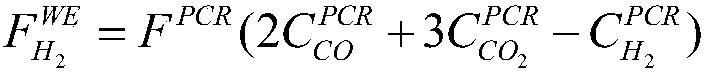

Method of using methanol, carbon dioxide and water to prepare high-quality synthetic gas

ActiveCN108408690AIncrease concentrationImprove energy efficiencyHydrogenElectrolysis componentsCatalytic reformingHigh energy

The invention provides a method of using methanol, carbon dioxide and water to prepare high-quality synthetic gas. The water generates oxygen and hydrogen in a water electrolytic cell at the same time; all or part of oxygen is mixed with methanol and carbon dioxide, and a mixture flows into a plasma catalytic reforming reactor to generate reforming product gas; the reforming product gas is mixed with hydrogen generated by a cathode of the water electrolytic cell to obtain the high-quality synthetic gas; methanol, carbon dioxide and the water are used as raw materials, so that the raw materialsare rich in resource and renewable, and emission reduction of CO2 is facilitated. The generated synthetic gas is high in concentration, meets a requirement that a molar ratio of methanol synthesis and Fischer-Tropsch synthesis (H2-CO2) / (CO+CO2) is equal to 2, and can be directly applied in methanol synthesis and Fischer-Tropsch synthesis without aftertreatment. Through plasma catalytic reformingand electrolytic water reaction coupling, electric energy is converted into chemical energy through a synthetic gas route, and a reaction system has the advantages of high energy efficiency, quick response and flexibility in regulation and is especially suitable for large-scale storage of regenerated electric energy.

