Vehicle exhaust waste heat thermoelectric conversion vehicle power supply system and control method

A technology for thermoelectric conversion and automobile exhaust, which is applied in electric vehicles, battery circuit devices, generators/motors, etc., and can solve the problems of difficult optimal working state of thermoelectric conversion modules, cost-effective device discount, and long additional cost recovery period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

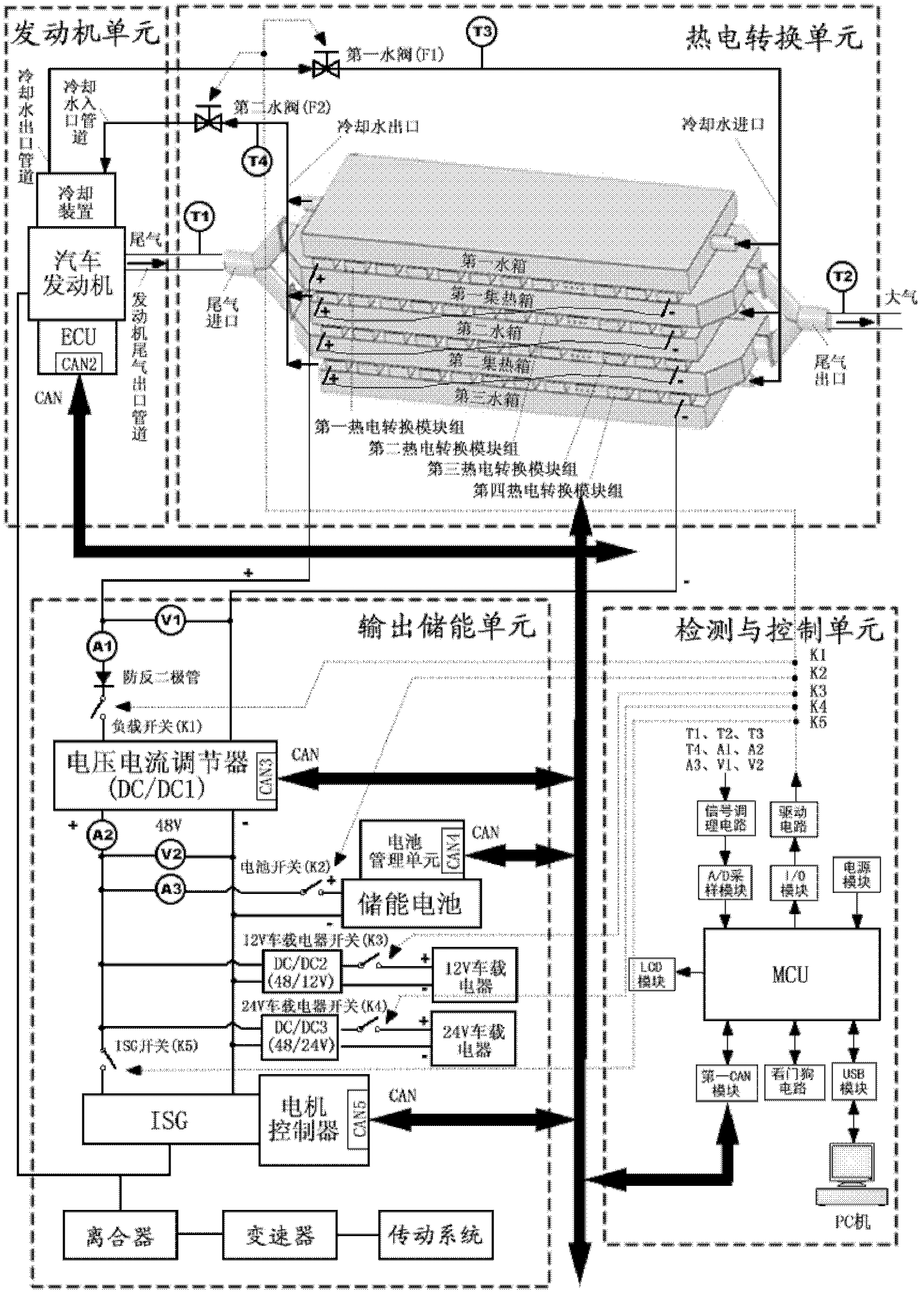

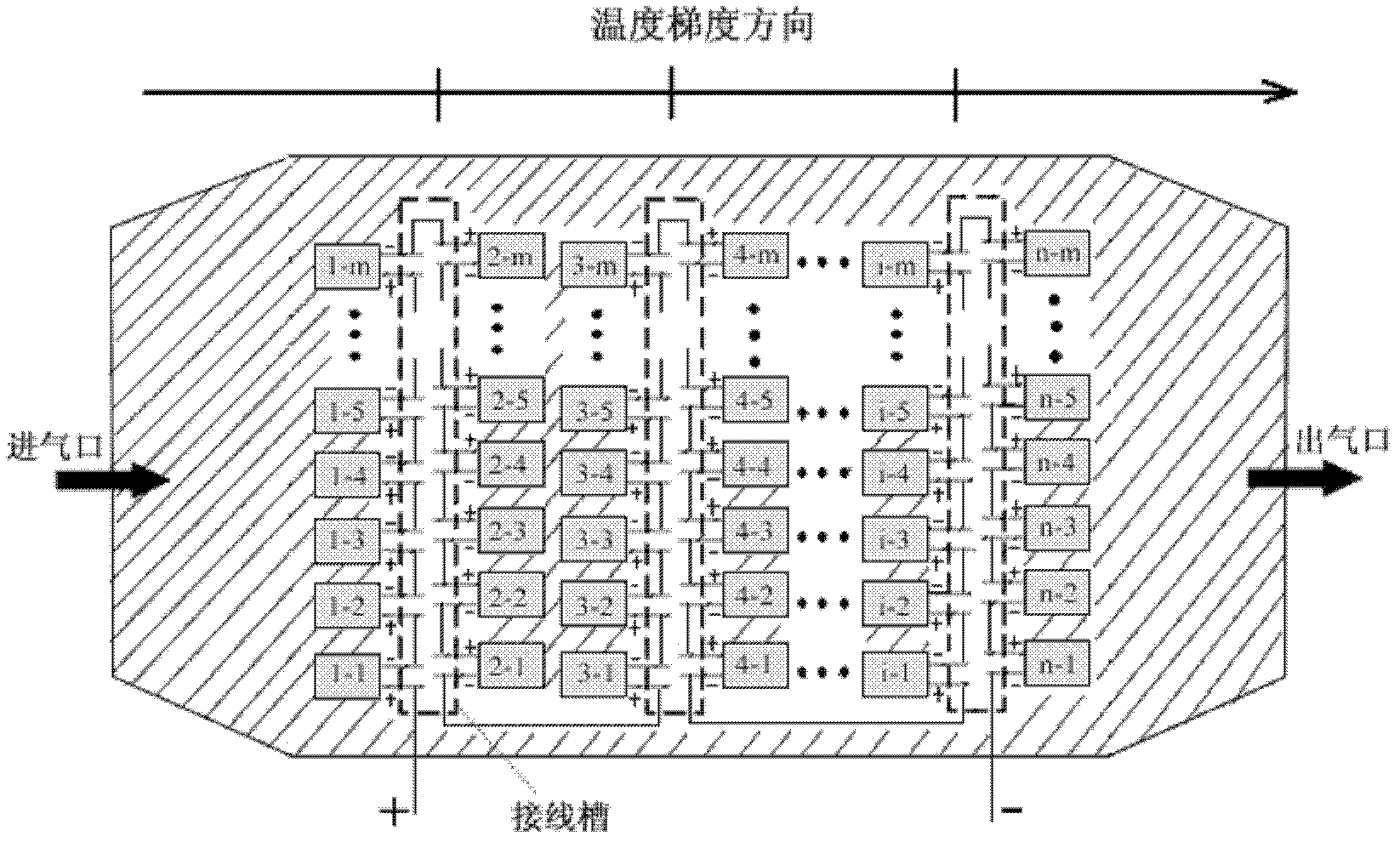

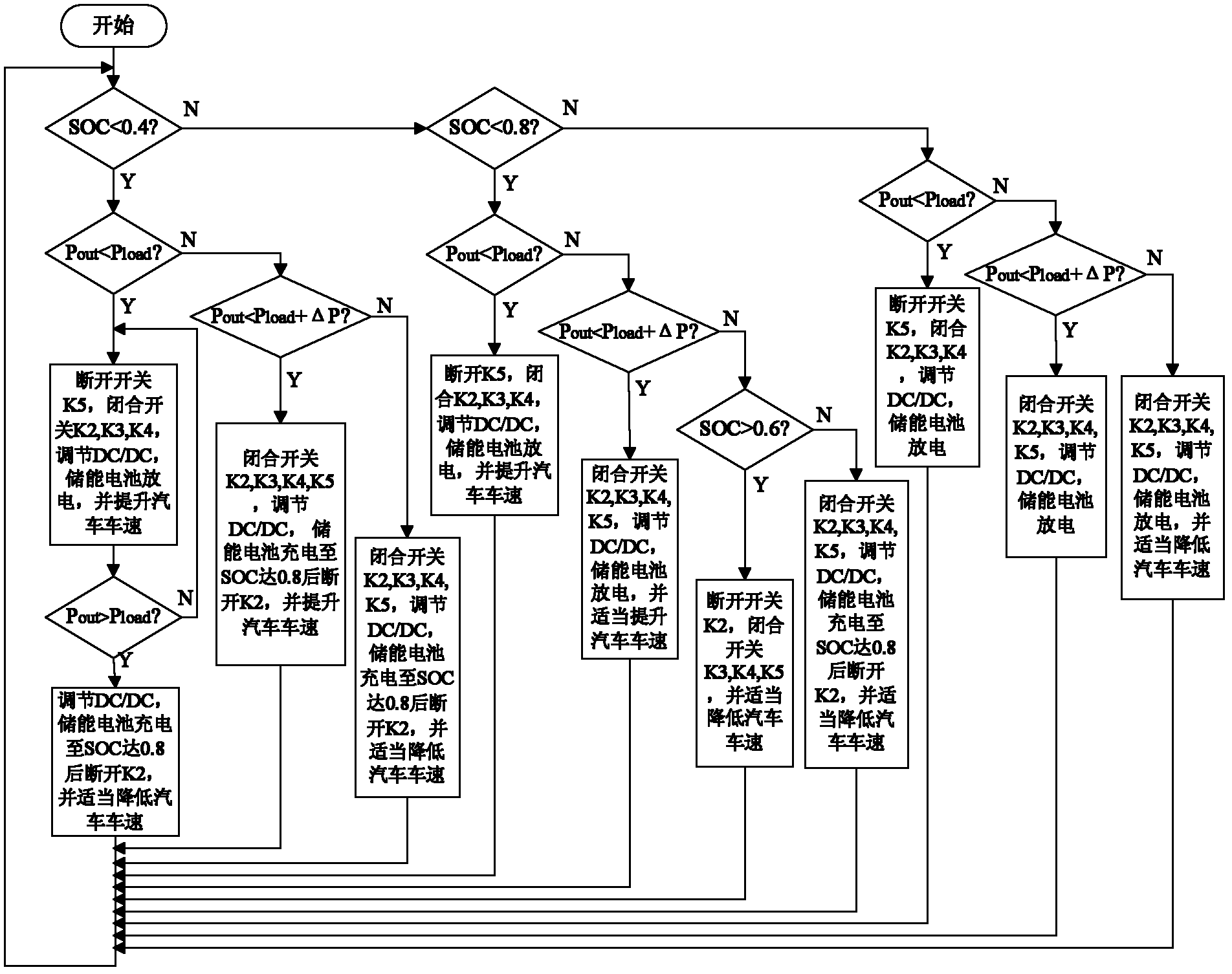

[0031] The main part of the present invention is made up of engine unit, thermoelectric conversion unit, output energy storage unit detection and control unit (as figure 1 shown), wherein: the engine unit sends the high-temperature exhaust gas discharged from the automobile engine and the cooling water in the cooling device into the thermoelectric conversion unit for heat transfer; the hot end of the thermoelectric conversion module in the thermoelectric conversion unit is in contact with the heat collector to absorb The heat, the cold end of which is in contact with the water tank is cooled by the cooling water flowing inside, so that the temperature difference between the hot and cold ends of the thermoelectric conversion module is constructed to generate DC power for outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com