Method for comprehensively treatment of pyrite and desulphurized gypsum by utilizing coal and system thereof

A desulfurized gypsum, comprehensive treatment technology, applied in chemical instruments and methods, sulfur compounds, carbon compounds, etc., can solve the problems of single treatment quality, complex process system, high treatment temperature, and achieve a wide range of applications, low energy consumption, and treatment. large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

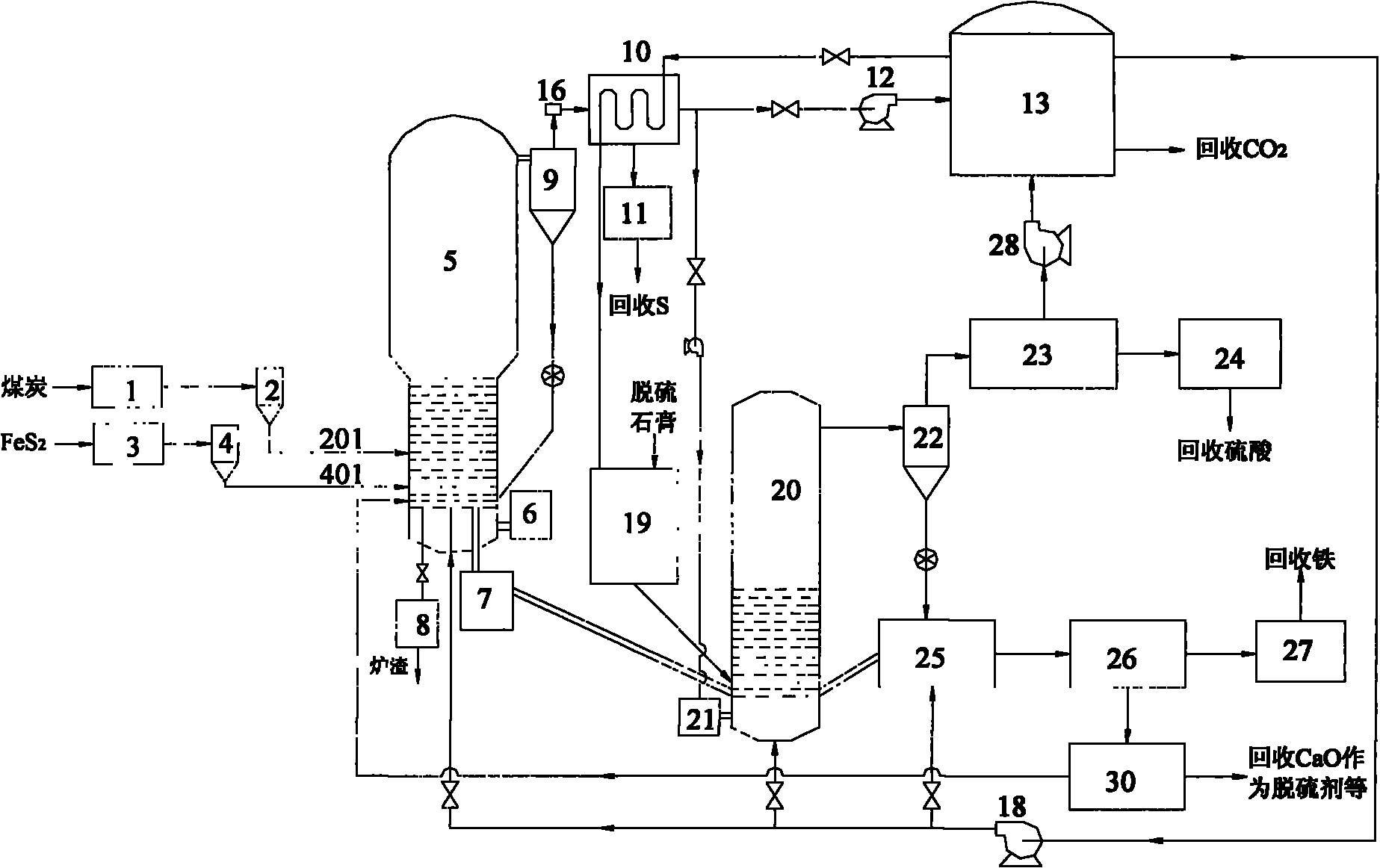

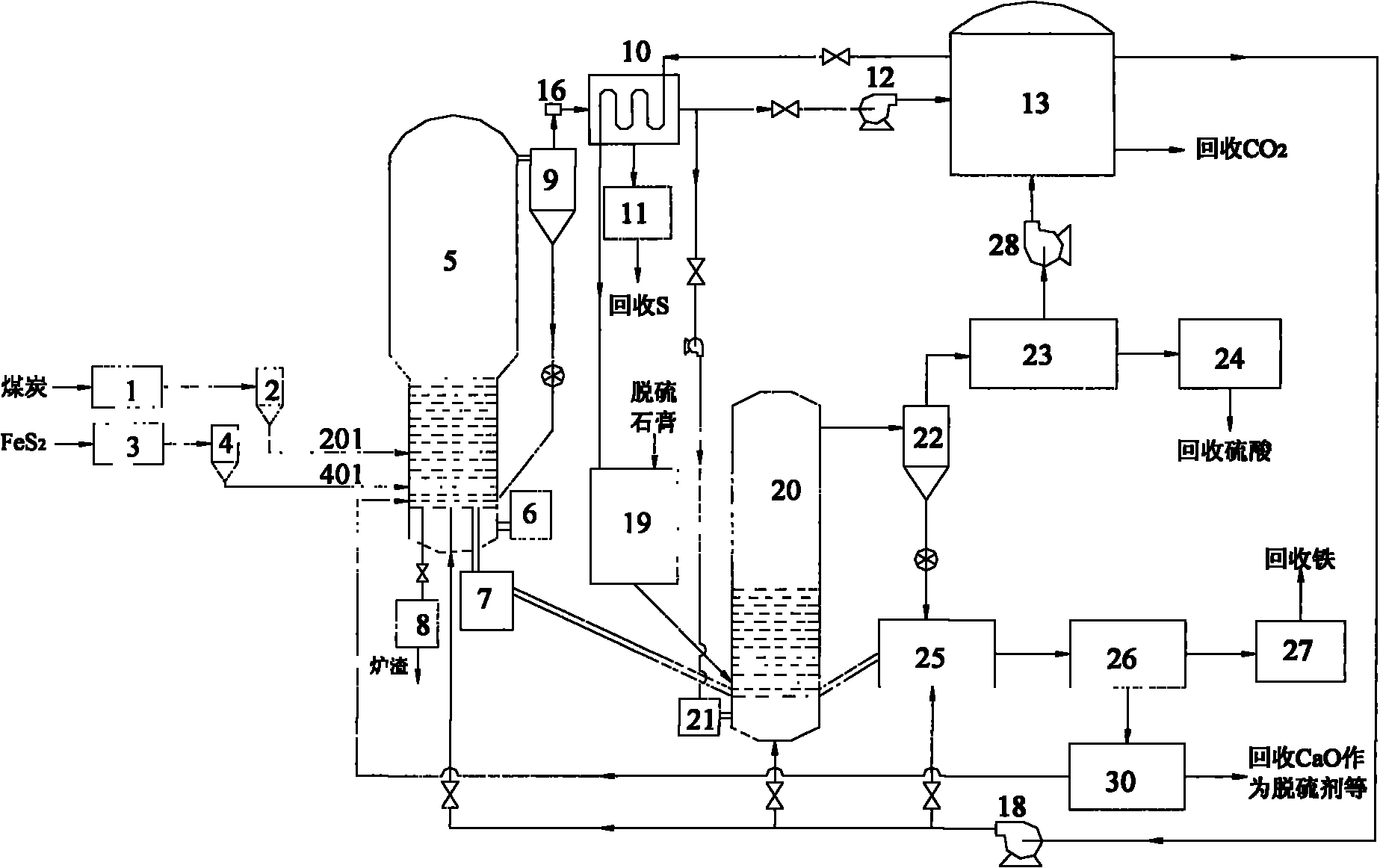

[0035] This embodiment consists of a fluidized bed pyrite decomposition device, a fluidized bed desulfurization gypsum reaction device, two reduction reaction decomposition devices and their corresponding auxiliary systems. figure 1 A schematic diagram of the system structure and process flow of this embodiment is given.

[0036] After the coal is pulverized by the coal mill 1, it is stored in the pulverized coal bin 2, and then the pulverized coal is sent to the fluidized bed pyrite decomposition device 5 through the feeding device 201; 2 Store in the pyrite bin 4 after being pulverized by the pyrite grinding machine 3, and then feed the FeS by the feeding device 401 2 The powder is sent into the fluidized bed pyrite decomposition device 5. The starting combustion chamber 6 (for starting the fluidized bed), the high-temperature non-mechanical valve 7 (for conveying high-temperature solid materials) and the slagging device 8 (for discharge solid ash). Coal, FeS 2 , and CaO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com