Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

136results about How to "Guaranteed temperature difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

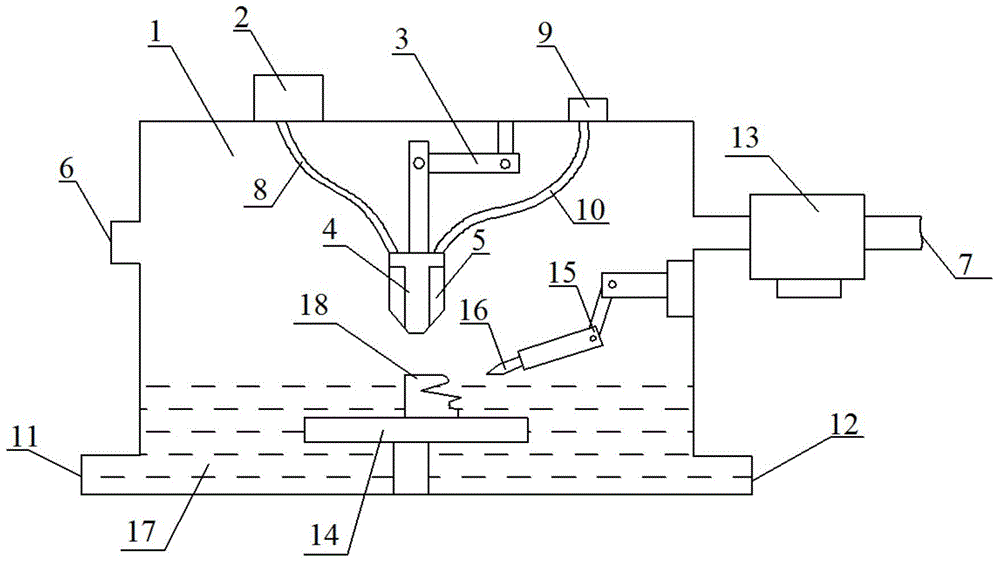

3D printing device and method

ActiveCN104960202AEnsuring Quality and ConsistencyEnsure consistencyAdditive manufacturing apparatusPneumatic pressureEngineering

The invention discloses a 3D printing device and method. The device comprises a printing chamber, a feeding device, a moving support, a printing spray head, a heating body, a pneumatic controller, a printing platform, a mechanical arm and a repairing tool bit. 3D printing is conducted in a melt extrusion condensing mode, the temperature difference of a material sprayed by the printing spray head and a workpiece is strictly controlled, the consistence and quality of the printed and condensed material are guaranteed, the requirement for the material is low, and most of the material can achieve 3D printing. In addition, the printing chamber is provided with the mechanical arm and the repairing tool bit which are used for printing and repairing on the workpiece at the same time, and the 3D printing technology is finally achieved. The 3D printing device and method have the advantages that precision is high, and the range of materials which can be machined is large.

Owner:HUAZHONG UNIV OF SCI & TECH

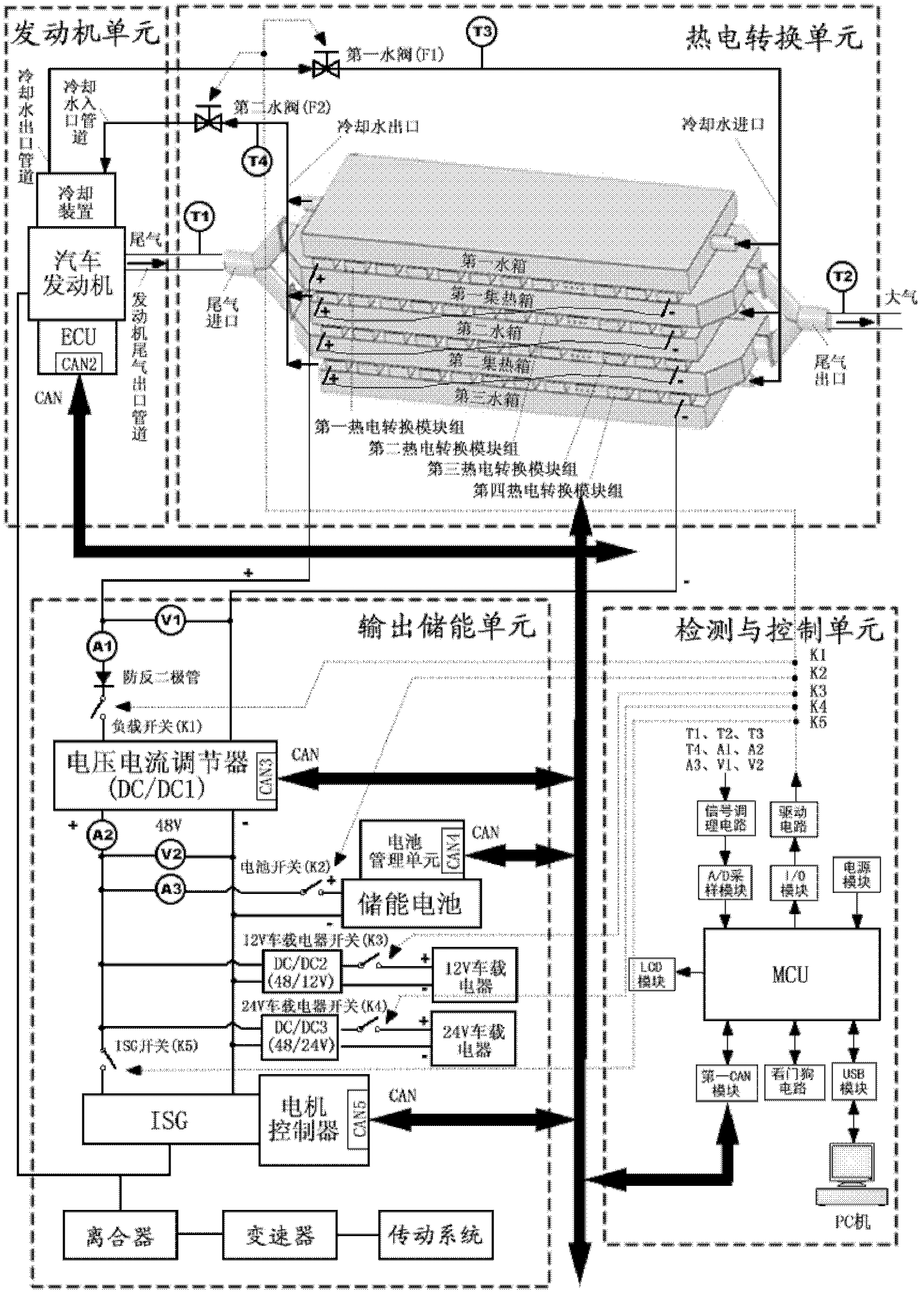

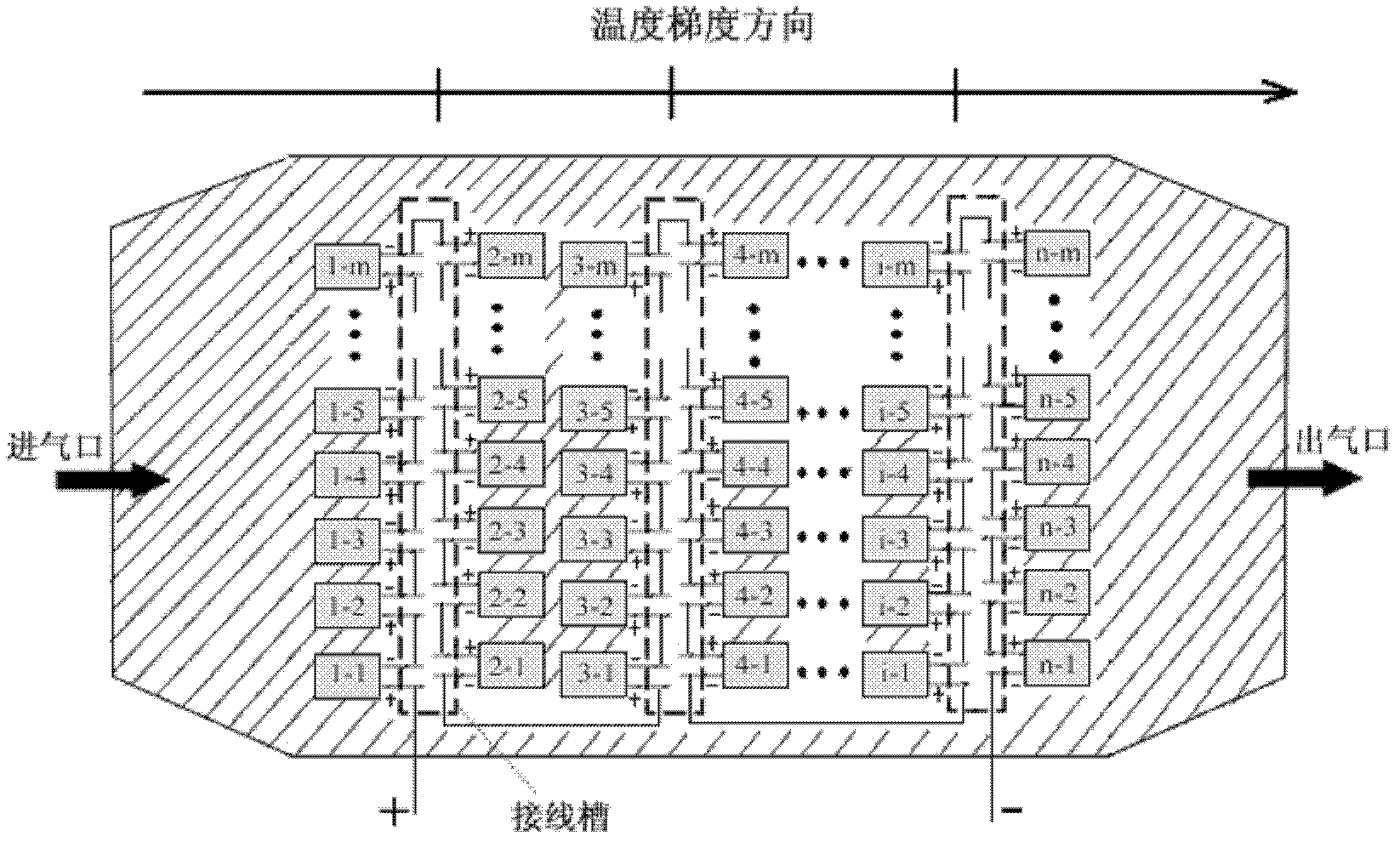

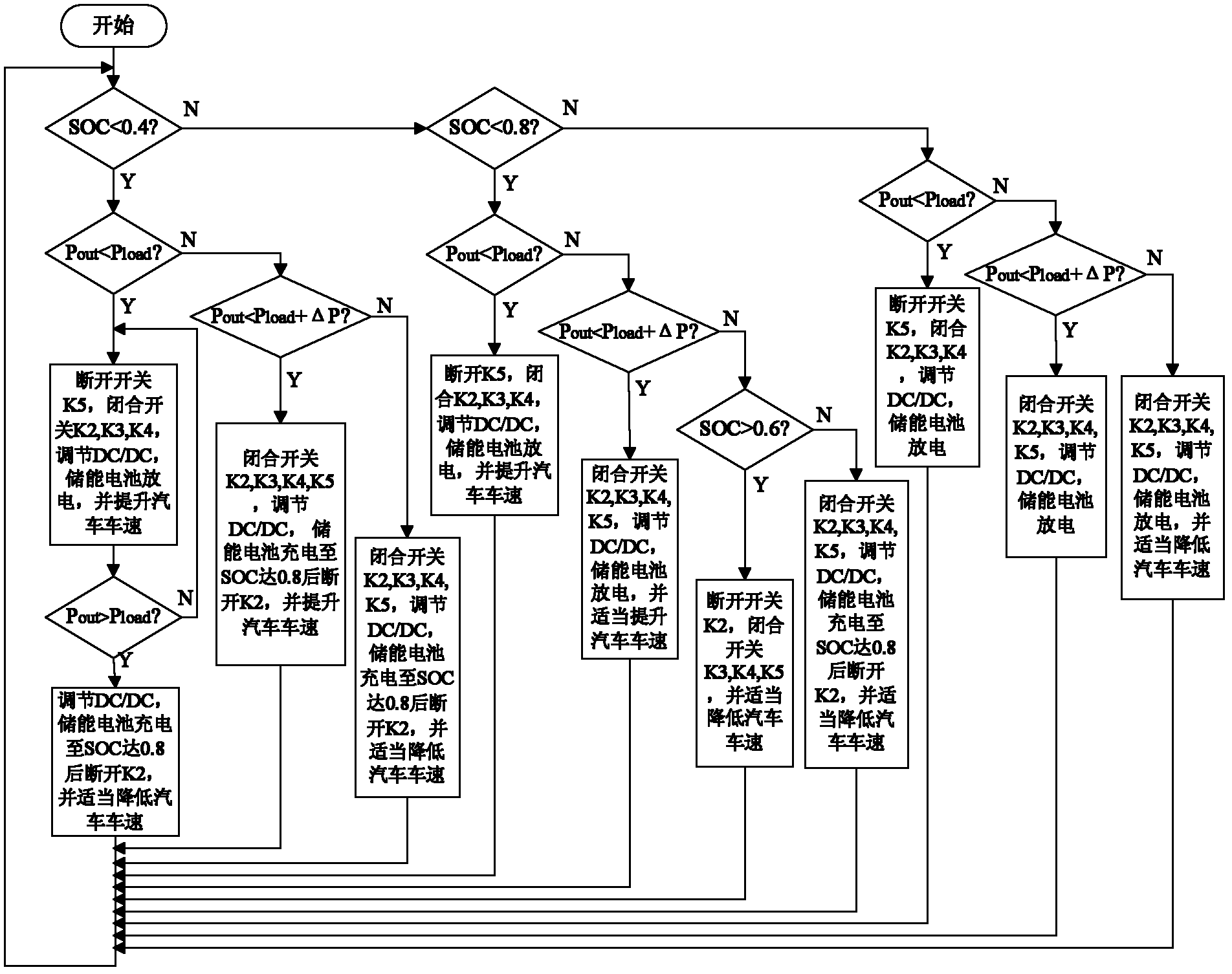

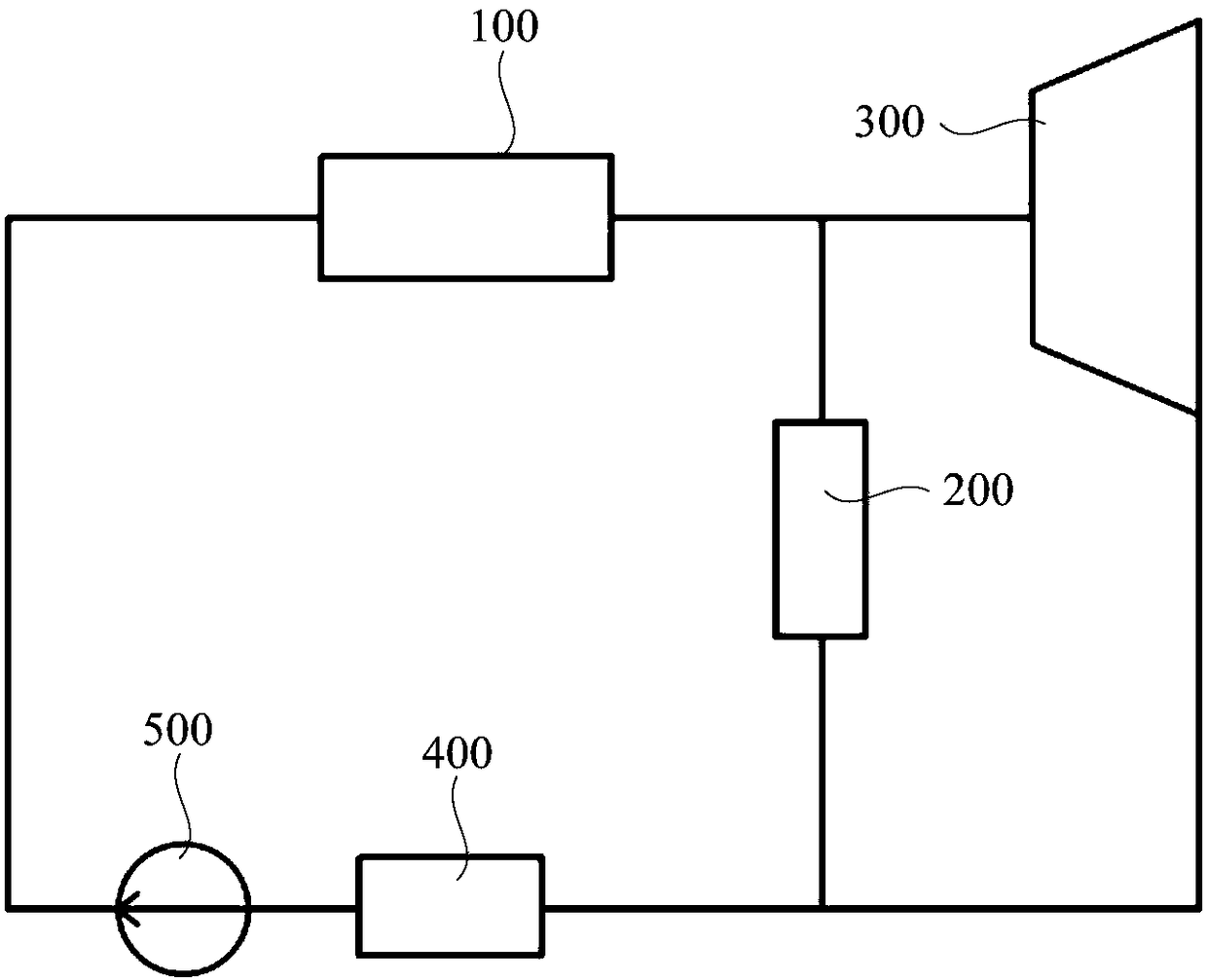

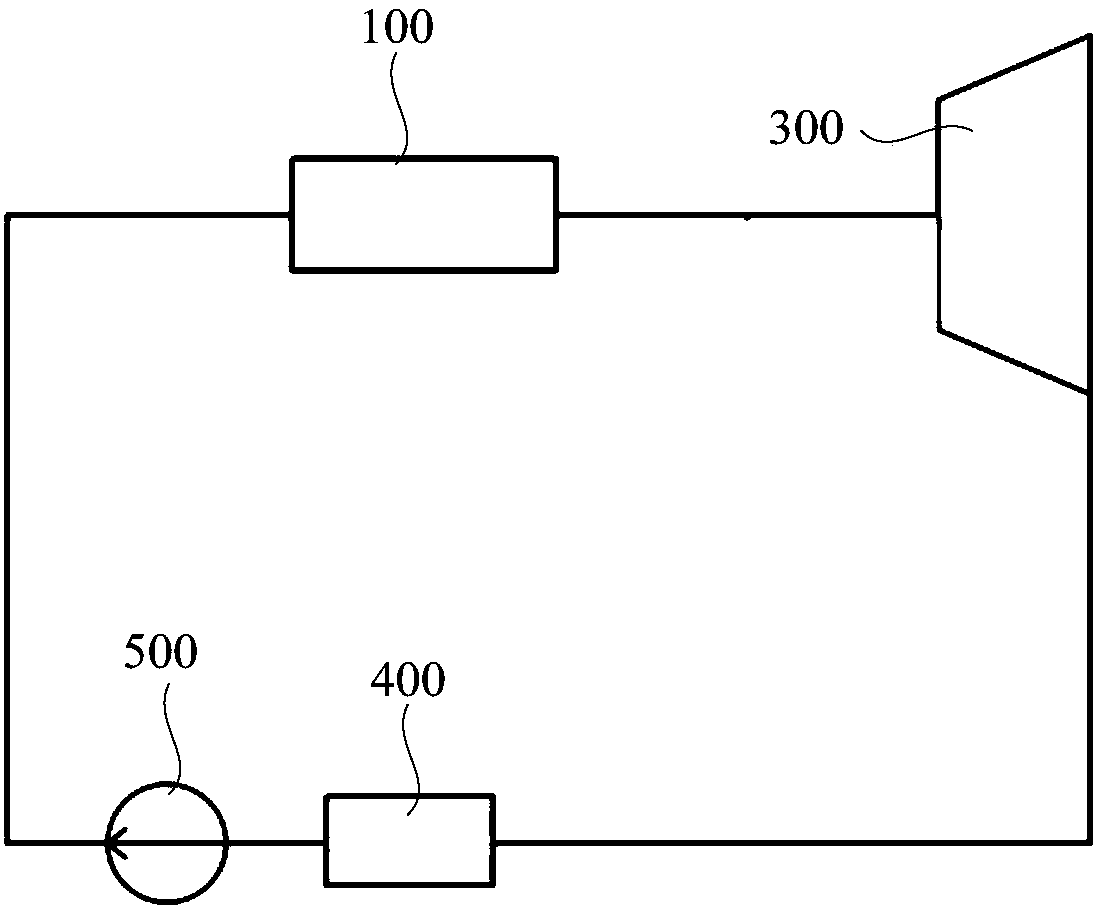

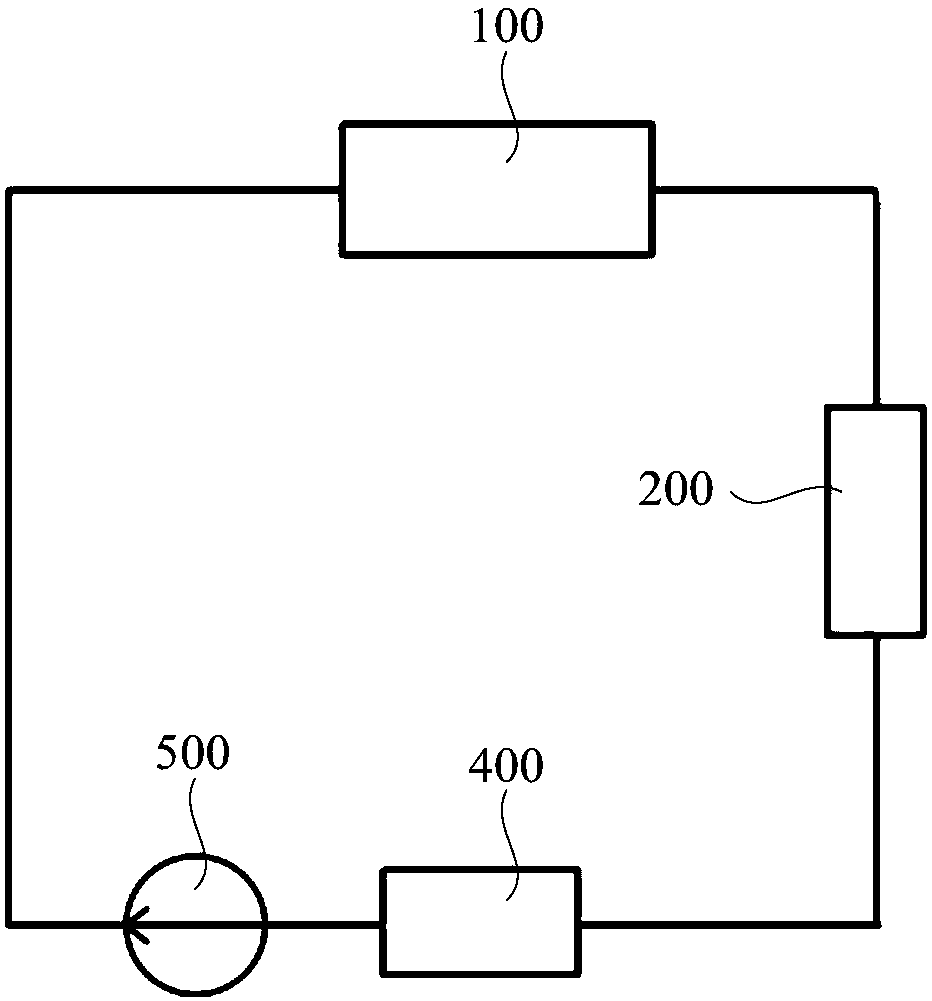

Vehicle exhaust waste heat thermoelectric conversion vehicle power supply system and control method

InactiveCN102281025AEmission reductionImprove work efficiencyBatteries circuit arrangementsElectric powerElectrical batteryAutomotive emissions

The invention relates to a thermoelectric conversion automotive power supply system using waste heat from automobile exhaust and a control method thereof, wherein the system is composed of an engine unit, a thermoelectric conversion unit, an output and electric energy storage unit and a detection and control unit. The system is characterized in that high temperature exhaust is discharged during the running of the engine and cooling water in a certain temperature range is provided; the heat brought by the high temperature exhaust is absorbed by hot terminals of a plurality of thermoelectric modules connected in series in the thermoelectric conversion unit, and cold terminals of the thermoelectric modules form temperature difference between the hot terminals and the cold terminals under thecooling effect of the cooling water of the automotive engine, so as to generate direct-current electric energy; the voltage and the current of the electric energy generated from the thermoelectric conversion unit are regulated by the output and electric energy storage unit, and the electric energy is used to supply on-vehicle appliances and ISG or charge the energy storage battery; the detection and control unit is used for detecting parameters, sending a control command and performing comprehensive energy management on the system. The system effectively recycles and utilizes the waste heat from the automobile exhaust, improves the economical efficiency of the fuel of the automotive engine, and is contributed to reducing the automobile exhaust emission.

