Oil-water mineral interface modifier for thick oil thermal recovery and preparation method thereof

A technology for thermal recovery and modifier of heavy oil, applied in the field of chemical agents, can solve the problems of poor huff and puff recovery effect, high price of high temperature resistant chemical agents, weak recovery rate, etc. Pollution, the effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

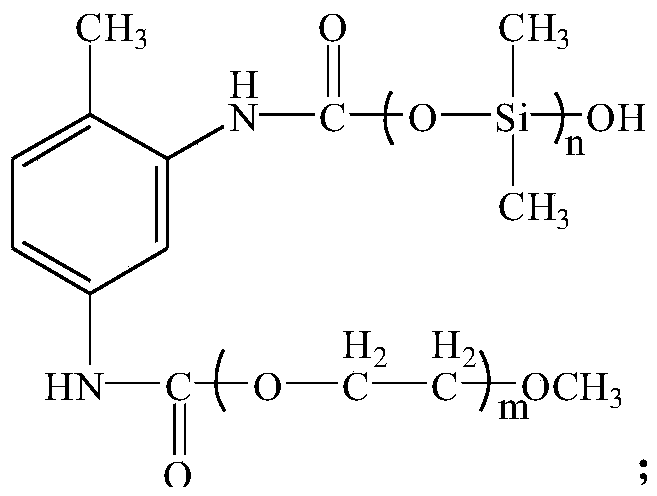

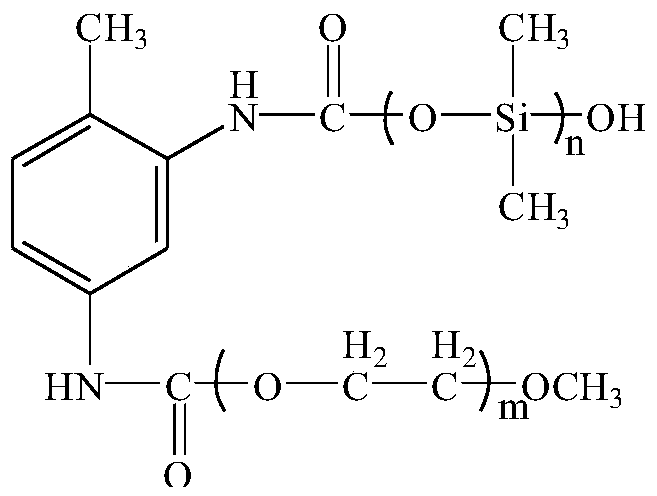

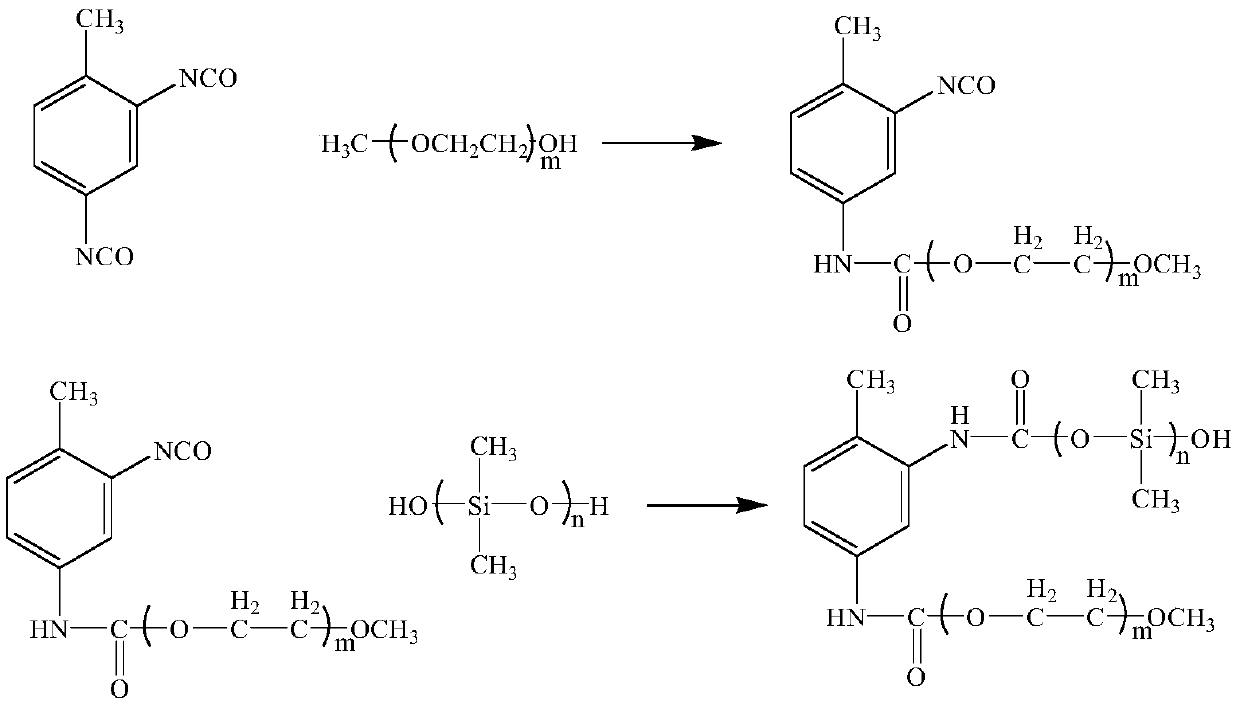

Image

Examples

Embodiment 1

[0026] (1) Add 1 mol of toluene diisocyanate, 1 mol of polyoxyethylene ether (9) and 870.75 g of solvent water into a four-necked flask with a thermometer, reflux condenser and stirrer, and heat while stirring at a stirring rate of 300 rpm, The heating temperature is 30°C, nitrogen is introduced for 5 minutes, 3.483g of the catalyst dibutyltin laurate is slowly added to the four-necked flask, nitrogen is continued, and the heating temperature of the four-necked flask is increased to 70°C, and the stirring rate is adjusted to 500rpm. After reacting for 4 hours, the temperature was lowered to room temperature to obtain an intermediate mixture.

[0027] (2) Add 1 mol of polymethylsiloxane (8) to the above-mentioned intermediate mixture, adjust the stirring rate to 400rpm, adjust the temperature to 80°C, and mix well, react for 2h, and cool to 30°C to obtain the final The product mixture.

[0028] (3) The above final product mixture was used to remove the solvent water with a rotary e...

Embodiment 2

