Pressing device for building insulation board processing

A technology of building thermal insulation and pressing device, which is applied in applications, household appliances, and other household appliances. It can solve the problems of poor finished insulation board effect, guaranteed pressing effect, and inclined pressing force, so as to save material discharge time and ensure Pressing effect, effect of preventing misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

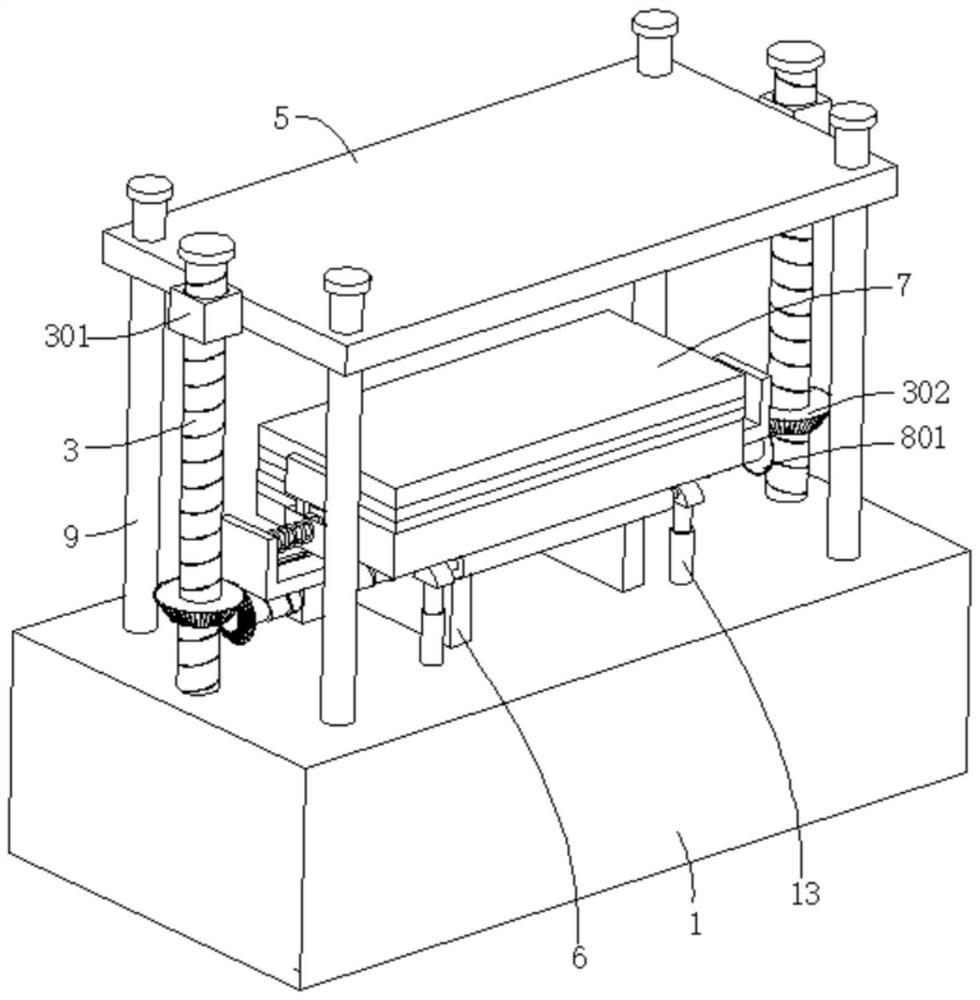

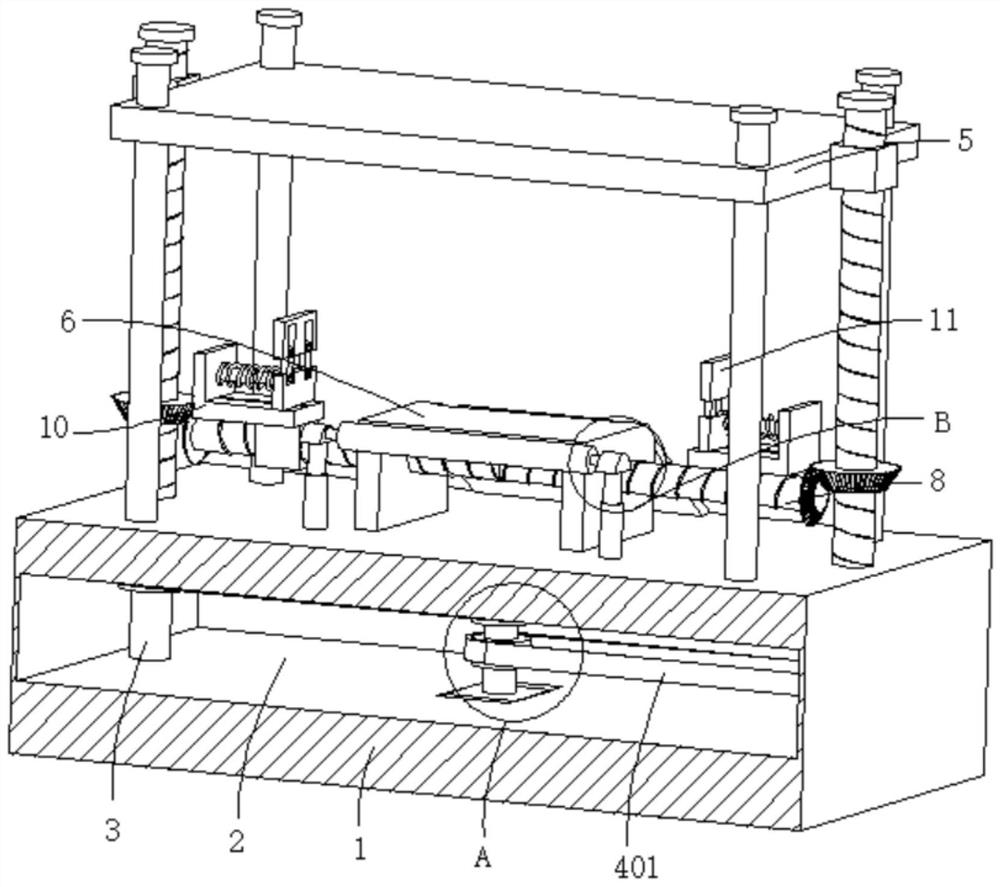

[0034] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 7, a pressing device for processing building insulation boards, comprising a base 1, a cavity 2 is excavated in the base 1, a motor 201 is fixedly connected to the inner wall of the cavity 2, a rotating shaft 202 is connected to the output end of the motor 201, and the two sides of the base 1 Both are connected with the first screw mandrel 3 through the first bearing rotation, and the two first screw mandrels 3 are respectively connected with the outer wall of the rotating shaft 202 with a matching synchronous wheel 4, and a synchronous belt 401 is connected between the two synchronous wheels 4, The outer walls of the two first screw mandrels 3 are threadedly connected with first sleeves 301, and a pressing plate 5 is connected between the two first sleeves 301. The top outer wall of the base 1 is connected with a workbench 6, and the outer wall of the workbench 6 is connected with a Insulation plate b...

