Polysulfonamide core-spun and wrapped composite yarns and conditioning friction tight composite spinning device thereof

A technology of sulfonamide and composite yarn, which is applied in the direction of spinning machine, continuous winding spinning machine, yarn, etc., and can solve the problems of non-abrasive parts, short service life, and low elongation at break of yarn sliver.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

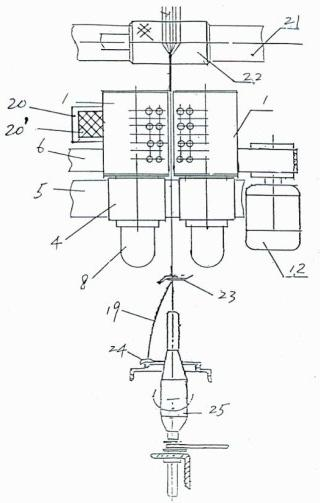

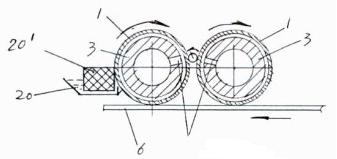

[0037] The diameter of air holes on the circumferential surface of the dust cage friction false twister adopted in the present invention is 0.6-0.9mm, the number of air holes is 900-1100, and the suction negative pressure adopted is 2400-3500Pa.

[0038] The production process of sulfone fiber core-spun composite yarn is as follows:

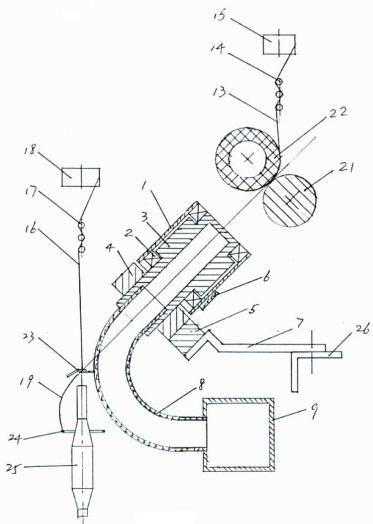

[0039] The drafting single-strand fiber bundle output from the front nip that front rubber roller 22 and front roller 21 form is twisted into yarn together with core filament 13, and is spun into the core-spun yarn that short fiber wraps long filament. The core-spun yarn enters the two dust cage friction false twisters 1 again, and is simultaneously subjected to the plasticizing of moisture in the wet tank 20 and the tight twisting action of the two dust cages, and then is output into the yarn guide hook 23, and is then The wrapped yarn 16 is wrapped and bundled, spun into a compact compound polysulfonamide core-wrapped composite yarn 19 , and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com