[0032] (1) Add 1 mol of toluene diisocyanate, 1.1 mol of polyoxyethylene ether (12) and 1256.3 g of solvent water into a four-necked flask with a thermometer, reflux condenser and stirrer, and heat while stirring at 360 rpm. , The heating temperature is 50 ℃, nitrogen is introduced for 6 minutes, 6.235g of catalyst dibutyl tin laurate is slowly added to the four-necked flask, nitrogen is continued, and the heating temperature of the four-necked flask is increased to 82 ℃, and the stirring rate is adjusted to 530 rpm After reacting for 5 hours, the temperature is lowered to room temperature to obtain an intermediate mixture.

[0033] (2) Add 1.1 mol of polymethylsiloxane (16) to the above-mentioned intermediate mixture, adjust the stirring rate to 450 rpm, and adjust the temperature to 85°C. After mixing uniformly, react for 3 hours and cool to 32°C to obtain The final product mixture.

[0034] (3) The above-mentioned final product mixture was removed with a rotary evaporator to re...

Embodiment 3

[0038] (1) Add 1 mol of toluene diisocyanate, 1.2 mol of polyoxyethylene ether (20) and 1741.5 g of solvent water into a four-necked flask with a thermometer, reflux condenser and stirrer, and heat while stirring at 400 rpm. , The heating temperature is 60℃, nitrogen gas is introduced for 8min, 8.359g of catalyst dibutyltin laurate is slowly added into the four-neck flask, nitrogen is continued, and the heating temperature of the four-neck flask is increased to 90℃, and the stirring rate is adjusted to 600rpm After reacting for 7 hours, the temperature is lowered to room temperature to obtain an intermediate mixture.

[0039] (2) Add 1.2 mol of polymethylsiloxane (20) to the above-mentioned intermediate mixture, adjust the stirring rate to 500rpm, adjust the temperature to 90°C, and after mixing uniformly, react for 5h and cool to 35°C to obtain The final product mixture.

[0040] (3) The above-mentioned final product mixture was removed with a rotary evaporator to remove the solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com