Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Achieve high temperature performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermostable, flame-resistant and oil-proof rubber sizing material and production method thereof

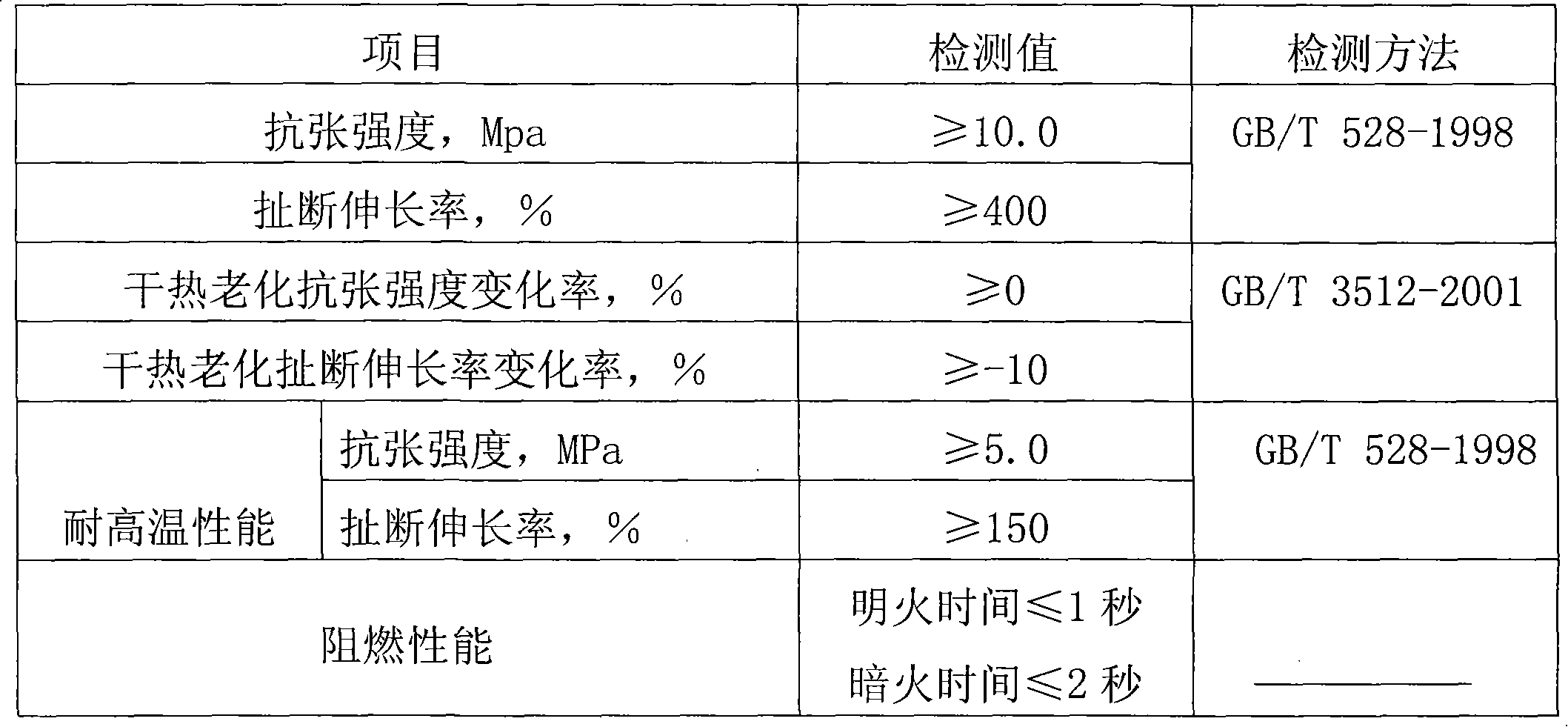

InactiveCN101250290AAchieve high temperature performanceAchieving Flame RetardancyFootwearAcrylonitrileUltra fast

The invention discloses rubber compound which is high temperature resistant, fire-proof and grease-proof and a production process, which is formed by raw materials with following weight: 100phr acrylonitrile butadiene, 2-3phr vulcanizing agent, 5-7phr zinc oxide, 2-3phr octadecanoic acid, 1-2phr medium accelerator, 3-4phr ultra fast accelerator, 30-40phr carbon black, 15-25phr softening agent 3-6phr anti-aging agent and 70-100phr halogen-free flame retardant. High temperature resistant and fire-proof sizing material which is produced through the sizing material formulation and the process realizes the high temperature resistance and fire-proof properties of acrylonitrile butadiene at the premise of non halogen-free environmental protection, is used to shoemaking production, and is suitable for work footwear under the condition of high temperature and temporary open flame.

Owner:JIHUA 3514 LEATHER & FOOTWARE

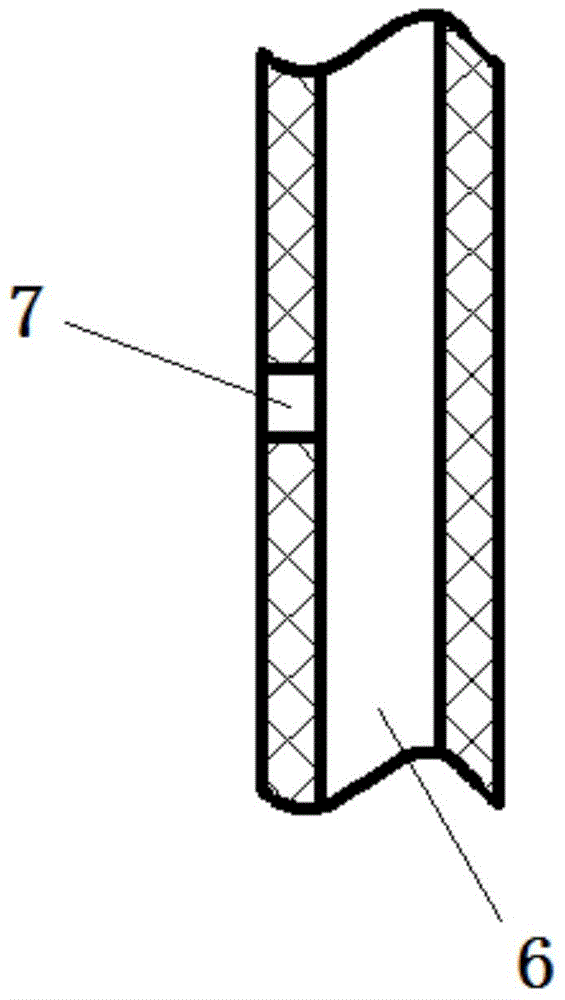

Heat insulated bridge solid steel door and window composite section bar and manufacturing method therefor

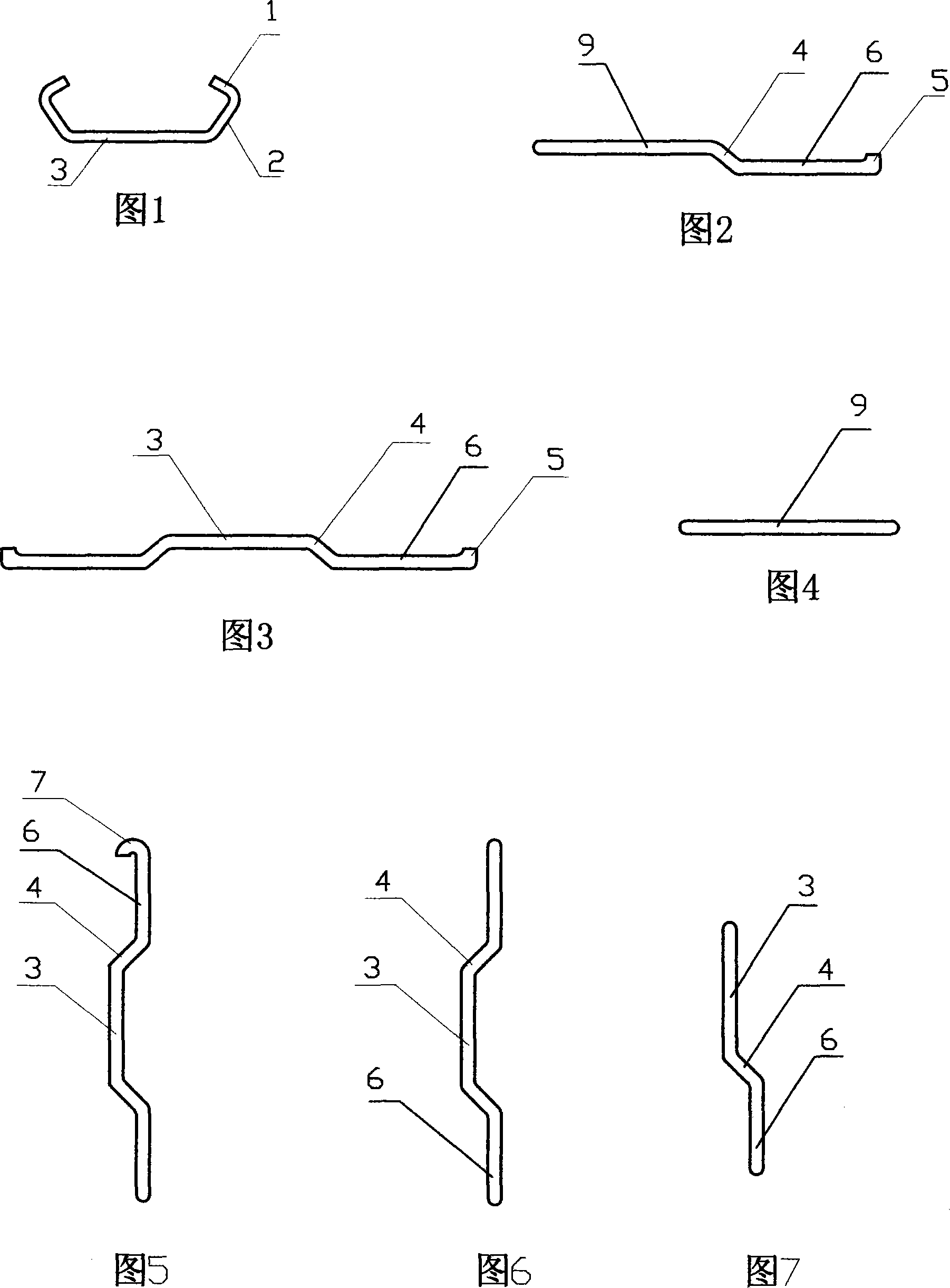

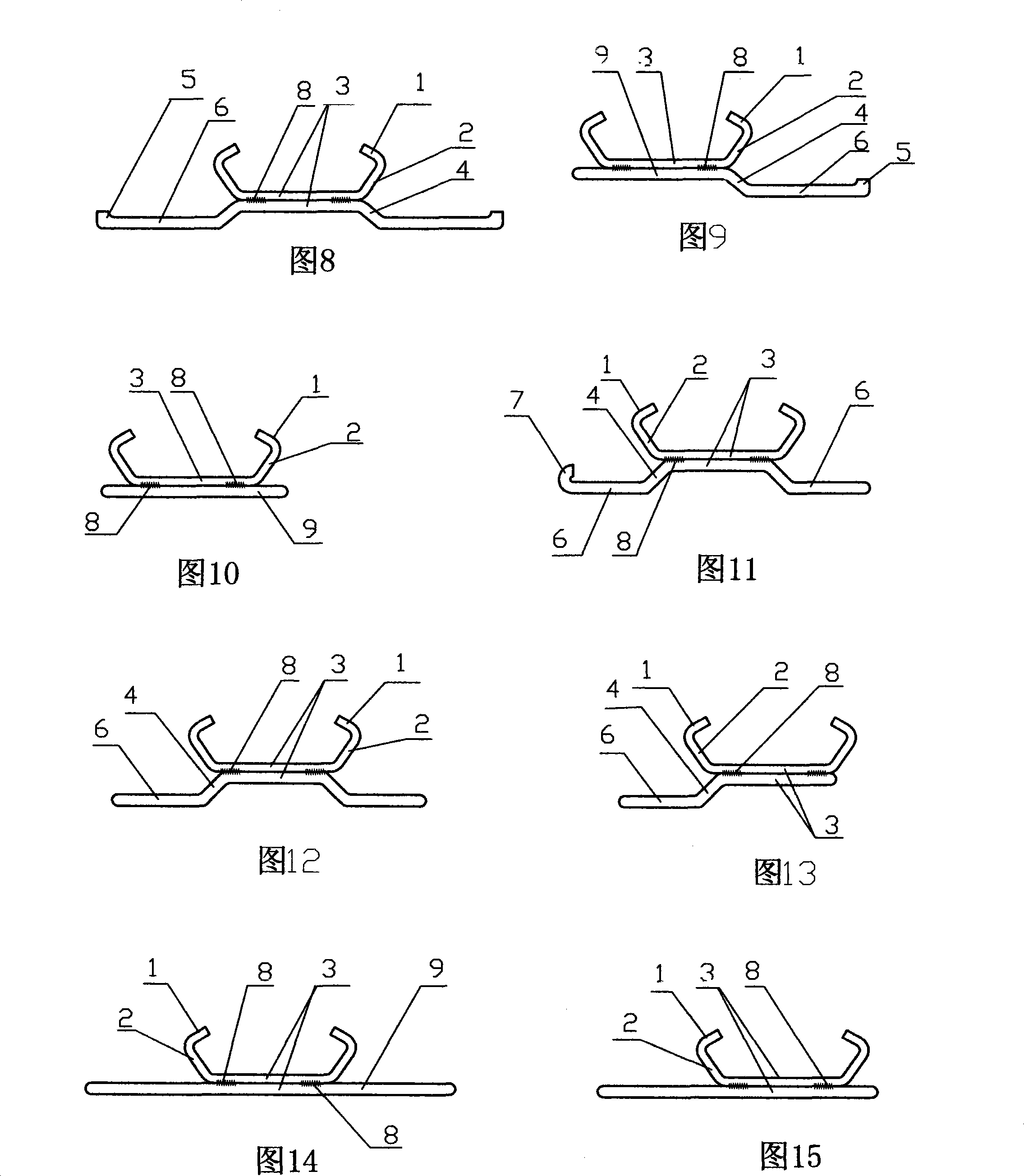

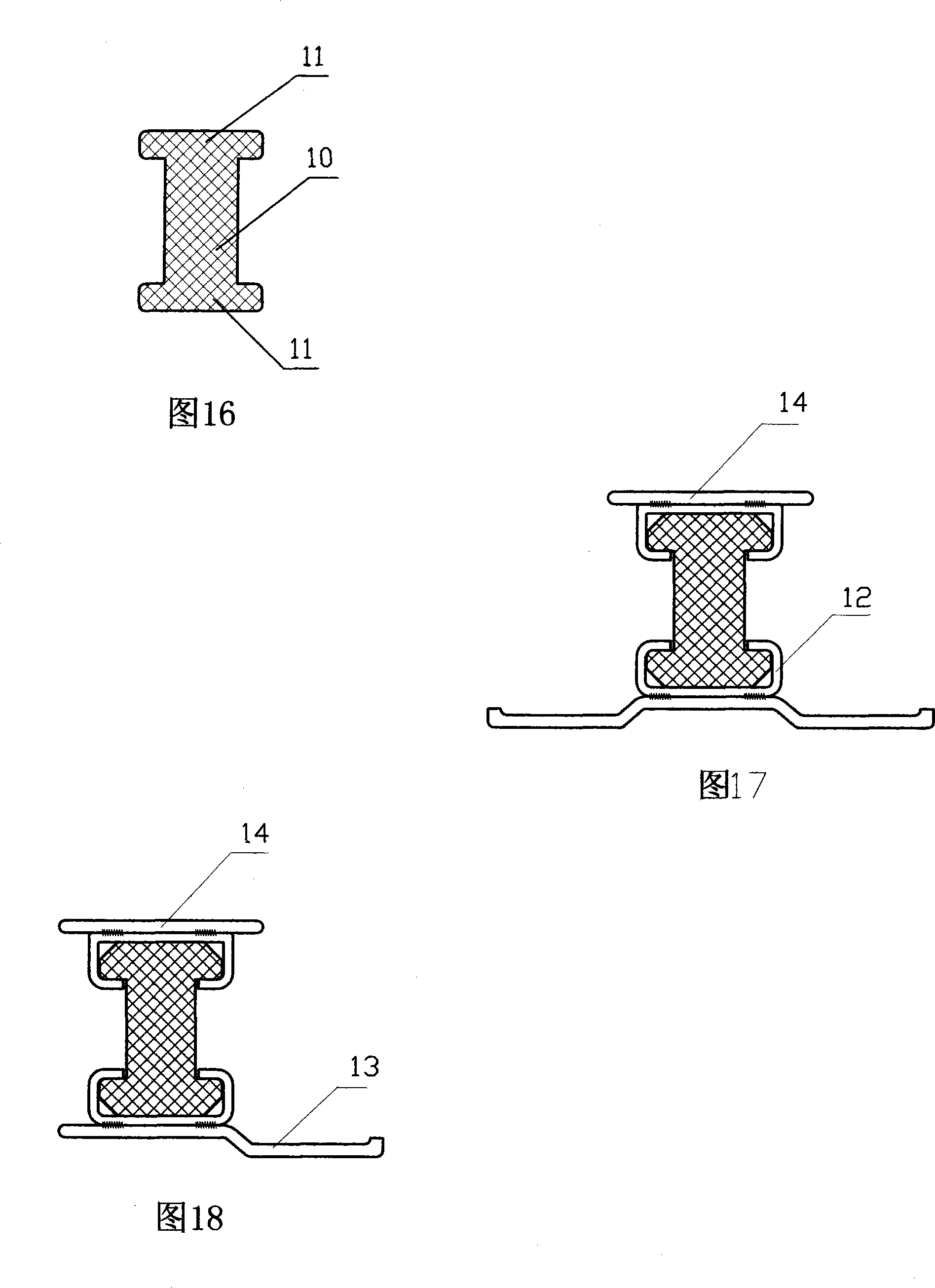

The present invention discloses a composite profile for thermal bridge solid-web steel doors and windows and a manufacturing method, relating to a steel door and window profile and a manufacturing method. The profile provided by the invention consists of a solid-web steel profile made from standard steel member and a nonmetallic heat insulation strip. The manufacturing method is that: firstly one to seven kinds of standard steel members are manufactured; secondly two standard members are seam welded into eight kinds of solid-web steel profiles; then two kinds of the solid-web steel profiles and one nonmetallic heat insulation strip are assembled into six kinds of composite profiles for thermal bridge solid-web steel doors and windows; and finally the coating and the assembly are carried out. Due to the small cross section, light weight, high strength, steel material saving and convenient assembly of the steel member, the profile provided by the present invention has the advantages of good heat insulation performance and high quality. The present invention also has the advantages of simple method, low equipment investment, standardized manufacture of the steel member, high efficiency and convenient popularization and application. Thus the present invention can be widely applied in the composite sections for thermal bridge solid-web steel doors and windows for the flat-opening door and window, the sliding door and window, the fixed window, the top-hinged swinging window and the manufacture.

