Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Guaranteed lamination effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

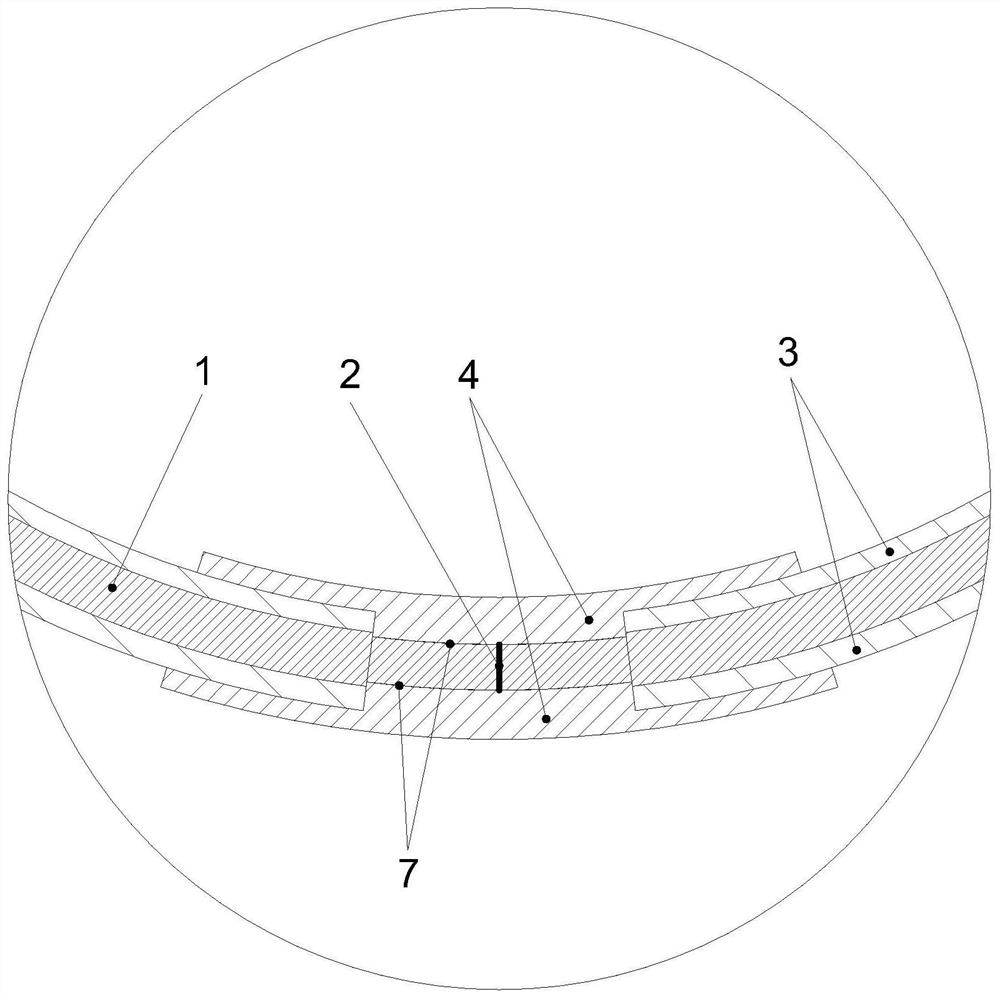

Embossing roll set and household paper manufactured by aid of same

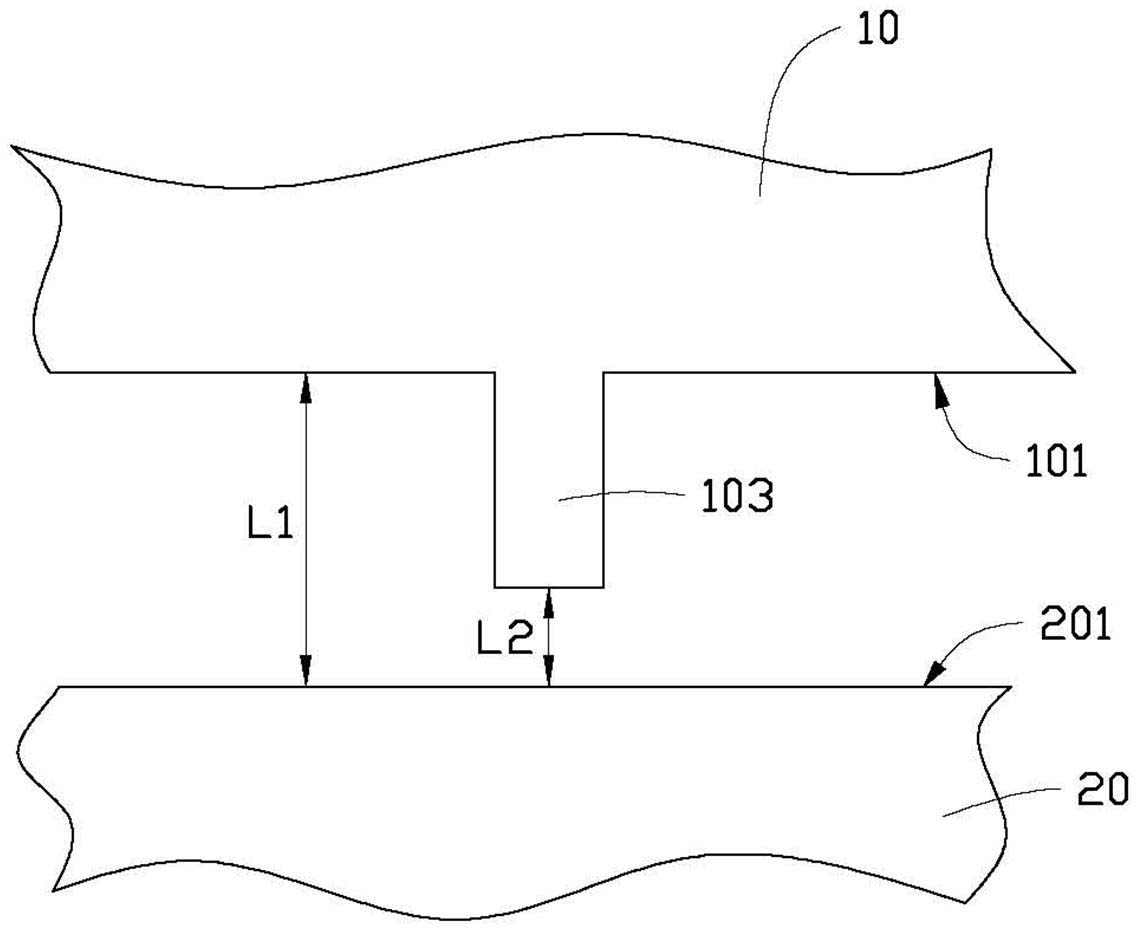

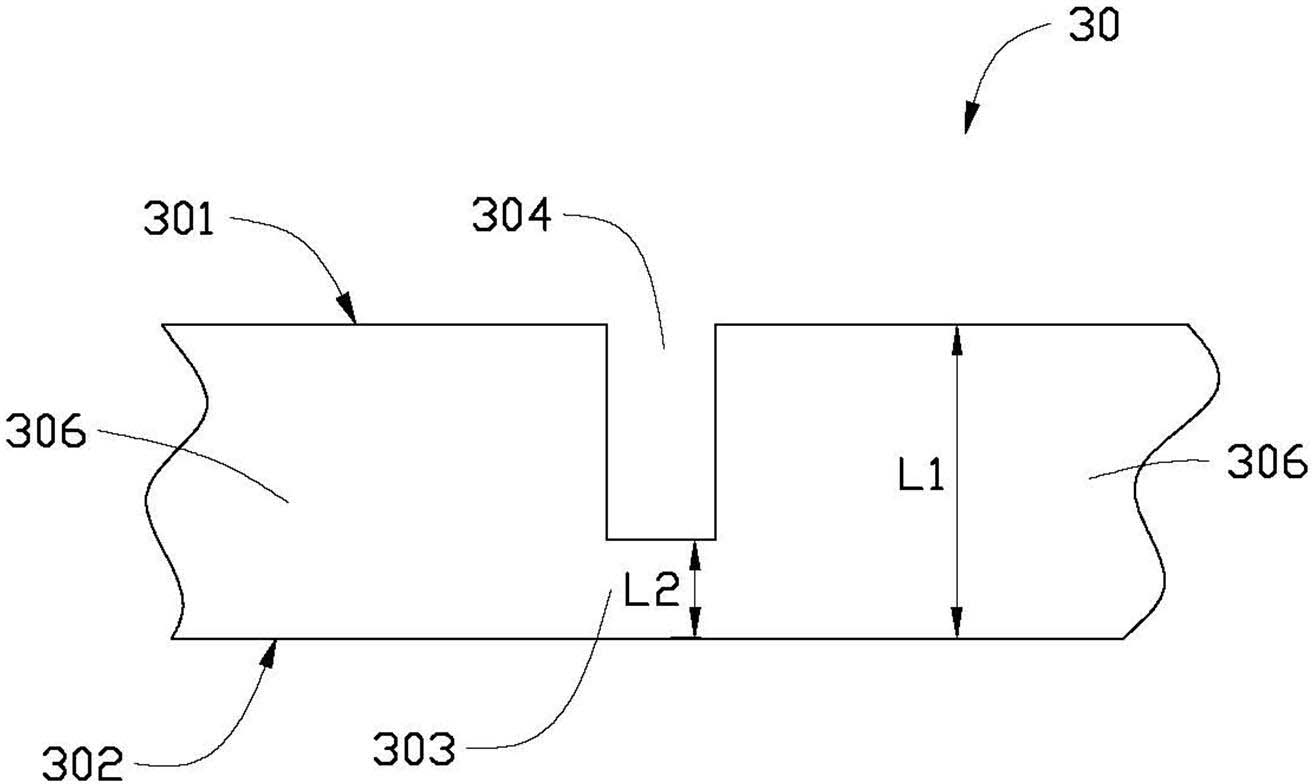

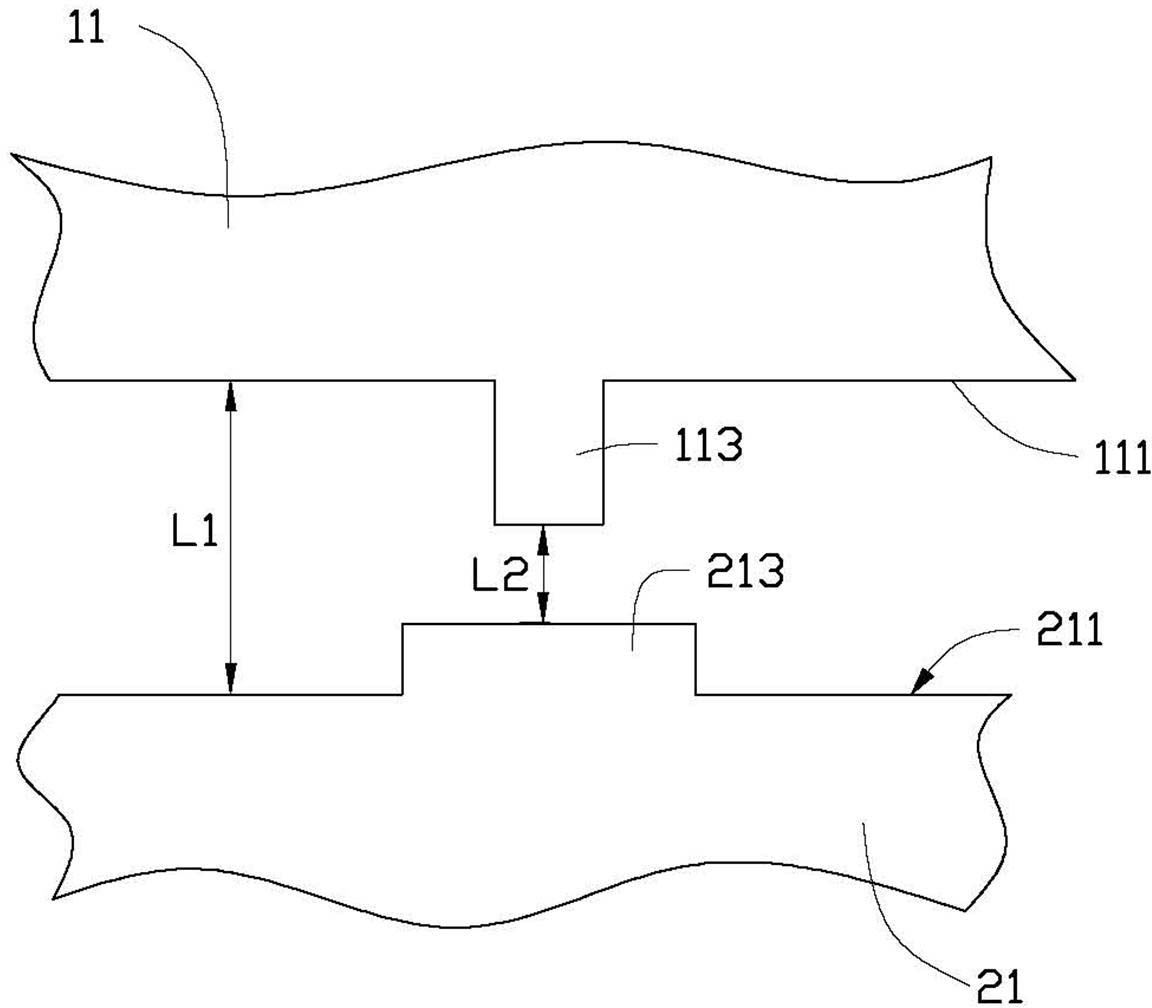

InactiveCN102555304AGuaranteed aestheticsGuaranteed lamination effectMechanical working/deformationFiberPulp and paper industry

Disclosed is embossed household paper. The thickness of household paper is T before the household paper is embossed, the thickness of a non-embossed portion of the household paper is L1 after the household paper is embossed, the L1 is smaller than the T, and the non-embossed portion of the household paper is pressed into a smooth and flat plane. The invention further provides an embossing roll set for manufacturing the household paper. The household paper manufactured by the aid of the embossing roll set has effects of embossing and calendaring, attractive and laminated effects of the household paper are guaranteed, simultaneously, the defect that fiber scraps of the surface of existing embossed paper are easy to drop off is overcome, and surface smoothness of the household paper is improved.

Owner:GOLD HONG YE PAPER

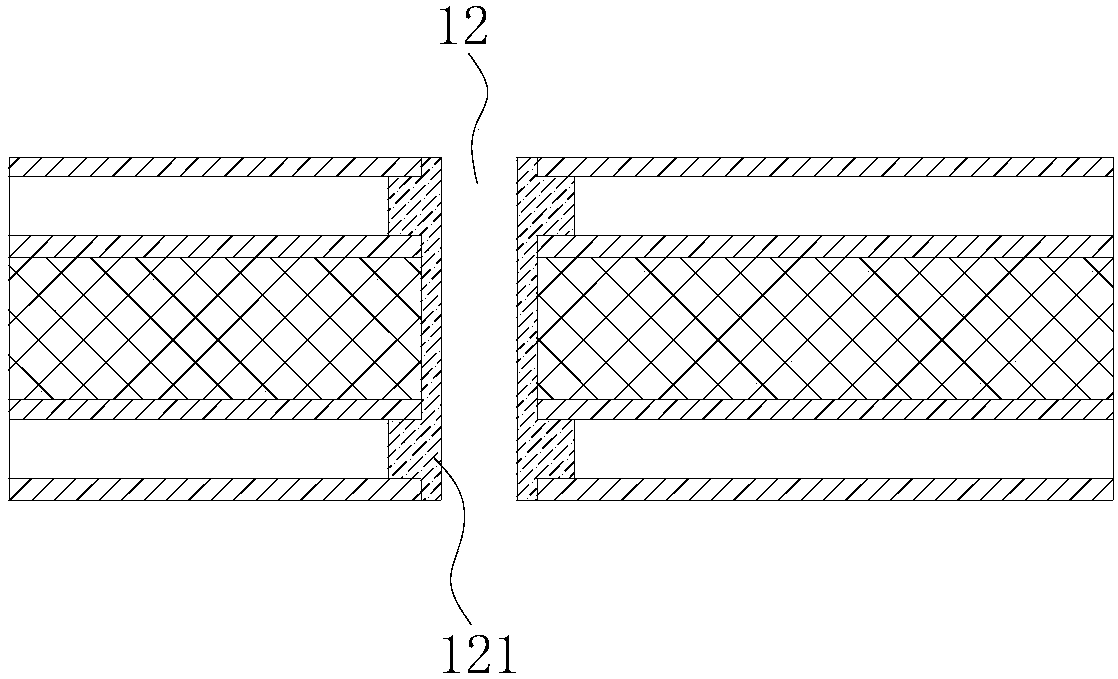

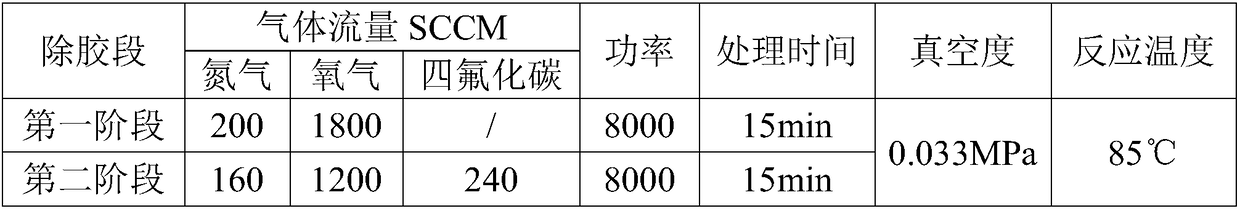

Manufacturing method for etch-back printed circuit board

ActiveCN105792527AImprove reliabilityDimensionally stablePrinted circuit aspectsPrinted element electric connection formationGlass fiberElectrical connection

The invention relates to the technical field of circuit board production, particularly to a manufacturing method for an etch-back printed circuit board. According to the invention, preset holes that correspond to through holes one by one and have apertures larger than those of the through holes are drilled in a prepreg and thus pieces of glass fiber cloth corresponding to the through holes needing follow-up etching back processing are removed in advance, and only resin in the holes needs to be removed at a de-smearing step, so that a problem that the glass fiber cloth can not be removed easily can be solved; and a good etch-back effect and a good hole wall effect can be formed and the inner layer circuit cooper can be exposed fully. After through hole metallization, three-dimensional connection is formed between the hole wall copper-plated layer and the inner layer circuit cooper, so that the two parts can be connected firmly and thus reliability of electrical connection between the inner layer and the outer layer can be improved. The apertures of the preset holes are set to be larger than those of the through holes by 0.05 mm; losing of too much resin for the prepreg can be avoided while the glass fiber cloth is removed completely; and the influence on compressing by the resin loss of the prepreg due to hole drilling can be reduced.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

Production technology for precoated sand recycling

The invention discloses a production technology for precoated sand recycling. According to the technical scheme, the production technology for precoated sand recycling is characterized in that waste precoated sand is recycled through crushing, multi-time screening, NaOH solution immersing, roasting, cooling, heating, mixing stirring, filtering, sand injecting and other technologies, and the precoated sand can be repeatedly recycled; and the circulation cost is very low, accordingly, the environment is protected, and resource waste is avoided.

Owner:TAIZHOU CHENS COPPER

Full-automatic bagging garbage can

The invention relates to a full-automatic bagging garbage can. The full-automatic bagging garbage can comprises a can body, two bag outlet devices arranged on the left side and the right side of the upper portion of the can body correspondingly, bottom seal edge cutting devices arranged on the lower sides of the bag outlet devices, and side edge seal devices arranged on the lower sides of the bottom seal edge cutting devices. Providing the full-automatic bagging garbage can is the purpose, the full-automatic bagging garbage can is capable of achieving automatic garbage can bagging, fully-loaded garbage bags can be automatically sealed, manual operation is not needed, and sanitation and convenience are achieved. The full-automatic bagging garbage can has the beneficial effects that the twobag outlet devices are arranged on the left side and the right side of the upper portion of the can body, the bag outlet devices are garbage bag rollers made of single-layer films, the single-layer films on the two sides are pasted and conveyed to the bottom seal edge cutting devices and the side edge seal devices through a bag feeding device, and garbage bags with the upper ends opened are formedthrough heat seal; since the left sides and the right sides of the garbage bags are fixed through the bag outlet devices, the upper ends can be naturally opened to form garbage throwing ports, and abag opening expanding device does not need to be specially arranged; and garbage bag roller producing and manufacturing are simple, and meanwhile replacement is convenient for users.

