Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Ablation resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic matrix composite material and preparation method thereof

ActiveCN110028330AStrong chemical bondGive full play to the synergistic antioxidant effectCarbon fibersHafnium

The invention provides a ceramic matrix composite material and a preparation method thereof, wherein a carbon fiber preform is used as a skeleton, and is immersed in a hafnium-tantalum-silicon ternarycomposite phose ceramic precursor solution, and curing and cracking are performed to prepare the composite material. According to the preparation method, a pyrolytic carbon interface layer is prepared on a carbon fiber preform by using a chemical vapor infiltration method, matrix densification treatment is performed by using a hafnium-tantalum-silicon ternary composite phose ceramic precursor impregnation cracking method, and finally pore sealing treatment is performed by using a chemical vapor infiltration method. According to the present invention, the method has characteristics of simple process and short development period; and the prepared ultra-high temperature ceramic matrix composite material has the uniform distribution of various components of the matrix, has characteristics ofultra-high-temperature resistance, oxidation resistance and ablation resistance, can be used as the high temperature thermal structure material for hypersonic vehicles and rocket propulsion systems, and has broad application prospects.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

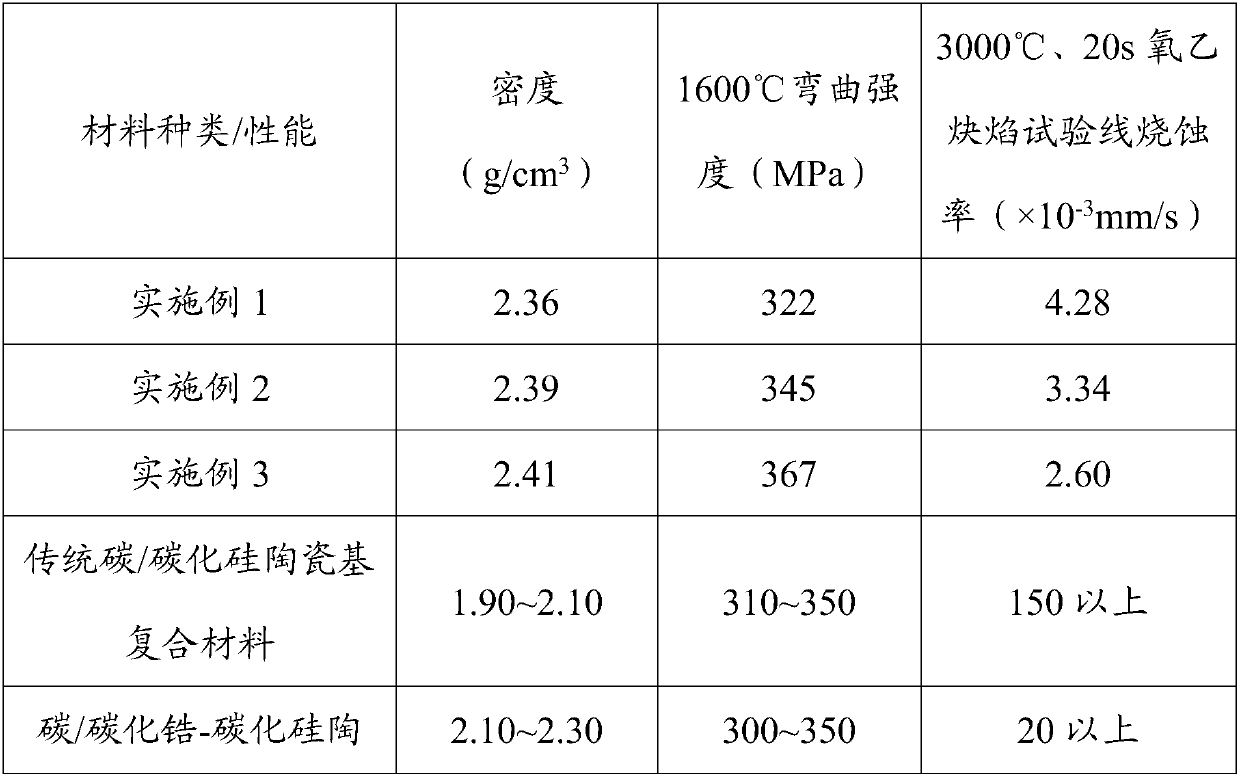

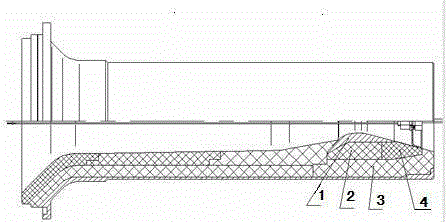

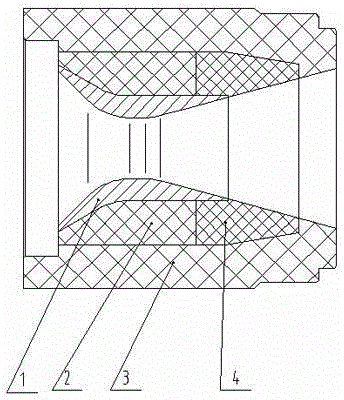

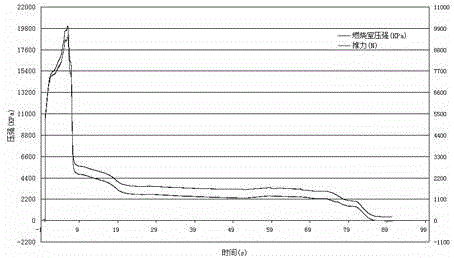

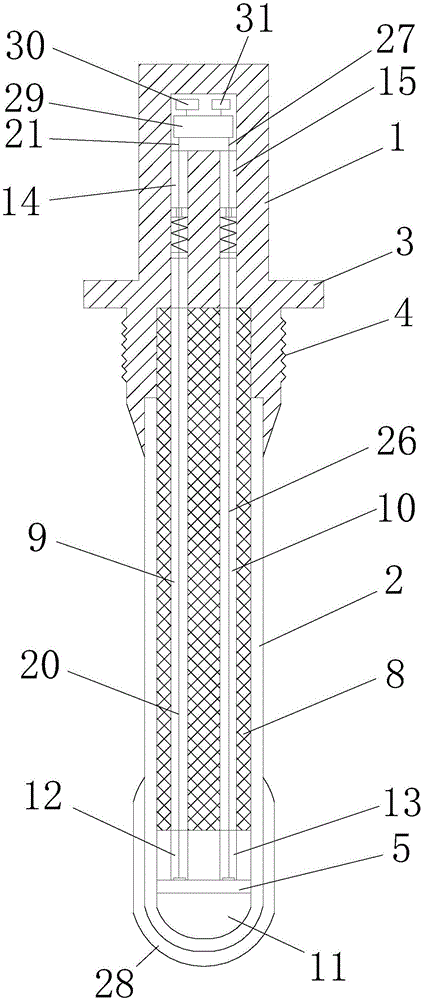

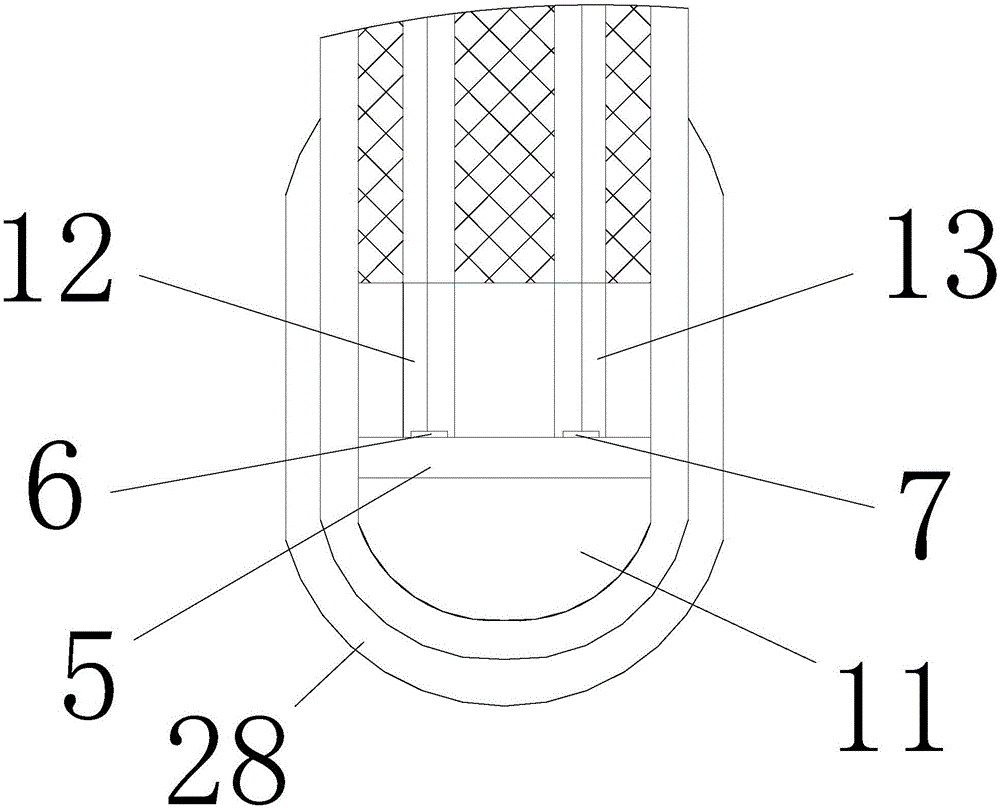

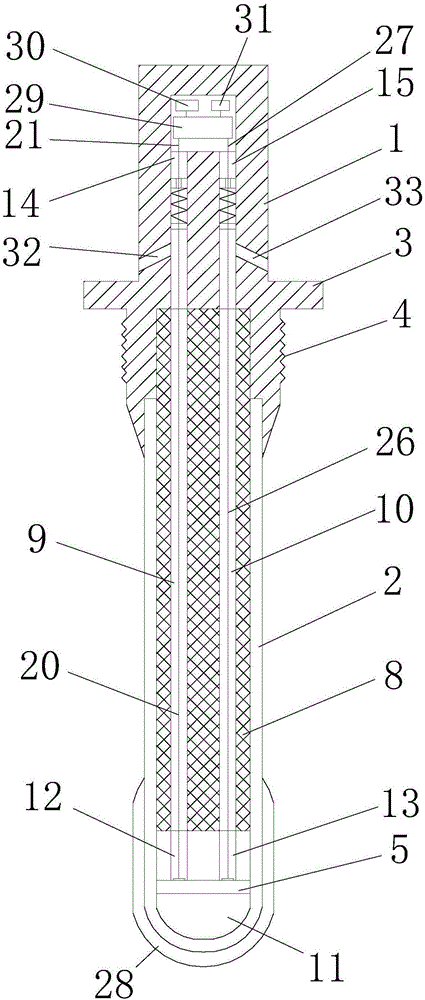

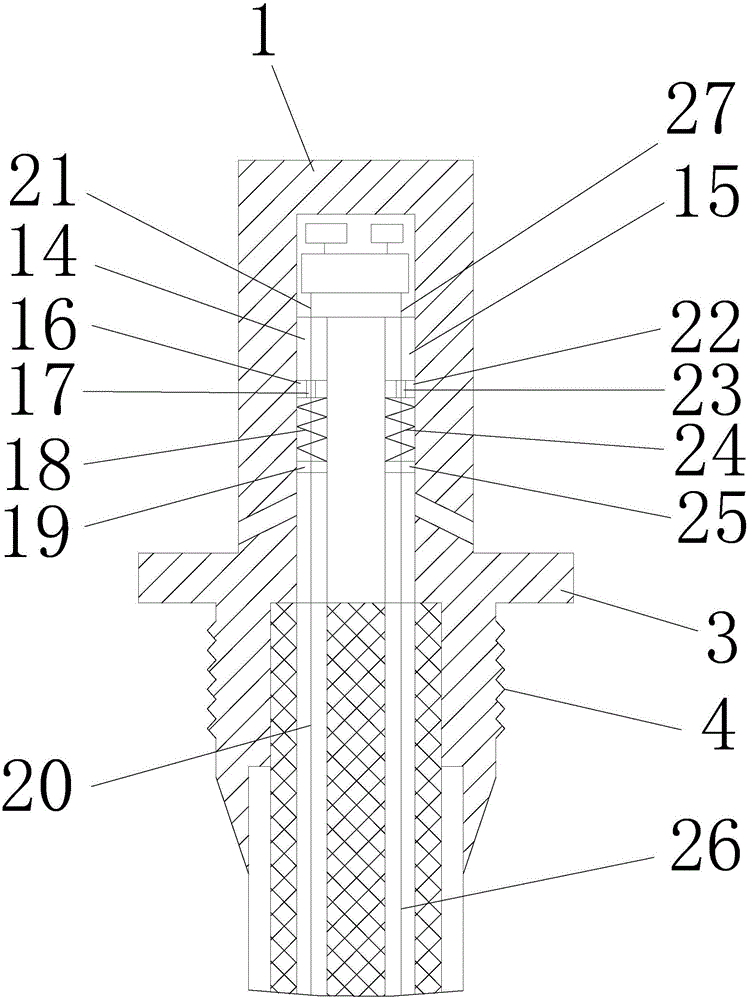

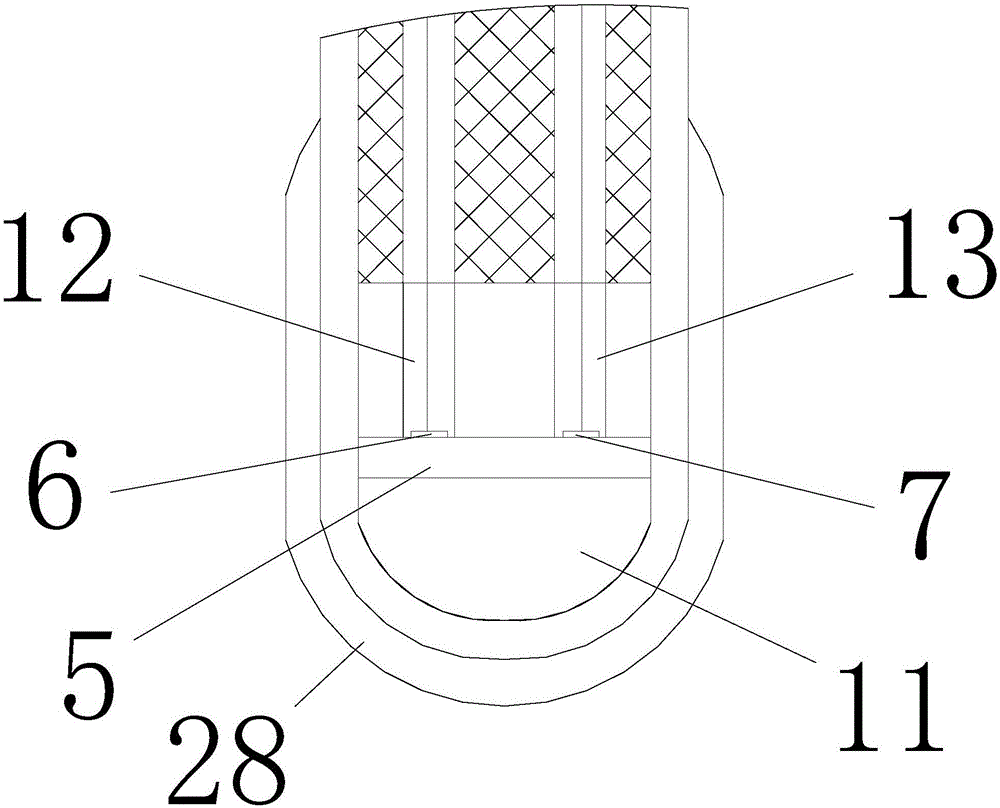

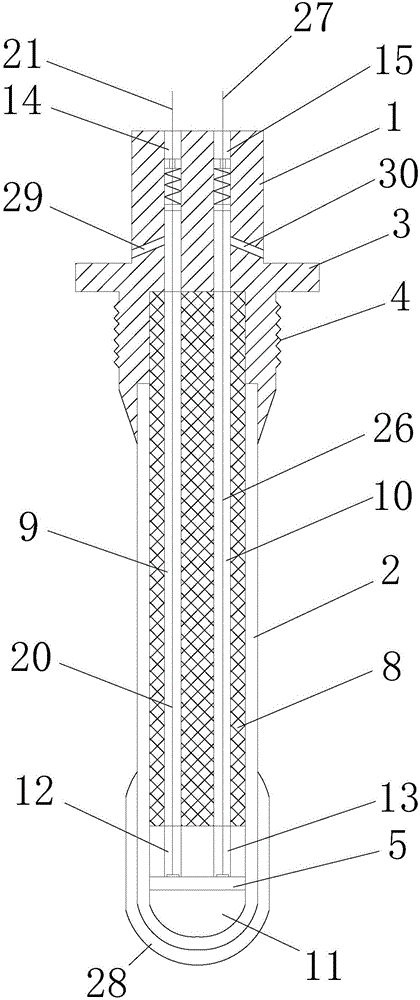

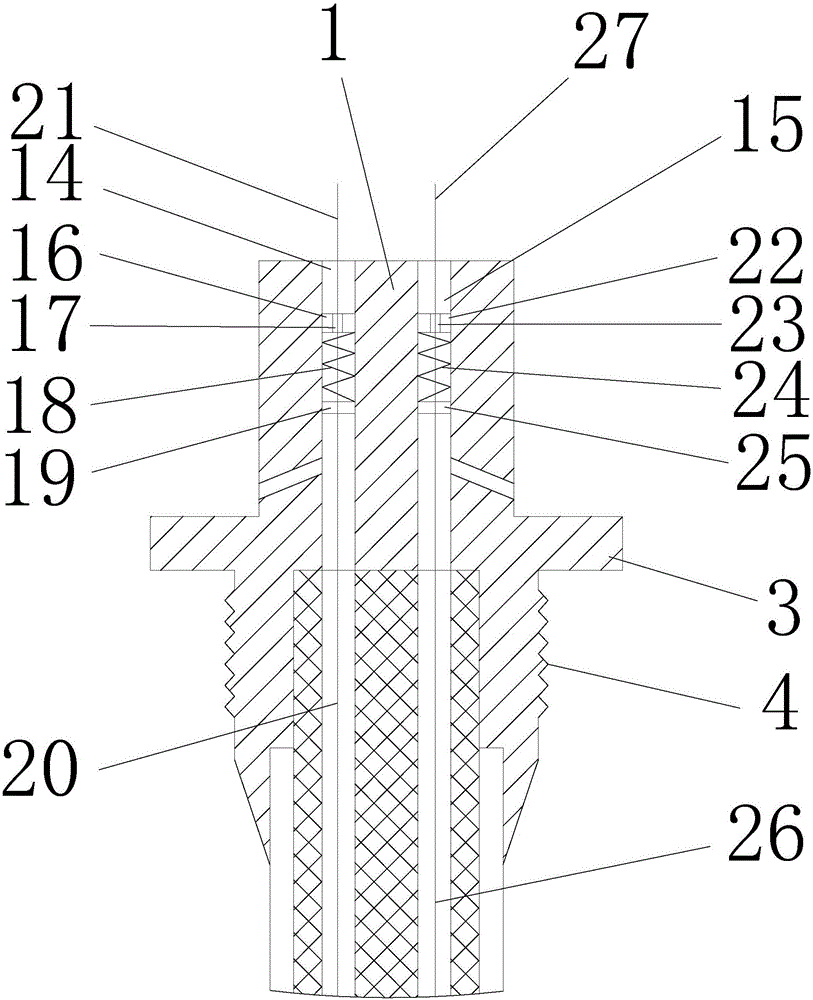

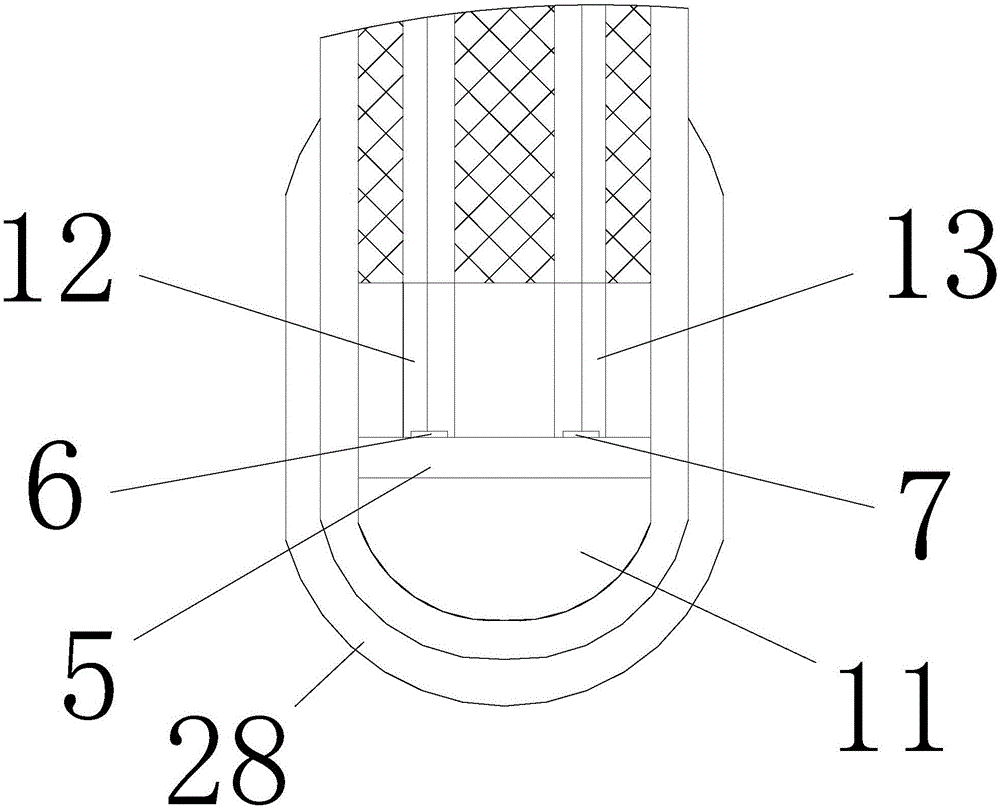

Large thrust ratio, long-working micro-ablation throat insert and throat structure of expansion section

The invention discloses a large thrust ratio, long-working micro-ablation throat insert and a throat structure of an expansion section. The throat structure comprises a throat insert, a backing, a bottom lining and a thermal insulation blanket of the expansion section; the external surface of the throat insert matches with a first step surface of the backing; the bottom of the backing is plastered on a second step surface of a bottom lining; the thermal insulation blanket of the expansion section matches with a third step surface of the bottom lining; the second step surface and the third step surface are on the same level; at the same time, the backing and the thermal insulation blanket of the expansion section are plastered in a circumference direction. <{EN3}>Compared with prior art, the advantages and beneficial effects are that large thrust ratio and long-working are satisfied; the throat assembly has the characteristics of micro-ablation; a good heat insulation effect in long working time is realized; intensity of a jet pipe housing is guaranteed; throat ablation amount is prevented from being overlarge and causing an obvious decrease of a secondary work pressure intensity; shock wave backflow can be prevented; and engine energy loss is avoided.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