Owner:WUHAN UNIV OF TECH

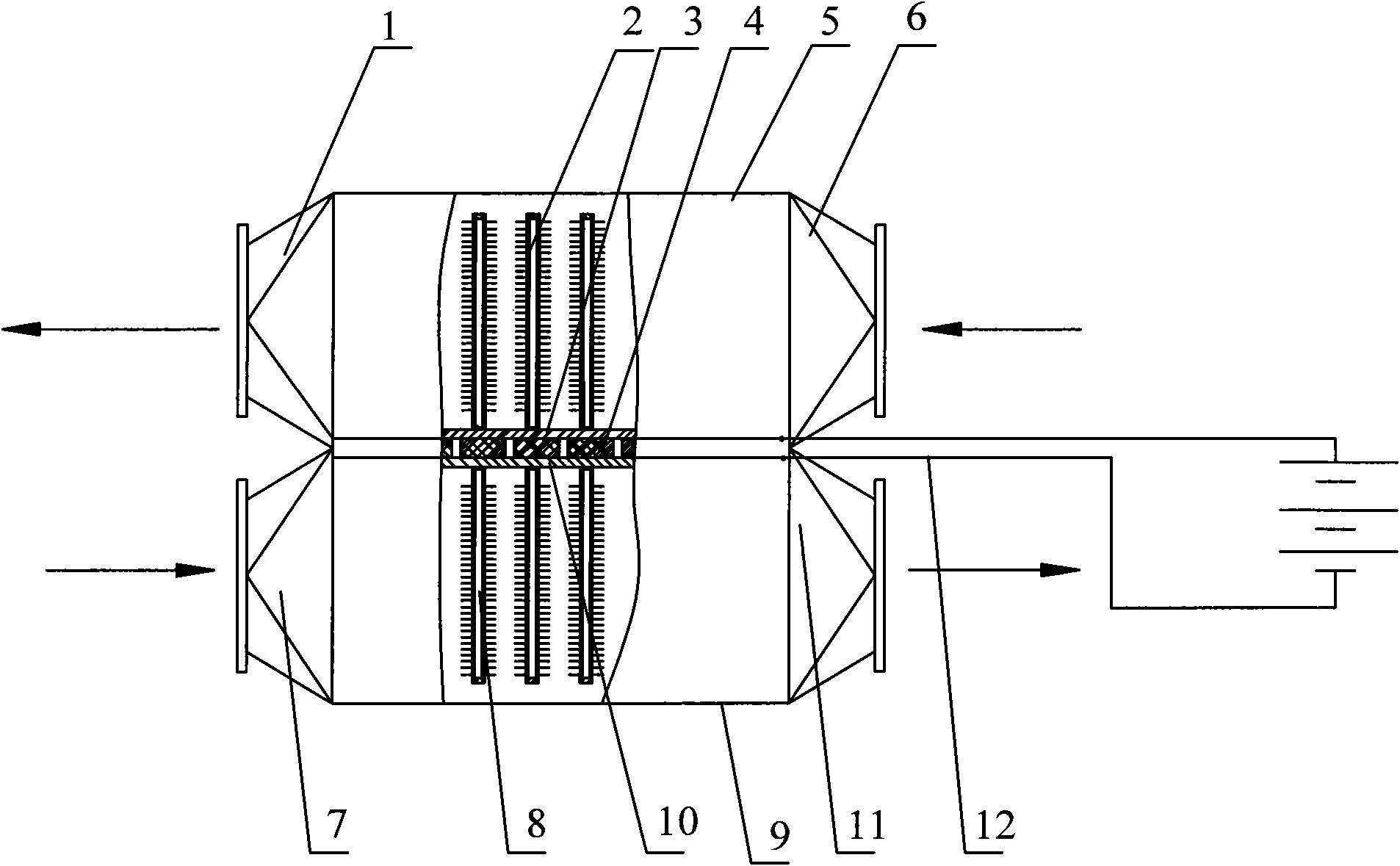

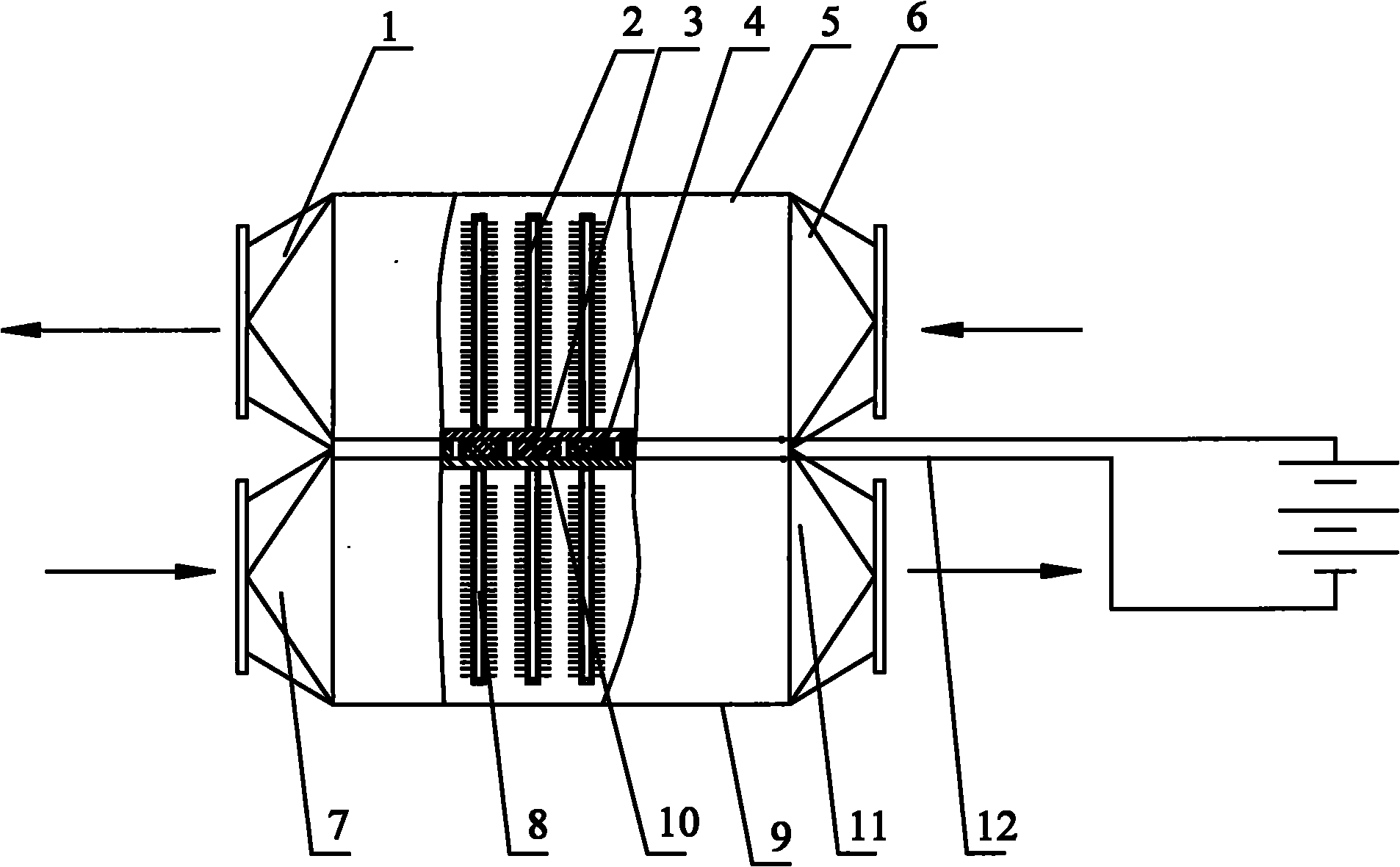

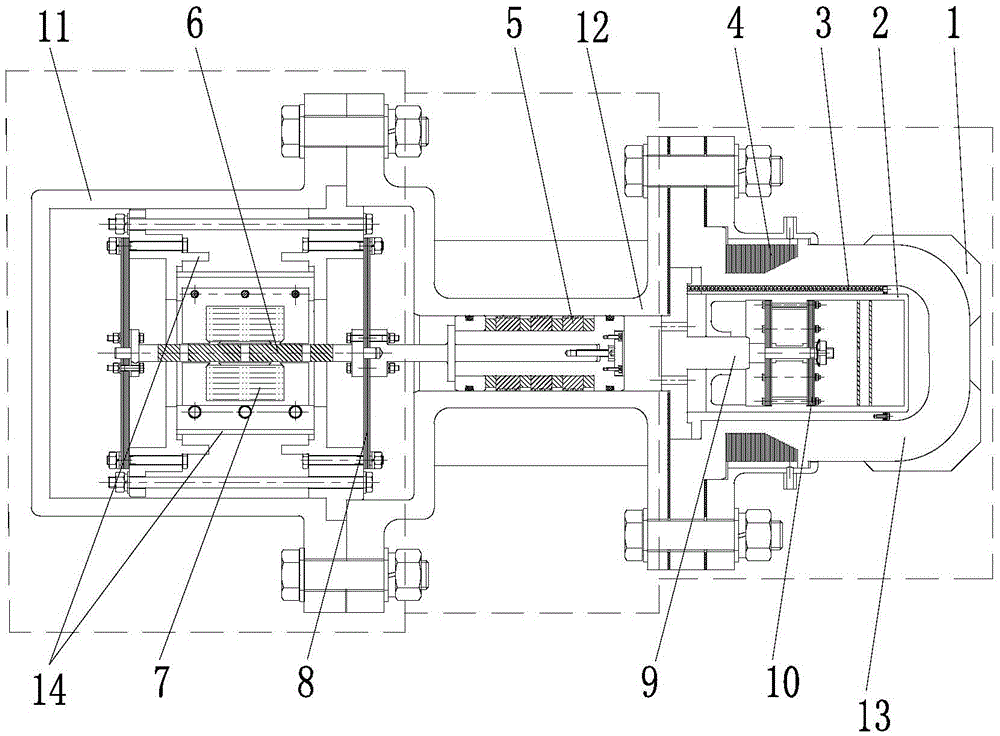

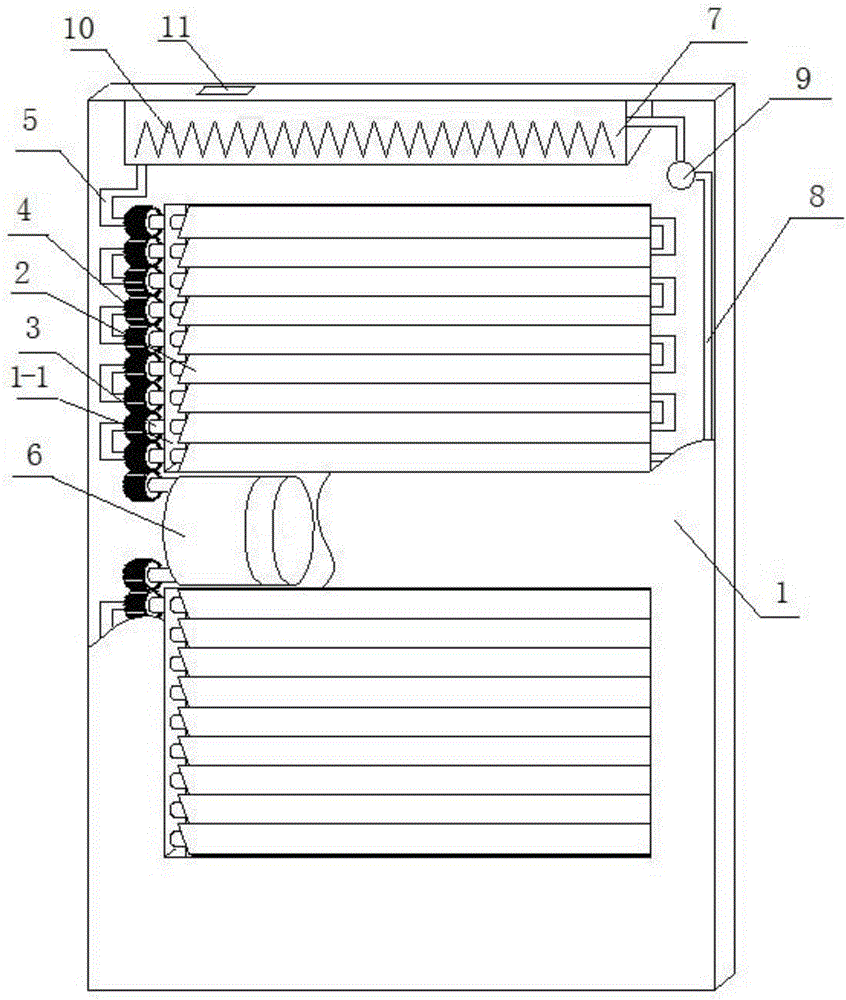

Low temperature smoke temperature difference generator

InactiveCN101882898AGuaranteed temperature differenceHigh thermal efficiencyGenerators/motorsElectric energyEngineering

The invention discloses a low temperature smoke temperature difference generator which comprises an air outlet section, a normal temperature hot pipe, a heat radiating guide plate, a semiconductor temperature difference module, an air shell, an air inlet section, a smoke inlet section, a low temperature hot pipe, a smoke shell, a heat collecting guide plate, a smoke outlet section and a lead, wherein the heat radiating guide plate and the heat collecting guide plate are respectively positioned at two opposite sides of the semiconductor temperature difference module, the normal temperature hot pipe is positioned above the heat radiating guide plate, the air outlet section and the air inlet section are respectively positioned at two opposite sides of the air shell, the lower temperature hot pipe is positioned below the heat collecting guide plate, the smoke inlet section and the smoke outlet section are respectively positioned at two opposite sides of the smoke shell, and the semiconductor temperature difference module is connected with the lead. By using low grade smoke discharged by a heating furnace air preheater to a chimney, part of low grade smoke is directly converted into usable electric energy by the lower temperature smoke temperature difference generator.

Owner:王峰

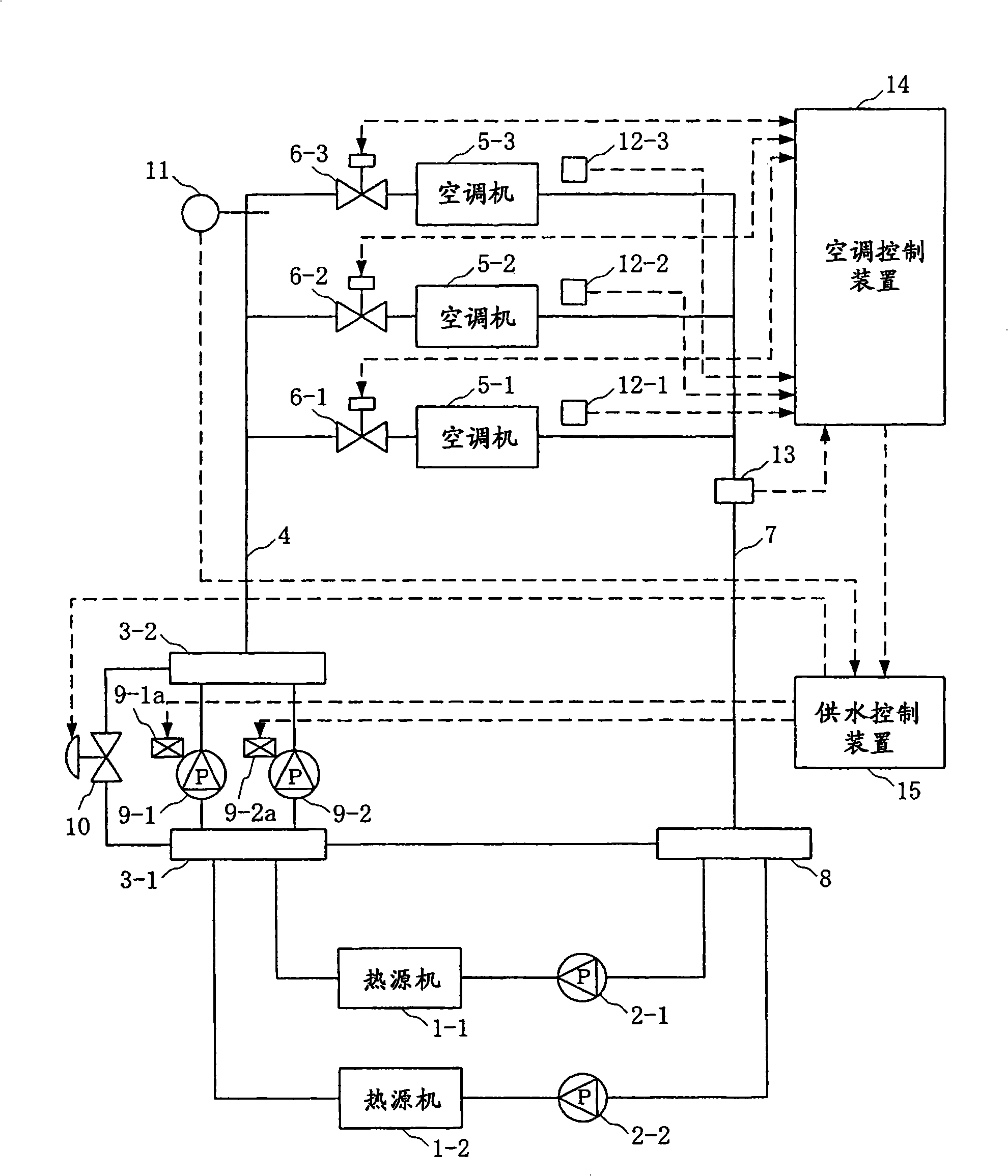

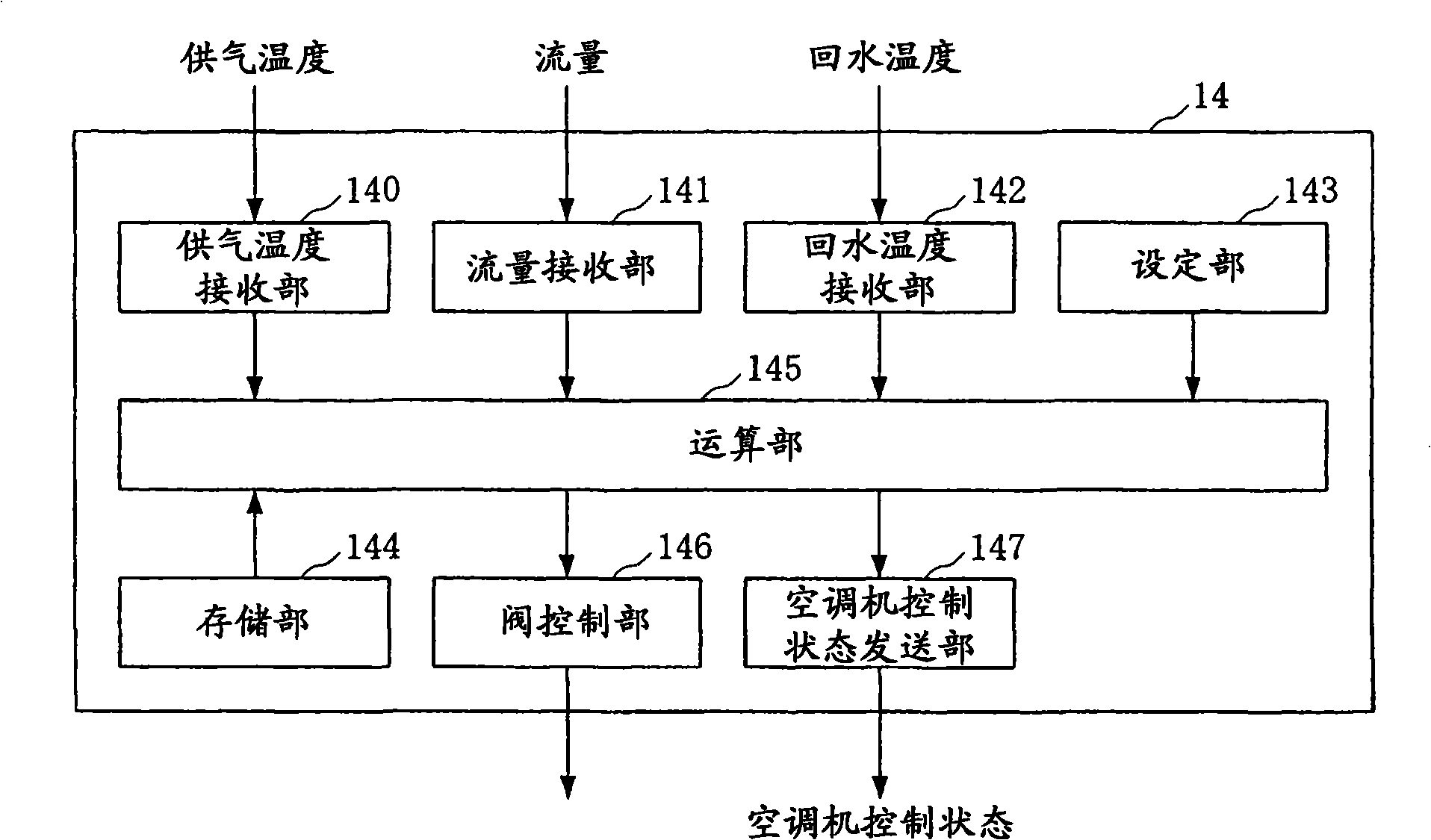

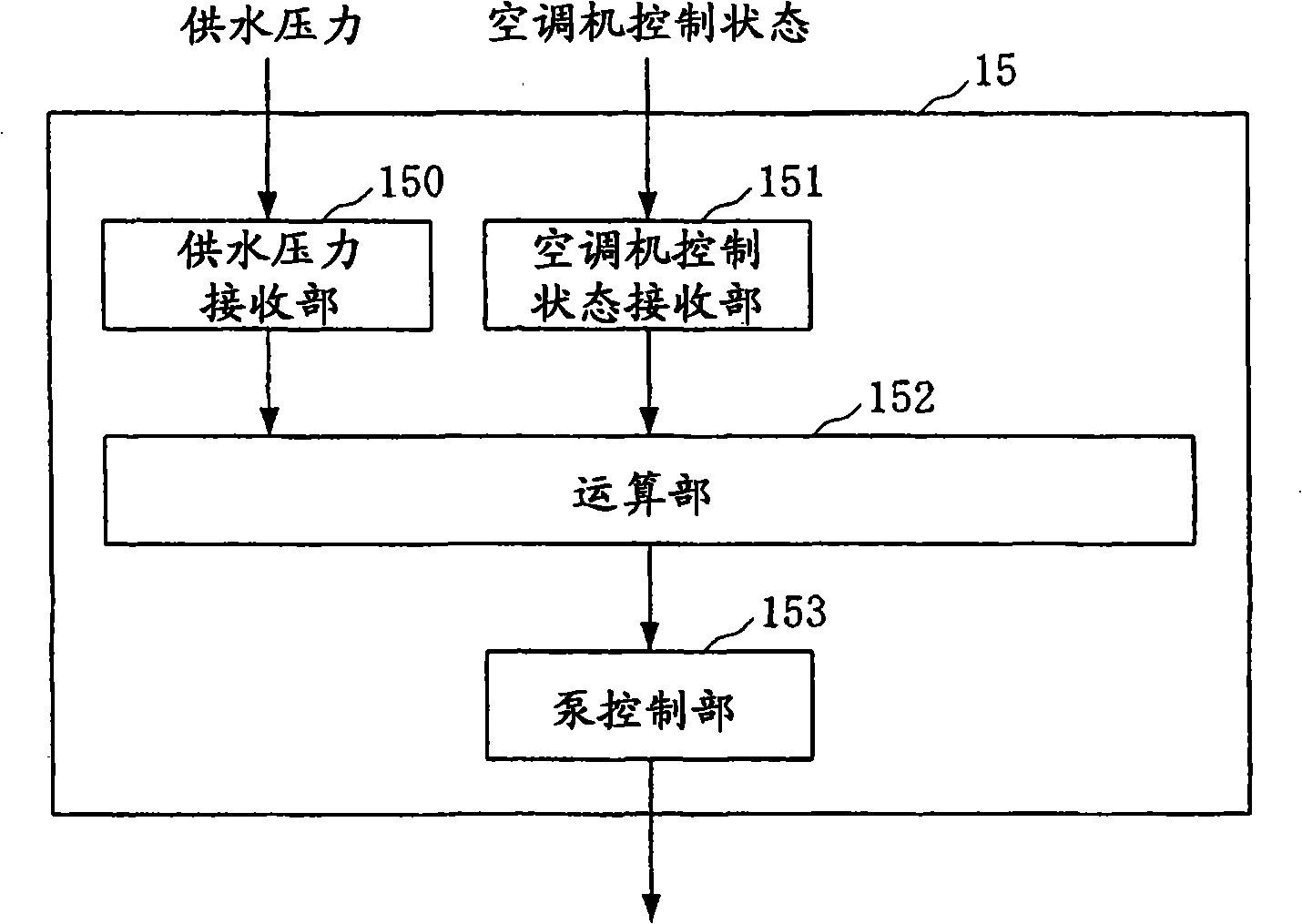

Air conditioner control system and method

InactiveCN101354170ACurb energy consumptionHigh energy consumptionMechanical apparatusSpace heating and ventilation safety systemsControl systemEngineering

The invention provides an air-conditioning control system for inhibiting energy consumption increment, which comprises pumps (9-1, 9-2) conveying cold water and hot water, air conditioners (5-1 to 5-3) receiving the supplied cold water and hot water, valves (6-1 to 6-3) controlling the flow of the cold water and hot water, a flow measuring mechanism arranged inside the valves (6-1 to 6-3), an air-conditioning control device (14) controlling the opening of the valves according to the partial difference of the air supply temperature sent from the air conditioners (5-1 to 5-3) and a set temperature and limiting the opening of the valves when the flow passing through the valves is over the maximum set flow to cause the flow passing through the valves to be maintained below the maximum set flow, and a control device (15) controlling water supply pressure according to the control state of the air conditioners (5-1 to 5-3) determined by the opening of the valves and the flow passing through the valves.