Owner:福建智锦科技有限公司

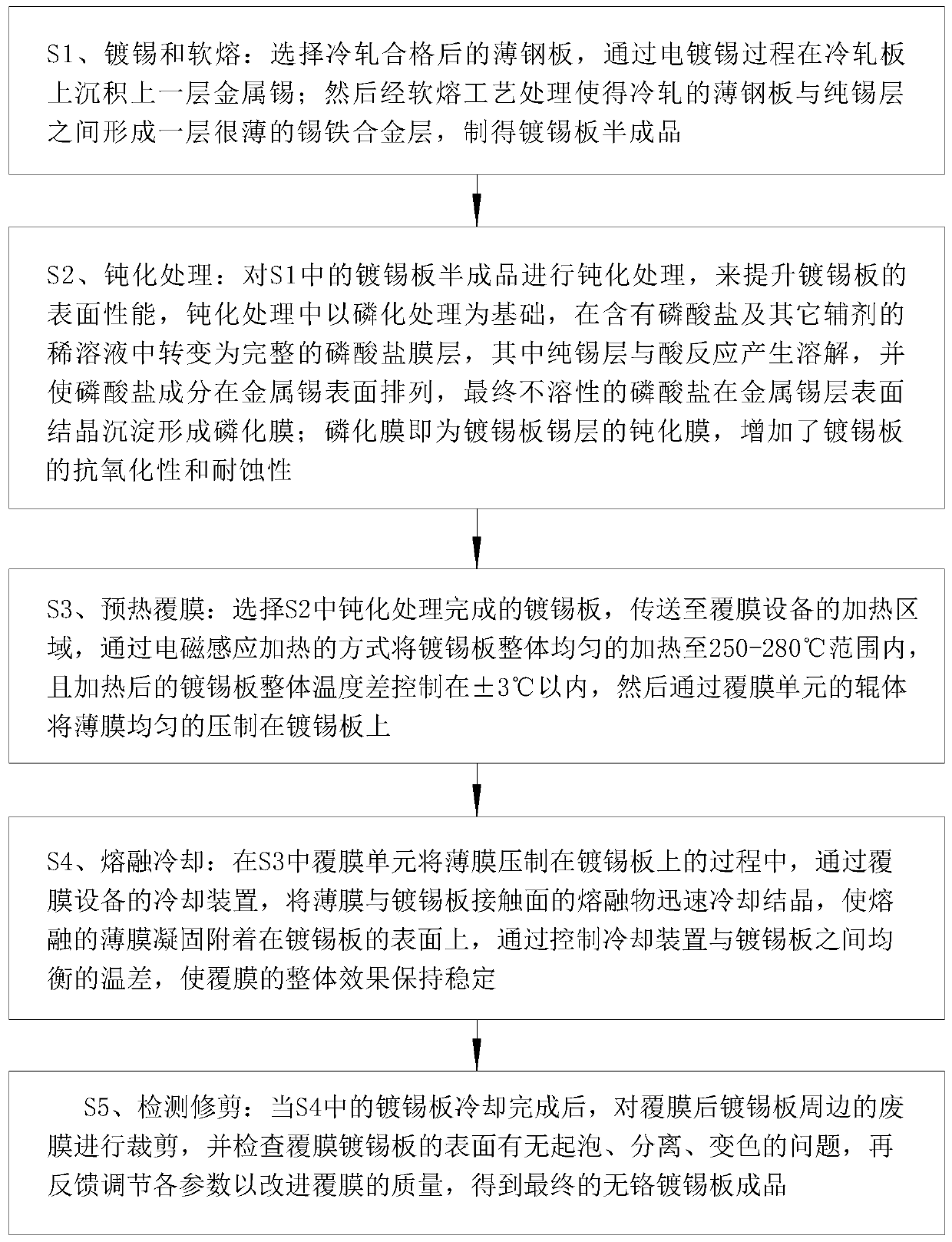

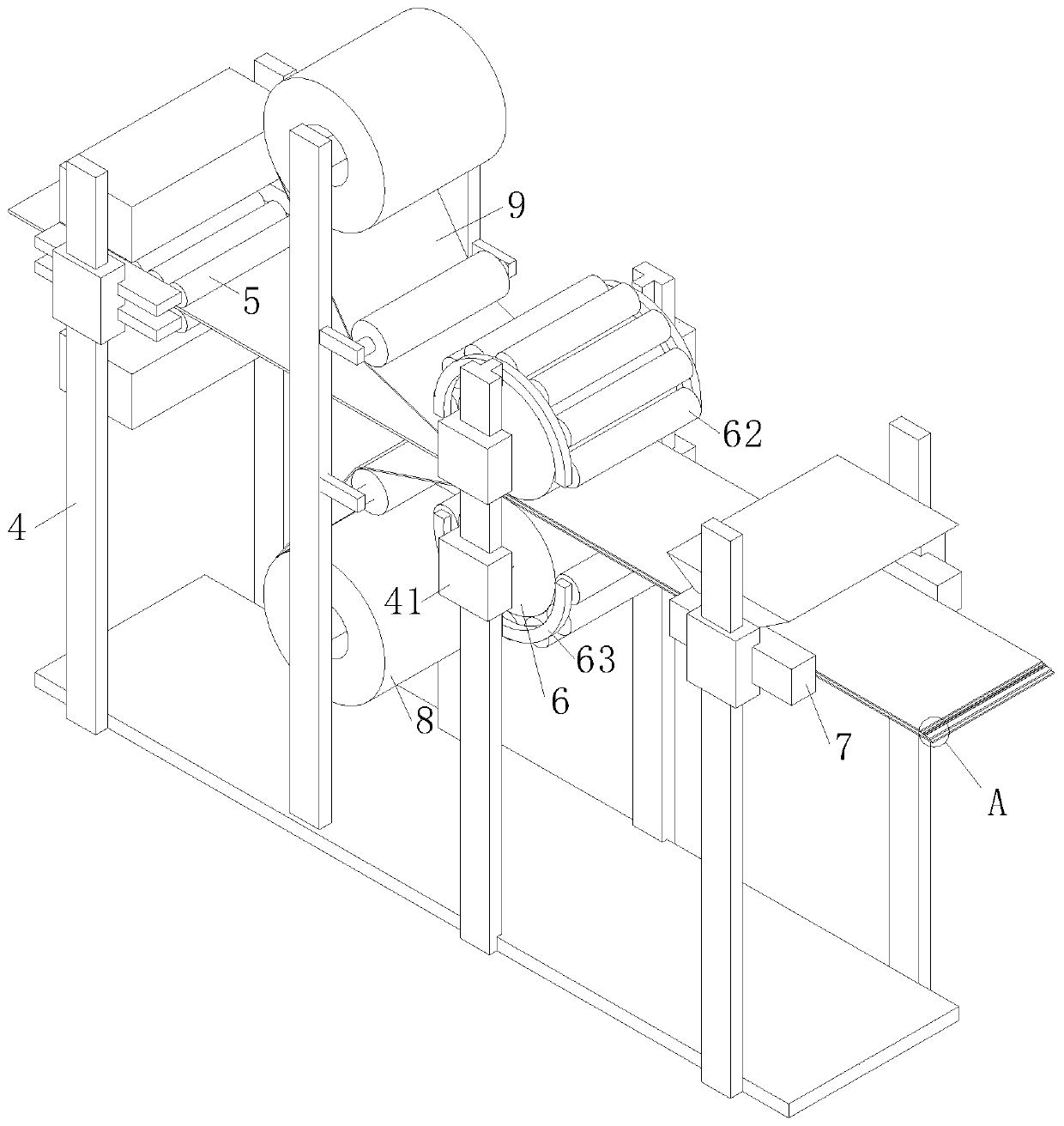

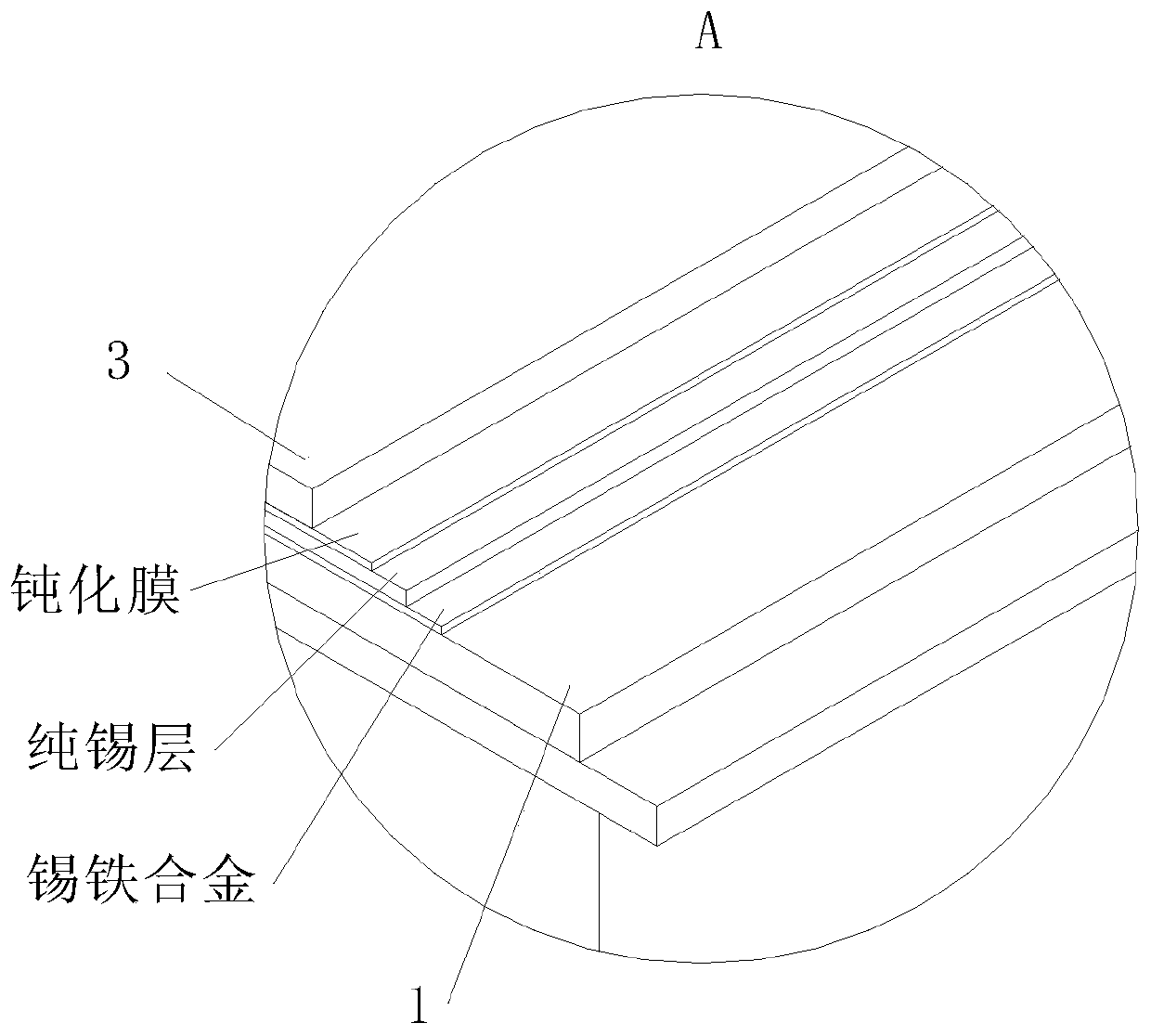

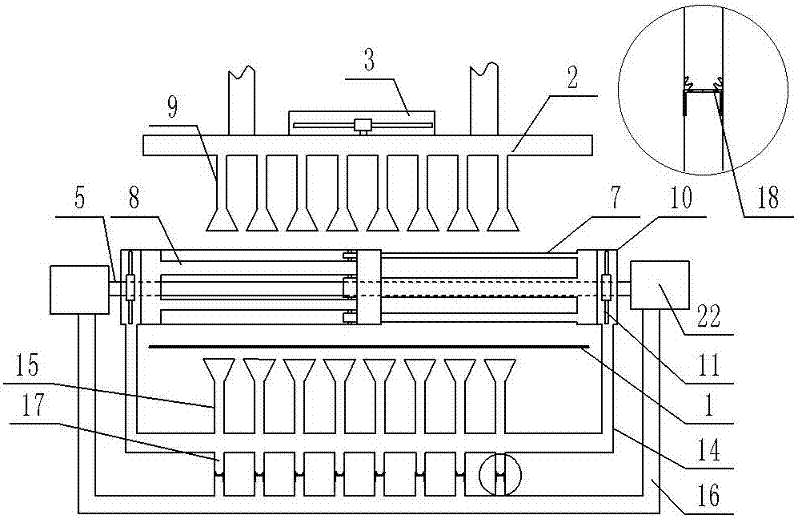

Chromium-free tinning plate and surface treatment method thereof

PendingCN111304706AGuaranteed lamination effectAvoid pollutionLaminationLamination apparatusTinningPhosphate

The invention relates to the technical field of tinning plates, in particular to a chromium-free tinning plate and a surface treatment method thereof. The chromium-free tinning plate comprises a steelbase plate, a tinning layer and a coating layer; the tinning layer is passivated on the steel base plate through a phosphate solution; and the coating layer is bonded to the passivated tinning layerthrough coating equipment. Because in the tinning process of the steel base plate, the phosphate solution is selected for passivation treatment to avoid environmental pollution caused by chromate passivatin, after the passivation of the phosphate solution, the quality of the tinning plate is affected, and the requirements of oxidation resistance and corrosion resistance of the tinning plate cannotbe met; and thus, through the coating layer arranged on the tinning layer, a chromate solution in the passivation process of the tinning plate is replaced by the phosphate solution, so as to avoid the pollution of the chromate to the environment, meanwhile the coating layer is arranged to protect the chemical stability of the surface of the tinning plate passivated by phosphate, and the use effect of the chromium-free tinning plate is maintained.

Owner:葛家玉

Sealing machine with adjustable sealing widths

ActiveCN107140265ARealize automatic shorteningChange air flowWrapper twisting/gatheringEngineeringBreathing

The invention relates to the technical field of packaging and sealing and discloses a sealing machine with adjustable sealing widths. The sealing machine comprises a conveying belt. Through grooves are formed in the conveying belt. A hot pressing roller and a wind box are arranged above the conveying belt. The wind box comprises a fan and is provided with first branch pipes. A wind guiding pipe is arranged under the conveying belt. Second branch pipes are arranged on the wind guiding pipe and directly face the first branch pipes. Each second branch pipe, the corresponding first branch pipe and the corresponding through groove form a ventilation set correspondingly. At least two ventilation sets are arranged. A shaft tube is arranged on the hot pressing roller in a penetrating mode and slidably connected with the hot pressing roller. The hot pressing roller comprises a first roller body and a second roller body. The first roller body is sleeved with the second roller body. The second roller body and the first roller body are slidably connected and both provided with heating sheets. One end of the wind guiding pipe faces the face, away from the second roller body, of the first roller body, and the other end of the wind guiding pipe faces the face, away from the first roller body, of the second roller body. The two ends of the wind guiding pipe extend in the axial direction of the first roller body. According to the sealing machine, the sealing widths of the sealing machine can be automatically adjusted.

Owner:CHONGQING HAOJIE FOOD

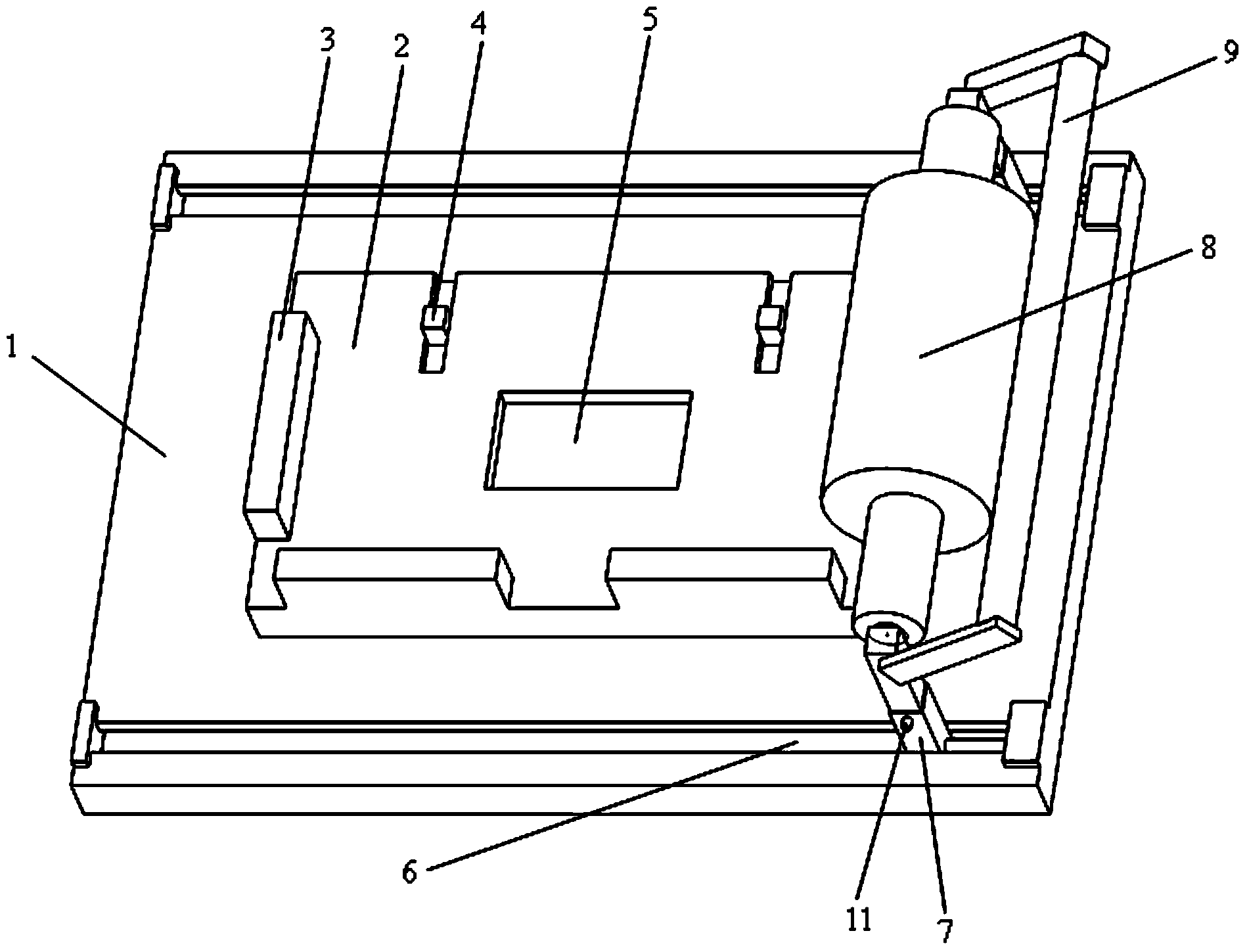

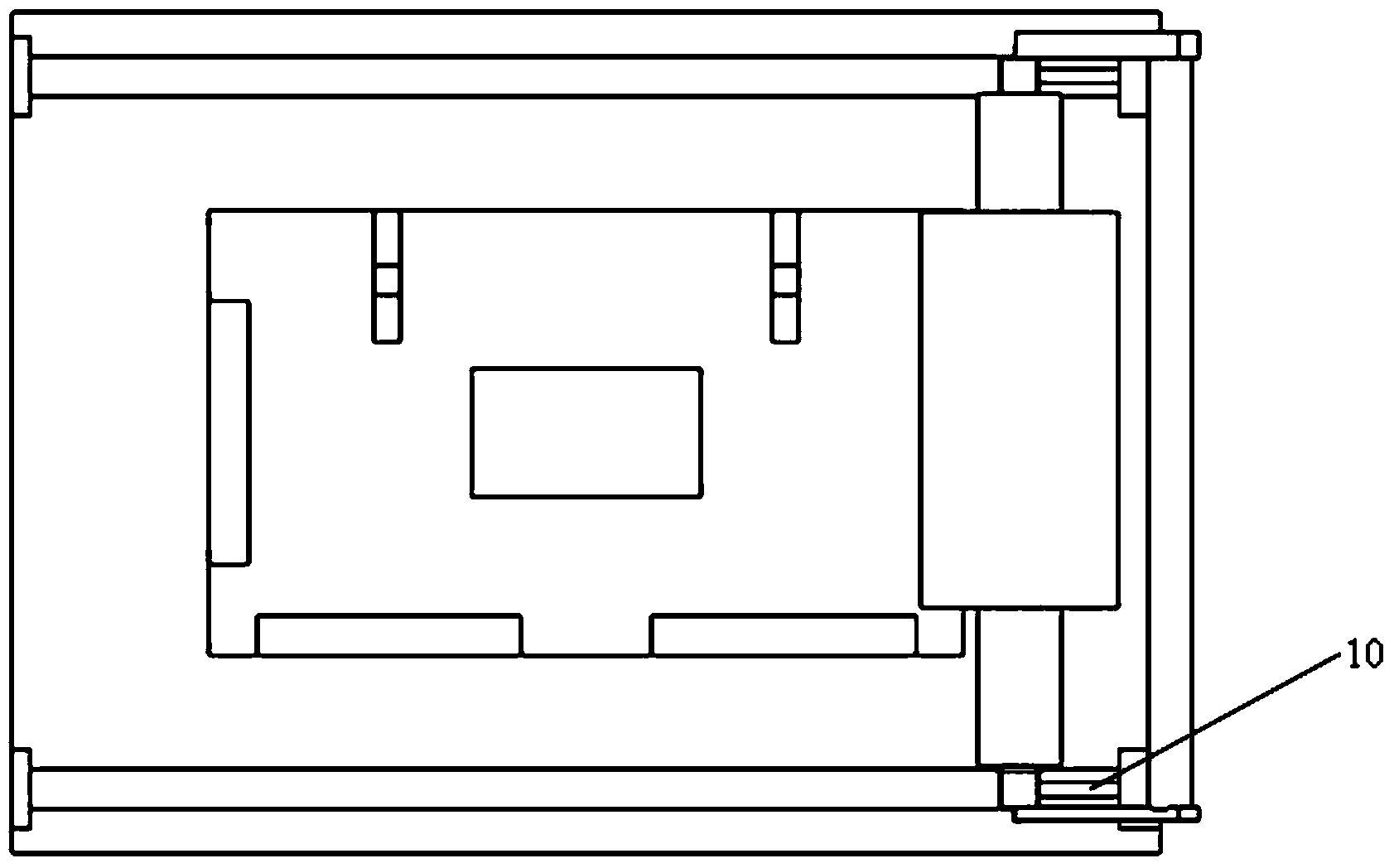

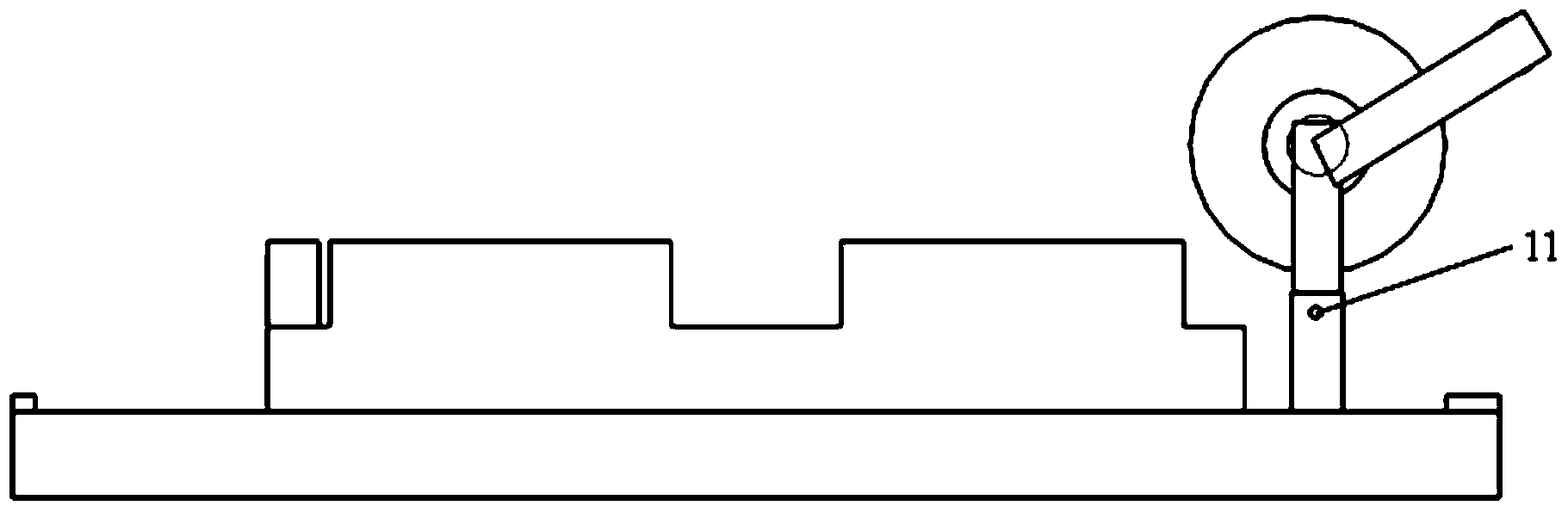

Glass laminating device

InactiveCN104230184AReasonable designSimple structureLamination ancillary operationsLaminationPlastic materialsEngineering

The invention discloses a glass laminating device, comprising a base, a positioning device and a laminating device, wherein the base is of a rectangular structure and is arranged at the bottom layer of the device; the positioning device is composed of a base plate, a positioning barrier strip, a positioning slide block and a positioning groove and is fixed on the base through bolts; and the laminating device is composed of a linear slide rail, a stretchable link, an idler wheel, a hand shank and a spring device. The idler wheel is made of a flexible plastic material, ensures a good laminating effect and avoids hard scratches in the rolling laminating process; and the laminating device has an automatic resetting function, so that the laminating efficiency is greatly improved. The glass laminating device is simple and reasonable in structure, low in manufacturing cost, and suitable for massive production and application of manufacturing enterprises of aluminum alloy doors and windows.

Owner:HEFEI JIAWEI DECORATION ENG

Film covering device for foam board

ActiveCN108163258AEasy to cleanImprove processing qualityWrapping material feeding apparatusPackaging protectionAgricultural engineering

The invention relates to the technical field of film covering equipment of vehicle foam boards and discloses a film covering device for a foam board. The film covering device for the foam board comprises a conveying platform. The conveying platform is provided with a rack. The rack is rotationally connected with a film pay-off roller and a film covering roller. The conveying platform is provided with an intermittent pushing mechanism, a first vertical plate connected in a sliding manner and a second vertical plate which is fixedly connected. The first vertical plate and the second vertical plate are both provided with strip-shaped holes, and the inner walls of the strip-shaped holes are provided with friction layers. The rack is further rotationally connected with a rotary table. The rotary table is in belt connection with a motor. The rotary table is provided with an eccentric column, a vertical rod is hinged to the eccentric column, a first push plate and a second push plate are hinged to the vertical rod, the first push plate is hinged to the first vertical plate, the second push plate is hinged to the second vertical plate, the first push plate and the second push plate are both connected with lead screws, the upper sides of the lead screws are provided with lead screw pairs, and the lead screw pairs are connected with fans. The outer side of the rotary table is provided with a first round wheel, the first round wheel is provided with a guide rod and a clamping groove, and the film covering roller is in belt connection with the first round wheel. According to the film covering device for the foam board, impurities on the foam board can be cleaned away.

Owner:重庆翰邦汽车配件有限公司

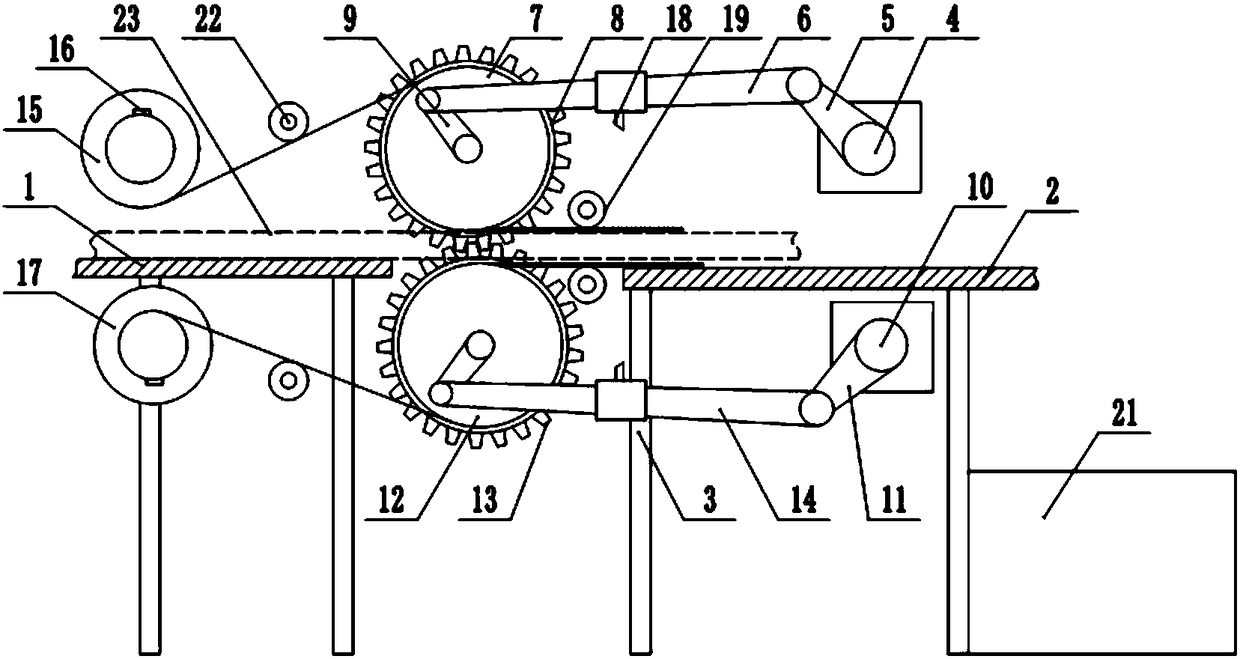

Printing film laminating device

InactiveCN108528035AIssues affecting qualityRealize automatic collectionLamination ancillary operationsLaminationDrive shaftEngineering

The invention relates to a printing film laminating device. The printing film laminating device comprises a machine frame, a first conveyor belt and a second conveyor belt, wherein a gap is formed between the first conveyor belt and the second conveyor belt; a driving shaft is arranged above the gap, a first driving rod is fixedly connected to the driving shaft, the first driving rod is connectedwith a second driving rod, a driving laminating roller is arranged over the gap, and a driving gear is fixedly connected to the driving laminating roller, the driving laminating roller is fixedly connected with a first connecting rod, and the free end of the first connecting rod is connected with the second driving rod; a driven shaft is arranged below the gap, the driven shaft is fixedly connected with a first driven rod, the first driven rod is connected with a second driven rod, a driven laminating roller is arranged under the gap, the driven laminating roller is coaxially and fixedly connected with a driven gear, the driven laminating roller is fixedly connected with a second connecting rod, and the second connecting rod is connected with the second driven rod; and a first stripping roller is arranged on one side of the driving laminating roller, a second stripping roller is arranged on one side of the driven laminating roller, and clamping plates are arranged on the first stripping roller and the second stripping roller correspondingly. According to the printing film laminating device, dust is not prone to adhere to the coating surface of a protective film of the device.