Owner:DALIAN UNIV OF TECH

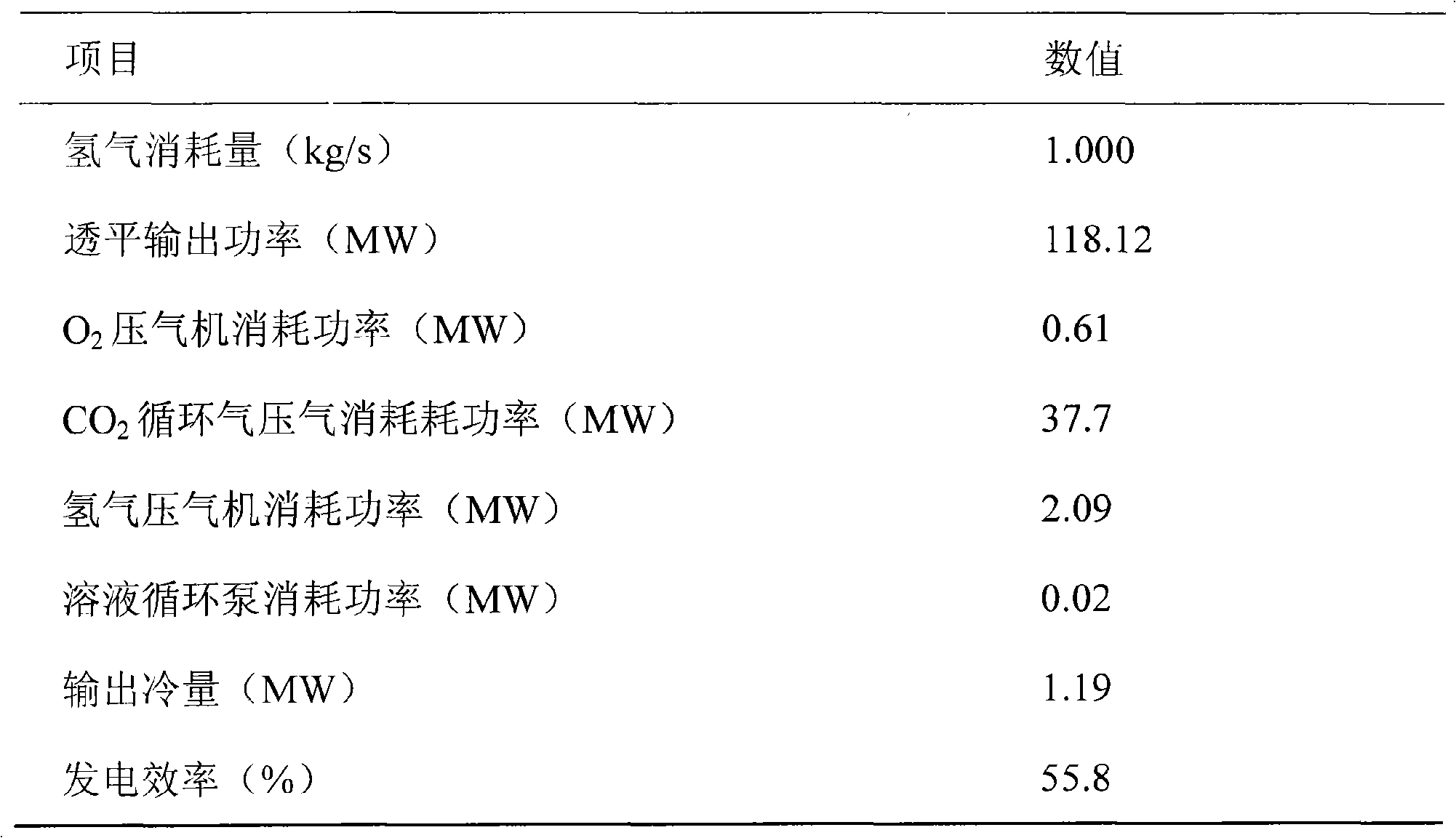

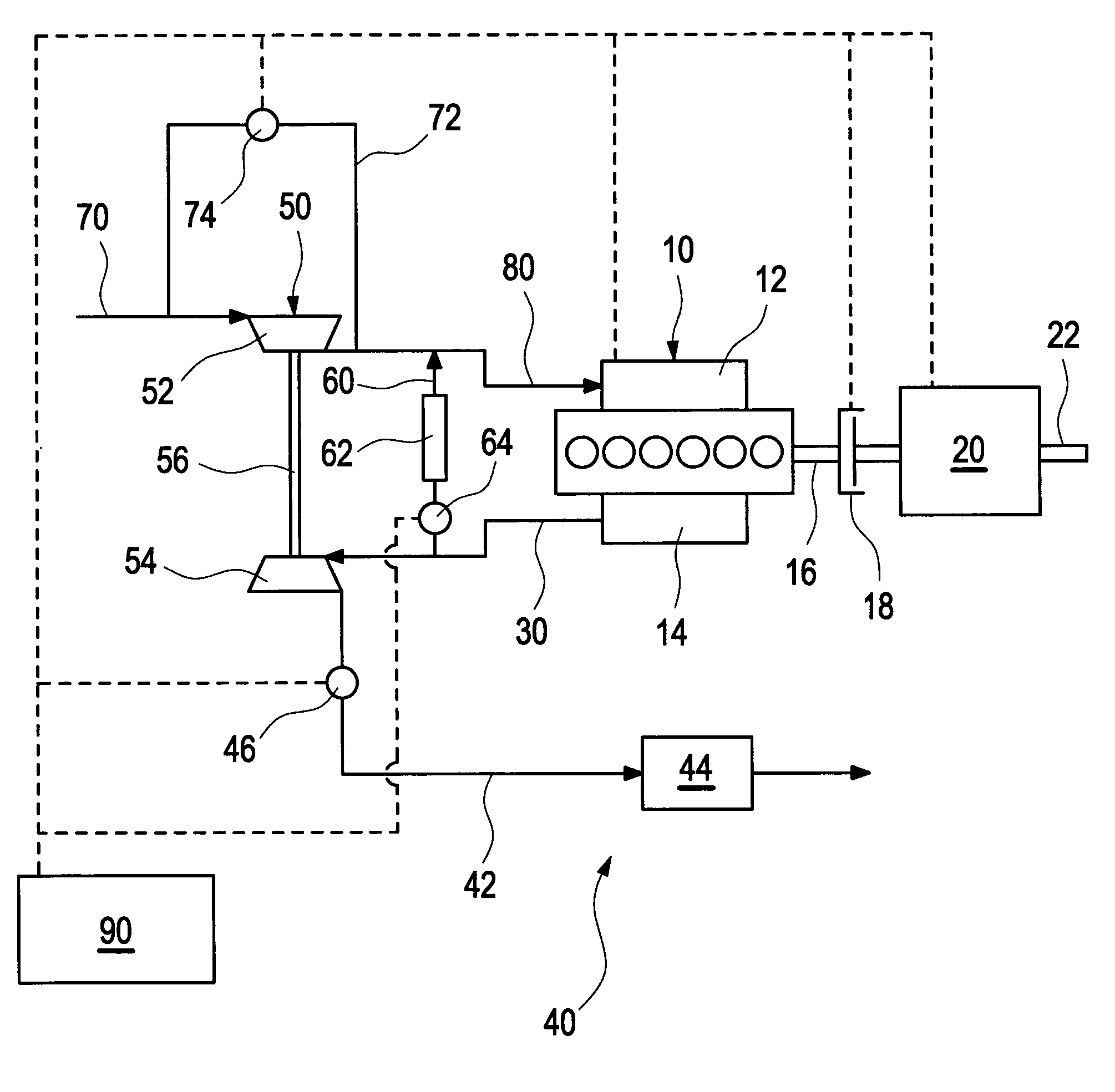

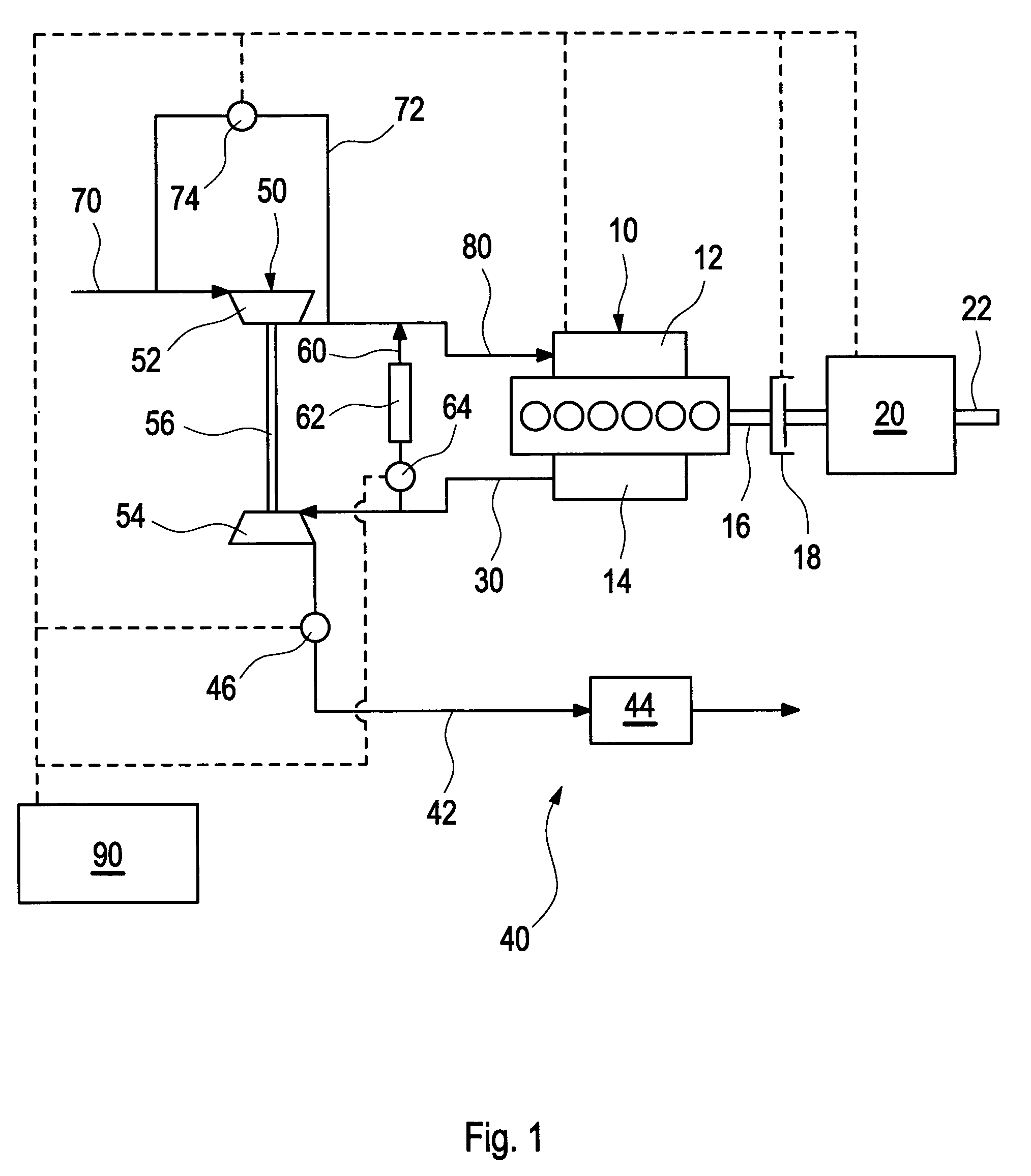

Power cycle method using hydrogen as fuel

InactiveCN101566103AImprove power generation efficiencyEfficient recyclingGas turbine plantsChemical reactionCombustion chamber

The invention provides a power cycle method using hydrogen as fuel. The method comprises the following steps that: H2 and CO2 are first subjected to inverse transform reaction and then used for chemical back heating of the O2 / CO2 power cycle using hydrogen as the fuel, and a gaseous material richly containing hydrogen is mixed with pressurized circulation gas of CO2; the mixing gas enters an inverse transform reactor to undergo an endothermic chemical reaction to form vapor and CO, and the heat needed in the reaction is provided by the turbine high-temperature discharged gas; the gas generated in the reaction and the pressurized oxygen gas enter a combustion chamber respectively to form high-temperature and high-pressure vapor and CO2; the high-temperature gas passes a gas turbine for turbine power generation; the turbine high-temperature discharged gas first provides heat for the inverse transform reactor, then rejects heat to a waste heat recovering system, and further is cooled and condensed, and H2O in the turbine high-temperature discharged gas is separated; and the remained circulation gas of CO2 is first cooled and supercharged and then returned to a circulation gas mixer. By the technology of chemical back heating, waste heat refrigeration and inlet gas cooling for the inverse transform reaction, the method realizes the highly efficient utilization of hydrogen, and can simultaneously generate electricity and refrigeration with high efficiency.

Owner:BEIJING UNIV OF CHEM TECH

Method for controlling an exhaust gas temperature

ActiveUS8849550B2Conducive to emission reductionImprove efficiencyAnalogue computers for vehiclesElectrical controlEngineeringOperation mode

A method is provided for controlling an exhaust gas temperature of an engine of a vehicle during interruption of fuel supply to the engine, wherein the engine drives a driveline of the vehicle. The method involves alternating between two or more operational modes, wherein at least one of the operational modes maintains a higher exhaust temperature than the one or more other operational modes.

Owner:VOLVO LASTVAGNAR AB

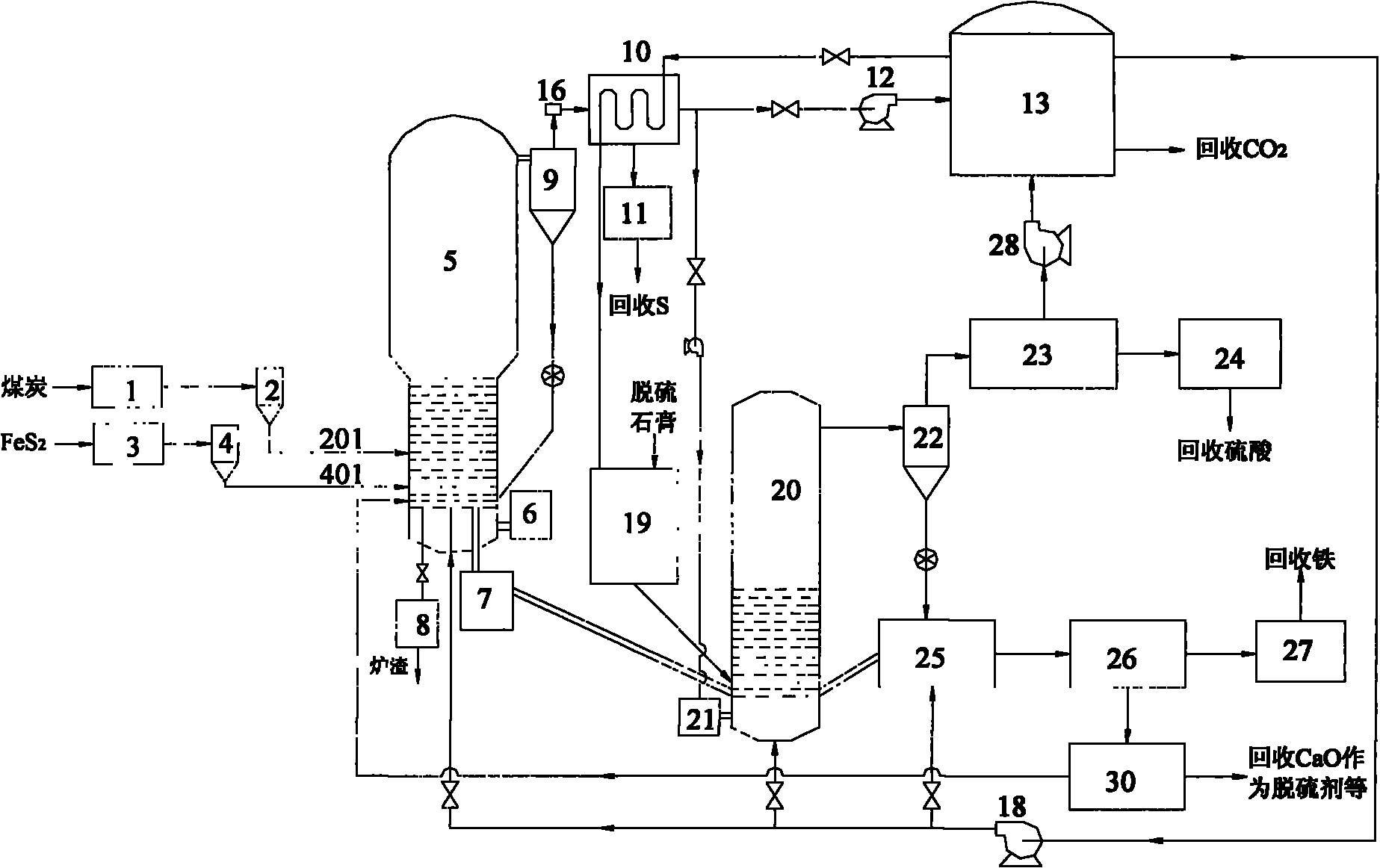

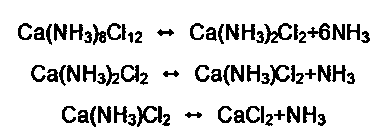

Method for comprehensively treatment of pyrite and desulphurized gypsum by utilizing coal and system thereof

