Polyurethane sealant with high thermal resistance and preparation method of polyurethane sealant

A polyurethane sealant, high heat resistance technology, used in polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve problems such as poor heat resistance of polyurethane sealants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Embodiment 1: A high heat-resistant polyurethane sealant described in this embodiment, which is prepared from polyether triols, dendritic polyester polyols, benzene-containing polyisocyanates, catalysts and fillers;

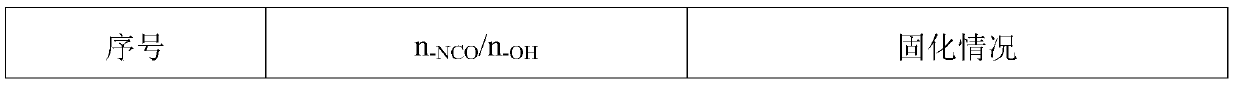

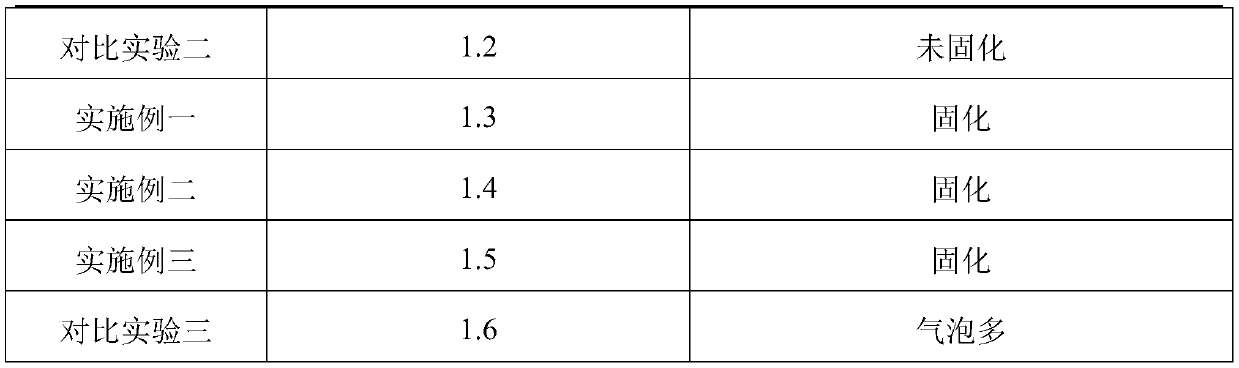

[0019] The ratio of the hydroxyl group of the polyether trihydric alcohol and the total number of moles of the hydroxyl group of the dendritic polyester polyol to the molar number of isocyanate groups containing benzene polyisocyanate is 1: (1.3~1.5); The molar ratio of the hydroxyl group of alcohol to the hydroxyl group of dendritic polyester polyol is 1:(0.01~0.143);

[0020] The mass percent of the catalyst in the high heat-resistant polyurethane sealant is 0.005% to 0.5%;

[0021] The mass percentage of the filler in the high heat-resistant polyurethane sealant is 0.08%-20%.

[0022] The beneficial effect of this embodiment is: dendritic polyester polyol has the advantages of unique structure, good fluidity, unique viscosity behavior and good heat res...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the benzene-containing polyisocyanate is toluene diisocyanate, diphenylmethane diisocyanate or polyphenyl polyisocyanate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the catalyst is one or several of dibutyltin dilaurate, tertiary amine catalysts and morpholine catalysts mixture. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Heat resistance | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com