Owner:重庆川之舟印务设计有限公司

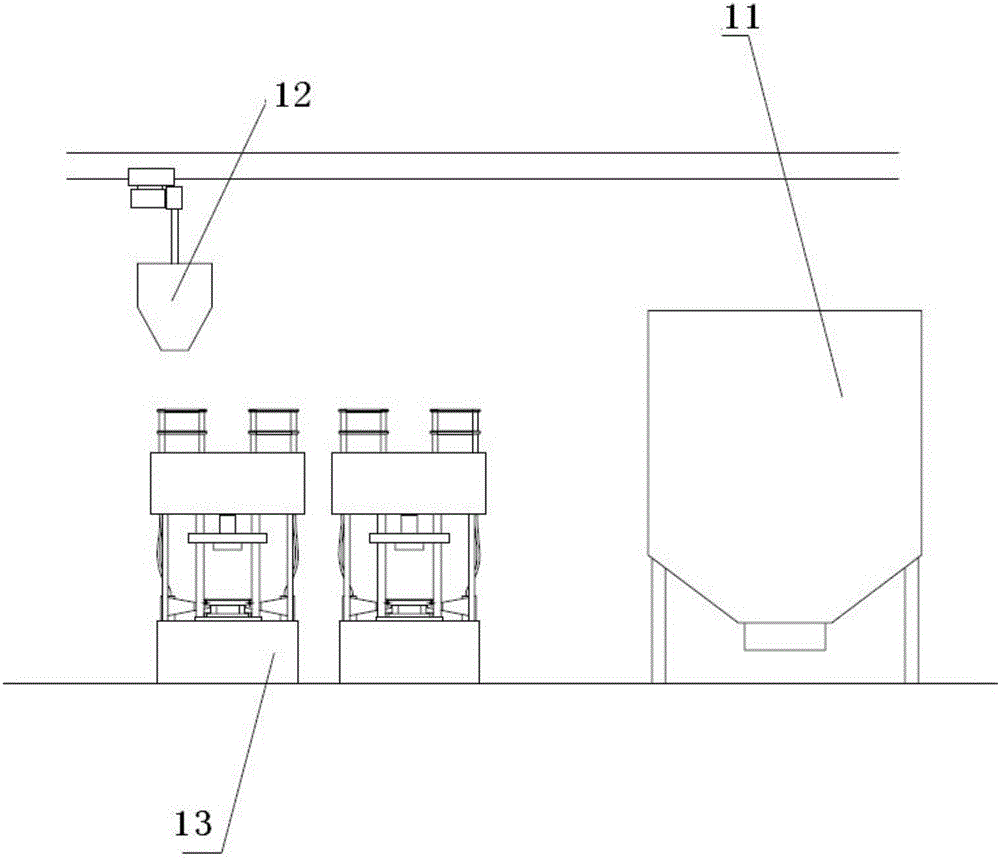

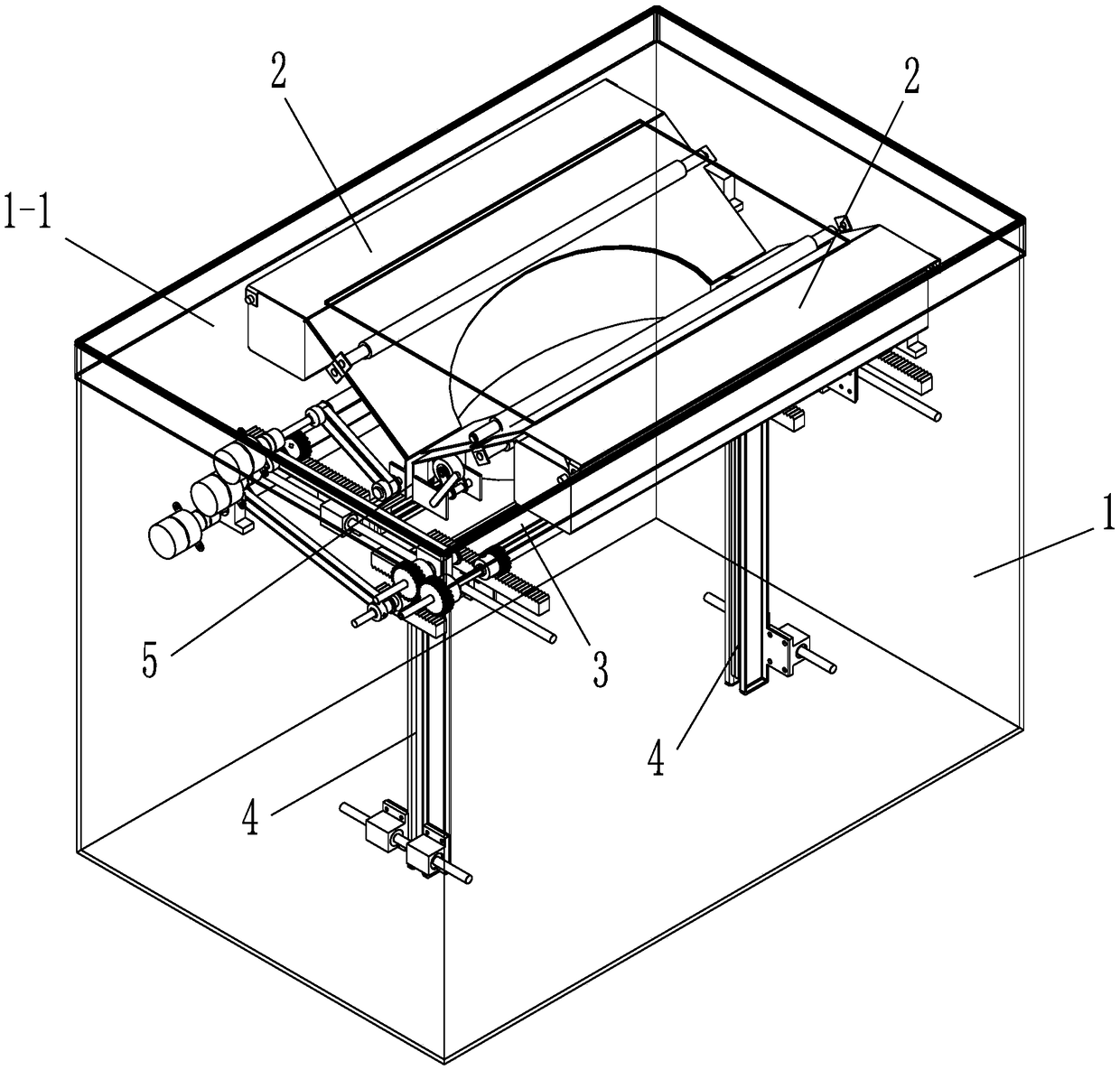

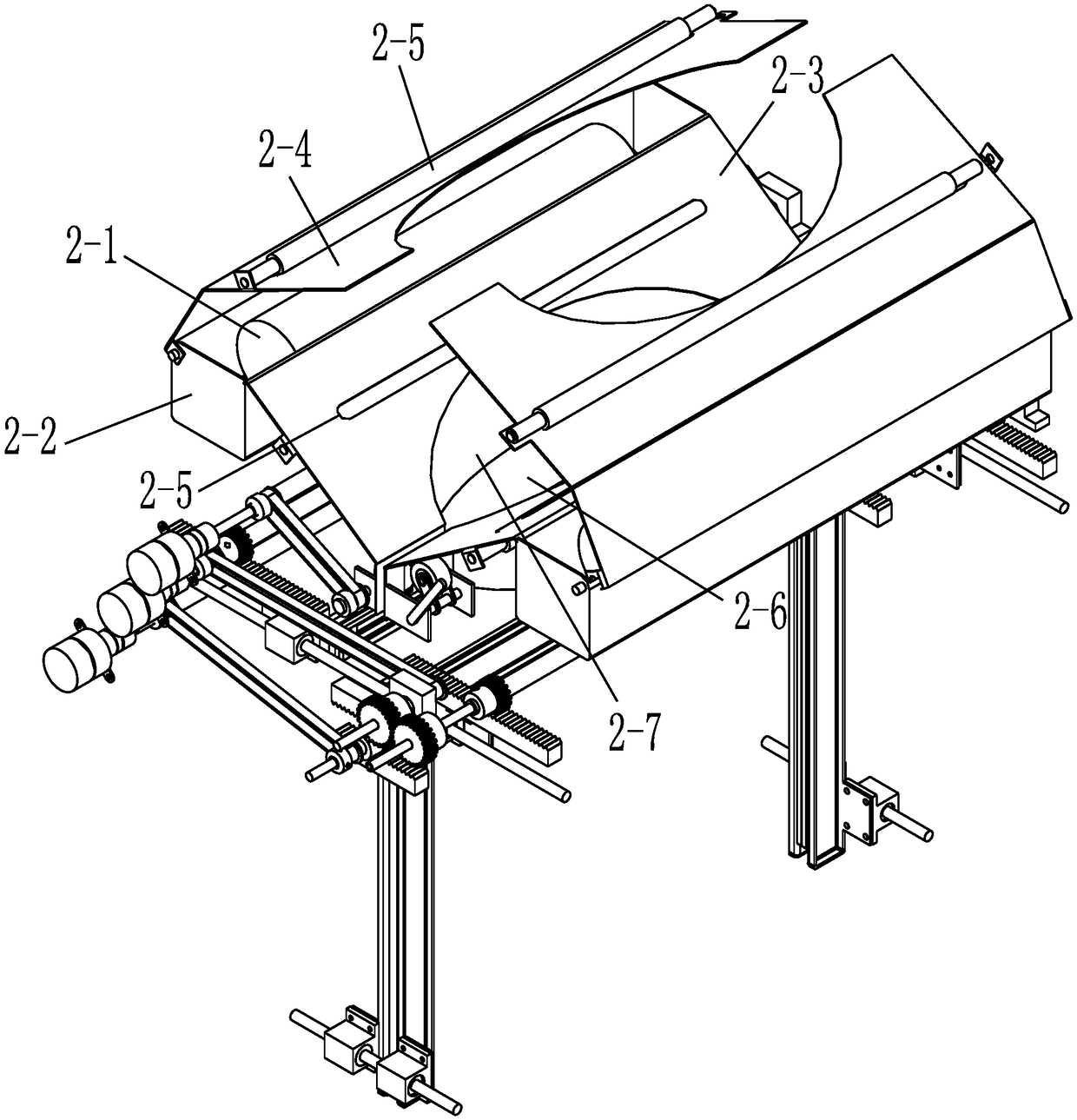

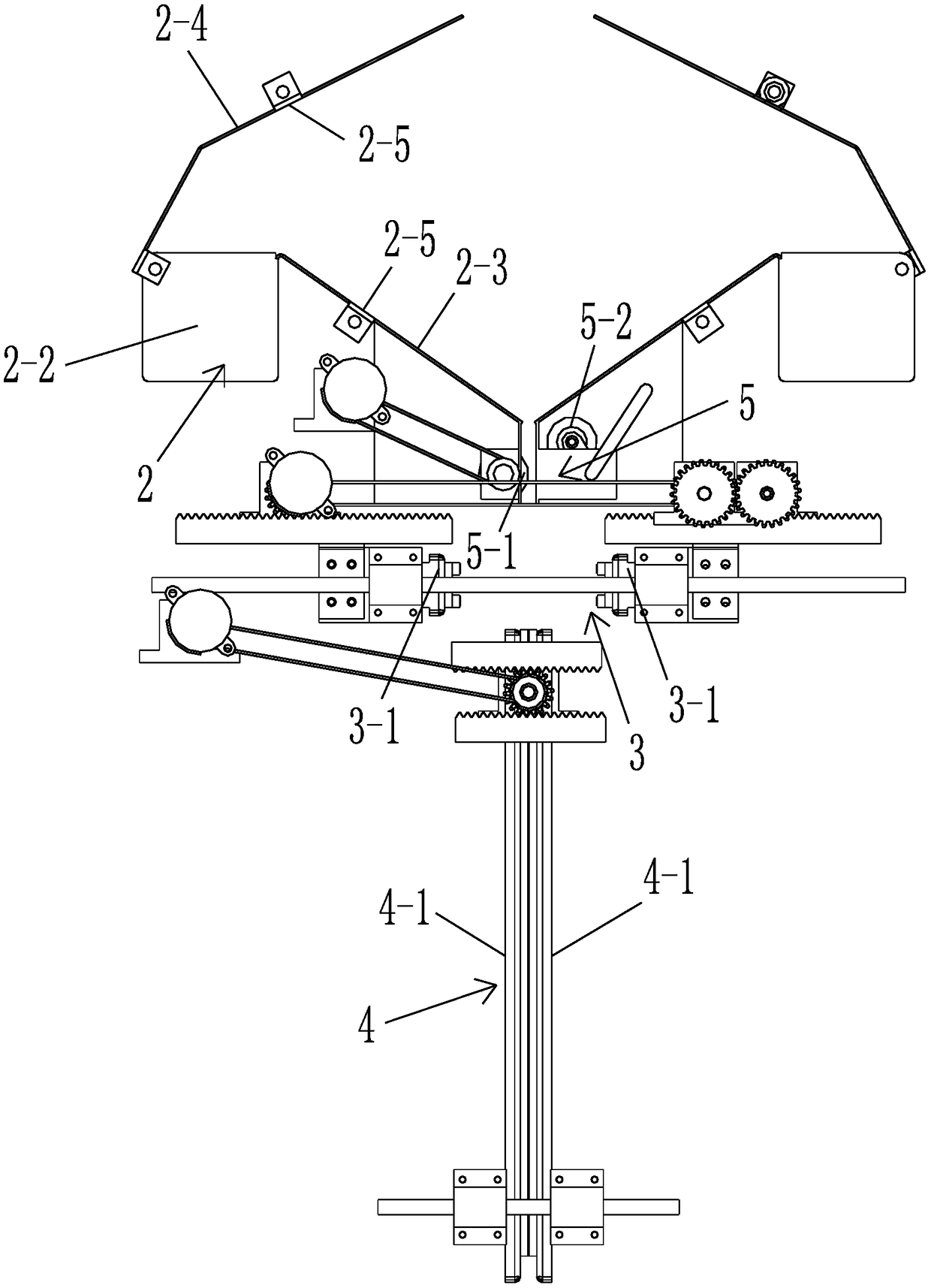

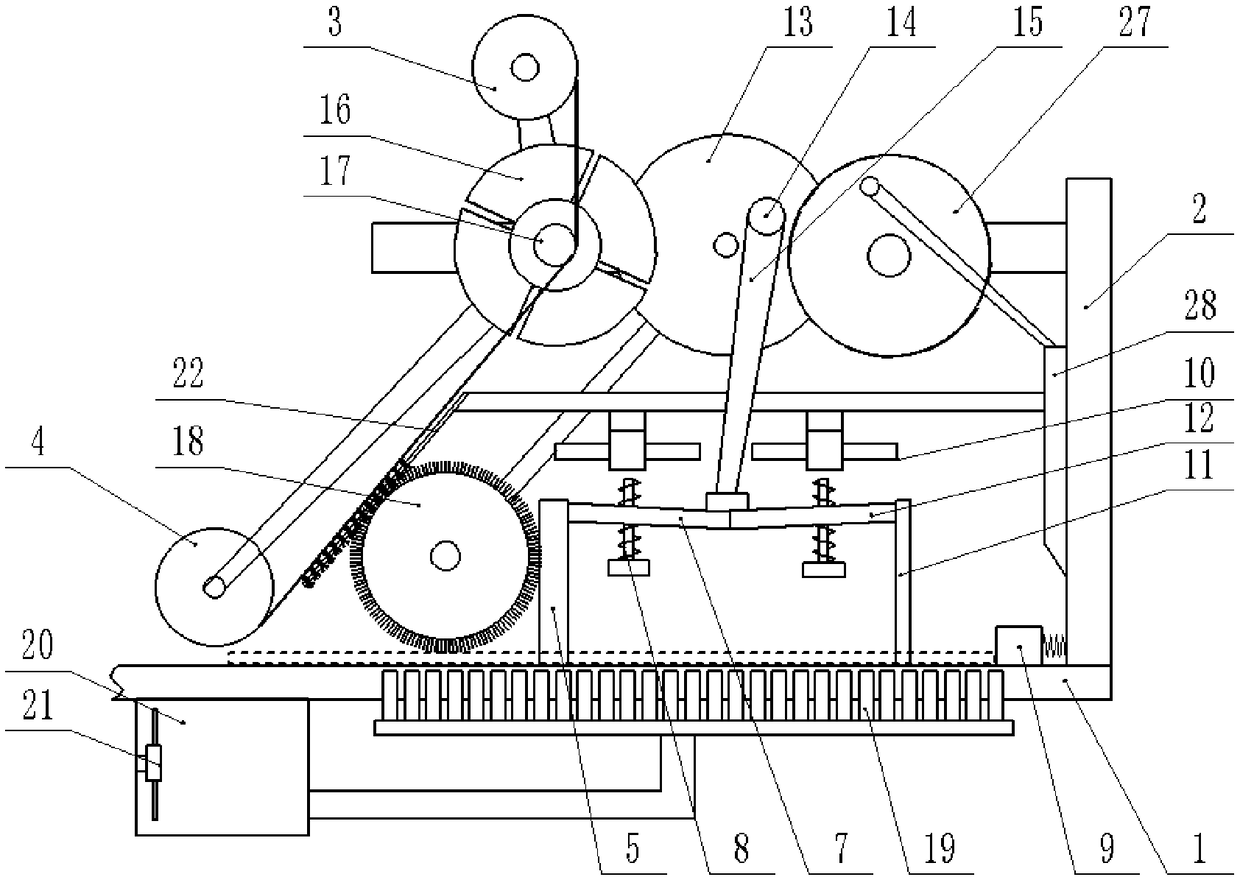

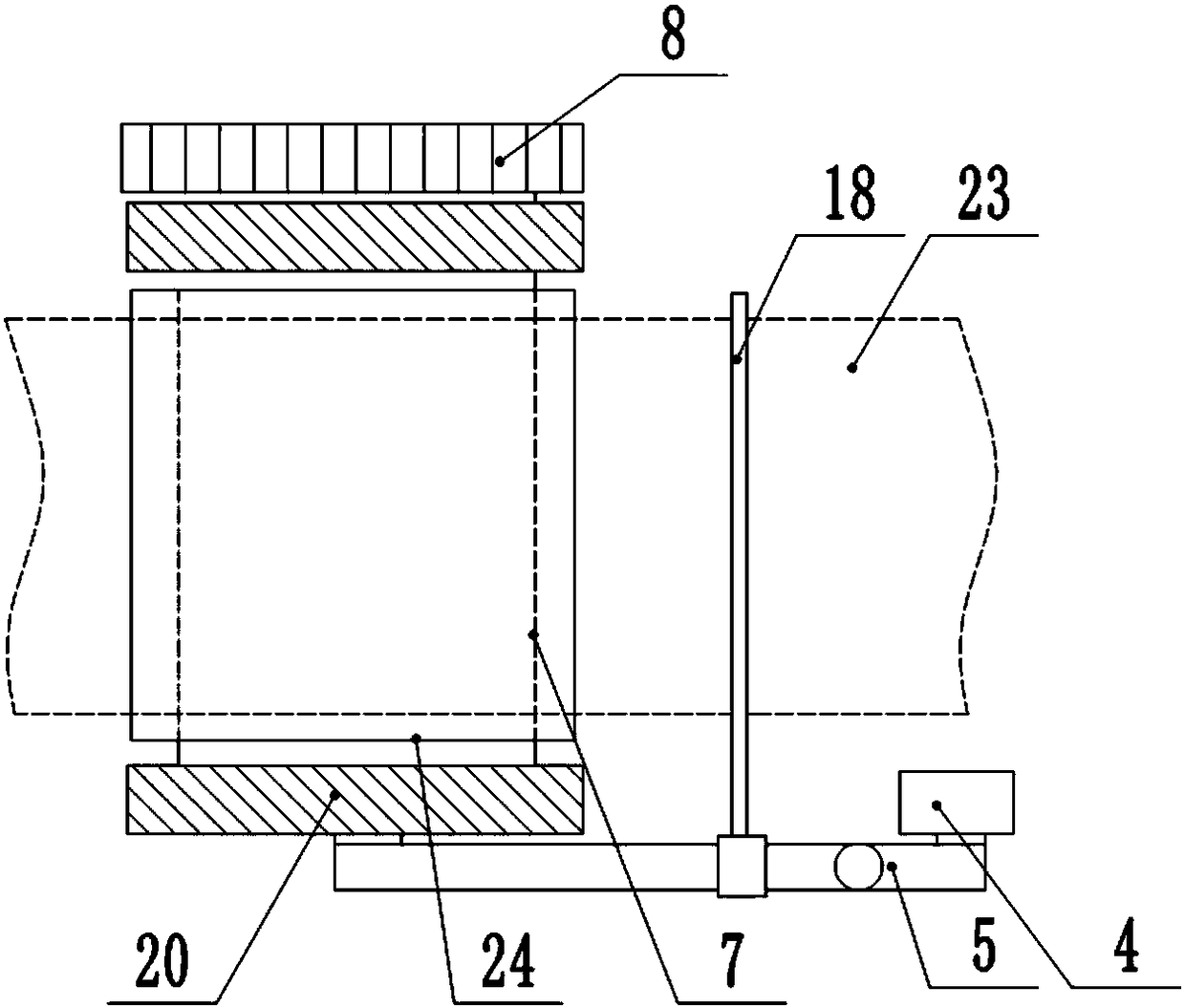

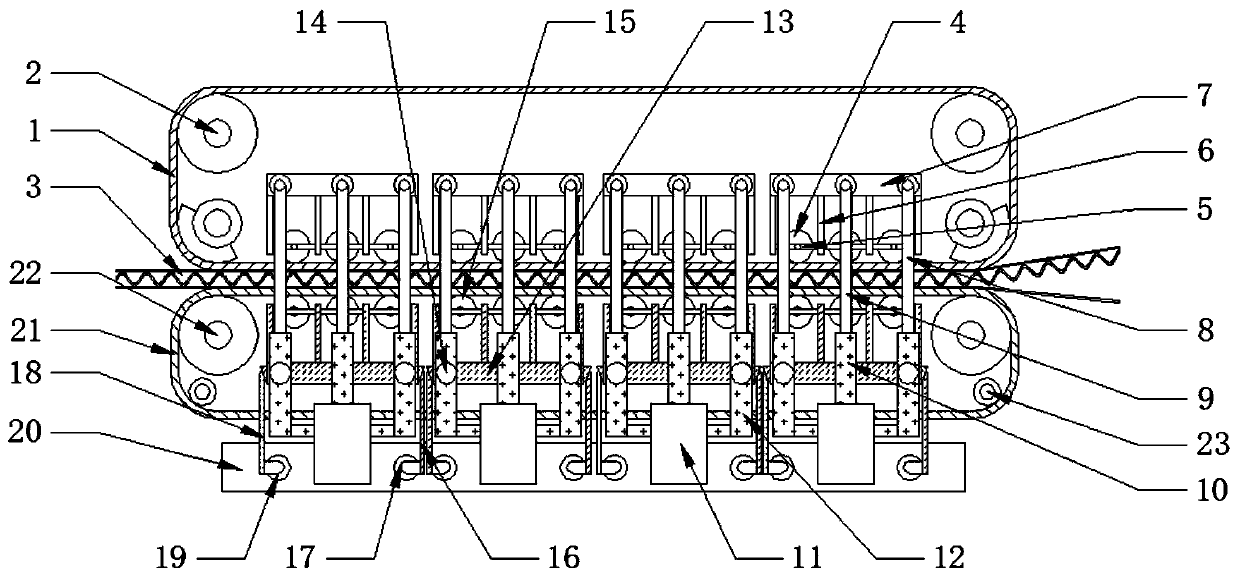

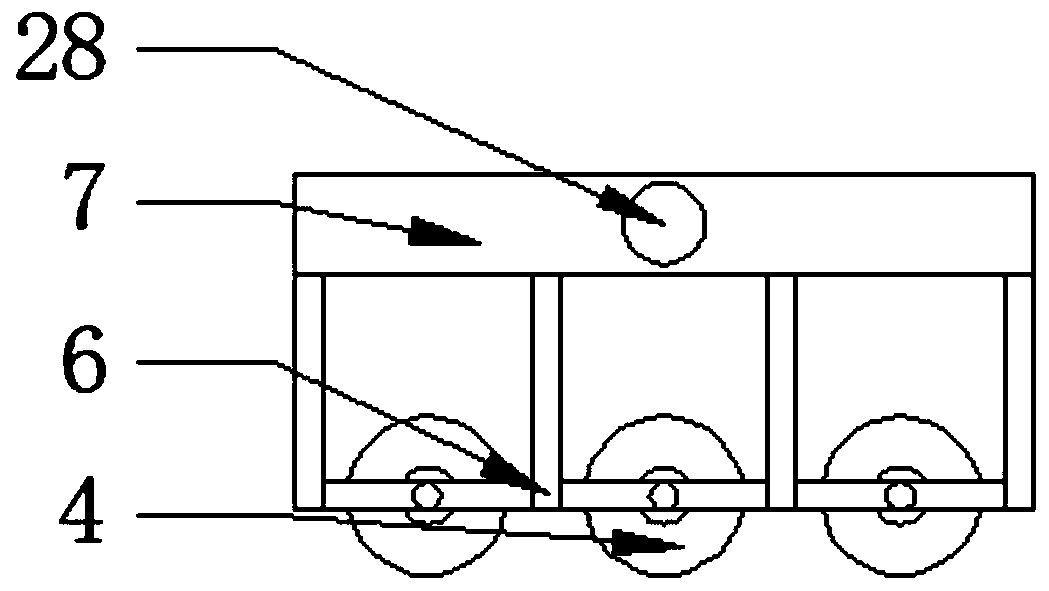

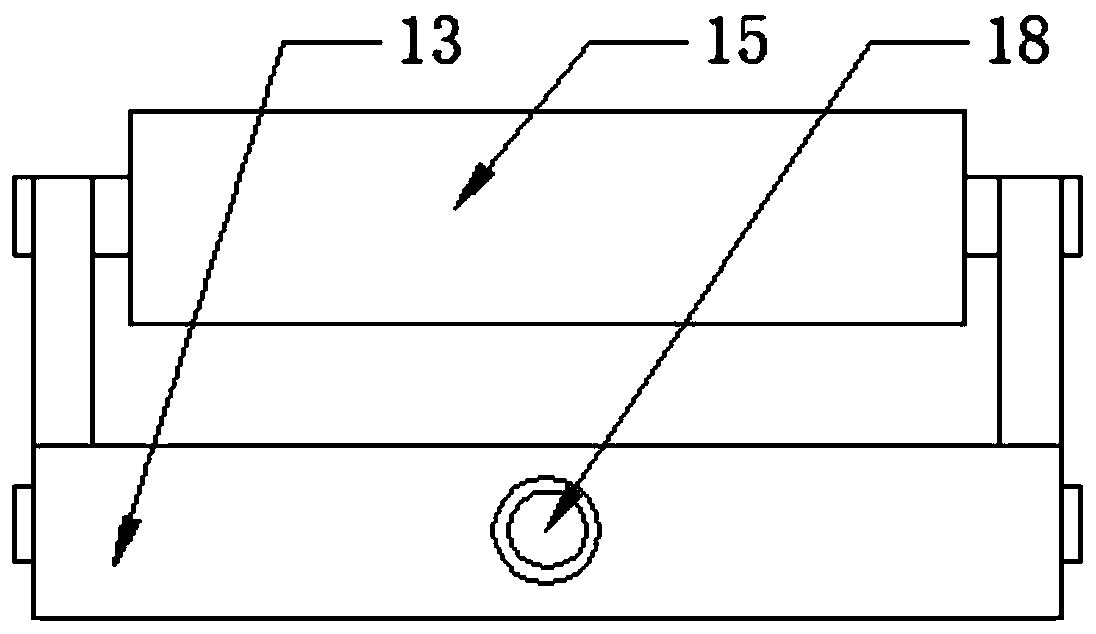

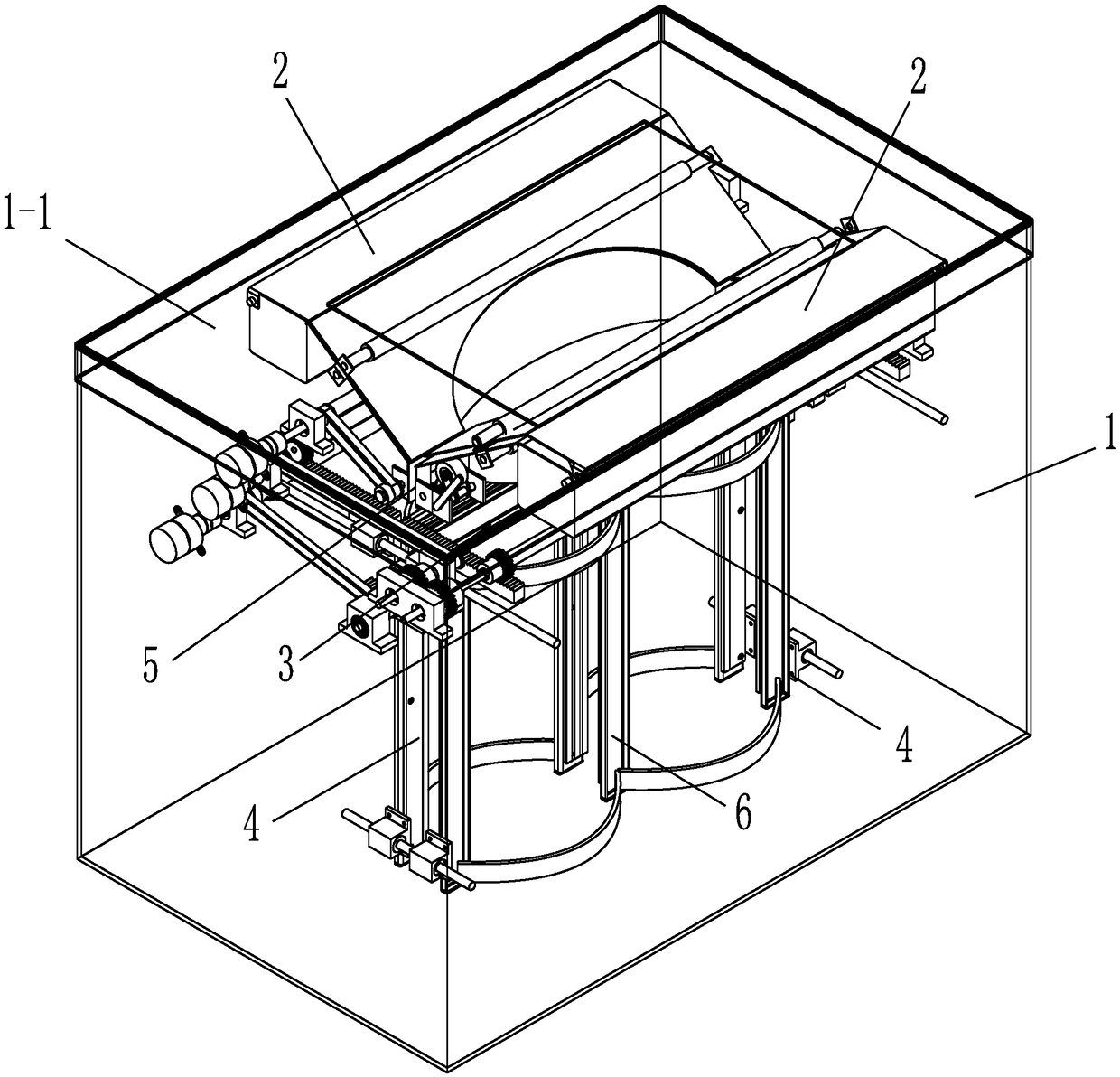

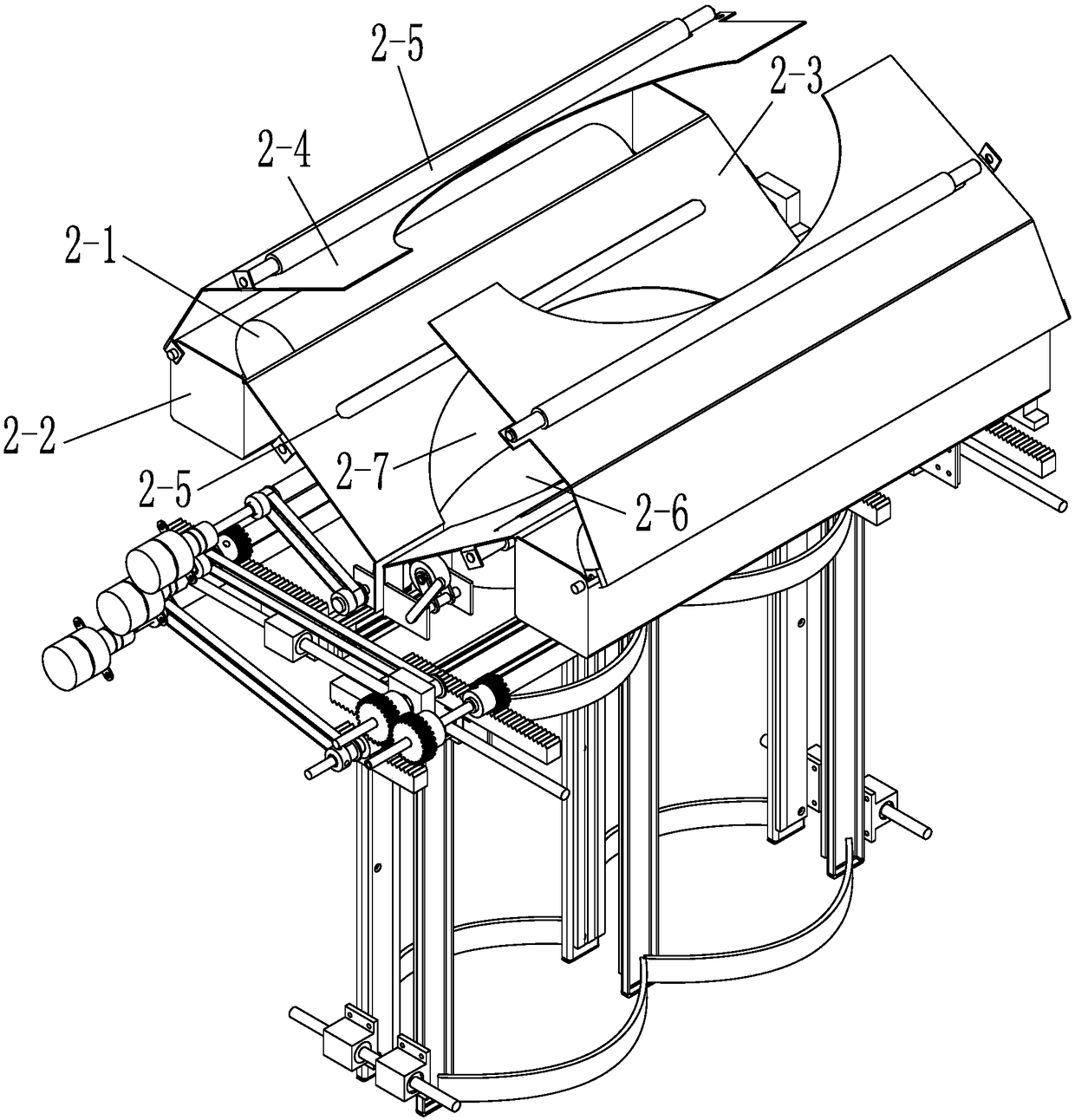

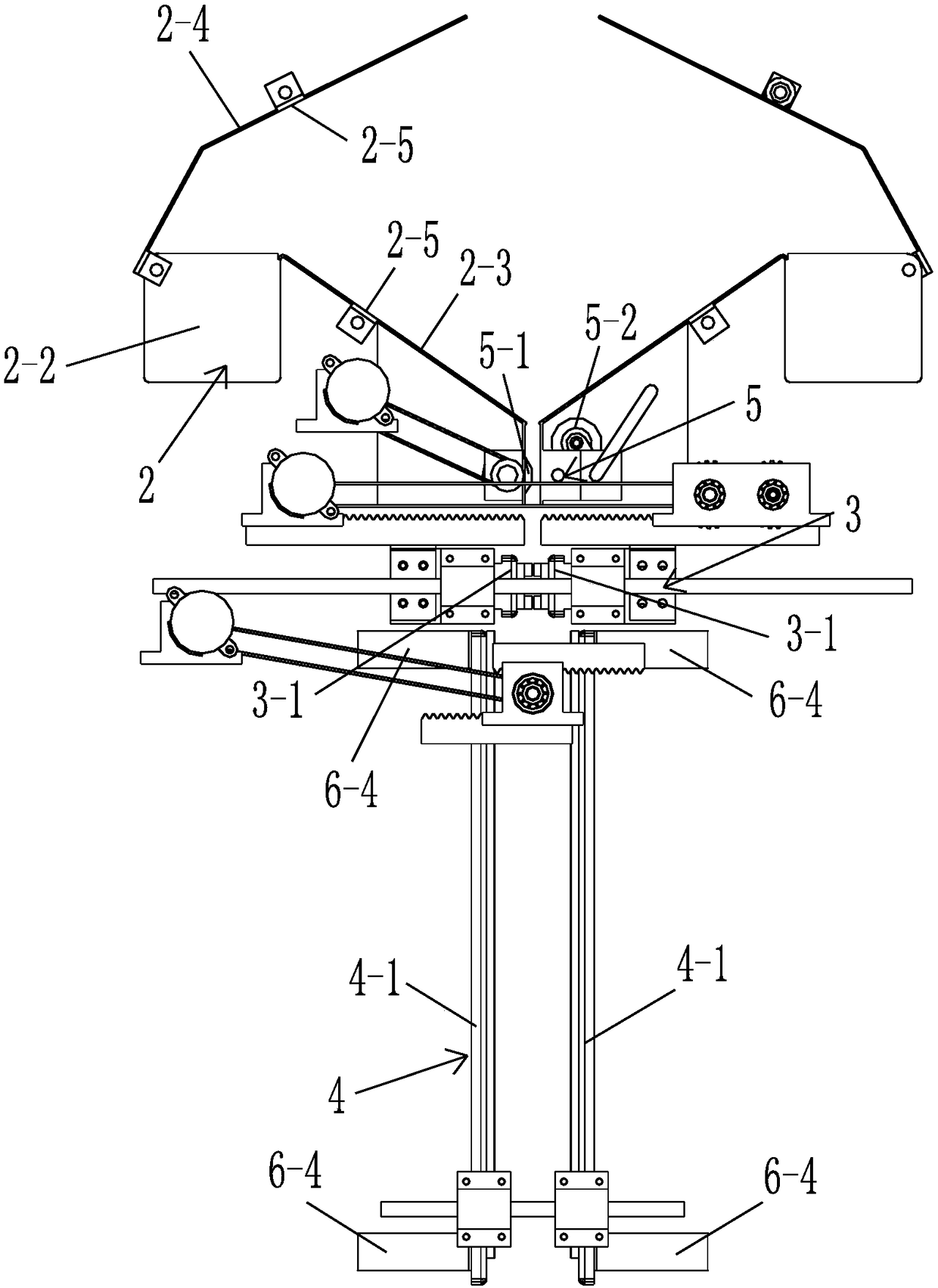

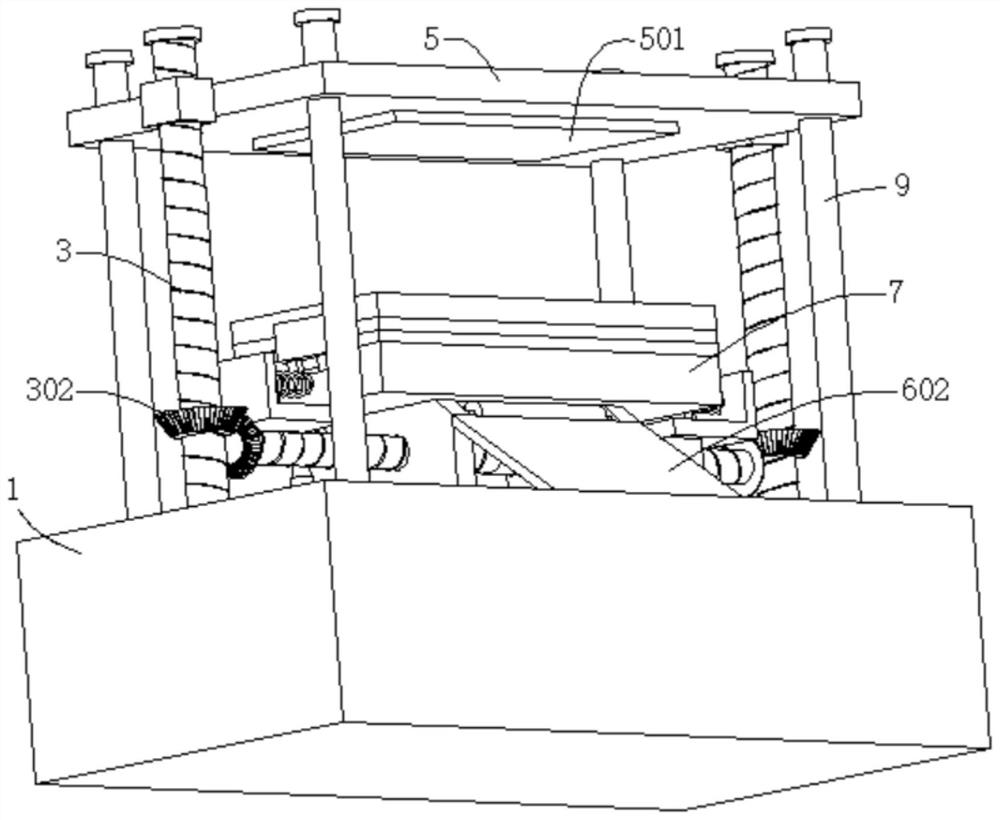

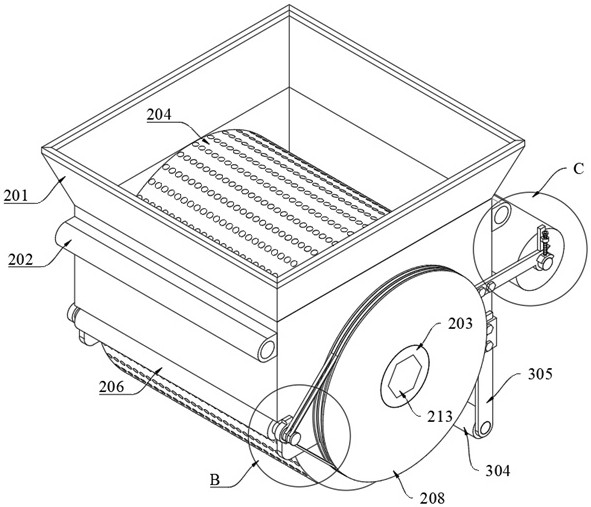

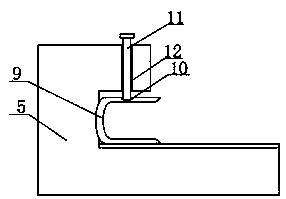

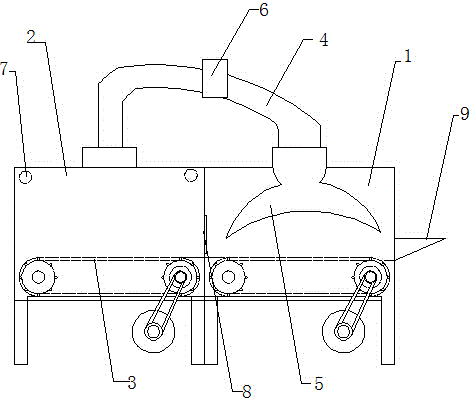

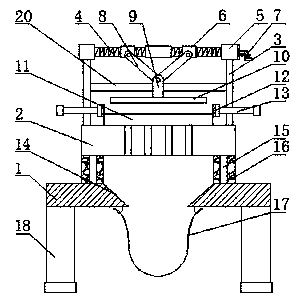

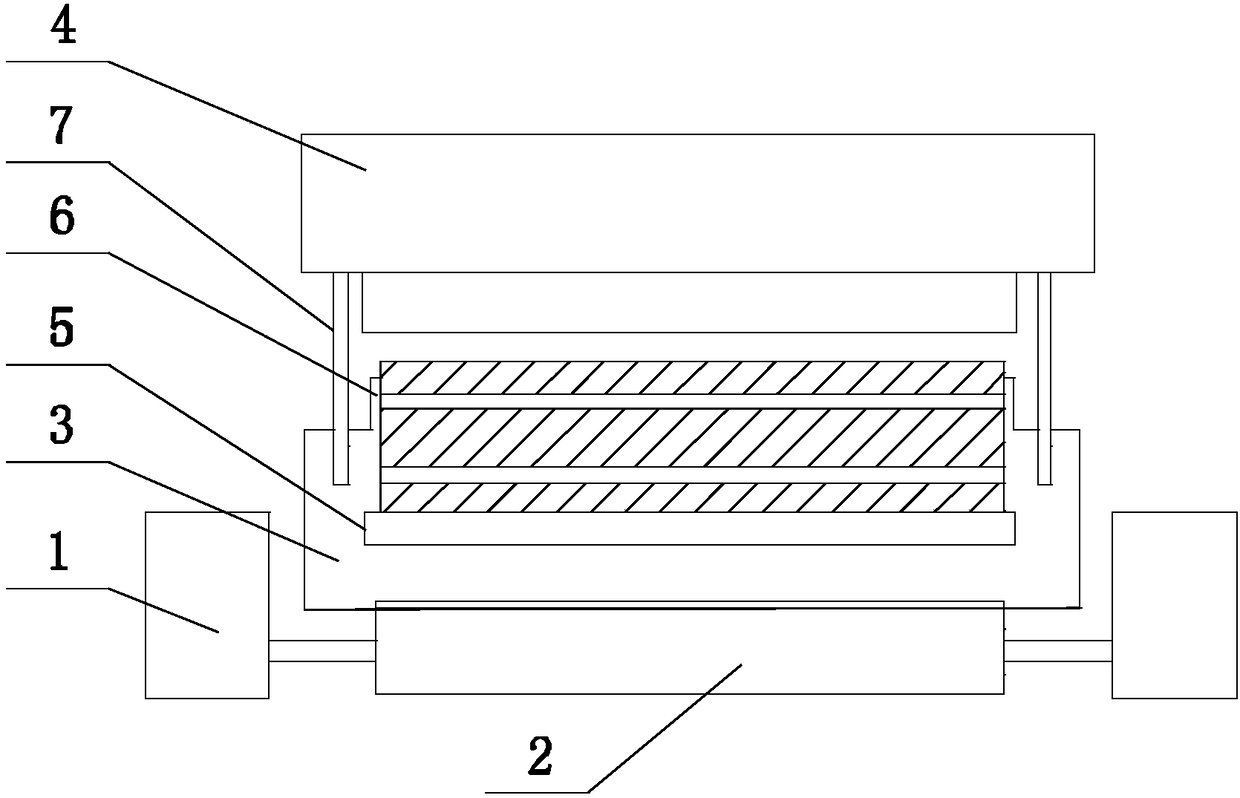

Double-faced machine for corrugated board production

InactiveCN110682607ARealize the function of group adjustmentGuaranteed lamination effectMechanical working/deformationEngineeringMachine

The invention relates to the technical field of corrugated board production and discloses a double-faced machine for corrugated board production. The double-faced machine comprises a conveying belt, wherein the conveying belt is fixedly installed on a first rotation shaft; gravity press rollers are fixedly installed inside the conveying belt; bottoms of the gravity press rollers are directly connected to the conveying belt; the gravity press rollers are installed on a first connecting rod in a rotatable manner; two ends of the first connecting rod are fixedly installed on a supporting rod; andthe upper part of the supporting rod is fixedly installed on a fixation frame. The double-faced machine disclosed by the invention has the beneficial effects that a group of the three gravity press rollers is fixedly installed on the fixation frame, and vertical motion of the fixation frame is driven by a lifting rod, so a function of grouped adjustment of the gravity press roller groups is realized; a compaction effect of the gravity press rollers on the conveying belt is ensured; loads caused by an overall lifting link of the device are relieved; vibration of the device caused by the excessive overall loads is avoided; and manufacture and processing of the double-faced machine are ensured.

Owner:江门市世昌纸业有限公司

Classification type fully-automatic bagging garbage can

PendingCN108820628AManufacturing is simpleEasy to replaceRefuse receptaclesEngineeringFully automatic