InactiveCN101870493ASimple structureLow operating temperatureCarbon compoundsSulfur compoundsCombustion chamberPyrite

The invention discloses a method for comprehensively treatment of pyrite and desulphurized gypsum by utilizing coal and a system thereof. Coal and CO produced by the same are taken as reducing agents, the pyrite is directly reduced into reduced ferrum Fe and simple substance sulphur S, the desulphurized gypsum is reduced and decomposed into lime CaO and SO2, SO2 is used for preparing sulphuric acid or simple substance sulphur, and the lime CaO can be returned to a desulphurization system to be used as desulphurizing agent or ferrous metallurgy auxiliary material, thus sulphur and ferrum resources are recycled. The system is composed of a fluidized bed pyrite decomposing device, a fluidized bed desulphurized gypsum reaction device, a pyrite feeding device, a coal feeding device, a CO rapid cooling device, a high temperature non-mechanical valve, a desulphurized gypsum drying and feeding device, an ash cooling device, a Fe / CaO collecting and sorting device, a CaO returning device, a combustion starting chamber, a CO combustion device, a CO2 / SO2 cooling and sulphuric acid producing device, a CO2 storage tank, a fan and pipelines.

Owner:NANJING NORMAL UNIVERSITY

Low-sulfur ester-based composite fuel oil

InactiveCN101812331AEasy to catch fireIncrease cetane numberBiofuelsLiquid carbonaceous fuelsBiodieselSulfur

The invention relates to low-sulfur ester-based composite fuel oil which can be used by automobile engines, various boilers and industrial furnaces. The ester-based composite fuel oil comprises biological diesel oil, dimethyl ether and an antioxidative stabilizer, wherein the biological diesel oil accounts for 51 to 99 weight percent of the ester-based composite fuel oil, the dimethyl ether accounts for 1 to 49 weight percent of the ester-based composite fuel oil, and the antioxidative stabilizer accounts for 0.0001 to 2 weight percent of the ester-based composite fuel oil. The fuel oil replaces high-price fossil fuel resources by low-cost renewable resources, belongs to oxygen-enriched fuel, has little theoretical air quantity required by combustion and sufficient combustion, can reduce the discharge quantity of flue gas, lowers the loss of the heat value of the discharge of the flue gas, lowers the concentration of sulfur and nitrogen compounds and granular dust in the discharged flue gas greatly and is beneficial to environmental protection, energy saving and discharge reduction.

Owner:KUNMING UNIV OF SCI & TECH

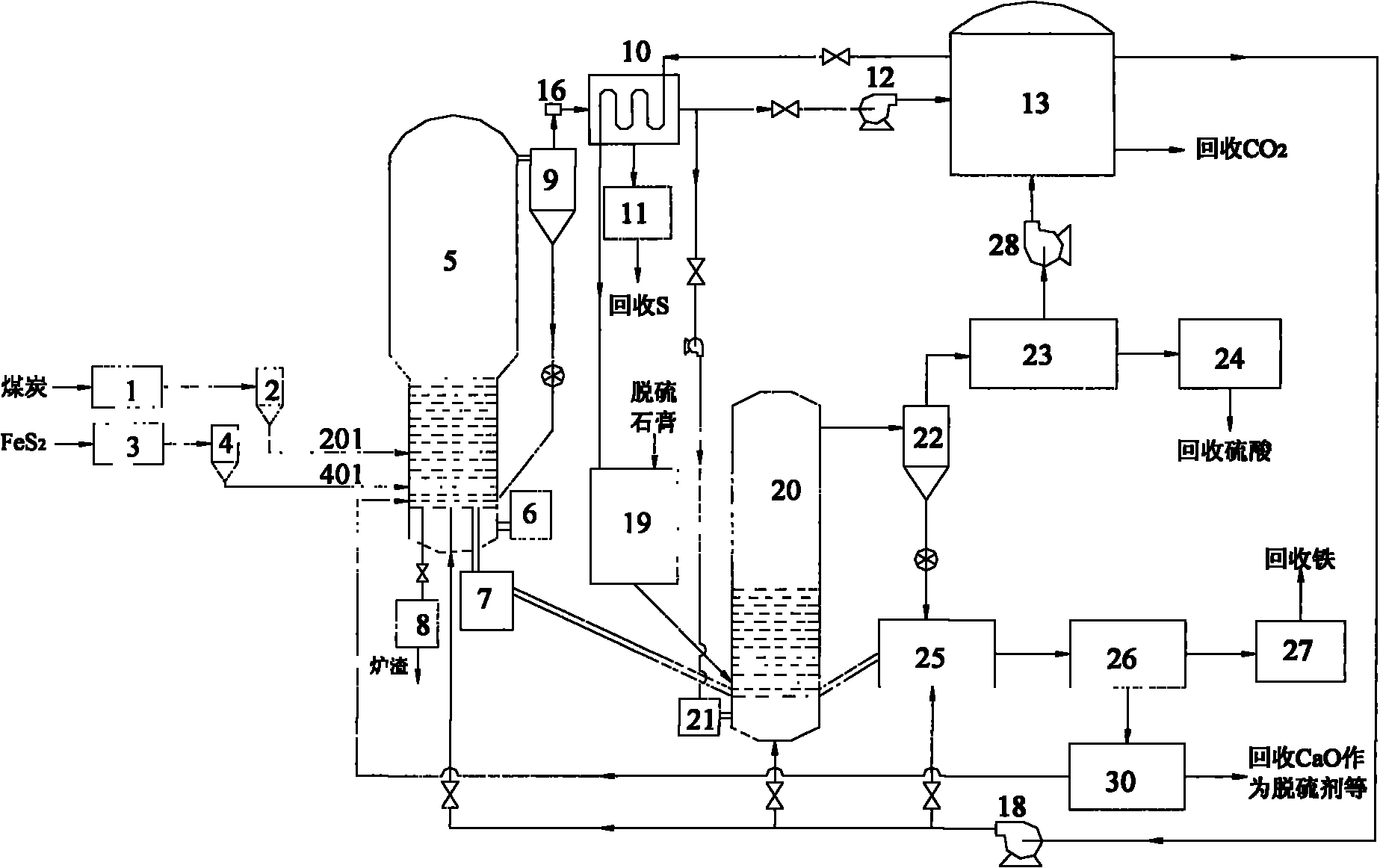

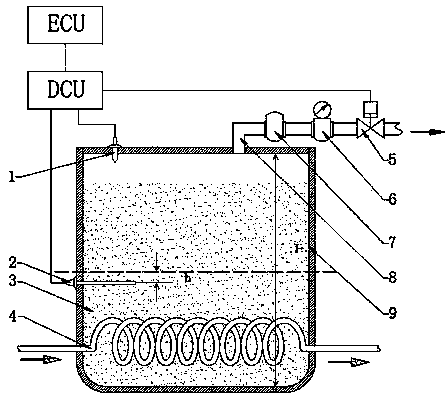

Ammonia gas metering method for solid ammonia storing system

ActiveCN103541796ASolve specific problems in metering usageMeet the requirements of emission standardsInternal combustion piston enginesExhaust apparatusEngineeringProcess engineering

The invention relates to an ammonia gas metering method for a solid ammonia storing system. The method is characterized by including the following steps that 1) a work condition signal of an engine is sent out by an electronic control unit (ECU), a command deceleration control unit (DCU) outputs signals according to system temperature to change the openness of an electromagnetic valve to control ammonia in a solid ammonia storing material to be evenly output; 2) when the DCU acquires analog signal input, the display internal pressure of a pressure sensor is larger than 200kpa, and the display internal temperature of a temperature sensor is larger than 60 DEG C, the 5-electromagnetic valve is opened. The temperature sensor, the pressure sensor, a filter, a stabilizing valve and an electromagnetic valve are combined in use. The method is applicable to silicon catalytic reduction (SCR) utilized by the national fourth discharging standard and above and also applicable to the future FCEV technology. The ammonia gas metering method is ingenious in idea, simple in process, easy to control, low in cost, safe and reliable, easy to maintain, high in accuracy and the like.

