Heat insulated bridge solid steel door and window composite section bar and manufacturing method therefor

A technology of composite profiles and steel profiles, applied in the field of steel doors and windows, can solve problems such as difficult manufacturing, uneconomical doors and windows, and unfavorable large-scale promotion and popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

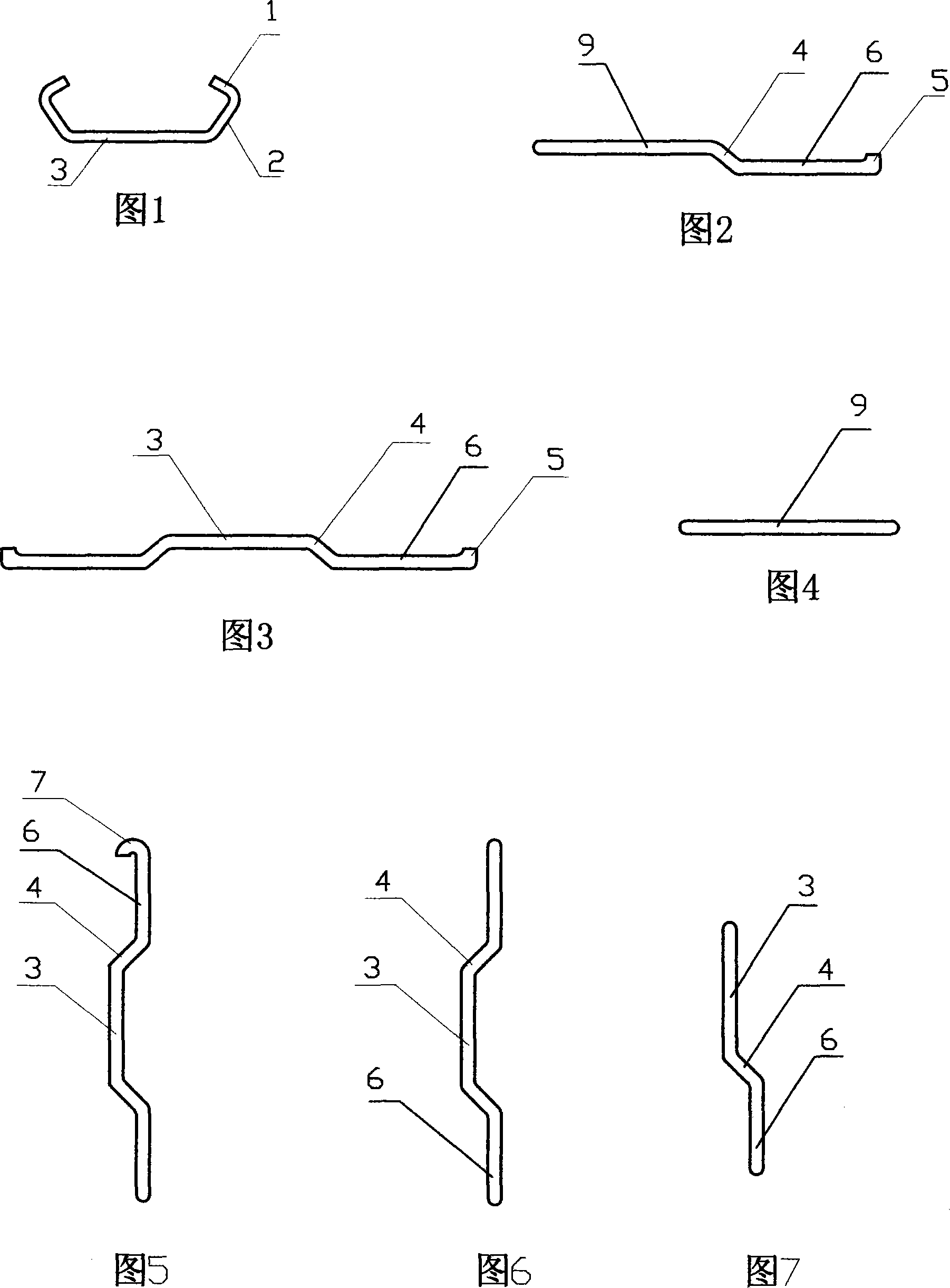

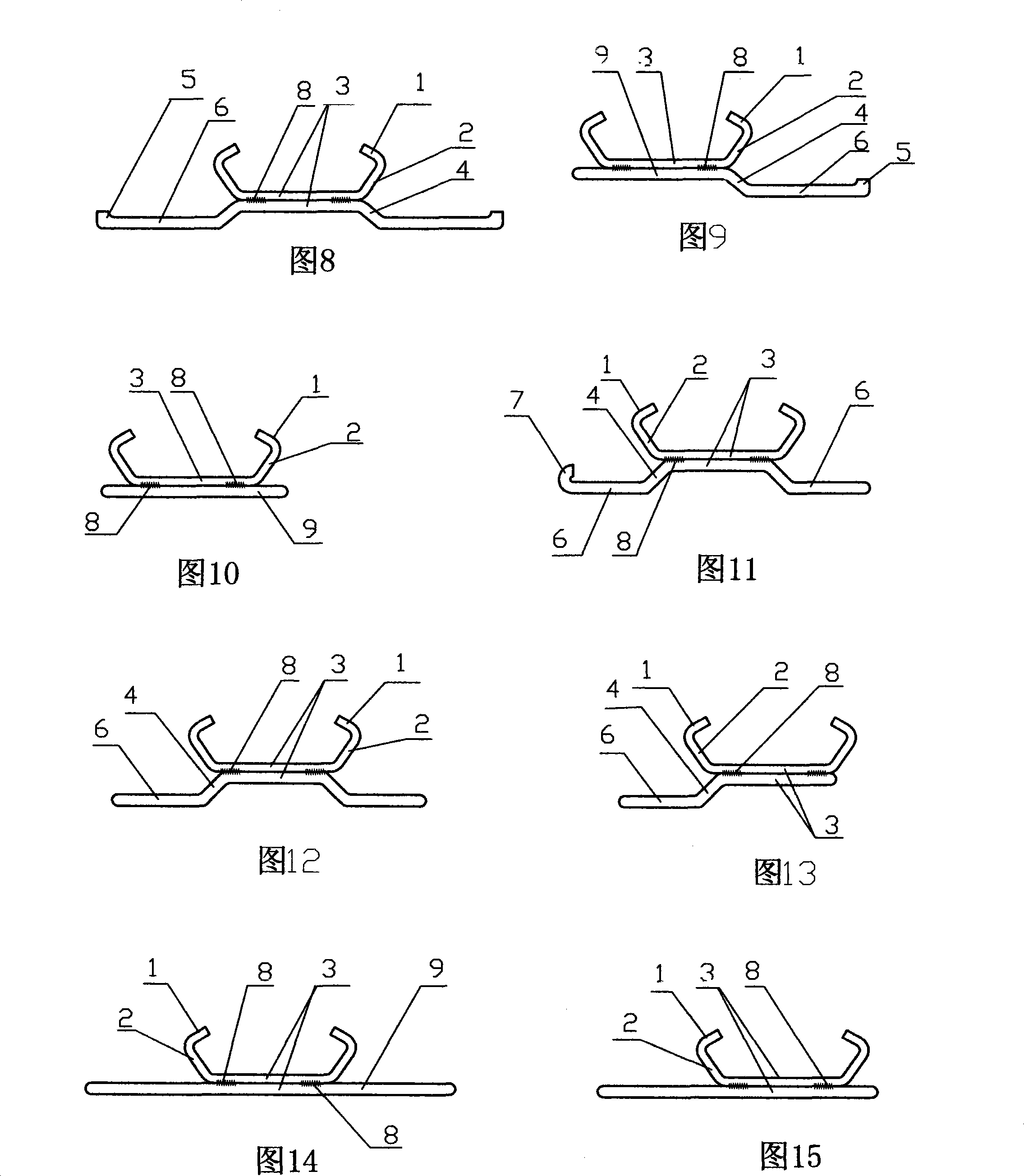

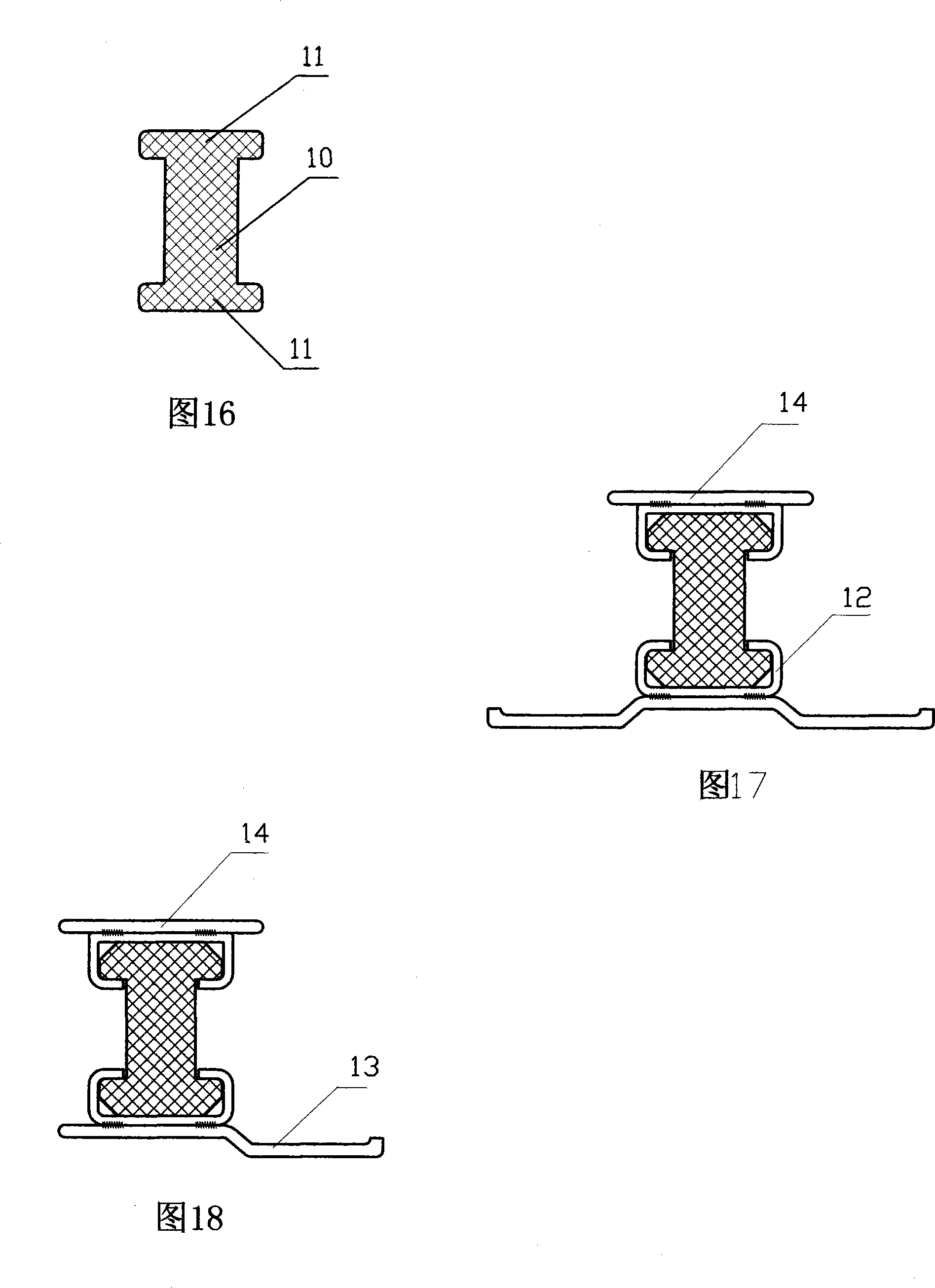

[0111] As shown in Figures 1-22, a solid-web steel door and window composite profile for a heat-breaking bridge is mainly composed of a solid-web steel profile composed of standard steel members and a heat-insulating strip. The heat-insulating strip is made of plastic, and the cross-sectional shape of the heat-insulating strip is "I" shape, the width of the heat insulation strip flange 11 is 15mm, the thickness is 6mm, the width of the heat insulation strip web 10 is 10mm, and the length is 16mm. The standard steel members that make up the solid web profiles 12-19 of steel doors and windows are 1.2mm thick steel strip linear sheets, and their width is determined