The invention relates to a classification type fully-automatic bagging garbage can. The classification type fully-automatic bagging garbage can comprises a can body, two bag output devices, a bottom seal edge cutting device, a side edge sealing device and a bag separating device, wherein the bag output devices are arranged at the left side and the right side of the upper portion of the can body correspondingly, and the bottom seal edge cutting device, the side edge sealing device and the bag separating device are arranged at the lower sides of the bag output devices. The classification type fully-automatic bagging garbage can has the advantages that multiple inner longitudinal press-fit assemblies are arranged between two outer longitudinal press-fit assemblies; each inner longitudinal press-fit assembly comprises two inner longitudinal press-fit blocks arranged at the left side and the right side of a double-layer thin film; the press-fit face of each inner longitudinal press-fit block is provided with two inner hot seal strips in a spaced manner from front to back; a longitudinal scalding-fracturing strip or longitudinal point scalding strips is arranged between every two inner hot seal strips; by means of the inner longitudinal press-fit assemblies, a bag body is divided into multiple independent small bags, and the small bags are used for containing different types of garbage; after the small bags are full and sealed, the different types of garbage are packaged independently; people can drop the small bags into a classification garbage can in a residential area conveniently; and secondary classification is achieved.

Owner:福州智澜科技有限公司

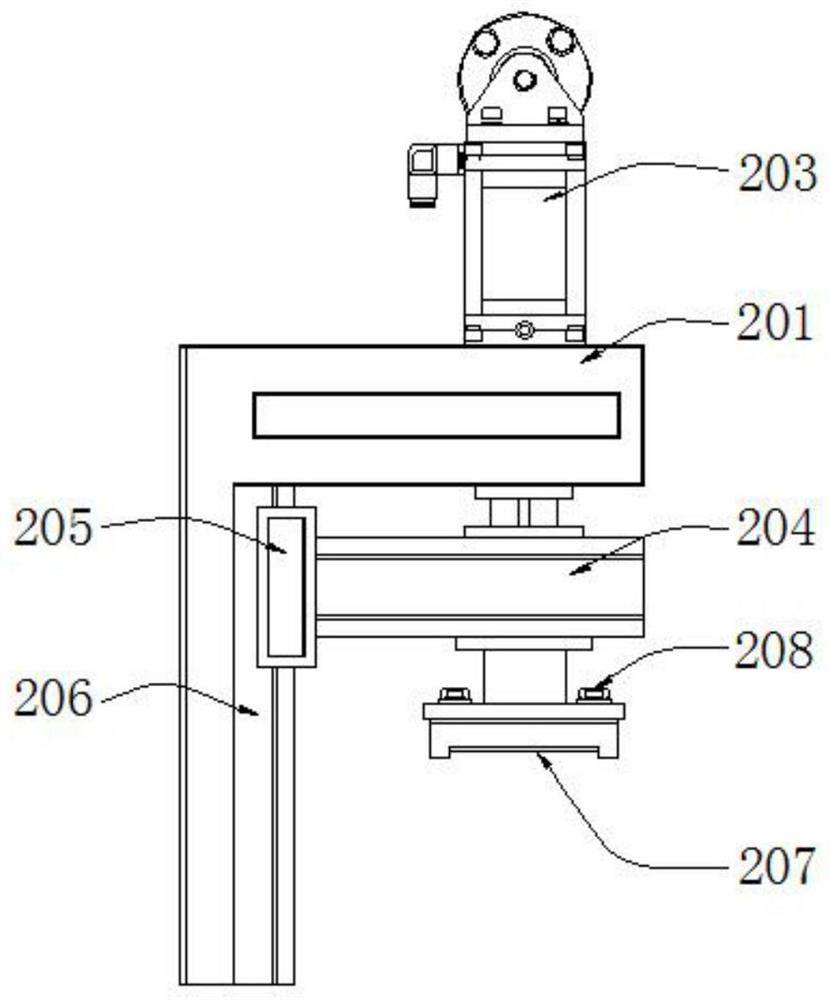

Pressing device for building insulation board processing

InactiveCN112297450ARealize clamping and fixingPrevent movementFlat articlesElectric machineArchitectural engineering

The invention discloses a pressing device for building insulation board processing, and belongs to the technical field of insulation board processing. The pressing device for building insulation boardprocessing comprises a base, wherein a cavity is formed in the base; a motor is fixedly connected to the inner wall of the cavity; a rotating shaft is connected to the output end of the motor; firstlead screws are rotationally connected to the two sides of the base through first bearings; the two first lead screws are connected with synchronous wheels matched with the outer wall of the rotatingshaft; a synchronous belt is connected between the two synchronous wheels; the outer walls of the two first lead screws are in threaded connection with first sleeves; a pressing plate is connected between the two first sleeves; and a workbench is connected to the outer wall of the top of the base. According to the pressing device, the pressing plate is used for clamping and fixing an insulation board body in the pressing process of the insulation board body, so that the force distribution can be more uniform to a certain extent, the pressing effect is guaranteed, the insulation board body is prevented from moving in the pressing process, the dislocation of multiple layers of boards is prevented, and the probability of defective products is reduced.