Owner:CHINA FIRST AUTOMOBILE

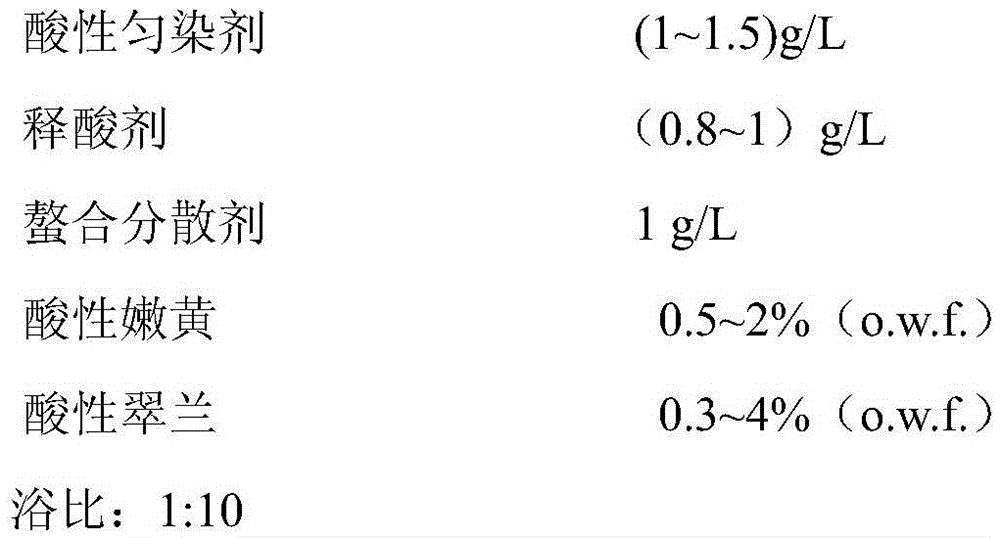

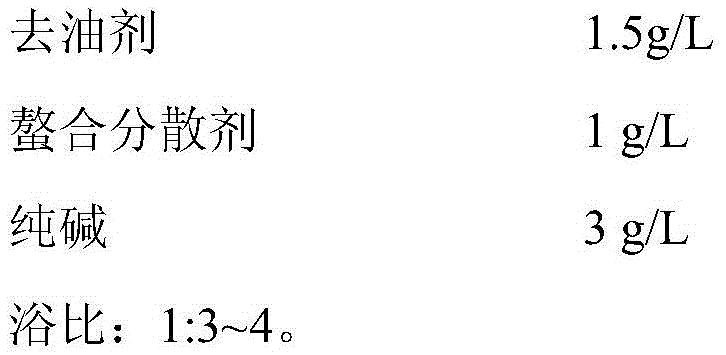

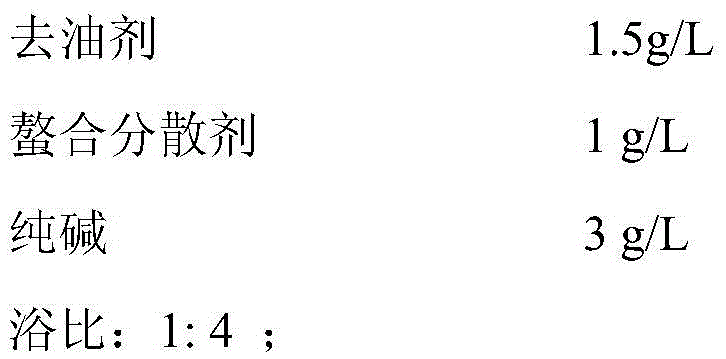

Dyeing and finishing process for green chinlon/spandex side stretch fabric

ActiveCN105544252AImproved synchronizationReduce competitionFibre typesHeating/cooling textile fabricsSynchronismDyeing

The invention provides a dyeing and finishing process for green chinlon / spandex side stretch fabric. The dyeing and finishing process comprises a dyeing process. A dyeing agent prepared from 1-1.5 g / L of acid leveling agent, 0.8-1 g / L of acid-releasing agent, 1 g / L of chelating dispersant, 0.5-2% (o.w.f.) of acid light yellow and 0.3-4% (o.w.f.) of acid emerald blue is adopted for the dyeing process. The bath ratio is 1:10, dyeing synchronism of acid light yellow and acid emerald blue is greatly improved, competition of two dyes for fiber dyeing is effectively retarded, and the dyeing defect phenomena generated during dyeing are reduced. Meanwhile, side-to-centre shading generated during warp beam dyeing is avoided, and reworking for dyeing defects is reduced.