Owner:YAMATAKE HONEYWELL CO LTD

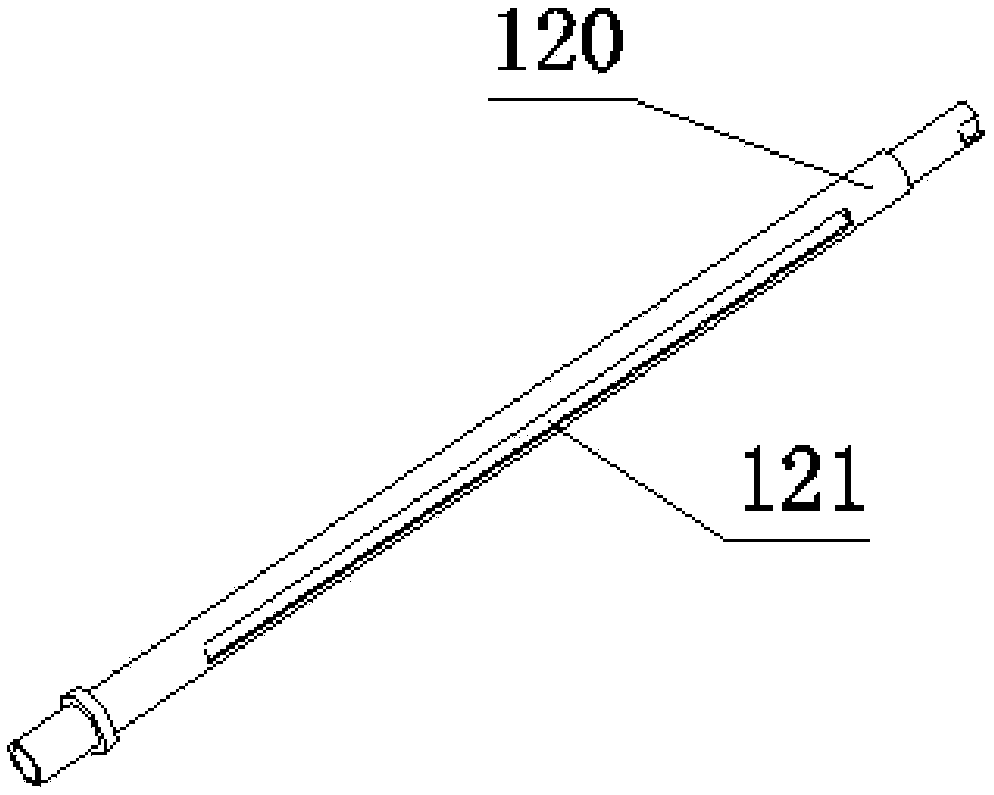

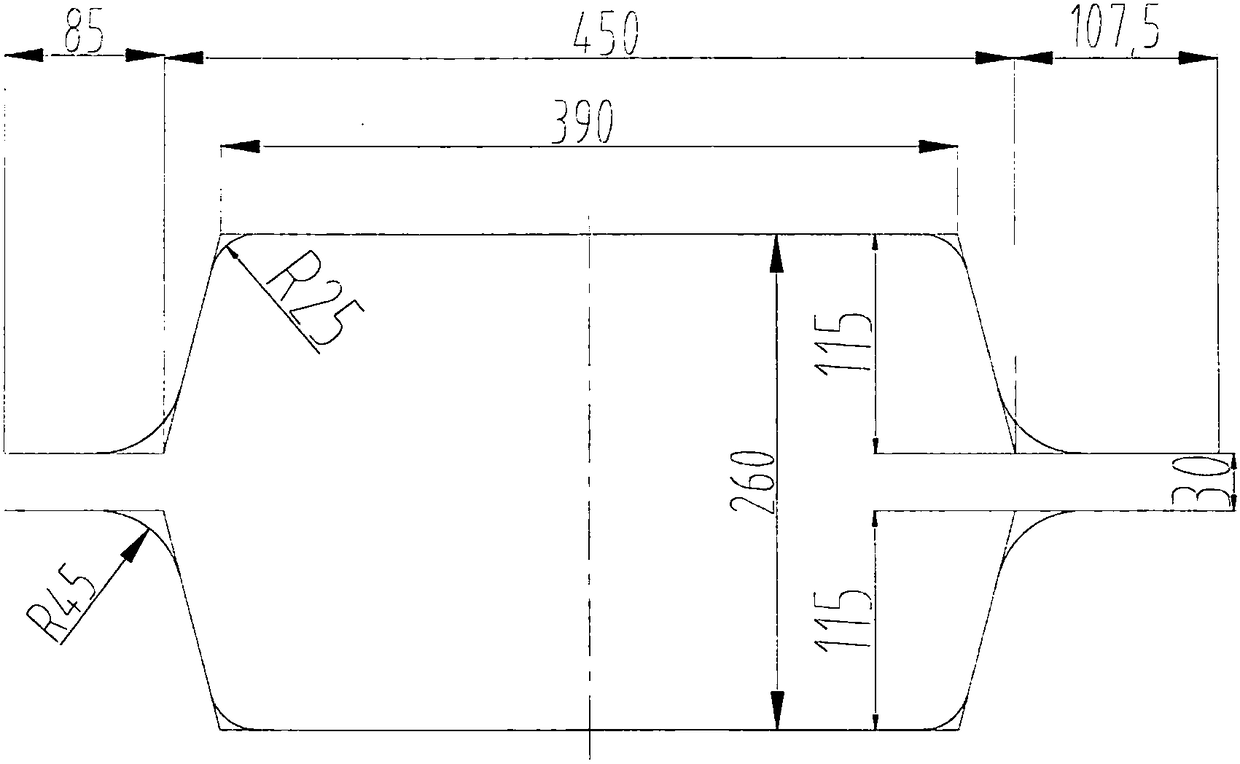

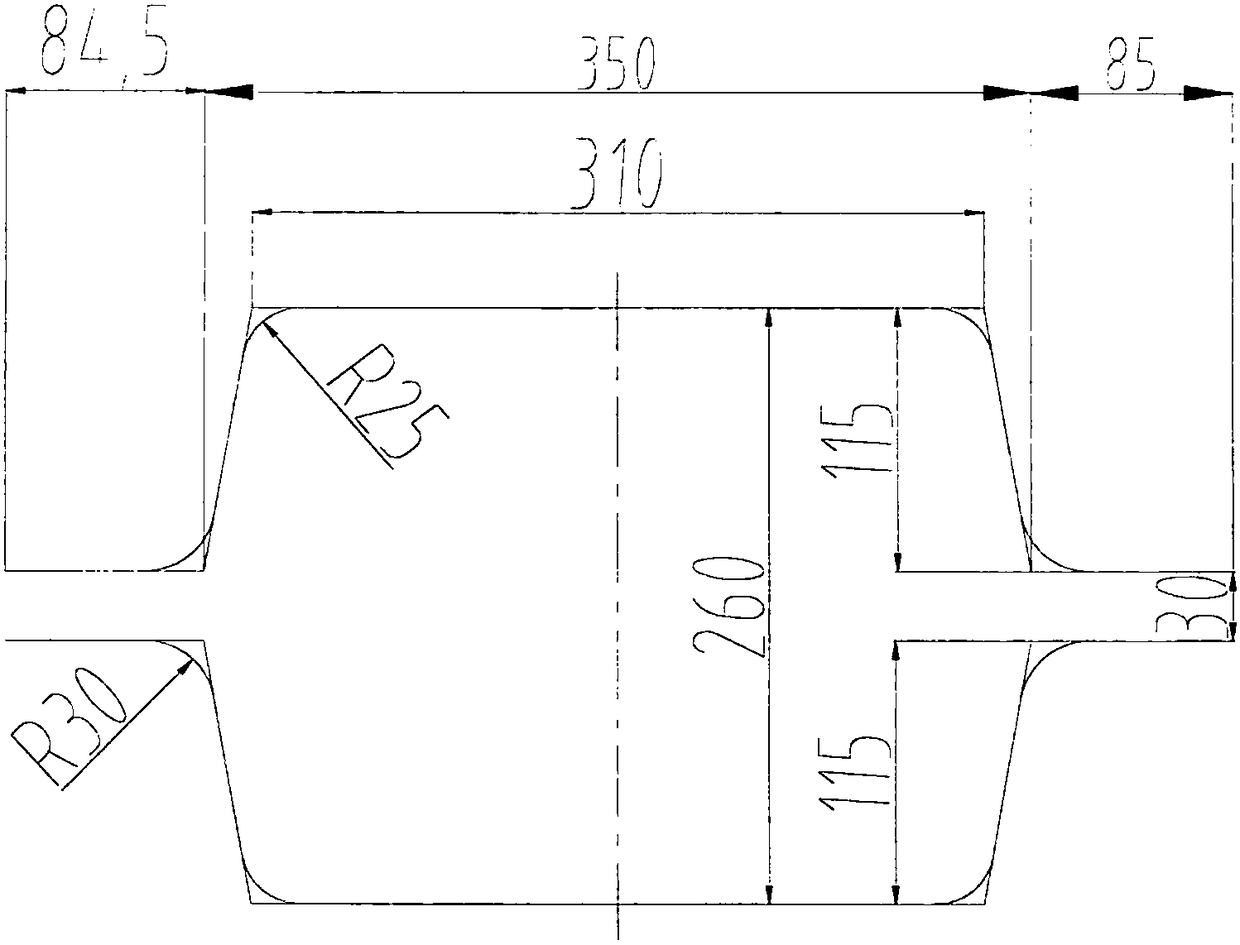

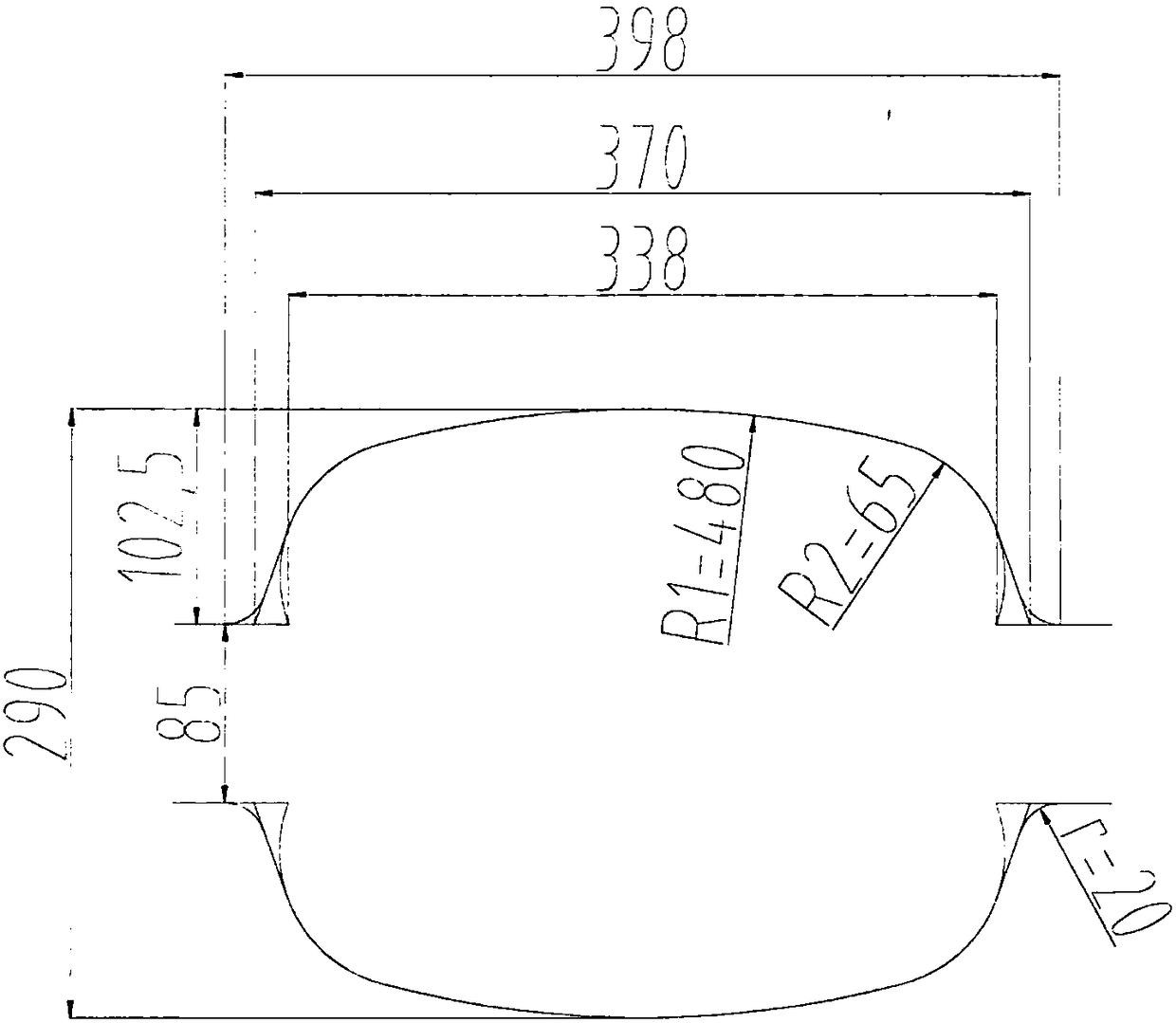

Bent pipe machining method and bent pipe

The invention provides a bent pipe machining method and a bent pipe, and belongs to the technical field of bent pipe machining. The method adopts an eccentric straight pipe and an induction heater. The method comprises the steps that S1, the eccentric straight pipe is mounted on a support table, a to-be-bent section is sleeved with an intermediate frequency induction heating ring, a first pipe section is movably mounted in a guiding assembly, the end of a second pipe section is clamped through a front chuck, and a rear pushing bent chuck clamps the end of the first pipe section and pushes thefirst pipe section to move in the direction of the to-be-bent section; and S2, intermediate frequency current is introduced into the intermediate frequency induction heating ring, the to-be-bent section is heated, when the temperature of the to-be-bent section is increased to a plastic state, the first pipe section is advanced through mechanical thrust, the to-be-bent section is bent, and the bentto-be-bent section is quickly cooled with a coolant. The bent pipe machining method adopts the eccentric straight pipe with the outer diameter being changed, the inner side thickening amount of the machined bent pipe is reduced, and the weight of a pipe system is reduced.

Owner:JIANGSU POWER EQUIP

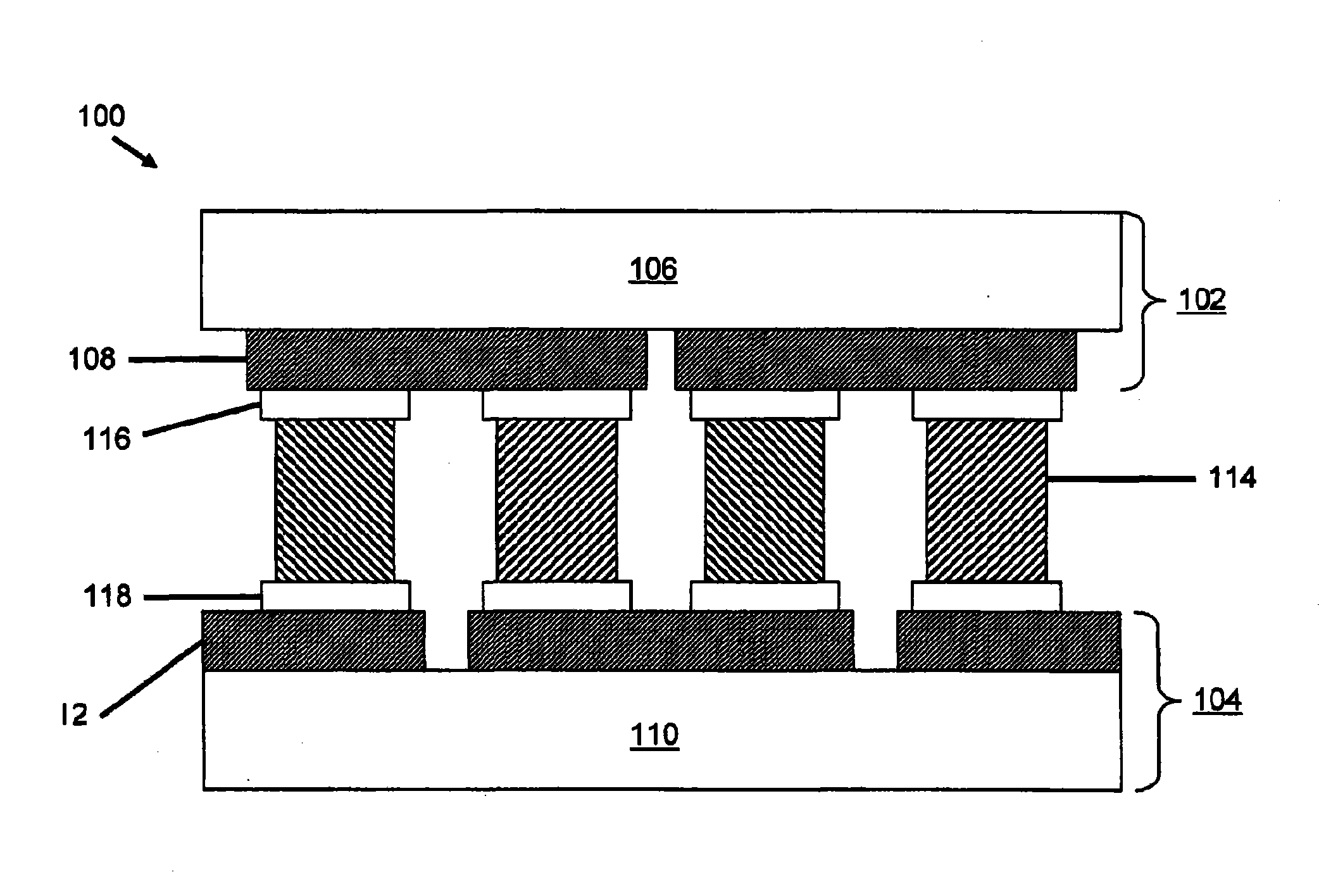

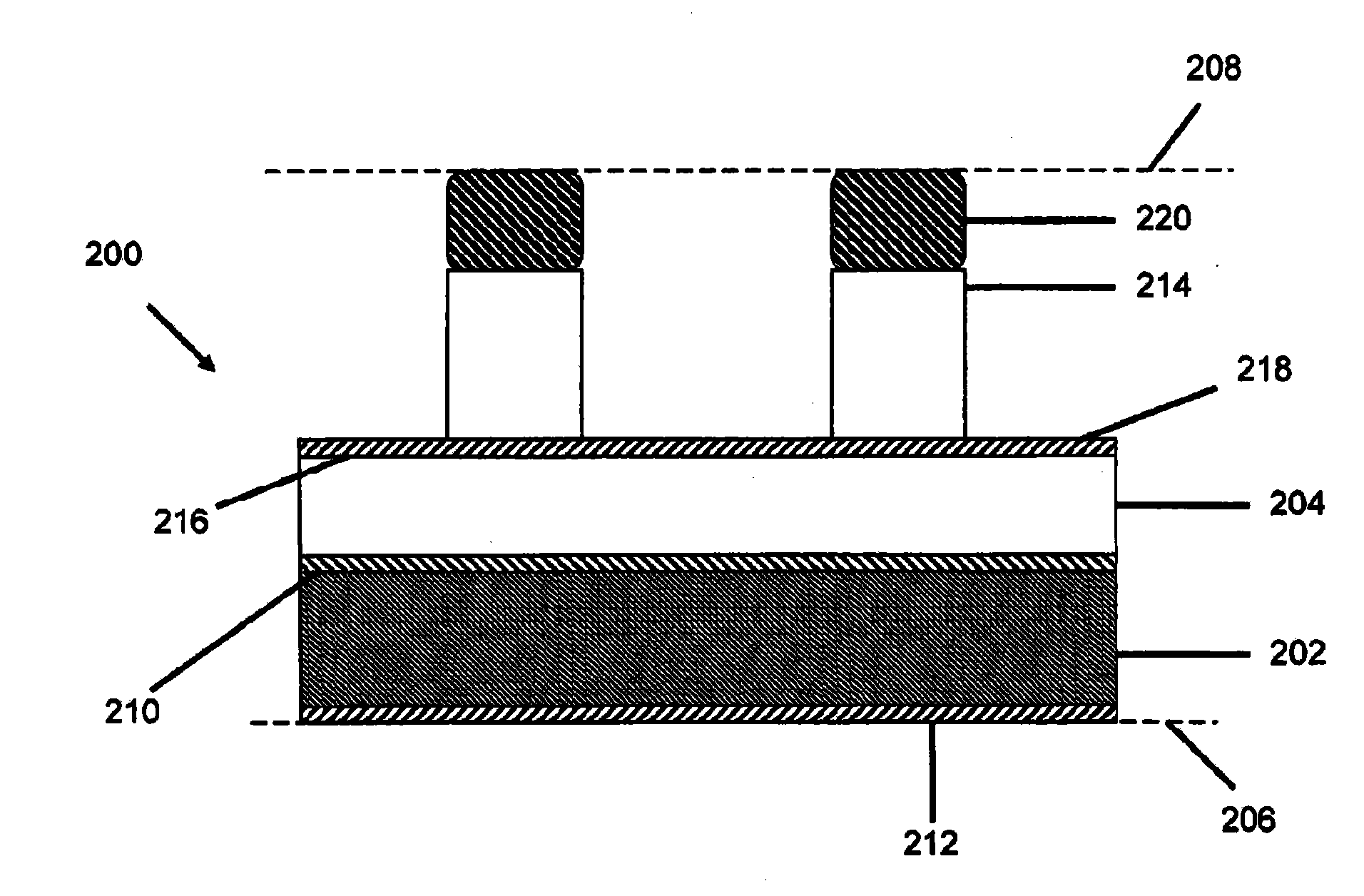

Metal-core thermoelectric cooling and power generation device

InactiveCN101978517ALow thermal conductivityGuaranteed temperature differenceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric coolingThermoelectric element

In various embodiments of the present invention, a thermoelectric device is provided. The thermoelectric device includes one or more thermoelements provided for transferring heat across the ends of the thermoelectric device. A method for making the thermoelectric device includes forming a metal substrate, and depositing one or more thermoelectric films on the metal substrate. Thereafter, one or more bumps are provided on one of the one or more thermoelectric films. Deposition of the one or more thermoelectric films on the metal substrate and the provision of the one or more bumps on the thermoelectric film result in the formation of a thermoelement.

Owner:SHEETAK INC

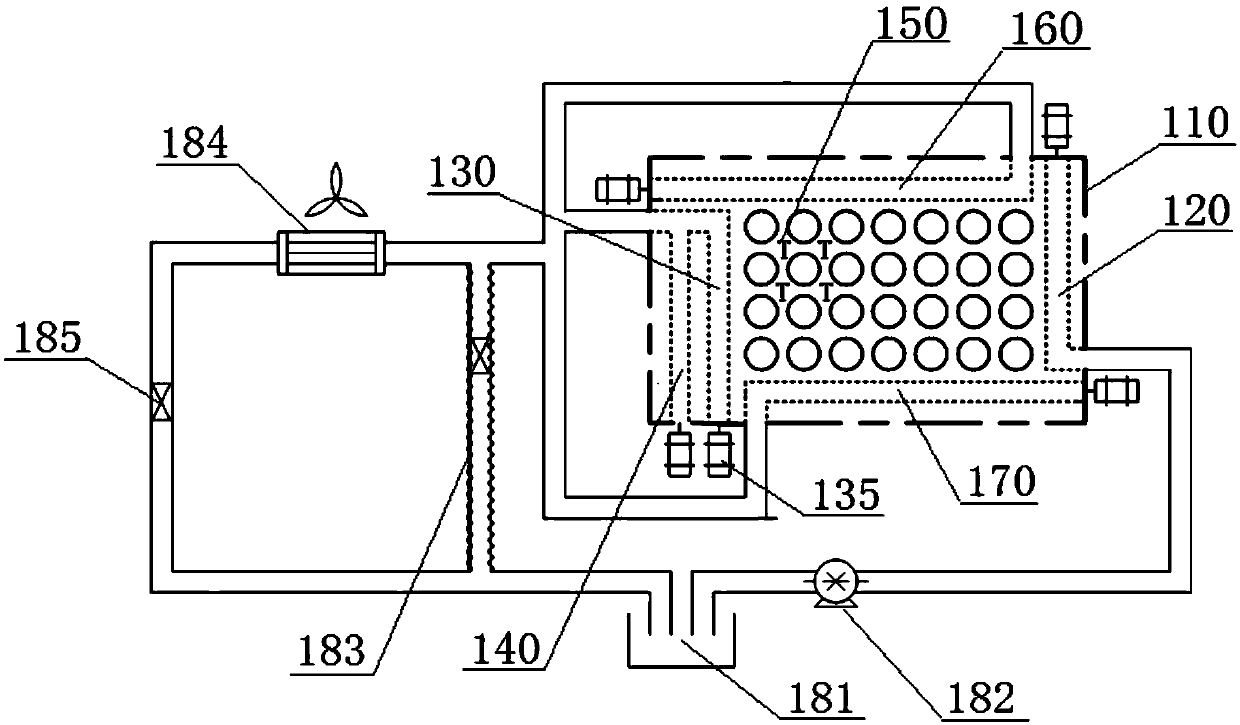

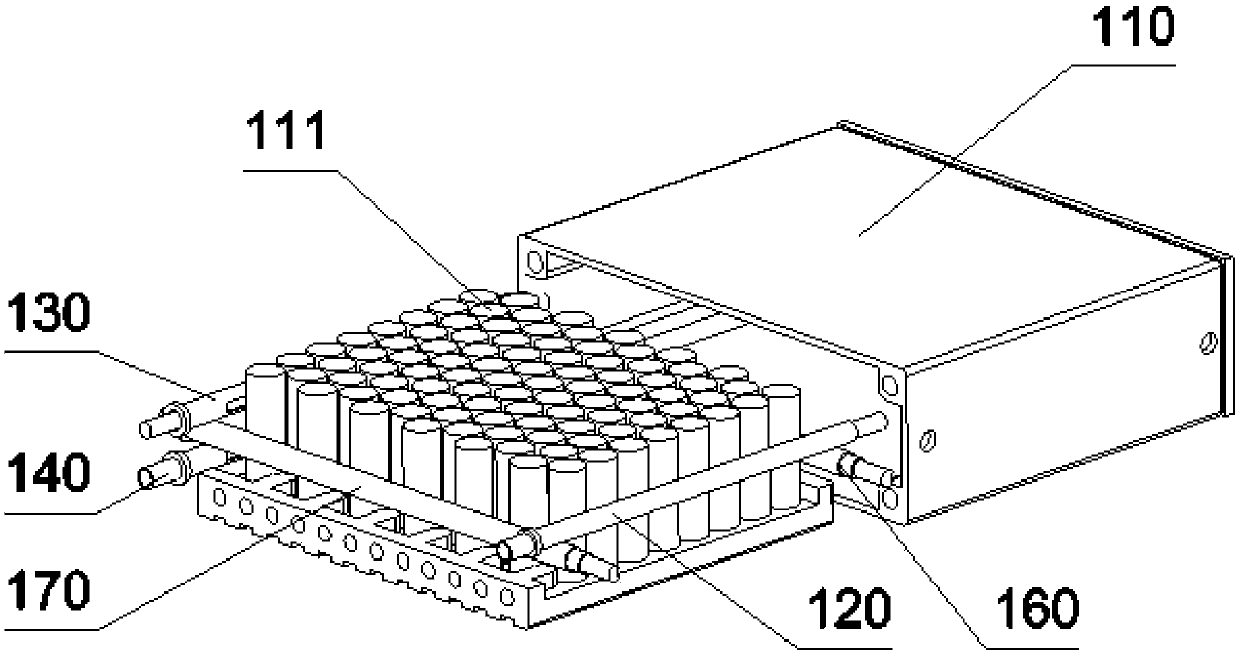

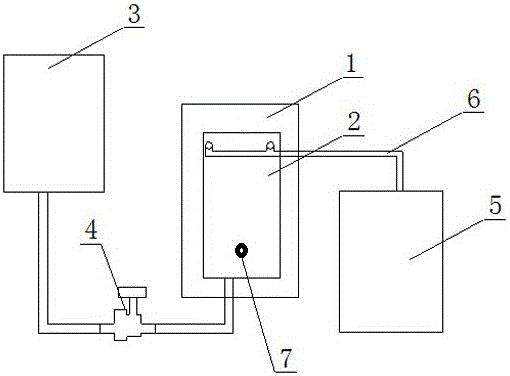

Heat management system for power batteries and control method

InactiveCN105186061ACompact structureReduce weightSecondary cellsVehicular energy storageTraffic capacityPower battery

The invention discloses a heat management system for power batteries. The heat management system comprises a battery box, a main oil inlet pipe, a main oil outlet pipe, a first oil outlet pipe, a temperature sensor and an external circulation system, wherein a main oil inlet tank is formed in the main oil inlet pipe; a main oil outlet tank is formed in the main oil outlet pipe; the width of the main oil outlet tank can be adjusted; a first oil outlet tank is formed in the first oil outlet pipe; the position of the first oil outlet tank can be adjusted back and forth oppositely to the length direction of the first oil outlet pipe; cooling liquid enters the battery box to exchange heat with a battery pack through the oil outlet tanks; and the widths of the oil outlet tanks and the position of the first oil outlet tank are adjusted according to the temperature value measured by the temperature sensor, so that the cooling liquid flows outside from the main oil outlet tank and the first oil outlet tank to increase the flow of the cooling liquid in a specific region. The invention further provides a heat management control method for the power batteries. According to the heat management control method, the condition that the battery pack works within an ideal temperature range can be ensured; and the condition that the temperature differences among various single batteries are within the ideal range can also be ensured.

Owner:JILIN UNIV

Method for producing large-specification circular blanks in rolling mode instead of forging mode

InactiveCN108356073AThe compression ratio meetsGuaranteed to burn throughRollsWork heating devicesHeating timeControl manner

The invention relates to a method for producing large-specification circular blanks in a rolling mode instead of a forging mode. The method mainly comprises the following steps that 1, rough rolling pass designing is conducted, specifically, rough-rolled holes are a combination of flat holes, box-type holes and intermediate billet finished holes; 2, firstly, the heating time before rough rolling is prolonged, secondly, the pass reduction of the front passes is made to be small while the pass reduction is increased in later passes in order to ensure rolling stability, and thirdly, the tapping temperature is improved, the number of rolling passes is reduced by adjusting the pass reduction; 3, firstly, two-radius oval holes with small long axes and short axes are adopted as finishing pass before finished products are formed, and secondly, circular holes are adopted as last pass for rolling; and 4, firstly, the position of the blanks in a furnace is adjusted, and it is ensured that the temperature difference of surfaces of the blanks is within 30 DEG C, secondly, the control mode of cooling water of a roller is adjusted, and thirdly, the assembly quality requirement is determined, quantitative management is conducted, and the assembly quality of a tool is ensured. The forging mode is replaced with the rolling mode through improvement of the rolling process and selection and designof the rolling mill passes, and the product competitiveness is improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

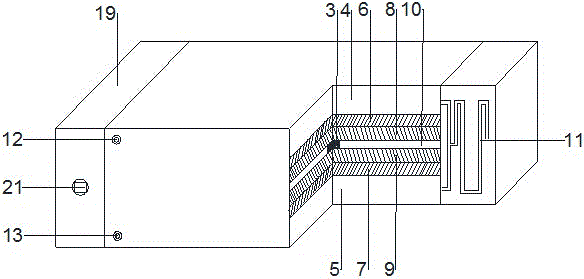

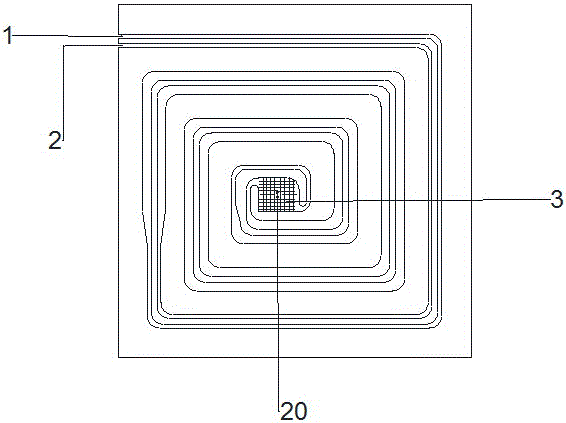

Micro-combustion thermoelectric generator based on porous medium micro-combustion

ActiveCN105827152AReduce volumeFix ignition problemsIndirect carbon-dioxide mitigationGenerators/motorsCombustion chamberPorous medium

The invention discloses a micro-combustion thermoelectric generator based on porous medium micro-combustion. The structure of the micro-combustion thermoelectric generator is displayed in a flake-shape, and is successively formed from top to bottom by a fuel storage layer, an upper thermoelectric generation sheet, an upper thermal insulation layer, a combustion module, a lower thermal insulation layer, a lower thermoelectric generation sheet, and an oxidant storage layer, wherein a combustion chamber is arranged at a hot end of each thermoelectric generation sheet; a gas preheating layer is arranged at a cold end of each thermoelectric generation sheet; the combustion module comprises an inlet channel, an outlet channel and a combustion chamber; the inlet channel is a square double helix parallel structure; the center combustion chamber is filled with porous mediums; and the upper and lower thermal insulation layers are filled by mixture of conduction oil and trace inert gas. The micro-combustion thermoelectric generator based on porous medium micro-combustion has the advantages of being high in energy, being small in volume, being light in weight, having no noise, being continuously stable and being low in discharge, and mainly aims at the mini electronic equipment field, and is suitable for the field and for power supply of mini precision portable equipment of the military and aerospace field.

