Thermoelectric conversion element and thermoelectric conversion module

A technology of thermoelectric conversion and components, which is applied in the direction of electrical components, thermoelectric device parts, and thermoelectric device manufacturing/processing, etc., which can solve the problems of low durability, trouble, and inclination of thermoelectric conversion element electrodes, etc., to achieve guaranteed temperature difference, Effect of improving durability, big temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

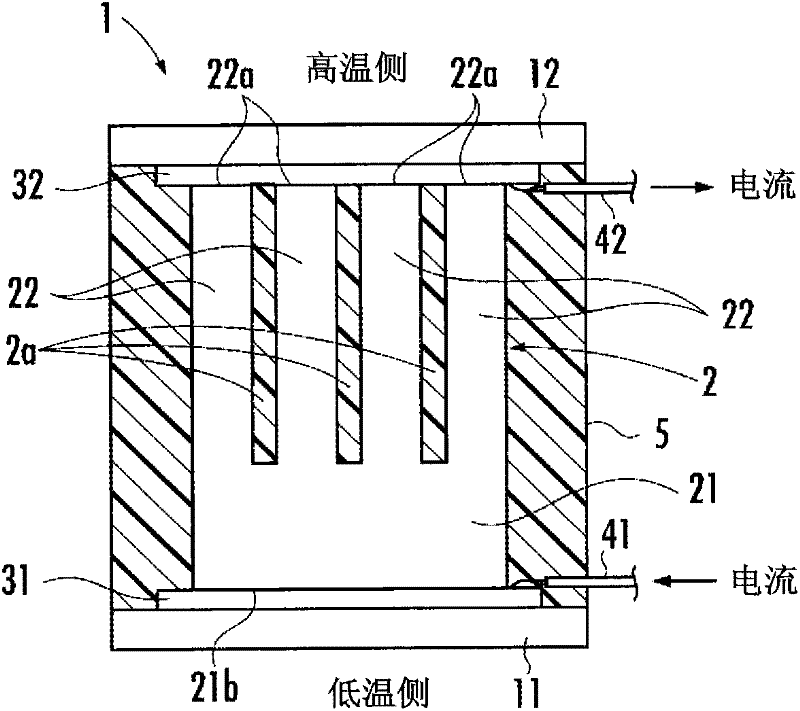

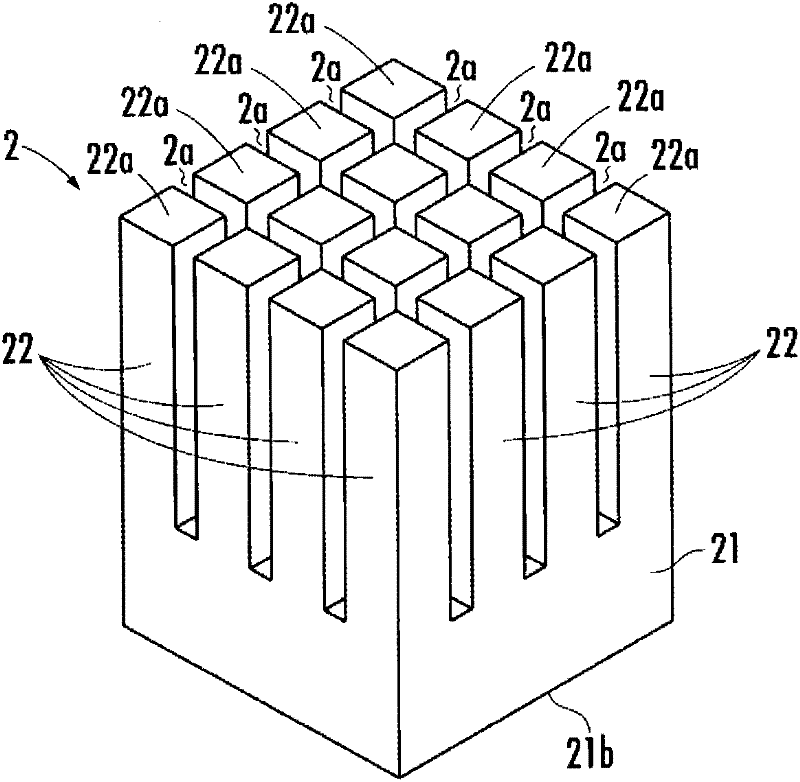

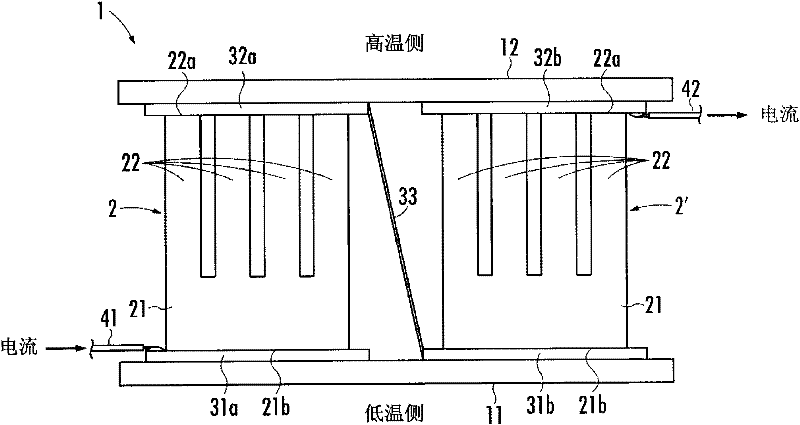

[0035] Reference figure 1 with figure 2 The thermoelectric conversion module using the thermoelectric conversion element according to the first embodiment of the present invention will be described, and the thermoelectric conversion module is used for power generation. The thermoelectric conversion module of the first embodiment includes a pair of substrates 11, 12 molded of alumina and having insulating properties, and first and second electrodes 31 made of copper plates and provided on the surfaces of the substrates 11, 12 opposite to each other. 32, and the magnesium silicide (Mg silicide) arranged between the two electrodes 31 and 32 2 Si) n-type thermoelectric conversion element 2.

[0036] In the prior art, materials BiTe, PbTe, and CoSb are used as materials for thermoelectric conversion elements. However, all these materials are harmful to the human body (including possibly harmful) and are expensive. Magnesium silicide (Mg 2 Si) is harmless to the human body, has littl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com