Power cycle method using hydrogen as fuel

A power cycle and fuel technology, applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc., to achieve the effect of energy saving and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

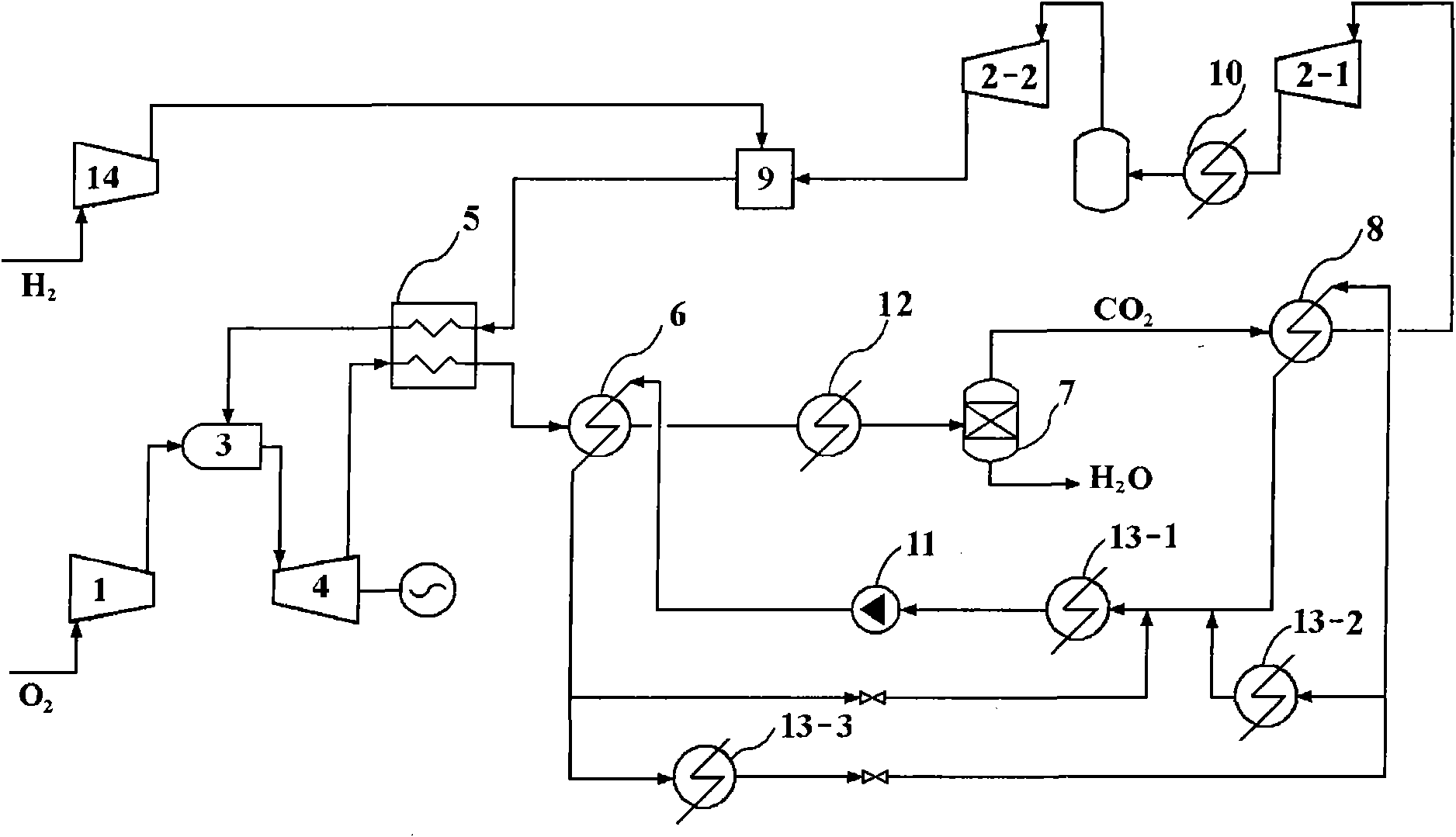

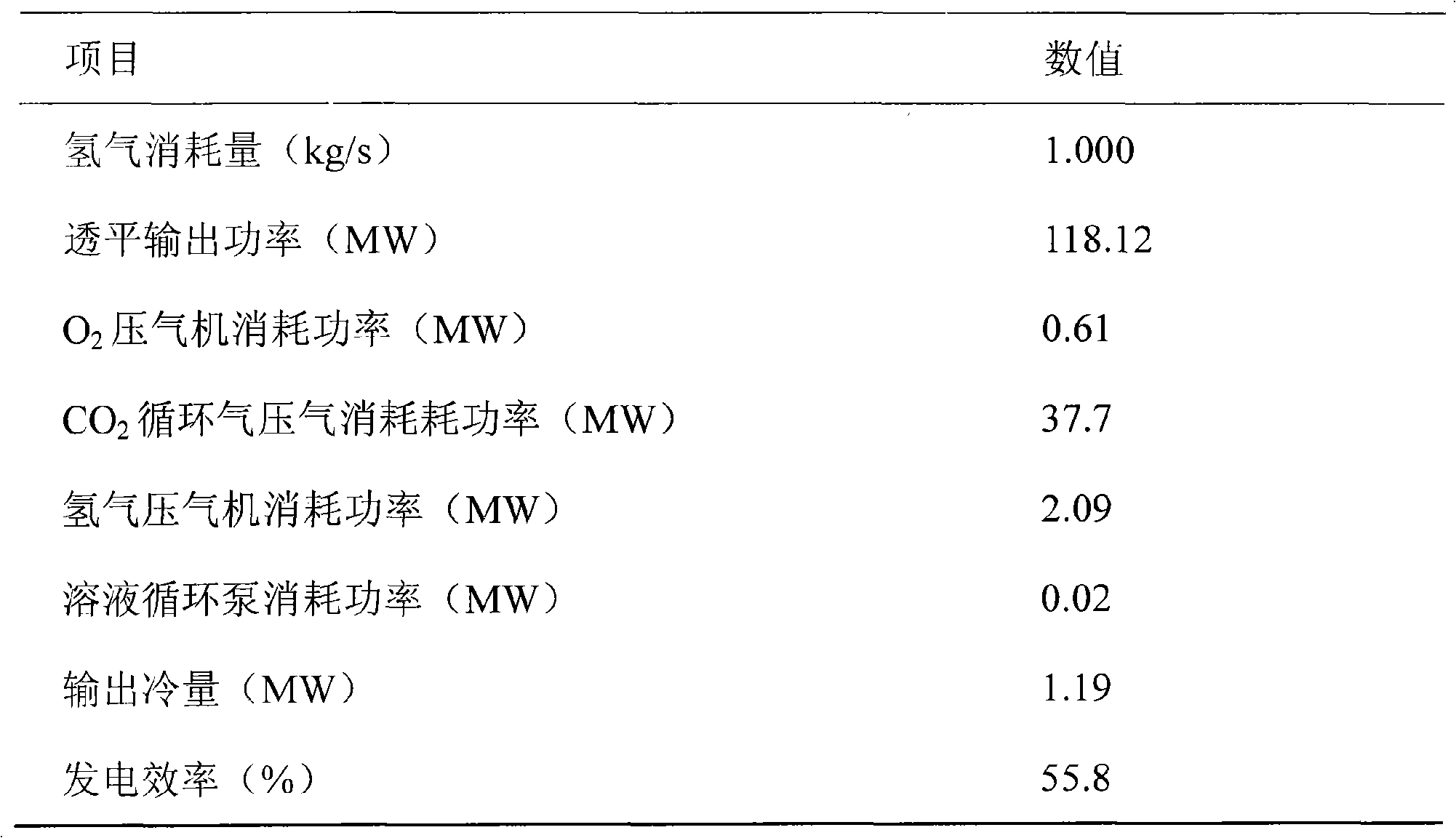

Embodiment 1

[0024] In the circulation system, from the hydrogen pipeline 1kg·s -1 flow of hydrogen, with cooling to 0°C in a cooler and CO 2 The two-stage compression of the circulating air compressor boosts the CO to 1MPa 2 According to the molar ratio of 1:9 in CO 2 Mix in the circulating gas mixer, enter the reverse conversion reactor, and reverse conversion reaction occurs at 860 ° C, the reverse conversion product generates CO (content 6.2%), then enters the combustion chamber, and is pressurized to 1MPa by a pure oxygen compressor. Oxygen undergoes a combustion reaction, and the 1300°C high-temperature gas generated by the combustion first enters the turbine to expand and do work. The turbine exhaust first enters the inverse conversion reactor for heat exchange, providing heat for the inverse conversion reaction, and its own temperature drops to 200°C; then enters the single-stage ammonia water absorption refrigeration cycle system, and is further cooled to 135°C in the heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com