Owner:HANGZHOU DIANZI UNIV

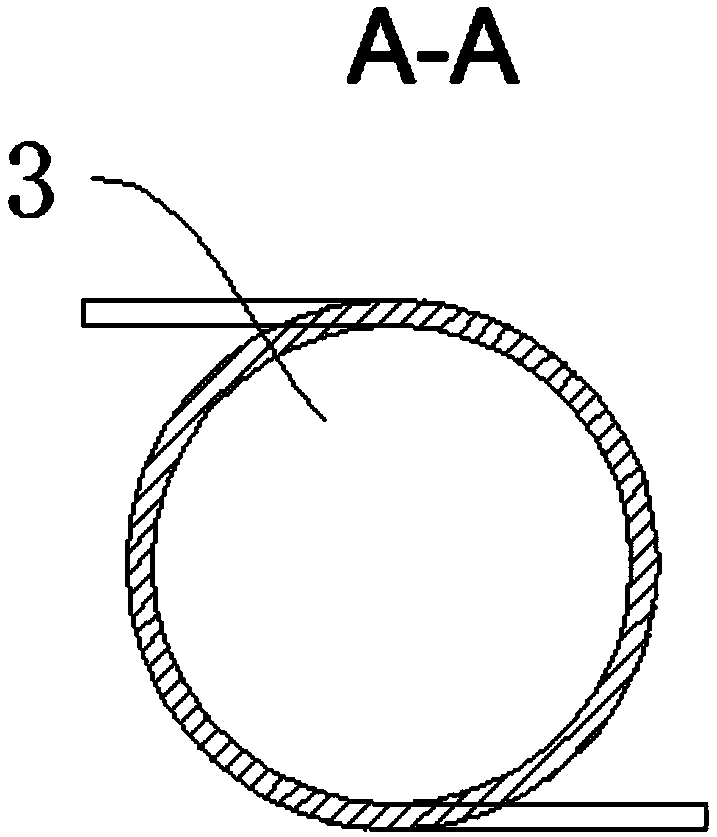

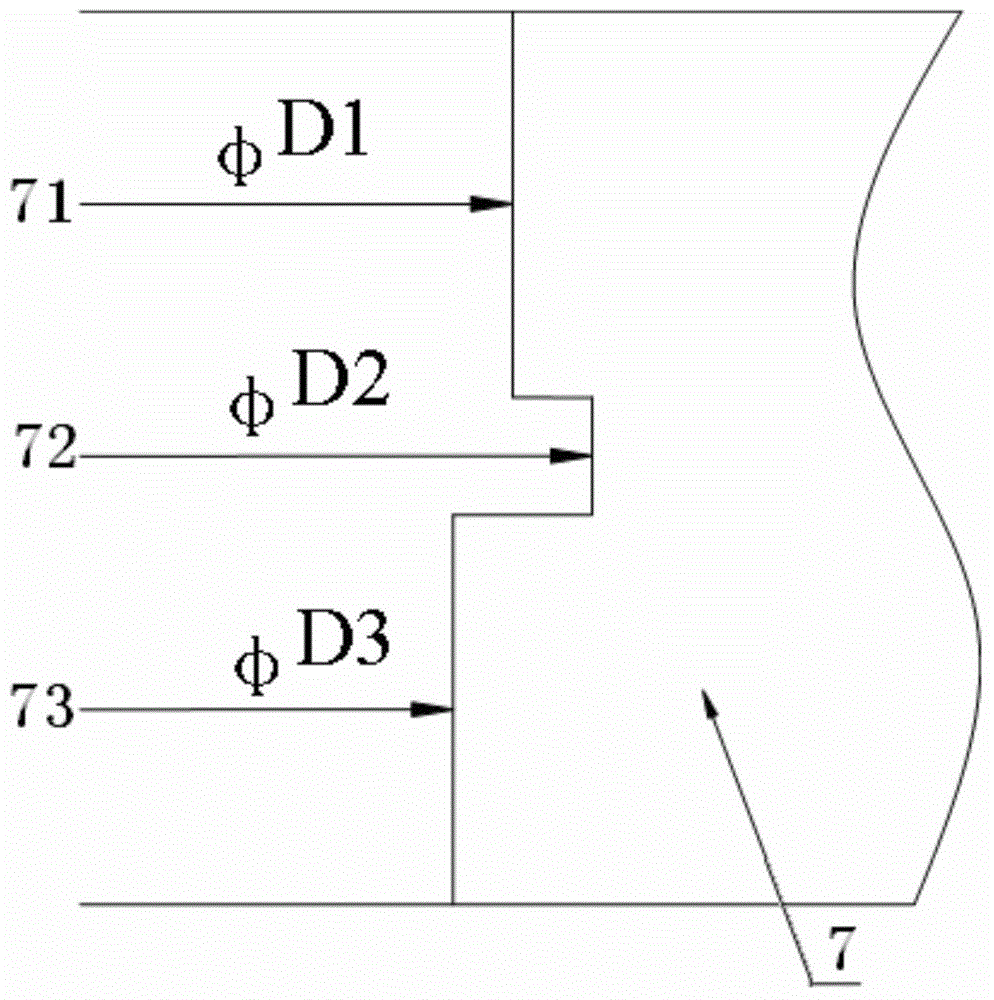

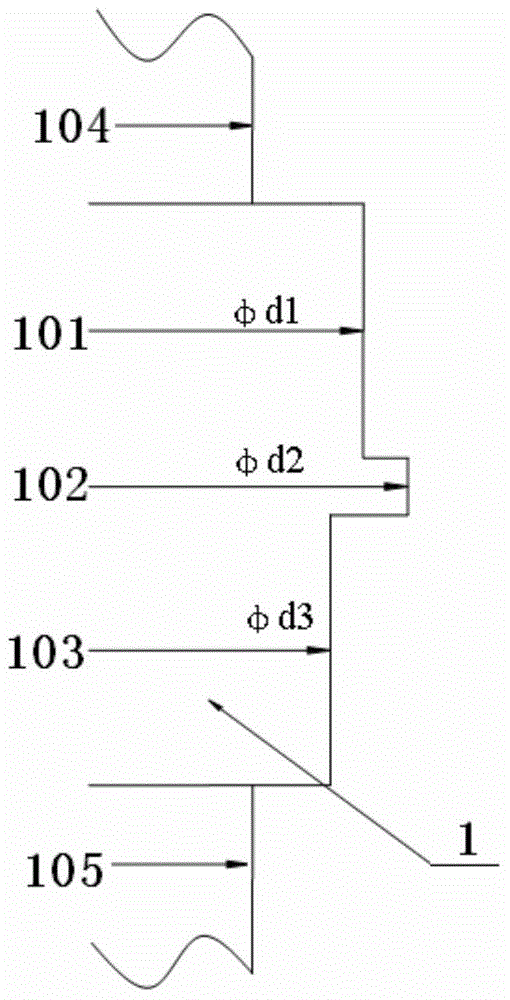

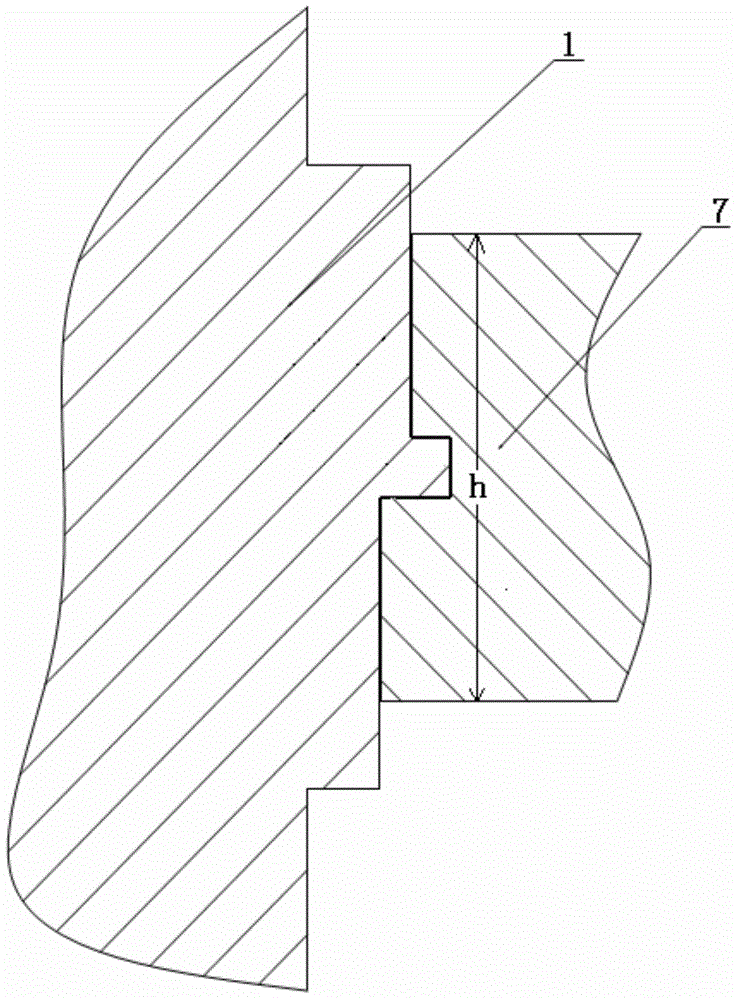

Cooling Roller

InactiveCN102284317AImprove heat absorption efficiencySimple structureGrain treatmentsThermodynamicsEngineering

The invention provides a cooling grinding roller used in a roller mill, comprising a grinding roller body, a stepped hole is arranged in the grinding roller body, a heat transfer medium is arranged in the stepped hole in the grinding roller body, and an inner hole is arranged in the grinding roller shaft , one end of the grinding roller shaft is set in the stepped hole of the grinding roller body, and is closely matched with the grinding roller body, and the other end of the grinding roller shaft is provided with a heat dissipation pipe, and the heat dissipation pipe communicates with the stepped hole in the grinding roller body through the inner hole of the grinding roller shaft to dissipate heat There are heat dissipation fins on the pipe, and the heat dissipation pipe corresponds to the enhanced heat dissipation device installed on the mill shell. It is a hollow structure made of the grinding roller shaft. One end of the grinding roller shaft is set in the inner cavity of the grinding roller, and the other end is Heat dissipation pipes are installed, the inner cavity of the grinding roller is equipped with a medium, and the heat generated by the grinding roller body is directly absorbed by the medium. The heat dissipation and cooling of the grinding roller body has a simple structure and good heat dissipation effect. The medium is directly in contact with the grinding roller body, and the heat absorption efficiency is high.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +2

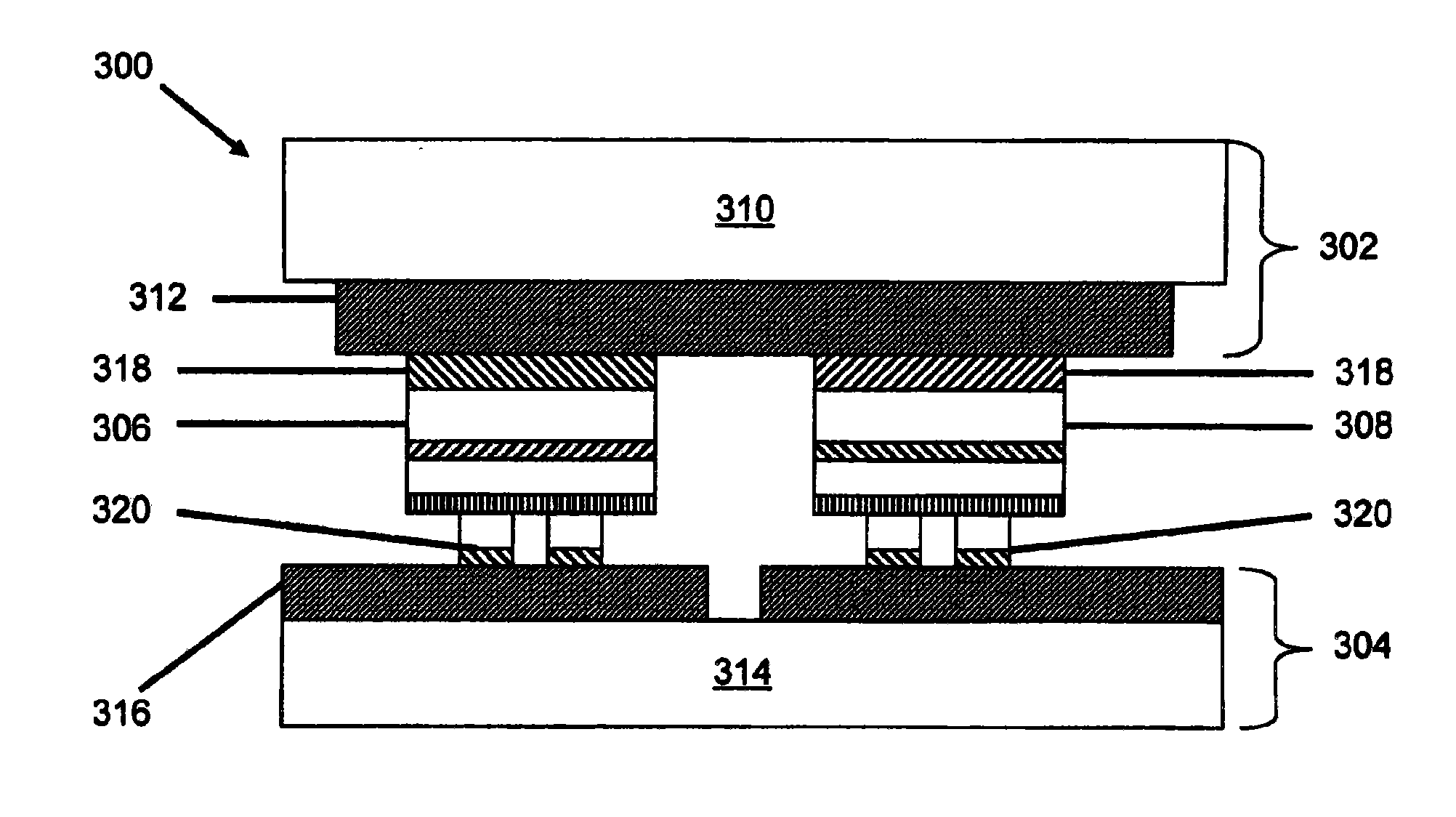

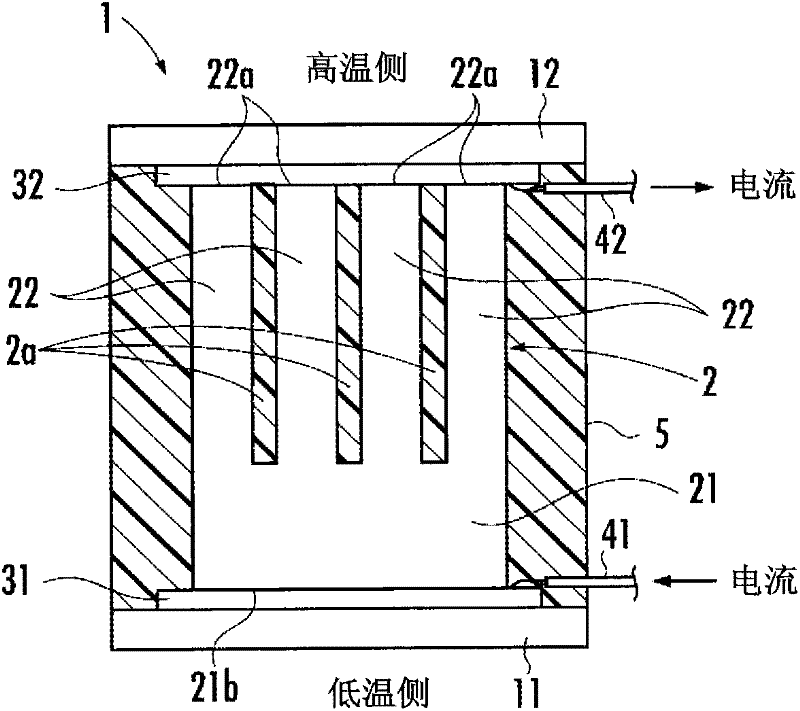

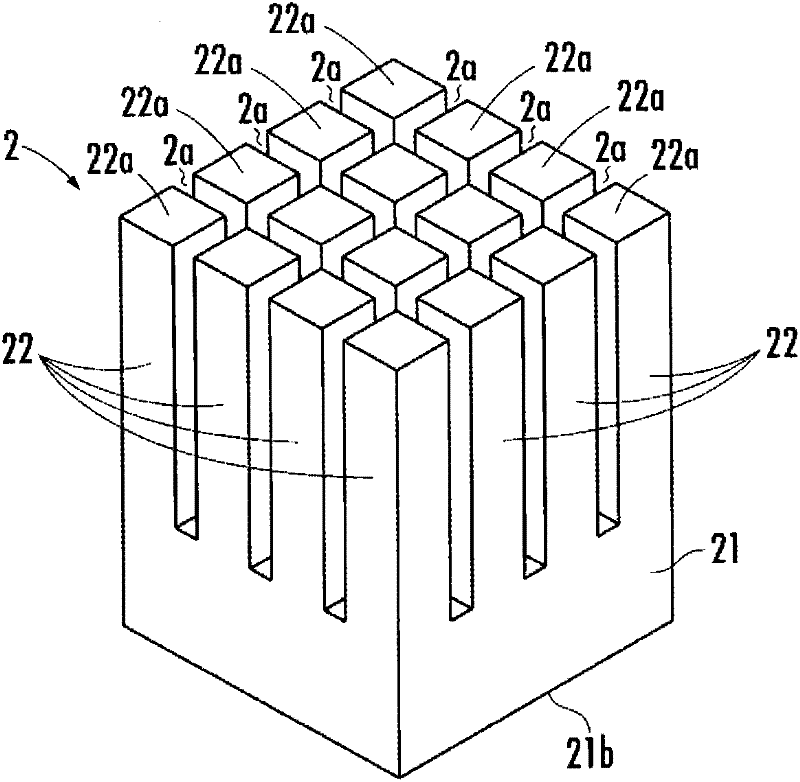

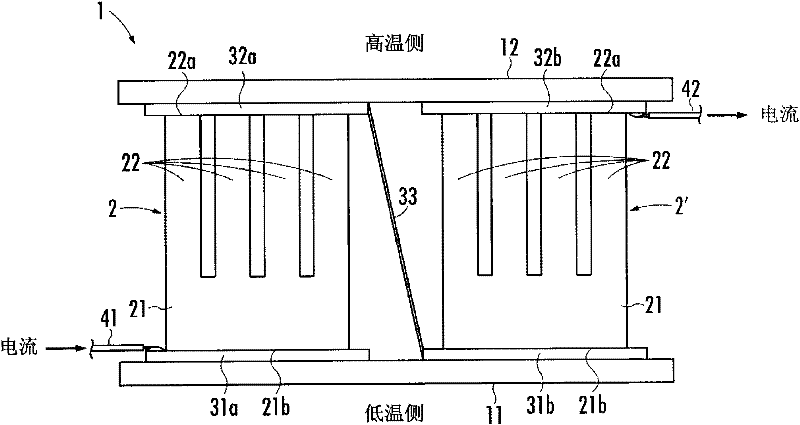

Thermoelectric conversion element and thermoelectric conversion module

InactiveCN102341927AImprove yieldWith fail-safe functionThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentElectricityEngineering

Disclosed is a thermoelectric conversion element which has improved yield and improved durability, can ensure a satisfactory level of difference in temperature between both end parts readily, can be connected to an electrode easily without inclining, and has improved mass productivity. Also disclosed is a thermoelectric conversion module comprising the thermoelectric conversion element. Specifically disclosed is a thermoelectric conversion element (2) comprising: multiple pillar-like sections (22) in each of which one end is electrically connected to a first electrode plate (32) and which are arranged at a given spacing from each other; and a joining section (21) which connects the other ends of the pillar-like sections (22) to each other and is electrically connected to a second electrode plate (31). A connection surface (21b) of the joining section (21) which is connected to the second electrode plate (31) has a larger surface area than the total surface area of end parts (22a) of the pillar-like sections (22).

