Profile steel stacking device

A stacking device and technology of section steel, which is applied in the stacking, transportation and packaging of objects, and can solve the problems of unable to stack section steel, loose bundles, poor stacking effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the purpose, features and functions of the present invention, the structure and functions of a preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

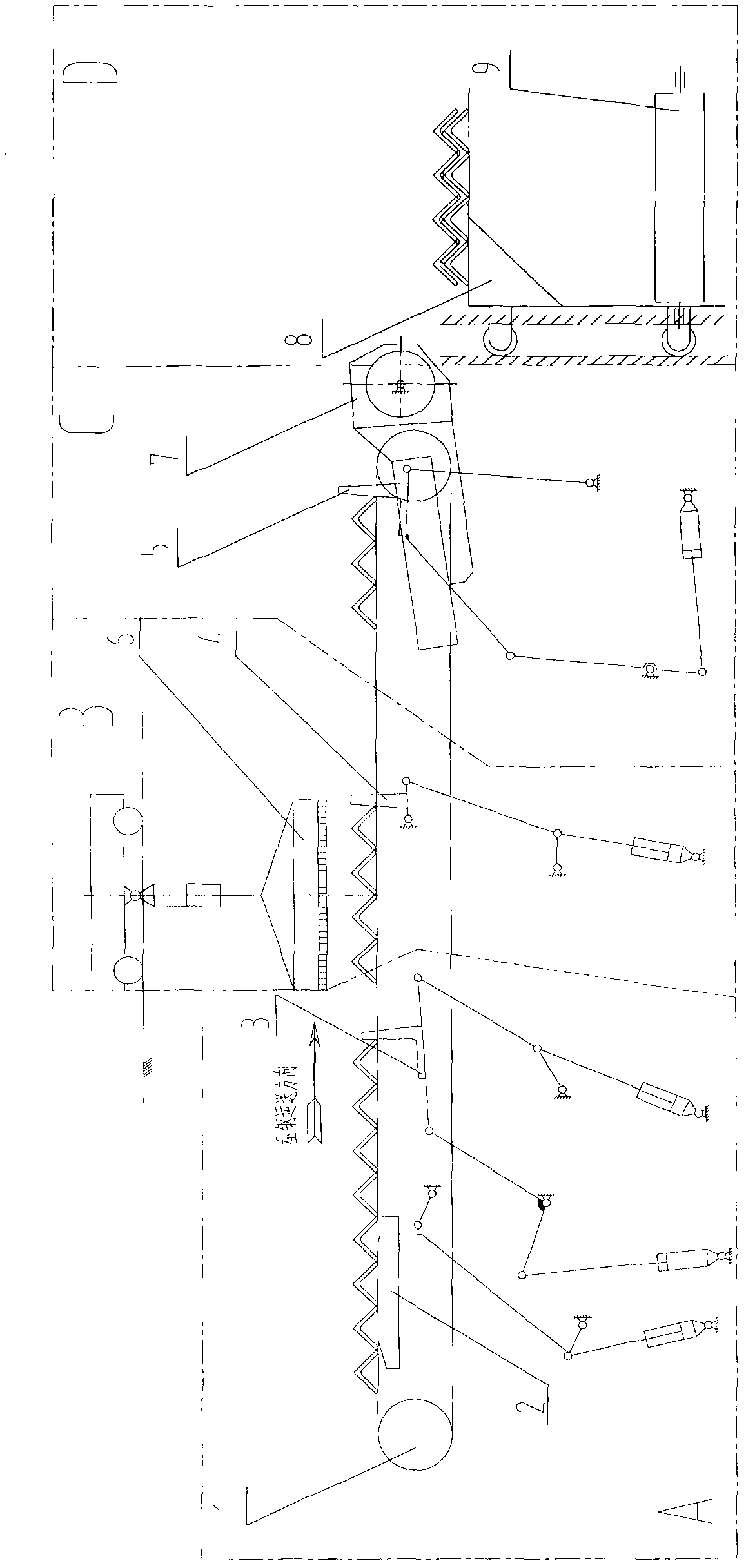

[0026] figure 1 It is a simplified schematic diagram of the structure of the section steel palletizing device described in this embodiment. It can be seen from the figure that the section steel palletizing device includes a transport steel separation unit A, a translation palletizing unit B, an overturning palletizing unit C and a palletizing output unit D . The transportation and steel sorting unit A is used to group the section steel after cold sawing to length in the finishing collection area and transport them to different palletizing units, so that the palletizing units can perform different palletizing pretreatments, which include chain Conveyor 1, steel separating device 2 and first baffle plate 3. The chain conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com