Low temperature smoke temperature difference generator

A technology of thermoelectric power generation and low-temperature flue gas, which is applied in the direction of generators/motors, electrical components, etc., can solve the problems of reducing the total efficiency of power generation, increasing energy consumption, and reducing power generation efficiency, so as to improve thermoelectric conversion efficiency, high-efficiency heat absorption and Effect of heat dissipation and saving cooling energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

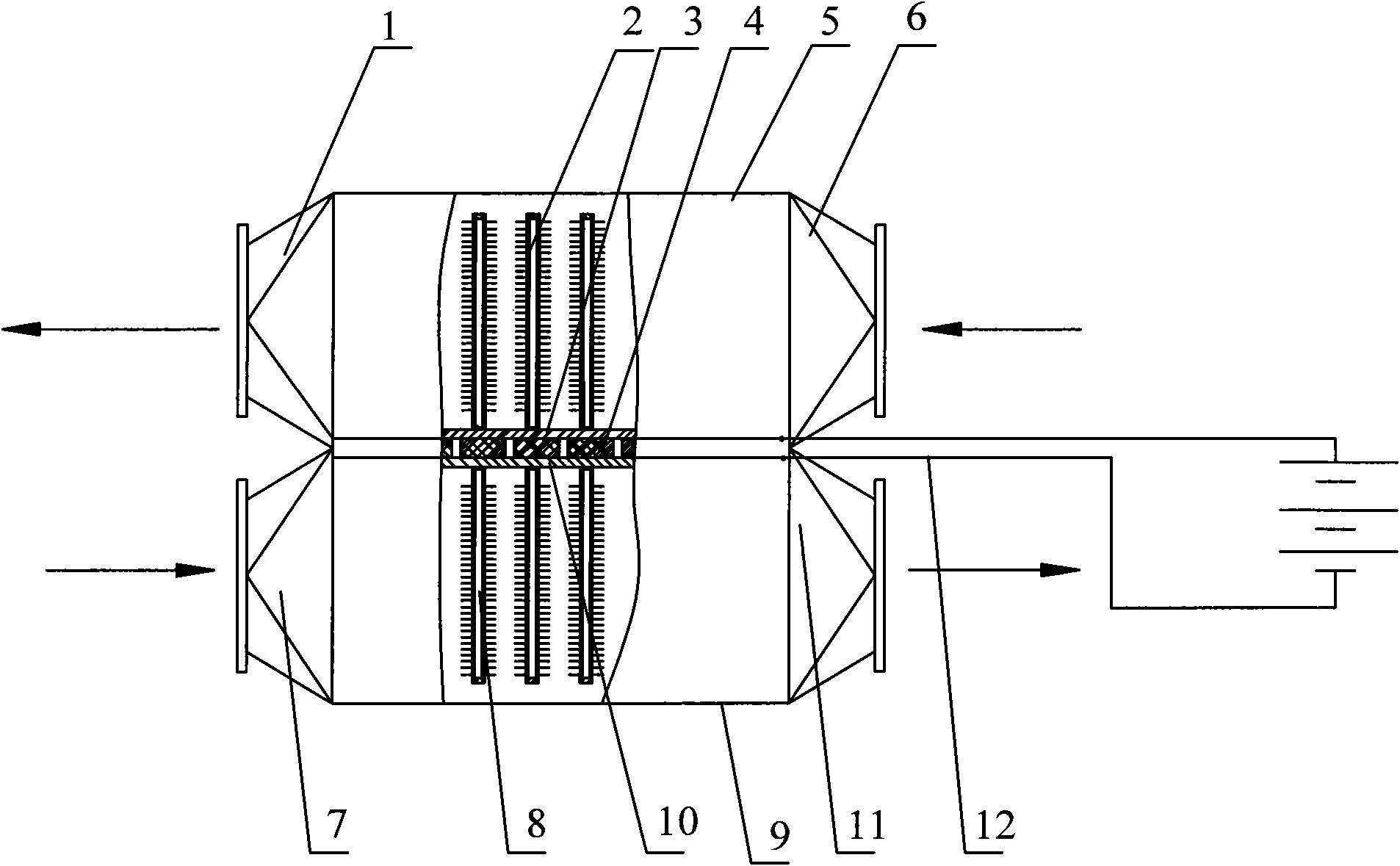

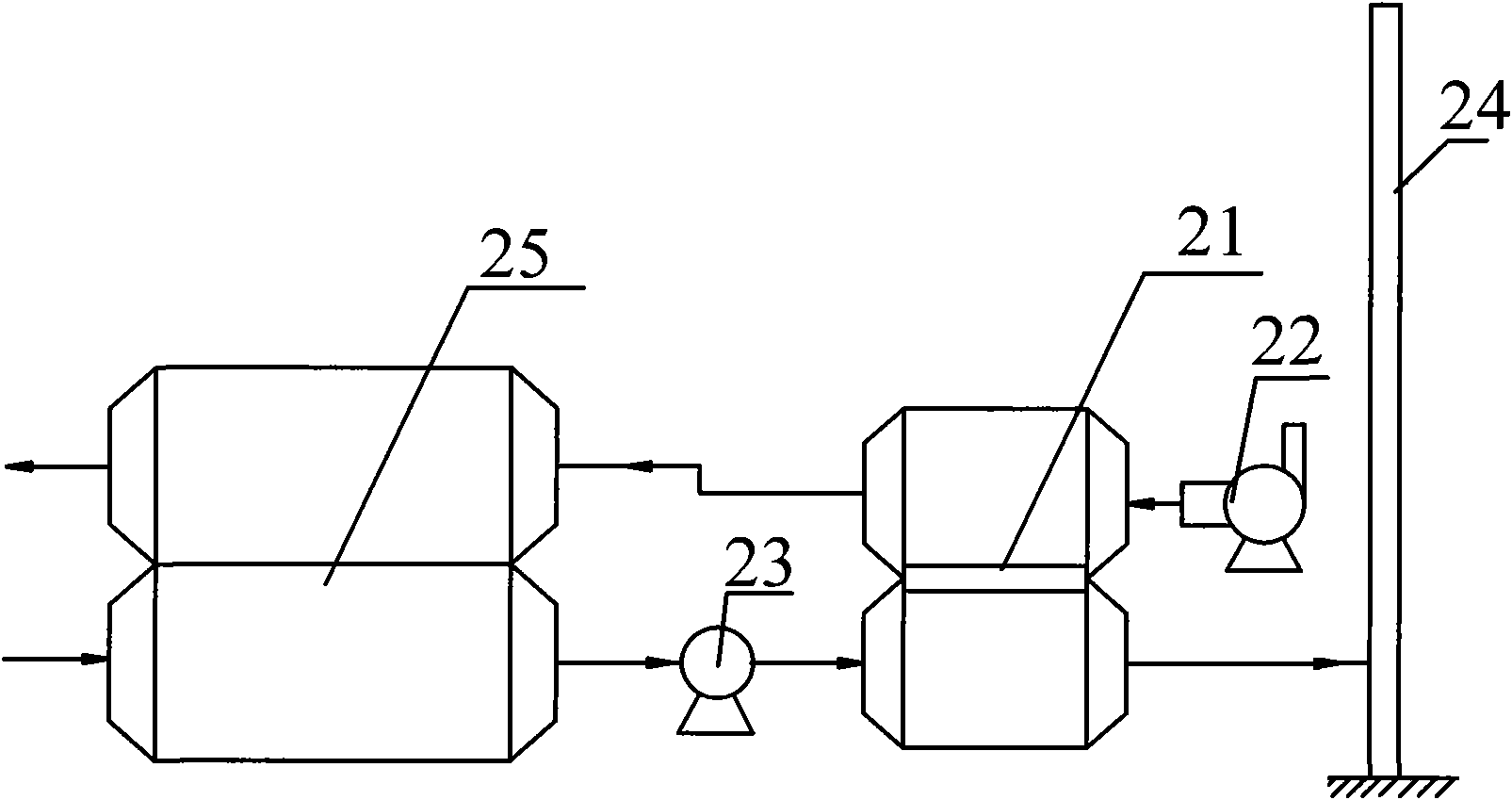

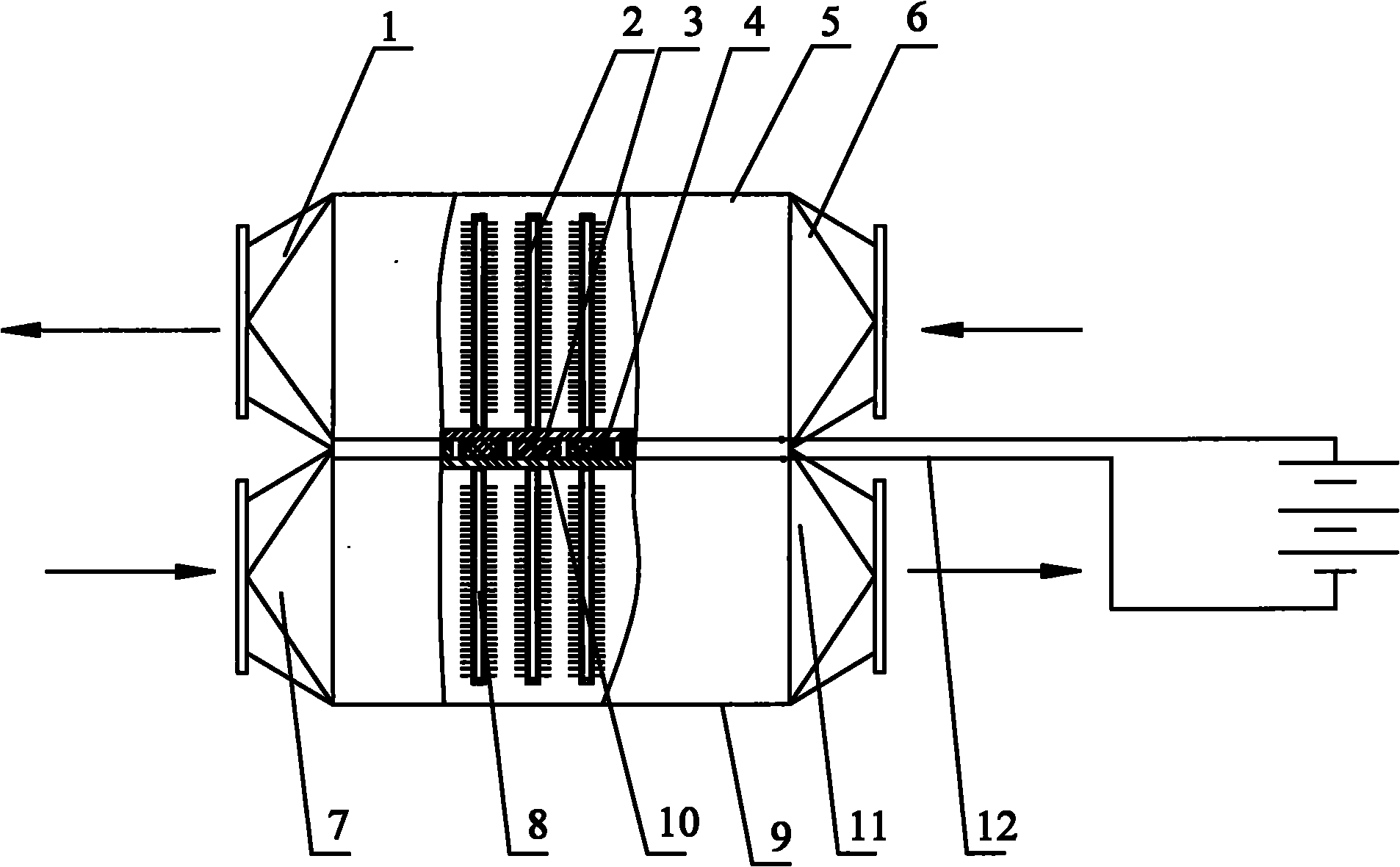

[0015] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0016] Thermoelectric power generation technology is a technology that uses the Seebeck effect (Seebeck Eiffct) of two connected conductors or semiconductors to convert heat energy into electrical energy. It is a circuit composed of two different types of semiconductors. When one end of the device is in a high temperature state and the other end is in a low temperature state, the formula for forming an electromotive force in the circuit is as follows:

[0017] ε=α s (T 2 -T 1 )................................................ ....................(1)

[0018] In formula (1): T1 is the temperature at the low temperature end, T2 is the temperature at the high temperature end, and αs is the Seebeck coefficient of the thermoelectric conversion material used. In application, multiple PN junctions are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com