Owner:杭州天宇印染有限公司

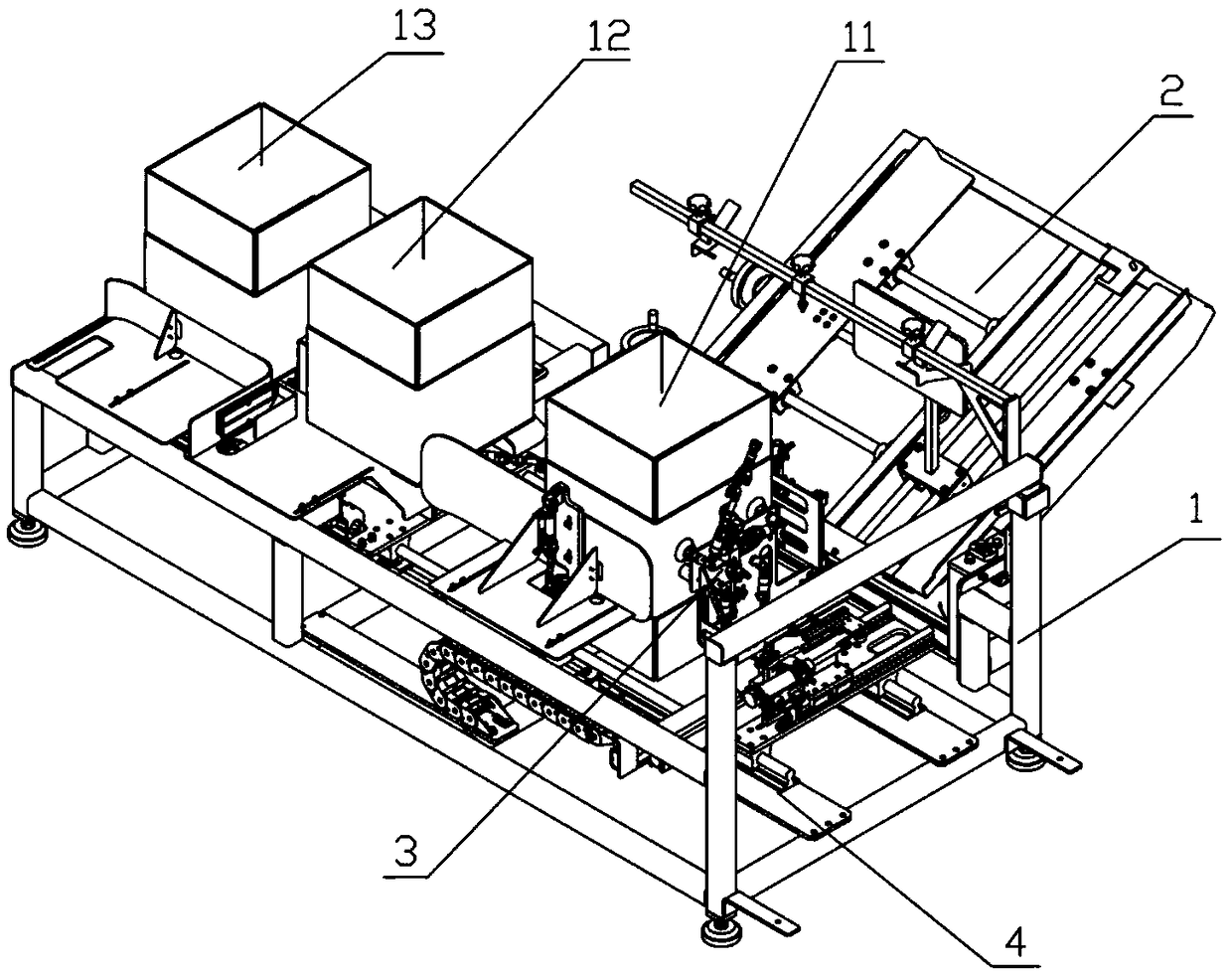

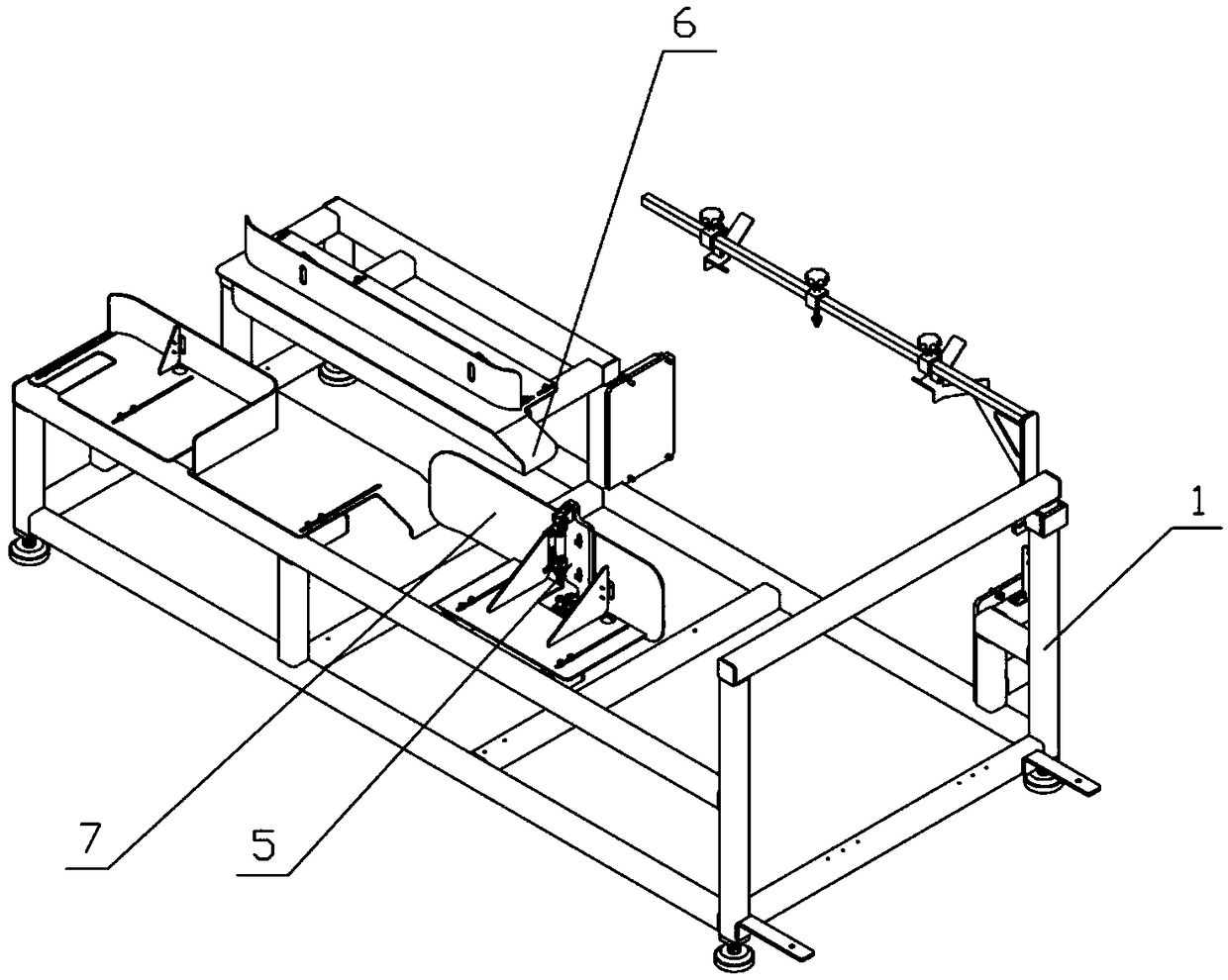

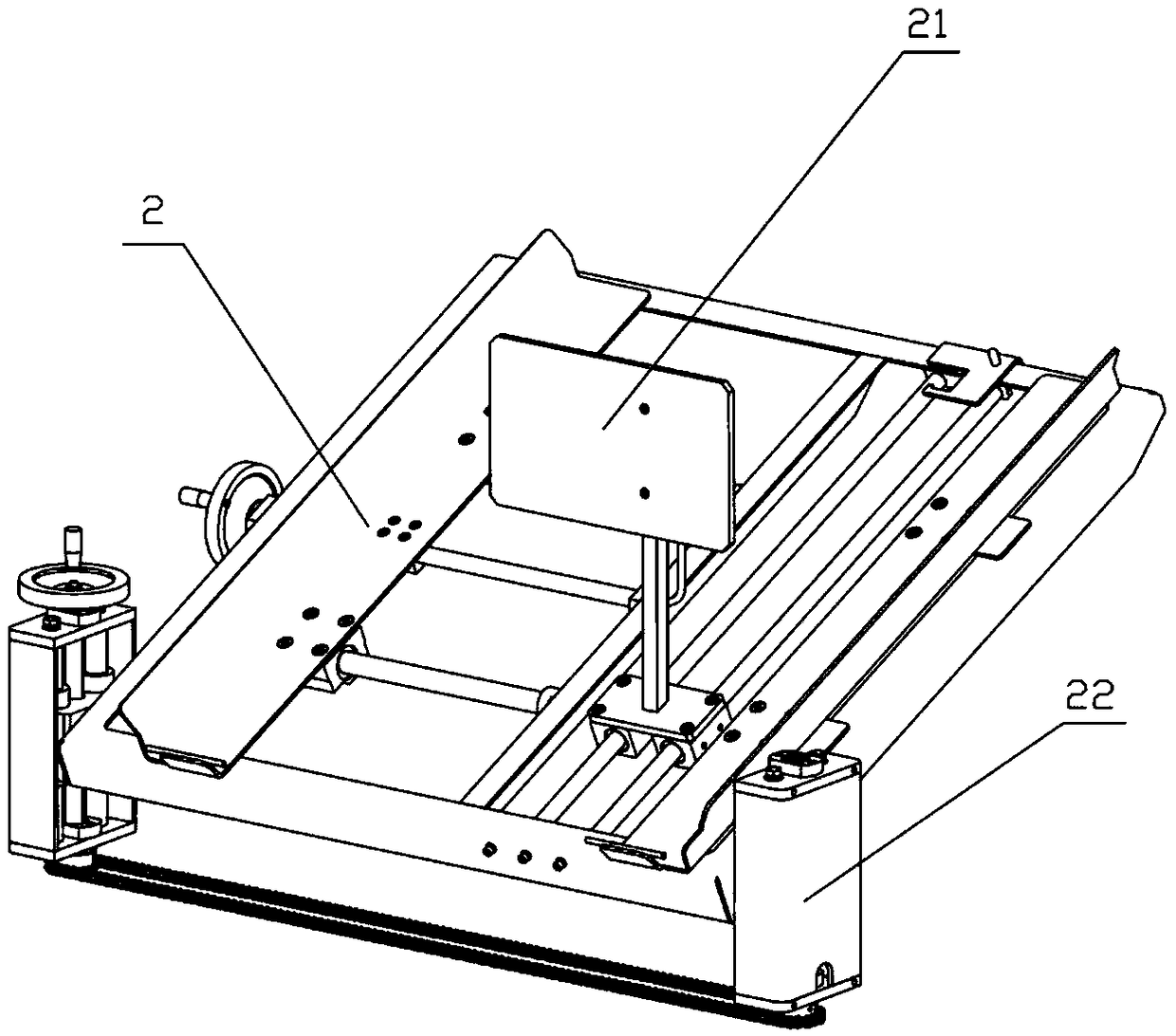

Paper box unpacking machine

PendingCN109080894AReduce equipment occupation space and equipment costsSolve the deformationPackagingPaper sheetEngineering

The invention discloses a paper box unpacking machine which comprises a rack, a paper warehouse, a rotary forming mechanism and a box feeding mechanism. The rotary forming mechanism and the box feeding mechanism are sequentially mounted on the rack. The paper warehouse is connected with the rack. The rotary forming mechanism comprises a box grabbing direct movement air cylinder used for obtainingpaperboards from the paper warehouse, a rotary air cylinder used for rotating the paperboards, an edge folding air cylinder A used for initial forming of the paperboards and a suction cup set A used for fixing the paperboards. An edge folding air cylinder B used for further forming of the paperboards, a guide plate and a forming plate are further arranged on the rack. A first station, a second station and a third station are sequentially arranged on the rack. The rotary forming mechanism is mounted at the first station. The box feeding mechanism is mounted at the second station. The third station is connected with an external conveying or box packing mechanism. By means of the paper box unpacking machine, the problems that at present, boxes cannot be transversely output, when the boxes areoutput by dual belts, the boxes will get stuck, box shells are worn, reliability is poor, and the traditional equipment structure is complex can be effectively solved.