Owner:重庆华厦门窗有限责任公司

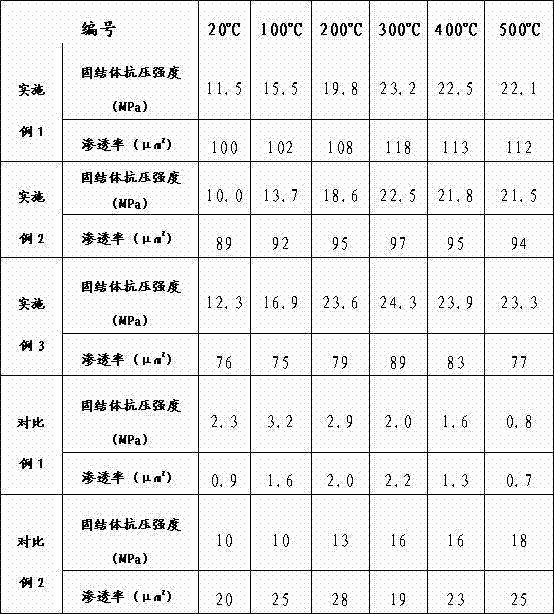

High-temperature-resistant sand-control support agent and high-temperature-resistant sand-control curing system

ActiveCN103173195AAchieve initial solidificationAvoid cakingDrilling compositionPhysical chemistryFirming agent

The invention discloses a high-temperature-resistant sand-control support agent, which comprises aggregate and a resin film wrapped on the surface of the aggregate, wherein the resin film comprises a heat-resistant solid phenolic resin film and a mixed resin film formed by mixing heat-resistant solid phenolic resin with liquid epoxy resin. The invention further discloses a high-temperature-resistant sand-control curing system, which comprises the high-temperature-resistant sand-control support agent and a curing liquid matched with the high-temperature-resistant sand-control support agent. The high-temperature-resistant sand-control support agent is thermally coated by adopting the heat-resistant solid phenolic resin and the liquid epoxy resin; a film coated layer is initially cured, so that the high-temperature-resistant sand-control support agent has initial compressive strength; when the curing liquid is injected into a stratum, the liquid epoxy resin can be reacted with a curing agent at a low temperature to carry out particle adhesion; solidification intensity required before injecting steam is achieved; along with rising of the temperature, the high-temperature-resistant phenolic resin begins to be reacted to generate high-temperature adhesion; and the solidification intensity of the sand-control support agent is further increased, therefore, normal-temperature curing and high-temperature-resistant performance are realized.

Owner:BEIJING RECHSAND SCI & TECH GRP

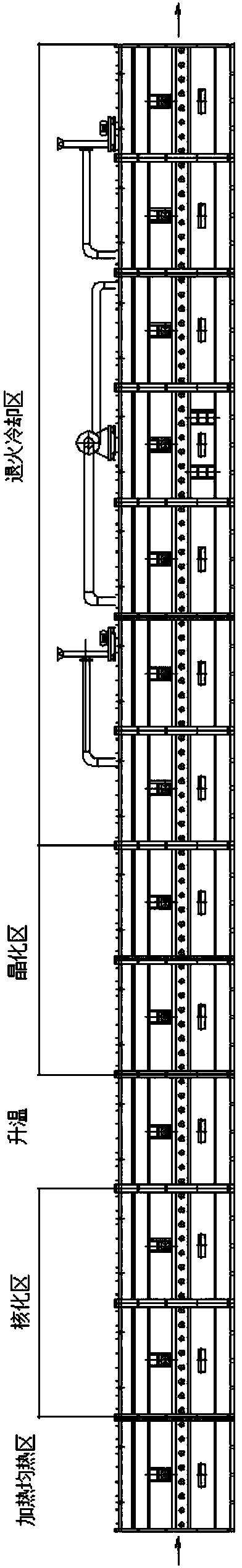

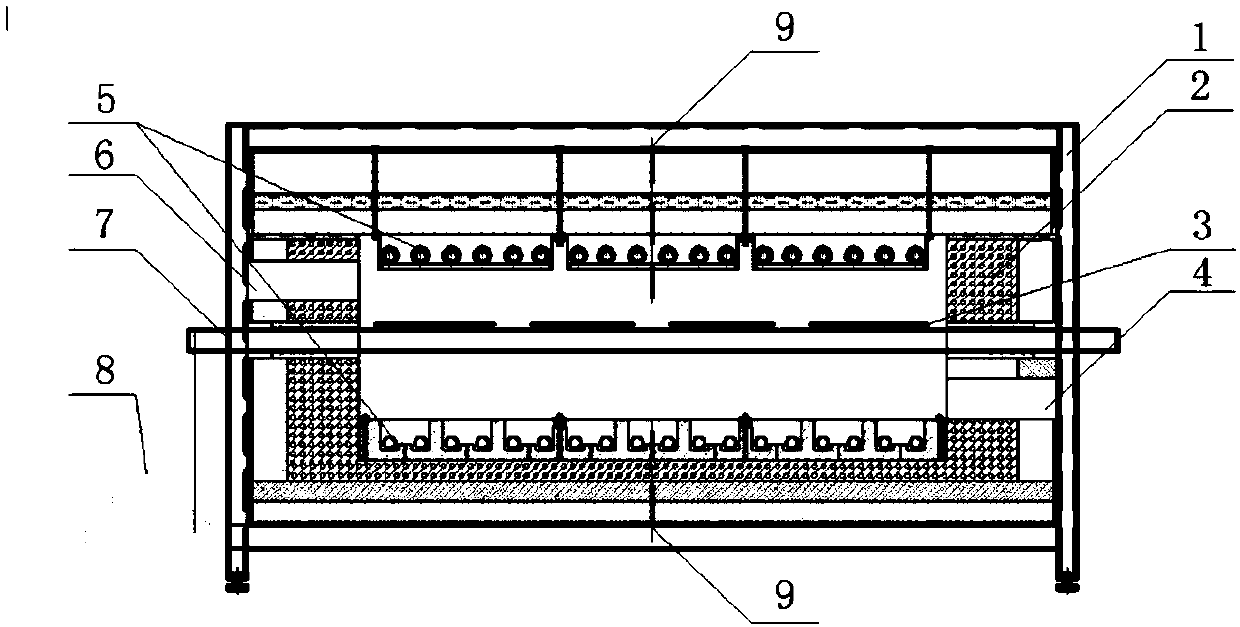

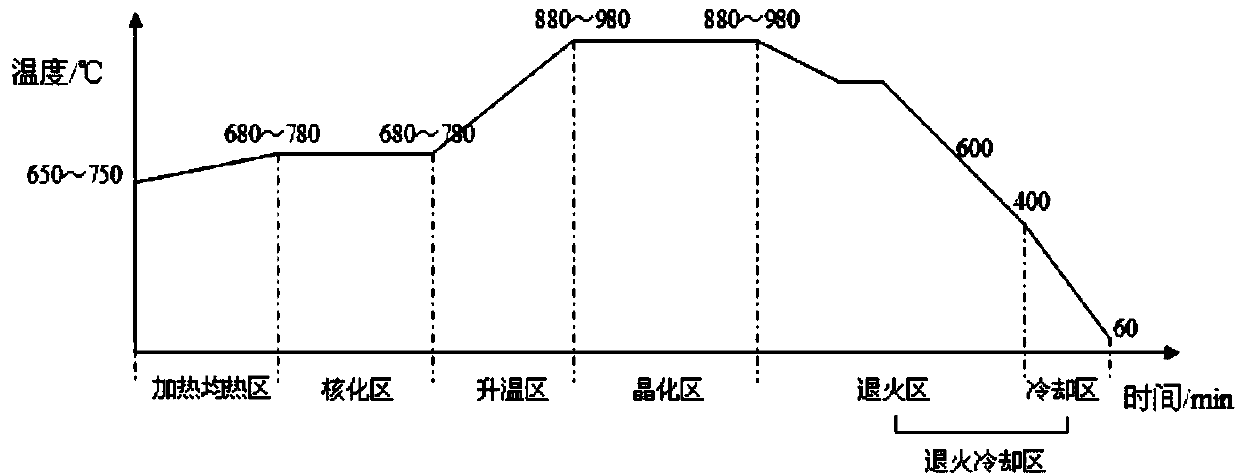

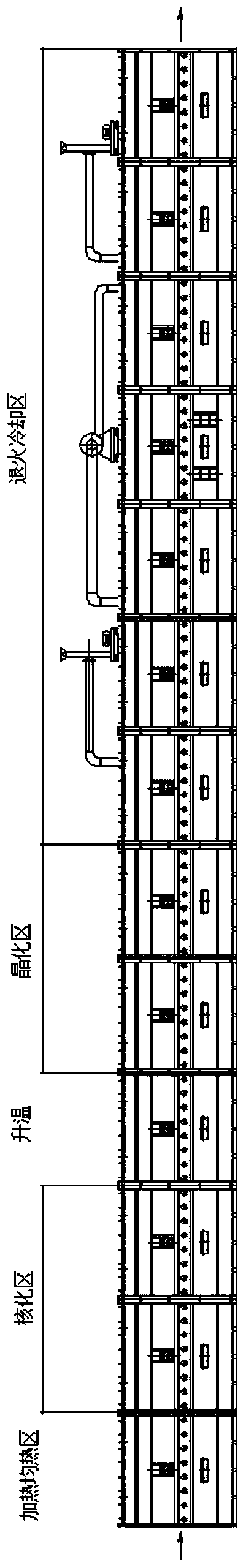

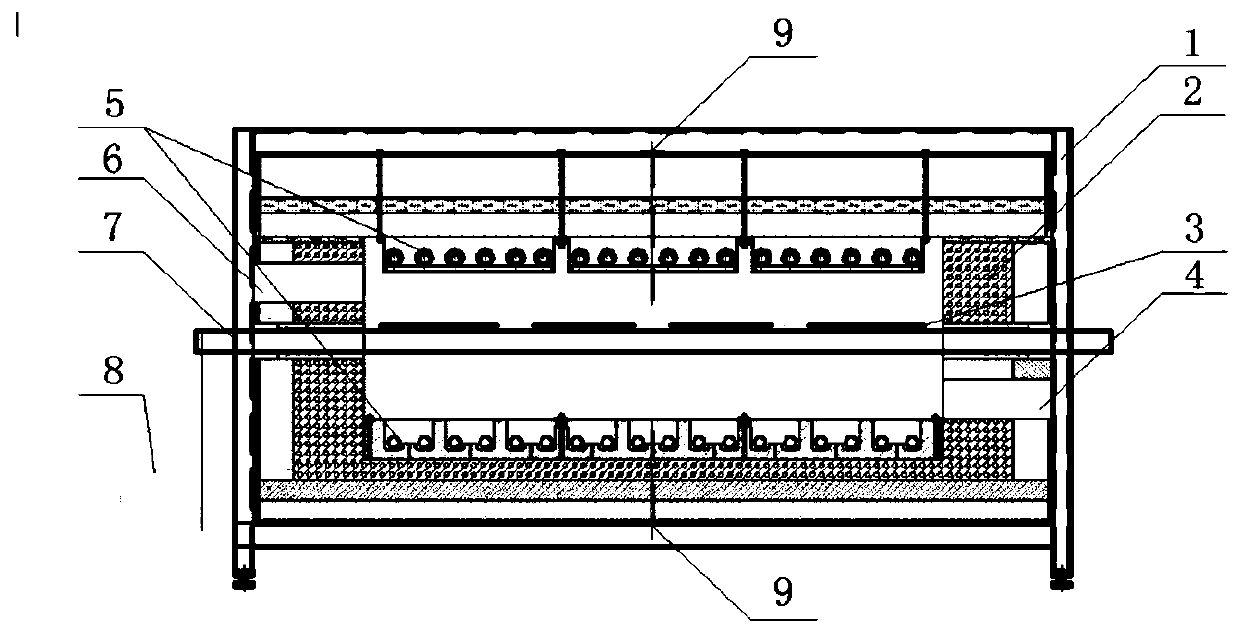

Architectural float glass ceramics crystallization annealing kiln and glass crystallization method

The invention relates to an architectural float glass ceramics crystallization annealing kiln, and belongs to the technical field of crystallization annealing of flat-plate glass ceramics. The crystallization annealing kiln is of a roller bed-type structure and comprises a kiln body with an outer wall of a steel structure and an inner wall made from a thermal insulation material. A nucleation zone, a crystallization zone, and an annealing cooling zone are sequentially arranged from an inlet to an outlet of the crystallization annealing kiln. The kiln side wall and the kiln bottom of the crystallization zone are made from a mullite thermal insulation material, and the kiln side walls and the kiln bottoms of the nucleation zone and the annealing cooling zone are both made from a poly-light high-aluminum thermal insulation material. The kiln roofs of the crystallization zone, the nucleation zone and the annealing cooling zone are all made from a ceramic fiberboard, and a fiber blanket isarranged between the steel structure and the thermal insulation material. The crystallization annealing kiln achieves crystallization annealing treatment of large-sized flat-plate glass ceramics molded by a float glass process.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE +1

