Polyether type polyurethane concrete paving material and preparation method thereof

A technology of polyether polyurethane and pavement materials, which is applied in the field of functional pavement materials, can solve the problems of complicated preparation methods and short construction retention time, so as to overcome serious diseases, avoid harmful gas emissions, and ensure comfort and safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

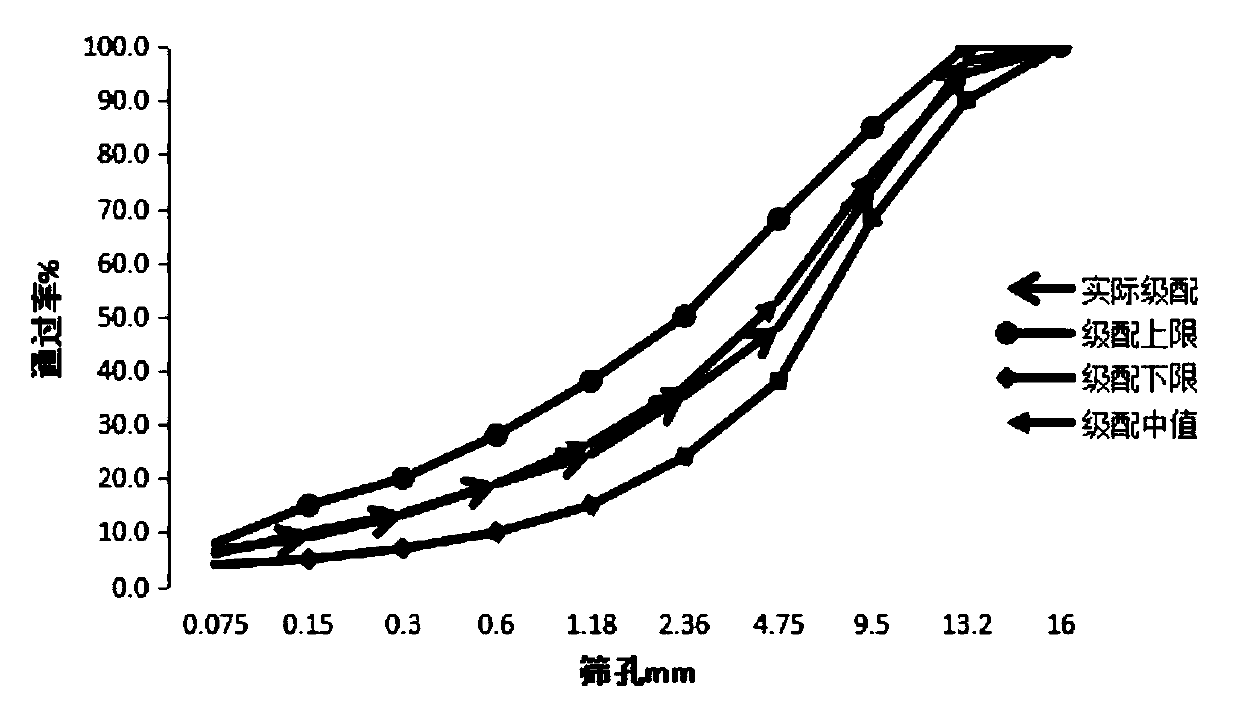

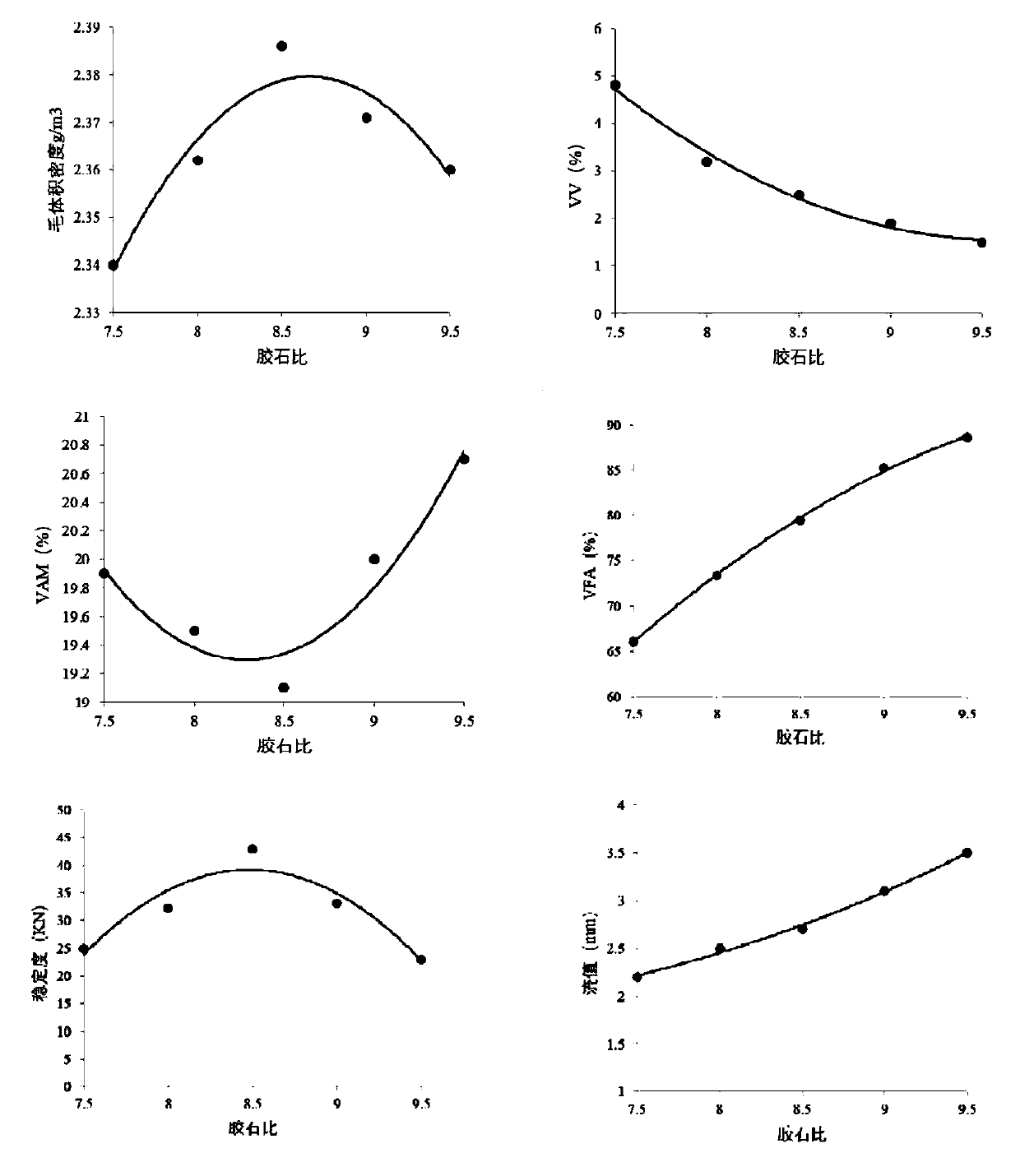

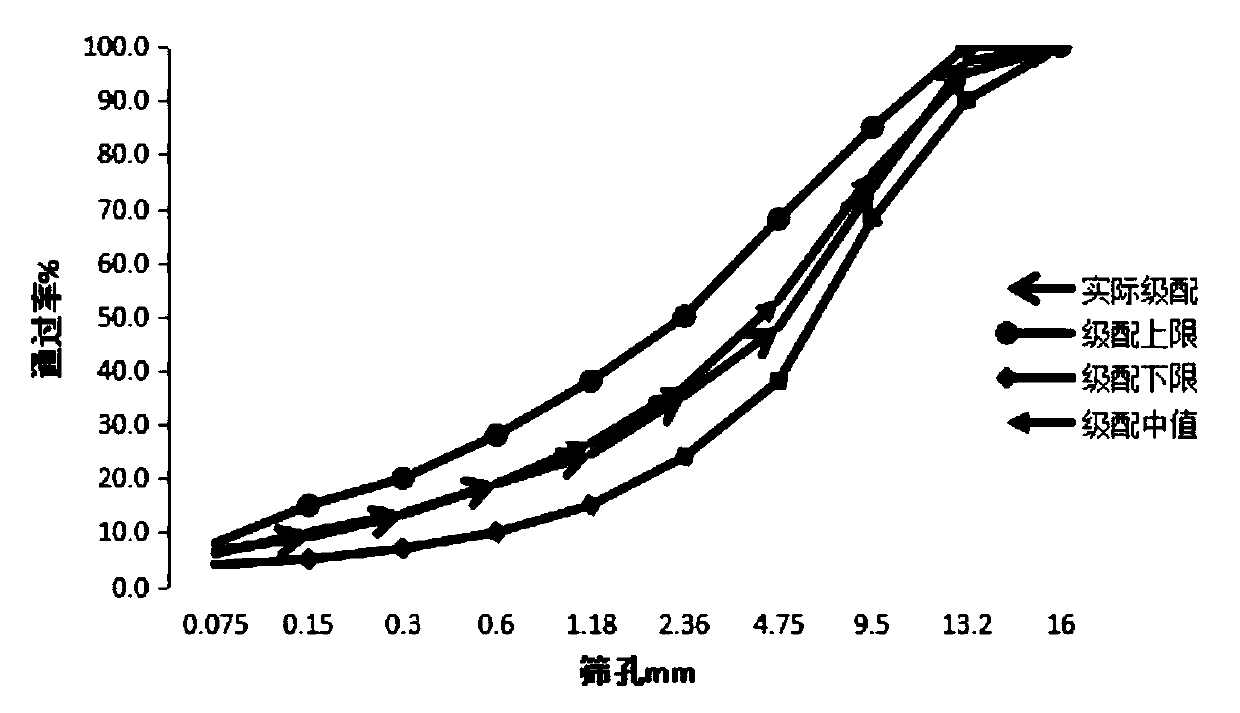

[0051] In this experiment, according to the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering", the Marshall design method was used to design the mix ratio of polyether polyurethane mixtures. Polyether polyurethane concrete can adopt various gradations such as: continuous dense gradation, open gradation and so on. The present invention takes continuous compact assembly (AC) as an example. At present, there is no uniform and standardized design requirement for cold-mix materials or polyether polyurethane