Owner:HUNAN KENON AUTOMATIC EQUIP

Method for preparing compound denitrification agent by means of waste organic solvents

ActiveCN105797568ASolve the technical problems of disposalThe technical method is simpleDispersed particle separationOrganic solventResource saving

A method for preparing a compound denitrification agent by means of waste organic solvents includes the steps that the waste water-borne organic solvents serve as raw materials to prepare the denitrification agent, solid mechanical impurities are removed from the waste organic solvents through filtering, 50-90 parts of the waste water-borne organic solvents and 10-50 parts of an amino denitrification agent are prepared by mass ratio and evenly mixed, and the compound denitrification agent is obtained.The technical method is simple, safe, practical, small in investment and low in processing and operation energy consumption, can completely solve the technical problem about disposal of waste organic solvents, especially waste organic solvents in the automobile manufacturing industry, and is free of secondary pollution.All material components in the waste organic solvents, including all hydrocarbon and water, are used in a recycling and harmless mode, resources can be saved, and environment-friendly and resource-saving society construction is facilitated.

Owner:湖南省小尹无忌环境能源科技开发有限公司 +1

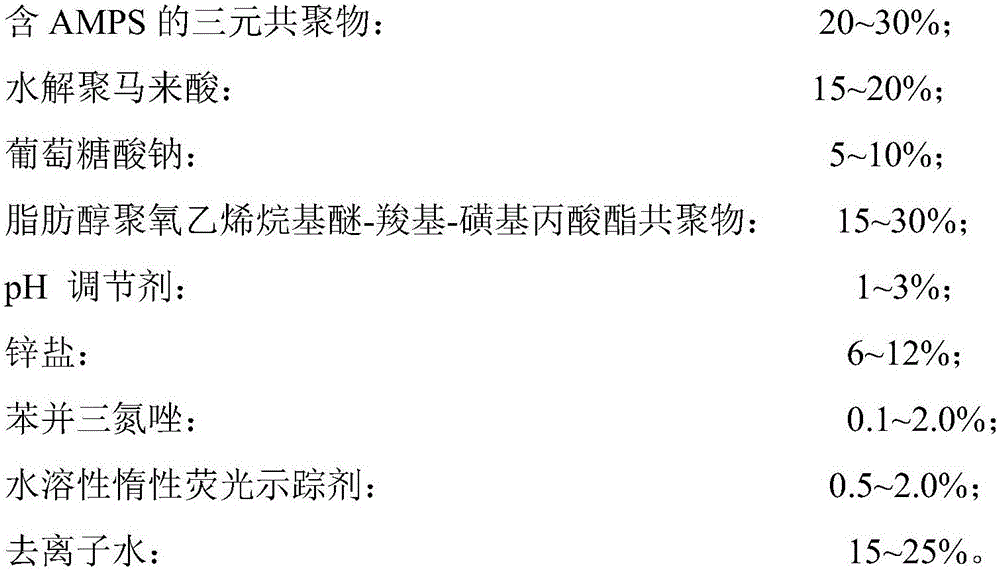

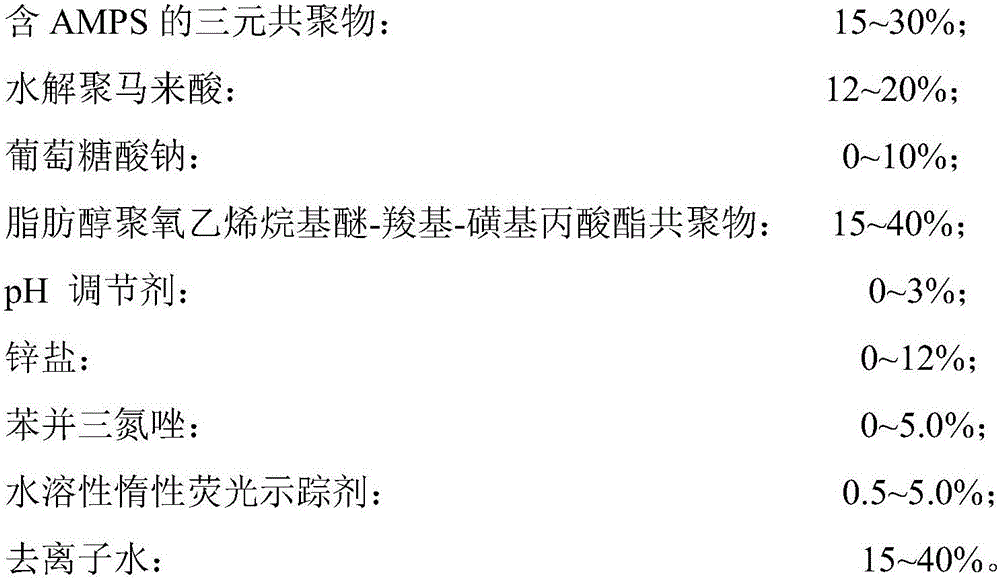

Non-phosphorus corrosion and scale inhibitor suitable for medium-and-low-hardness and strong-corrosion water and application of non-phosphorus corrosion and scale inhibitor

ActiveCN106082457AGood corrosion inhibitionGood synergySpecific water treatment objectivesTreatment using complexing/solubilising chemicalsWater qualityGluconic acid

The invention relates to a non-phosphorus corrosion and scale inhibitor suitable for medium-and-low-hardness and strong-corrosion water and application of the non-phosphorus corrosion and scale inhibitor. The non-phosphorus corrosion and scale inhibitor is prepared from the following ingredients by weight percent: 15-30% of an AMPS-containing terpolymer, 12-20% of hydrolyzed polymaleic acid, 0.1-10% of sodium gluconate, 15-40% of a fatty alcohol polyoxyalkylene alkyl ether-carboxyl-sulfopropionate copolymer, 0.1-3% of a pH regulator, 0.1-12% of zinc salt, 0.1-5.0% of benzotriazole, 0.5-5.0% of a water-soluble inert fluorescent tracer and 15-40% of deionized water. Compared with the prior art, the non-phosphorus corrosion and scale inhibitor provided by the invention solves the problem that a common non-phosphorus corrosion and scale inhibitor cannot draw the corrosion and scale inhibition function into consideration during concentration of a circulating water system. The non-phosphorus corrosion and scale inhibitor is favorable in performance and good in stability, has general applicability to medium-and-low-hardness and strong-corrosion water, and has the characteristics of no phosphorus, environmental friendliness and high efficiency.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

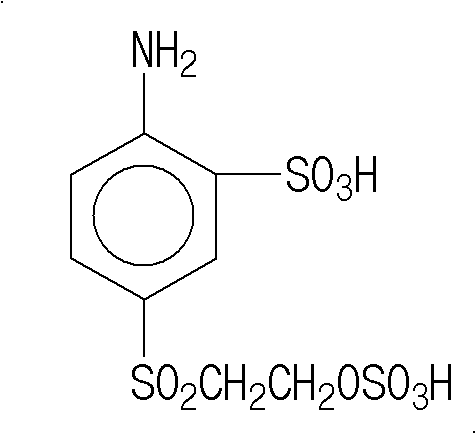

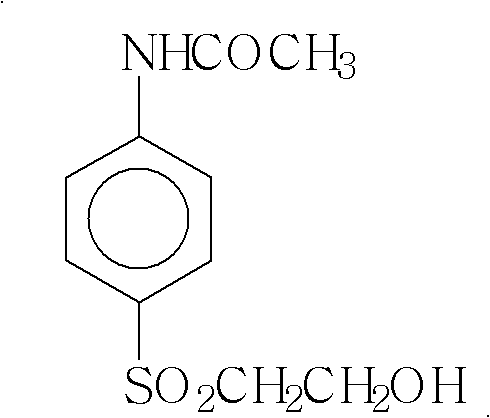

Preparation method of sulfonated para-ester serving as dye intermediate

InactiveCN102391163AEasy to save energyConducive to emission reductionOrganic chemistryOrganic compound preparationSalting outEsterification reaction

The invention relates to a preparation method of sulfonated para-ester serving as a dye intermediate. The method comprises the following steps of: (d) undergoing a sulfonation, esterification and hydrolysis reaction: adding para-beta-hydroxyethyl sulfuryl antifebrin into 105 percent sulfuric acid, controlling the temperature at 20-40 DEG C, stirring uniformly, slowly raising the temperature to 120 DEG C, reacting for 3.5 hours, lowering the temperature to 50 DEG C, dropwise adding water, raising the temperature to 96+ / -1 DEG C, undergoing a hydrolysis reaction for 10 hours, and lowering the temperature to 25 DEG C to obtain a sulfonated para-ester reaction liquid; (e) diluting; and (f) salting out to obtain the sulfonated para-ester. Compared with the conventional preparation process, the preparation method has the advantages of replacement of sulfonation, esterification and hydrolysis reactions in three independent units by a reaction in one unit and removal of waste acid produced by reactions in two units.