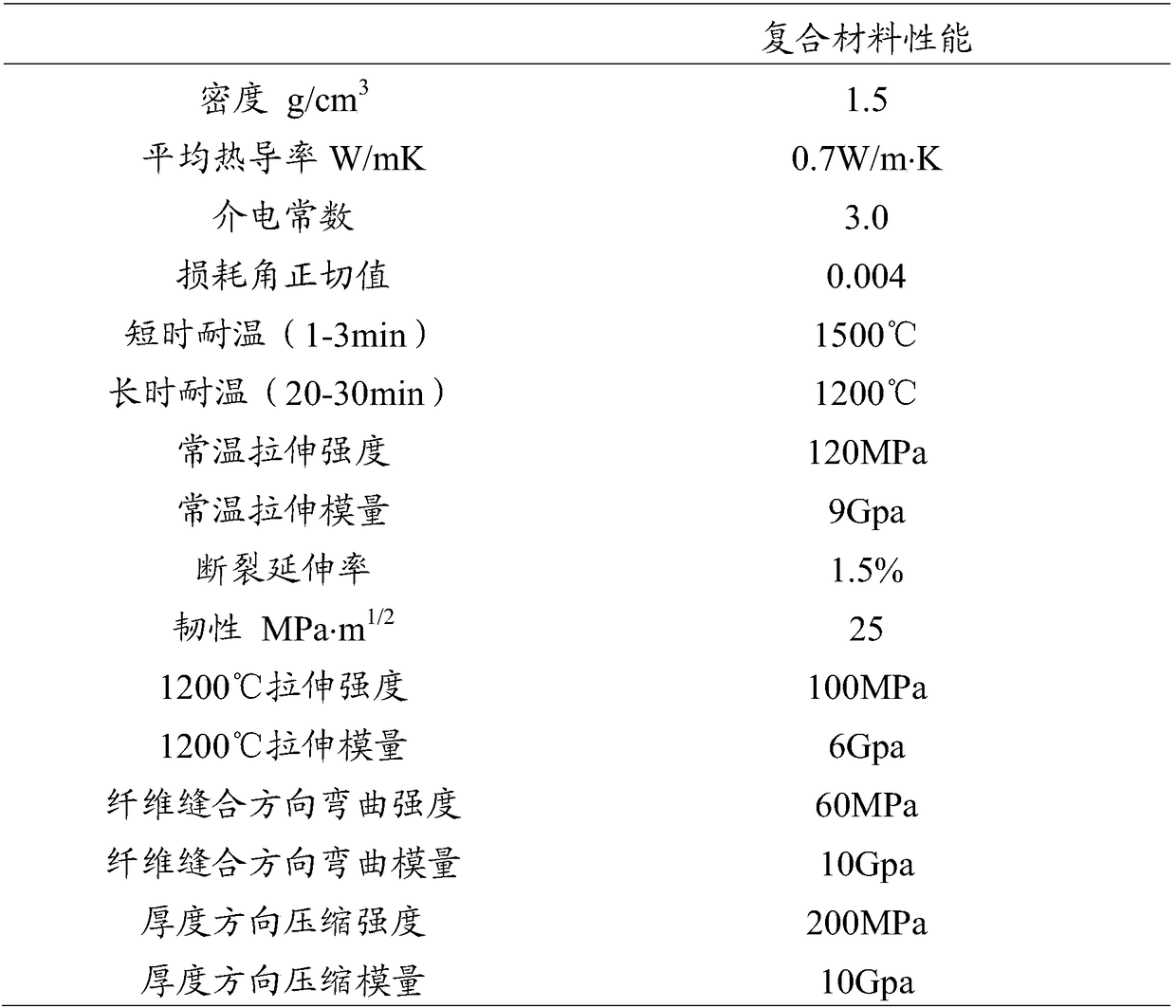

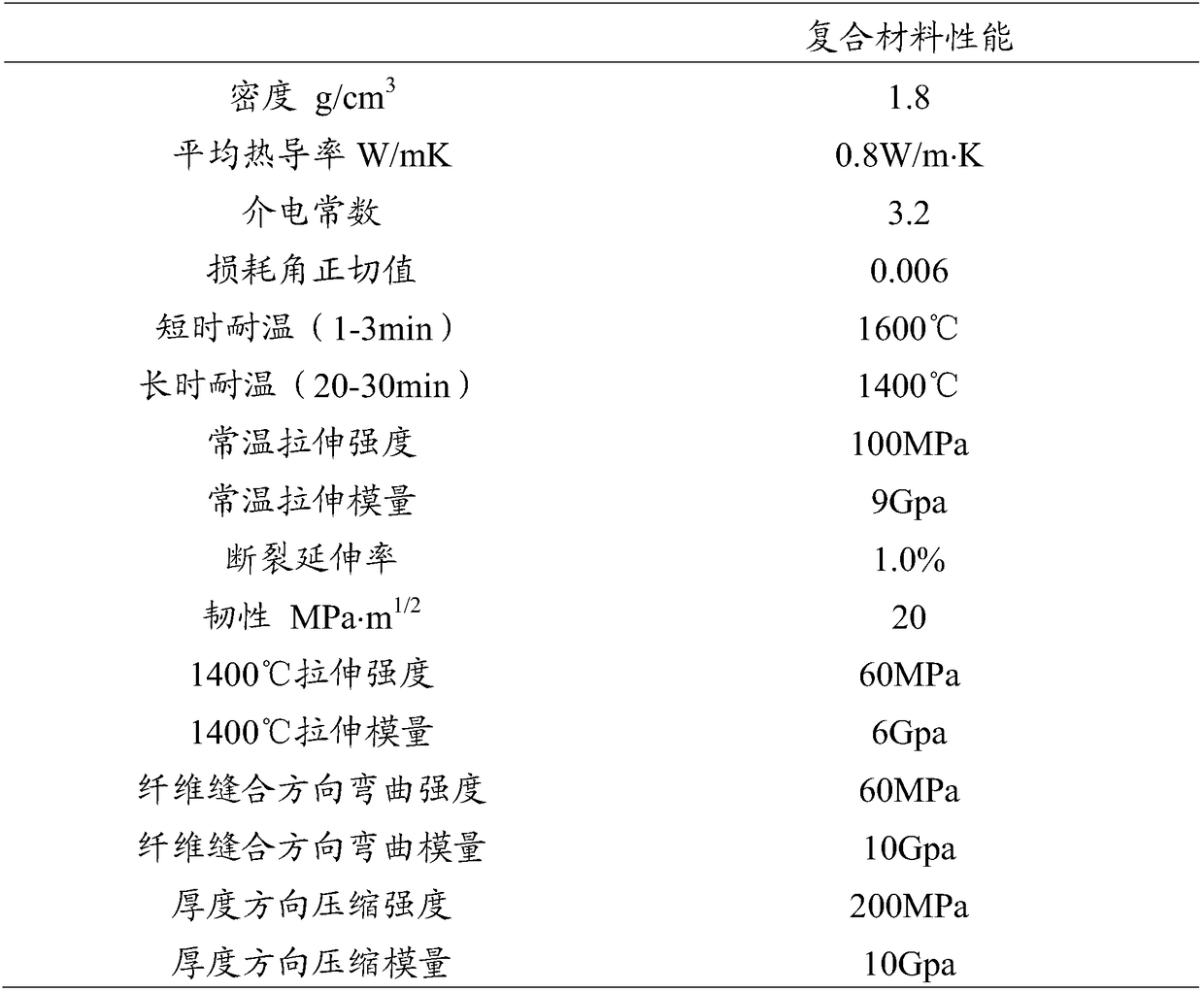

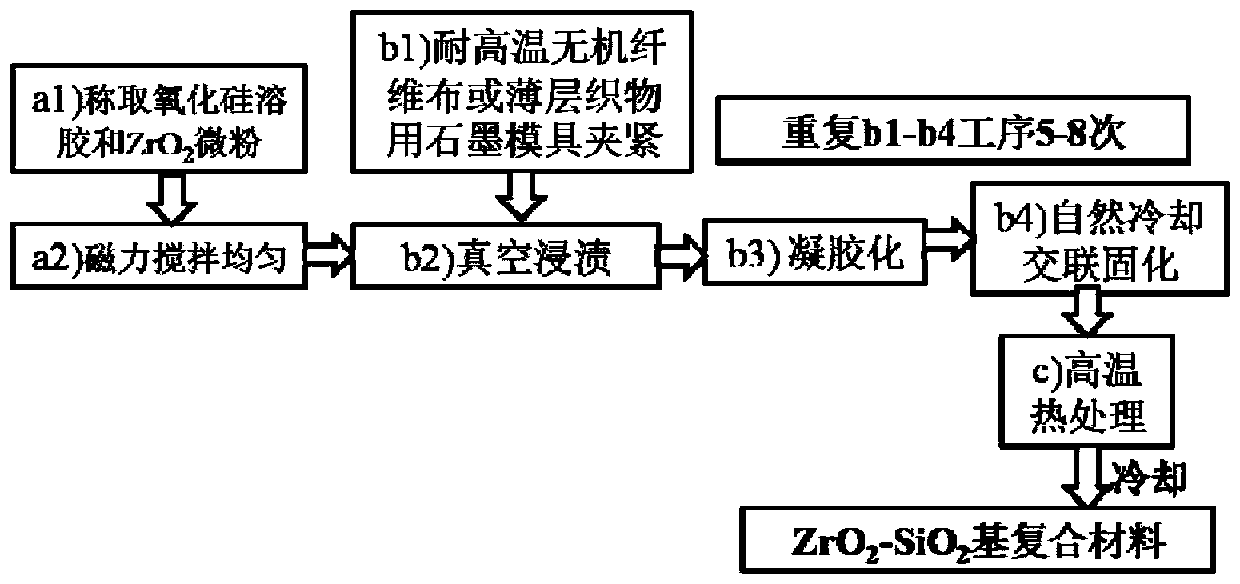

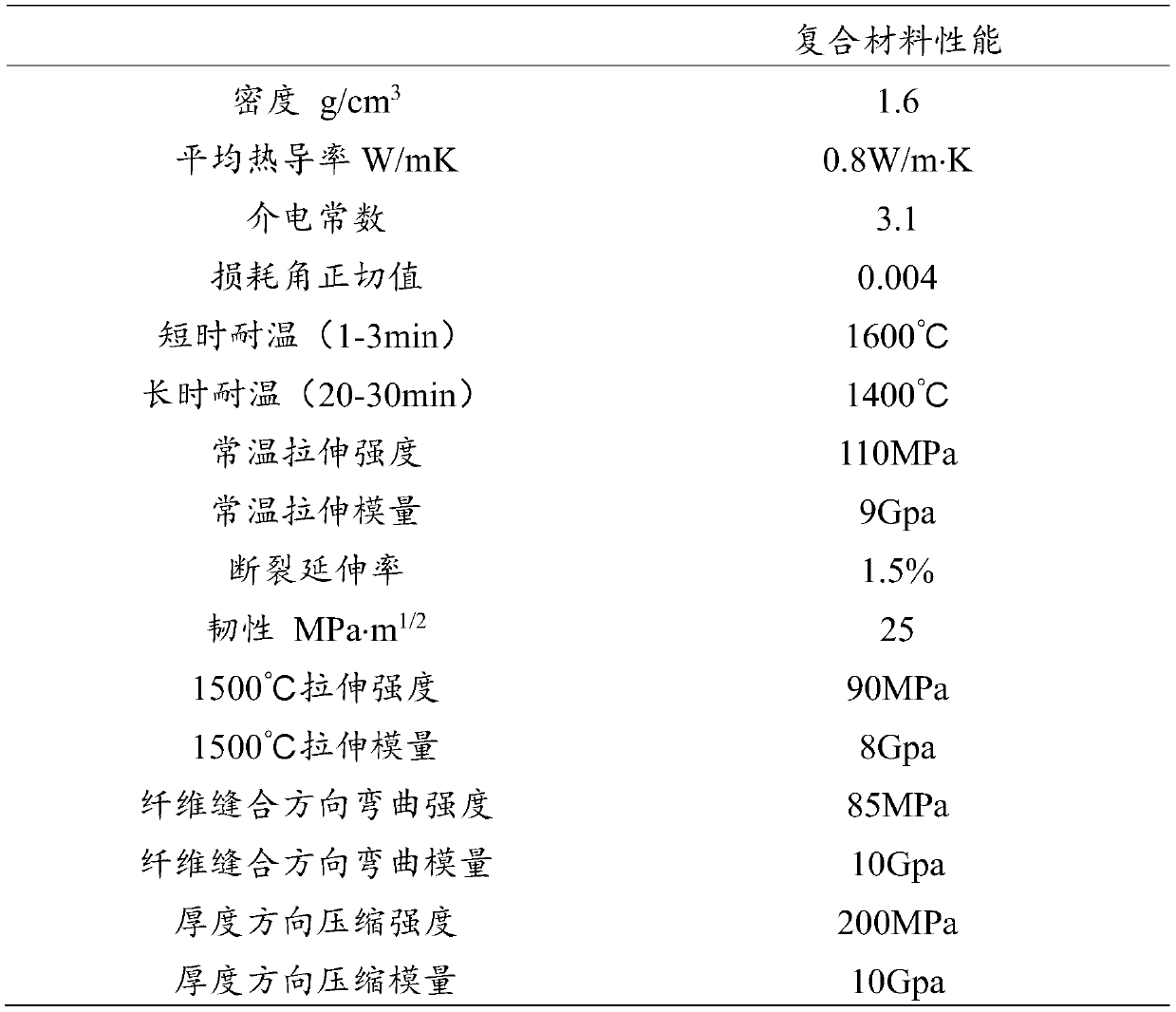

Al2O3-SiO2 based composite material and rapid preparation method thereof

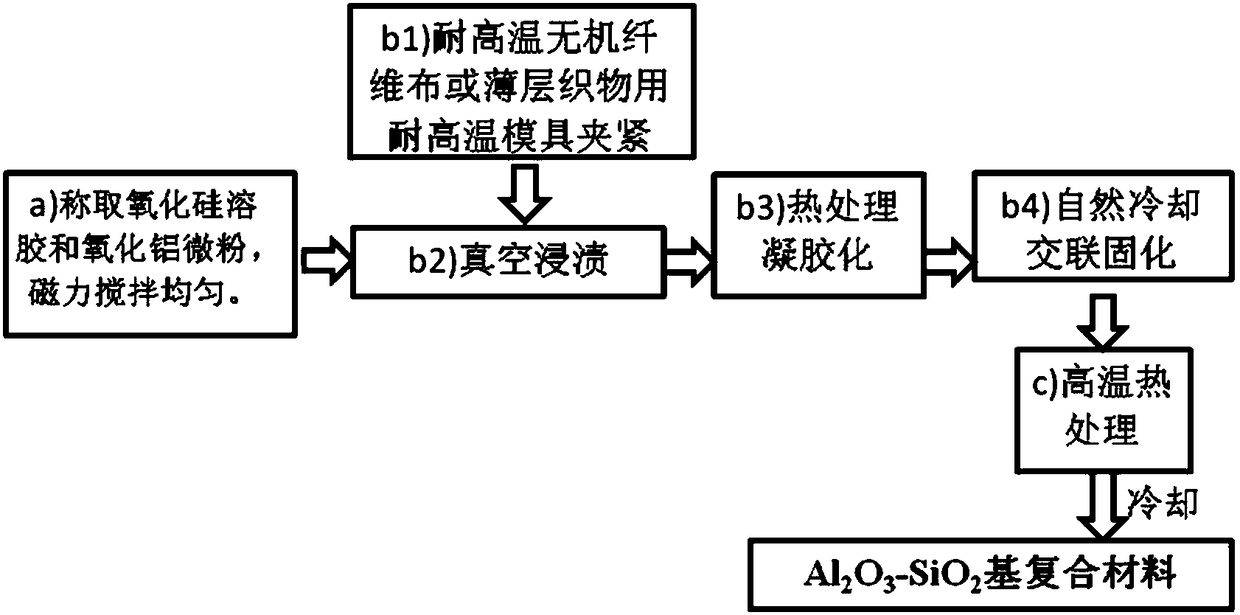

The invention discloses a rapid preparation method of an Al2O3-SiO2 based composite material. The method comprises the following steps: a) weighing silica sol and an alumina micro powder according toa certain ratio, adding the alumina micro powder into the silica sol, performing magnetic stirring for more than two hours, and forming a turbid liquid of a silica sol doped alumina micro powder; b) clamping high-temperature resistant inorganic fiber cloth or a thin-layered fabric by a high-temperature resistant mold, vacuumizing in a vacuum container, and sucking the turbid liquid of a silica soldoped alumina micro powder for performing mass-impregnation; rapidly transferring the high-temperature resistant inorganic fiber cloth or thin-layered fabric impregnated with turbid liquid into a drying oven to perform heat treatment, and enabling the inorganic fiber cloth or thin-layered fabric to gel; naturally cooling to a room temperature so as to perform cross-linked curing, and repeatedly performing mass-impregnation-gelling-natural cooling for 5-10 times; c) performing high-temperature heat treatment on obtained hard solids in a muffle furnace, and finally cooling to the room temperature, so as to obtain the Al2O3-SiO2 based composite material.

Owner:湖南福易达电子科技有限公司

Silicone rubber heat-insulating material for integral solid rocket ramjets and preparation method thereof