Embodiment 2

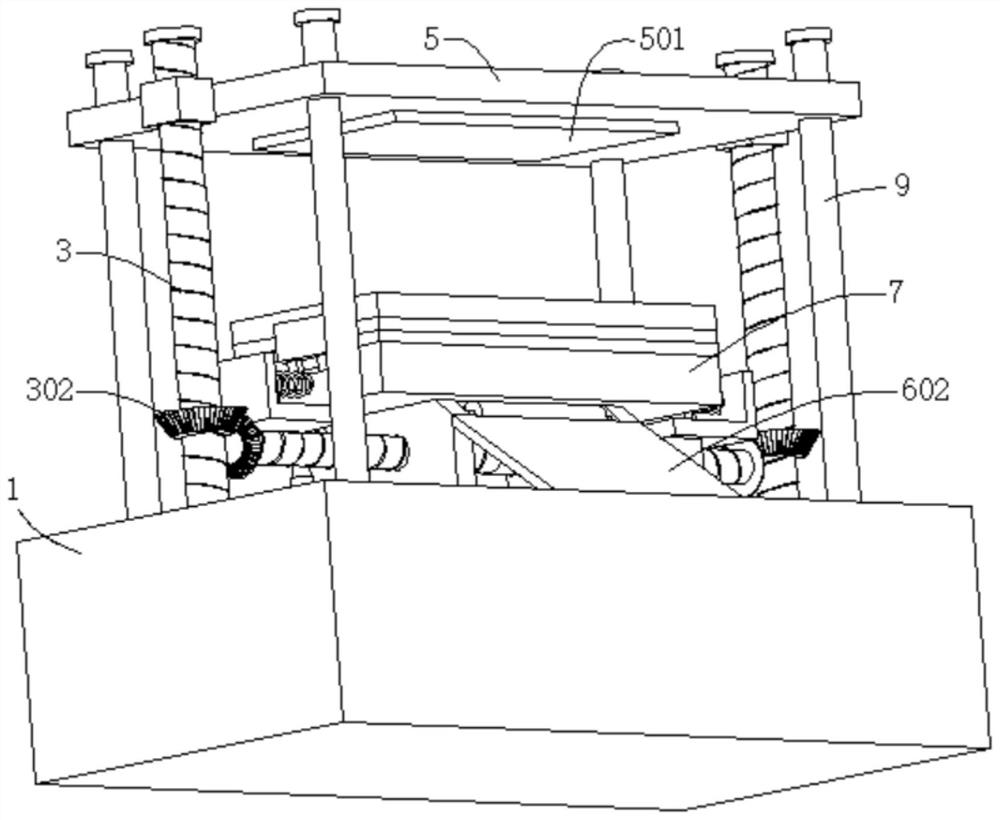

[0039] refer to figure 1 , figure 2 and Figure 7 , a pressing device for processing building insulation boards, which is basically the same as that of Embodiment 1, furthermore, two groups of guide rods 9 are connected to the outer wall of the base 1, and each group of guide rods 9 is provided with two, and four guide rods 9 are respectively located at the four corners of the pressing plate 5, and the pressing plate 5 is slidably connected to the outer wall of the guide rod 9; the pressing plate 5 slides on the outside of the guide rod 9 when the first sleeve 301 moves down, which is conducive to improving the pressure of the pressing plate 5. Downshifting stability.

[0040] The bottom wall of the pressing plate 5 is connected with a rubber pad 501; when the pressing plate 5 moves downward to carry out the pressing process, it plays a buffering role, which can avoid damage to the heat preservation plate body 7 due to the excessive pressure of the pressing device to a cert...

Embodiment 3

[0044] refer to figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 , a pressing device for processing building insulation boards, which is basically the same as that of Embodiment 1, furthermore, electric telescopic rods 13 are connected to both sides of the top outer wall of the base 1, and the end of the electric telescopic rod 13 away from the base 1 is connected to a fixed Block 131 , a second rotating shaft 132 is connected between the two fixed blocks 131 , and a second roller 133 is sleeved on the outer wall of the second rotating shaft 132 , and the second roller 133 is movable against the insulation board body 7 .

[0045] The outer wall of the workbench 6 is dug with a first groove 601, the first rotating shaft 6011 is connected between the inner walls on both sides of the first groove 601, and the outer wall of the first rotating shaft 6011 is sleeved with a first roller 6012, and the insulation board body 7 is slidably connected to the The outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com