Owner:TIANJIN DEK CHEM

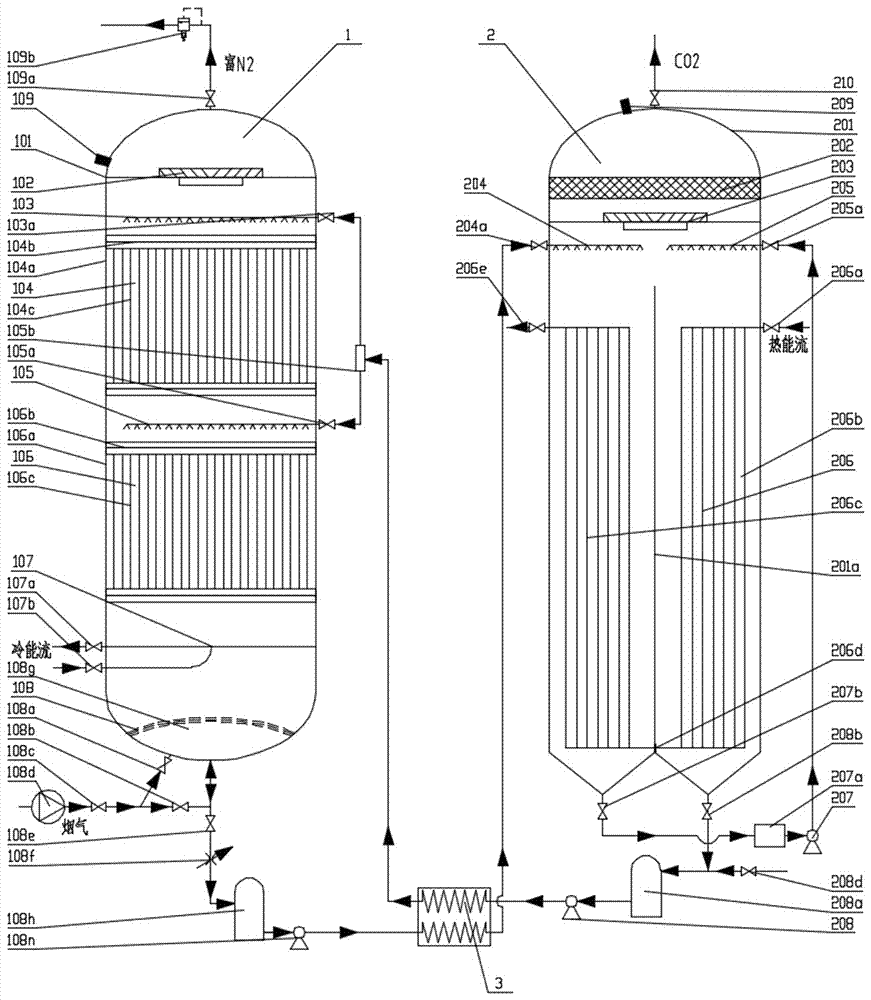

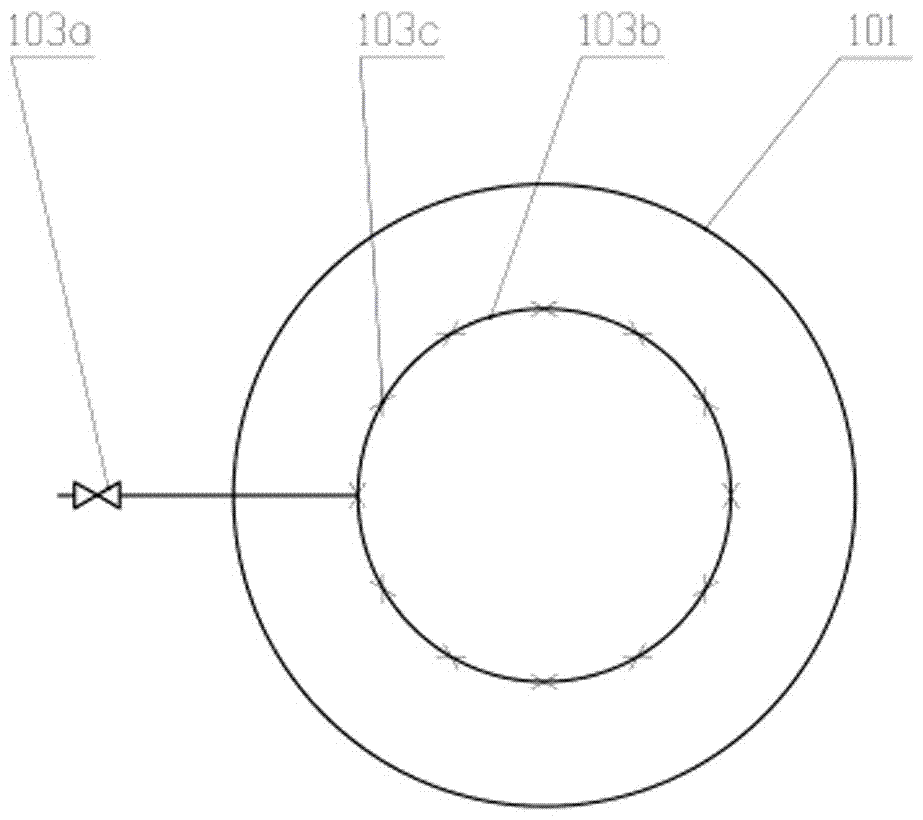

Absorption-reactivator for continuously trapping carbon dioxide in flue gas

ActiveCN106914104AEasy to controlMeet purity requirementsGas treatmentDispersed particle separationTrappingSolvent free

The invention relates to an absorption-reactivator for continuously trapping carbon dioxide in flue gas. The absorption-reactivator comprises a flue gas CO2 continuous absorption regeneration unit, the flue gas CO2 continuous absorption regeneration unit is formed by a continuous CO2 absorbing tower, a continuous CO2 regeneration tower, a cold / heat exchange device which are connected in series; and the continuous CO2 absorbing tower and the continuous regeneration tower are communicated through the cold / heat exchange device. The absorption-reactivator breakthroughs the equipment technical bottleneck of traditional trapping of CO2 in industrial flue gas, especially that a secondary pollution-free hydrate method for trapping CO2 is difficult to adapt the large-flow continuous trapping, and the invention creatively develops the apparatus for continuously trapping carbon dioxide in flue gas by the hydrate method, the apparatus has the advantages of novel and simple structure as well as easy control, and creates the equipment condition for large-scale continuous trapping of CO2 by a post-combustion method, and especially creates the equipment condition of large-scale continuous trapping of industrial flue gas CO2 by solvent-free or auxiliary agent secondary pollution.