Owner:TOKYO UNIVERSITY OF SCIENCE +1

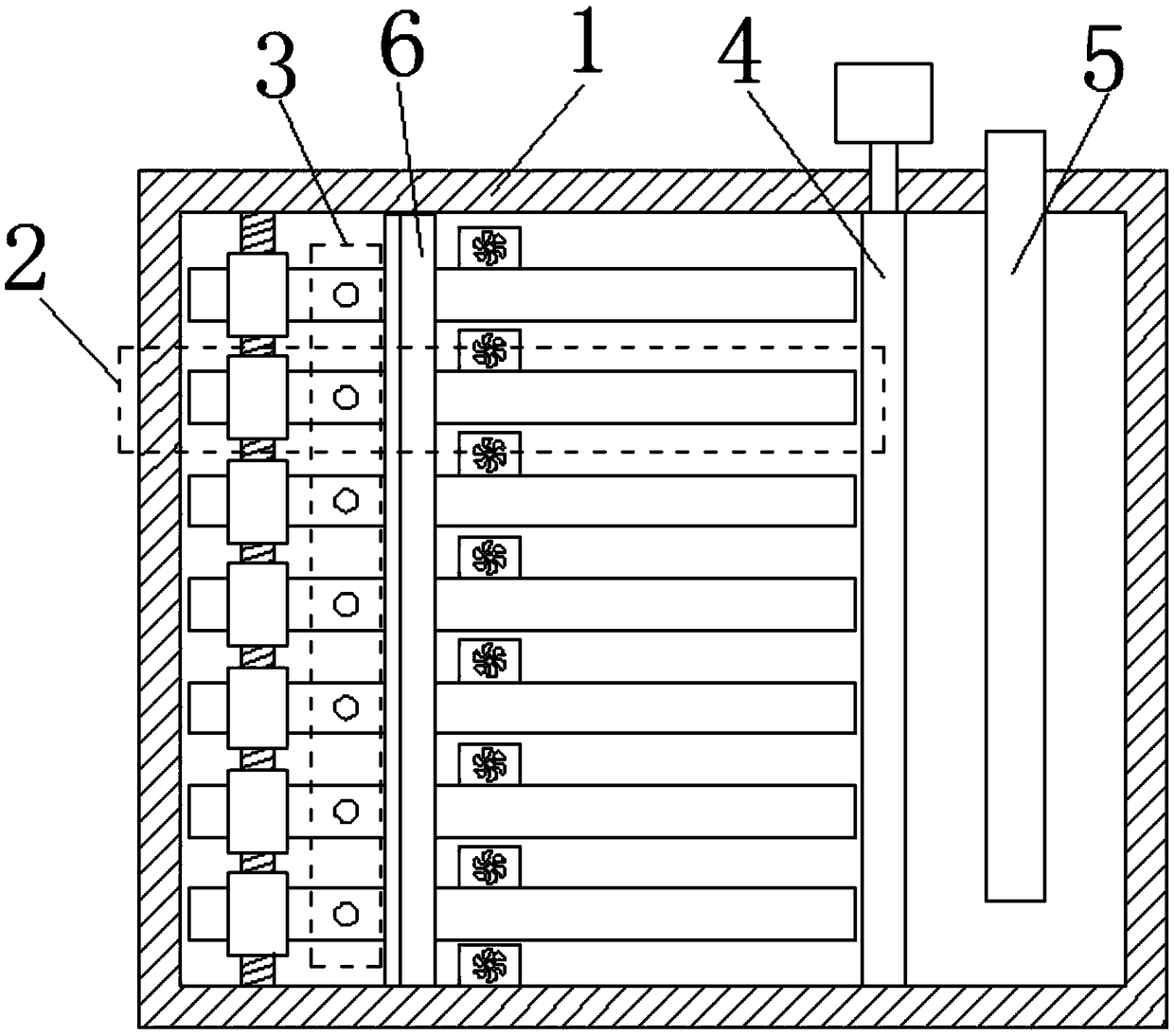

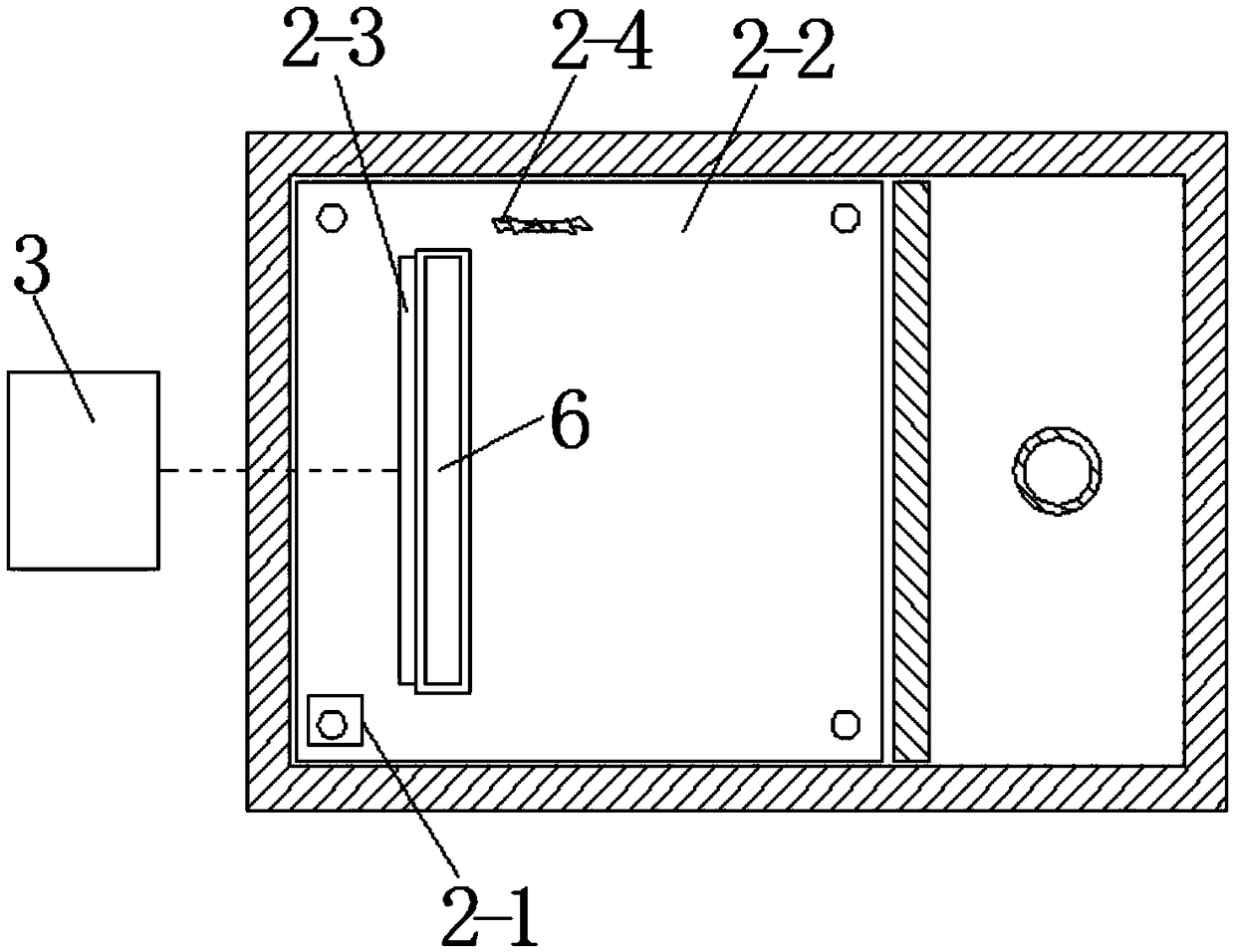

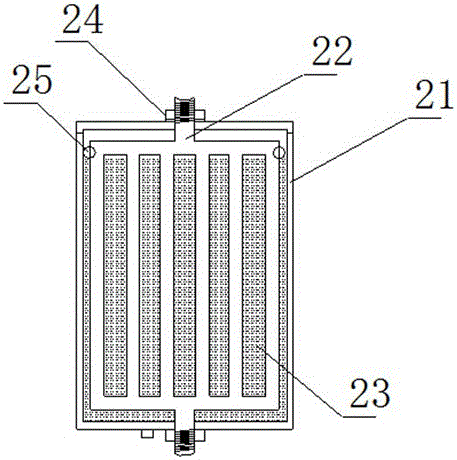

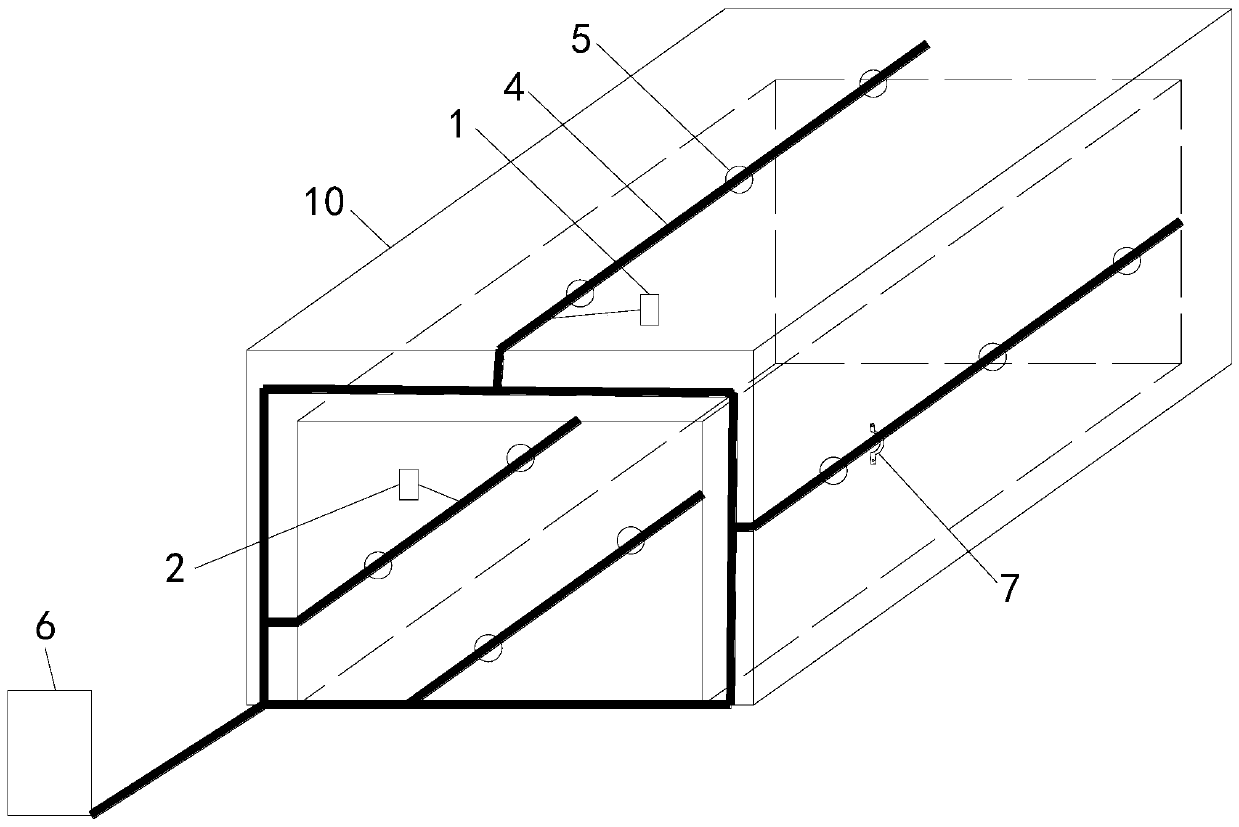

Building material volatility detection device simulating geothermal environment

ActiveCN109270113AAchieve temperature controlStable temperatureMaterial thermal analysisEngineeringTemperature difference

The invention belongs to the technical field of volatility detection, and particularly relates to a building material volatility detection device simulating a geothermal environment. The building material volatility detection device comprises a box, layer units, a differential temperature device, an isolating valve, a sampling pipe and a building material plate, a plurality of layer units are parallelly arranged inside the box to form a plurality of differential temperature volatilization layers, the building material plate vertically penetrates the layer units, the differential temperature device comprises a plurality of differential temperature ends with different temperature, each differential temperature end is correspondingly arranged on one layer unit, detection plates are verticallyarranged in different differential temperature volatilization layers, each differential temperature volatilization layer individually controls temperature through the differential temperature device, so that the surfaces of small-sized building materials generate different-gradient temperature difference, volatilization experiments are performed under the condition of keeping the temperature difference, the actual temperature gradient of the small-sized building materials under geothermal conditions is simulated, and volatility detection experiments are performed.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

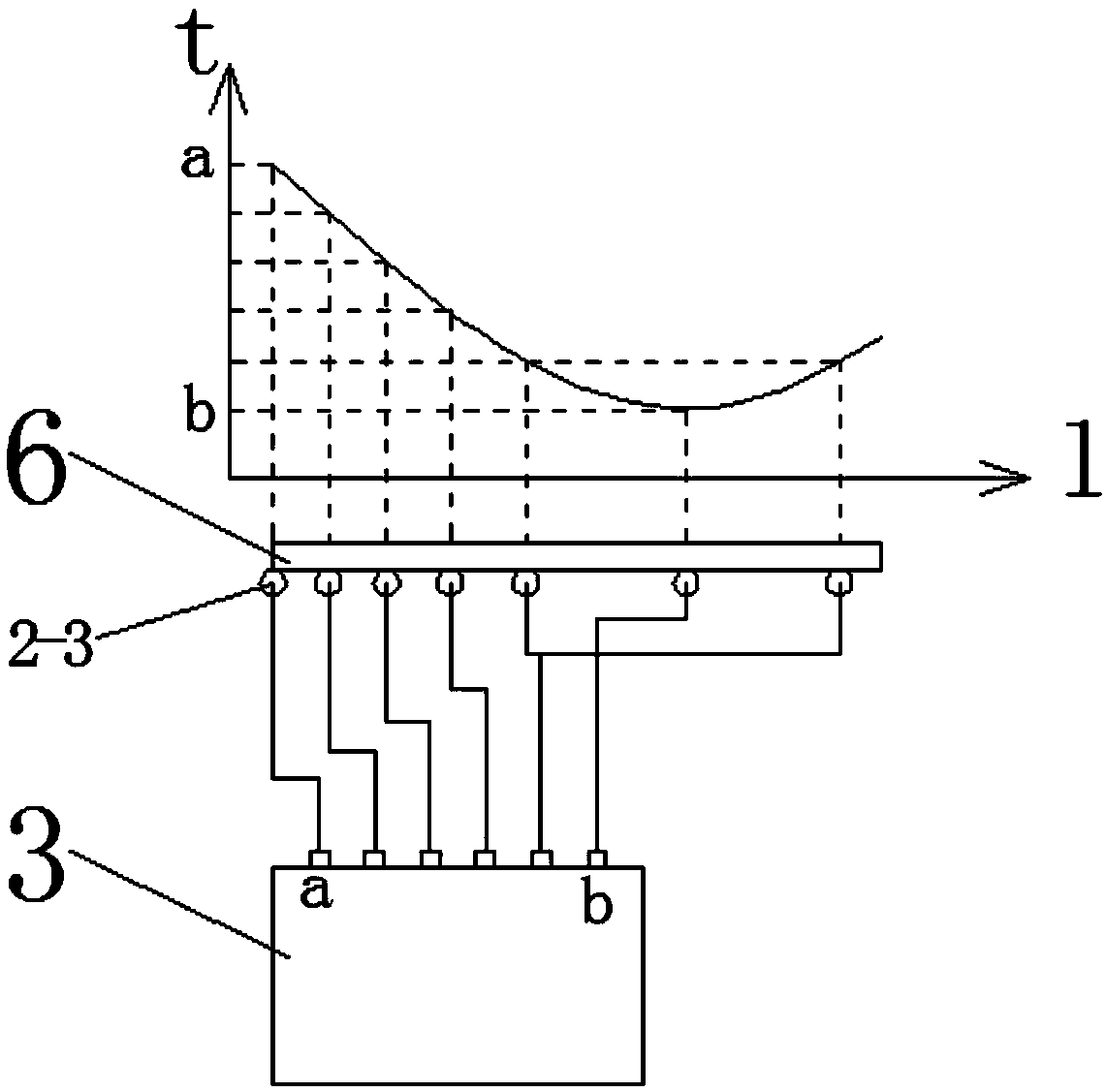

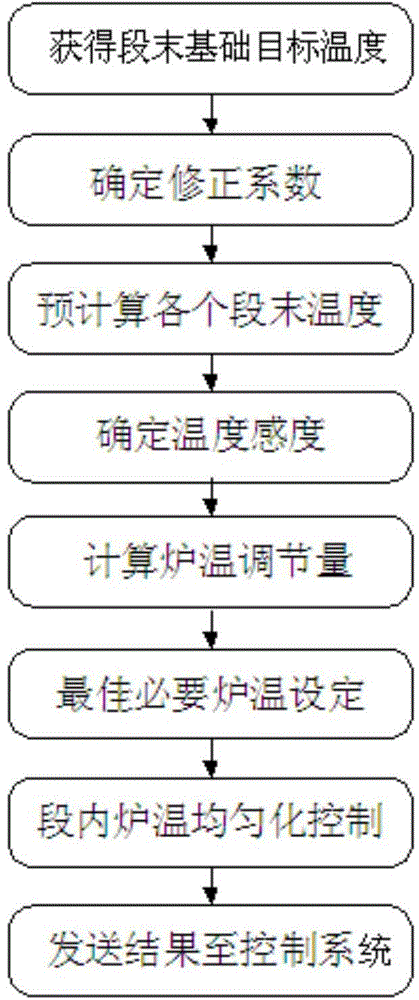

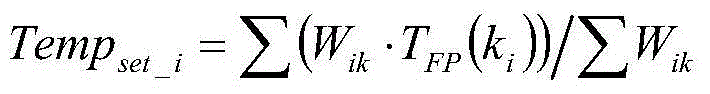

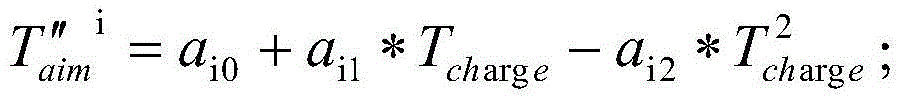

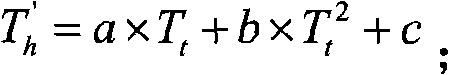

Hot rolled slab heating control method based on section terminal temperature

ActiveCN105385843AReach target temperatureHigh temperature control accuracyTemperature control deviceHeat treatment process controlTemperature controlFurnace temperature

The present invention discloses a hot rolled slab heating control method based on section terminal temperatures. The method comprises: determining the target section terminal temperature of a slab at each heating sections; predicting the section terminal temperatures of the slab at each heating section by using the standard furnace temperatures and the slab temperature predicting models of each heating section; determining the sensitivity of the slab on the furnace gas temperatures of each heating section in a heating furnace at the section terminal temperatures of each heating section; according to the sensitivity and the deviation between the predicted section terminal temperatures and the target section terminal temperatures of each heating section, determining the furnace gas temperature adjusting amounts of each heating section; according to the furnace gas temperature adjusting amounts of each heating section and the standard furnace temperatures of each heating section, determining the optimal furnace gas temperature setting values of the slab at each heating section; and carrying out homogenized control on the furnace gas temperature in the heating furnace. With the method of the present invention, it can be ensured that the slab achieves the section terminal target temperature, and can further be ensured that the temperature different between the upper surface and the lower surface of the slab is controlled within the predetermined range so as to effectively avoid the product defect and improve the temperature control precision.

Owner:BAOSHAN IRON & STEEL CO LTD

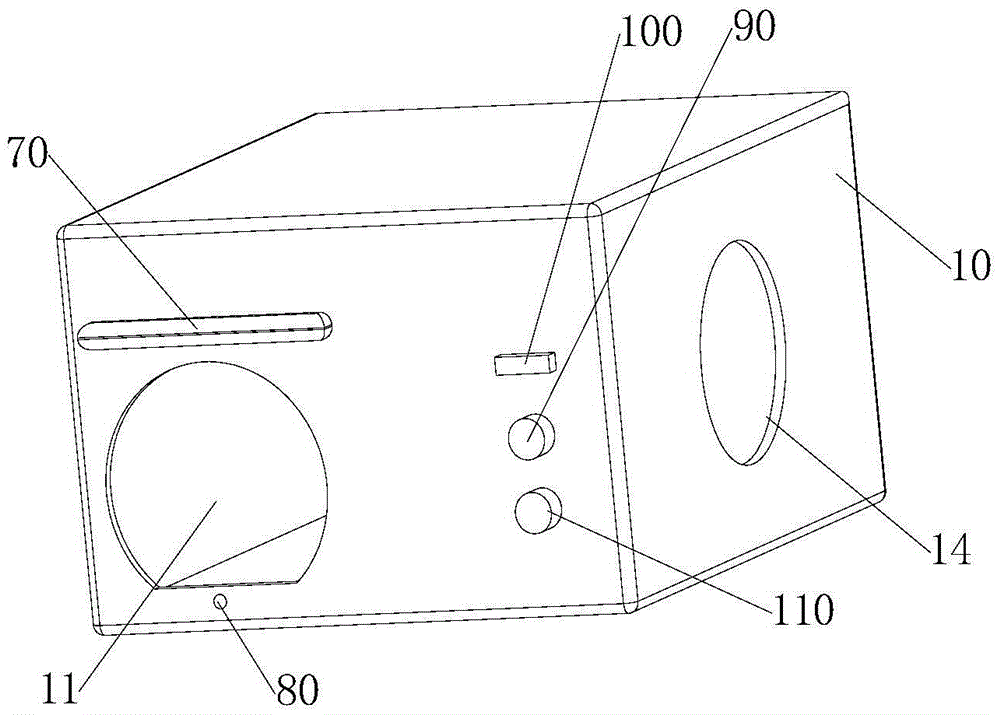

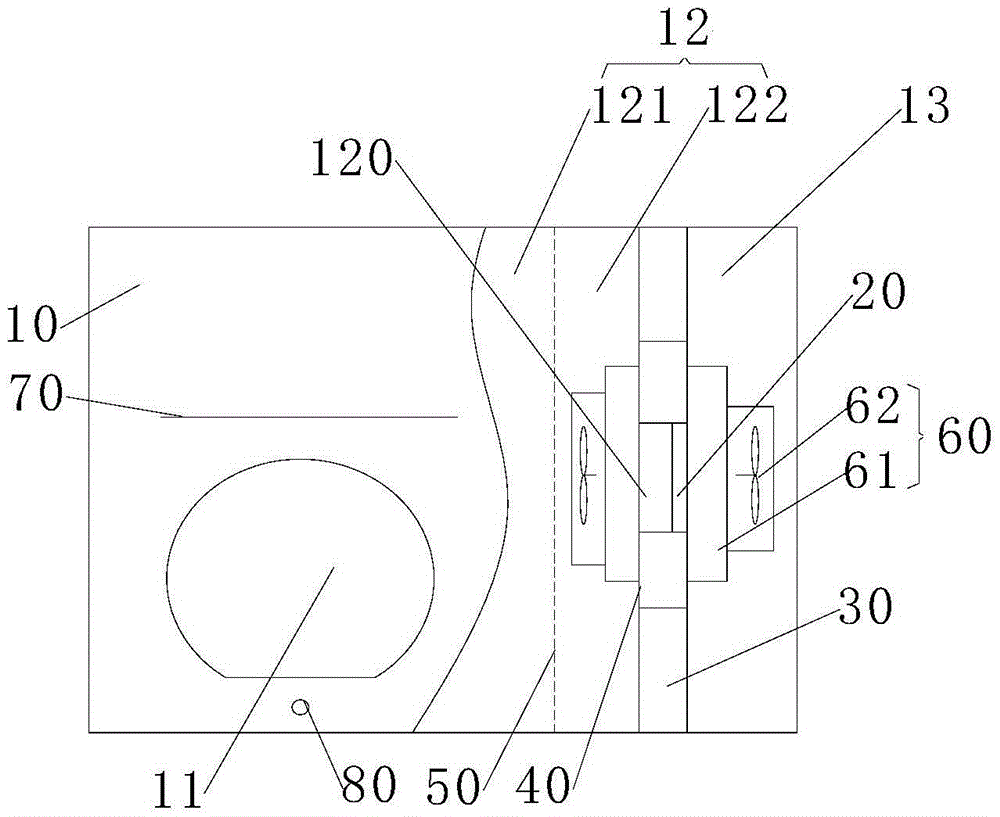

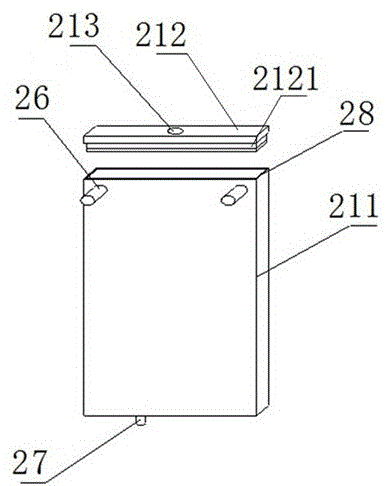

Temperature control device

ActiveCN105571197AEasy to put inEasy to take outMachines using electric/magnetic effectsRefrigeration safety arrangementElectricityTemperature control

The invention provides a temperature control device. The temperature control device comprises a box, a semiconductor part, a control circuit and a power supply part, wherein the box is provided with an opening allowing a user to put objects into the box or take the objects out of the box; the semiconductor part is arranged in the box for dividing an internal space of the box into a first heat exchange cavity and a second heat exchange cavity; a first heat exchange end of the semiconductor part is positioned in the first heat exchange cavity; a second heat exchange end of the semiconductor part is positioned in the second heat exchange cavity; the opening is communicated with the first heat exchange cavity; and the power supply part supplies electricity to the semiconductor part through the control circuit. The temperature control device solves the problem of inconvenience for keeping temperature and cold of objects in the prior art.