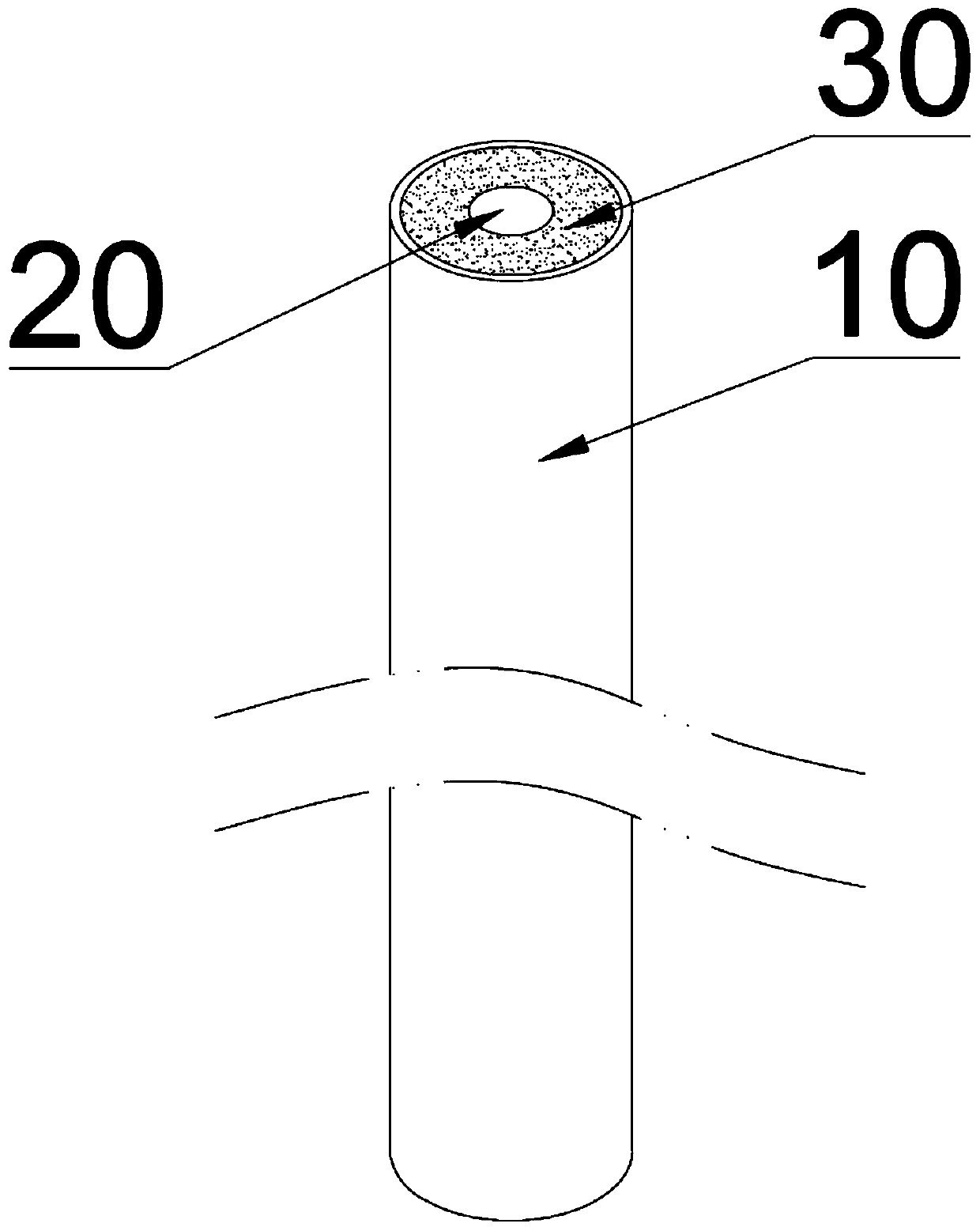

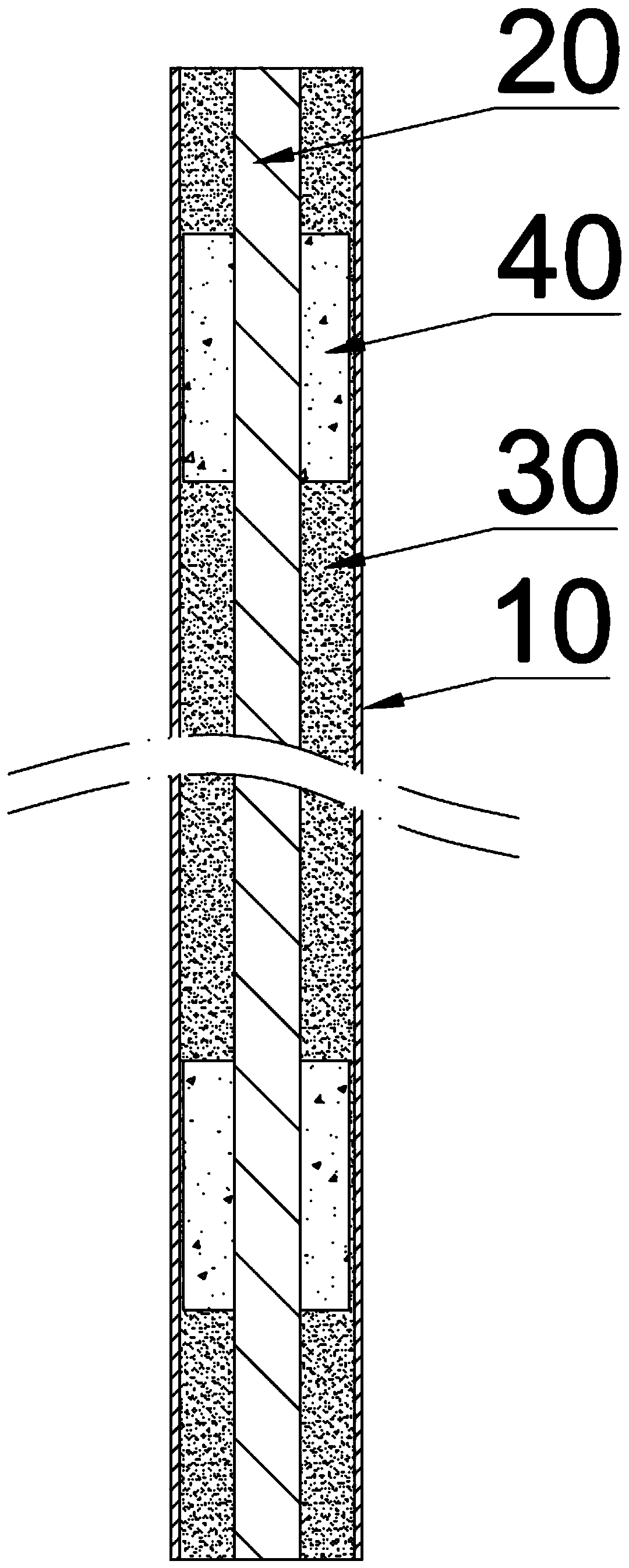

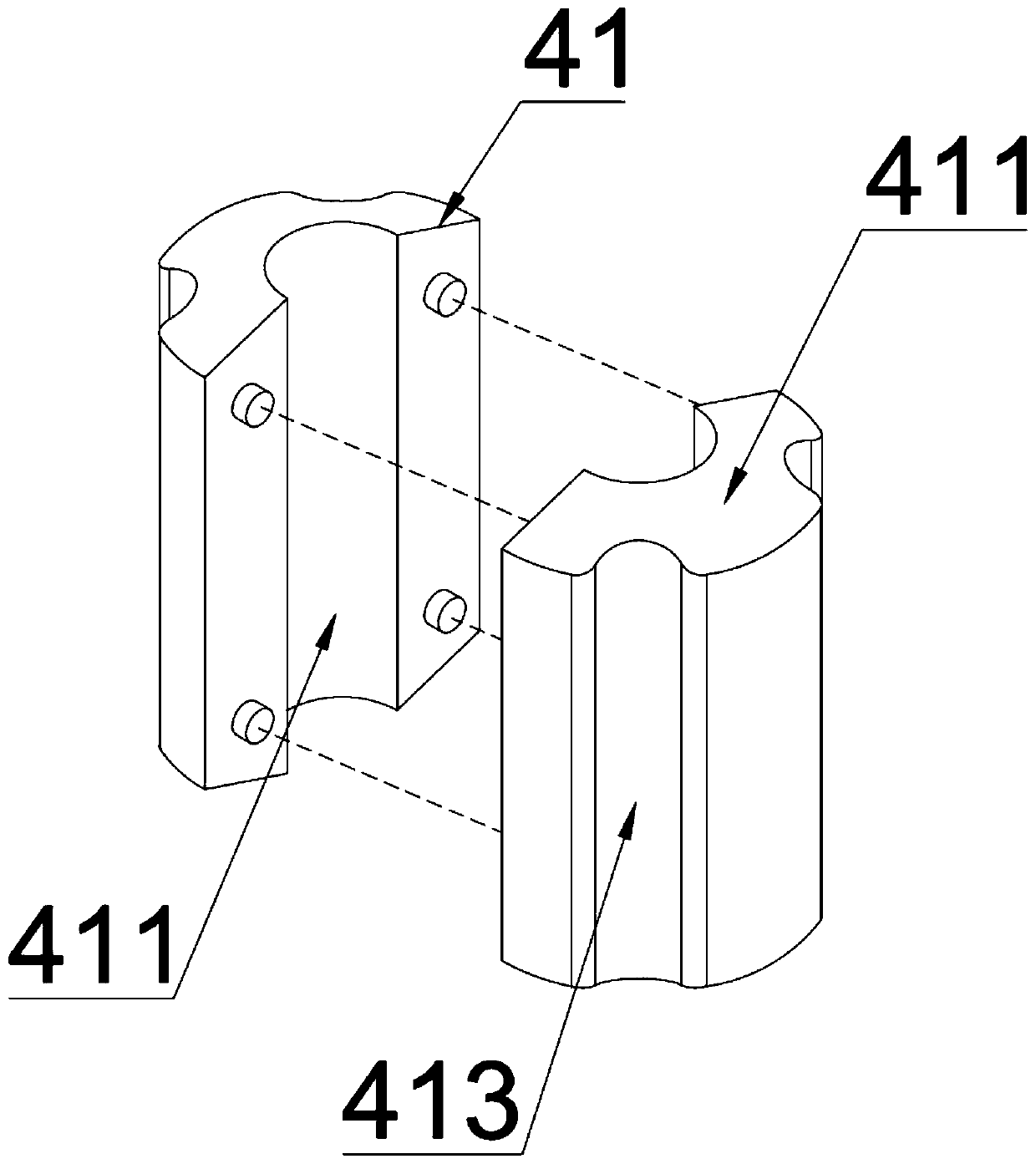

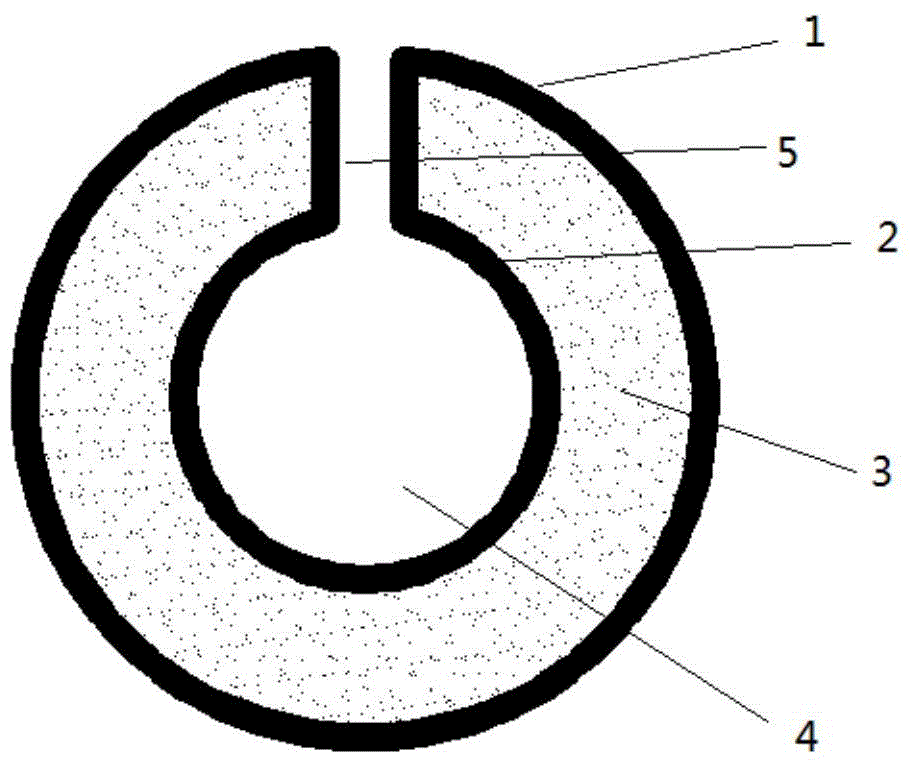

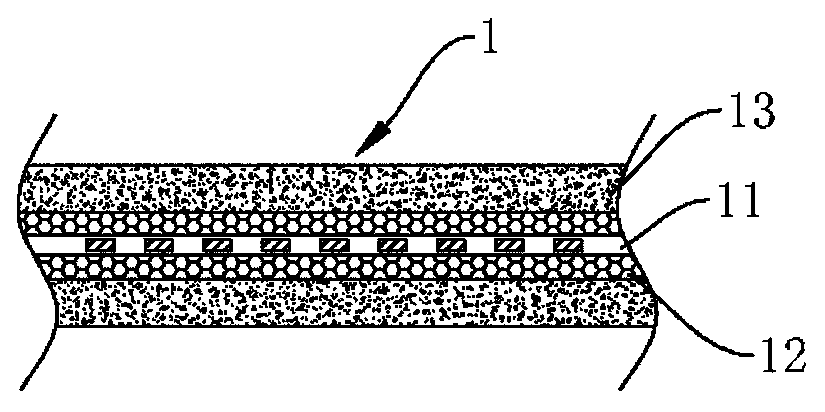

Mineral insulated fireproof cable and preparation method thereof

InactiveCN111354505AAchieve insulationAchieve high temperature performanceClimate change adaptationInsulated cablesCopper conductorEngineering

The invention discloses a mineral insulated fireproof cable. The mineral insulated fireproof cable comprises a cable core, a magnesium oxide filling layer and a seamless copper pipe which are sequentially arranged from inside to outside; the cable core is a single-strand copper conductor, and the cable core and the copper pipe are coaxially arranged. The magnesium oxide filling layer is densely and seamlessly filled between the cable core and the copper pipe, the magnesium oxide filling layer comprises magnesium oxide powder and magnesium oxide pipe columns which are sequentially arranged at intervals along the axis direction of the cable core, and the magnesium oxide pipe columns are sleeved on the cable core. The mineral insulation fireproof cable comprises a cable core, a magnesium oxide filling layer and a seamless copper pipe which are sequentially arranged from inside to outside. The fireproof insulation characteristic is good. The magnesium oxide filling layer is densely and seamlessly filled between the cable core and the copper pipe to realize insulation, fire resistance and high temperature resistance of the cable, and the magnesium oxide filling layer belongs to an inorganic filling material, so that the problem of insulation aging does not exist, and the service life of the cable can be more than three times that of a common cable.

Owner:广州市穗羽电线电缆有限公司

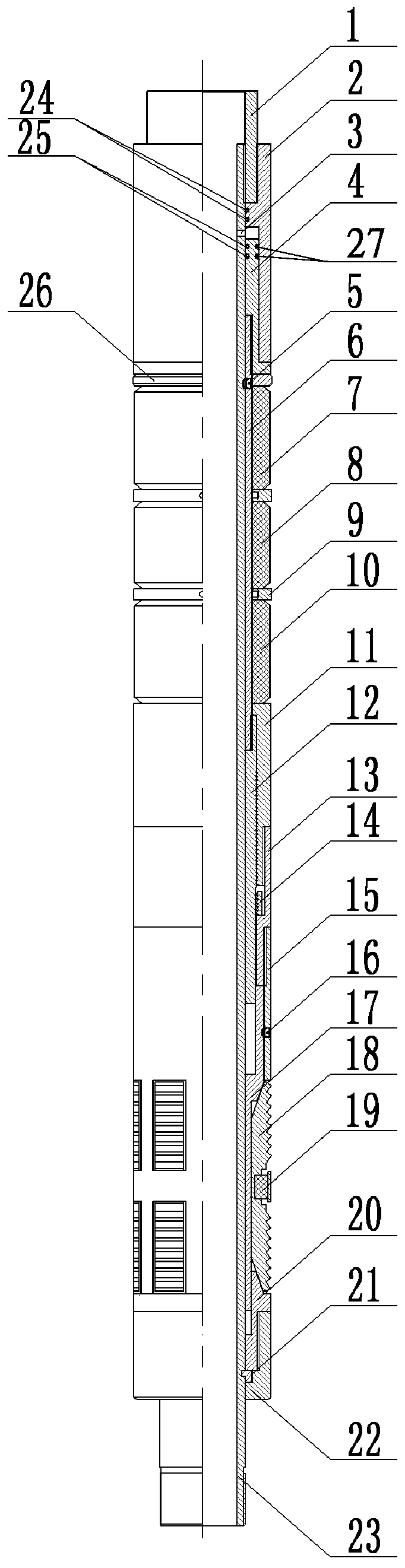

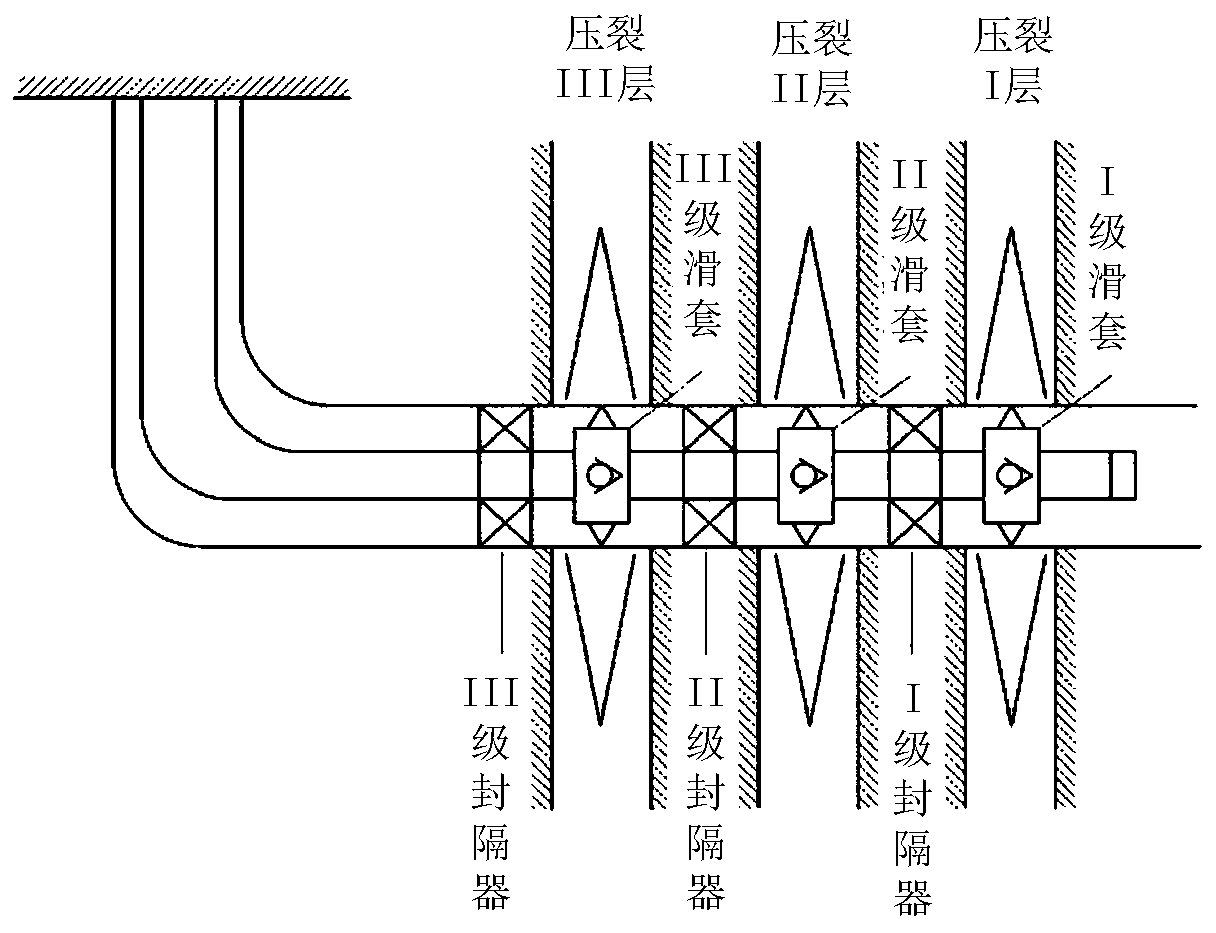

Multi-stage separate layer fracturing degradable packer and fracturing string

PendingCN110295867ATo achieve a large diameterAchieve high temperature performanceFluid removalWell/borehole valve arrangementsRelative motionEngineering

The invention discloses a multi-stage separate layer fracturing degradable packer and a fracturing string. The packer comprises a slip mechanism, a stepping mechanism, a rubber sleeve mechanism and apiston mechanism which are sequentially arranged on the outer side of a central pipe in a sleeving mode from bottom to top; slip setting of the slip mechanism is achieved through relative movement ofan upper cone and a lower cone; the piston mechanism located above the rubber sleeve mechanism communicates with an annulus space of the central pipe through a hydraulic hole formed in the central pipe, a rubber sleeve set is driven to be set, and the position of the piston mechanism is locked through the stepping mechanism, and the rubber sleeve mechanism is maintained in the setting state; in addition, all the parts adopt degradable materials and non-degradable materials in a matched mode, so that degradation and unsetting are achieved; and the multi-stage separate layer fracturing degradable packer and a construction string thereof have the characteristics of large diameter, high temperature resistance, high pressure resistance, easy flowback and degradability, and are combined with sliding sleeves to form a fracturing string applicable to deep well and horizontal well fracturing construction, and the problem that existing packers are difficult to get out of shafts after being stuckand buried by sand is effectively solved.

Owner:CNPC BOHAI DRILLING ENG

High-temperature curing adhesive for bonding electric insulators and preparation method thereof

InactiveCN101633827AAchieve high temperature performanceEasy to useNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolysulfide rubberTriethoxysilane

The invention discloses a high-temperature curing adhesive for bonding electric insulators and a preparation method thereof. The curing adhesive comprises the following material components in parts by weight: 100 parts of bisphenol-A epoxy resin, 80 to 95 parts of methyl tetrahydrophthalic anhydride, 20 to 40 parts of polysulfide rubber, 0.10 to 0.30 part of hexamethylene tetramine, 3.5 to 5.0 parts of 3-aminopropyltriethoxysilanes, 20 to 60 parts of 400-mesh silica and 1.0 to 3.0 parts of fumed silica. By modifying the specific formula of the adhesive, the invention can prevent the electric insulators from sagging during the curing process and keep up the shape of the electric insulators after the adhesive is coated; and meanwhile, the bonding strength of the electric insulator interface is subject to the design requirements for the bonding strength of interfaces in insulator products.

