Method for producing large-specification circular blanks in rolling mode instead of forging mode

A production method and large-scale technology, applied in the direction of rolling, metal rolling, metal rolling, etc., can solve the problems of the load impact of the finishing rolling mill, unfavorable control of deformation uniformity, and difficult support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0054] The invention relates to a method for producing a large-size round billet by rolling instead of forging. The method mainly includes the following contents:

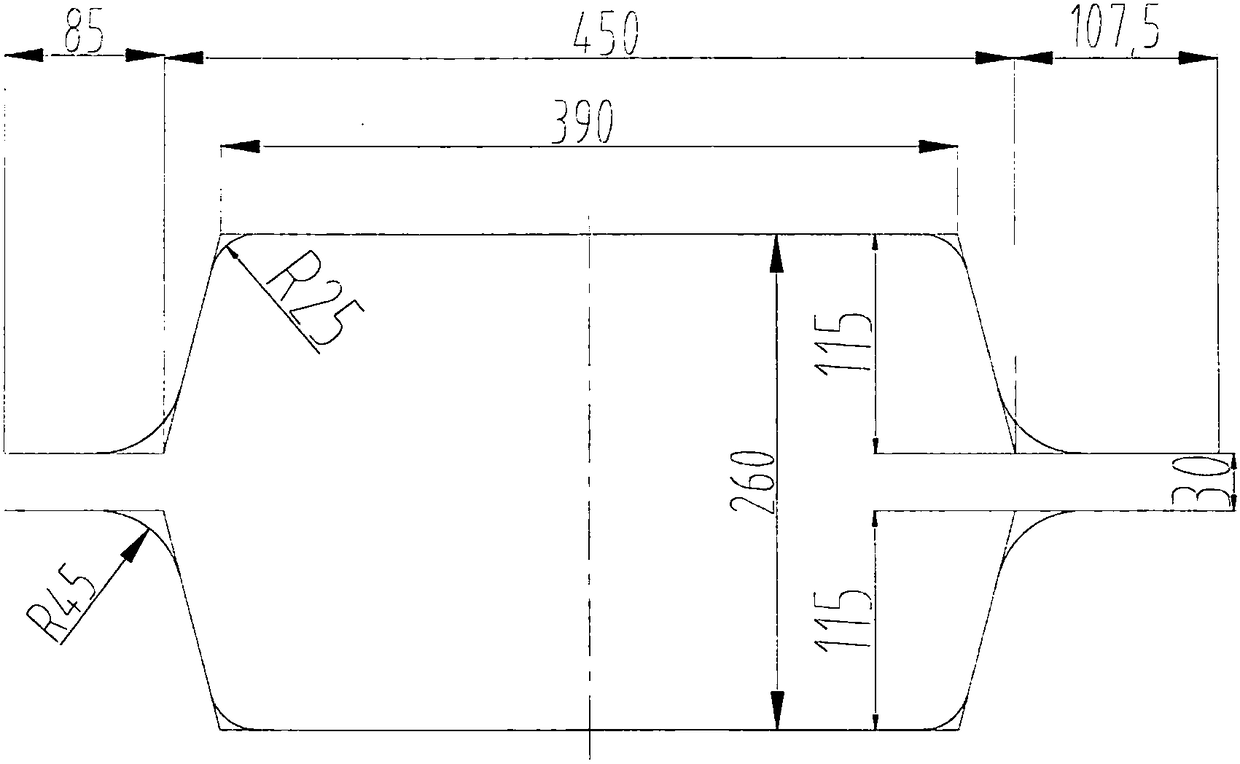

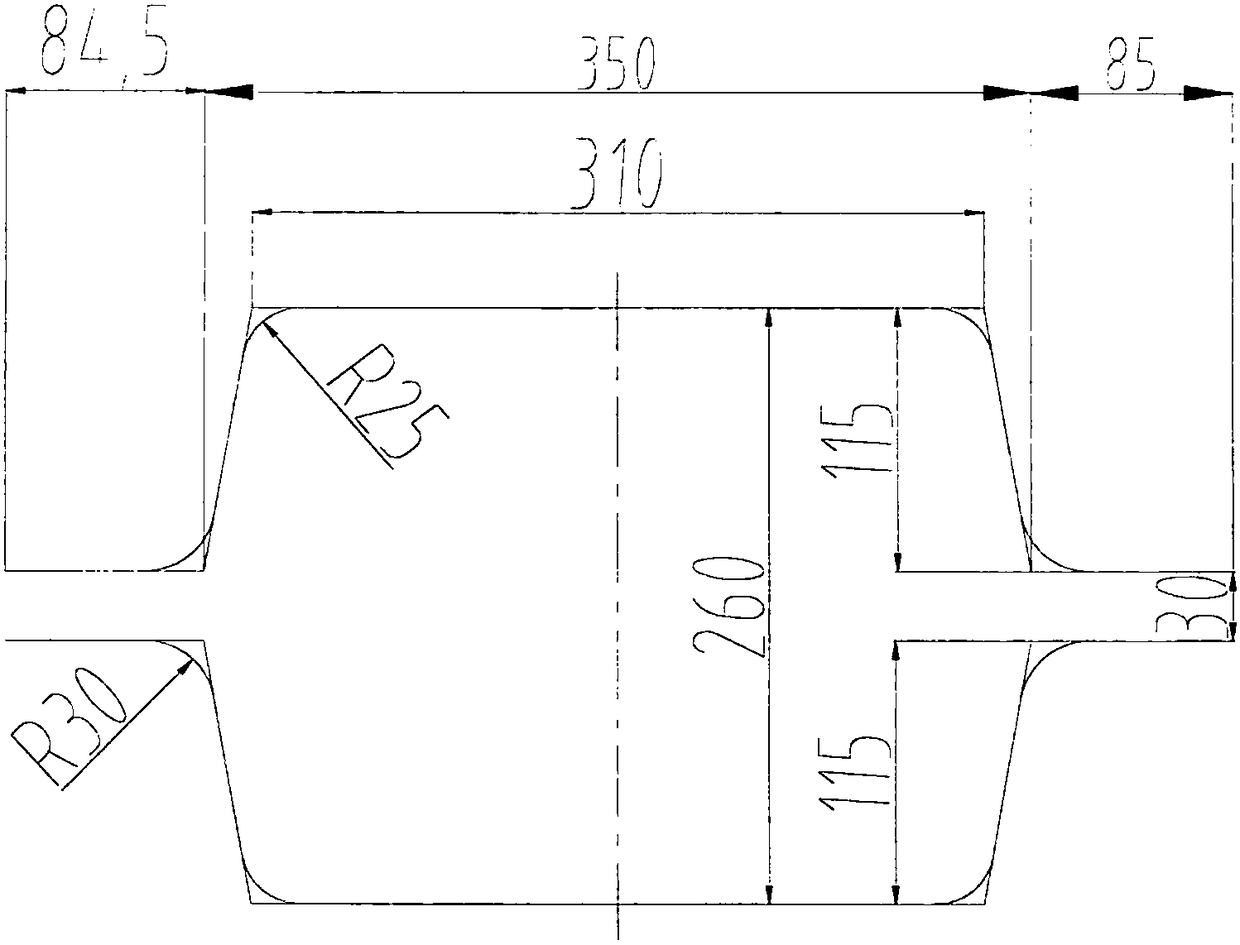

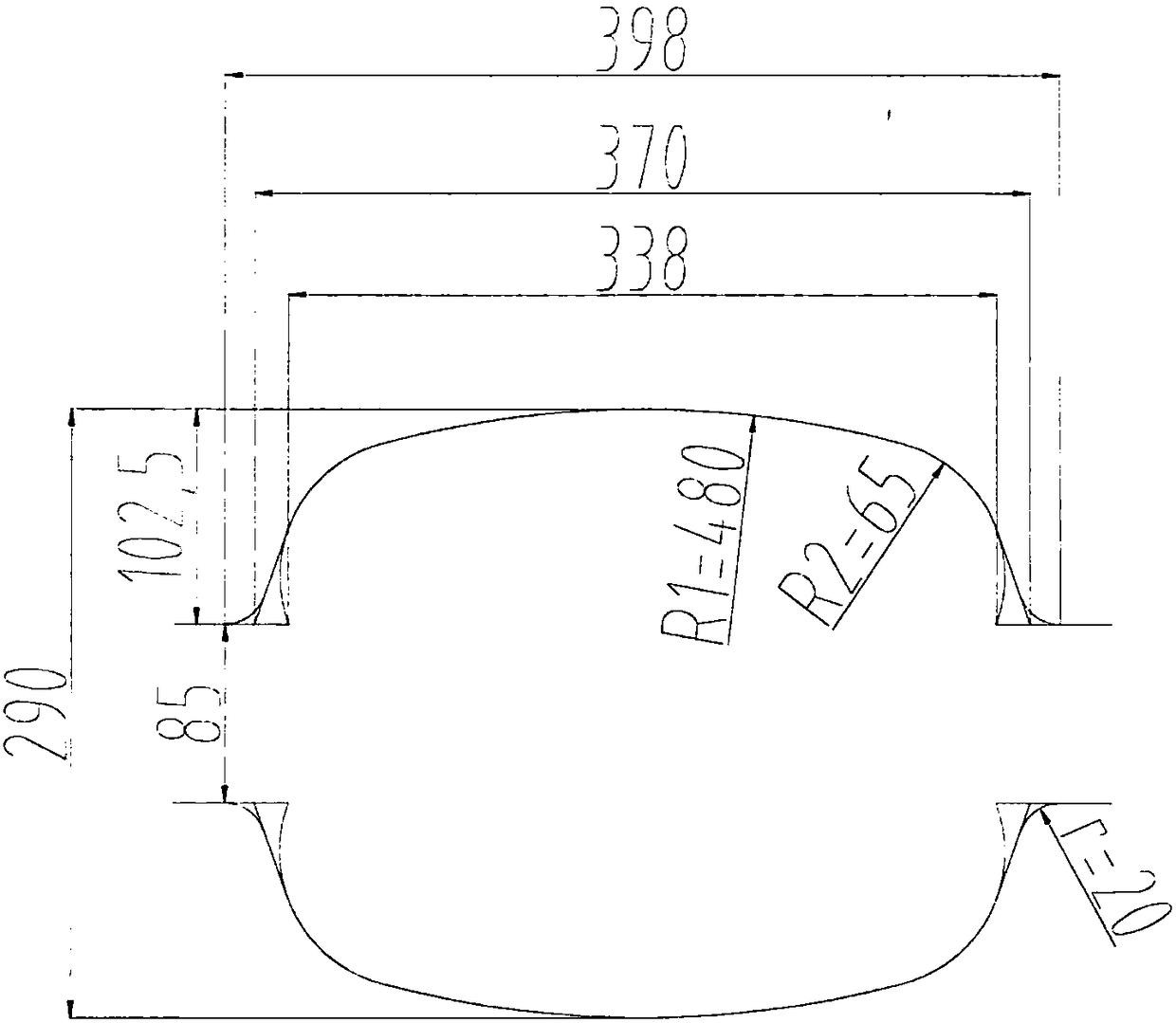

[0055] Step 1. Rough rolling pass design

[0056] 1.1. Selection of billet

[0057] Large-scale products are mainly used in machinery manufacturing industries such as steel for oil field drilling tools and large motor shafts. The mechanical properties of round steel products are particularly demanding, so the compression ratio of the product must be considered. The existing billet 390*510 such as rolling Made into 350 rounds and 300 rounds, the compression ratio is only 2.1 and 2.8, but the customer requires the product to have a compression ratio of at least 3, so combined with the large-size continuous casting billet, the billet is positioned as a 600 round continuous casting bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com