Antibacterial and anti-mosquito aramid fabric and preparation method thereof

An anti-mosquito and aramid fiber technology, applied in the field of textile fabrics, can solve problems such as general heat insulation performance, unfavorable human health, and potential safety hazards for firefighters, and achieve the effects of reducing bacterial growth, stabilizing the acidic dispersion environment, and good mosquito repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

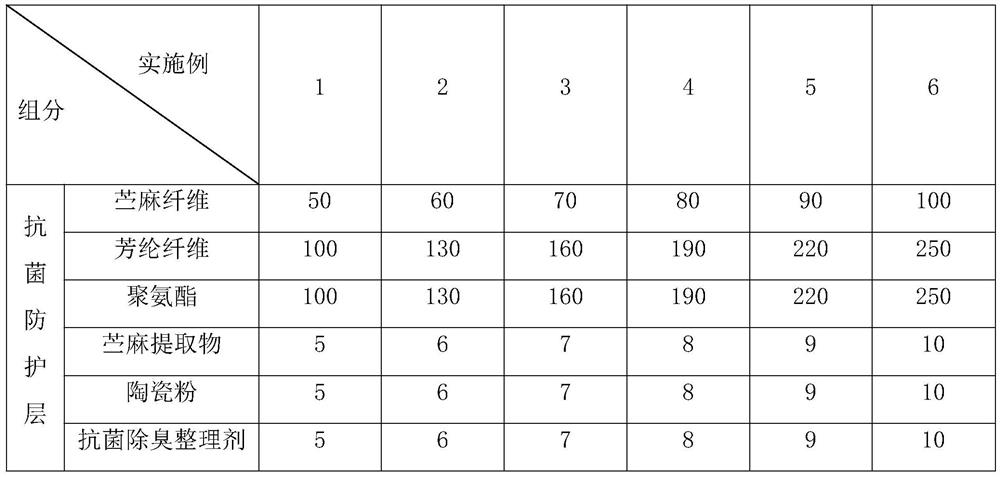

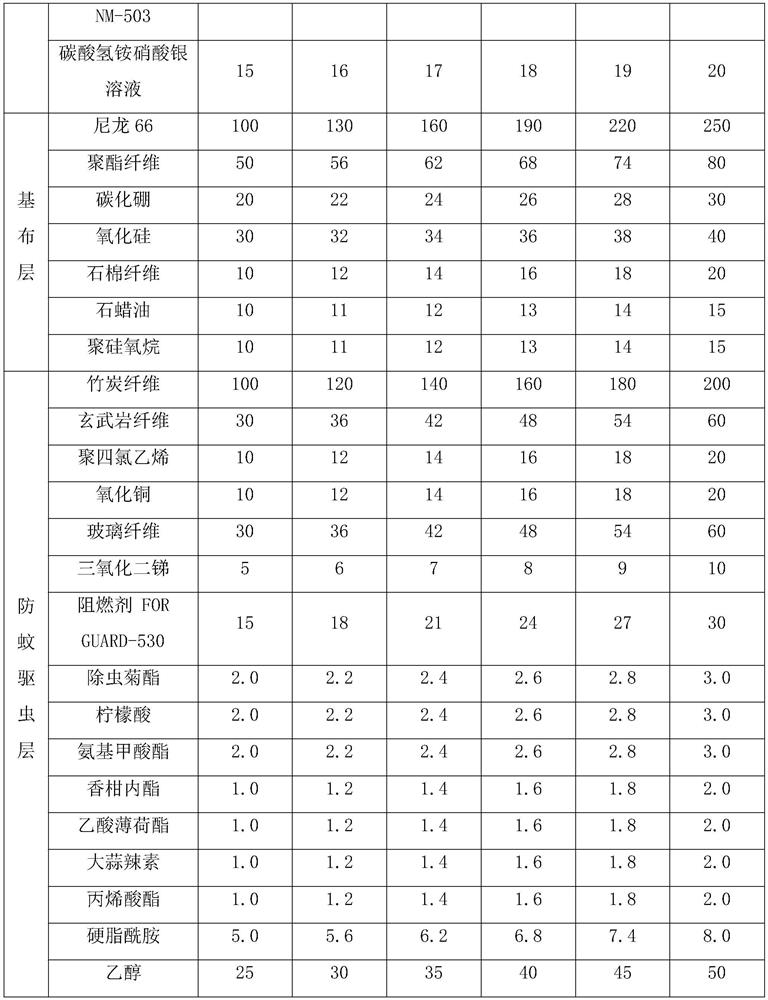

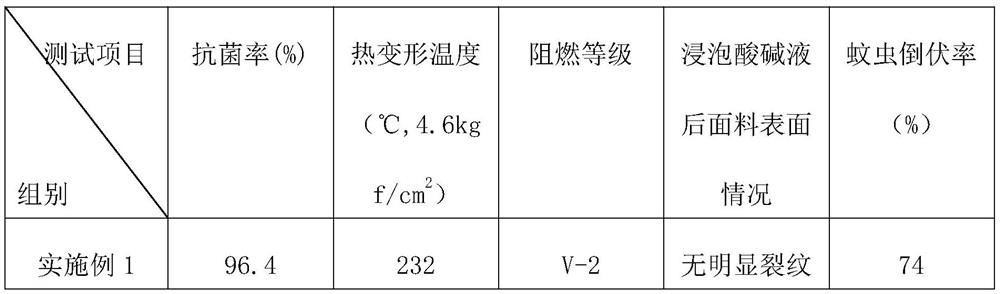

Examples

preparation example 1

[0060] An antibacterial component, its preparation method is as follows:

[0061] The components of the following proportions are mixed and added to 25kg ethanol: pyrethrin 2kg, citric acid 2kg, carbamate 2kg, citrus lactone 1kg, menthyl acetate 1kg, allicin 1kg, acrylate 1kg, water bath 100 Add 5 kg of stearylamide under the condition of ℃ and stir for 30 minutes, and stir to form a uniform solution to prepare the antibacterial component.

preparation example 2

[0063] A thermal insulation component, the preparation method of which is as follows:

[0064] After choosing 10kg of asbestos fiber as the matrix and weaving it into a board, mix 10kg of polysiloxane powder with 10kg of paraffin oil and heat and melt at 80°C. After stirring evenly, soak and apply it on the asbestos fiber, and then cool and consolidate at room temperature. The preparation of the thermal insulation component can be realized.

preparation example 3

[0066] A kind of flame retardant component, its preparation method is as follows:

[0067] Choose 30kg of non-combustible glass fiber as the matrix, mix 5kg of antimony trioxide and 15kg of flame retardant FORGUARD-530 into 90% ethanol solution, and bend and loosen the glass fiber in the ethanol solution for 30min to make the glass fiber There are small gaps on the surface and gaps between the monofilament glass fibers, so that antimony trioxide and flame retardant FORGUARD-530 can be adsorbed on the surface of the glass fibers, and then dried and consolidated at 120°C for 5 minutes to form a barrier. Combustible ingredients.

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com