Owner:陈波浪

Film covering equipment for combination plate production

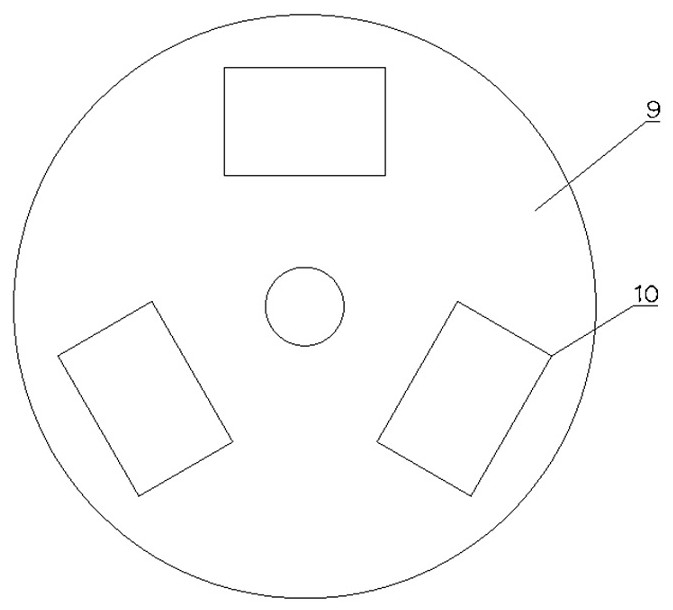

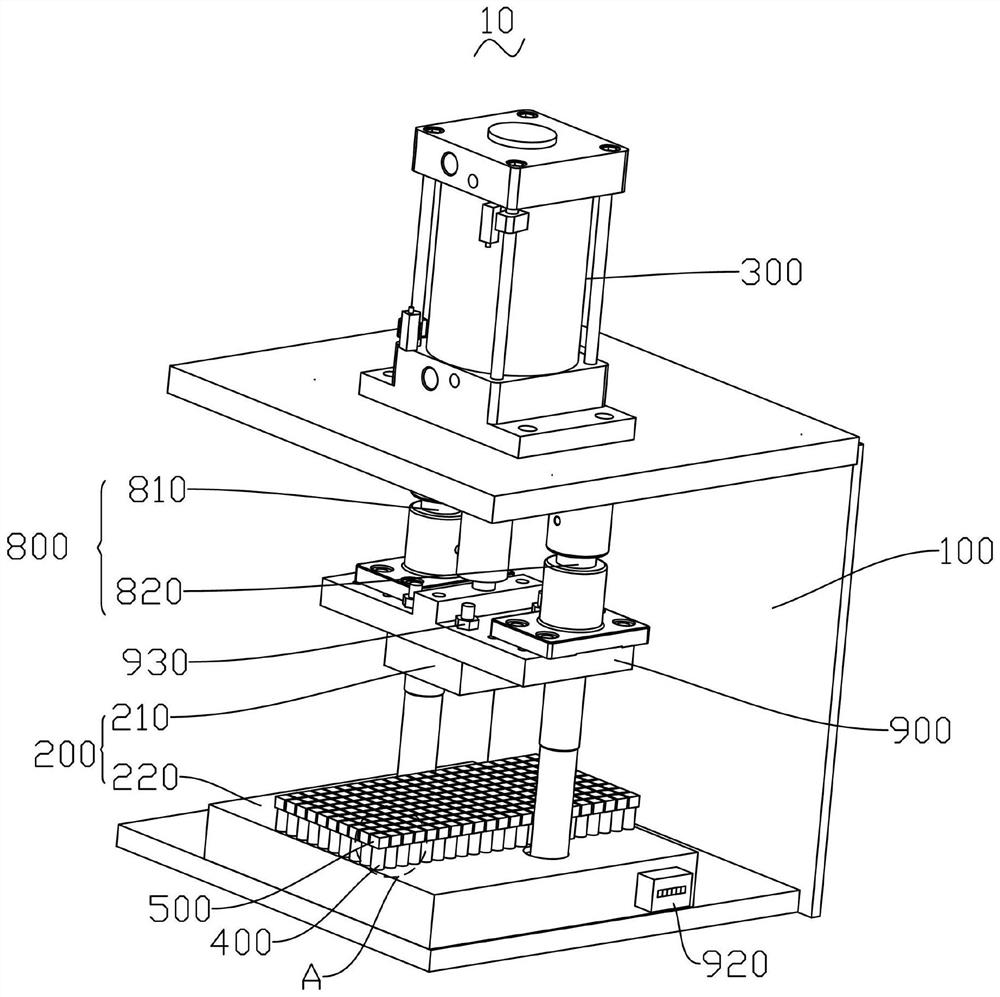

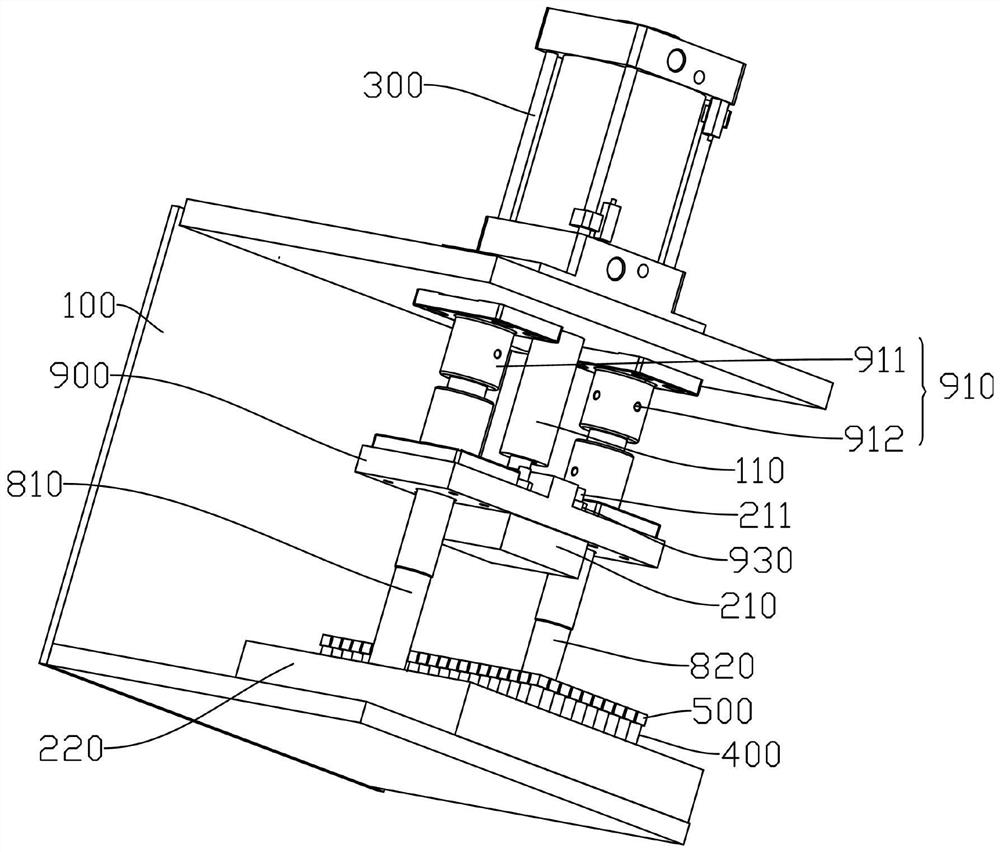

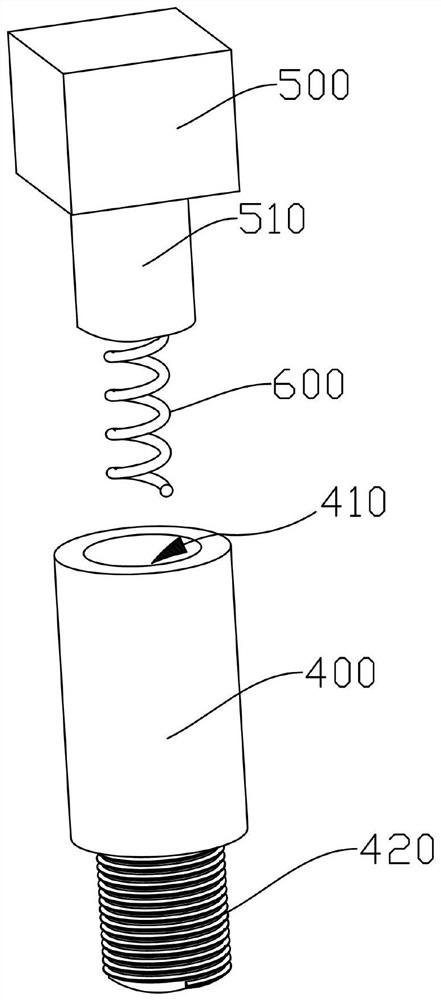

PendingCN113844150AEasy to fixEasy to leave automaticallyLaminationLamination apparatusStructural engineeringRotating disc

The invention is suitable for the technical field of PCB production equipment, and provides film covering equipment for combination plate production. The film covering equipment comprises: an equipment main body for supporting; a feeding mechanism arranged on the equipment main body and used for storing and loading combination plates for film covering, wherein the feeding mechanism comprises a rotating disc rotating intermittently, and a plurality of mounting grooves used for containing the combination plates are formed in the rotating disc. and a pressing mechanism arranged on the equipment main body, wherein the pressing mechanism comprises a sliding rod arranged on the equipment main body in an up-down reciprocating sliding mode, an extrusion plate is arranged in the middle of the bottom of the sliding rod, fixing assemblies are arranged on the two sides of the extrusion plate correspondingly, and each fixing assembly comprises a plurality of abutting balls which are elastically arranged on the sliding rod and are lower than the extrusion plate. According to the invention, a continuously-sliding sliding rod is arranged to drive an extrusion plate to drive abutting balls to move up and down in a reciprocating mode, and a rotating disc rotates, so that combination plates are continuously provided, and continuous pressing is achieved.

Owner:AOSHIKANG TECH CO LTD

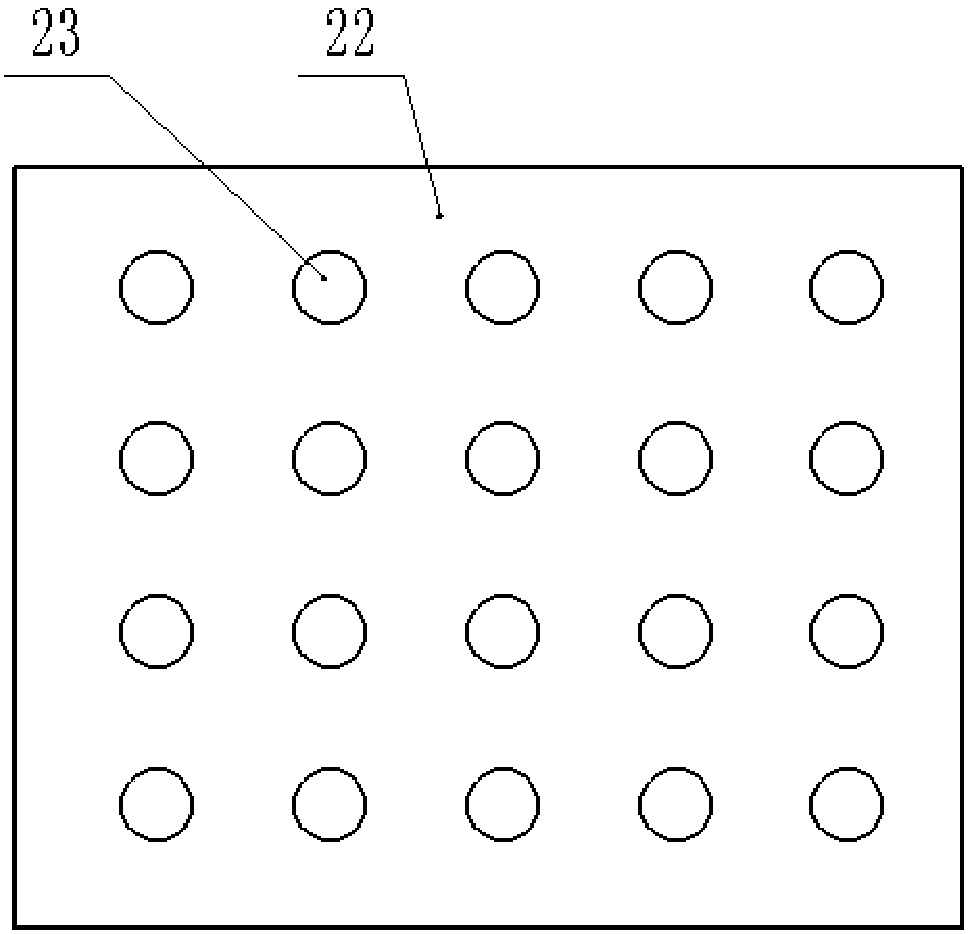

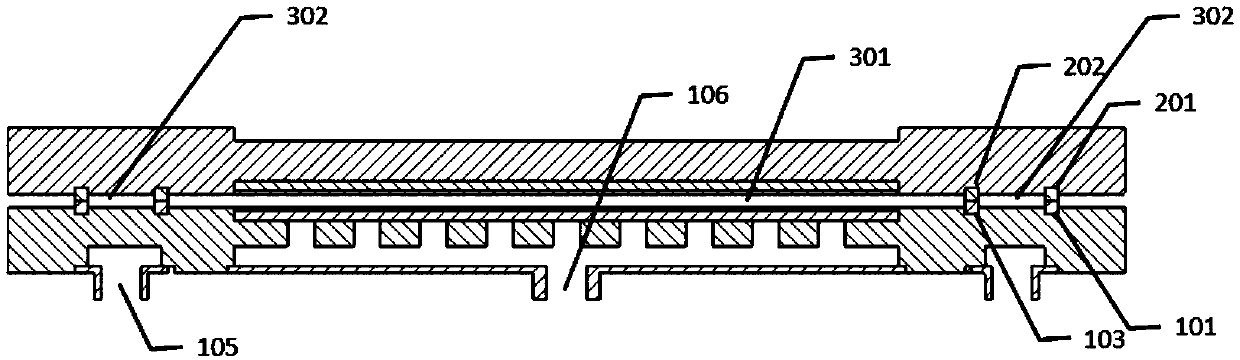

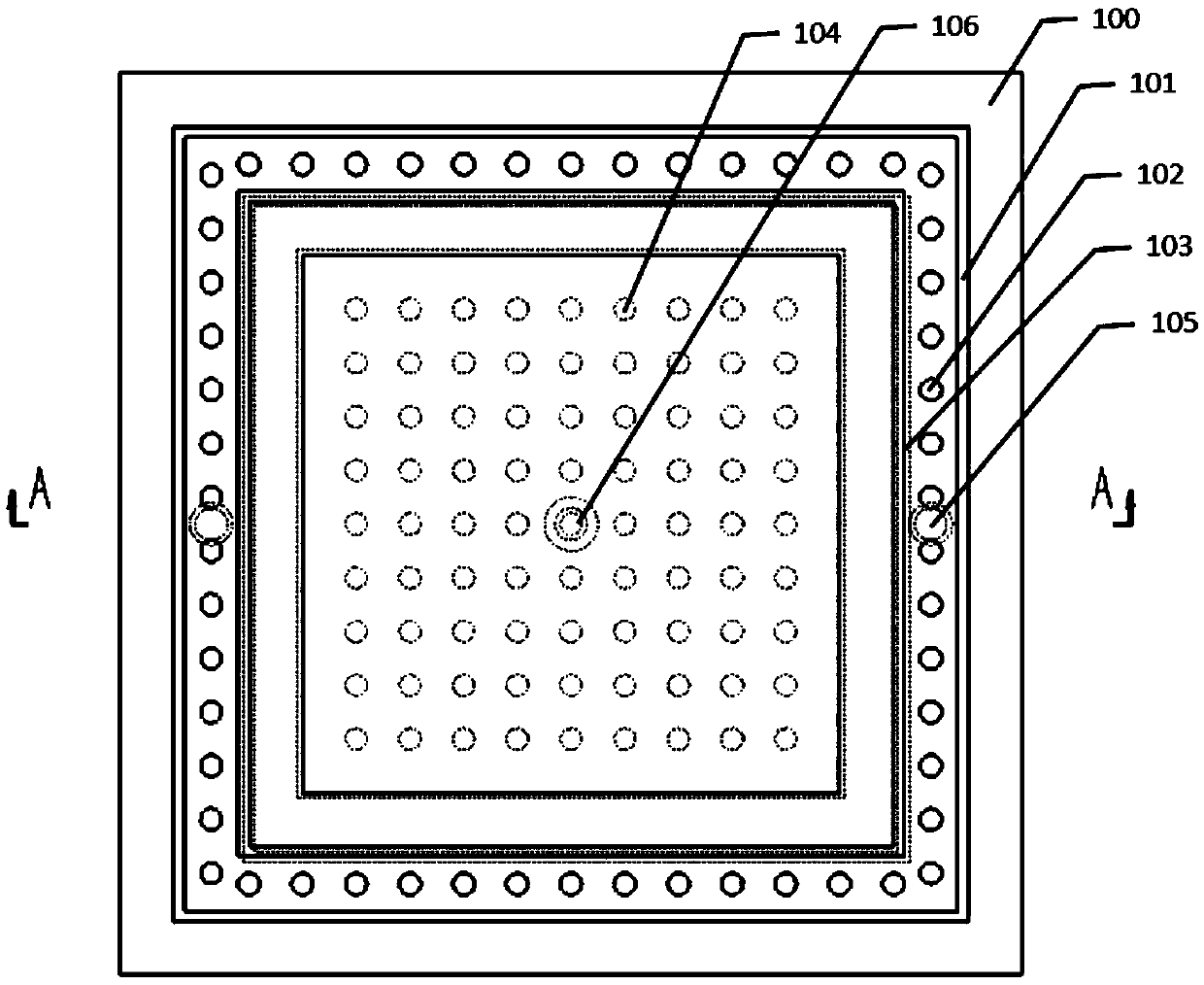

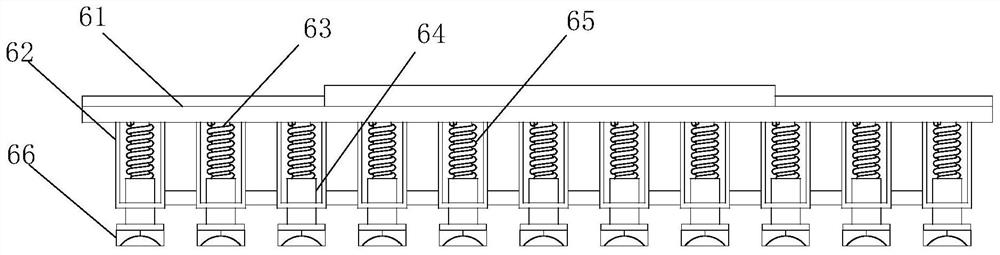

High-strength multilayer circuit board online pressing device

ActiveCN114245622AGuaranteed smoothIncrease elasticityMultilayer circuit manufactureStructural engineeringRubber sheet

The invention relates to an online pressing device for a high-strength multilayer circuit board. The online pressing device comprises a rack, a pressing assembly, a driver, a plurality of supporting columns, a plurality of rubber blocks and a plurality of elastic pieces, the driver is arranged on the rack; the pressing assembly comprises a pressing plate and a base plate, the driver is in driving connection with the pressing plate, the base plate and the pressing plate are oppositely arranged, the base plate is connected with the rack, the driver is used for driving the pressing plate to be close to or away from the base plate, and the pressing plate is a first rubber plate; the supporting columns are arranged on the face, facing the pressing plate, of the base plate in a protruding mode, the supporting columns are arranged in a matrix mode, one end of each supporting column is provided with a telescopic cavity, each rubber block is provided with a connecting part in a protruding mode, each elastic piece is arranged in the corresponding telescopic cavity, each connecting part is inserted into the corresponding telescopic cavity, one end of each elastic piece is connected with the corresponding connecting part, and the other end of each elastic piece is connected with the corresponding rubber block. And the other end of the elastic piece is connected with the bottom of the telescopic cavity, so that each rubber block forms an independent subarea on the substrate, the lamination device can adapt to positioning of multi-layer circuit boards with different specifications, and the applicability of the lamination device is improved.

Owner:惠州城市职业学院

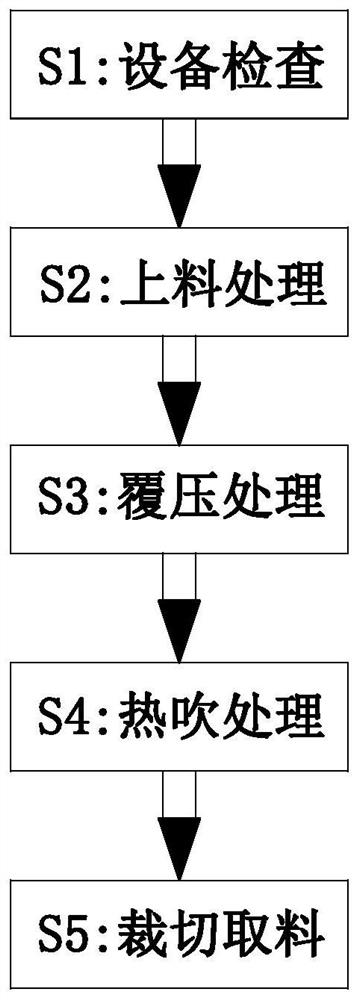

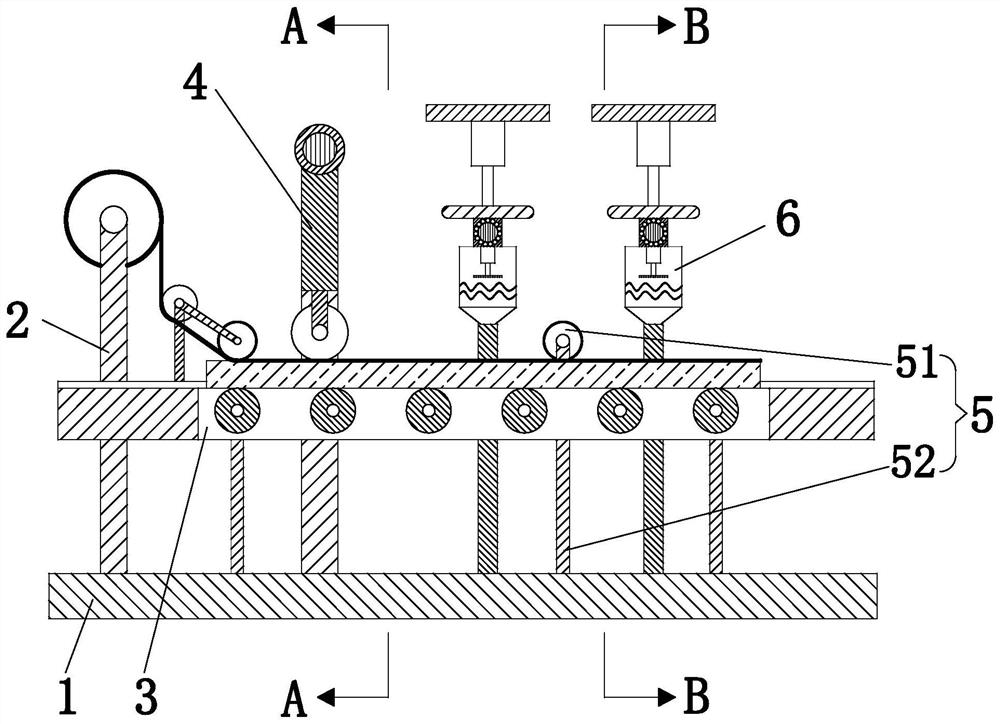

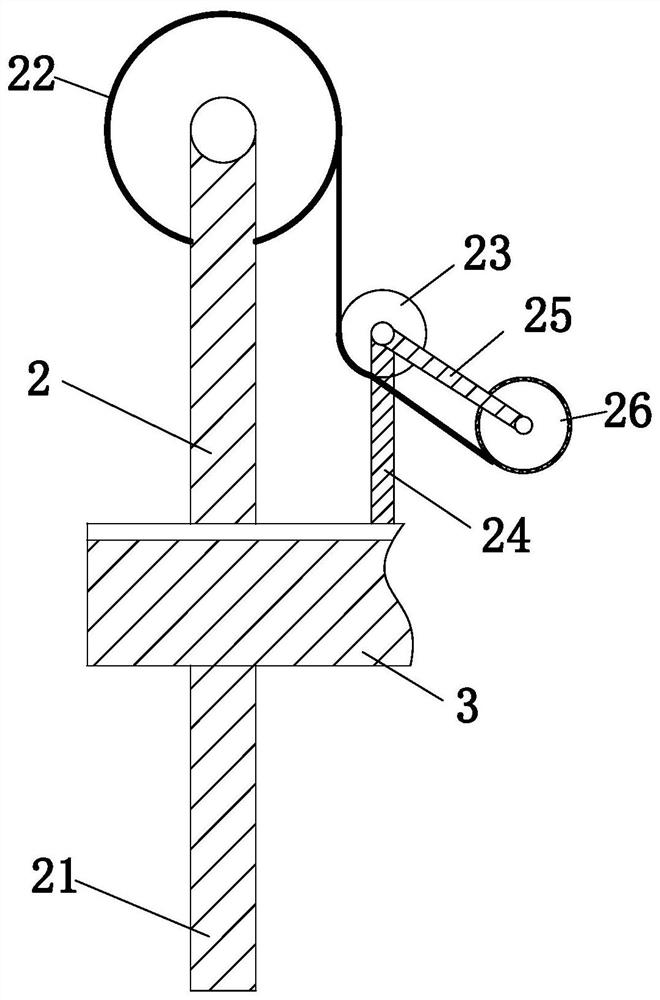

Manufacturing and processing method of heat-preservation, energy-saving and decoration integrated plates

InactiveCN112318865AChange the conveying directionImprove efficiencyCovering/liningsFlat articlesHeat conservationPlastic film

The invention relates to a manufacturing and processing method of heat-preservation, energy-saving and decoration integrated plates. Manufacturing and processing equipment of the heat-preservation, energy-saving and decoration integrated plates comprises a bottom plate, an unwinding device, a conveying device, a film covering device, a smoothing mechanism and hot blowing devices, wherein the unwinding device is arranged at the left end of the bottom plate, the conveying device is placed on the right side of the unwinding device, the film covering device is installed at the position, close to the left end, of the conveying device, the smoothing mechanism is arranged on the right side of the film covering device, and the hot blowing devices are symmetrically arranged on the left side and theright side of the smoothing mechanism. The method can solve the following defects possibly existing in an existing film covering mode of the heat-preservation, energy-saving and decoration integratedplates: a, plastic films are manually laid on the heat-preservation, energy-saving and decoration integrated plates and are manually flattened, the flattening effect is difficult to judge, and the required time is long, so that the film covering efficiency is low, and the film covering effect is poor; and b, when the number of the heat preservation, energy-saving and decoration integrated platesis large, much labor force is input in the film covering process, consumed time is long, efficiency is reduced, and benefits of enterprises are affected.

