Plywood pressing device

A technology of plywood and pressing table, which is applied in the direction of manufacturing tools, wooden veneer joints, wood processing appliances, etc. It can solve the problems of poor plywood limit effect and poor pressing effect, so as to ensure the pressing effect and guarantee The effect of the stamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

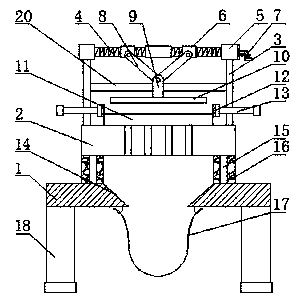

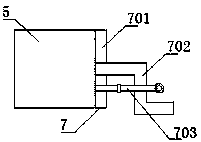

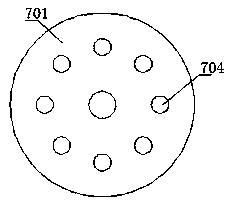

[0019] Example: such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a plywood pressing device includes a worktable 1 and a pressing table 2, four support columns 18 are fixed at the four corners of the bottom of the workbench 1, and a tapered groove 14 is provided in the middle of the top of the workbench 1. Both sides of the top of the tapered groove 14 are provided with a support plate 15, and both sides of the support plate 15 are provided with a sound insulation layer 16, the top of the support plate 15 is fixedly provided with a pressing table 2, and the top of the pressing table 2 is fixedly provided with a lower pressing plate 11. Through-holes 19 are provided at the corresponding positions of the pressing table 2 and the lower pressing plate 11, columns 3 are fixed on both sides of the top of the pressing table 2, and clamping screws 13 are arranged on both sides of the lower pressing plate 11, and the clamping screw 13 is threadedly connected with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com