Ammonia gas metering method for solid ammonia storing system

A metering method and ammonia storage technology, which is applied in the field of ammonia gas metering in solid ammonia storage systems, can solve the problems of reduced adsorption capacity, affecting use effects, low adsorption and desorption efficiency, etc., and achieves benefits for emission reduction, reliability and The effect of improved accuracy and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

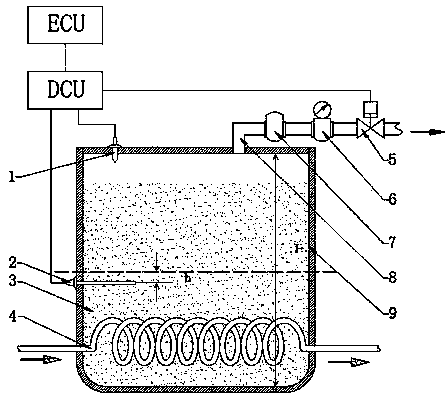

Embodiment 1

[0026] Prepare a stainless steel pressure-resistant storage tank with an effective volume of 32L, fill the storage tank with 15kg of solid ammonia storage material, and complete the ammonia filling; complete the connection of the antifreeze conduit and the ammonia gas inlet and outlet, complete the wiring of the ECU and DCU, and purchase commercially available of precision solenoid valves, temperature sensors, pressure sensors and regulator valves, in accordance with figure 1 The layout completes the connection with the storage tank; there is no filter installed before the solenoid valve on the ammonia pipe; then the system is matched with the 8.6L engine stand, in which the antifreeze pipe is connected to the engine cooling circuit to provide a heat source; The reliability test was carried out at the rated engine speed of 2100rpm and the torque of 1200 Nm. After 38 hours, the NOX at the SCR outlet was measured to exceed the standard, and the purification rate was lower than ex...

Embodiment 2

[0028] Adopt the ammonia storage system prepared by embodiment 1, according to figure 1 The layout completes the connection with the storage tank; the solenoid valve on the ammonia pipe is not equipped with a pressure stabilizing valve; and then the system is matched with the 8.6L engine stand, in which the antifreeze pipe is connected to the engine cooling circuit to provide a heat source ;The reliability test was started at the rated engine speed of 2100rpm and the torque of 1200 Nm. Within 1 hour of the test, the pressure reading indicated by the pressure sensor of the system was 550kpa, and the ammonia smell at the outlet of the SCR was obvious, showing that the amount of ammonia escaped was as high as 125ppm ; It is judged that the ammonia gas flow is too large due to the high pressure in the pipeline.

Embodiment 3

[0030] Still adopt the ammonia storage system prepared by embodiment 1, according to figure 1 Complete the connection with the storage tank; install not only the filter but also the pressure stabilizing valve before the solenoid valve on the ammonia delivery pipe; then match the system with the 8.6L engine stand, where the antifreeze pipe is connected to the engine cooling circuit , so as to provide a heat source; the reliability test operation was started at the rated engine speed of 2100rpm and the torque of 1200 Nm. During the test for 150 hours, there was no "stuck" phenomenon of the solenoid valve, and there was no obvious ammonia smell at the outlet of the SCR. The amount of ammonia gas escaped is as high as 3~7ppm; it is judged that the system is normal;

[0031] First of all, it is determined by the display results of the pressure sensor and temperature sensor whether the system has the basic conditions for releasing ammonia. The pressure sensor shows that the internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com