Owner:CHINA XD ELECTRIC CO LTD

Nano crystal Cr2N/amorphous WC superhard film with superlattice structure and preparation method thereof

InactiveCN101824595AAchieve superhard effectExpand the scope of engineering applicationsLayered productsVacuum evaporation coatingSputteringAmorphous phase

The invention relates to a nano crystal Cr2N / amorphous WC superhard film with a superlattice structure and a preparation method thereof, belonging to the technical field of material surfaces. The superhard film is formed by alternately depositing an electric arc ion plated nano crystal phase Cr2N layer and a magnetron sputtering plated amorphous phase WC layer, and a modulating period of a superlattice ranges from 10nm to 20nm, and the thicknesses of a Cr2N monolayer and a WC monolayer are respectively 8-14nm and 2-6nm. The alternate distribution of the Cr2N layer and the WC layer realizes the component diversification and structure multi-stratification of a Cr-N base film and solves the problem that the Cr-N base film with stronger oxidation resistance is difficult to obtain superhigh hardness; and meanwhile, the amorphous WC layer further improves the oxidation resistance and the corrosion resistance of the Cr-N base film and meets the surface strengthening requirement on various products not capable of being carried out heat treatment.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

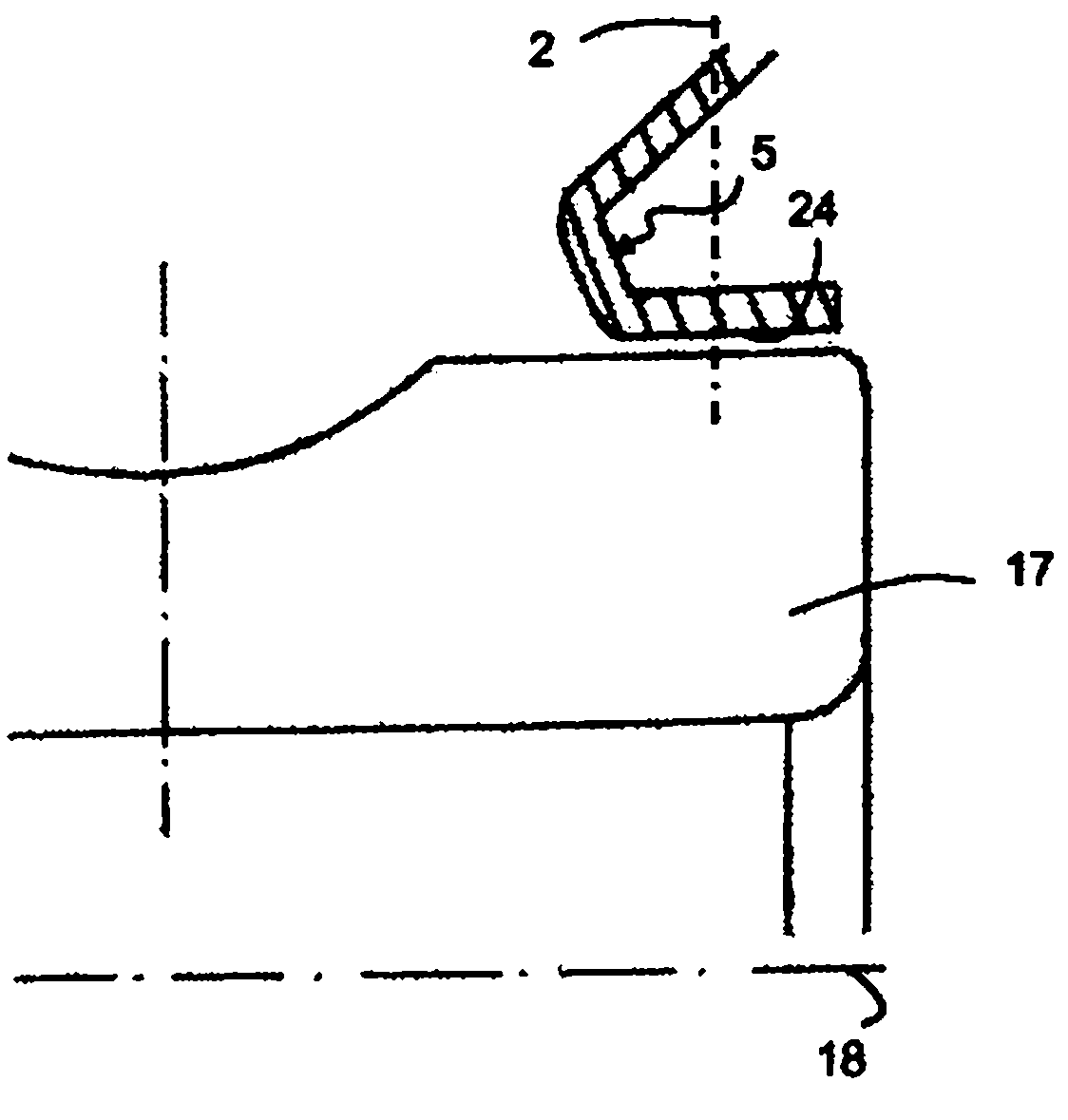

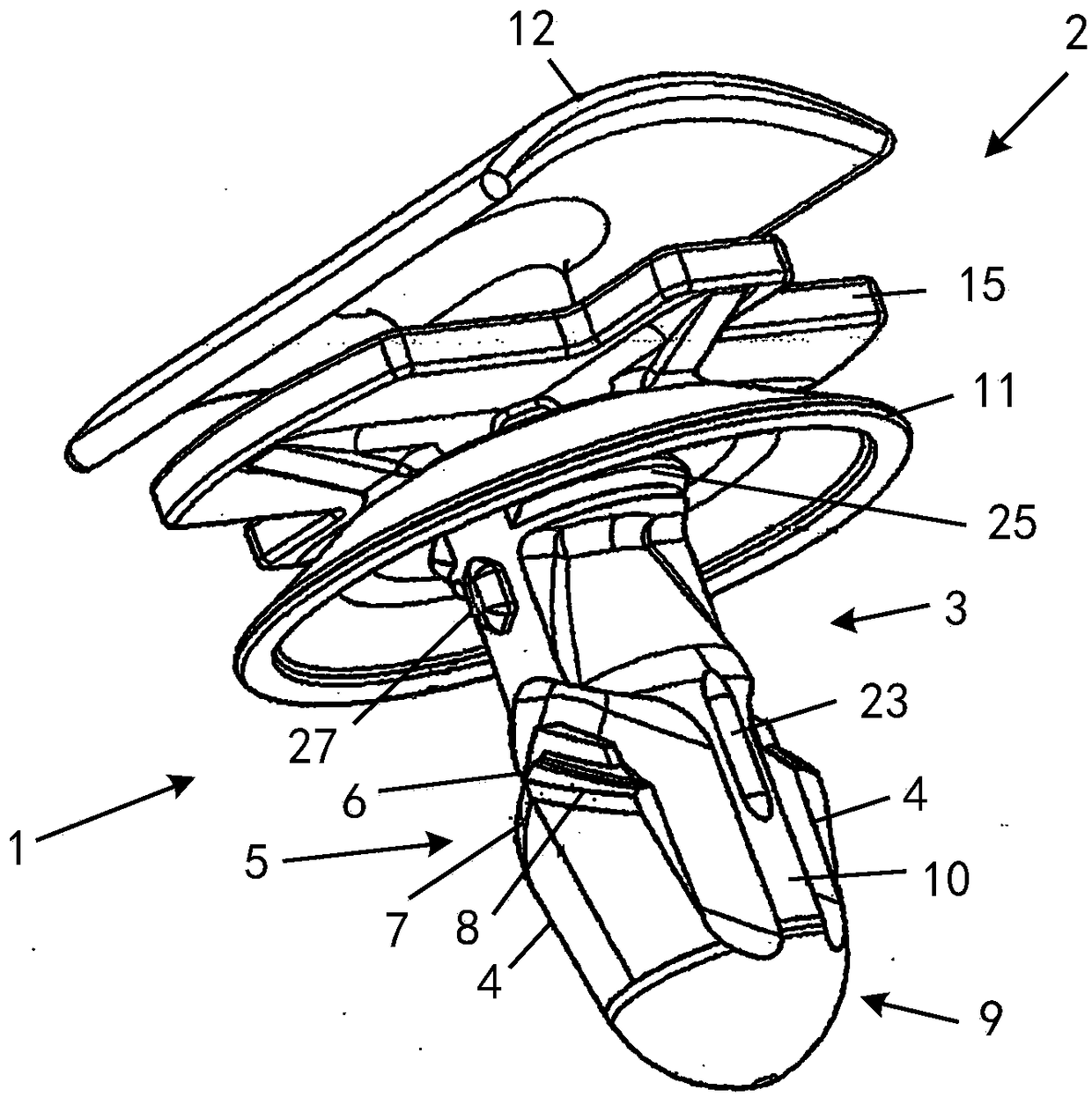

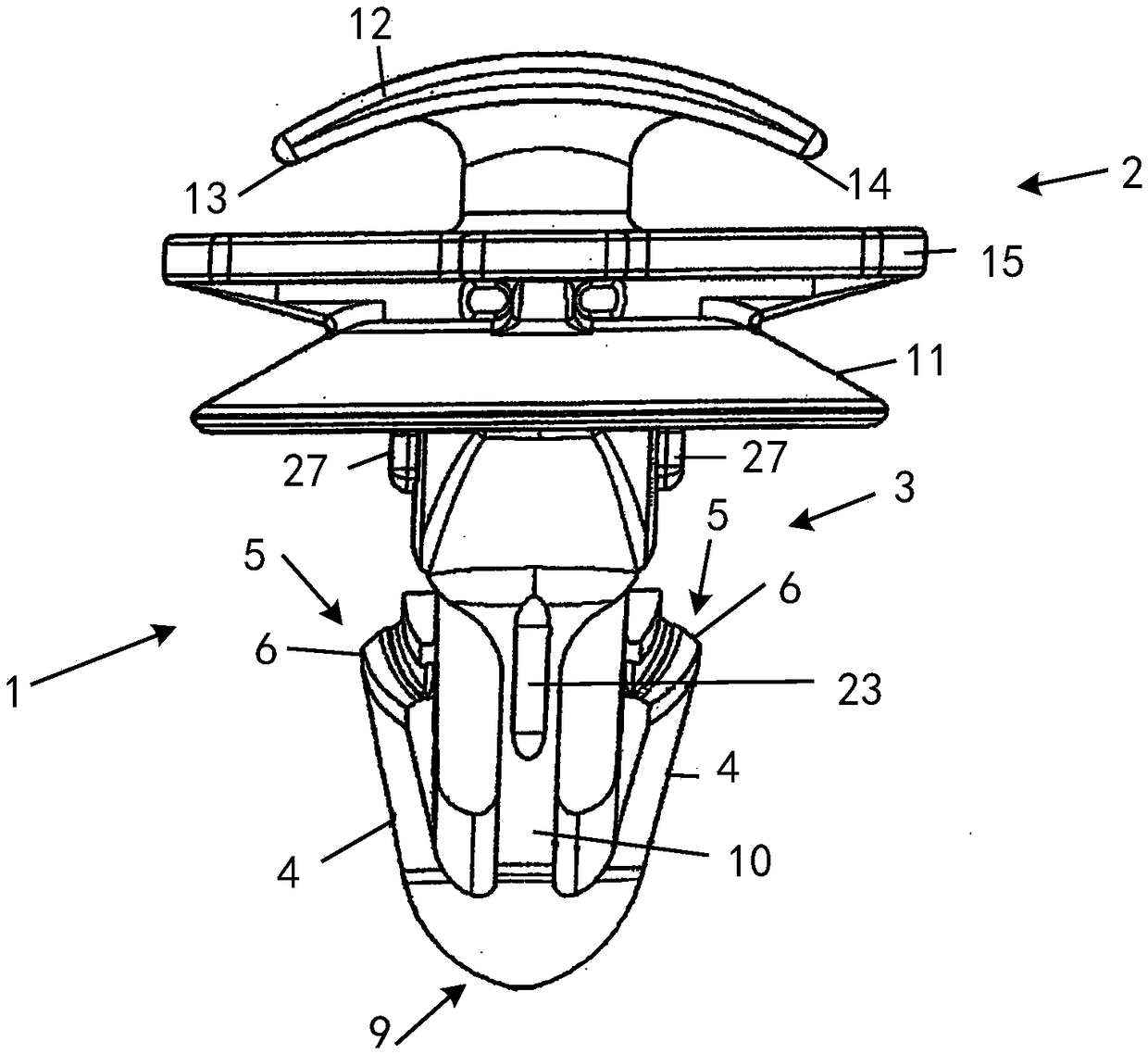

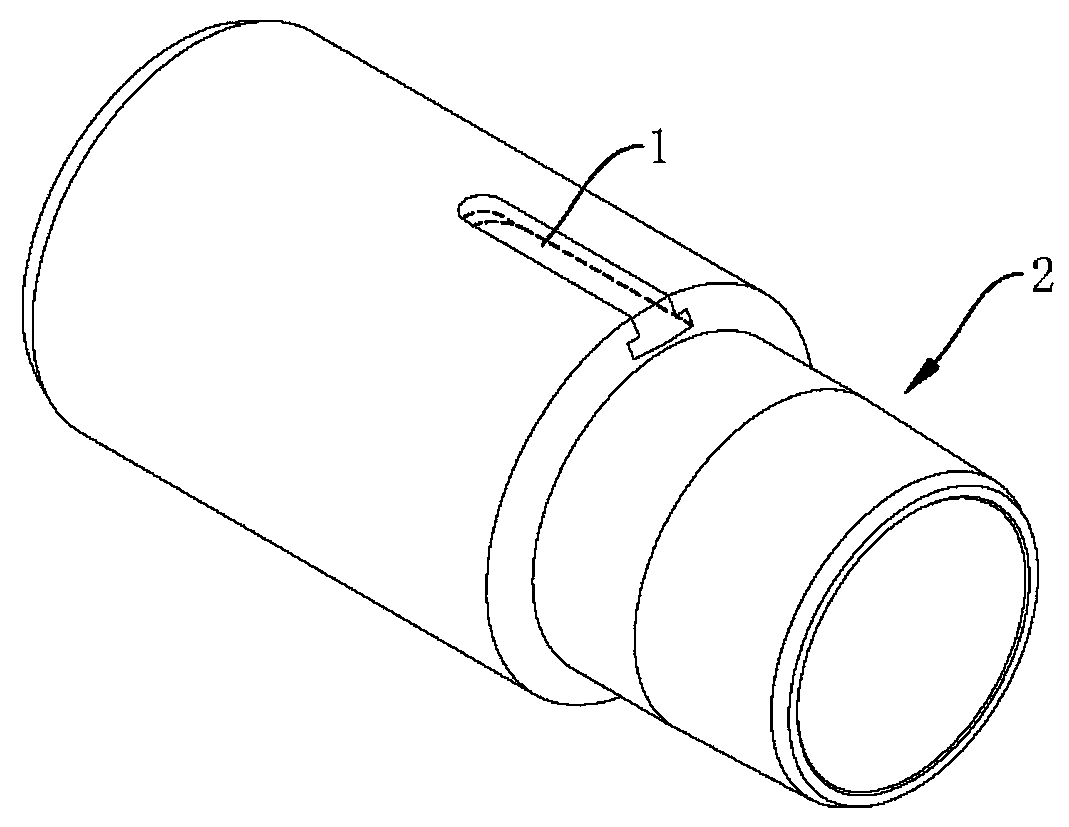

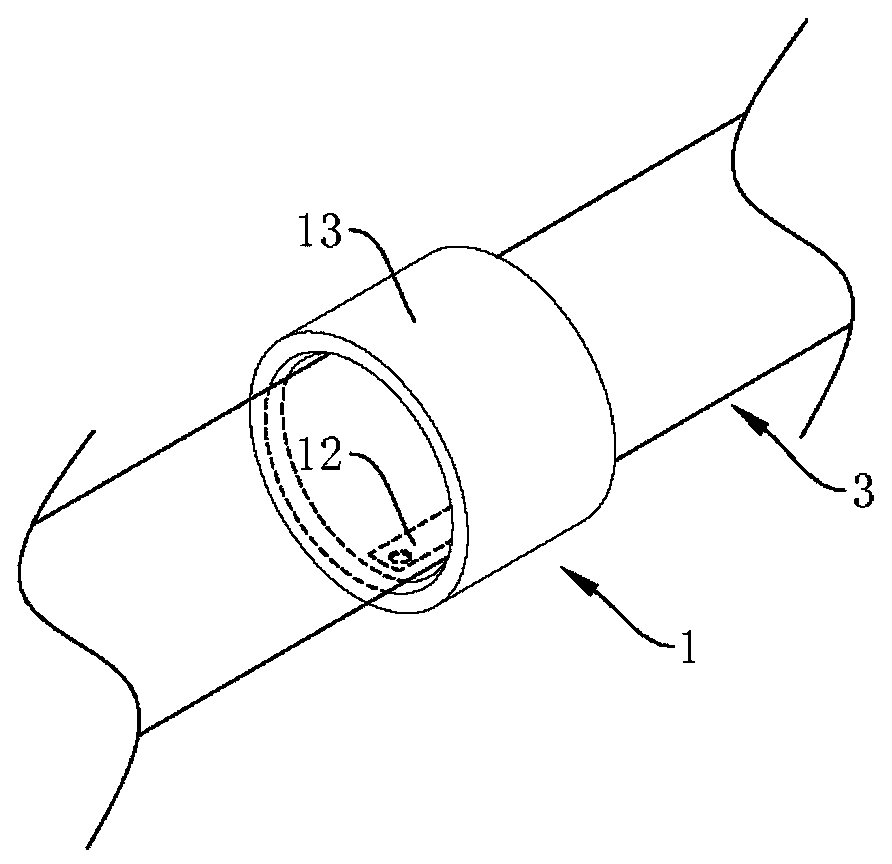

Sealing assembly for a rolling bearing

ActiveCN102428285AAvoid enteringReduce entryBall bearingsBearing componentsRolling-element bearingMechanical engineering

The invention relates to a sealing assembly for a rolling bearing, the sealing assembly having at least one cover element (1) for covering a bearing gap along a cover plane (2), the cover element (1), for securing purposes, having a securing section and a sealing collar as well as a base part (3) connecting the securing section and the sealing collar, and at least one sealing surface (6, 7, 9, 10) being provided on the sealing collar for non-contact sealing. According to the invention, at its starting section, the sealing collar extends from the base part (3) diagonally toward the inner side of the cover element (1) facing the bearing interior and at its end section it extends from the inside toward the outer side of the cover element (1) facing away from the bearing interior. At the same time, the sealing collar forms a sealing surface (7, 10) substantially perpendicular to the cover plane (2) and at the end of the end section at least one edge (4) impeding the inflow of impurities into the bearing interior.