according to the use of door and window steel profiles. Standard steel members include 1 type of "U"-shaped linear member, 1 type of straight linear member and 5 types of flat linear members, a total of 7 standard parts:

[0112] The standard part 1 is a "U"-shaped linear member, and the bottom is a straight flat web 3...

Embodiment 2

[0138] A kind of solid-web steel door and window composite profile of a heat-insulating bridge is characterized in that: the heat-insulating strip is plastic, the width of the heat-insulating strip flange 11 is 20 mm, the thickness is 8 mm, the width of the heat-insulating strip web 10 is 15 mm, and the length is 10 mm. 26mm. The standard steel components that make up the steel doors and windows solid-belly profiles 12-19 are 2.0mm thick steel strip linear sheets.

[0139] The included angle between the wing 2 of the standard part 1 and the straight flat web 3 is 110°, and the included angle between the wing hook 1 and the wing 2 is 85°.

[0140] The width of the slope indentation 4 of the five flat linear components is 5 mm, the angle between the straight flat web 3 is 45°, the width of the piping 5 on the edge of the side wing plate 6 is 2.5 mm, and the semicircle of the edge of the side wing plate 6 The radius of the hook 7 is 2.5 mm.

[0141] The width of the straight pl...

Embodiment 3

[0143] A kind of solid-web steel door and window composite profile of a heat-insulating bridge, characterized in that: the heat-insulating strip is made of wood material, the width of the heat-insulating strip flange 11 is 25mm, and the thickness is 10mm, and the width of the heat-insulating strip web 10 is 20mm and the length is 33mm. The standard steel components that make up the solid-belt profiles 12-19 of steel doors and windows are 3.0mm thick steel strip linear sheets.

[0144] The included angle between the wing 2 of the standard part 1 and the straight flat web 3 is 130°, and the included angle between the wing hook 1 and the wing 2 is 90°.

[0145] The width of the slope indentation 4 of the five flat linear components is 7 mm, the angle between the straight flat web 3 is 45°, the width of the piping 5 on the edge of the side wing plate 6 is 3.0 mm, and the semicircle of the edge of the side wing plate 6 The radius of the hook 7 is 5.0mm.

[0146] The width of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com