Owner:GREE ELECTRIC APPLIANCES INC

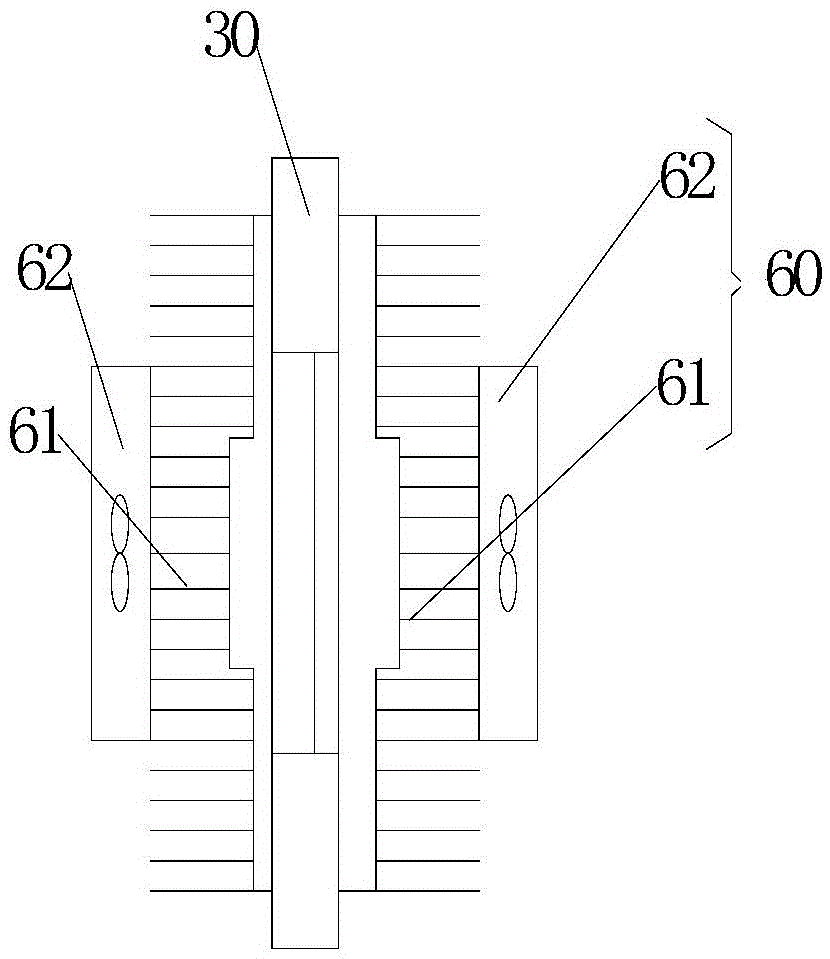

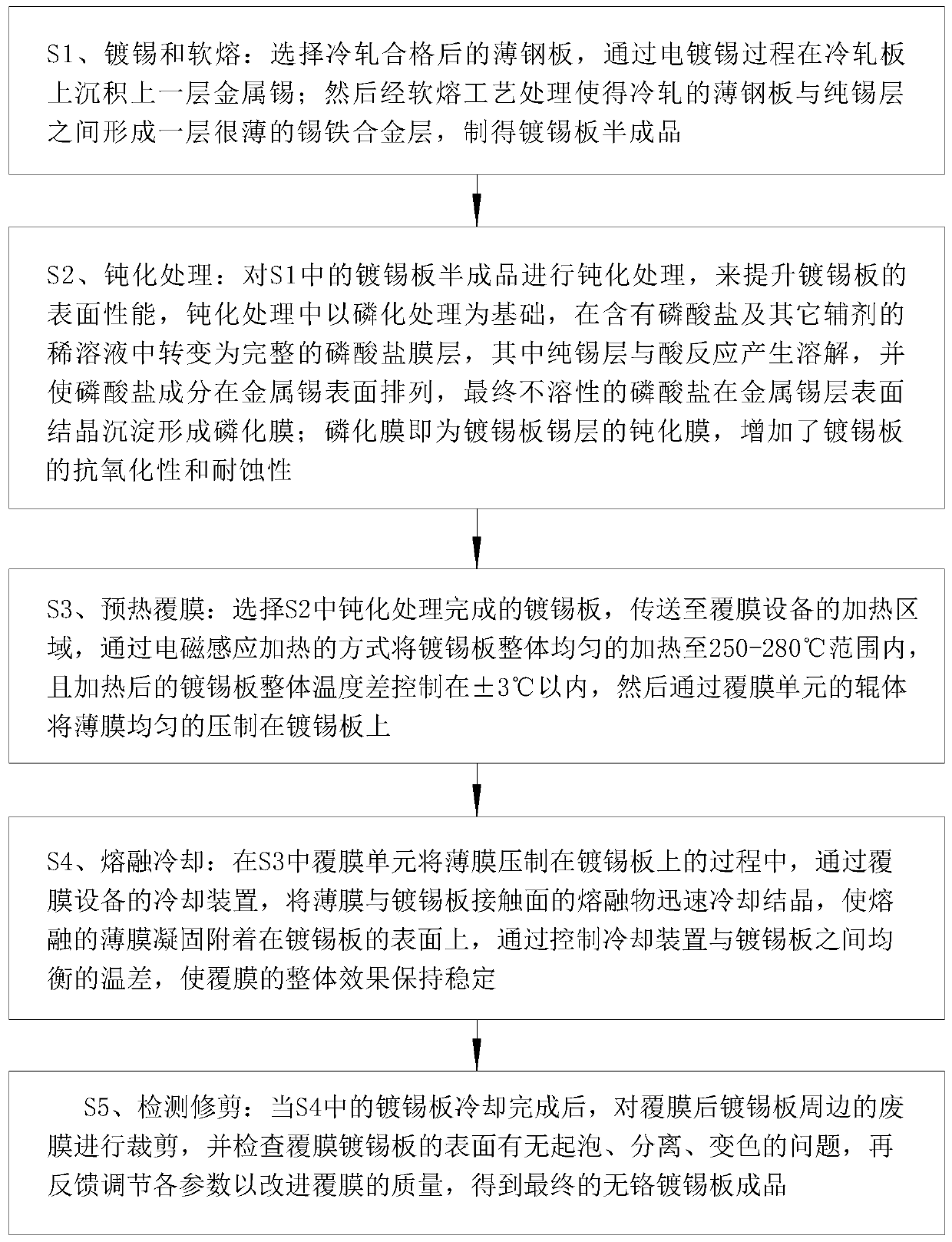

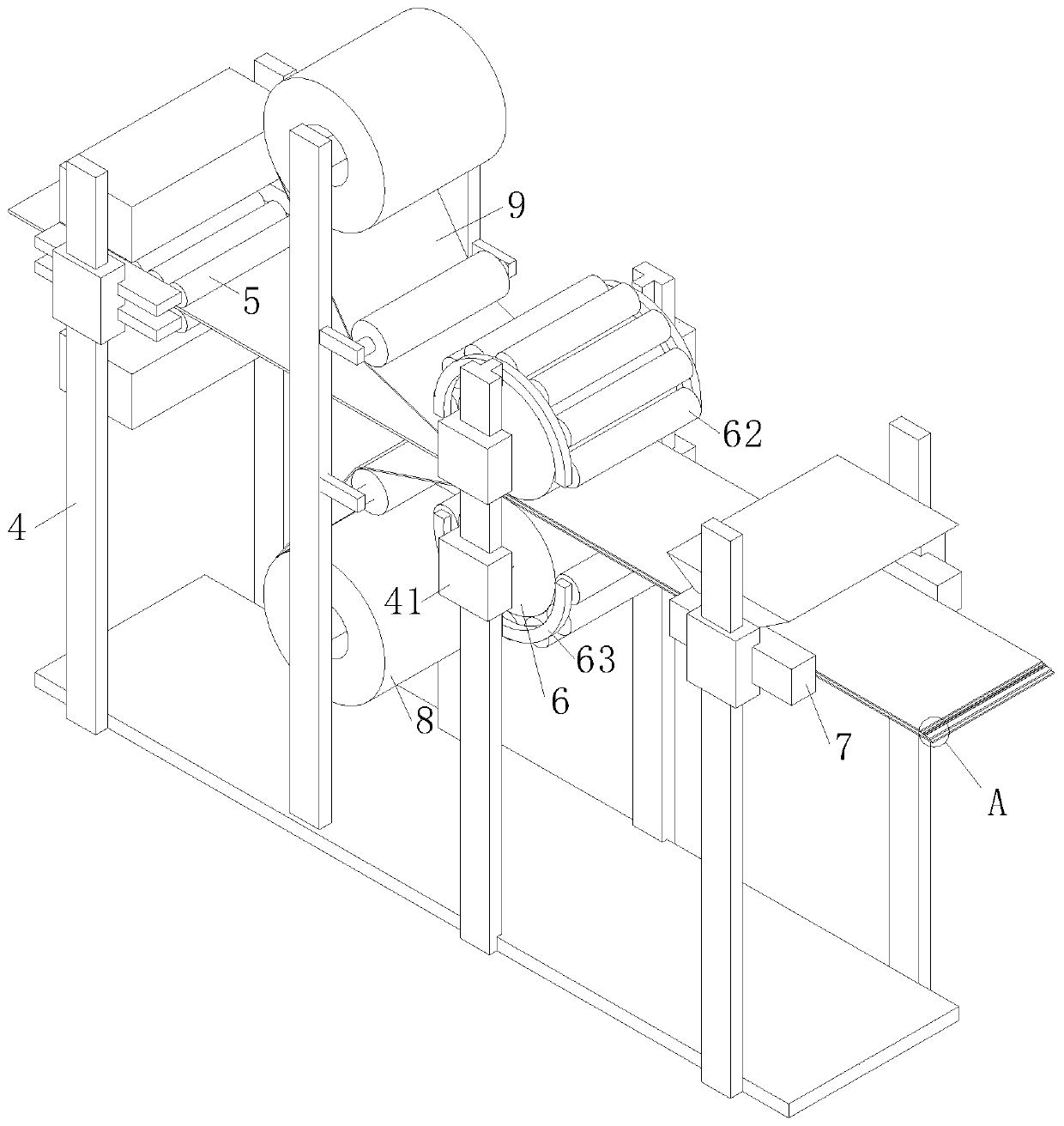

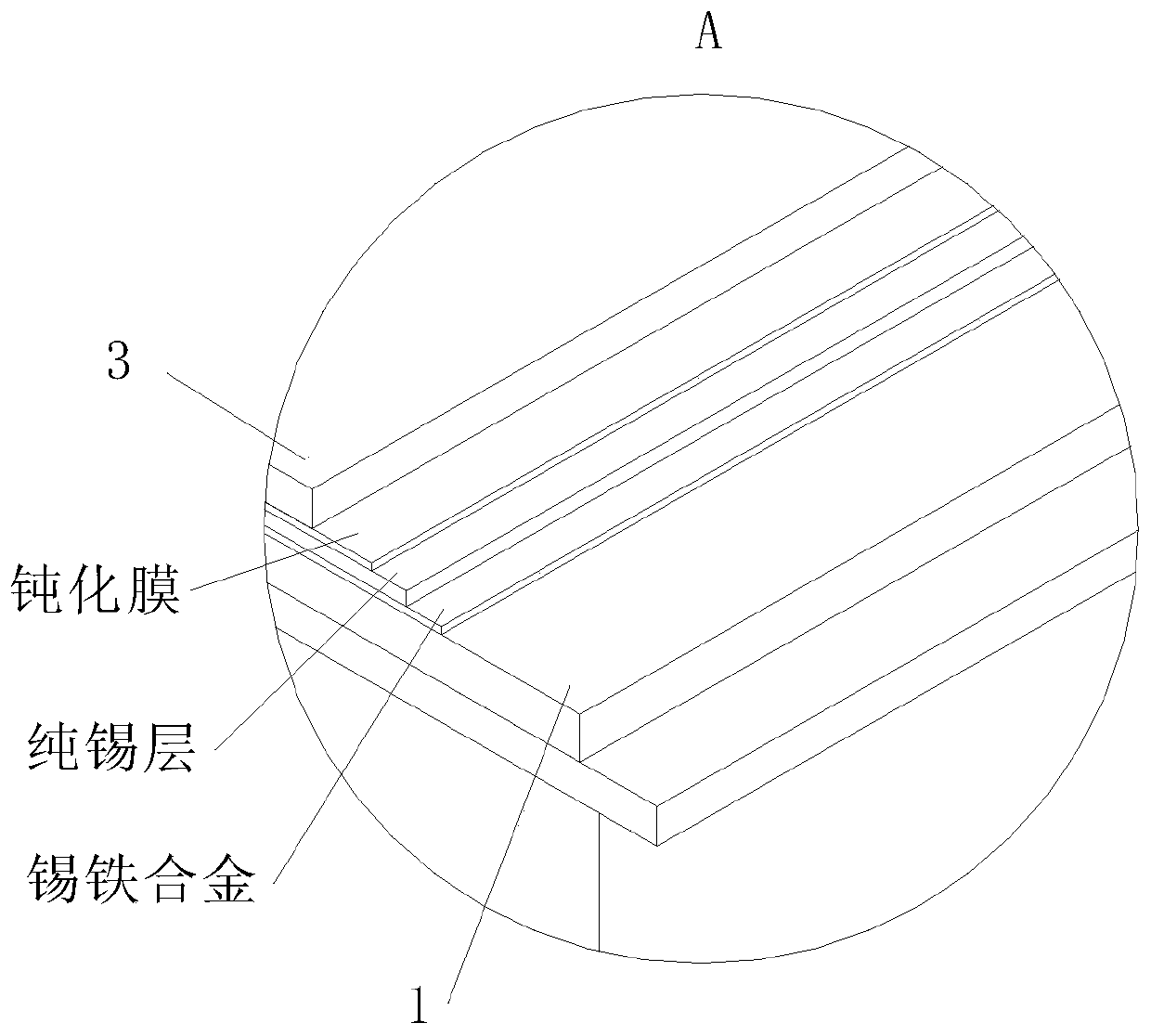

Chromium-free tinning plate and surface treatment method thereof

PendingCN111304706AGuaranteed lamination effectAvoid pollutionLaminationLamination apparatusTinningPhosphate

The invention relates to the technical field of tinning plates, in particular to a chromium-free tinning plate and a surface treatment method thereof. The chromium-free tinning plate comprises a steelbase plate, a tinning layer and a coating layer; the tinning layer is passivated on the steel base plate through a phosphate solution; and the coating layer is bonded to the passivated tinning layerthrough coating equipment. Because in the tinning process of the steel base plate, the phosphate solution is selected for passivation treatment to avoid environmental pollution caused by chromate passivatin, after the passivation of the phosphate solution, the quality of the tinning plate is affected, and the requirements of oxidation resistance and corrosion resistance of the tinning plate cannotbe met; and thus, through the coating layer arranged on the tinning layer, a chromate solution in the passivation process of the tinning plate is replaced by the phosphate solution, so as to avoid the pollution of the chromate to the environment, meanwhile the coating layer is arranged to protect the chemical stability of the surface of the tinning plate passivated by phosphate, and the use effect of the chromium-free tinning plate is maintained.

Owner:葛家玉

Hot demounting method for roll collar of horizontal roll of rolling mill

ActiveCN104801942ASmooth disengagementGuaranteed temperature differenceMetal working apparatusThermal expansionEngineering

The invention provides a hot demounting method for a roll collar of a horizontal roll of a rolling mill. The hot demounting method orderly comprises the steps of 1, removing rust and fatlute on the surface of the horizontal roll, 2, placing the horizontal roll vertically and keeping partial horizontal roll comprising the roll collar in a sealed space, 3, preheating the outer roll surface of the roll collar to increase the temperature to the outer roll surface of the roll collar to the range of 170 to 200 DEG C, and meanwhile, increasing the temperature of inner roll surface of the roll collar to the range of 90 to 120 DEG C, 4, heating the outer roll surface of the roll collar, the upper end face of the upper part of the roll collar and the inner roll surface of the upper part of the roll collar, so that the roll collar can be detached from a roll shaft when the expansion quantity of the roll collar exceeds the expansion quantity of the roll shaft. The hot demounting method is capable of greatly improving the working efficiency; in the hot demounting method, the satisfied temperature difference between the roll shaft and the roll collar can be well guaranteed by thoroughly utilizing the thermal expansion effect of the roll collar and the roll shaft, and consequently, the roll collar can be smoothly detached from the roll shaft.

Owner:SHANDONG IRON & STEEL CO LTD

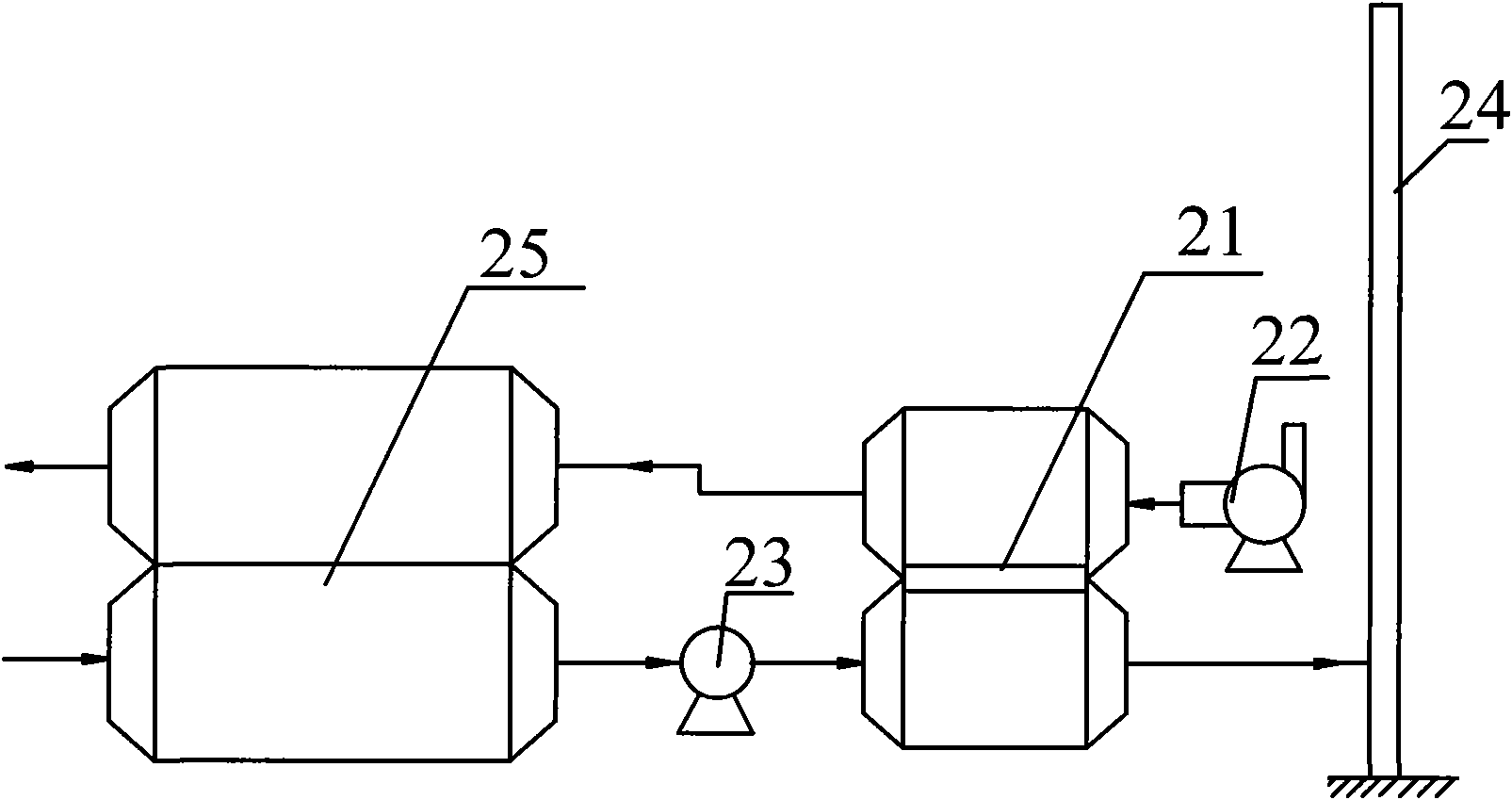

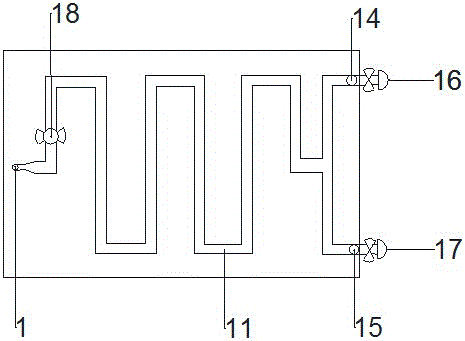

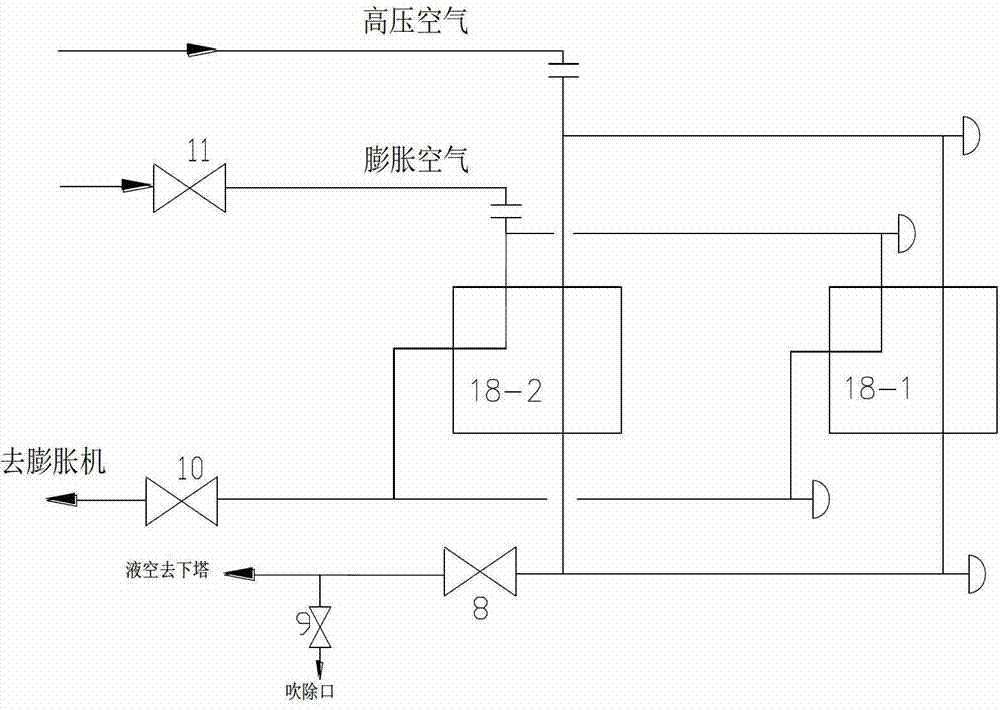

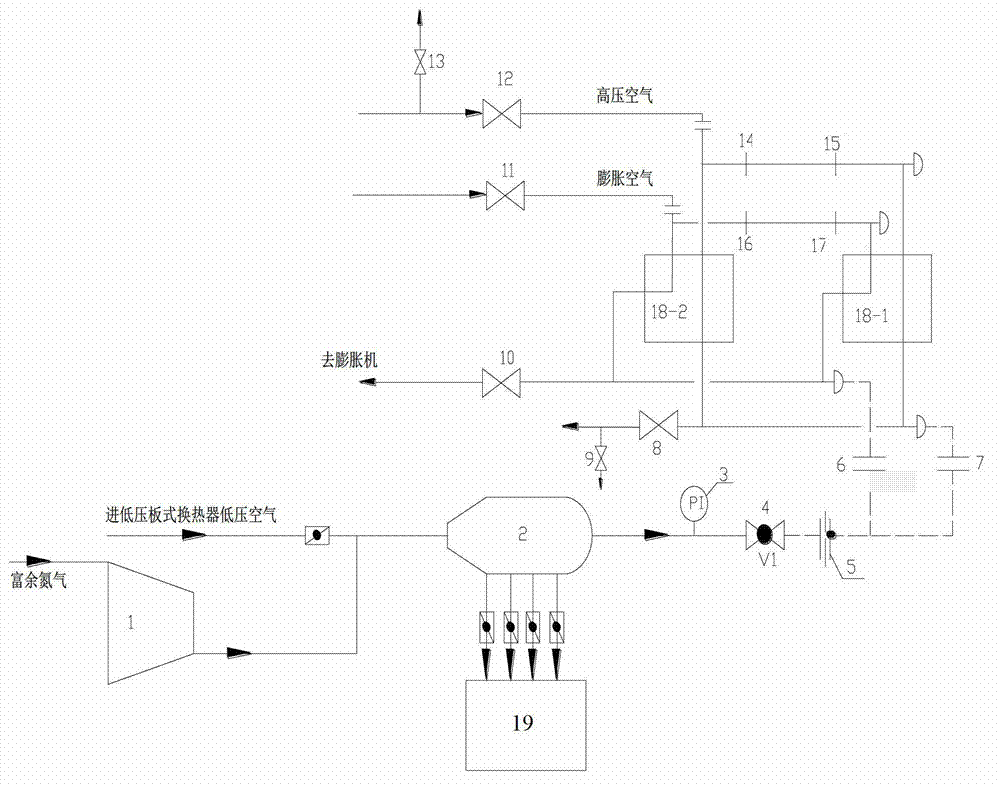

Method and system for internal compression process space division reducing high-pressure plate type heat exchanger temperature differences

The invention discloses a method for internal compression process space division reducing high-pressure plate type heat exchanger temperature differences. The method comprises steps of (1) subjecting surplus nitrogen to pressure-boosting of a turbocompressor and feeding the surplus nitrogen to a reverse blow tube line; and (2) dividing the nitrogen which is obtained in the step 1 into two channels, feeding one channel of the nitrogen to a high-pressure air passage of high-pressure plate type heat exchangers and feeding the other channel to an expansive air passage of the high-pressure plate type heat exchangers. The system comprises two high-pressure plate type heat exchangers, wherein a pipe section is cut off respectively in middle sections of the high-pressure air passage and the expansive air passage, a sweeping port of high-pressure air and a sweeping port of expansive air are arranged at positions of heat end inlets of the high-pressure plate type heat exchangers respectively, the two sweeping ports are connected with a sweeping pipeline, and a nitrogen turbocompressor, a gas distributor, a sweeping gas pressure gauge, a sweeping gas inlet high plate valve and a sweeping gas flow gauge are connected sequentially to form the sweeping pipeline. By the aid of the method and the system, the problem that the high-pressure plate type heat exchanger temperature differences are large is solved, and the device can operate for a long period stably.

Owner:YANKUANG GRP CO LTD

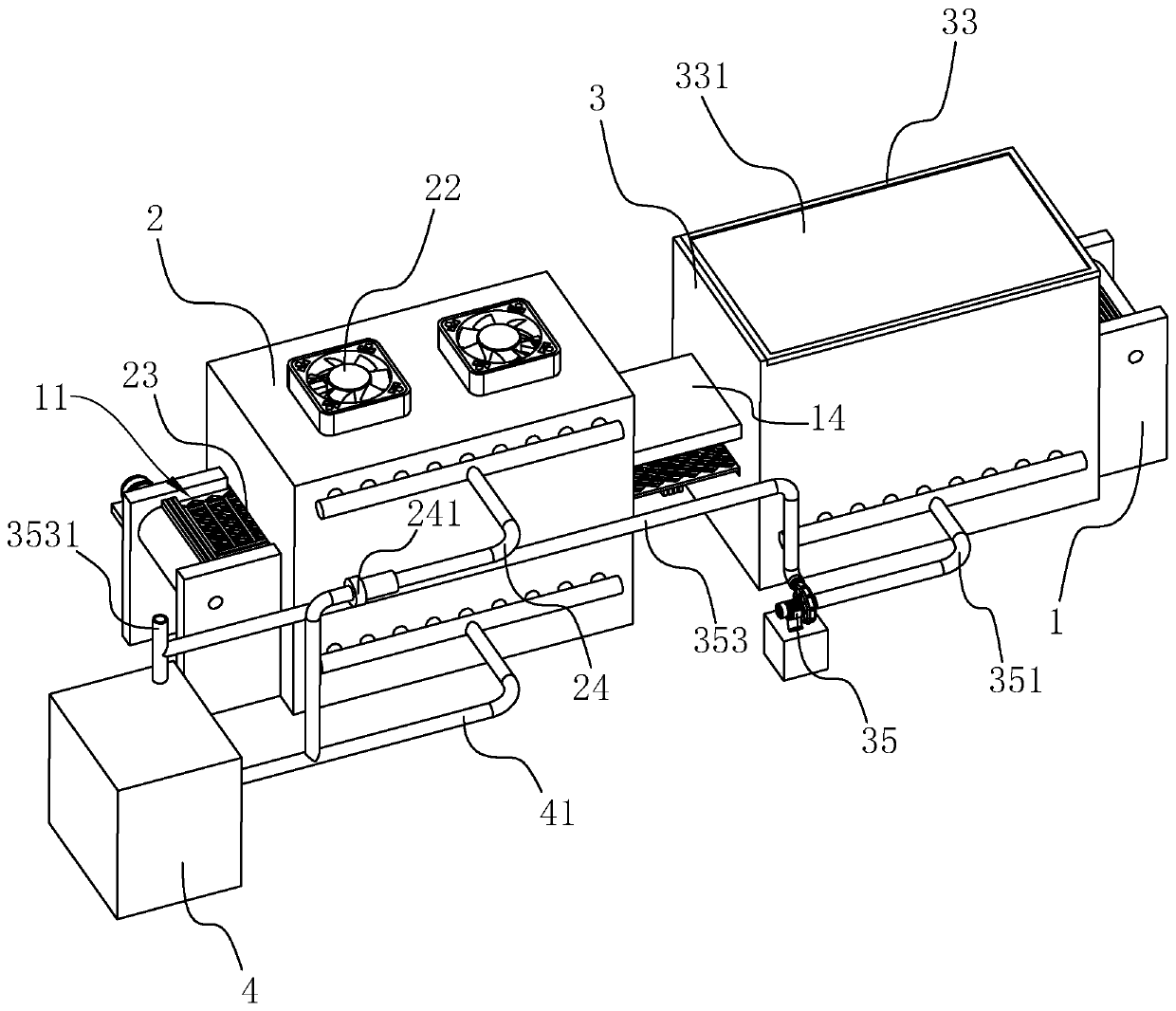

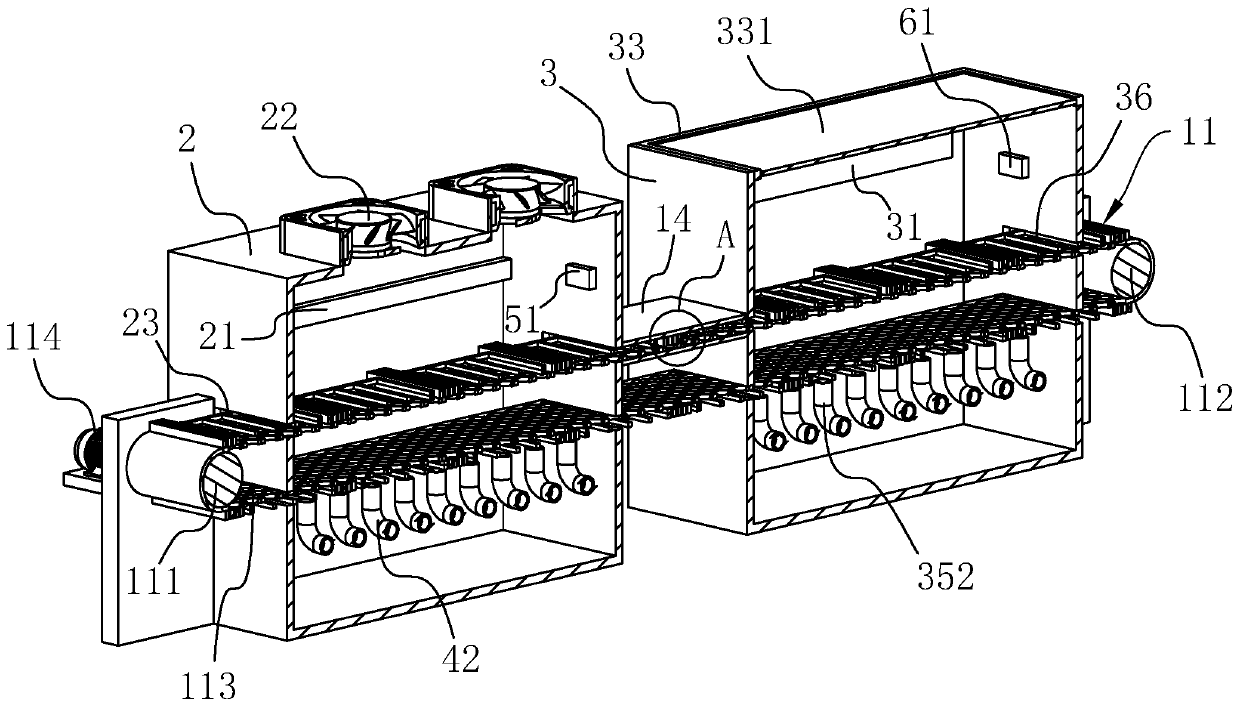

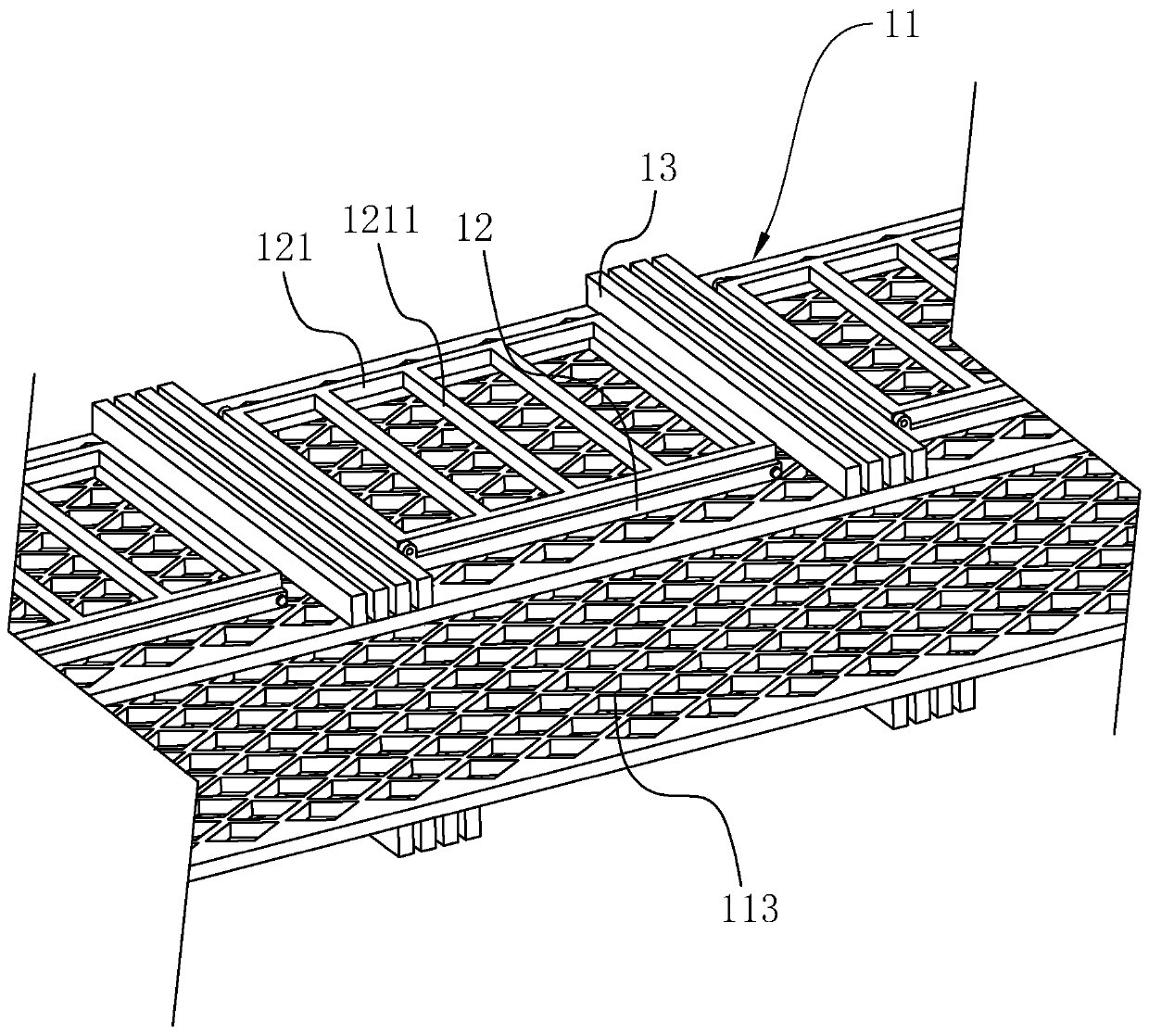

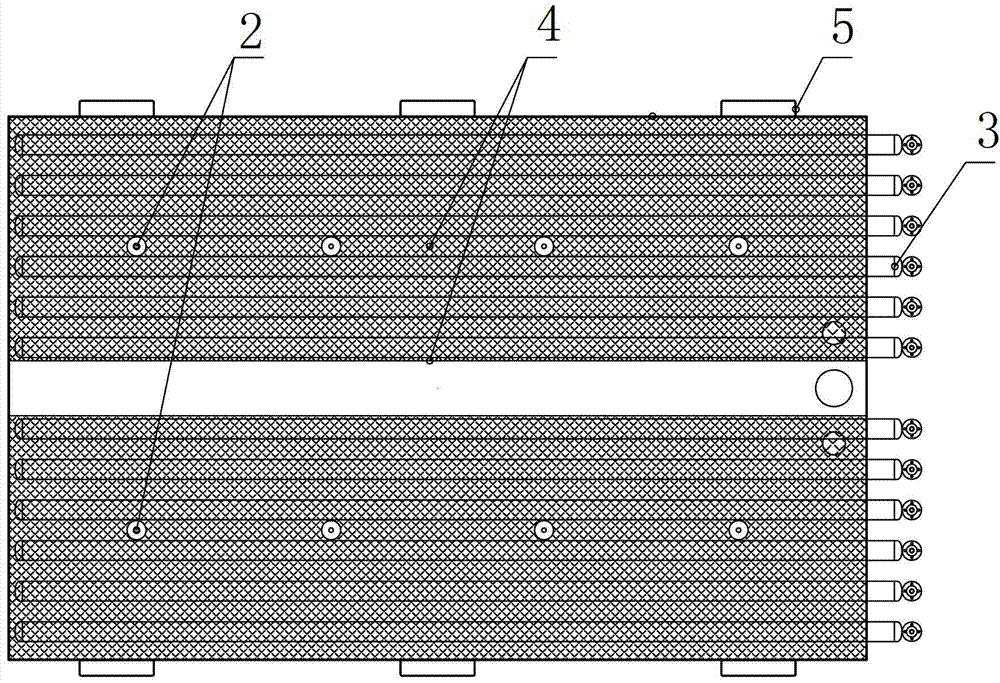

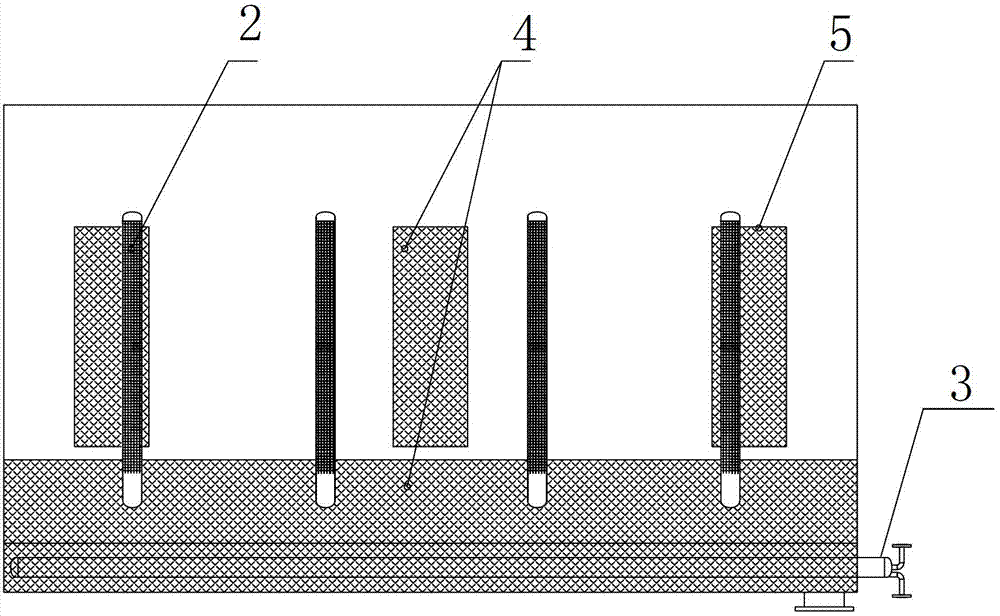

Fabric steaming and sizing device

ActiveCN109944004AGuaranteed temperature differenceEnough temperature differenceTextile treatment machine arrangementsTextile treatment carriersTemperature controlTemperature difference