Owner:SCHAEFFLER TECH AG & CO KG

High-temperature-resistant wave-proof sleeve

ActiveCN104844904AImprove high temperature resistanceImprove shielding effectInsulated cablesInsulated conductorsNickelSurface layer

The invention discloses a high-temperature-resistant wave-proof sleeve. The wave-proof sleeve is formed by a plurality of braiding lines through braiding, wherein each braiding line comprises a line core and a skin adhered to the surface layer of the line core, and the skin comprises nano-silicon carbide, polyethylene resin, modified epoxy resin, carbon powder and nickel powder, wherein relative to 10 parts of the nano-silicon carbide by weight, the content of the polyethylene resin by weight is 30-50 parts by weight, the content of the modified epoxy resin is 20-50 parts by weight, the content of the carbon powder is 5-10 parts by weight and the content of the nickel powder is 5-10 parts by weight. By adhering the skin prepared by using the nano-silicon carbide, polyethylene resin, modified epoxy resin, carbon powder and nickel powder in a mixing manner to the surface layers of the braiding lines in the design, the wave-proof sleeve produced by adopting the material and the method is enabled to realize high-temperature-resistant performance while having a good shielding effect, thus better using performance is achieved, the service life is prolonged and the maintenance cost is reduced.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

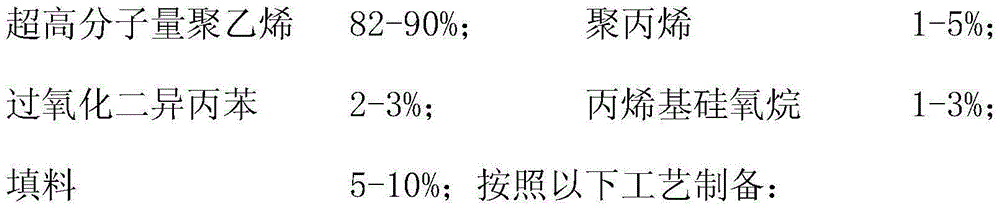

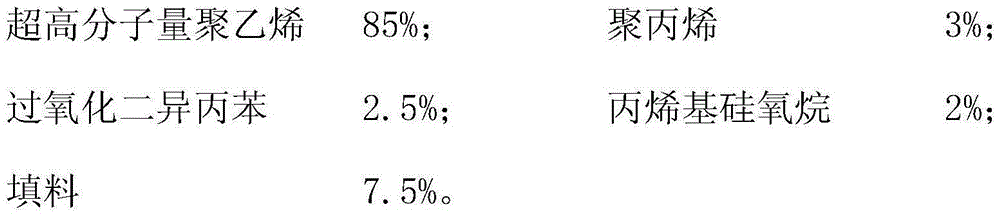

Ultra-high molecular weight polyethylene lining pipe

InactiveCN105199204AImprove liquidityExcellent thermal decompositionPolymer sciencePlastic materials

The invention discloses an ultra-high molecular weight polyethylene lining pipe. Raw materials including ultra-high molecular weight polyethylene, polypropylene, dicumyl peroxide, allyl siloxane and fillers are proportioned according to formula requirements, the raw materials are crushed and mixed by a mixing type particle crusher, then the grain size of powder materials is determined through a vibrating screen, and finally the proportioned raw materials are extruded to form the lining pipe through a plastic material extruding machine. By adding the dicumyl peroxide, the polypropylene and the allyl siloxane, the raw materials can be better decomposed under heating during injection molding, the flowability of plastic injection can be improved and the impact strength can be improved; by adding needle-shaped siliceous lime, the thermal deformation temperature can be improved; thereby through the combination of the raw materials, the effects of corrosion resistance, wear resistance and high temperature resistance are realized.

Owner:胜利油田金岛实业有限责任公司

Organic polybasic carboxylic acid and diverter acid applicable to high-temperature carbonate reservoir acidification and preparation method thereof

ActiveCN103896792ASlow reaction rateNo surface dissolutionOrganic compound preparationAmino-carboxyl compound preparationAcetic acidCarboxylic acid

The invention discloses organic polybasic carboxylic acid and diverter acid applicable to high-temperature carbonate reservoir acidification and a preparation method thereof. The organic polybasic carboxylic acid is tetraacetic glutamate and has a chemical structural formula represented by a formula shown in a drawing. The organic polybasic carboxylic acid disclosed by the invention has the characteristics of high-temperature resistance and no generation of precipitates and residues.

Owner:四川安东油气工程技术服务有限公司

Multi-coelomopore inorganic composite rollable heat-insulating material

The invention provides a multi-coelomopore inorganic composite rollable heat-insulating material. The heat-insulating material is obtained through preparation of inorganic modified colloid, mixing of vitrified microbeads and modified titanium dioxide, pretreatment of inorganic fiber, pulping and mixing, standing for defoaming, forming and drying. The heat-insulating material is rollable, resistant to high temperature, simple and convenient to construct, high in binding strength and flexibility and suitable for serving as a heat-insulating roll in use.

Owner:ZHONGHAI RUNDA NEW MATERIAL TECH CO LTD

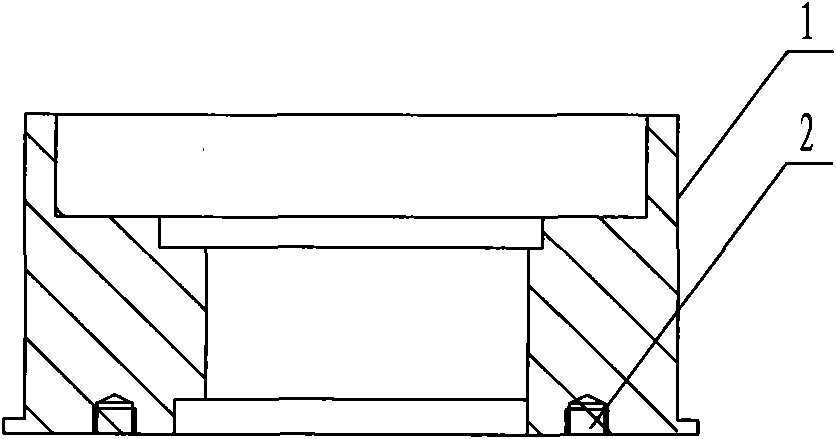

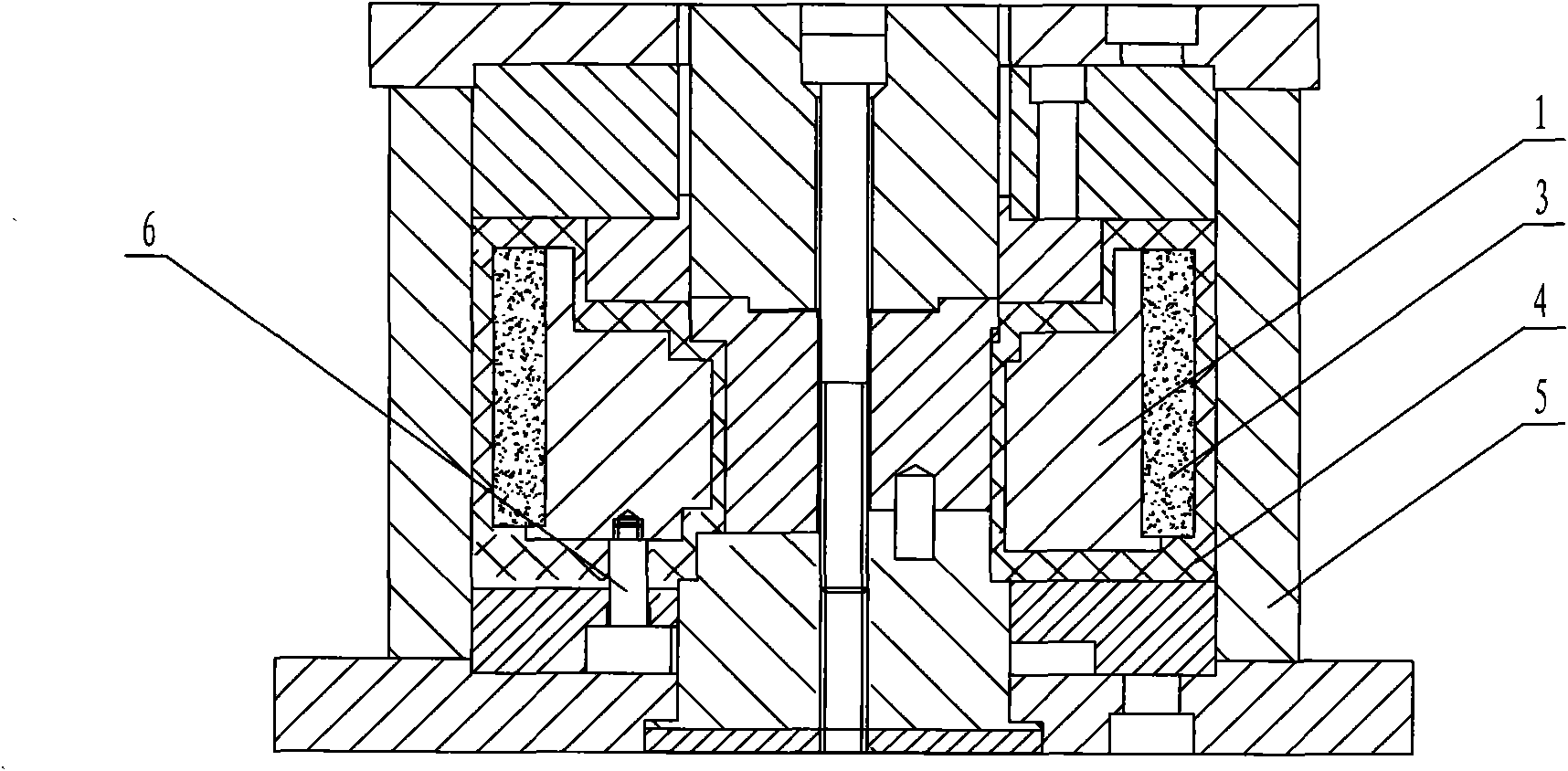

Production process of inner magnetic rotor of magnetic drive pump

InactiveCN101852216AAchieve high temperature performanceGuaranteed full coveragePump componentsPumpsEngineeringSealant

The invention relates to a production process of an inner magnetic rotor of a magnetic drive pump, which comprises the following steps: uniformly coating glue liquid on the outer surface of a cleaned inner magnetic rotor body, pasting a magnetic material on the inner magnetic rotor body, curding for 2 hours at the temperature of 180 DEG C; sheathing the inner rotor body pasted with the magnetic material on a mould; adding fluorinated ethylene propylene (FEP) in the mould, heating to be 300-320 DEG C, keeping the temperature for 2-3h; pressing on a press with the pressure of 10-15MPa, and keeping the pressure for 30-40min and slowly cooling; processing a plug by using a tetrafluoroethane bar stock; and winding a tetrafluoroethane seal belt, coating acid-resisting antiseptic sealant, and twisting into a taper pipe thread of the pressed inner rotor. The invention ensures the whole encapsulating thereof through the pressing process and the sealing technology, does not leak, can improve the operational performance of high temperature of the magnetic rotor and transmitting performance of a strong corrodent, has the simple manufacture process and low production cost, and can completely ensure the operation performance of the inner magnetic rotor.

Owner:鸿浩泵业有限公司

Device for retaining a component to be secured to a support part, system, and use of a device for retaining a component

InactiveCN109311432AImproved snug and reliable holdAchieve chemical resistanceSnap-action fastenersSheet joiningEngineeringMechanical engineering

Owner:A RAYMOND & CO

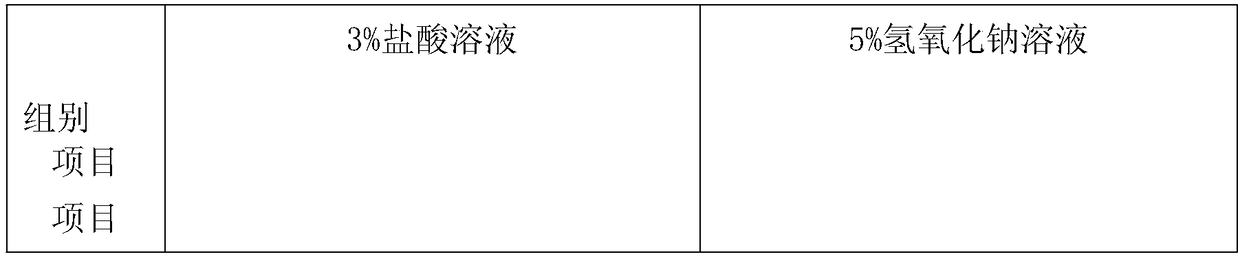

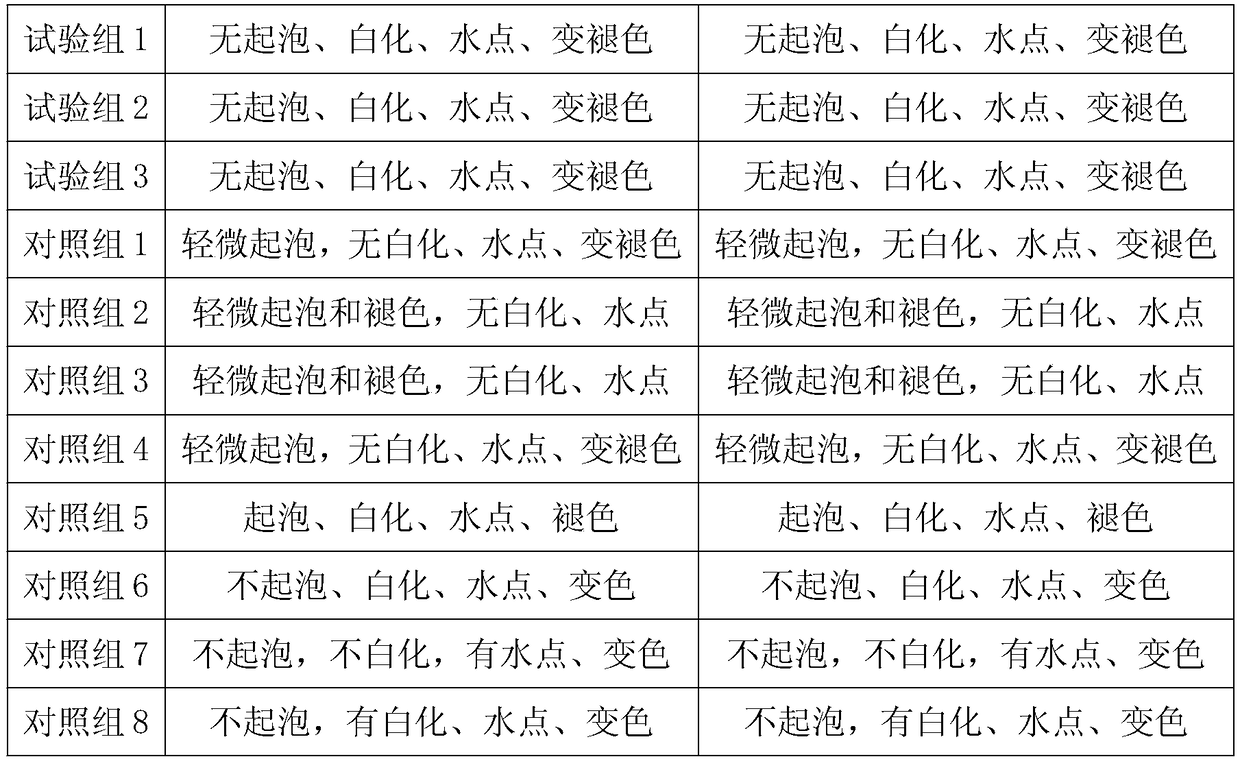

Metal packaging coating and preparing method thereof

InactiveCN109207025AReduce the content of heavy metal ionsReduce the content of harmful substancesFireproof paintsAnti-corrosive paintsSolventUrea

The invention discloses metal packaging coating and a preparing method thereof, belonging to the technical field of packaging coating. The coating includes following raw materials: bisphenol A glycidyl ether epoxy resin, modified phenolic resin, amino resin, waterborne polyurethane resin, nanometer fumed silica, pigment, silicon sol, zinc oxide, silicone acrylic emulsion, sodium borate, urea, cyclohexylamine benzoate, nanometer ferric oxide, nanometer alumina, a solvent and an auxiliary agent. The coating is prepared by softening, stirring, cooling, and other steps. The coating has excellent acid and alkali resistance, resistance to high temperature, environment protecting performance, safety and no toxicity.

Owner:CHANGSHA XIAORU INFORMATION TECH CO LTD

Flux-cored wire for surfacing repair

ActiveCN104551436AAchieve high temperature performanceAchieving wear resistanceWelding/cutting media/materialsSoldering mediaCarbideWeld seam

The invention relates to the technical field of welding, and discloses a flux-cored wire for surfacing repair. The flux-cored wire comprises a flux-cored wire main body, wherein the flux-cored wire main body comprises a metal layer wrapping a flux core; the flux core comprises the following components in percentage by weight: 0.1 to 5 percent of C, 0.8 to 3 percent of Mn, 0.5 to 2 percent of Si, 3 to 25 percent of Cr, 1 to 4 percent of Mo, 1 to 10 percent of W and the balance of Fe. According to the flux-cored wire, Mo is added into a conventional flux core formula, so that the performance of high temperature resistance and abrasion resistance of a welding material is achieved, the strength of a welding seam is ensured, and a welding layer is favorably prevented from being stripped in large scale; by Mo in steel, the hardenability and the thermal strength can be improved, the temper brittleness is prevented, and the residual magnetism and the coercive force are improved; silicon does not form carbide, so that a powerful function of promoting the graphitization of carbon is realized.