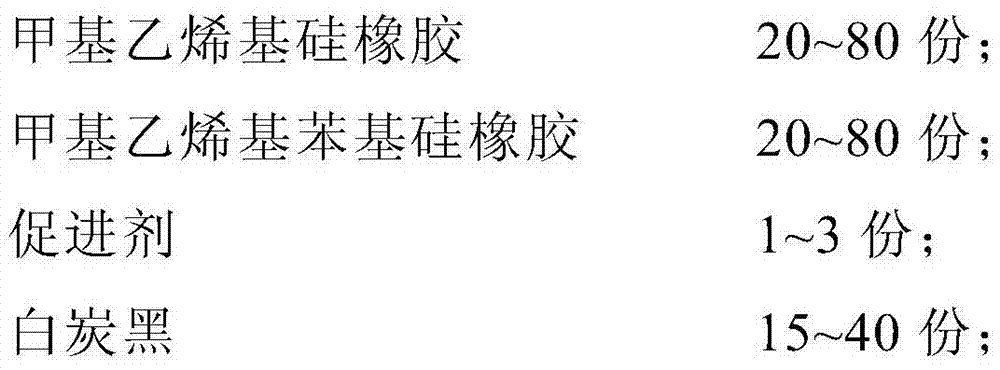

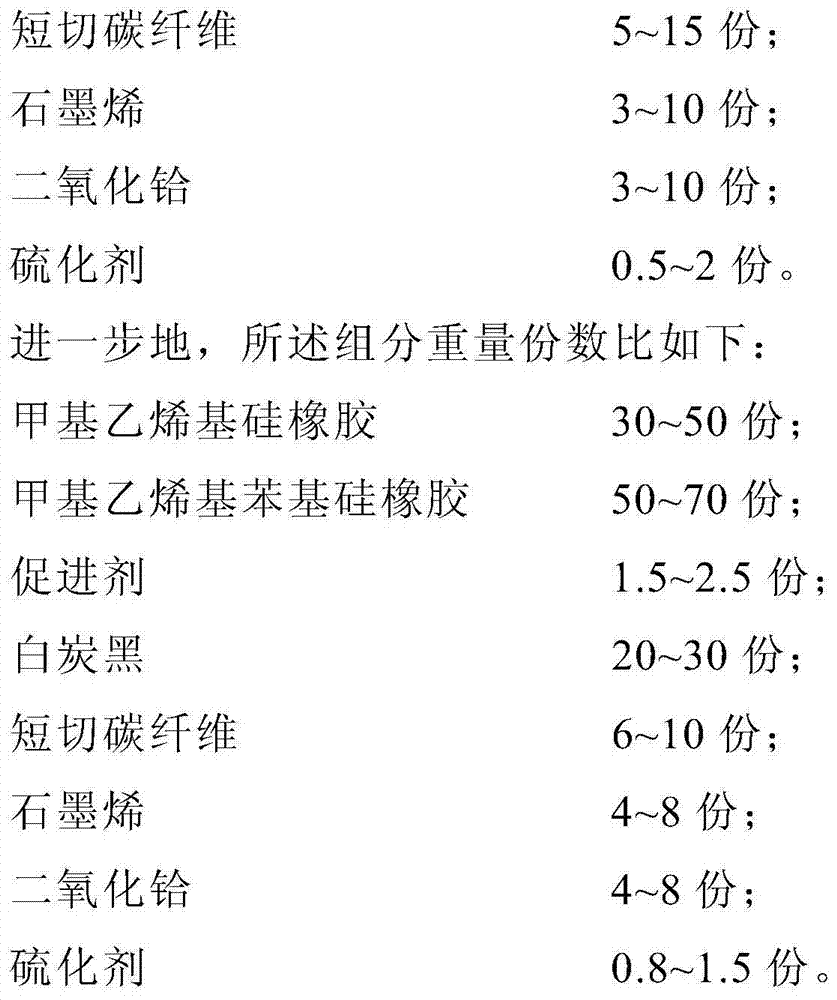

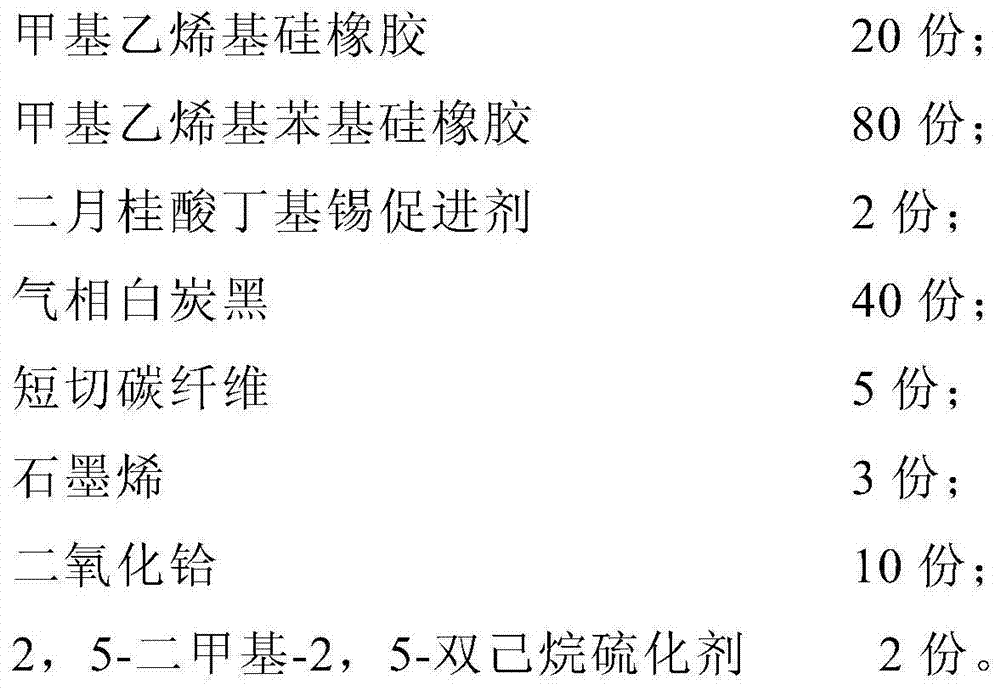

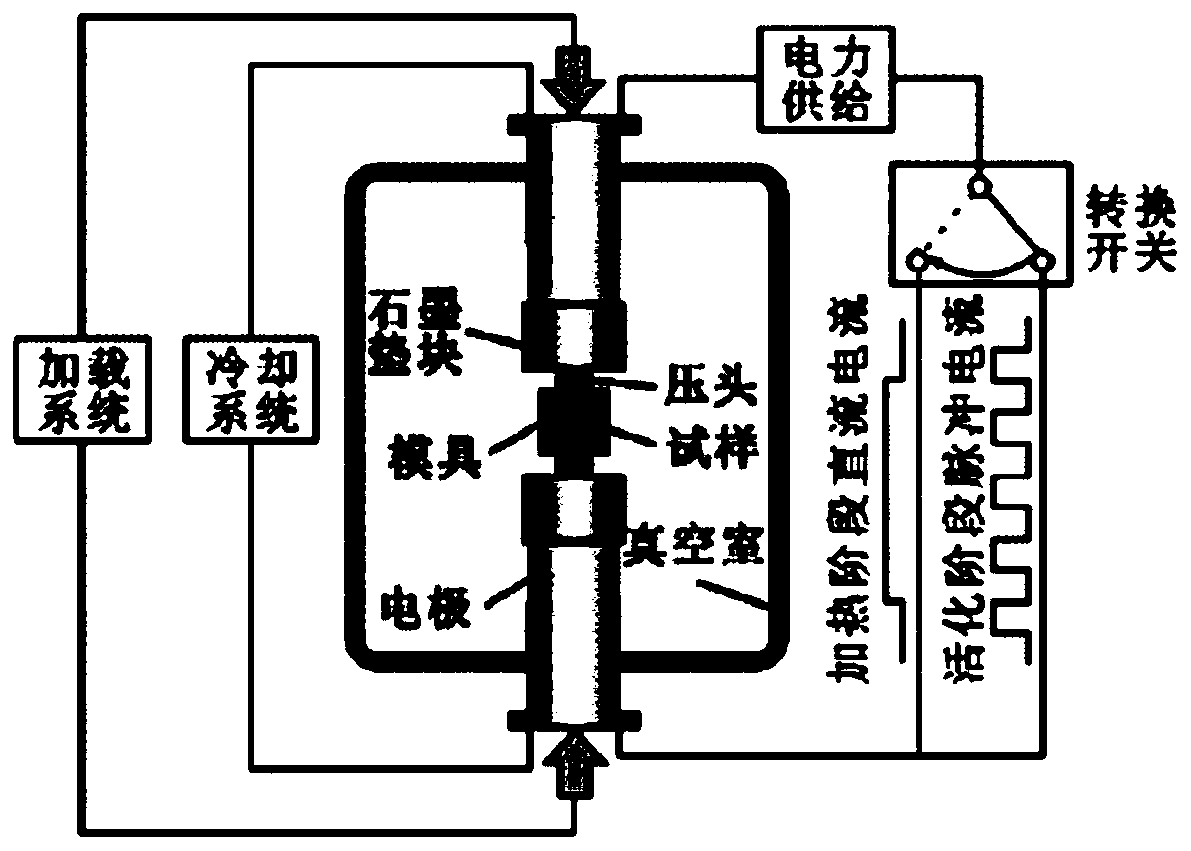

The invention discloses a silicone rubber heat-insulating material for integral solid rocket ramjets and a preparation method thereof. The silicone rubber heat-insulating material comprises the following components in parts by weight: 20-80 parts of methylvinyl silicone rubber, 20-80 parts of methylvinylphenyl silicone rubber, 1-3 parts of accelerator, 15-40 parts of silica white, 5-15 parts of chopped carbon fiber, 3-10 parts of graphene, 3-10 parts of hafnium oxide and 0.5-2 parts of vulcanizing agent. The silicone rubber heat-insulating material for integral solid rocket ramjets can form a high-melting-point ceramic-like layer in the ablation process, has the advantages of high temperature resistance, ablation resistance, favorable elasticity, high micromolecule migration resistance and the like, and can satisfy the operating environments of oxygen enrichment, high-temperature high-speed gas flow and particle erosion.