The invention discloses a fabric steaming and sizing device, and belongs to the field of fabric steaming devices. The fabric steaming and sizing device comprises a machine frame and a conveying belt connected to the machine frame. The conveying belt comprises a mesh-shaped belt. A heating box and a cooling box are fixedly connected with the position, corresponding to the conveying belt, of the machine frame. The end, close to the cooling box, of the heating box is fixedly connected with a channel. The other end of the channel is fixedly connected to the bottom of the cooling box. The conveyingbelt penetrates through the heating box, the channel and the cooling box. An electric heating plate is fixedly connected into the heating box. A refrigerator is fixedly connected into the cooling box. The electric heating plate and the refrigerator are connected with a control circuit. The control circuit comprises a first temperature collecting module, a second temperature collecting module, a high-temperature control module and a temperature difference control module. The control circuit controls the electric heating plate and the refrigerator according to the temperatures in the heating box and the cooling box. The fabric steaming and sizing device has the advantages that the temperatures in the heating box and the cooling box can be accurately controlled, residual moisture in fabricscan be taken away during refrigeration of an exhaust fan, and the quality of the finished fabrics is ensured.

Owner:北京君杰一鸣企业服装发展有限公司

Cooling system of condenser of intelligent household appliance

InactiveCN105972875AMeet supply and demandGood effectEvaporators/condensersPositive temperature coefficient thermistorsWater useTemperature control

The invention discloses a cooling system of a condenser of an intelligent household appliance and relates to the field of cooling of condensers. The cooling system of the condenser of the intelligent household appliance comprises a refrigerating household appliance shell and the condenser vertically installed on the refrigerating household appliance shell; the condenser is composed of a condensing device and a cooling shell arranged outside the condensing device in a sleeving manner; a thermistor is arranged in the cooling shell; a water storage tank is connected to the bottom end of the cooling shell through a water pipe; a temperature control flow control valve is arranged on the portion, between the cooling shell and the water storage tank, of the water pipe and electrically connected with the thermistor; a recycling water tank is connected to the upper end of the cooling shell through the water pipe; after absorbing heat released by the condensing device and being subjected to temperature rise, cooling water enters the recycling water tank through the water pipe and can be used for hot water used for domestic trivia; the supply and demand of family hot water are met while it is guaranteed that the effect is good, and environment protection and conservation are achieved; and the thermistor arranged in the cooling shell controls the temperature control flow control valve to automatically achieve control over the flow of the cooling water so that an optimal cooling effect can be achieved.

Owner:CHENGDU KECHUANGCHENG TECH

Weather-compensating method for controlling temperature of heating and ventilating return water

InactiveCN101737847AGuaranteed temperature differenceSave energySpace heating and ventilation safety systemsLighting and heating apparatusEngineeringTemperature difference

The invention relates to a method for saving energy of a heating and ventilating air conditioner, in particular to the weather-compensating method for controlling the temperature of heating and ventilating return water. The invention aims to solve the problems that because the temperature difference between supplied water and return water cannot be effectively controlled in a control process of a heating and ventilating air conditioner in the prior art, excessive energy consumption and the like are caused by providing an effective, energy-saving and weather-compensating method for controlling the temperature of the heating and ventilating return water. The invention adopts a main technical scheme that: the weather-compensating method for controlling the temperature of the heating and ventilating return water comprises a water supply pipeline; the water supply pipeline is provided with a regulating valve; the regulating valve performs control through an actuator; the actuator performs regulation through a thermostatic controller; a thermal signal terminal a and a thermal signal terminal b are arranged on the thermostatic controller; and the thermostatic controller compares the signal value of the thermal signal terminal a with the signal value of the thermal signal terminal b, calculates the signal values and realizes the regulation of the rate of water inflow through controlling the opening of the actuator.

Owner:HANGZHOU ZETA TECH

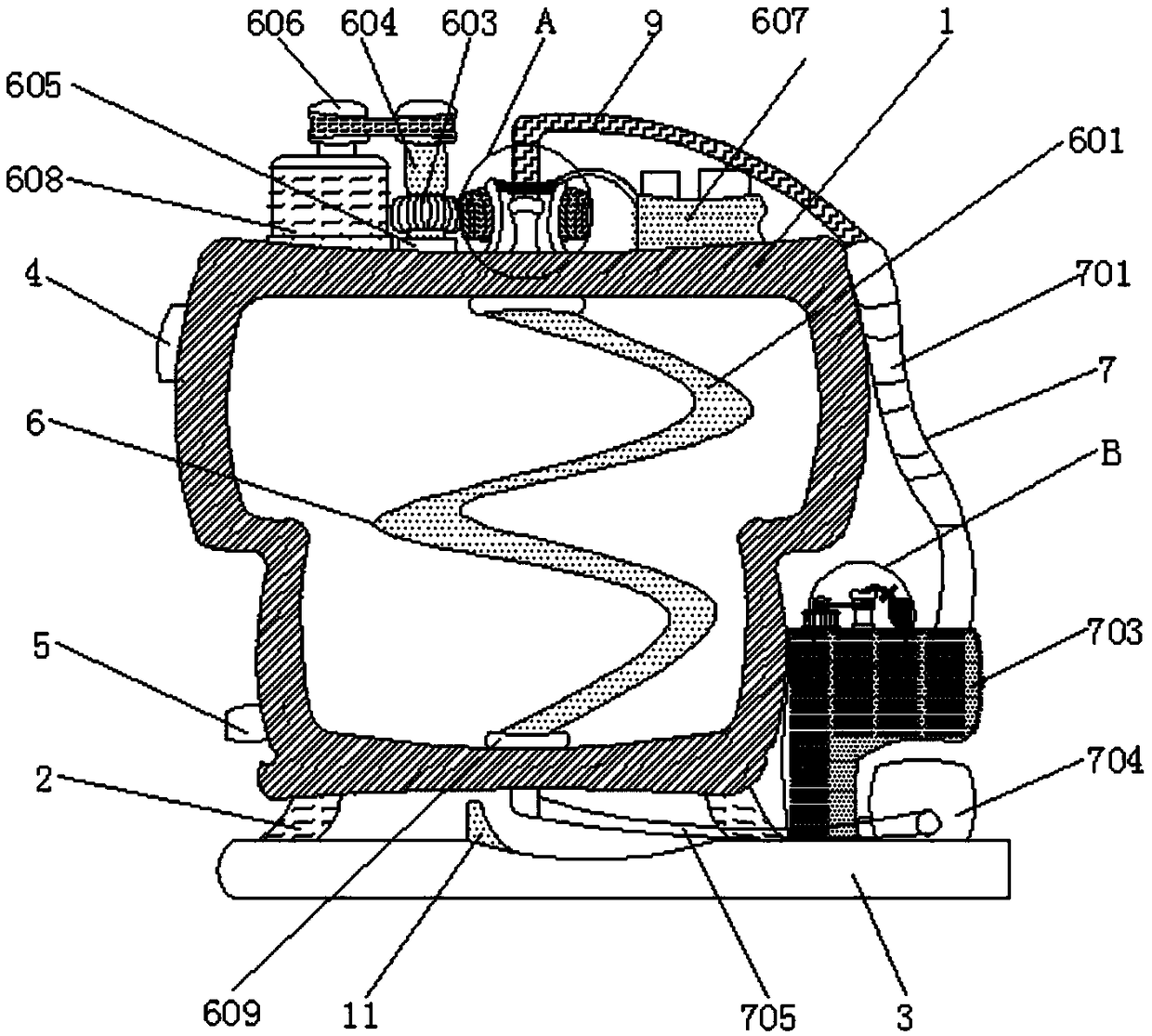

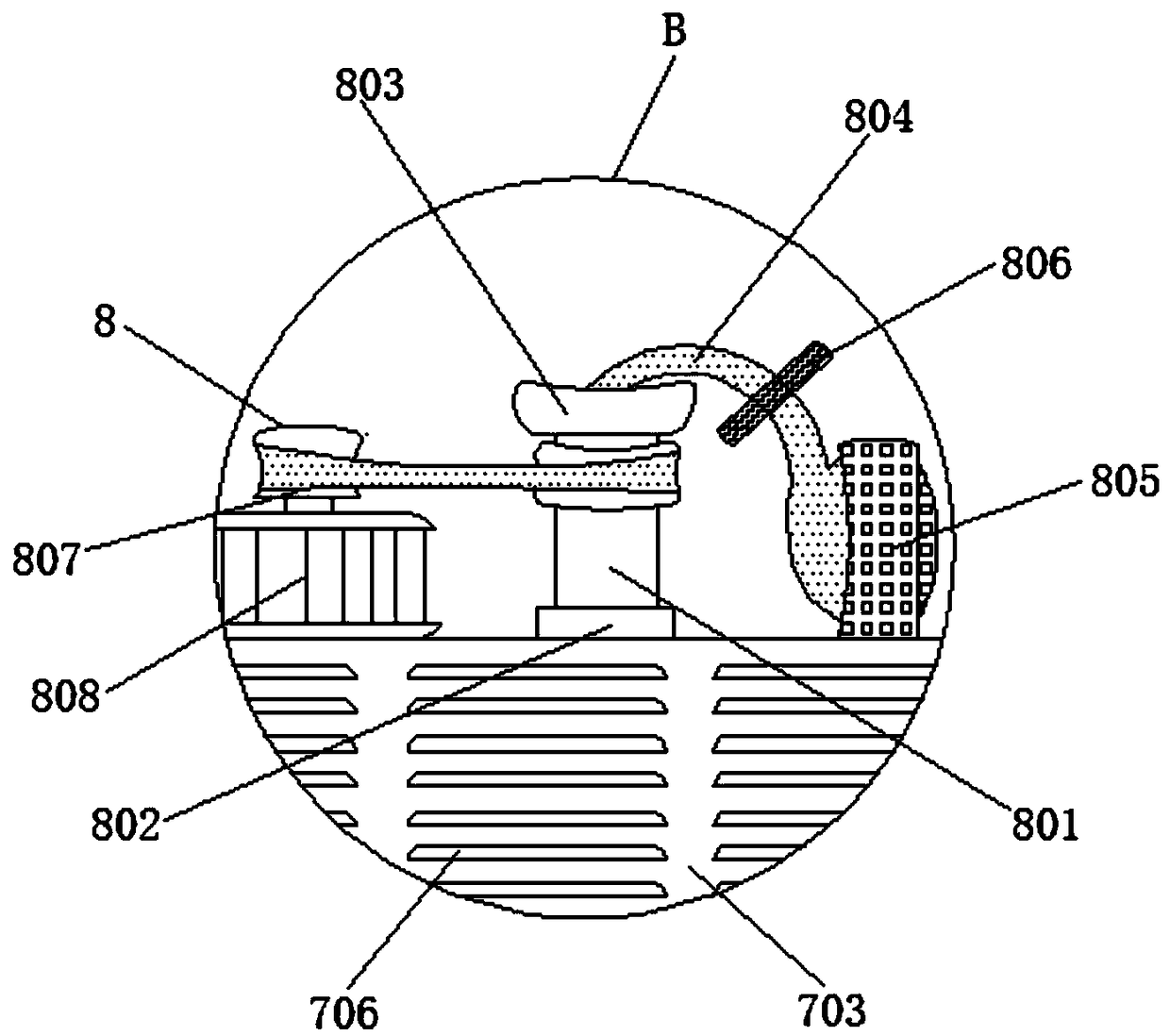

Small free piston type solar generator system

InactiveCN105484896AFacilitates processing and assemblyReduced assembly precision requirementsEngine sealsFrom solar energySolar generatorMagnetic flux

The invention discloses a small free piston type solar generator system. The small free piston type solar generator system comprises a free piston type solar engine part and a permanent magnet linear generator part. The free piston type solar engine part comprises a heat exchanger and a power transmission device. The heat exchanger comprises a high-temperature-end heater, a regenerator and a cooler. The power transmission device comprises a distribution piston in an air cylinder and a power piston outputting mechanical energy. Heat energy of gas media is increased through the heater. The gas media flow circularly in the sealed air cylinder, the power device is driven to reciprocate, and heat energy can be converted into mechanical energy. The permanent magnet linear generator part comprises a permanent magnet motor rotor and a motor winding stator. The power piston in linear reciprocating motion is connected with the permanent magnet motor rotor. The stator in linear reciprocating motion enables inner magnetic flux in the winding stator to change, and mechanical energy can be converted into electric energy. The small free piston type solar generator system can be used for power generation devices with a solar heat source and other concentrated heat sources.

Owner:XI AN JIAOTONG UNIV

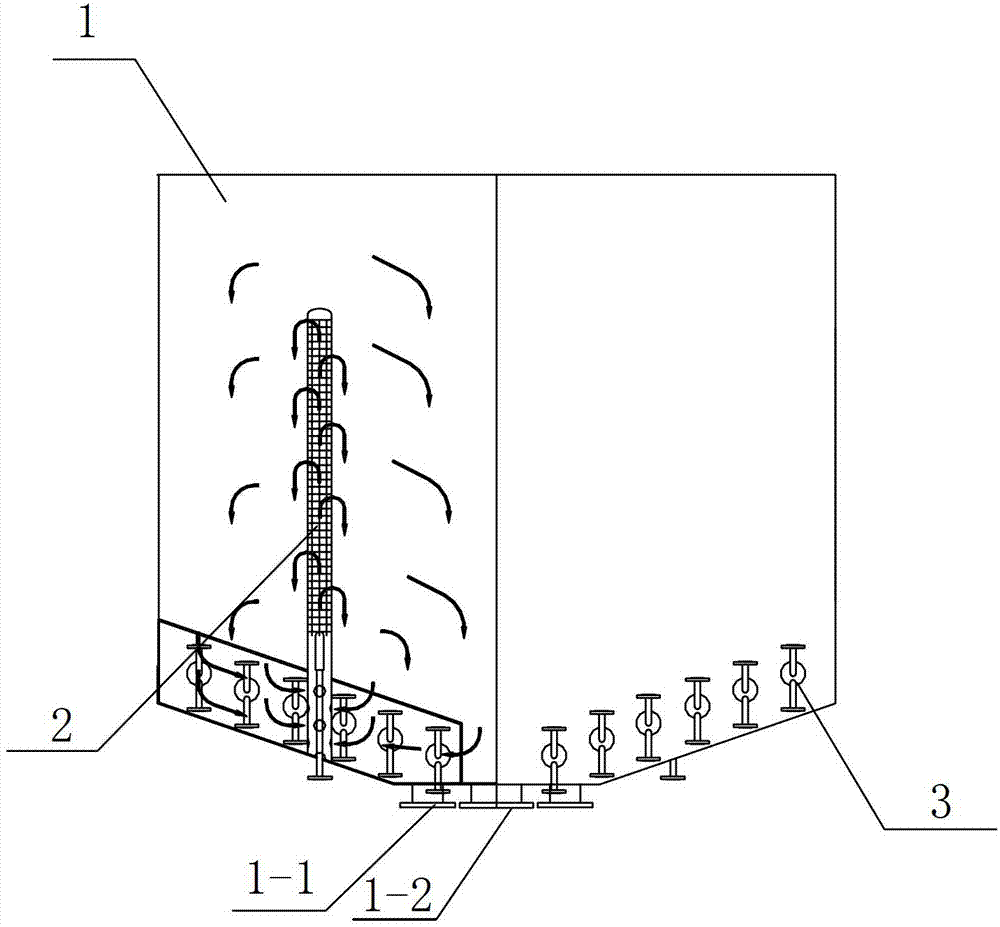

A gelatin extraction device for gelatin production

ActiveCN103289577AEffect of heating performanceGuaranteed uniformityGlue/gelatin preparationTemperature differenceGelatin

The invention discloses a gelatin extraction device for gelatin production. The device includes a gelatin extraction body. A feeding port, an exhaust port, and an water inlet are arranged on the upper surface of the gelatin extraction body, and a water outlet and a deslagging port are arranged on the lower surface of the gelatin extraction body. The bottom of the inner chamber of the gelatin extraction body is provided with multiple heating tubes, and each heating tube is provided with an independent steam connector. The bottom of the inner chamber of the gelatin extraction body is also provided with an air lift. According to the invention, multiple heating tubes and the air lift are provided at the bottom of the inner chamber of the gelatin extraction body, so the bottom of the inner chamber of the gelatin extraction body is guaranteed to have a uniform heating; compressed air is employed to stir liquid materials in the gelatin extraction body, which allow the liquid materials to produce relatively intense convection, so that the temperature uniformity of the liquid materials of different parts is achieved, and a temperature difference of less than two DEG C is guaranteed; and the gelatin extraction body has a volume range of from 10m3 to 120m3, so the gelatin extraction device also has the advantage of large capacity.

Owner:TIANJIN WANFENG CHEM EQUIP

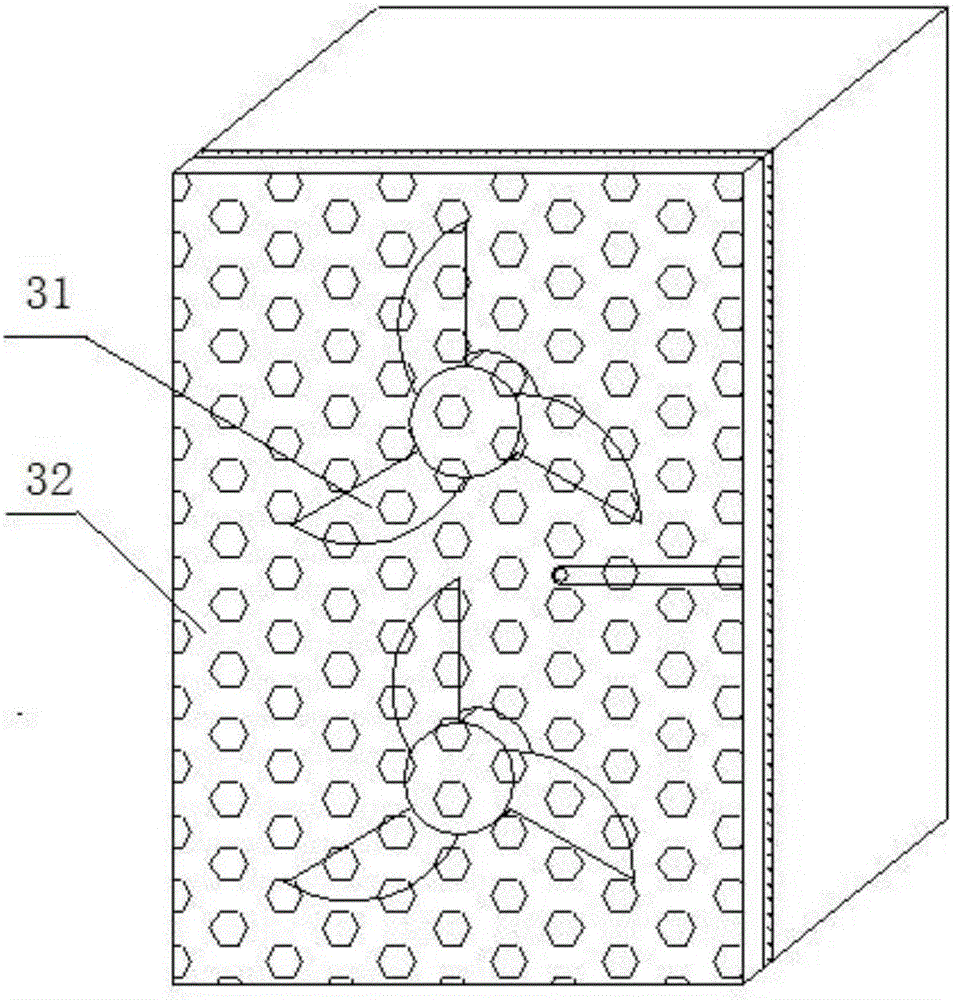

Energy-saving wall cloth

InactiveCN101839046ABarrier deliveryGuaranteed temperature differenceCovering/liningsInfraredSurface layer

The invention relates to the field of building decoration materials, in particular to an energy-saving wall cloth for obstructing heat radiation. The main technical characteristics are that: the energy-saving wall cloth consists of a pressure-sensitive adhesive layer protective membrane, a pressure-sensitive adhesive layer, an aluminum foil, a surface layer wall cloth and a surface layer wall cloth protective membrane, wherein a wall cloth center layer is the aluminum foil; the inner side of the aluminum foil is provided with the pressure-sensitive adhesive layer and the pressure-sensitive adhesive layer protective membrane in turn; and the outer side of the aluminum foil is provided with the surface layer wall cloth and the surface layer wall cloth protective membrane in turn. The energy-saving wall cloth can effectively obstruct the indoor and outdoor heat transfer in an infrared radiation mode while realizing a decorative function, and can effectively maintain the indoor and outdoor temperature differences and improve the indoor heat moderation while saving energy.

Owner:魏勇

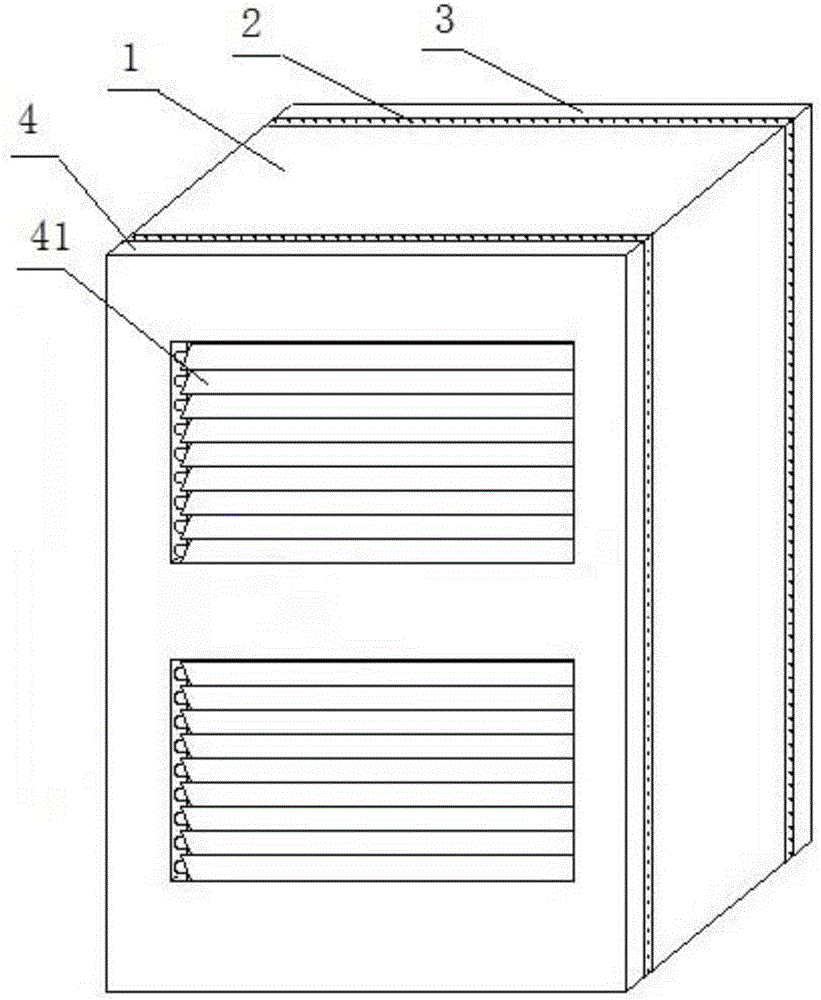

Computer dustproof case with high heat dissipation performance

InactiveCN106445009ALower the temperatureGuaranteed temperature differenceDigital processing power distributionHeat transmissionRefrigeration

The invention discloses a computer dustproof case with high heat dissipation performance and relates to the field of design and manufacture of computer hardware. The computer dustproof case comprises a case body, wherein the left and right opposite side walls of the case body are set as a gas outlet side plate and a gas inlet side plate respectively; a dustproof net layer is disposed between the gas inlet side plate and the case body; multiple refrigeration plates are inlaid inside the gas inlet side plate and the dustproof net layer; clearance is formed between the refrigeration plates; and the gas outlet side plate comprises a through hole plate, and an exhaust fan is disposed on the inner side of the through hole plate. According to the invention, dustproof effects are enhanced, and heat transmission effects are ensured; and the disposed dustproof net layer is equivalent to a blocking layer disposed between a host and external environments, so that noise is reduced, and the problem of large noise of a computer host in the prior art can be solved.