Owner:深圳正宇机电科技有限公司

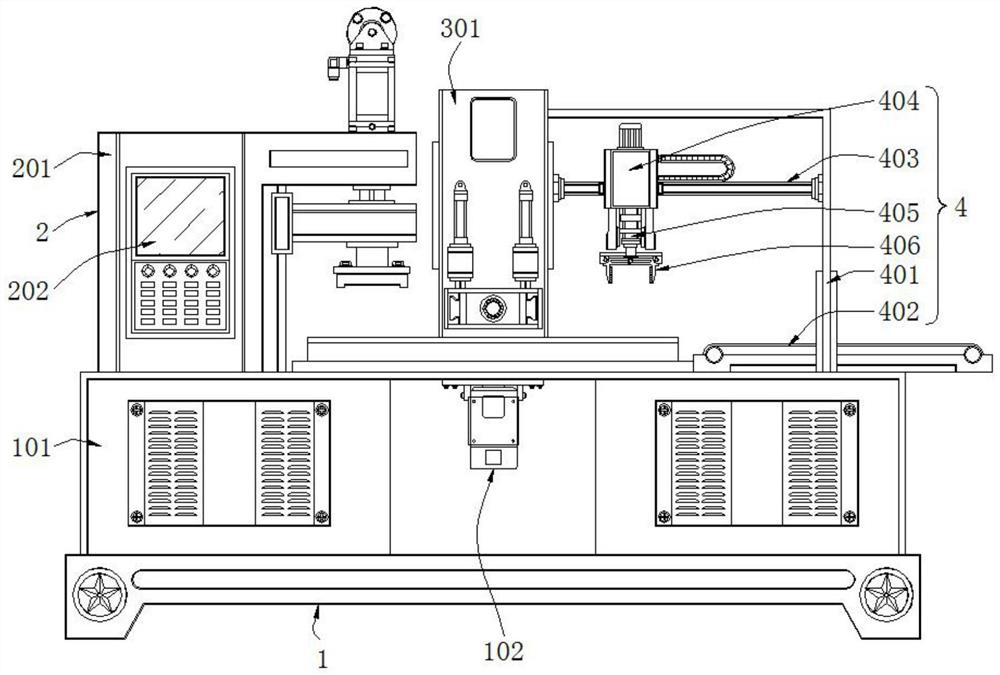

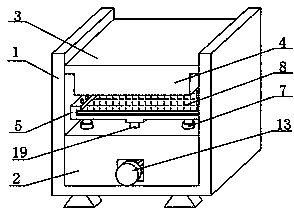

Electronic cigarette pressing and testing all-in-one machine

PendingCN113303518AEasy to useEasy to replaceMeasurement devicesTobaccoStructural engineeringElectronic cigarette

The invention discloses an electronic cigarette pressing and testing all-in-one machine, and relates to the technical field of electronic cigarette processing. The machine comprises a main machine body and a testing assembly, the left side of the upper end of the main machine body is provided with a pressing assembly, the testing assembly is arranged in the rear middle of the upper end of the main machine body, and the testing assembly comprises a connecting seat, an adjusting cylinder, a fixing frame, limiting sliding rails, limiting sliding blocks, a placement carrier plate, a testing plug connecting groove and a testing plug. According to the invention, the height of the testing plug can be adjusted according to the model of an actually tested electronic cigarette through the lifting fixing frame, so that the connection accuracy between the testing plug and the electronic cigarette is ensured; and the limiting slide blocks arranged at the two sides of the placement carrier plate cooperate with the limiting slide rails arranged at the two sides in the fixing frame, so that the placement carrier plate can be pushed by an electric push rod at the inner rear end to horizontally and linearly move, an automatic plugging test between the placement carrier plate and the electronic cigarette is realized, and the actual use effect of the all-in-one machine is improved.

Owner:SHENZHEN HANQINGDA TECH CO LTD

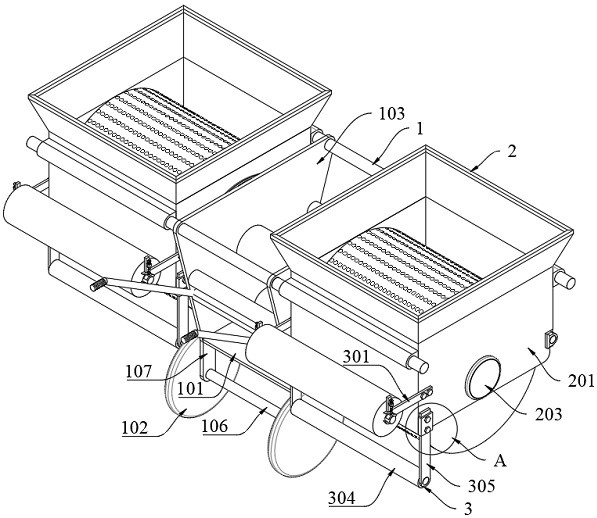

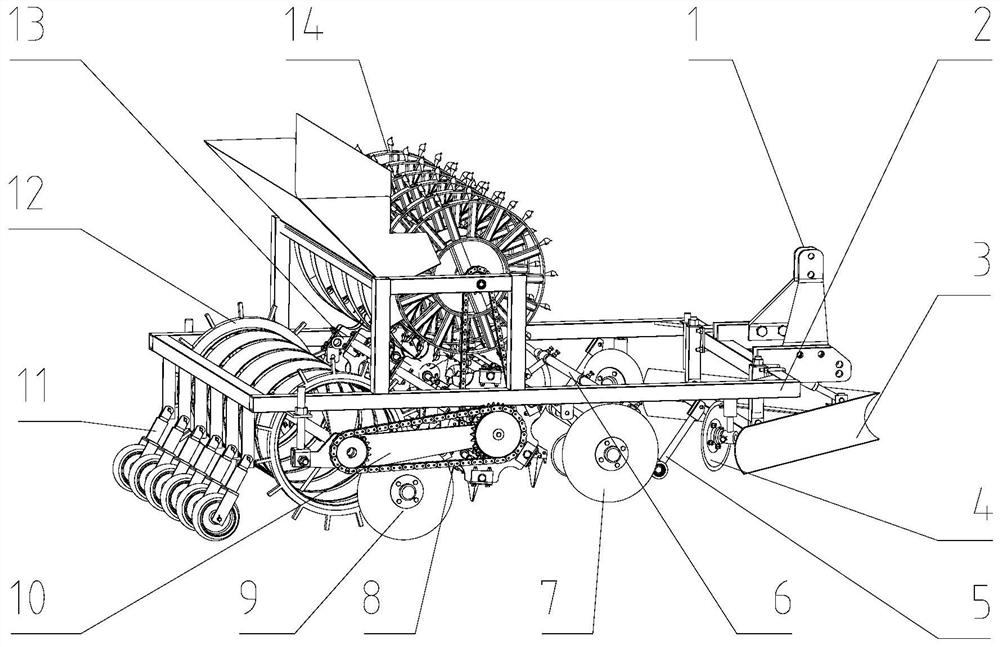

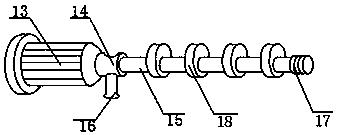

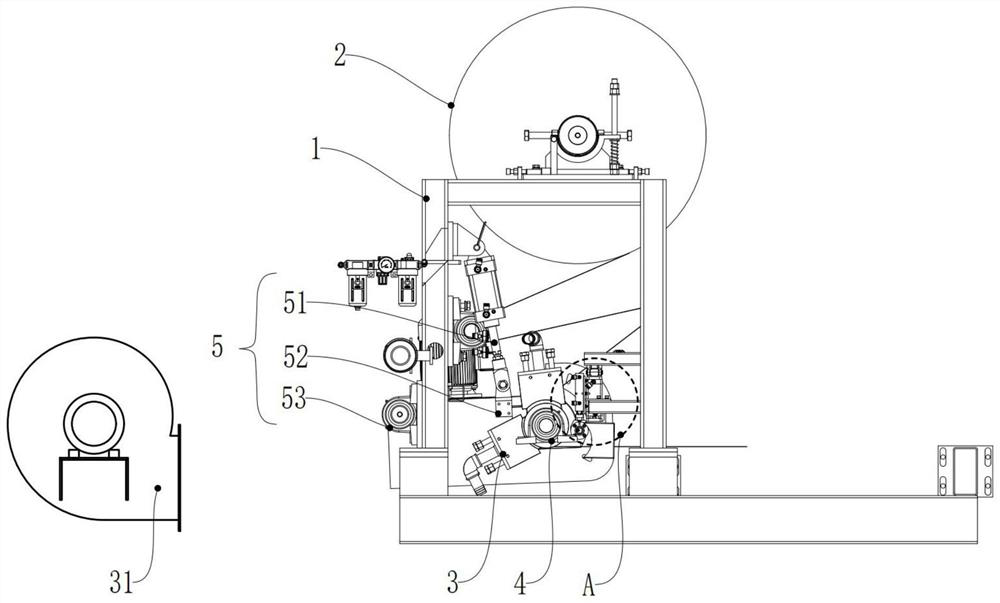

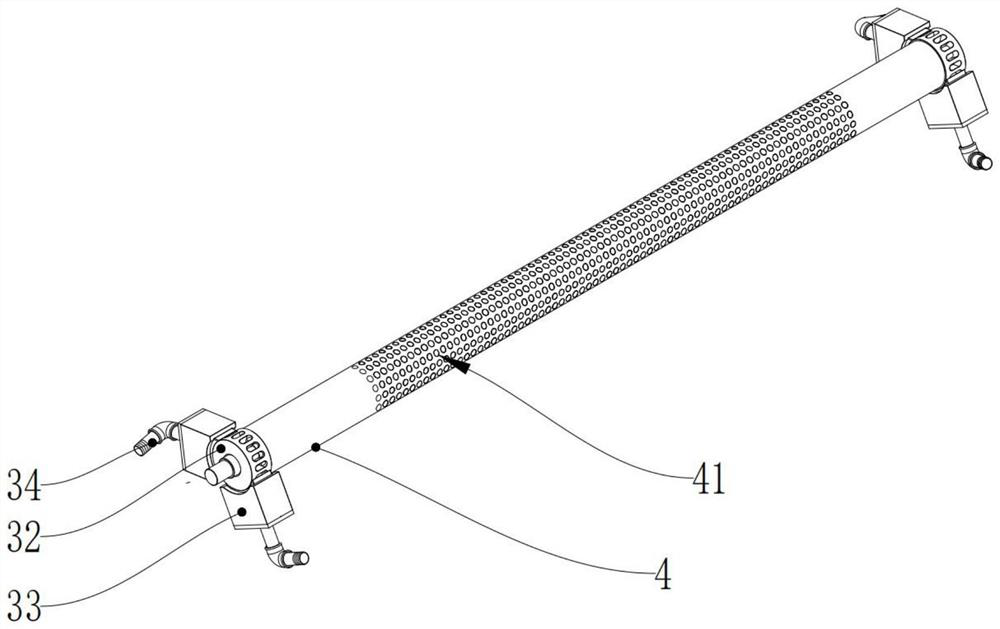

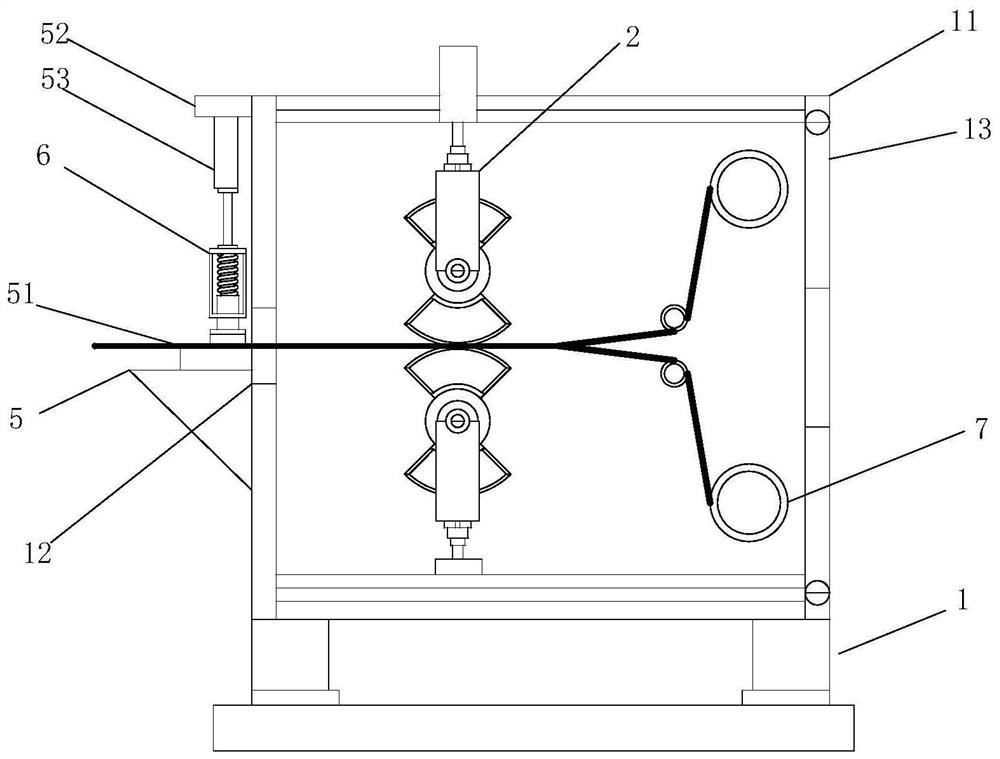

Broadcast sowing and ground cloth covering device

InactiveCN113099789AGuaranteed lamination effectSpread evenlySeed depositing seeder partsBroadcast seedersDrive shaftAgricultural engineering

The invention provides a broadcast sowing and ground cloth covering device. The broadcast sowing and ground cloth covering device comprises a transfer mechanism, broadcast sowing mechanisms and a film covering mechanism, the transfer mechanism comprises a transfer plate, multiple pairs of rollers are symmetrically arranged at the bottom of the transfer plate, supporting plates are arranged at the two ends of the top of the transfer plate, sliding rods are inserted into the tops of the supporting plates, and driving shafts are rotationally connected to the middles of the supporting plates; the broadcast sowing mechanisms are horizontally and slidably arranged at the two ends of the sliding rods, each broadcast sowing mechanism comprises a cavity, limiting cylinders are arranged on the outer walls of the two side walls of the cavity, the sliding rods are slidably sleeved with the limiting cylinders, the bottom of the cavity is rotationally connected with a rotating shaft, the rotating shaft is sleeved with a sowing roller, a sowing groove is formed between the sowing roller and the inner wall of the other side wall of the cavity, and an adjusting roller is rotationally arranged at the sowing groove; and the film covering mechanism comprises a pair of supporting rods, one ends of the supporting rods are fixed to the cavities, clamping grooves are formed in the other ends of the supporting rods, film covering rollers can be installed in the clamping grooves, and the film covering rollers are matched with guide rollers. According to the invention, seeds can be uniformly sown on a heap box, the ground cloth can be automatically laid after sowing is completed, the ground cloth can be kept in a tensioning state by adjusting the rotation resistance of the film covering rollers, and the film covering effect is guaranteed.

Owner:乐山长藿中药材有限公司

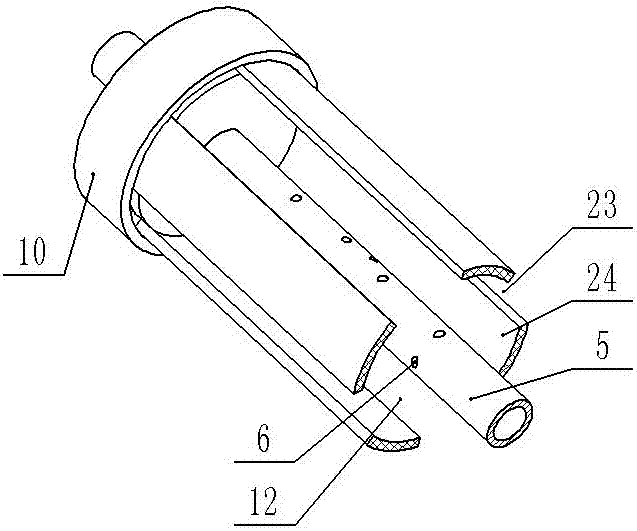

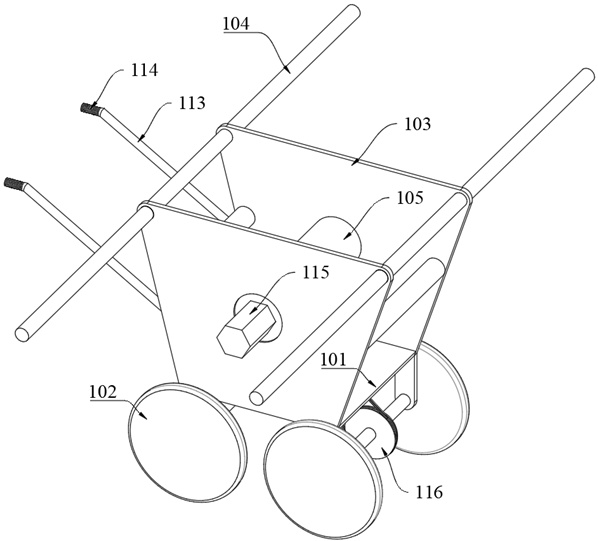

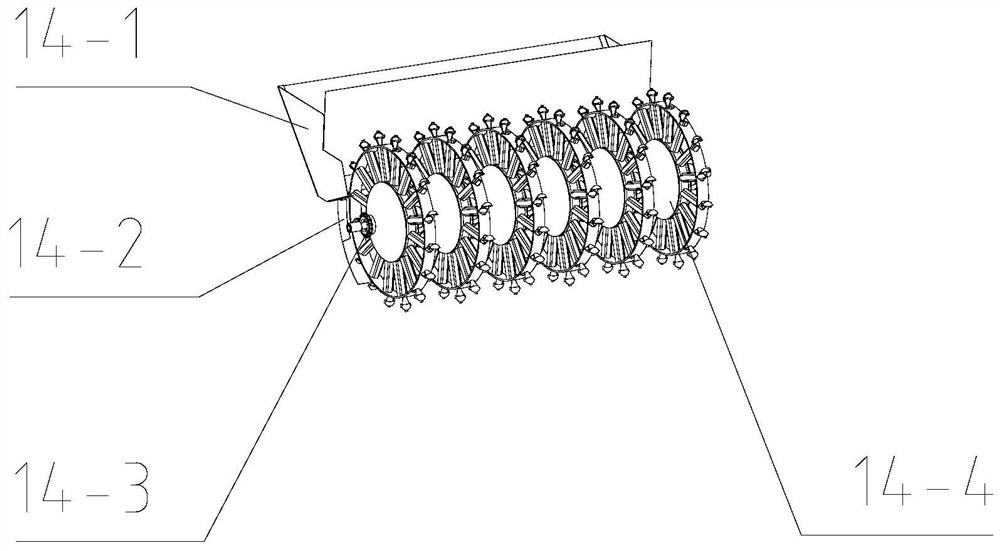

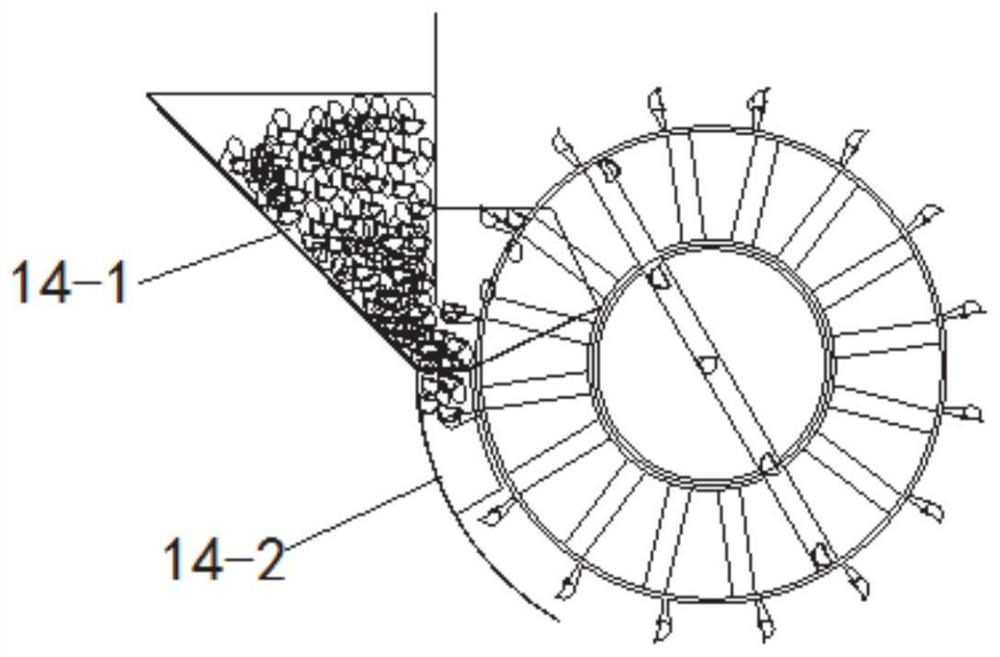

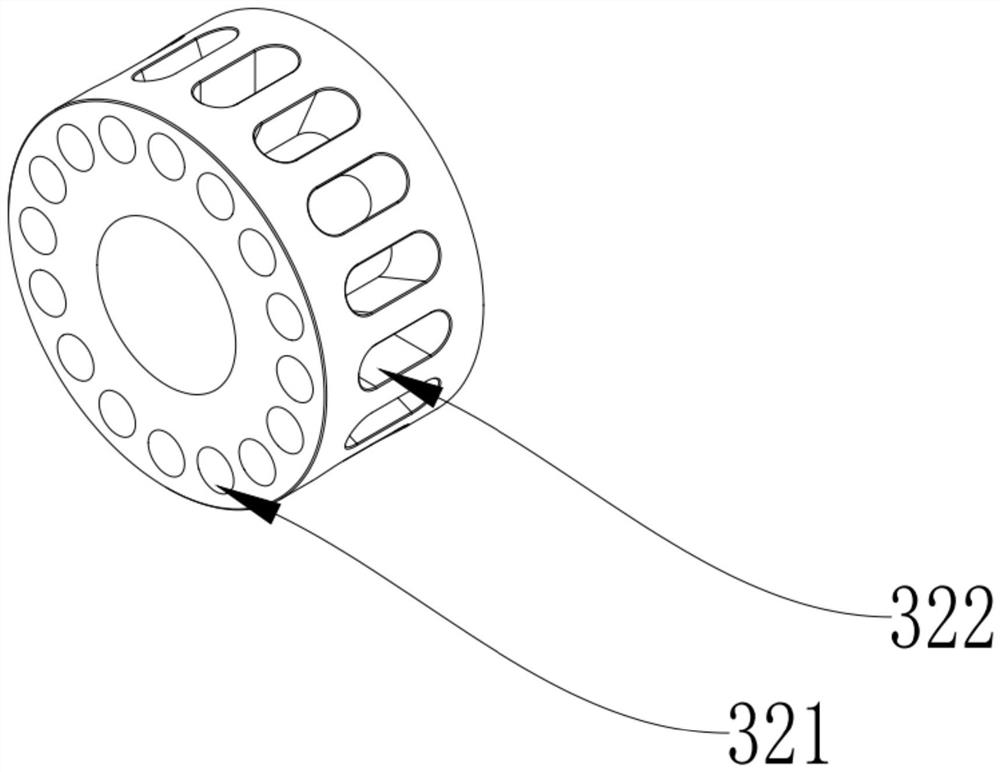

Inner channel type seed taking and direction changing device and on-film garlic planting machine

ActiveCN111919558ARealize continuous operationRealize directional deliveryClimate change adaptationPotato plantersAgricultural engineeringAllium sativum