Owner:长沙紫宸科技开发有限公司

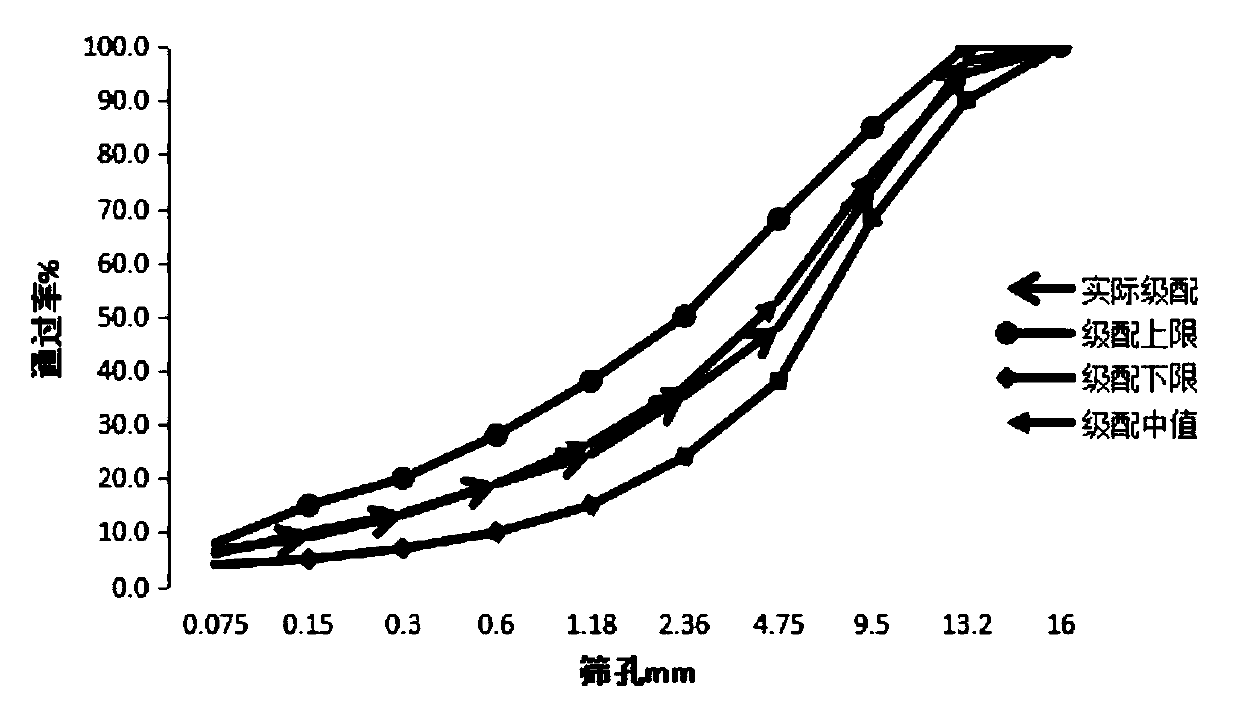

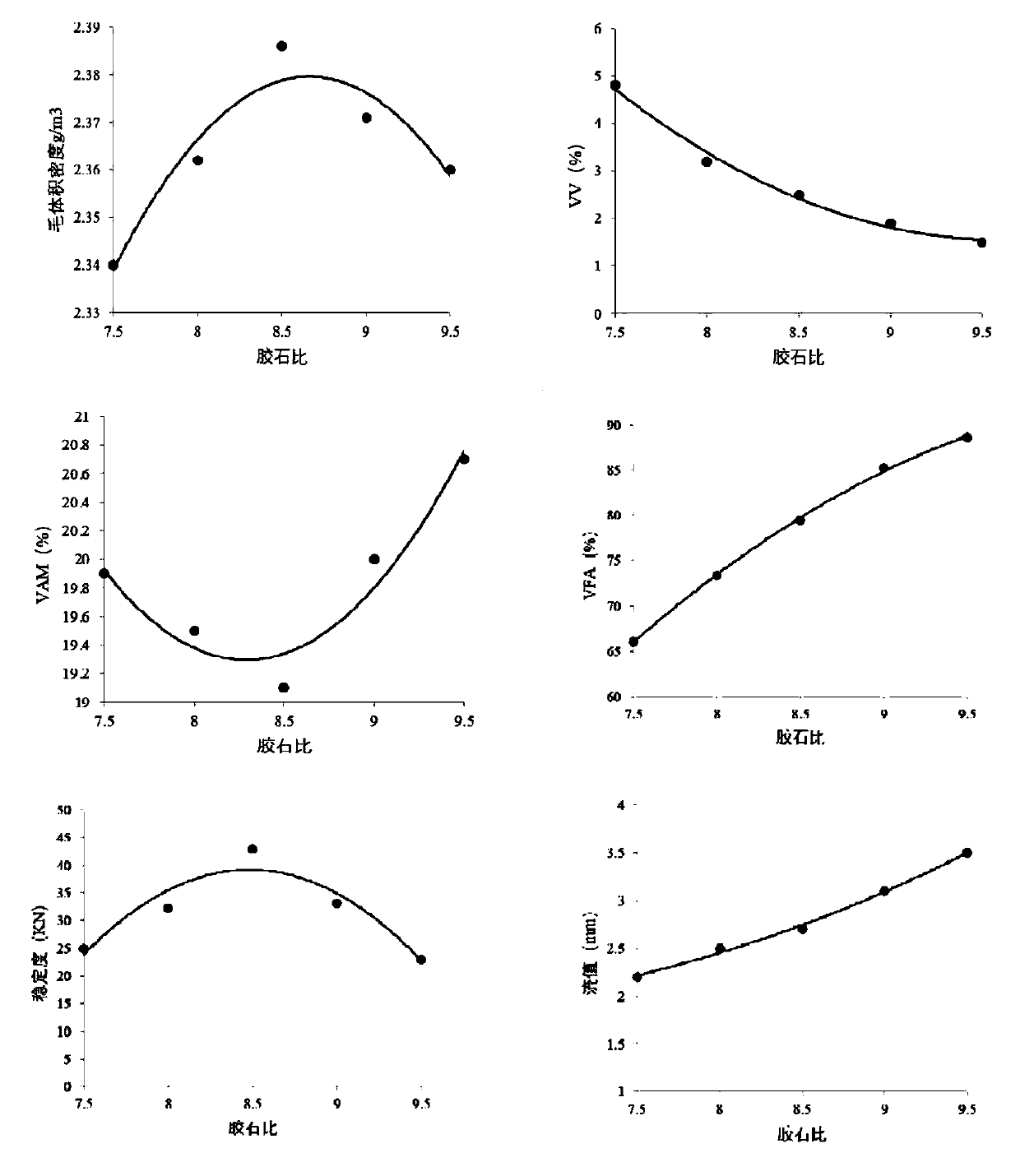

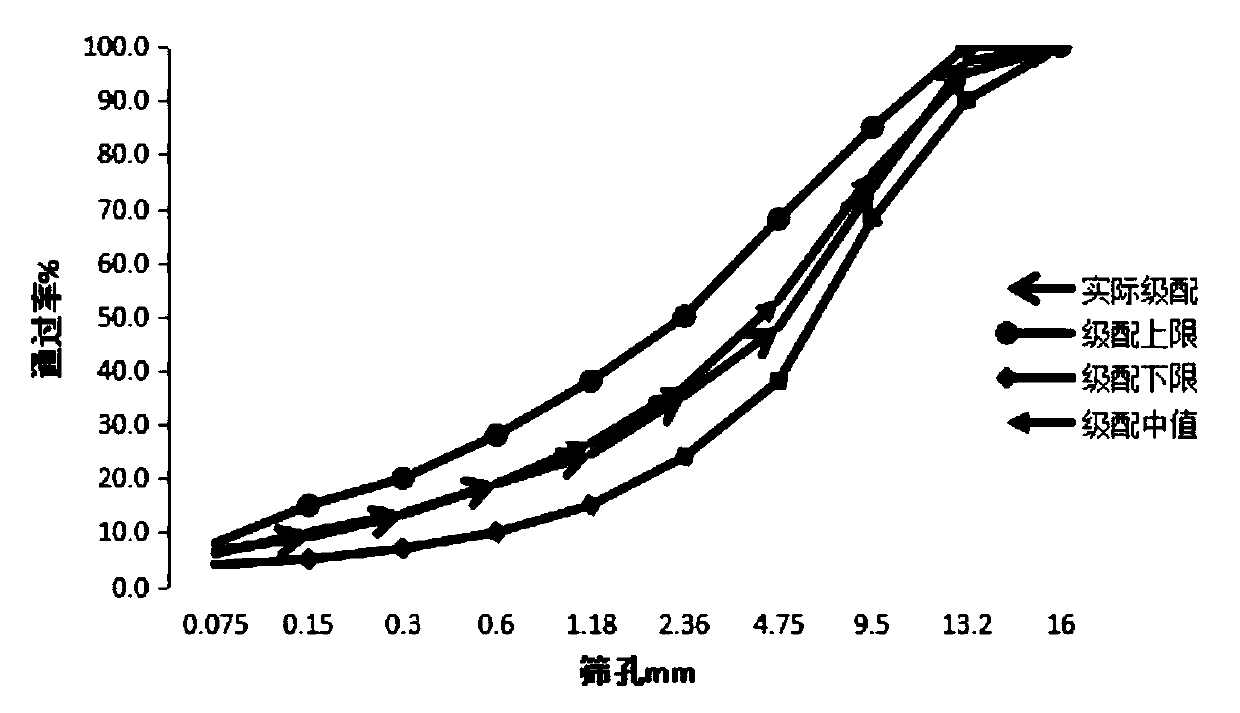

Polyether type polyurethane concrete paving material and preparation method thereof

InactiveCN111138116AImprove road performanceGood anti-aging performancePolymer sciencePolyether polyurethane

The invention provides a polyether type polyurethane concrete material and a preparation method thereof. The polyether type polyurethane concrete is combined with mineral aggregate by using a polyether type polyurethane binder instead of asphalt as a cementing material, and production and construction can be conducted at normal temperature by using common mixing equipment. The polyether polyurethane concrete adopts a cold mixing and cold paving construction mode, and has the advantages that a construction period is prolonged and harmful gas emission in the mixing process is avoided. The polyether type polyurethane concrete material disclosed by the invention has excellent pavement performance and ageing resistance. According to the polyether type polyurethane concrete material and the preparation method thereof, the use quality and the service life of a pavement structure are improved, and the driving comfort and safety of a driver are guaranteed.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE +7

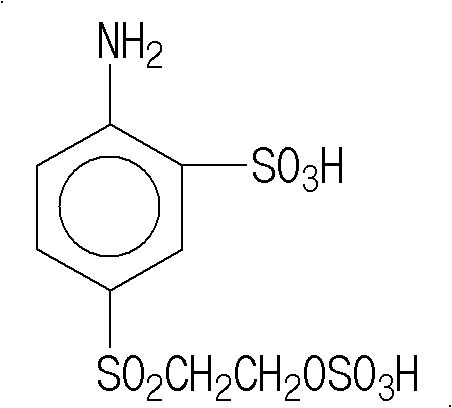

Preparation process of 4-beta-sulfatoethylsulfonyl aniline-2-sulfonic acid

InactiveCN102311372AEasy to save energyConducive to emission reductionOrganic chemistryOrganic compound preparationSalting outAniline

The invention relates to a preparation process of 4-beta-sulfatoethylsulfonyl aniline-2-sulfonic acid. The preparation process comprises the following steps: sulfochlorination, reduction, condensation, sulfonation, esterification and hydrolysis of acetanilide, dilution, salting-out, commercialization, and finished product packaging. In comparison of previous preparation processes, the preparation process of the present invention which has the advantages of changing three individual unit reactions of sulfonation, esterification, and hydrolysis into one unit reaction, and removing the waste acid amount of two unit reactions is excellent in energy saving and emission reduction.

Owner:TIANJIN DEK CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com