Owner:CHENGDU YANXINGGUO TECH CO LTD

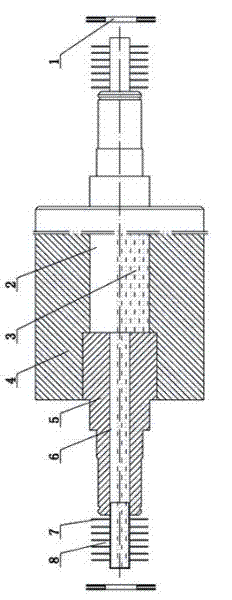

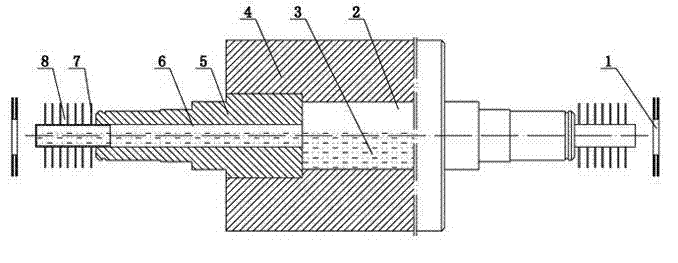

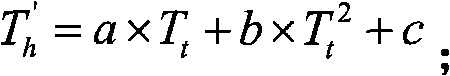

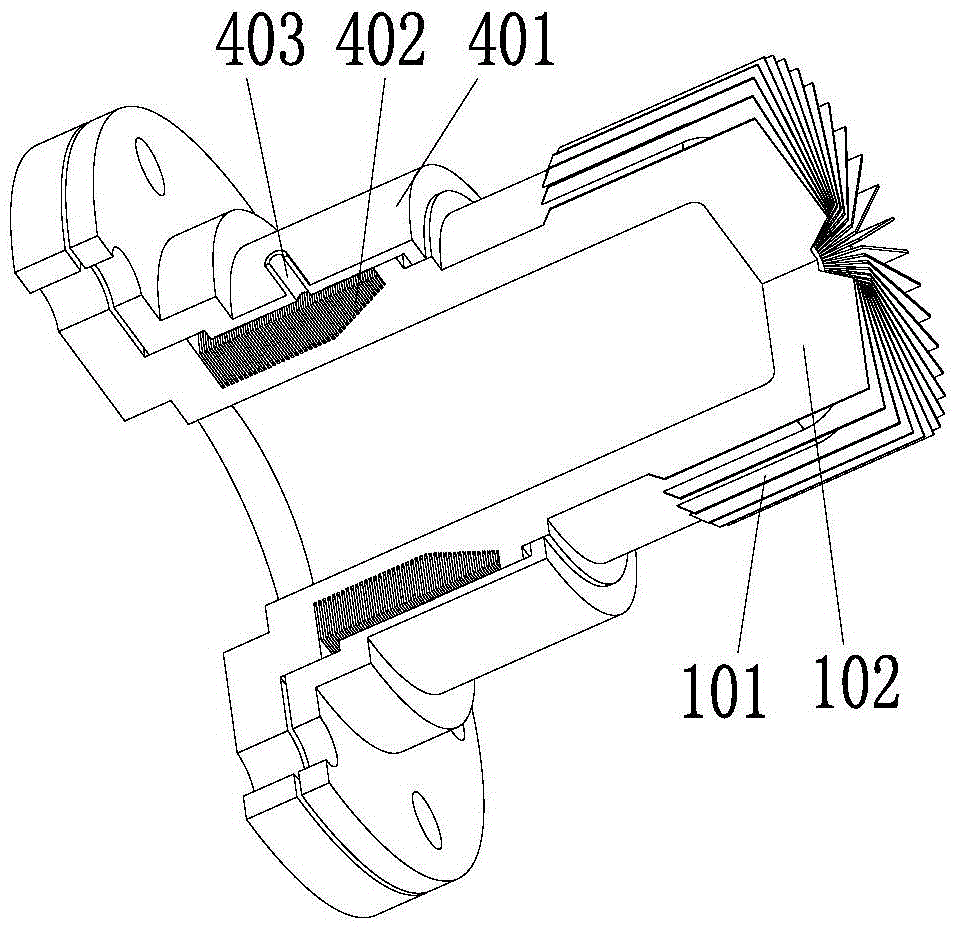

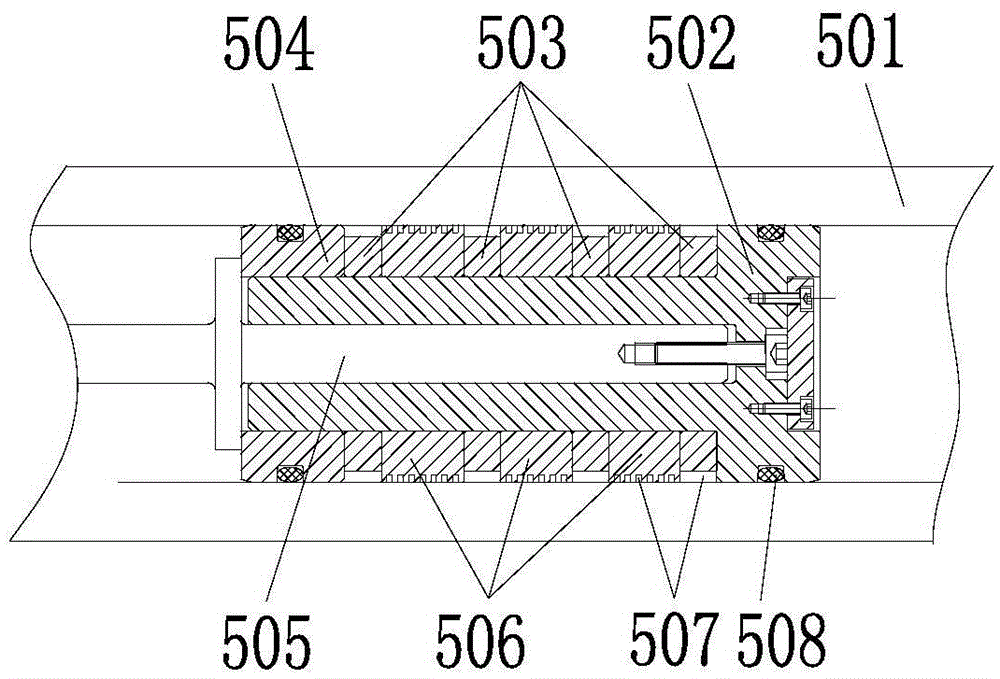

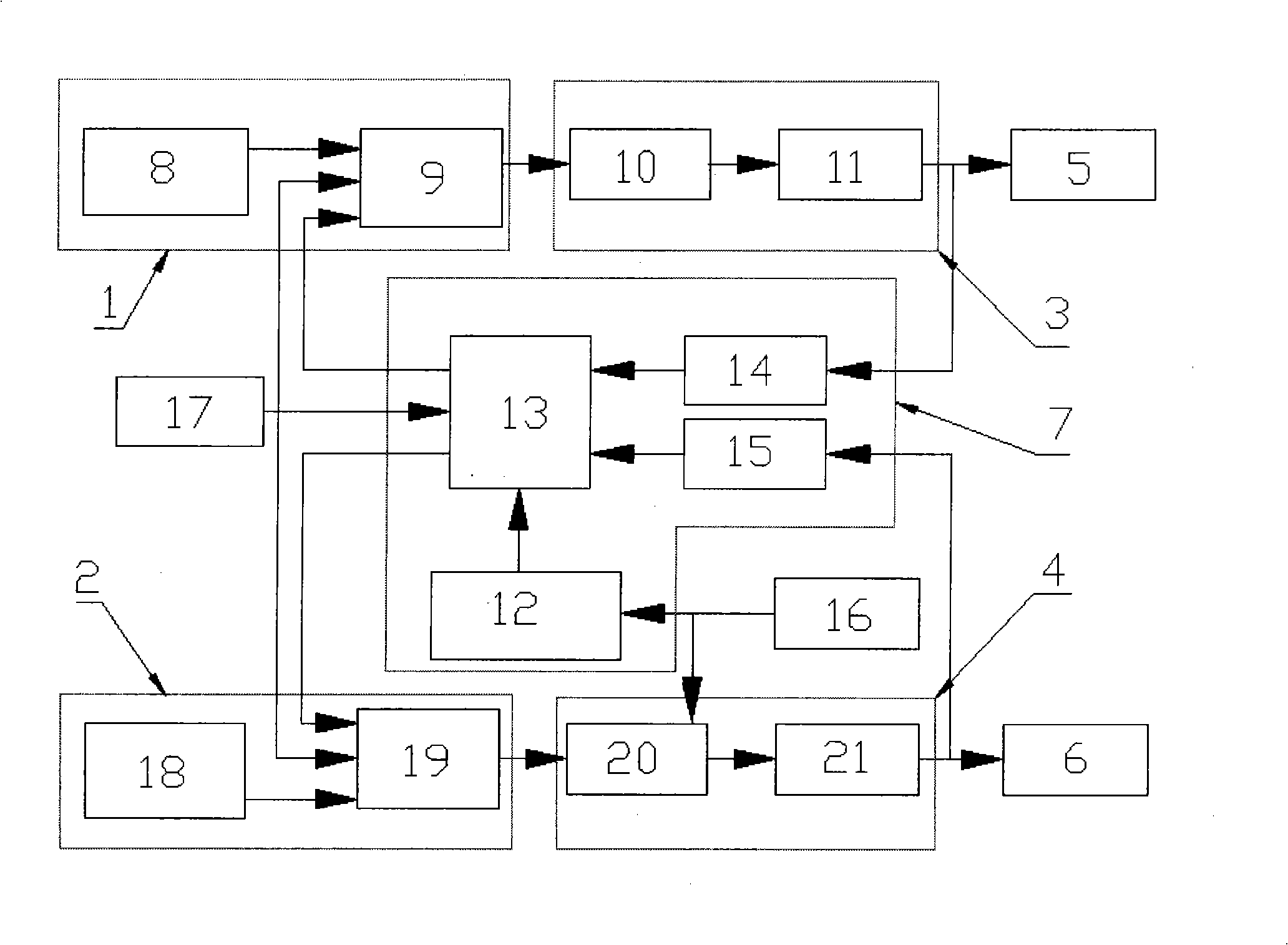

Temperature detection and control system of medium frequency hydraulic pipe bender

InactiveCN101539459AGuaranteed temperature differenceEasy to detectRadiation pyrometryTemperature control using electric meansAutomatic controlControl system

The invention relates to a temperature detection and control system of a medium frequency hydraulic pipe bender, which comprises programmable and control interfaces (1, 2), wherein the programmable and control interface 1 is connected with a medium frequency power supply controller 3 which is connected with a medium frequency induction heating ring 5, the programmable and control interface 2 is connected with a stepping motor and a drive control unit 4 which are mechanically fixedly connected with a medium frequency induction heating ring 6; the medium frequency power supply controller 3, the stepping motor and the drive control unit 4 are all connected with a temperature detection processing unit 7, an infrared swing temperature measurement mechanism 12 in the temperature detection processing unit 7 transmits real-time signals into a temperature identifier 13, the real-time signals are compared with signals transmitted by the programmable and control interfaces (1, 2) and are processed so as to achieve the purposes of heating a steel pipe and adjusting the distance between the induction ring and the steel pipe and ensure that the temperature difference of an inner arc and an outer arc is within set temperature, thereby realizing temperature detection and automatic control of the medium frequency hydraulic pipe bender.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

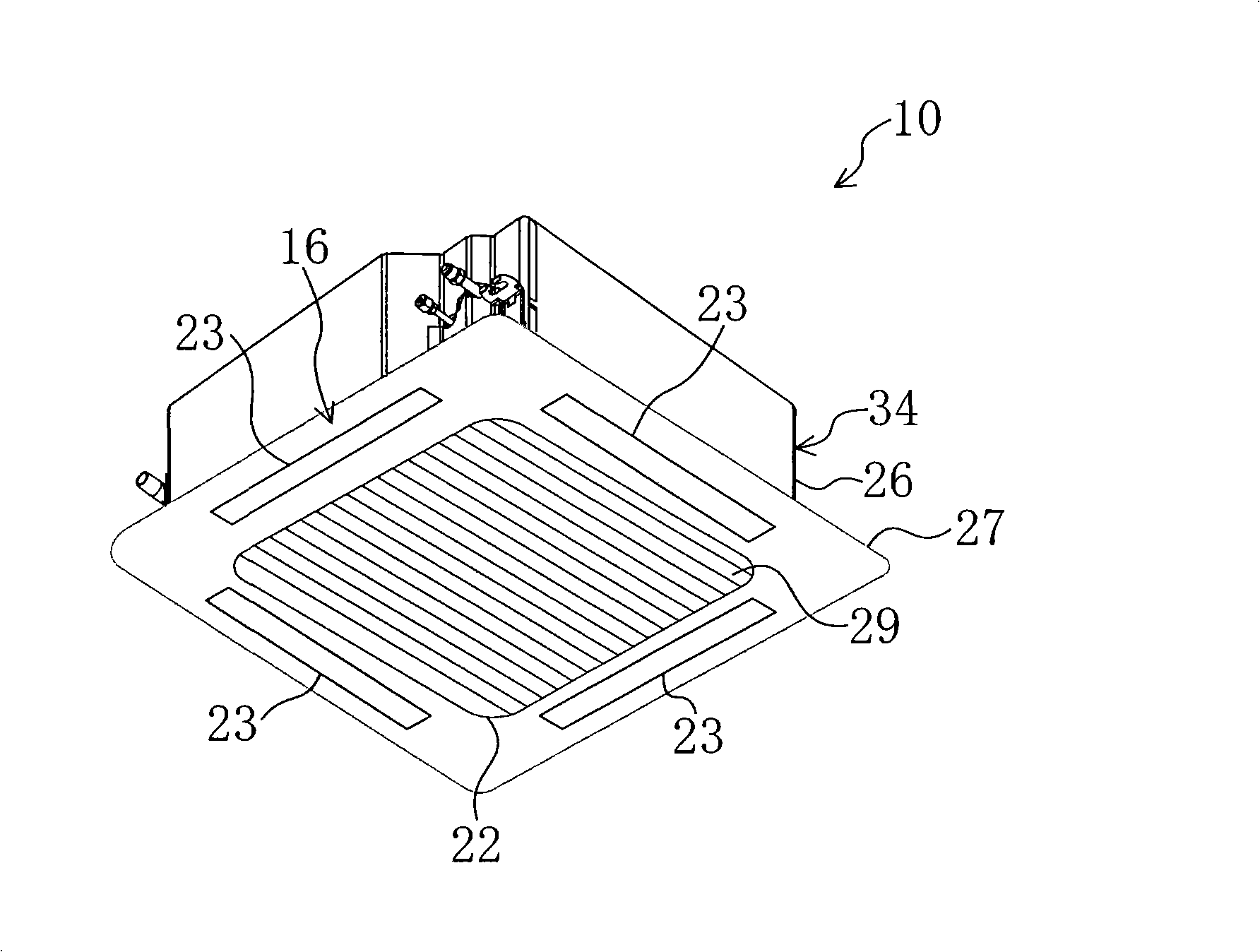

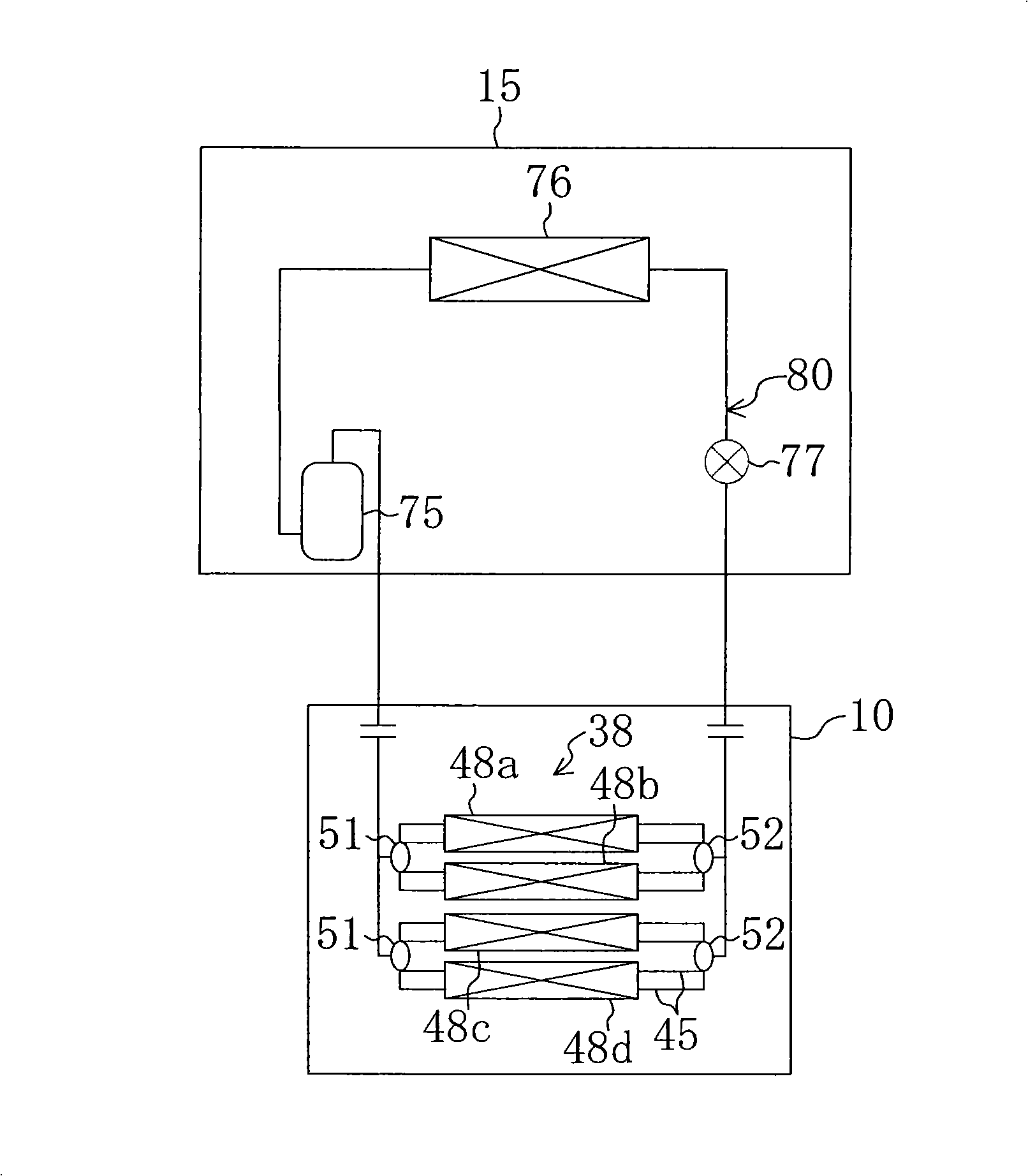

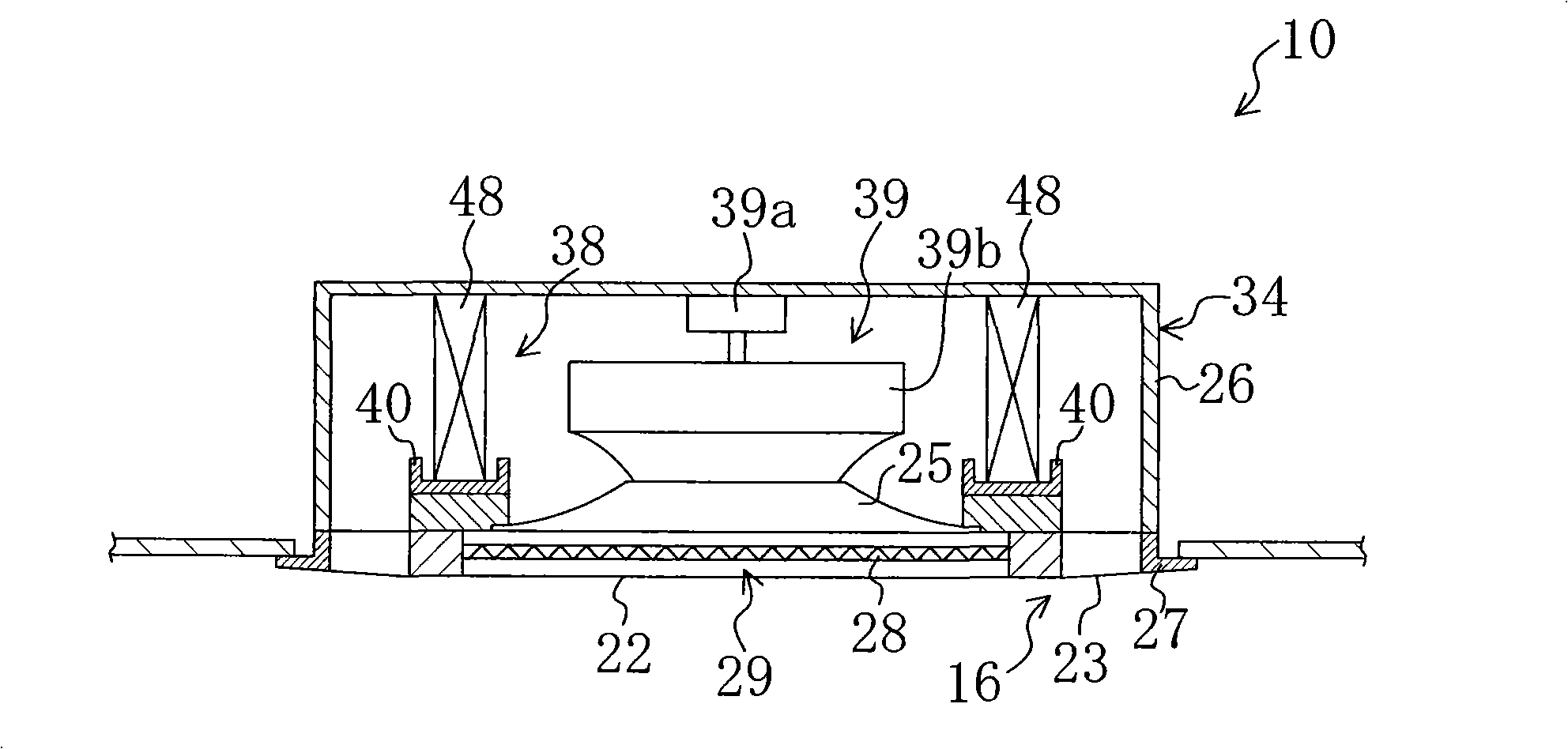

Indoor unit of air conditioner

ActiveCN101517335AImprove comfortReduce temperature differenceCompression machines with non-reversible cycleEvaporators/condensersEngineeringRefrigerant

An indoor unit for a multi-directional air supply air conditioner capable of performing at least a heating operation includes: an indoor fan (39) for sucking air in an axial direction thereof and radially blowing out the air; and a heat exchange part (38), connected in a refrigerant circuit (80) and disposed to surround the indoor fan (39), for exchanging heat between the air blown out of the indoor fan (39) and refrigerant in the refrigerant circuit (80). The heat exchange part (38) includes a plurality of heat exchangers (48) separated from each other along the direction of the perimeter thereof and connected in parallel with each other in the refrigerant circuit (80).

Owner:DAIKIN IND LTD

Maintenance adjusting device of mass concrete member and using method of maintenance adjusting device

PendingCN109853975AAvoid wastingSprinkle water evenly to cool downBuilding material handlingControl theoryWater pipe

The invention provides a maintenance adjusting device of a mass concrete member and a using method of the maintenance adjusting device, and belongs to the technical field of mass concrete member maintenance technology. According to the problems that in maintenance construction of an existing mass concrete member, working without interruption cannot be achieved by depending on manual watering maintenance, and the pouring quality of the mass concrete member is difficult to guarantee, the maintenance adjusting device of the mass concrete member comprises water pipe lines, a plurality of spray heads, a first temperature sensing controller, a second temperature sensing controller and a control cabinet, wherein the water pipe lines are distributed on the surface of the mass concrete member; thespray heads separately communicate with the water pipe lines, and the spray heads are arranged on the surface of the mass concrete member; the first temperature sensing controller is arranged in the mass concrete member; the second temperature sensing controller is arranged on the surface of the mass concrete member; and the control cabinet is in signal connection with the first temperature sensing controller and the second temperature sensing controller, and the control cabinet is connected with an electric valve of the water pipe lines.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

Dairy product cooling device based on water cooling mode

ActiveCN108827030AImprove cooling effectFaster coolingStationary tubular conduit assembliesCold airMotor drive

The invention provides a dairy product cooling device based on a water cooling mode, and relates to the field of dairy product cooling. The cooling device solves the problem that the existing diary product cooling is large in water consumption and poor in cooling effect. The cooling device comprises a cooling box, and the bottom of the cooling box is welded to the top of a base through overhead legs, and the side wall of the cooling box close to the top is provided with a feeding port, and the side wall of the cooling box close to the bottom is provided with a discharging pipe in communication, and a water and air integrated cooling mechanism is arranged inside the cooling box. The cooling device introduces water to a water cooling pipe inside a cooling elbow to promote cooling, and an airpump introduces outside cold air into the cooling elbow through an air guide pipe. A gear motor drives the cooling elbow through a pulley to rotate inside a dairy product to promote uniform temperature reduction of the dairy product and also drive stirring of the dairy product to expose the portion with higher temperature to promote cooling.

Owner:青海雪峰牦牛乳业有限责任公司

Photo-thermal system and photo-thermal power station

ActiveCN108087849AImprove qualityGuaranteed temperature differenceSolar heating energyFrom solar energyThermal energyDevice form

The invention discloses a photo-thermal system. The photo-thermal system comprises a photo-thermal collector and a solid heat storage device; wherein the solid heat storage device comprises a solid heat storage base body and heat exchange pipelines, and the heat exchange pipelines are arranged in the solid heat storage base body, and is used for exchanging heat with the solid heat storage base body; and heat storage inlets of the heat exchange pipelines communicate with steam outlets of the photo-thermal collector, heat storage outlets of the heat exchange pipelines communicate with water return inlets of the photo-thermal collector, so that the photo-thermal collector and the solid heat storage device form a heat energy storage loop. The embodiment of the invention further discloses a photo-thermal power station. According to the scheme, the problems that the power generation efficiency is low, device investment cost is high and the safety coefficient is low due to the fact that heatenergy storage of an existing photo-thermal power generation system by utilizing heat conduction oil or molten salt can be solved.

Owner:BEIJING TERASOLAR PHOTOTHERMAL TECH CO LTD

Computer case side cover with water cooling system

InactiveCN106371534AReduce the temperatureGuaranteed temperature differenceDigital processing power distributionHeat transfer efficiencyEngineering

The invention discloses a computer case side cover with a water cooling system, and relates to the field of design and manufacturing of computer hardware. The computer case side cover with the water cooling system comprises a body, wherein at least one mounting cavity is formed in the middle of the body; a plurality of transversely-arranged water cooling sheets are arranged inside the mounting cavity; the water cooling sheets are connected with water cooling hard tubes; the two ends of the water cooling hard tubes stretch into the body; water cooling hose pipes are arranged among the water cooling hard tubes; the water cooling hose pipes sequentially connect the water cooling hard tubes from the upper part to the lower part; the water cooling hose pipe at the upmost end is connected with a water cooling tank; a refrigerator is arranged inside the water cooling tank; a reflowing water pipe is arranged between the water cooling hard tube at the lowermost end and the water cooling tank; a circulating water pump is arranged on the reflowing water pipe. Through arrangement of the water cooling sheets in the computer case side cover, the temperature of air passing through the computer case side cover is reduced, so that the temperature of air entering a computer case is reduced, the difference between the air inlet temperature and the internal temperature inside a mainframe is ensured, the heat transfer efficiency is improved, and the problem that in the prior art, a computer mainframe has an non-ideal heat-dissipating effect in summer is solved.

Owner:CHENGDU YANXINGGUO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com