Industrial waste residue soil stabilizer and preparation method and construction method thereof

A technology of soil stabilizer and industrial waste, which is applied in the field of civil engineering and construction materials, can solve the problems of pollution, low utilization rate of solid waste, high storage cost, etc., and achieve the effect of broad application prospects, low cost, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

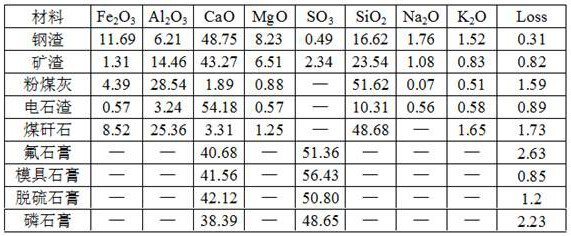

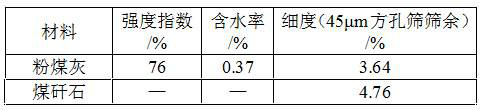

Method used

Image

Examples

Embodiment 1

[0048] The industrial waste slag soil curing agent of the present invention is prepared by 30% of steel slag powder, 30% of slag powder, 10% of fly ash, 10% of phosphogypsum, 5% of coal gangue powder, and 15% of carbide slag;

[0049] During preparation, first add fly ash, coal gangue powder, phosphogypsum, steel slag powder and slag powder into the coulter mixer in sequence, mix at high speed for 30 minutes at a speed of 1500r / min, finally add calcium carbide slag, and continue mixing for 20 minutes After a few minutes, pack it into a bag and keep it sealed.

[0050] Mix the prepared industrial waste soil stabilizer into the soil according to 3%, 6%, 9%, and 12% of the dry weight of the soil, and measure the optimum moisture content of the mixture; add water and mix with the optimum moisture content of the mixture Uniformly compacted and formed, and maintained according to the test method. After reaching the age, test the properties of the solidified soil. The test results a...

Embodiment 2

[0052] The industrial waste slag soil curing agent of the present invention is prepared by 20% of steel slag powder, 30% of slag powder, 15% of fly ash, 12% of mold gypsum, 5% of coal gangue powder, and 18% of carbide slag;

[0053] The preparation method is the same as in Example 1.

[0054] Mix the prepared industrial waste soil solidifier into the soil according to 6% of the dry weight of the soil, and measure the optimal moisture content of the mixture; add water to mix and evenly compact the mixture according to the test method Carry out maintenance, and after reaching the age, test the various properties of the solidified soil. The test results are shown in Table 7 and Table 8 below.

Embodiment 3

[0056] The industrial waste slag soil curing agent of the present invention is prepared by 20% of steel slag powder, 30% of slag powder, 25% of fly ash, 10% of mold gypsum, 5% of coal gangue powder, and 10% of carbide slag;

[0057] The preparation method is the same as in Example 1.

[0058] Mix the prepared industrial waste soil solidifier into the soil according to 6% of the dry weight of the soil, and measure the optimal moisture content of the mixture; add water to mix and evenly compact the mixture according to the test method Carry out maintenance, and after reaching the age, test the various properties of the solidified soil. The test results are shown in Table 7 and Table 8 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com