New process for co-producing ultra-fine white carbon black and calcium carbonate

A technology of white carbon black and calcium carbonate, applied in the direction of calcium carbonate/strontium/barium, silicon dioxide, silicon oxide, etc., can solve a large number of acidic saline wastewater, large average particle size of white carbon black, and wide particle size distribution range. and other problems, to achieve the effect of reducing energy consumption, good social benefits and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

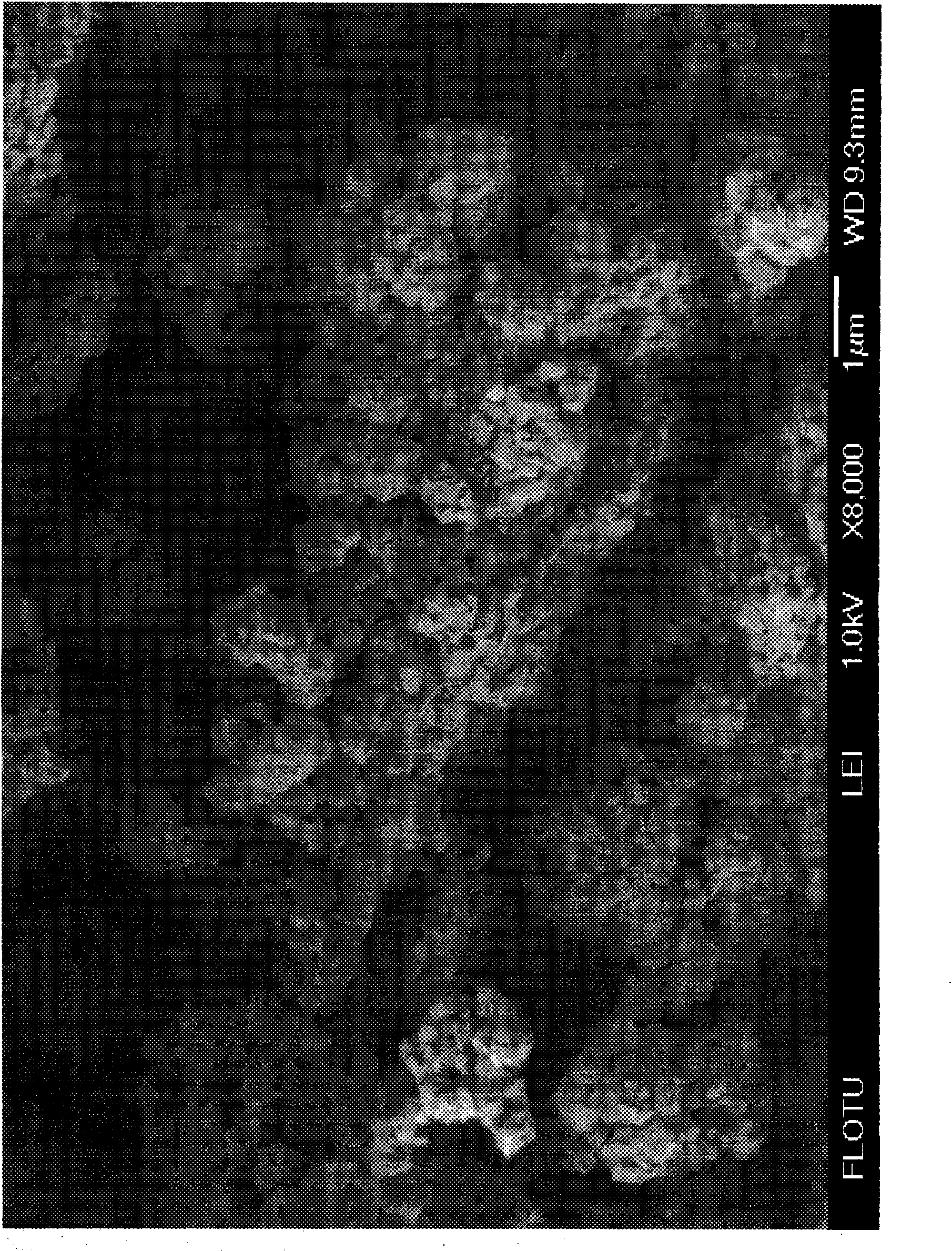

[0027] 1.1. Preparation of white carbon black

[0028]Add 440 kg of the sodium silicate solution obtained in 1.4 into the pressure-resistant dripping tank. The carbonization reactor is a loop reactor with an ultrasonic generator. Turn on the ultrasonic wave and the external circulation pump. The maximum output power of the ultrasonic generator is 1000W, and the frequency is 20-30KHz. Add 400kg of water and 6kg of sodium chloride into the carbonization reactor, add sodium silicate solution dropwise into the reaction tower when the temperature is 80-85°C and the system pressure is 0.1MPa, and at the same time, carbon dioxide and silicic acid are introduced into the gas distributor. After adding 44kg of sodium solution, stop adding, stop feeding carbon dioxide when the pH drops to 7-8, break the colloid after standing for 25 minutes, continue to add sodium silicate solution dropwise and feed carbon dioxide until the pH is 8-9 During the process, solid-liquid separation was carrie...