Owner:SHANGHAI SHIWEI WELDING IND

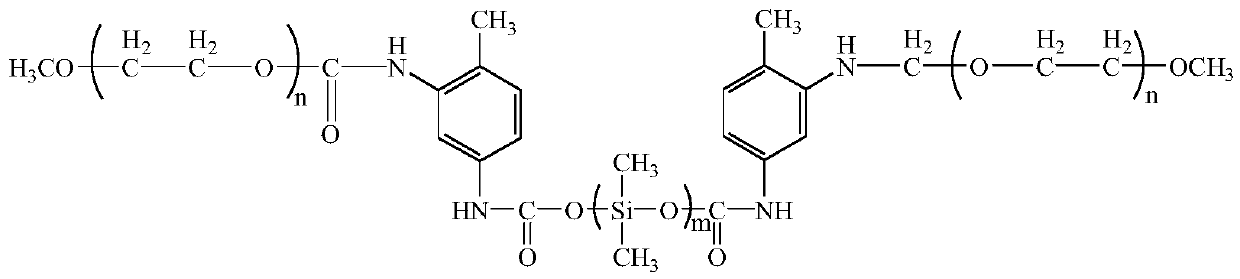

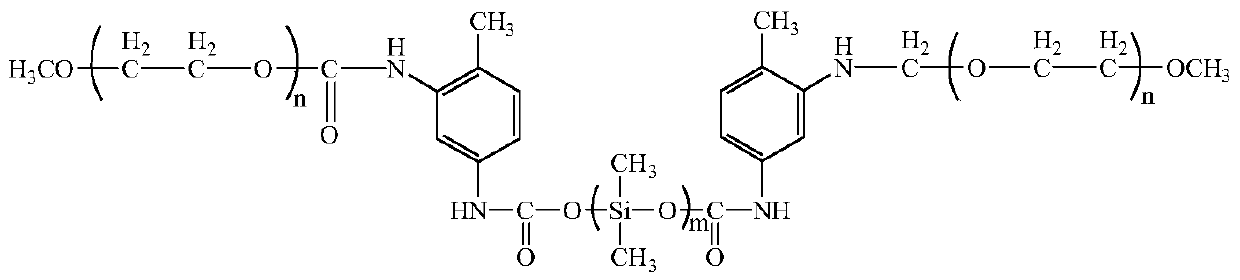

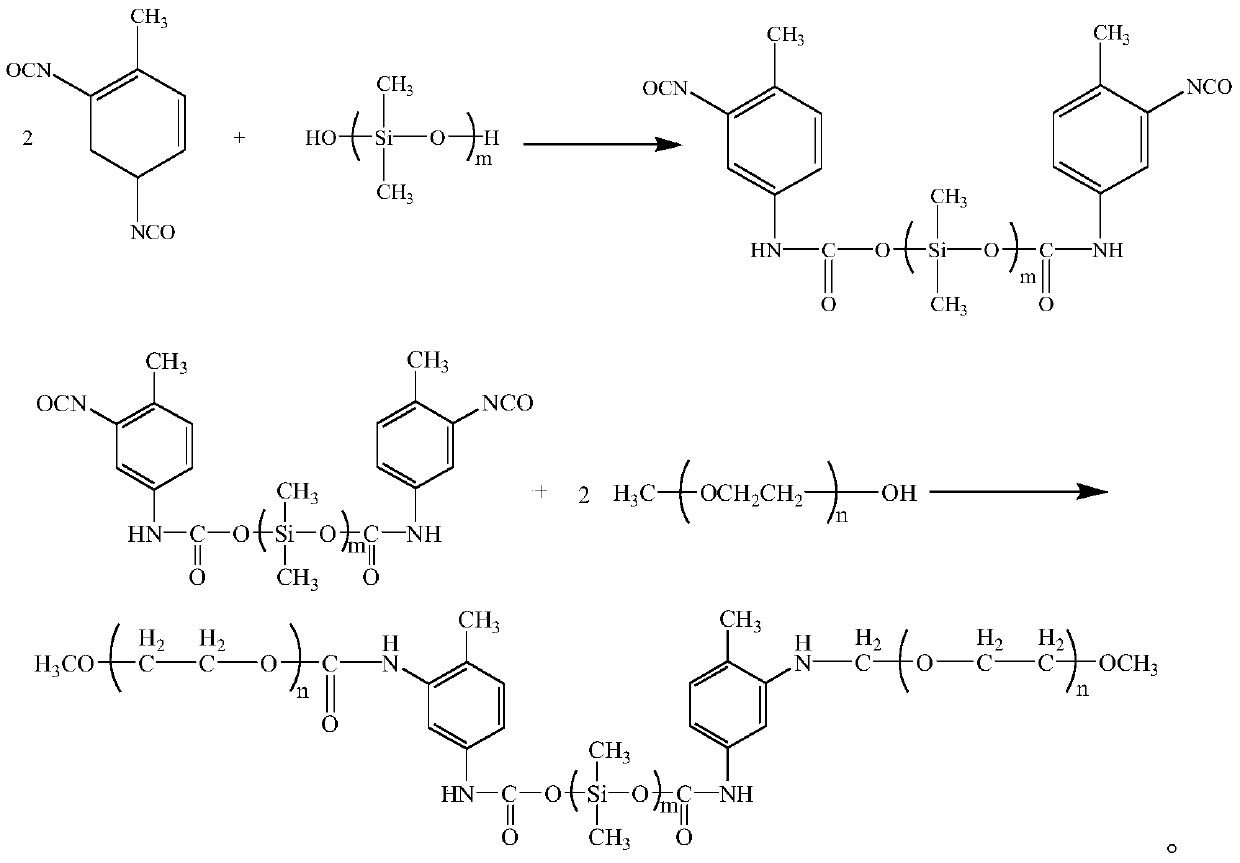

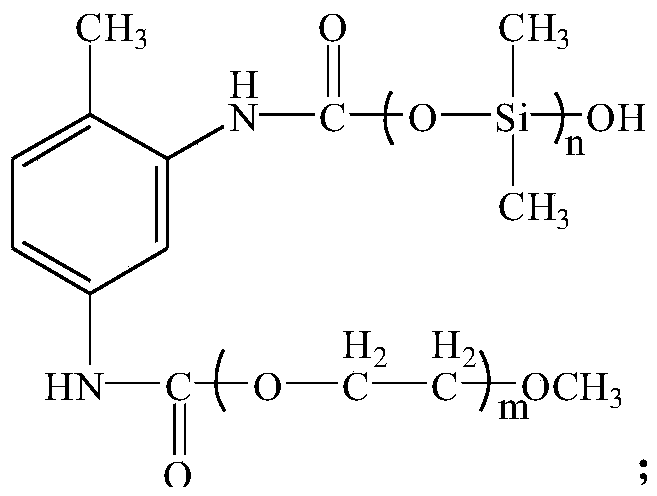

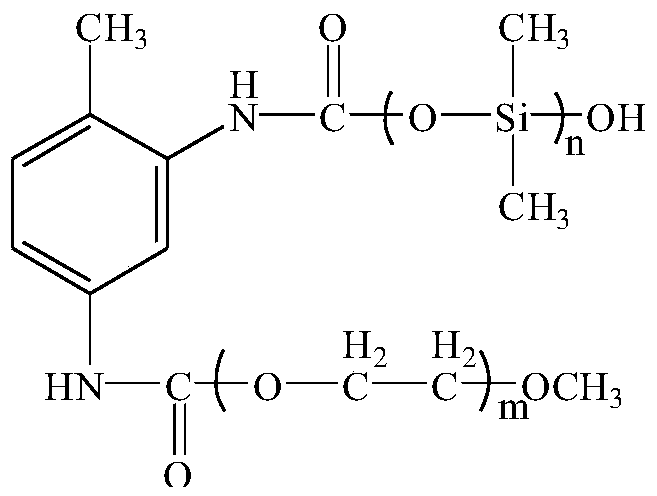

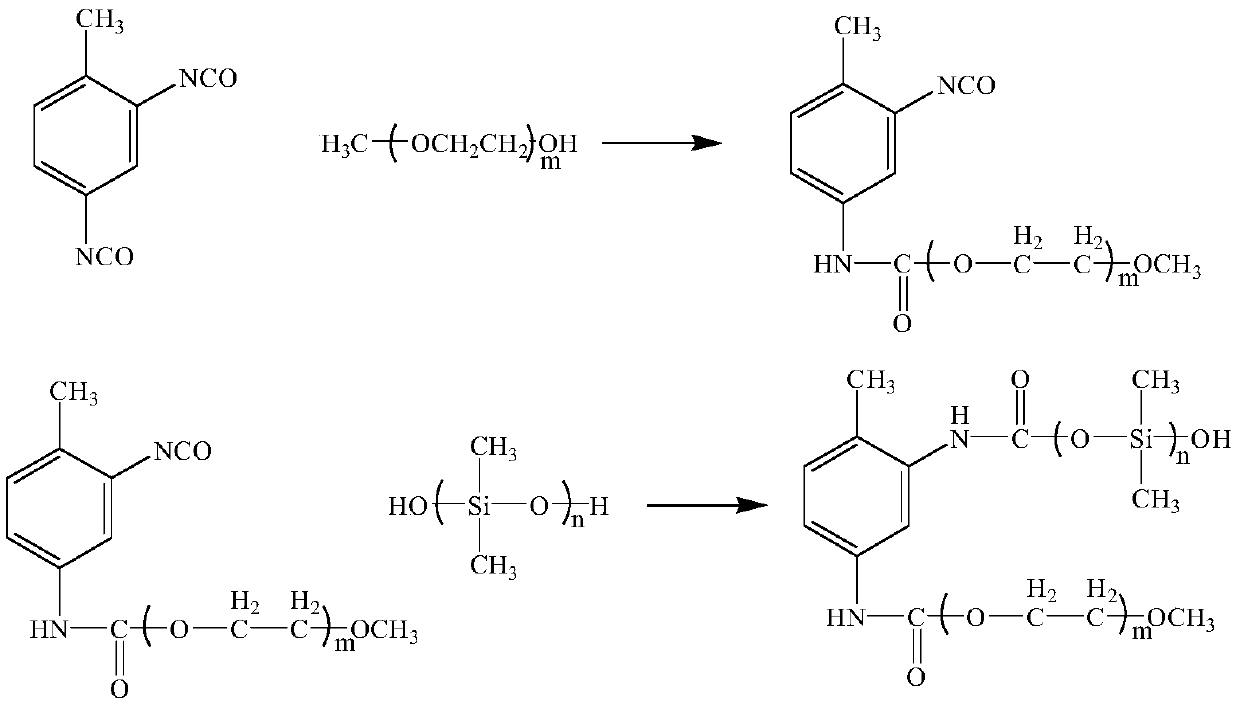

High-efficiency water-soluble viscosity-reducing oil-washing agent for heavy oil thermal recovery and preparation method of oil-washing agent

ActiveCN110643340AReduce the amount of adsorptionAchieve high temperature performanceDrilling compositionOil viscosityMethyl palmoxirate

The invention relates to a chemical agent used in the process of heavy oil recovery, and in particular relates to a high-efficiency water-soluble viscosity-reducing oil-washing agent for heavy oil thermal recovery and a preparation method of the oil-washing agent. The viscosity-reducing oil-washing agent is formed by reacting toluene diisocyanate with polymethylsiloxane to form an intermediate, and reacting the intermediate with polyoxyethylene ether, wherein the molar ratio of the toluene diisocyanate to the polymethylsiloxane and to the polyoxyethylene ether is 1:(0.4-0.5):(1-1.2), and preferably 1:0.45:1.05. The viscosity-reducing oil-washing agent provided by the invention has the dual functions of high-efficiency oil washing and emulsifying and viscosity reducing, can reduce viscosityof ordinary heavy oil and extra-heavy oil by more than 98%, and has the static oil washing rate of more than 50% at a concentration of 1000 ppm; at the same time, the oil-washing agent has strong salt and temperature resistance, and is suitable for heavy oil thermal recovery development, the salt resistance achieves 100000 mg / L or more, the temperature resistance achieves 320 DEG C or more, so that the oil-washing agent can fully meet application conditions in a conventional thermal recovery heavy oil reservoir field.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil-water mineral interface modifier for thick oil thermal recovery and preparation method thereof

ActiveCN110643341AAchieve high temperature performanceReduce the amount of adsorptionDrilling compositionOil viscosityChemical agent

The invention relates to a chemical agent used in a thick oil recovery process, in particular to an oil-water mineral interface modifier which is used in thick oil thermal recovery and has the functions of changing wettability of a reservoir and reducing viscosity by emulsification. The oil-water mineral interface modifier is prepared by the following steps: carrying out free radical polymerization on toluene diisocyanate and polyoxyethylene ether in water to obtain a single polyurethane intermediate; and then carrying out a reaction on the single polyurethane intermediate with polymethylsiloxane to obtain the oil-water mineral interface modifier. The oil-water mineral interface modifier has the advantages of wide raw material source, simple synthesis process, and clean and pollution-freeprocess; the raw materials are easy to obtain, transport and store; and the yield is high and is larger than 99.0%. The oil-water mineral interface modifier can resist to a temperature of 350 DEG C orabove, has mineralization resistance of 100000mg / L or above, can reduce viscosity of common thick oil and extra-thick oil to be 200 mPa*s or below at a concentration of 1000ppm, has a viscosity reduction rate of more than 98%, and has a static oil washing rate of more than 50%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technological method for thermal shaping clean production of light alloy die casting and product

The invention relates to a technological method for thermal shaping clean production of a light alloy die casting and a product. The technological method for thermal shaping clean production of the light alloy die casting comprises the following steps of: 1, providing a cast light alloy die casting, and carrying out surface treatment, polishing, cleaning and drying on the cast light alloy die casting; 2, heating the light alloy die casting, and removing internal stress of the light alloy die casting; 3, alternately carrying out hot treatment and cold treatment on the light alloy die casting; 4, removing structures with non-appearance requirements from the surface of the light alloy die casting; and 5, spraying an anti-corrosion temperature-resistant protective layer to the surface of the light alloy die casting, and drying the anti-corrosion temperature-resistant protective layer. According to the technological method for thermal shaping clean production of the light alloy die castingand the product, as the light alloy die casting is treated through a plasma or chemical surface treating agent method first, no toxic effect exists, environment friendliness is achieved, and clean production is achieved; and thermal shaping treatment and cold shaping treatment are conducted alternately, the flatness is controlled to be within 0.02 mm, the protective layer is sprayed after the structures with non-appearance requirements are removed from the surface, and therefore, chemical corrosion resistance, high temperature resistance and the like are achieved.

Owner:FUJIA ELECTRONICS KUSN

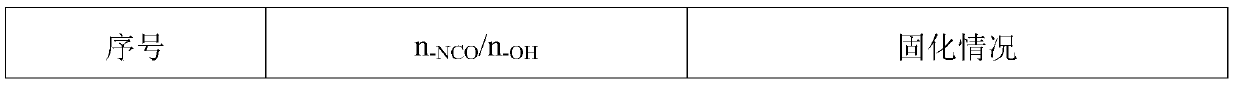

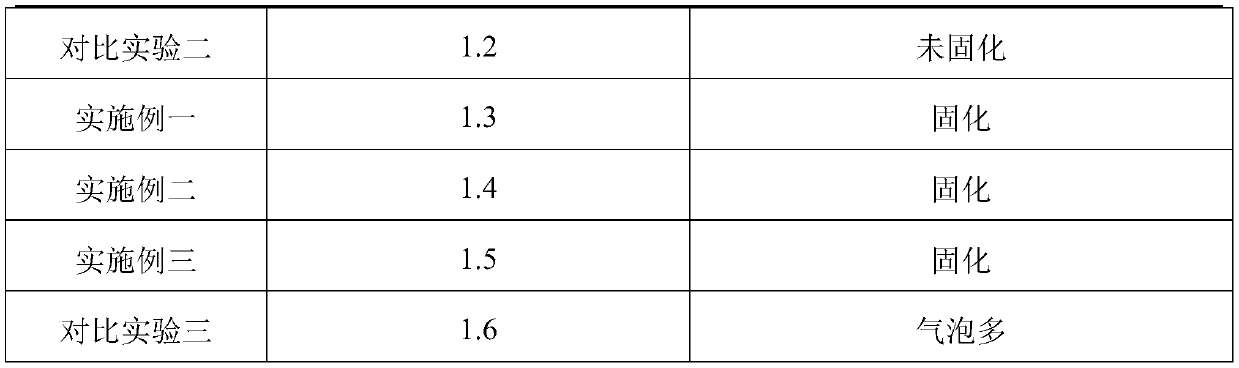

Polyurethane sealant with high thermal resistance and preparation method of polyurethane sealant

ActiveCN110540826AUnique structureImprove liquidityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerIsocyanate

The invention discloses a polyurethane sealant with high thermal resistance and a preparation method of the polyurethane sealant. The invention relates to the polyurethane sealant and the preparationmethod thereof and aims to solve the problem that a polyurethane sealant which is prepared by using a conventional method is poor in thermal resistance. The polyurethane sealant with high thermal resistance is prepared from trihydric alcohol, dendritic polyester polyol, benzene-containing polyisocyanates, a catalyst and a filler. The preparation method comprises the following steps: putting trihydric alcohol, benzene-containing polyisocyanates and dendritic polyester polyol into a three-neck bottle, introducing nitrogen to implement a polymerization reaction so as to obtain a polyurethane prepolymer, sequentially putting the catalyst and the filler into the polyurethane prepolymer, and performing sealed stirring and vacuum defoaming. The invention discloses the polyurethane sealant with high thermal resistance and preparation of the polyurethane sealant.