The invention discloses an inner channel type seed taking and direction changing device and an on-film garlic planting machine, solves the problems that a garlic seed metering device in the prior artis unstable in work and cannot guarantee planting upright degrees of garlic, and has the advantages of achieving directional sowing and improving the planting upright degrees of garlic seeds. The specific scheme is as follows: the inner channel type seed taking and direction changing device comprises a seed box, a garlic groove and at least one seed taking and direction changing unit, wherein thesize of the top of the seed box is larger than that of the bottom of the seed box, the whole garlic groove is arc-shaped, the garlic groove is formed below the seed box, the seed box and the garlic groove are located on one side of the at least one seed taking and direction changing unit, the adjacent seed taking and direction changing units are connected, each seed taking and direction changing unit comprises a rotatable seed taking disc and seed taking spoons arranged in the circumferential direction of the seed taking disc, a plurality of conveying pipes are supported through the seed taking disc, direction turning pipes are fixed to a rack, the size of one side of the transverse section of a garlic seed turning channel in each direction turning pipe is larger than that of the other side, and each direction turning pipe and the conveying pipes on the top end side and the bottom end side of the direction turning pipe can be located on a same straight line.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

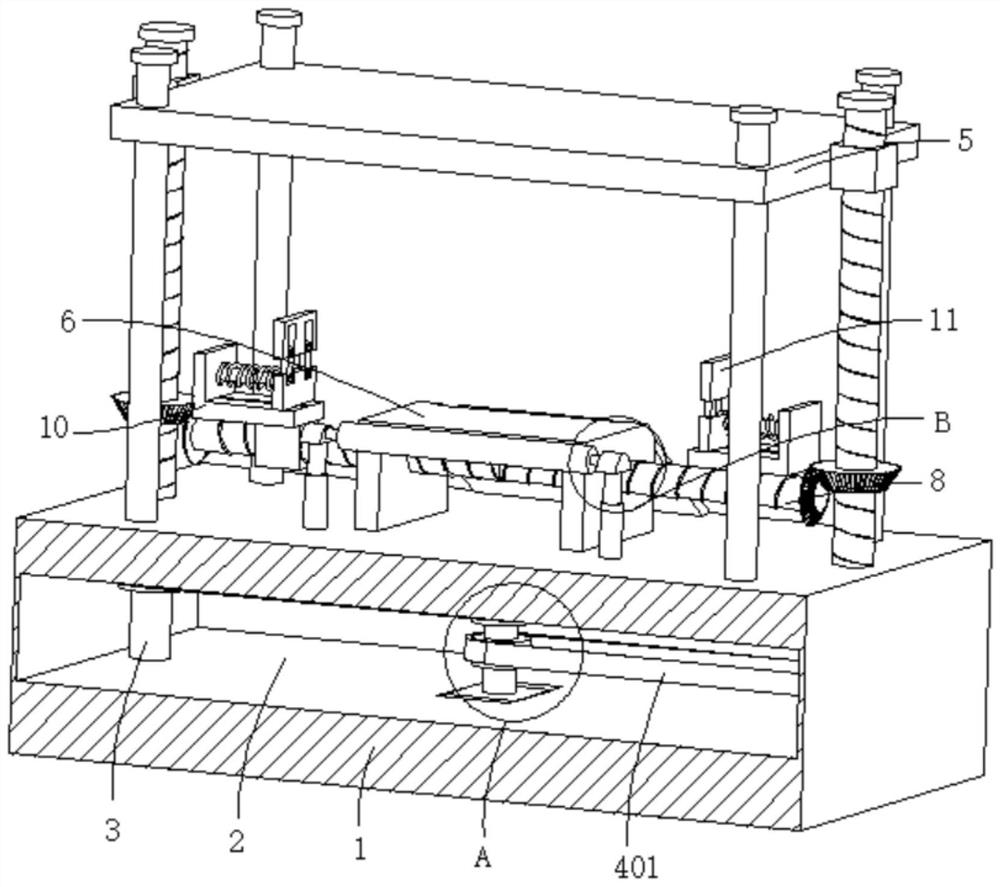

Press-fitting device and method for corrugated paper board production

InactiveCN110744867ATo achieve the pressing effectUniform strengthMechanical working/deformationStructural engineeringMechanical press

The invention discloses a press-fitting device and method for corrugated paper board production. The press-fitting device comprises a device body. A transmission box is mounted at the bottom of the device body, an upper support is welded to the middle position of the upper end face of the device body, a pressing plate is fixedly mounted at the lower end of the upper support, a mounting table is movably arranged between the transmission box and the pressing plate, sliding rods are welded to the positions of the four corners of the lower end of the mounting table, four sets of sliding barrels acting on the sliding rods are arranged at the positions of the four corners of the upper end of the transmission box in a penetrating manner, and a corrugated paper board is put in the mounting table.According to the press-fitting method for corrugated paper board production, by means of synchronous circumferential motion of four sets of cams, four sets of T-type rods move upwards to jack the mounting table, the corrugated paper board on the mounting table suffers from the pressure effect of the pressing plate above the corrugated paper board, a press-fitting effect is achieved, it is guaranteed that the strength applied during mechanical press-fitting is uniform, the press-fitting device and method are suitable for different working conditions, and better use prospects are brought.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

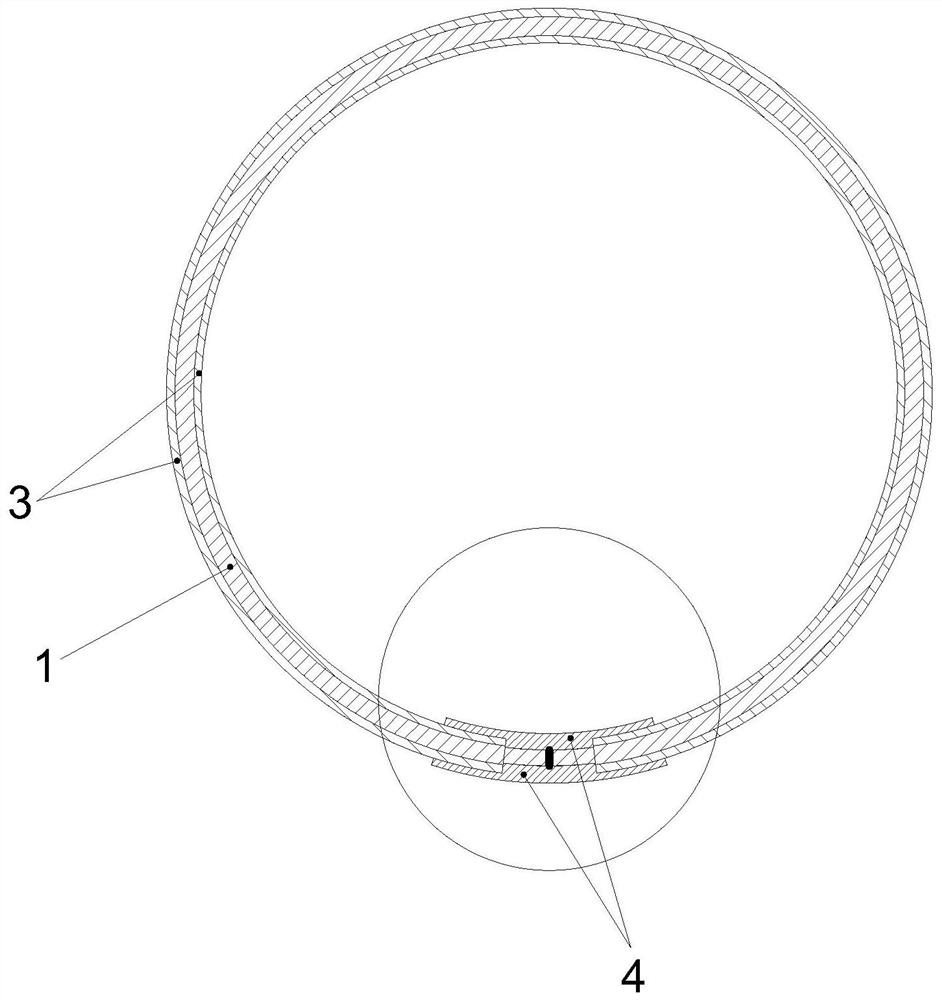

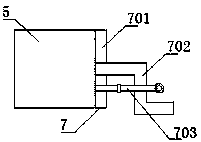

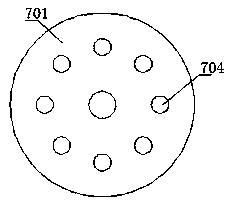

Film covering equipment

PendingCN114523654AReduce wrinklesGuaranteed to open normallyFinal product manufactureMetal working apparatusThin membraneEngineering

The film laminating equipment comprises a mounting bracket, a film roller and a film laminating mechanism, the film covering mechanism comprises a vacuumizing assembly, a film covering assembly and a rolling roller; the film roller is mounted on the mounting bracket and is used for bearing a film; the rolling roller is provided with a plurality of air hole groups; the plurality of air hole groups are connected with the vacuumizing assembly, so that the outer surface of the rolling roller has adsorption force; and the film covering assembly is used for driving the rolling roller to lift up and down. The vacuumizing assembly is communicated with the air hole set, so that the rolling roller generates adsorption force, the rolling roller pulls the film through the adsorption force, the film is kept flat, wrinkles are reduced, and it is guaranteed that the film is opened. More preferably, the rolling roller is driven by the film laminating assembly to lift up and down, the film covering the plate is pulled, wrinkles and overlapping of the film are reduced, the film laminating effect is guaranteed, and the film laminating device is suitable for laminating base materials with various thicknesses.

Owner:VEEGOO TECH CO LTD

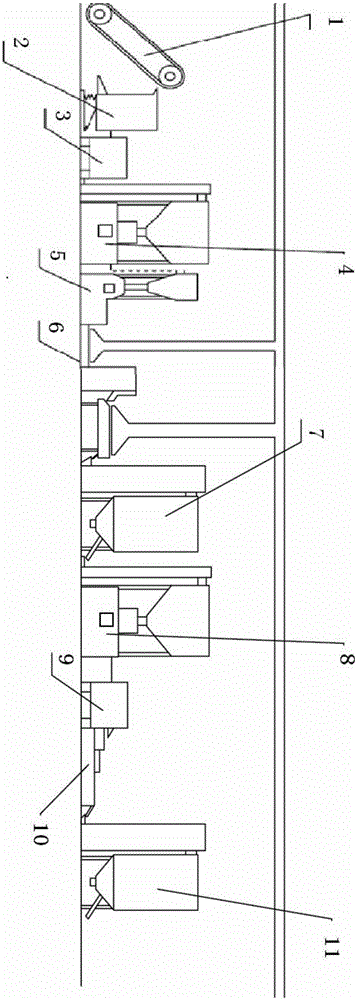

Shoemaking production line press fitting-drying combined mechanism

The invention discloses a shoemaking production line press fitting-drying combined mechanism comprising a press fitting box and a drying box, and a transfer mechanism arranged on the bottom of the press fitting box and the drying box; the drying box is matched with a press fitting inflated bag on the inner side of the press fitting box through an inflate tube; the inflate tube is provided with an inflate blower; the top of the drying box is provided with an electric heating device; the shoemaking production line press fitting-drying combined mechanism enables hot air thermal circulation in the press fitting box and the drying box, thus ensuring shoe body to be evenly heated; the inflated bag is filled with hot air, thus ensuring stitching effect.

Owner:TIANJIN YONGLIANG RUBBER & PLASTIC PROD

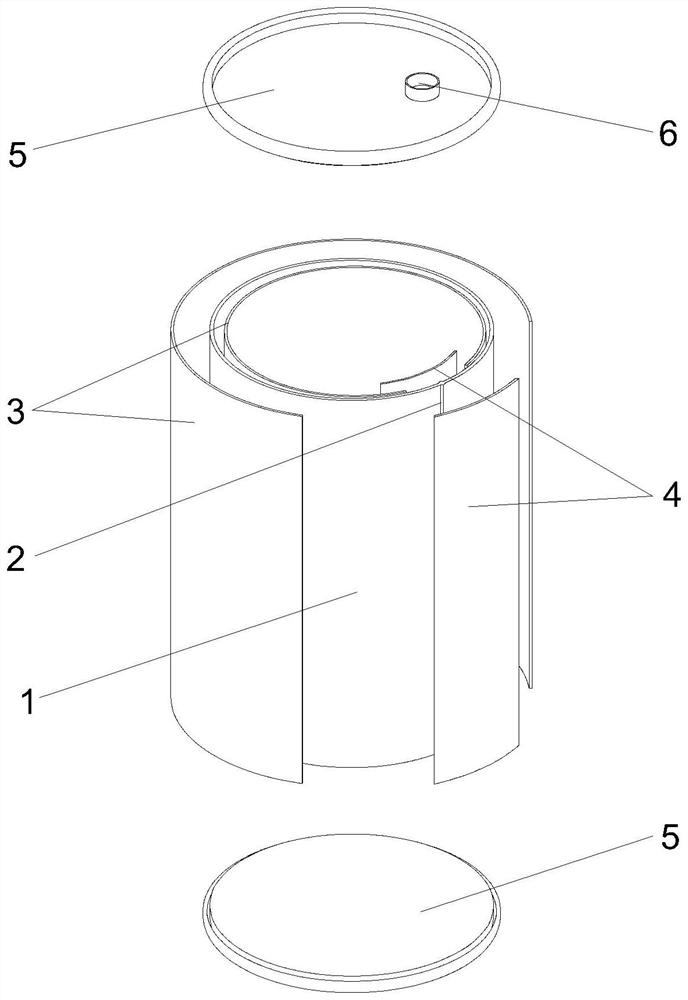

Film-coated barrel and preparation method thereof

PendingCN112777080AEasy to useGuaranteed service lifeLaminationLamination apparatusStructural engineeringWeld seam

The invention relates to a film-coated barrel and a preparation method thereof. The barrel comprises a barrel body formed by winding and welding a metal plate, end covers used for sealing the two ends of the barrel body, film-coated layers attached to the inner and outer surfaces of the barrel body and the end covers and film repairing layers attached to the inner and outer surfaces of the welding position of the barrel body. In the preparation process, the method mainly comprises the steps that the film-coated layers are attached to the front end face and the back end face of the metal plate, cutting is conducted, edge milling or edge grinding is conducted on the two ends, the barrel body is formed through welding, film repairing is conducted on welding seams, and edge curling and fixing are conducted on the end covers. Surface treatment of the barrel body is achieved in the mode that the inner surface and the outer surface of the barrel body are coated with films, and the problems that environmental pollution generated by spraying seriously exceeds the standard and the input cost is too high are solved. In the film covering process, the barrel body is provided with the welding seams, so that surface film covering treatment at the welding seams is achieved in a film repairing mode, and the using effect and the service life of the barrel body are effectively guaranteed.

Owner:苏州贝氏包装科技有限公司

Coated sand recycling production process

InactiveCN107774893AAvoid cakingReduce manufacturing costMould handling/dressing devicesFiltrationMaterials science

Owner:QINGDAO TIANDI CASTING CO LTD

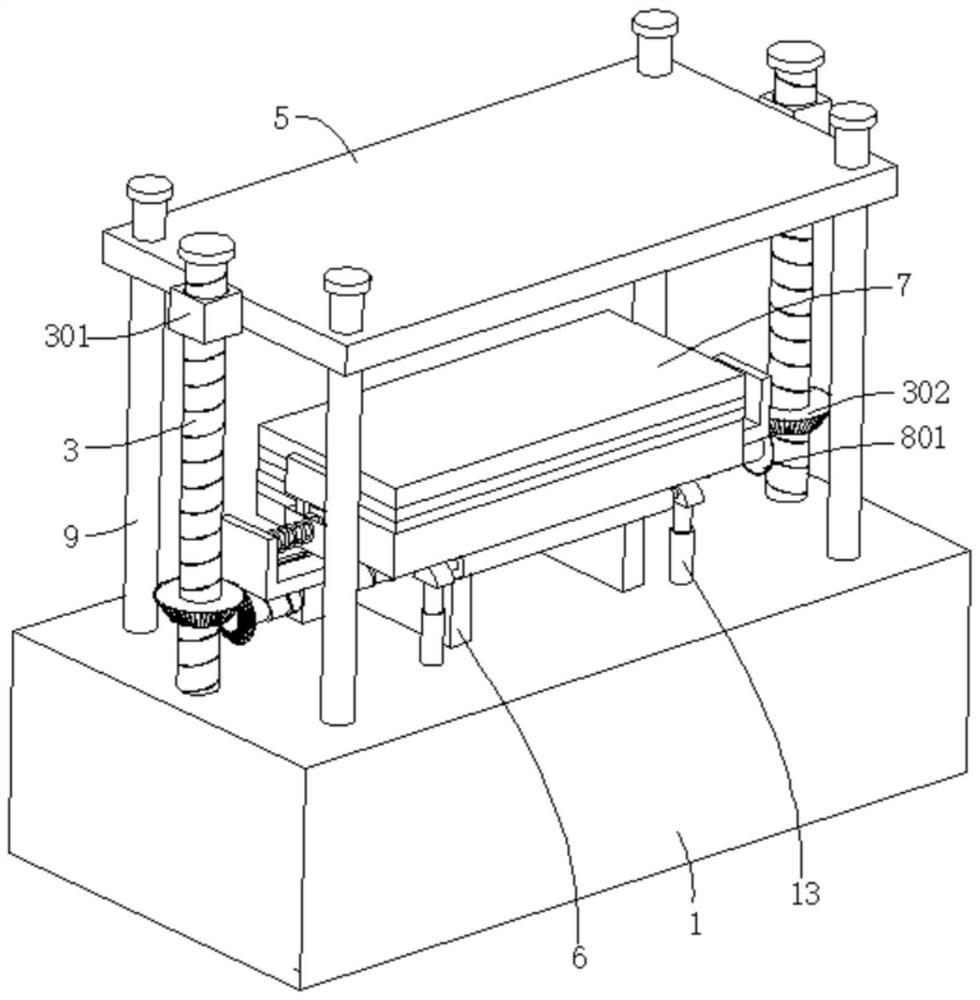

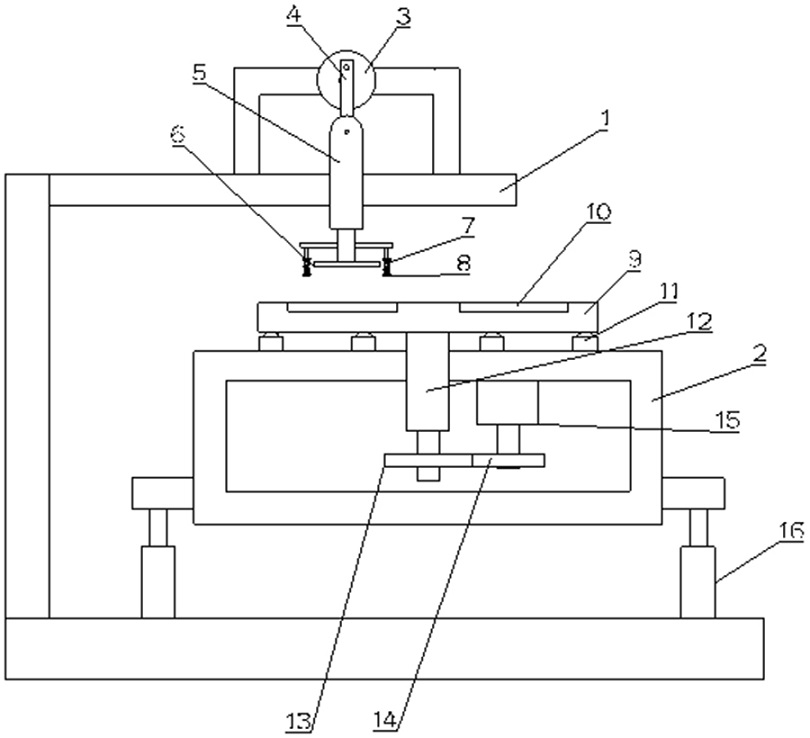

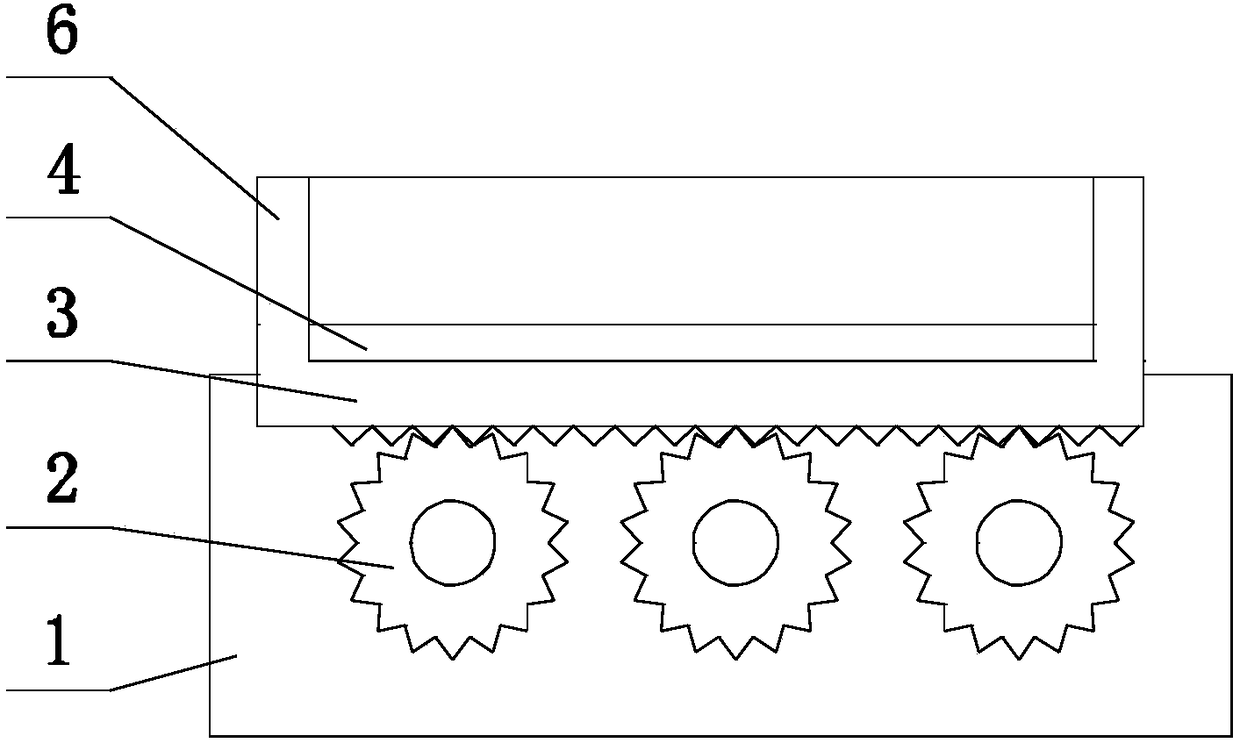

Plywood pressing device

InactiveCN109291166AGuaranteed lamination effectGuaranteed stamping effectWood veneer joiningPunchingEngineering

The invention discloses a plywood pressing device which comprises a worktable and a pressing table. Supporting plates are arranged on two sides of the top of a cone-shaped groove, a lower pressure plate is fixed to the top of the pressing table, clamping screws are arranged on two sides of the lower pressure plate, annular fixed blocks are fixed to the inner sides of the two clamping screws, an upper pressure plate is arranged on the top of the lower pressure plate, bearing pedestals are fixed to the top ends of two columns, a screw is rotatably connected between the two bearing pedestals, andone end of the screw is fixedly connected to a locking device. By means of the locking device, the position of the upper pressure plate can be locked when the upper pressure plate and the lower pressure plate press the plywood, so that layers of the plywood are tightly adhered to bonding resin, and the press fit effect is ensured. As the clamping screws are arranged on two sides of the lower pressure pate, the clamping screws are in threaded connection to the columns and annular fixed blocks are fixed to the inner sides of the two clamping screws, the plywood placed on the top of the fixed plate can be limited, so that the punching effect is guaranteed.

Owner:宿迁市三泰木业有限公司

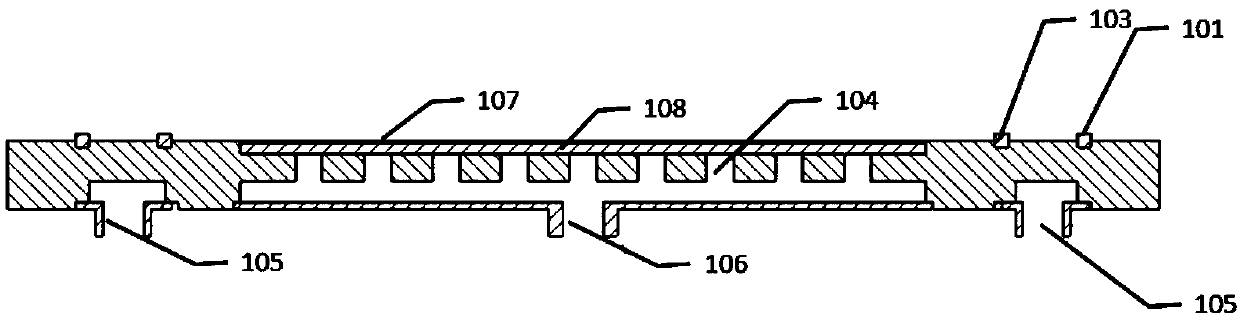

Laminating device and using method thereof

PendingCN110416350AImprove the sealing effectGuaranteed lamination effectFinal product manufacturePhotovoltaic energy generationSilver pasteVacuum pumping

The invention relates to the field of solar cell manufacturing, and discloses a laminating device and a using method thereof; the laminating device comprises a substrate and a top plate, wherein a first laminating groove is formed in the upper end surface of the substrate; an inner sealing gasket located on the periphery of the first laminating groove and an outer sealing gasket positioned outsidethe inner sealing gasket are arranged between the substrate and the top plate; a sealing cavity is defined by the substrate, the top plate, the inner sealing gasket and the outer sealing gasket; a first vacuumizing hole communicated with the first laminating groove and a second vacuumizing hole communicated with the sealing cavity are formed in the lower end surface of the substrate; and the using method comprises the following steps of performing buckling and sealing, and carrying out vacuum pumping and laminating. The laminating strength of the solar cell matrix is realized by controlling the vacuumizing degree, the laminating effect is ensured, the connecting effect of silver paste is better, and the reliability of the solar cell product is improved; and the sealing cavity is vacuumized through the second vacuumizing hole, so that the vacuum degree of the laminating device and the vacuumizing speed of the laminating cavity are improved.