Embodiment 2

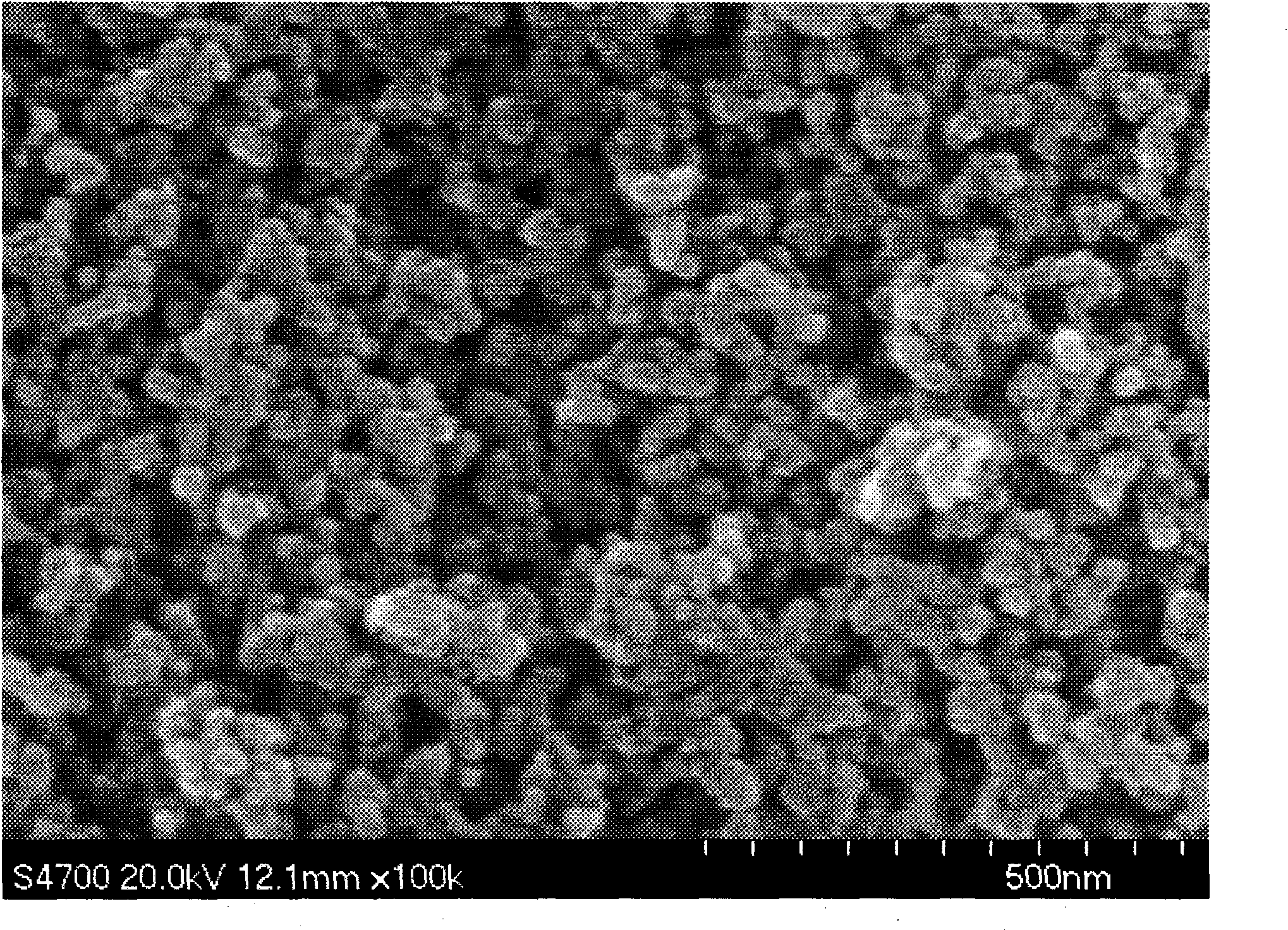

[0037] 2.1. Preparation of white carbon black

[0038] Add 440kg of the sodium silicate solution obtained in 2.4 into a pressure-resistant dropping tank. The carbonization reactor is a loop reactor with an ultrasonic generator. Turn on the ultrasonic wave and the external circulation pump. The maximum output power of the ultrasonic generator is 1000W, and the frequency is 20-30KHz. Put 400kg of water and 6kg of sodium chloride in the carbonization reactor. When the temperature is 80-85°C and the system pressure is 0.1MPa, add sodium silicate solution dropwise into the reaction tower and simultaneously feed carbon dioxide and silicic acid through the gas distributor. After adding 44kg of sodium solution, stop adding, stop feeding carbon dioxide when the pH drops to 7-8, break the colloid after standing for 25 minutes, continue to add sodium silicate dropwise and feed carbon dioxide until the pH is between 8-9 During the process, solid-liquid separation was carried out while it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com