Owner:QIQIHAR UNIVERSITY

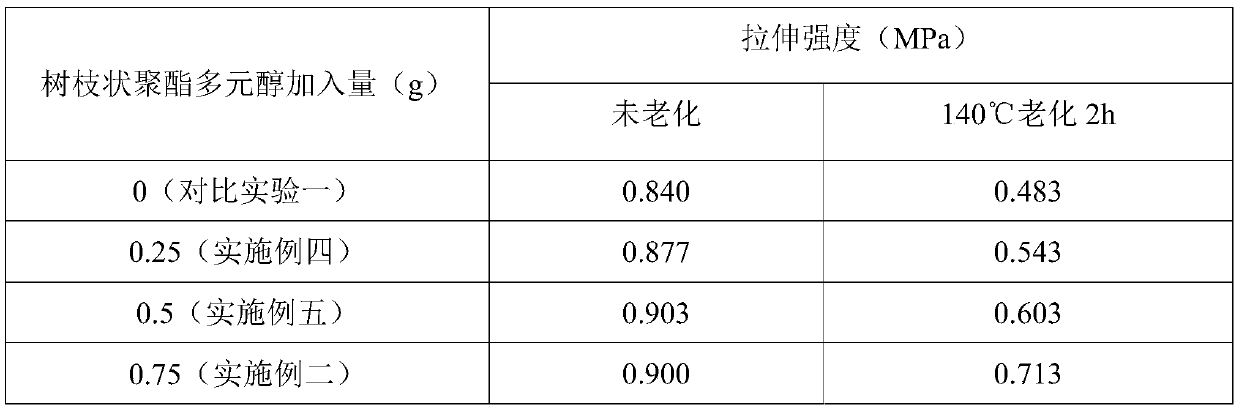

Antibacterial and anti-mosquito aramid fabric and preparation method thereof

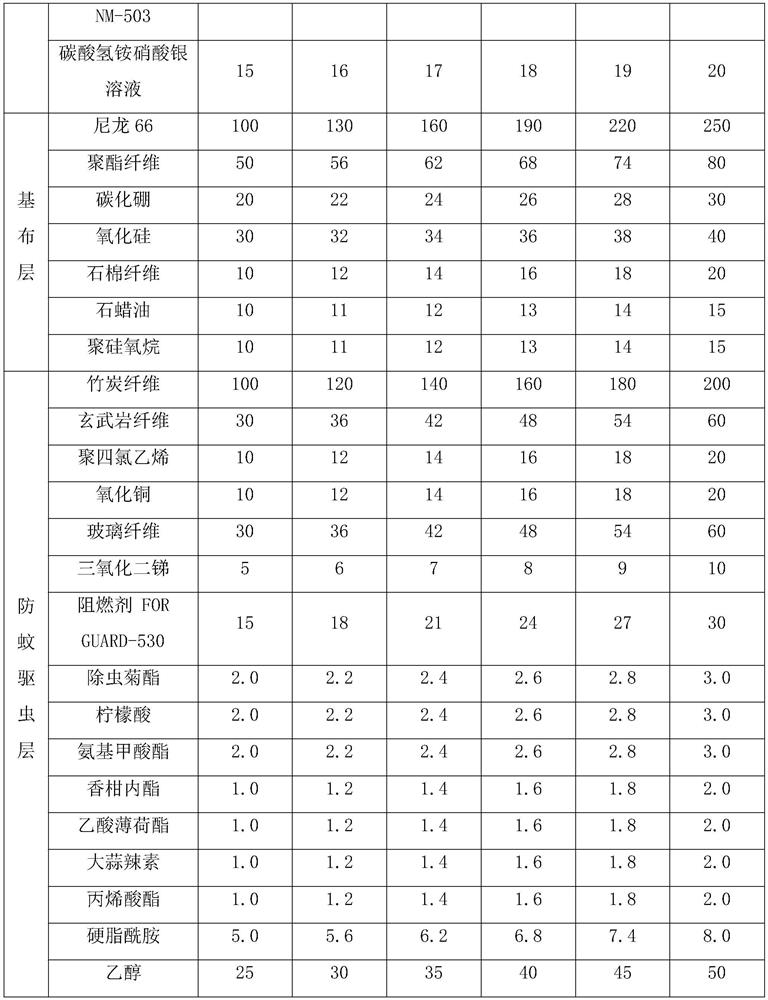

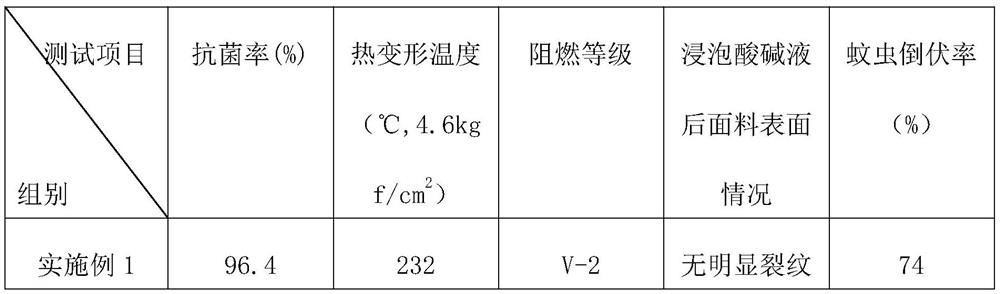

PendingCN113291019ASatisfy fire protectionLarge range of protectionLamination ancillary operationsBiochemical fibre treatmentNylon 66Acrylate ester

The invention relates to an antibacterial and anti-mosquito aramid fabric and a preparation method thereof. The antibacterial and anti-mosquito aramid fabric comprises an antibacterial protective layer, a base cloth layer and an insect-repelling and anti-mosquito layer which are sequentially overlapped; wherein the antibacterial protective layer is prepared from the following components in parts by weight: 50 to 100 parts of ramie fiber; 100 to 250 parts of aramid fiber; 100 to 250 parts of polyurethane; and 40 to 80 parts of an antibacterial component; the base cloth layer is prepared from the following components in parts by weight: 100 to 250 parts of nylon 66; 100 to 150 parts of a high temperature resistant component; and 30 to 50 parts of a heat insulation component; the insect-repelling and mosquito-preventing layer is prepared from the following components in parts by weight: 100 to 200 parts of bamboo charcoal fiber; 60 to 100 parts of a corrosion-resistant component; 50 to 100 parts of a flame retardant component; and 15 to 30 parts of a mosquito-preventing and insect-repelling finishing agent, which is prepared from pyrethrin and one or more of the following components: citric acid, carbamic acid ester, bergamolactone, menthyl acetate, allicin, acrylic ester, stearamide and ethanol. The antibacterial and anti-mosquito aramid fiber fabric is good in anti-mosquito and insect-repelling effect and has the advantages of being antibacterial, resistant to high temperature, high in flame retardance and the like.

Owner:上海铭茜实业有限公司

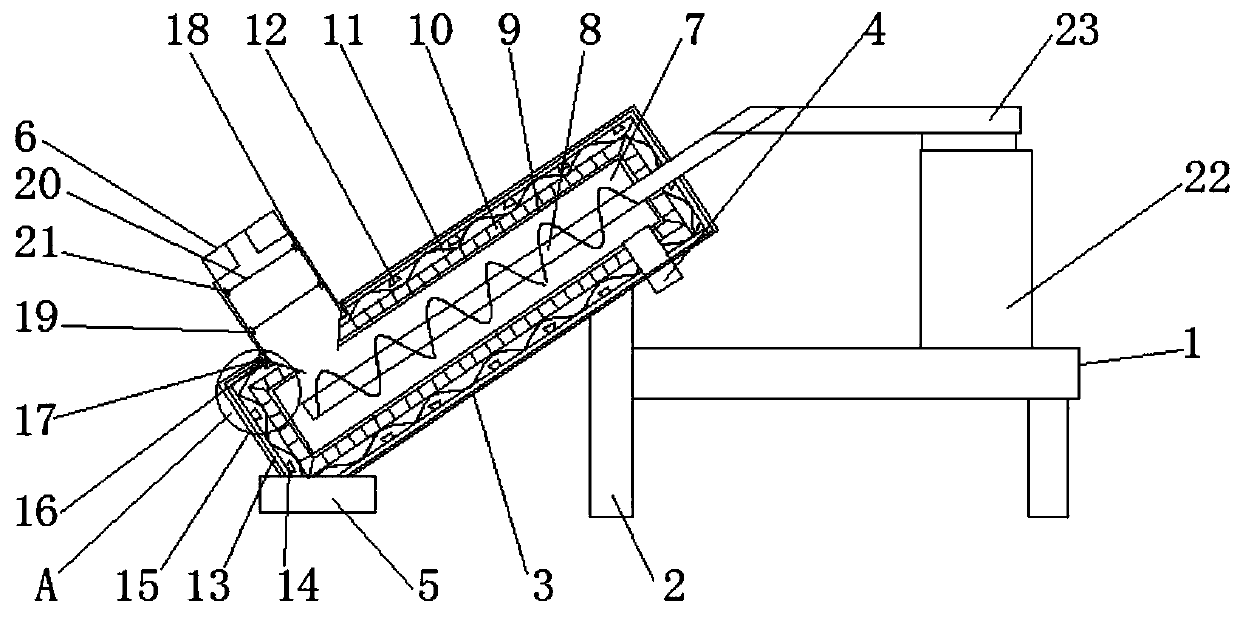

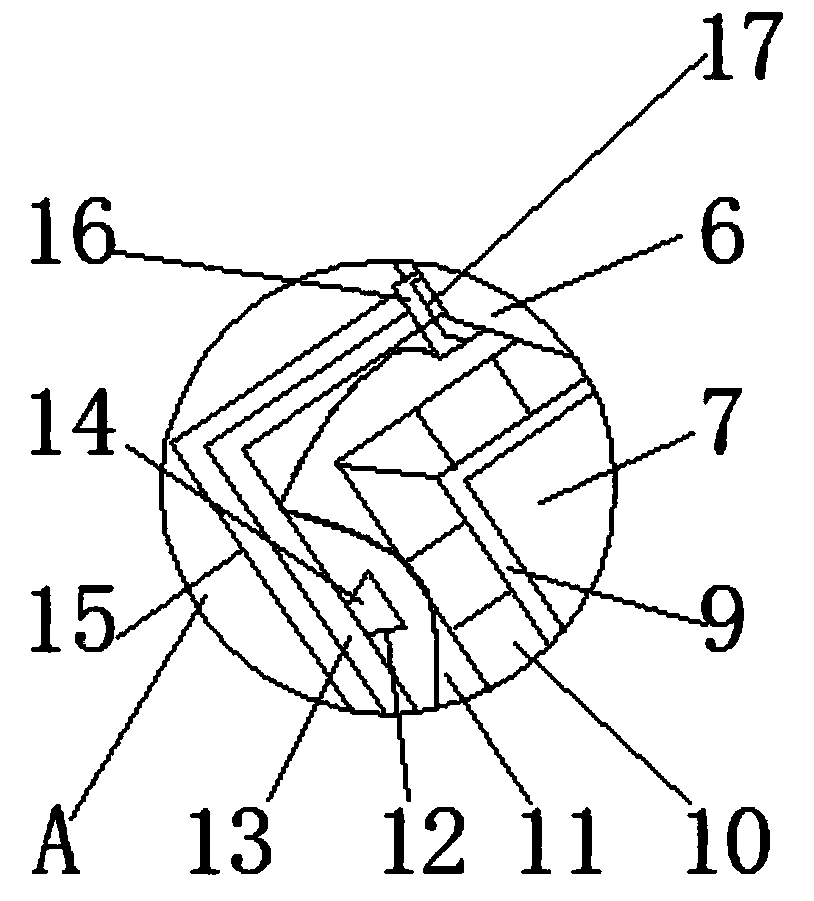

An automatic feeding device for steelmaking

ActiveCN107985936BImprove high temperature resistanceExtended service lifePackagingSteelmakingWear resistant

The invention discloses an automatic feeding device for steelmaking. The automatic feeding device for steelmaking comprises a body. One side of the bottom of the body is provided with a vertical column. The top of the vertical column is provided with a feeding bin. A discharging opening is formed in the position, located on one side of the vertical column, of the bottom of the feeding bin. A fixedseat is arranged at the bottom of the other side of the feeding bin. A feeding opening is formed in one side of the top of the feeding bin. The interior of the feeding bin is provided with a materialconveying cavity. The material conveying cavity is internally provided with spiral blades. The inner side of the material conveying cavity is provided with a wear-resistant ceramic layer. The outer side of the wear-resistant ceramic layer is provided with an isolating layer. The outer side of the isolating layer is provided with a corrugated layer. The outer side of the corrugated layer is provided with a vacuum layer. The outer side of the vacuum layer is provided with a protective plate. A sealing piece is arranged at the connection position of the feeding opening and a feeding bin shell. The outer side of the feeding opening is provided with a heat insulating layer. The interior of the feeding opening is provided with a plurality of sets of filtering mechanisms. A motor is arranged atthe position, on one side of the feeding bin, of the vertical column. An output shaft of the motor is connected with a coupling. The automatic feeding device for steelmaking is simple in structure, convenient to operate, good in high-temperature resistance and long in service life, and can conduct filtering and screening on materials.

Owner:HUIZHOU DUOPULE COMM

Intelligent internet-of-things oil extraction management system and method

InactiveCN110378451ARealize early warning promptAvoid confusionCo-operative working arrangementsWear resistantData acquisition

The invention discloses an intelligent Internet of Things oil extraction management system and an intelligent Internet of Things oil extraction management method. The system comprises an RFID tag device. The RFID tag device comprises an RFID Internet of Things chip, a high-temperature-resistant protection layer and a wear-resistant centralizing block. The RFID Internet of Things chip provides a unique identification for oil extraction equipment, and stores the management information of the oil extraction equipment. The RFID read-write device is in communication connection with the RFID internet-of-things chip and is used for reading, writing and recording equipment information of the RFID internet-of-things chip. The data processing device is in communication connection with the RFID read-write device and is used for acquiring and processing data in the RFID read-write device. The invention further discloses an intelligent internet-of-things oil extraction management method. Compared with an original manual mode, the working efficiency is improved. The personnel cost investment is reduced, and the correct data acquisition is guaranteed. Work errors are reduced, and the automatic management is achieved.

Owner:SHANDONG SHOUGUANG KUNLONG PETROLEUM MACHINERY

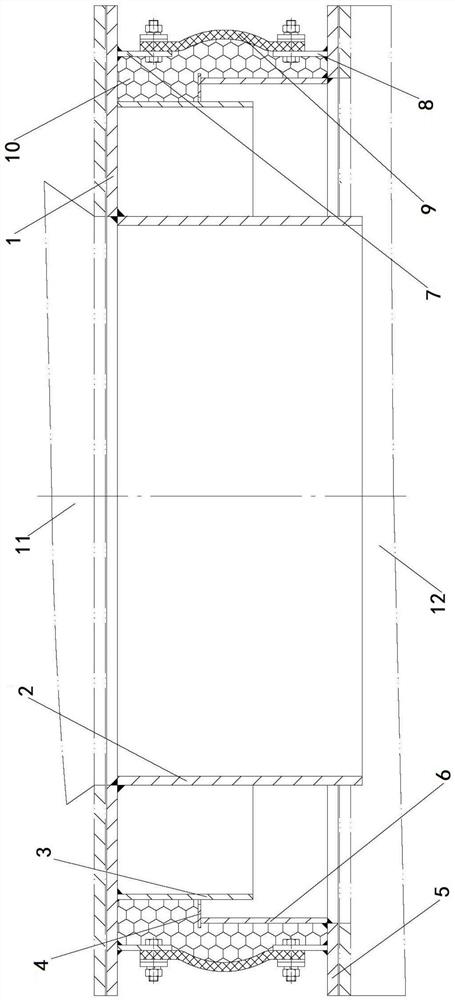

Boiler slag well and hydraulic crushing shutoff door expansion joint connecting system

PendingCN112879933AReduce the temperatureAchieve flexible expansionLighting and heating apparatusThermal insulationBoiler slag

The invention discloses a boiler slag well and hydraulic crushing shutoff door expansion joint connecting system. The system comprises an annular upper plate which is installed on the bottom face of an upper slag well and provided with a slag discharge port, an inner pipe body installed on the annular upper plate, a first adjusting pipe body located at the outer side of the inner pipe body and installed on the annular upper plate, an annular sealing plate arranged on the first adjusting pipe body in a sleeving manner, a lower plate arranged on the top surface of a lower hydraulic crushing shutoff door, a second adjusting pipe body positioned at the outer side of the first adjusting pipe body and arranged on the lower plate, an upper baffle arranged on the annular upper plate, a lower baffle arranged on the lower plate, a bent nonmetal temperature-resistant pressure-bearing sealing element mounted on the upper baffle and the lower baffle through fastening bolts, and a temperature-resistant thermal insulation material arranged in a cavity defined by the annular upper plate, the lower plate, the first adjusting pipe body, the second adjusting pipe body, the sealing plate, the upper baffle plate, the lower baffle plate and the bent nonmetal temperature-resistant pressure-bearing sealing element. The system is resistant to high temperature, capable of expanding in all directions and long in service life. The system can be widely applied to a boiler deslagging system.