Owner:紫石能源有限公司

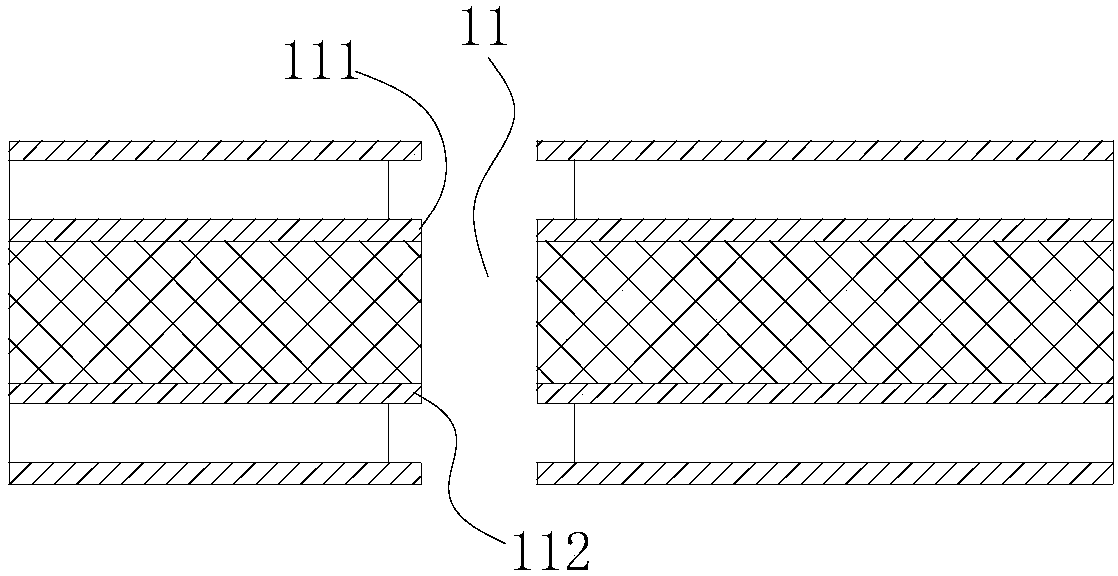

A method of manufacturing a printed circuit board

ActiveCN105792527BImprove reliabilityDimensionally stablePrinted circuit aspectsPrinted element electric connection formationGlass fiberElectrical connection

The invention relates to the technical field of circuit board production, in particular to a method for manufacturing a recessed printed circuit board. The present invention firstly drills preset holes on the prepreg that are one-to-one corresponding to the through holes and whose aperture is larger than the through holes, thereby removing the corresponding glass fiber cloth on the subsequent through holes that need to be etched back in advance. It only needs to remove the resin in the hole, which solves the problem that it is difficult to remove the glass fiber cloth, and can form a good effect of etch and hole wall, so that the inner layer copper can be fully exposed, and the hole wall is plated with copper after the through hole is metallized A three-dimensional connection can be formed with the copper of the inner layer, making the connection between the two stronger, thereby improving the reliability of the electrical connection between the inner and outer layers. The aperture of the preset hole is set to be 0.05mm larger than the aperture of the through hole, which can fully remove the glass fiber cloth without causing the prepreg to lose too much resin, reducing the impact of the prepreg on the lamination caused by the loss of resin due to drilling.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

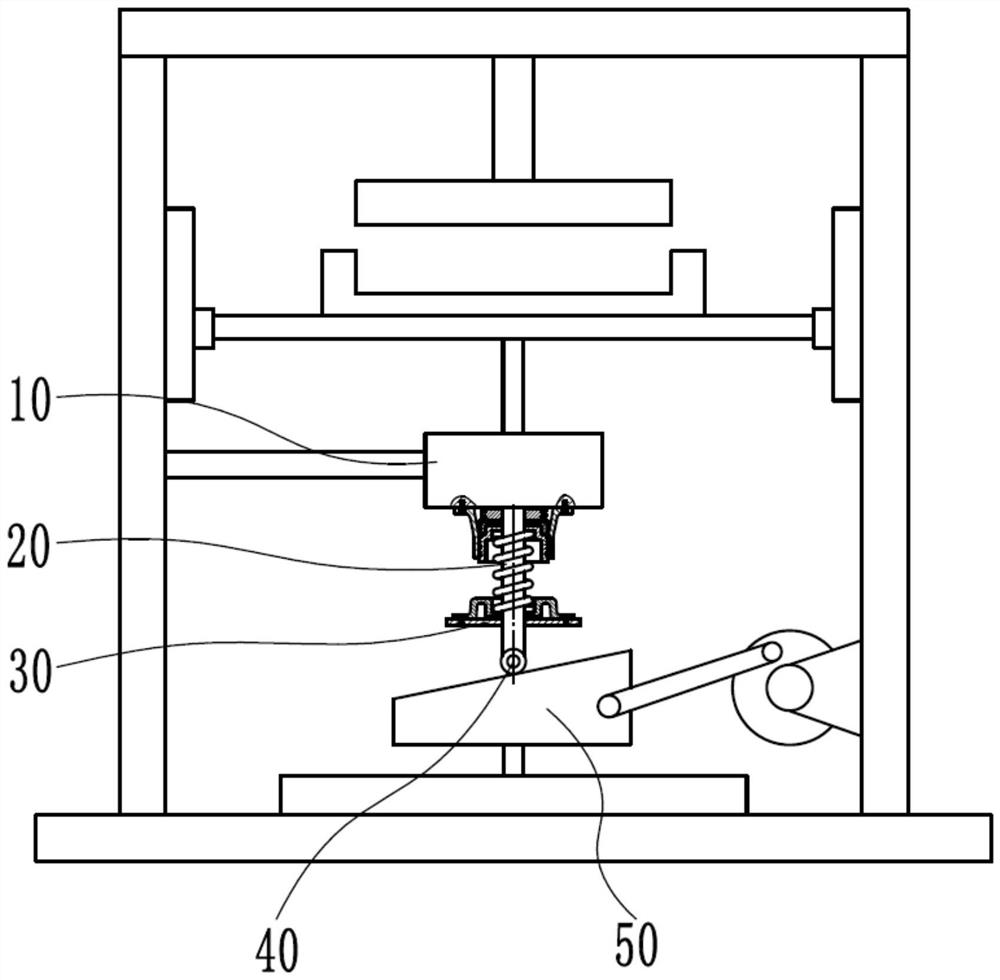

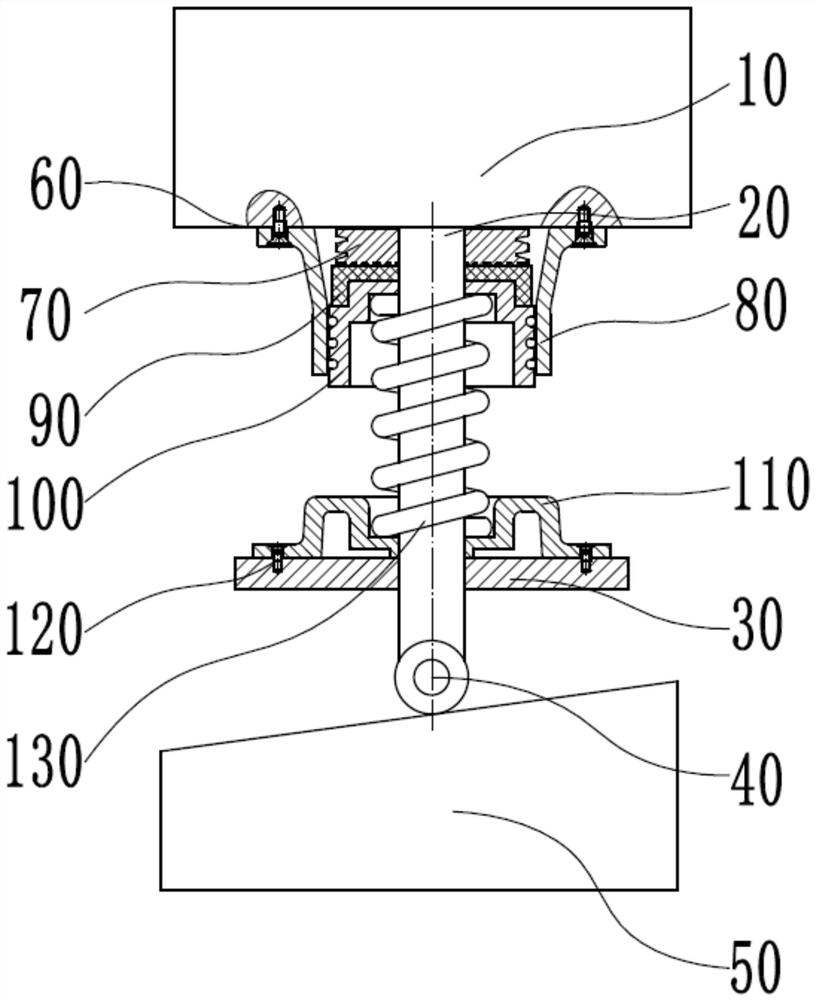

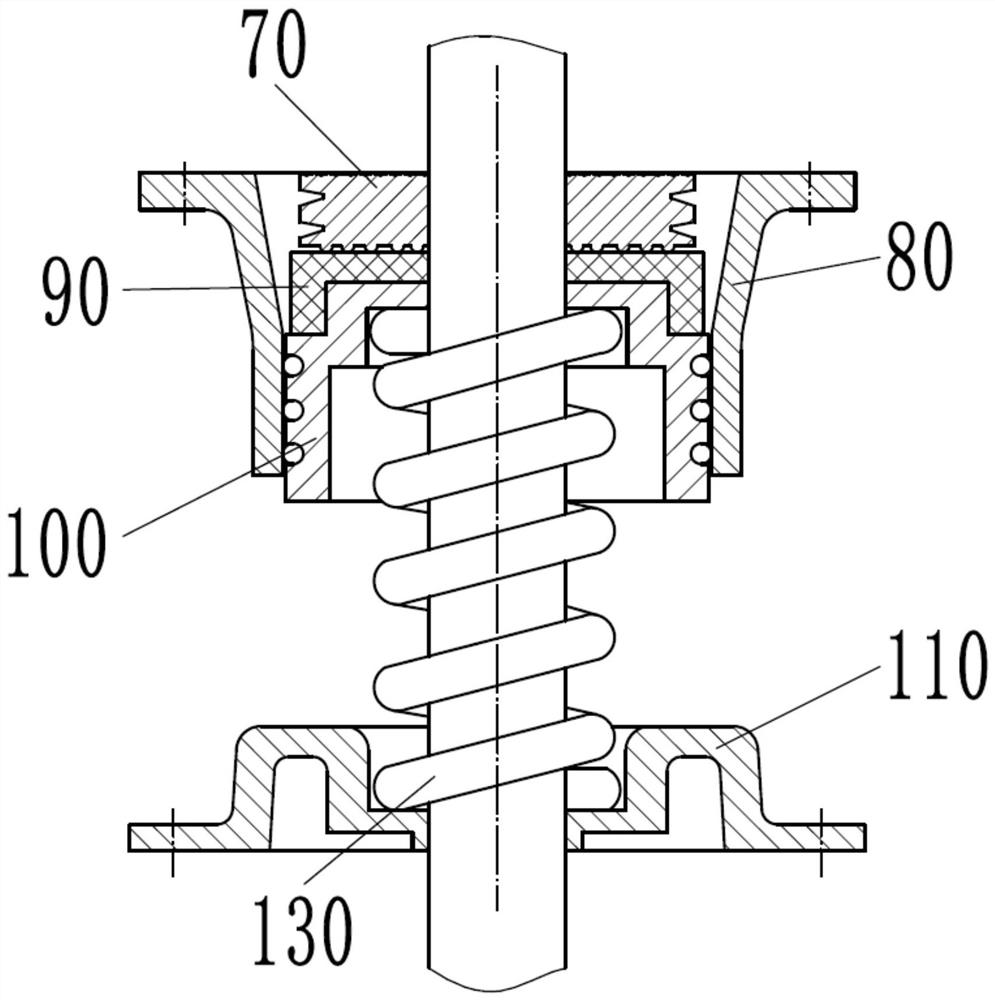

A shoe sole pressing machine

ActiveCN109171113BPlay the role of orientationPrevent lateral forceShoe gluingStructural engineeringMechanical engineering

The application provides a sole pressing machine, which includes a guide sleeve, a guide rod, a wedge block, an upper spring seat assembly and a lower spring seat. The upper spring seat assembly includes a guide sleeve, a telescopic column, a rubber pad and a buffer body. The guide sleeve is fixed at the lower end of the guide sleeve. The rubber pad is sleeved on the guide rod and installed on the upper end of the telescopic column. The buffer body is movably sleeved on the guide rod, and the buffer body is located between the rubber pad and the guide sleeve. The upper end of the spring is in contact with the telescopic column. The spring seat is fixed on the fixed plate, and the lower end of the spring is in contact with the lower spring seat. The shoe sole pressing machine provided by the present application adopts the above-mentioned structure, so that the wear between the guide rod and the guide sleeve can be reduced during the process of the guide rod moving up and down.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

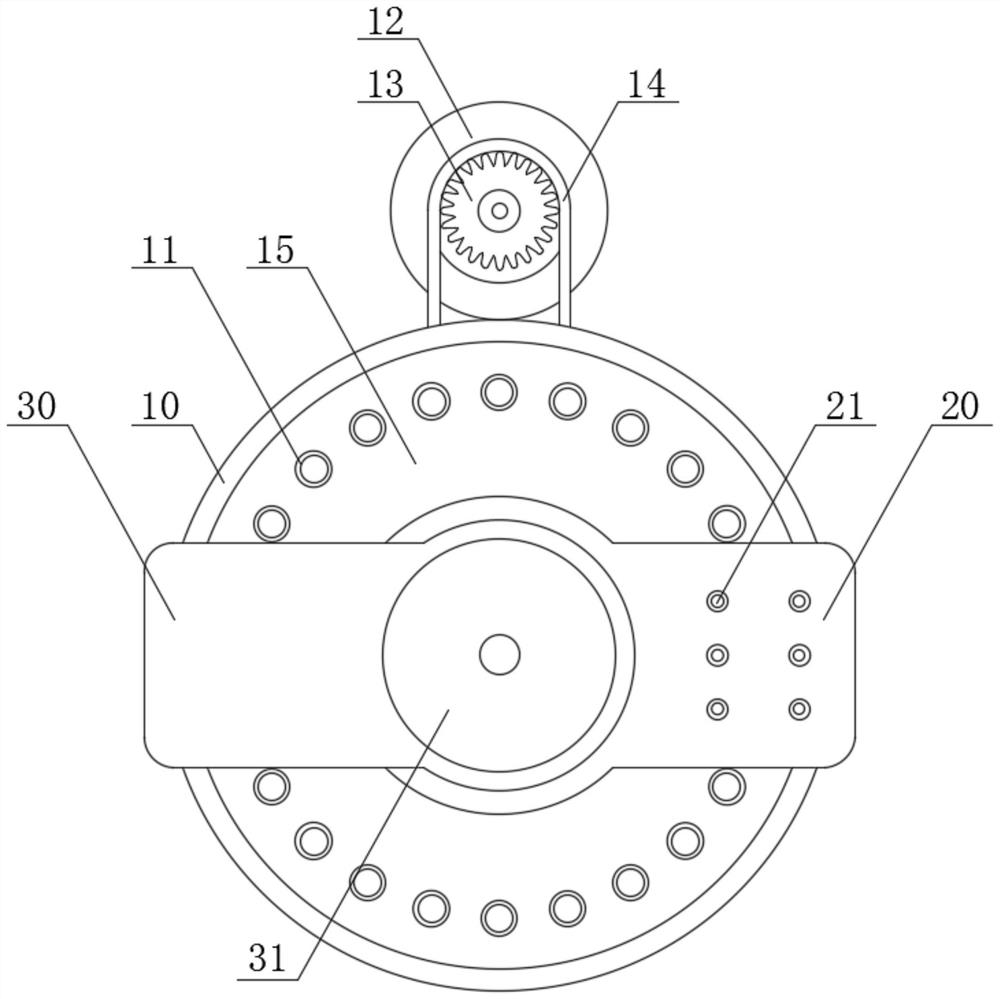

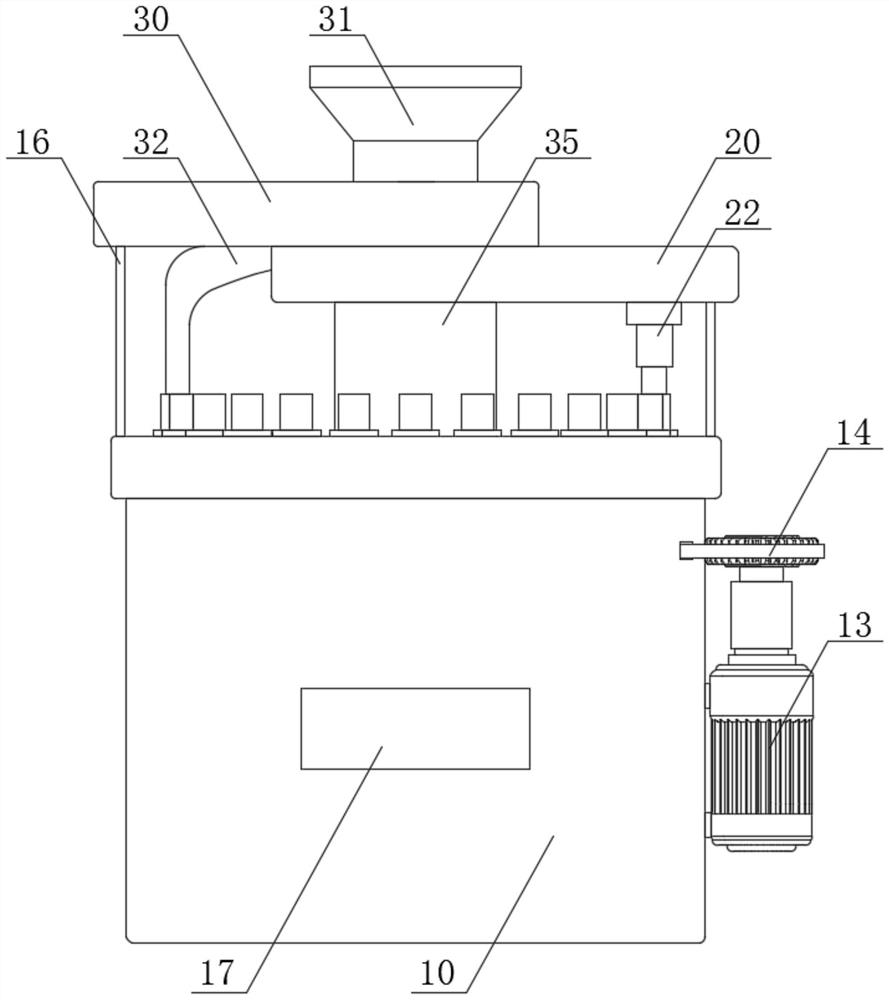

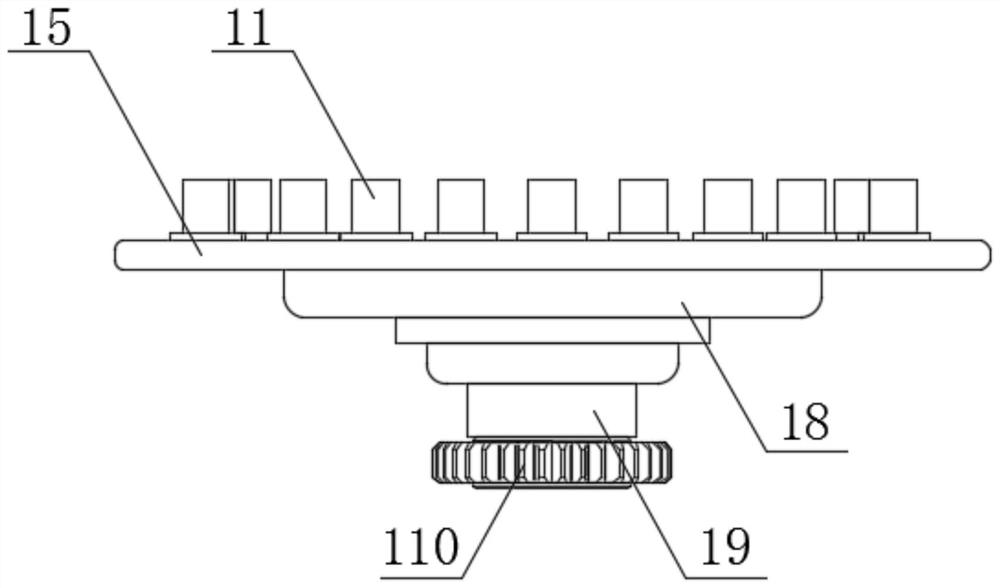

Automatic pre-pressing machine for spring production

The invention discloses an automatic pre-pressing machine for spring production. The automatic pre-pressing machine comprises: a base, wherein a connecting ring is welded to the upper portion of the inner side wall of the base, a supporting column is arranged in the middle of the inner portion of the base, a discharging groove is further formed in the position, close to the front wall, of the inner portion of the base, a discharging port is formed in the front surface of the base, a stepping motor is further arranged on one side of the base, and a gear is welded to the power output end of the motor; and a rotating plate, arranged on the upper surface of the base, wherein a plurality of spring sleeves are arranged on the surface of the rotating plate. Through an arranged second connecting plate and an auxiliary structure matched with the second connecting plate, a material plate can be driven to vibrate through vibration of a telescopic motor, a vibration feeding structure is formed, the feeding angle of materials can be guaranteed through a feeding hole formed in the bottom of a feeding groove, and therefore, an entering spring can move along the arc-shaped structure of the material plate and finally directly falls into the spring sleeve.

Owner:卓越五金弹簧(深圳)有限公司

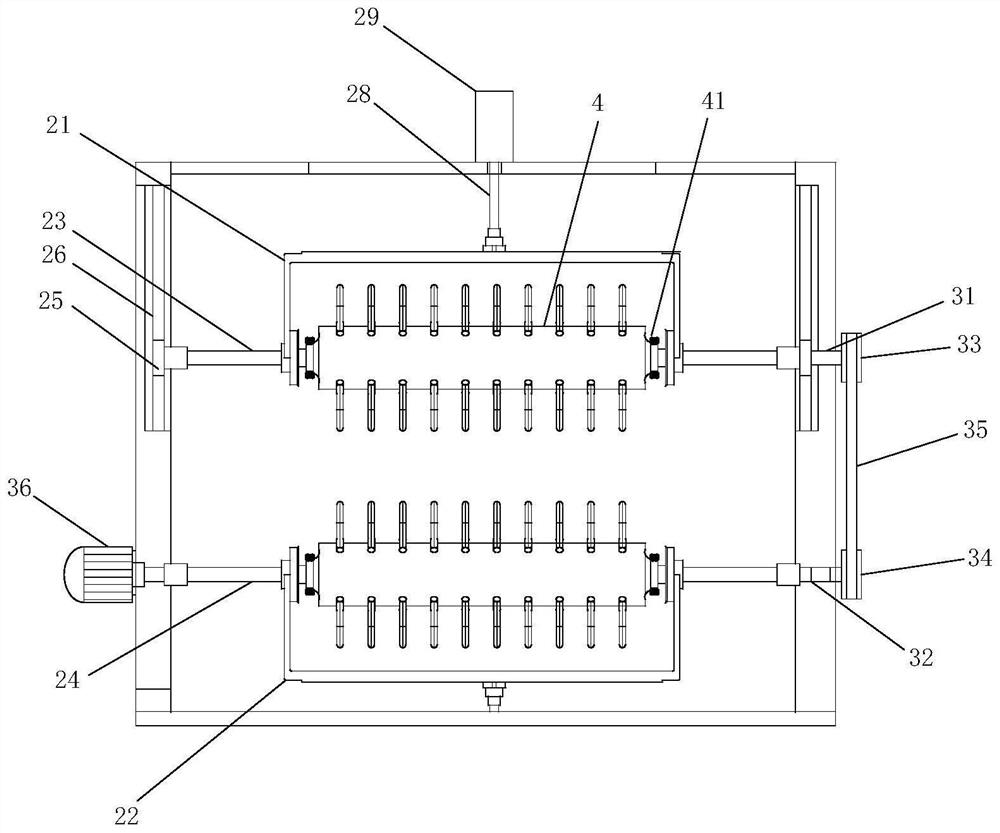

Laminating device for double-sided double-glazed photovoltaic assembly

PendingCN108437602AUniform pressureGuaranteed lamination effectLaminationLamination apparatusEngineeringMechanical engineering

The invention discloses a laminating device for a double-sided double-glazed photovoltaic assembly. A plurality of driving rollers are sequentially rotatably mounted on a supporting rack, the outer walls of the driving rollers are provided with driving gears which are annularly distributed around the outer walls of the driving rollers, a mounting seat is positioned on the driving rollers, a mounting position for storing the photovoltaic assembly is arranged at the top of the mounting seat, transmission gears cooperating with the driving gears are arranged at the bottom of the mounting seat, asupporting coaming plate is arranged in the periphery of the mounting position, a pressing surface is arranged at the bottom of a pressing mechanism, and the projection of the supporting coaming plateand the mounting position on the plane of the pressing surface is positioned on the pressing surface. The driving rollers cooperate with the gears at the bottom of the mounting seat to achieve transmission of the mounting seat in a transmitting channel, the pressing mechanism laminates the photovoltaic assembly on the mounting seat, and the supporting coaming plate supports the pressing surface,so uniform compression and good laminating effect of the photovoltaic assembly are ensured.

Owner:ANHUI ELECTRIC GRP SHARES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com