Film-coated barrel and preparation method thereof

A film-coating and film-coating technology, which is applied in the direction of chemical instruments and methods, other household appliances, coverings/exterior coatings, etc., can solve the problems of poor film covering effect and low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

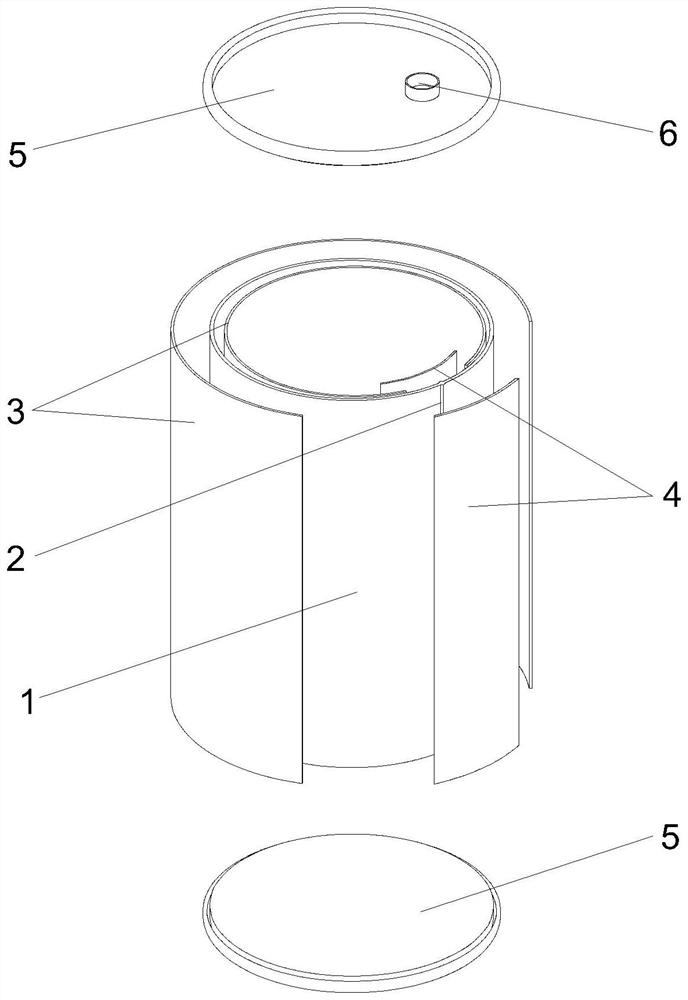

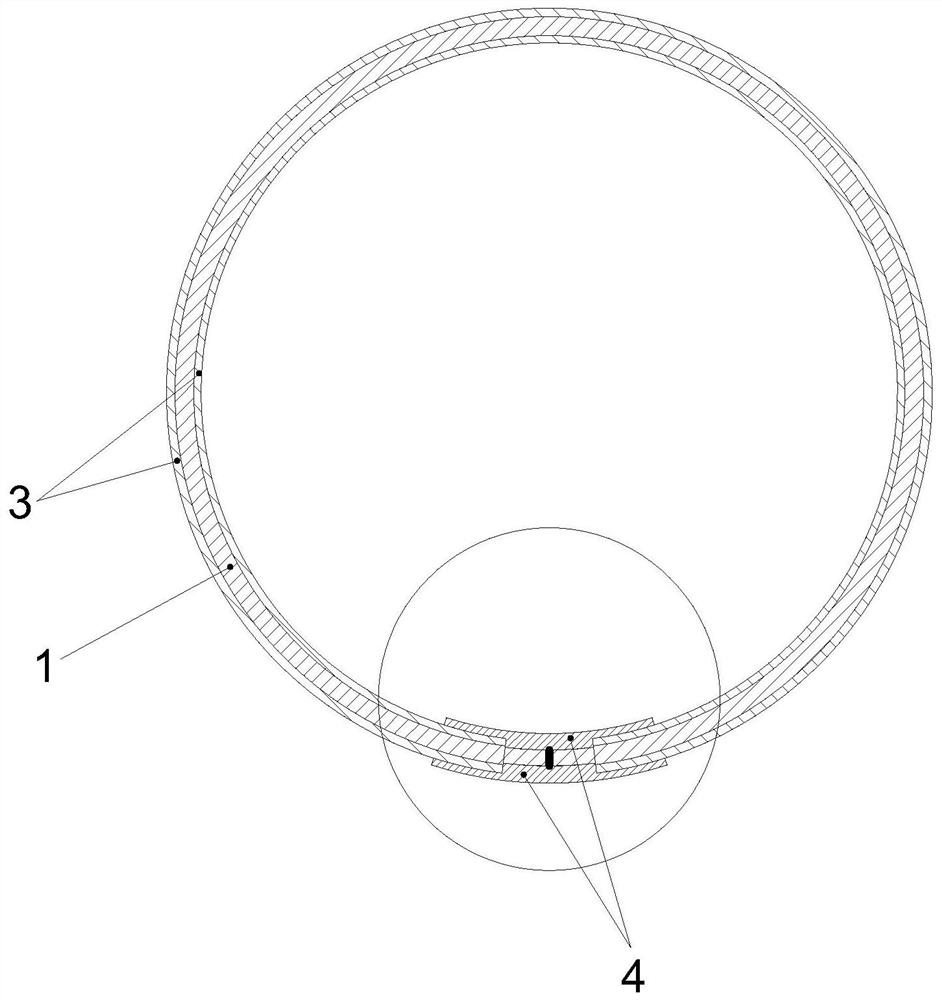

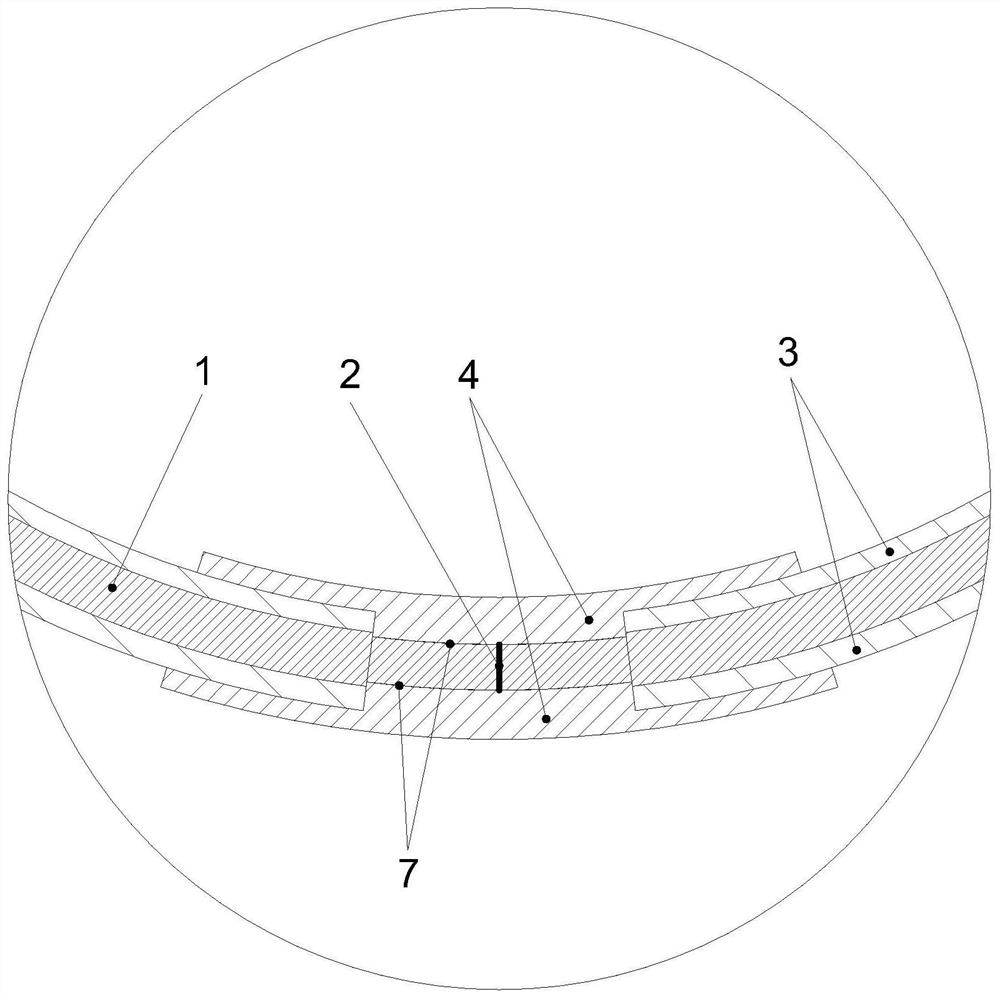

[0031] like Figure 1-3 As shown, a film-coated barrel includes a barrel body 1 formed by winding and welding metal plates, an end cover 5 for sealing both ends of the barrel body 1, and attached to the inner and outer surfaces of the barrel body 1 and the end cover 5 The coating layer 3 and the repairing film layer 4 attached to the inner and outer surfaces of the barrel body 1 at the welding position.

[0032] The barrel body 1 is a hollow cylindrical structure with openings at both ends, and the side wall has a weld 2 along the direction parallel to the central axis; the inner and outer surfaces on both sides of the weld 2 are milled to form a repairing film surface 7, and the coating layer 3 is pasted. Attached to the inner and outer surfaces of the barrel to remove the area where the film repair surface 7 is removed, the film repair layer 4 is attached...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com