materials, but for hot-mix or cold-mix pavement materials, our design purpose is that its performance meets our requirements, because Referring to the Marshall design method and taking into account the durability factor, the optimal amount of adhesive is determined mainly by using the design void ratio and mineral material void ratio as reference indicators combined with gross bulk density, flow value, and Marshall stability as auxiliary indicators.

[...

Embodiment 2

[0060] A polyether type polyurethane concrete pavement material and its preparation method, its mixing ratio design method and test piece performance testing method are the same as in Example 1, the difference is that the curing time of the prepared polyether type polyurethane concrete test piece is 24 hours. After curing, the polyether polyurethane concrete specimens were tested for high temperature performance, low temperature performance, water stability performance and fatigue performance, as shown in Table 2.

[0061] Table 2 Test results

[0062]

[0063] It can be seen from the data in the table that after changing the curing time, the high temperature performance, low temperature performance, water stability performance and fatigue performance of polyether polyurethane concrete are all lower than those in Example 1.

Embodiment 3

[0065] A polyether type polyurethane concrete pavement material and its preparation method, its mixing ratio design method and test piece performance testing method are the same as in Example 1, the difference is that the curing temperature of the prepared polyether type polyurethane concrete test piece is 30°C . After curing, the polyether polyurethane concrete specimens were tested for high temperature performance, low temperature performance, water stability performance and fatigue performance, as shown in Table 3.

[0066] table 3

[0067]

[0068] It can be seen from the data in the table that after changing the curing time, the high temperature performance, low temperature performance, water stability performance and fatigue performance of polyether polyurethane concrete are all lower than those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com