Owner:QINGDAO DANENG ENVIRONMENTAL PROTECTION INC

An annealing kiln for crystallization of architectural float glass-ceramics and a method for crystallization of glass

The invention relates to an architectural float glass ceramics crystallization annealing kiln, and belongs to the technical field of crystallization annealing of flat-plate glass ceramics. The crystallization annealing kiln is of a roller bed-type structure and comprises a kiln body with an outer wall of a steel structure and an inner wall made from a thermal insulation material. A nucleation zone, a crystallization zone, and an annealing cooling zone are sequentially arranged from an inlet to an outlet of the crystallization annealing kiln. The kiln side wall and the kiln bottom of the crystallization zone are made from a mullite thermal insulation material, and the kiln side walls and the kiln bottoms of the nucleation zone and the annealing cooling zone are both made from a poly-light high-aluminum thermal insulation material. The kiln roofs of the crystallization zone, the nucleation zone and the annealing cooling zone are all made from a ceramic fiberboard, and a fiber blanket isarranged between the steel structure and the thermal insulation material. The crystallization annealing kiln achieves crystallization annealing treatment of large-sized flat-plate glass ceramics molded by a float glass process.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE +1

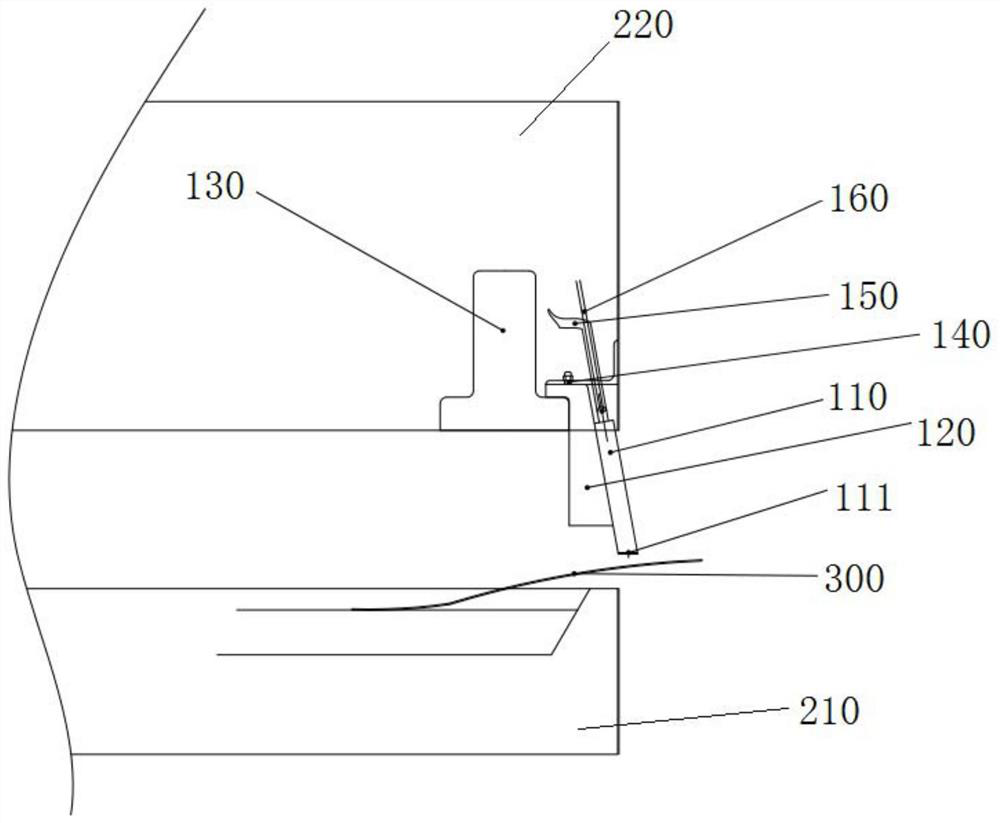

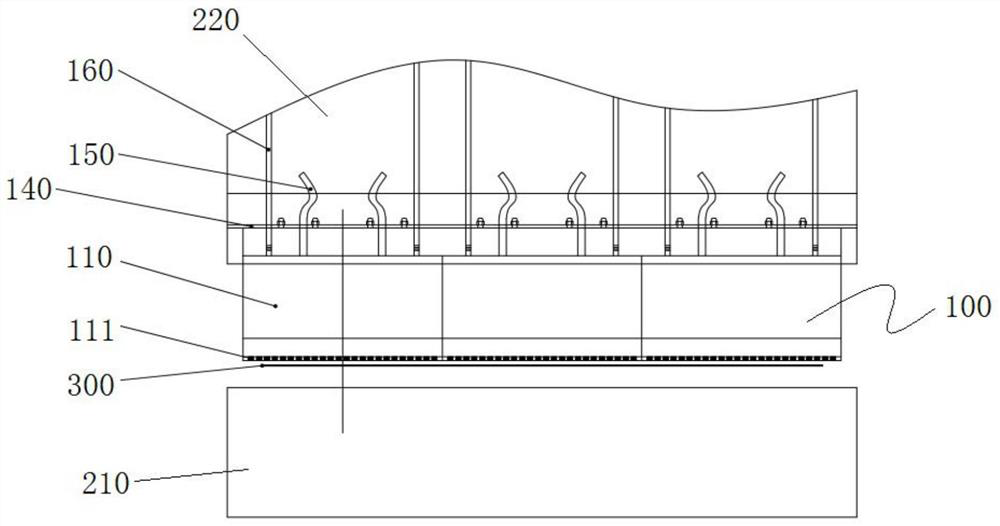

Tin bath sealing equipment and glass production system

The invention discloses tin bath sealing equipment and a glass production system. The tin bath sealing equipment comprises an curtain assemblies (100), wherein each air curtain assembly (100) is arranged at the tail end of a tin bath in the length direction of the tin bath, and the air curtain assembly (100) comprises a gas bag (110) made of cast iron; the gas bag (110) is located above a bottom groove (210) of the tin bath, an air outlet (111) is formed in the end, which faces the bottom groove (210) of the tin bath, of the gas bag (110), and the gas bag (110) is configured to be capable of being communicated with a nitrogen source so as to form a nitrogen curtain at the air outlet (111); and the number of the air curtain assemblies (100) is multiple, and the multiple air curtain assemblies (100) are adjacently arranged in the width direction of the tin bath. According to the tin bath sealing equipment, the atmosphere between the tin bath and a slag box can be effectively separated, and an excellent sealing effect is provided.

Owner:河北光兴半导体技术有限公司 +2

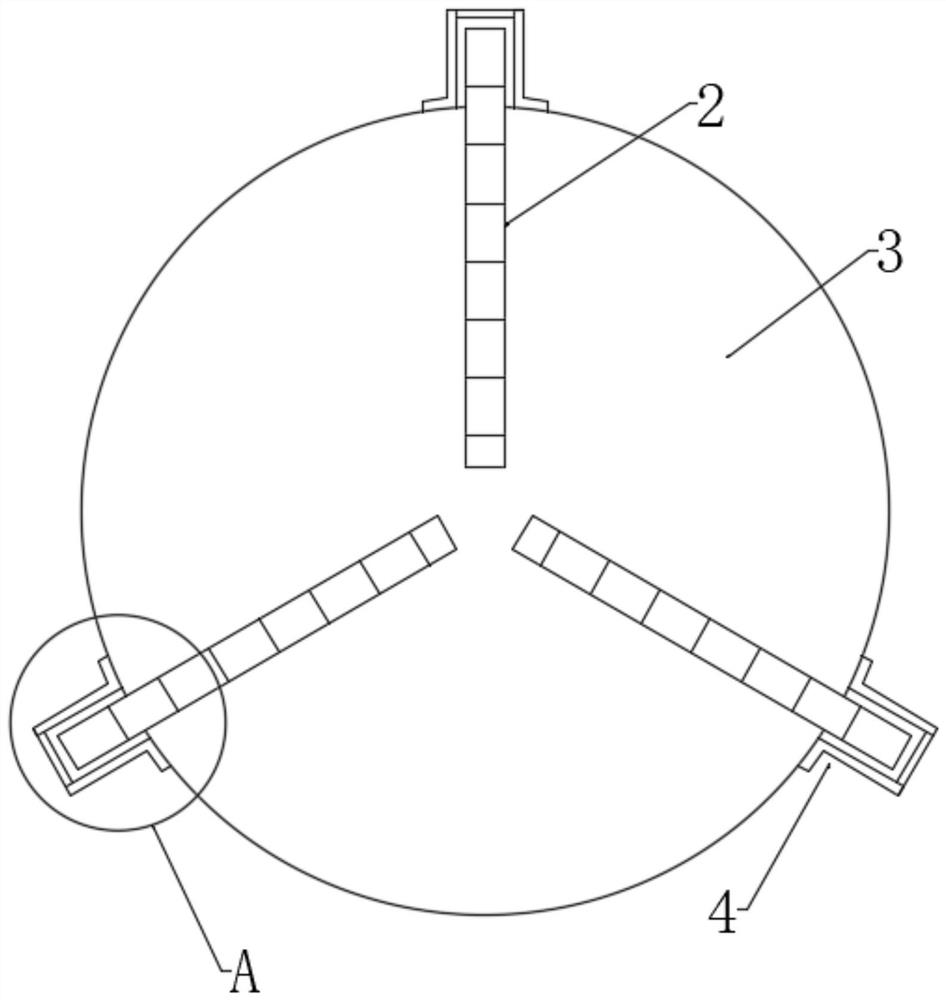

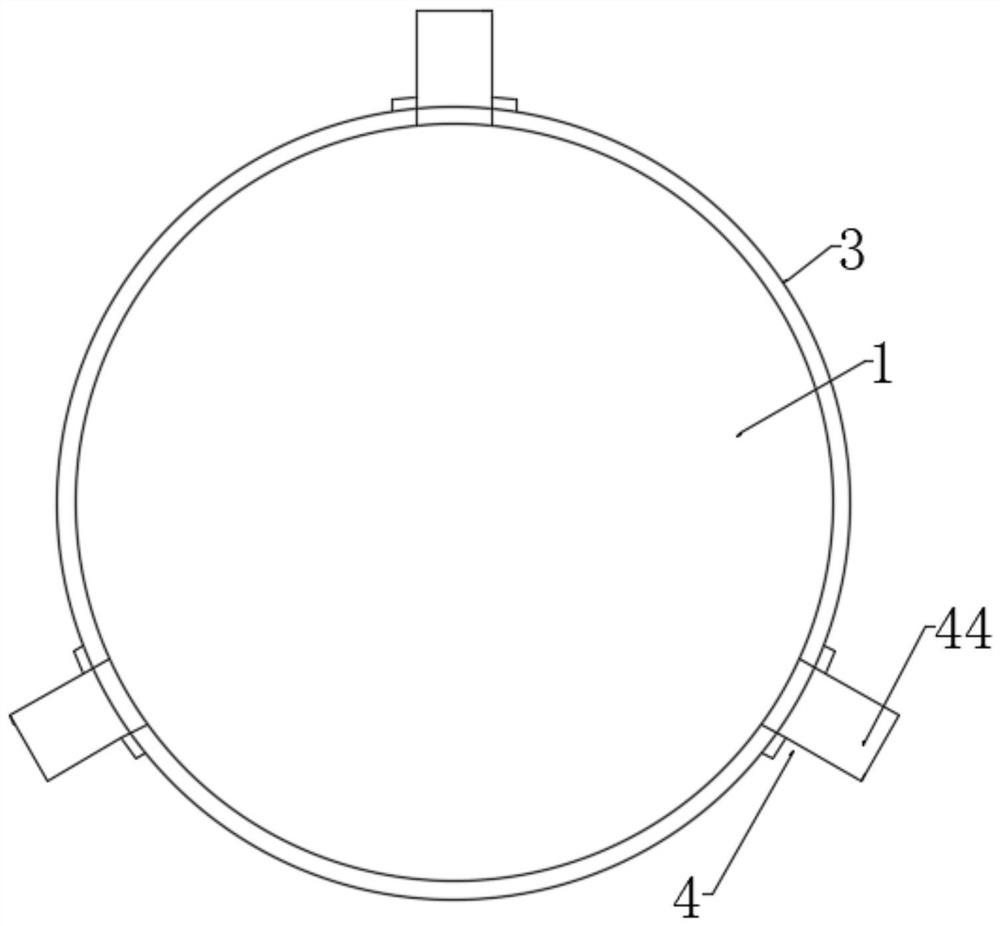

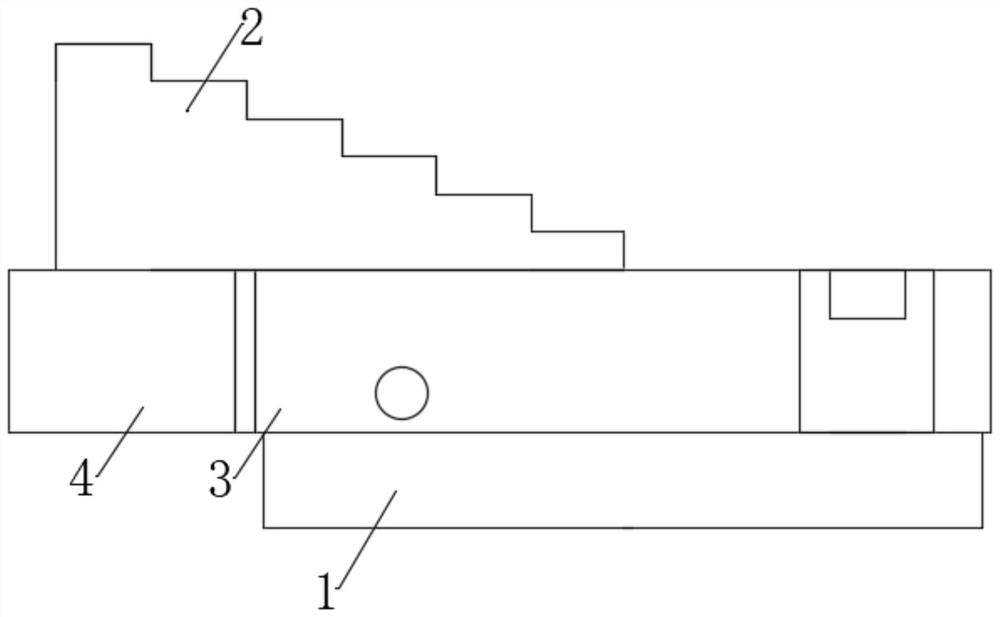

High-temperature-resistant dustproof chuck device

ActiveCN113385705AReduce temperature riseAvoid enteringAuxillary equipmentChucksSurface engineeringEngineering

The invention relates to the technical field of surface engineering, and particularly discloses a high-temperature-resistant dustproof chuck device. The device comprises a chuck body, clamping jaws installed on the chuck body, a dustproof cover arranged on the chuck body in a sleeving mode and coaxial with the chuck body, and shielding covers installed on the outer side of the dustproof cover and communicating with the interior of the dustproof cover; the dustproof cover is provided with a groove used for installing the chuck body, and a gap exists between the bottom of the groove and the upper surface of the chuck body; and the shielding covers and the clamping jaws are arranged in a one-to-one correspondence mode. According to the device, dust can be prevented from entering gaps between the clamping jaws and the chuck body, and the device is resistant to high temperature.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

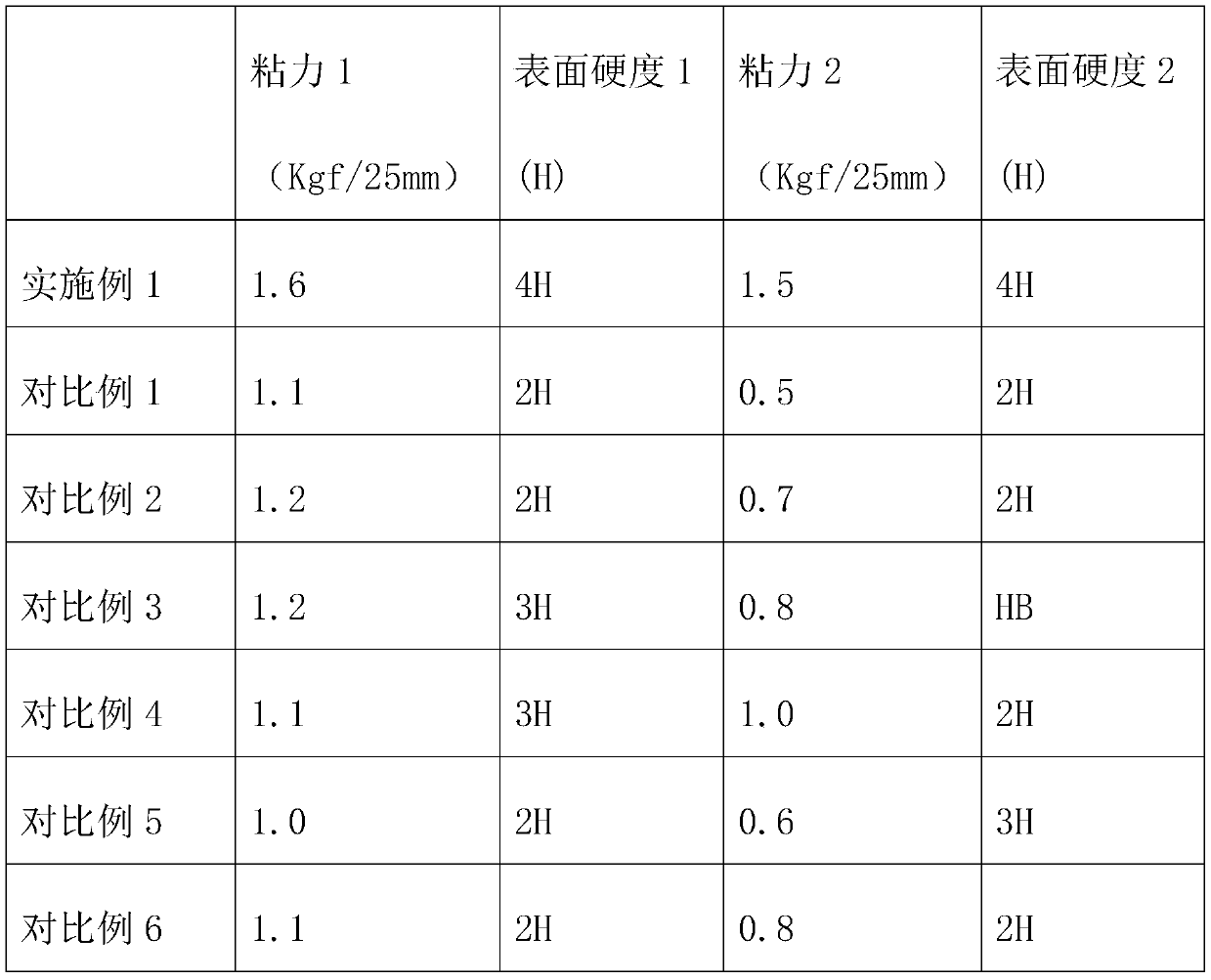

High-temperature-resistant and scratch-resistant PI battery label material and preparation method thereof

ActiveCN111105698AImprove scratch resistanceTo achieve the purpose of modificationStampsPolyurea/polyurethane coatingsImidePolymer science

The invention provides a high-temperature-resistant scratch-resistant PI battery label material and a preparation method thereof. The high-temperature-resistant scratch-resistant PI battery label material comprises a scratch-resistant resin coating, a PI polyimide film, high-temperature-resistant glue and a release film from top to bottom, wherein the scratch-resistant resin coating is prepared from modified polyurethane resin, isocyanate, ethyl acetate and anhydrous toluene; the preparation method of the modified polyurethane resin comprises the following steps: in a first stage, adding reactive acrylamide, 2,6-dicarboxyl naphthalene and acetic anhydride, and carrying out a chemical crosslinking reaction with polyurethane resin; and in a second stage as an internal adding stage, discharging acid through high-temperature stirring.

Owner:SHENZHEN LICHANGSHI ADHESIVE PROD

A kind of high temperature and anti-scratch pi battery label material and preparation method thereof

ActiveCN111105698BImprove scratch resistanceTo achieve the purpose of modificationStampsPolyurea/polyurethane coatingsImideAcetic anhydride

The invention provides a high-temperature-resistant and scratch-resistant PI battery label material and a preparation method thereof, which comprise from top to bottom: a scratch-resistant and scratch-resistant resin coating, a PI polyimide film, a high-temperature-resistant glue, and a release film; The anti-scratch resin coating comprises: modified polyurethane resin, isocyanate, ethyl acetate, anhydrous toluene; The preparation method of described modified polyurethane resin is: first stage by adding reactive acrylamide, 2,6-dicarboxynaphthalene , acetic anhydride, and polyurethane resin for chemical cross-linking reaction; the second stage is the internal addition stage, and the acid is stirred out at high temperature.

Owner:SHENZHEN LICHANGSHI ADHESIVE PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com