Owner:湖北三江航天江北机械工程有限公司

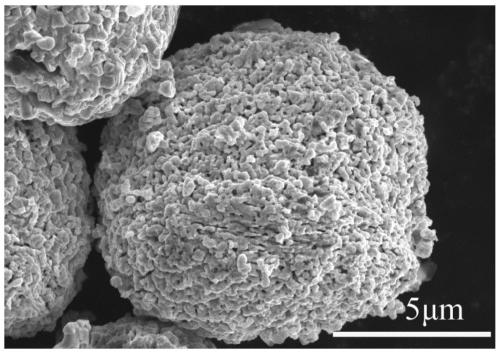

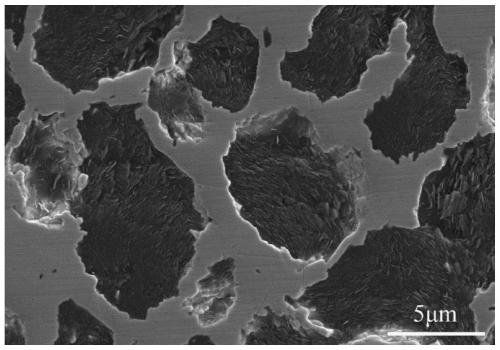

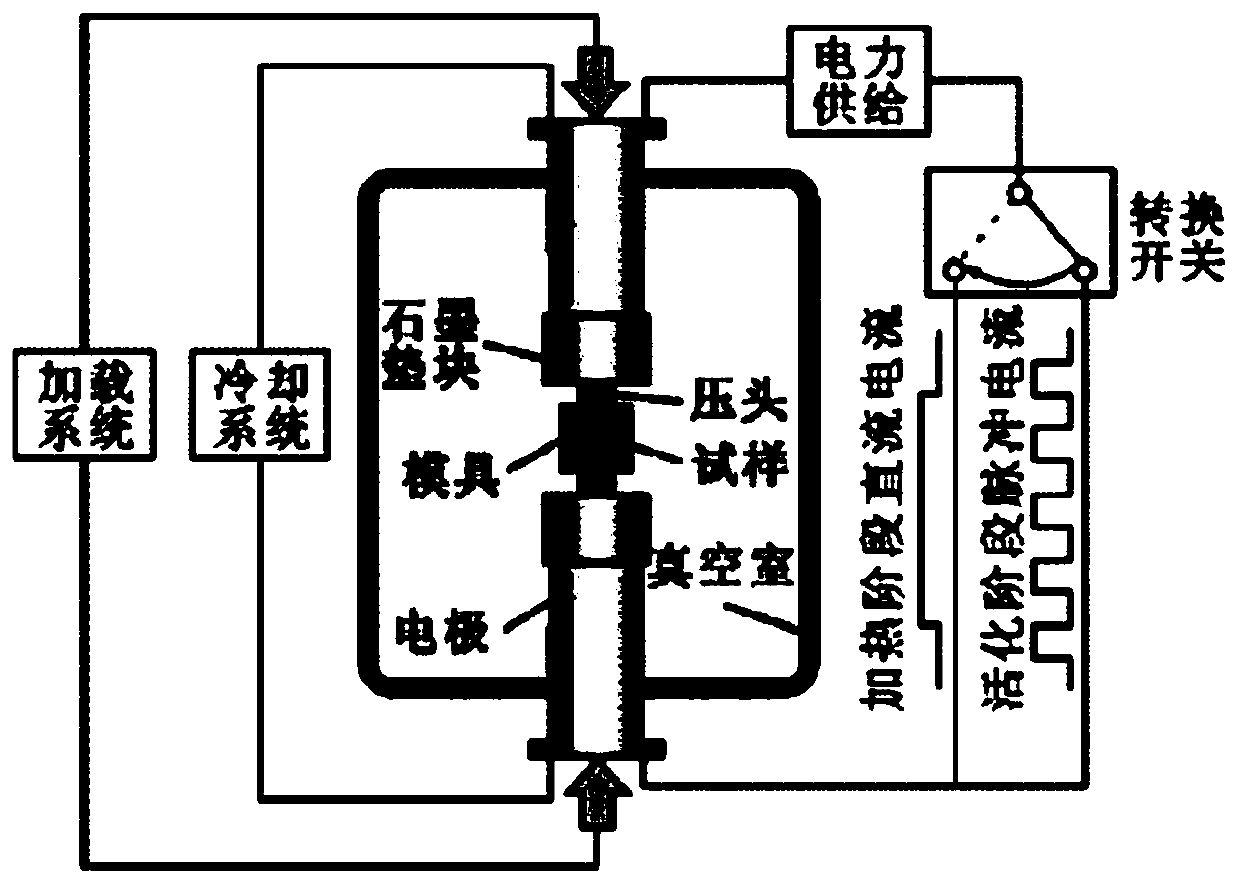

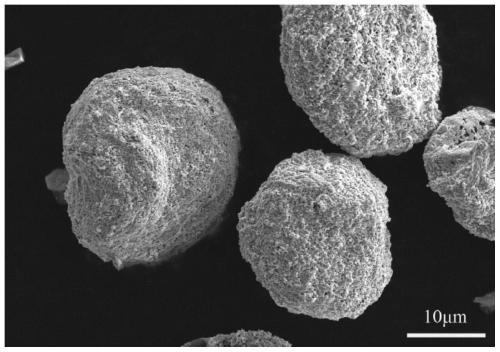

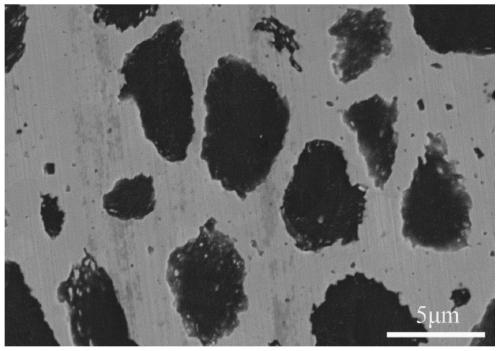

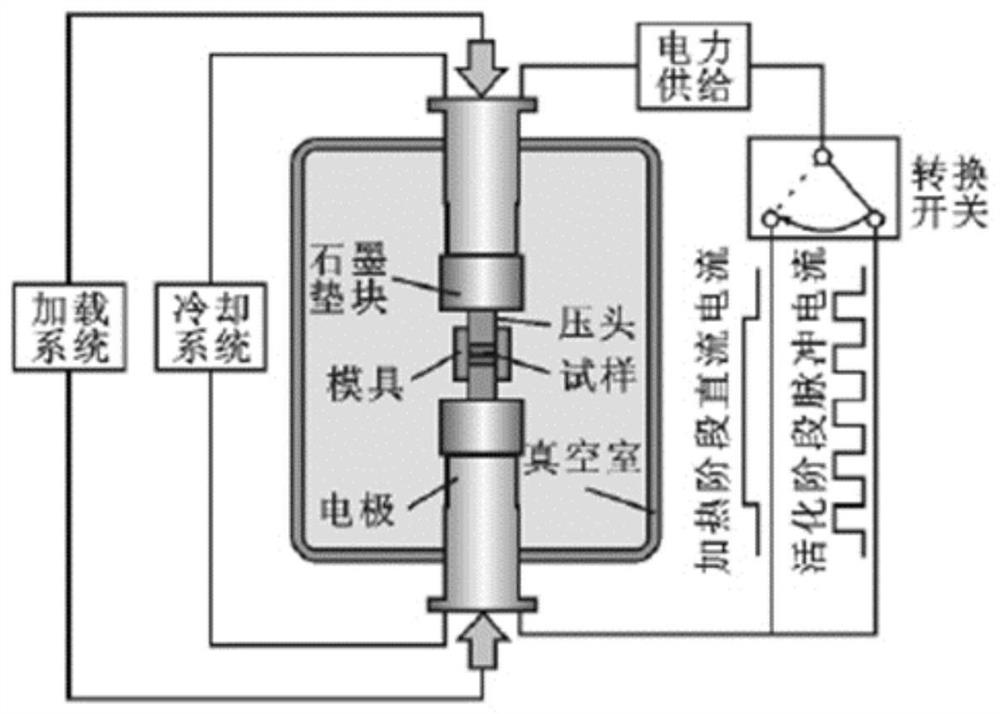

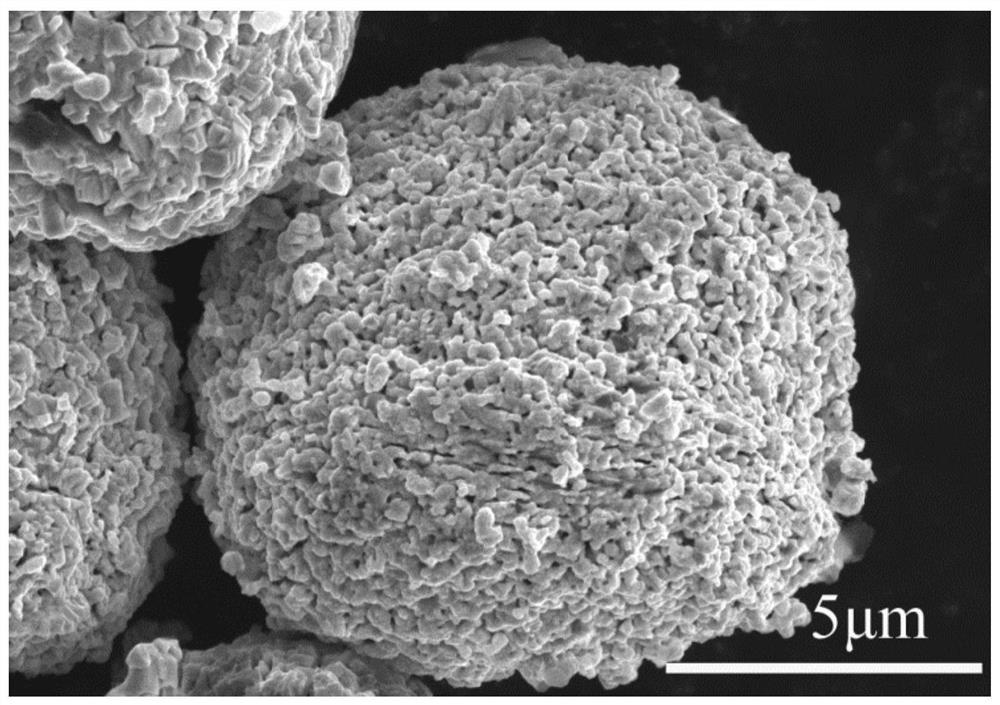

Tungsten carbide reinforced carbon matrix composite material and preparation method

The invention discloses a tungsten carbide reinforced carbon matrix composite material and a preparation method. Mesocarbon microbeads are adopted as the matrix, and tungsten carbide ceramic is adopted as the reinforcement phase and is evenly distributed among the carbon microbeads so as to form a three-dimensional network tungsten carbide skeleton reinforced isotropic structure. The preparation method includes: firstly taking tungsten oxide particles and mesocarbon microbeads as the raw materials to prepare uniform and thickness controllable tungsten carbide coating coated mesocarbon microbead powder by molten salt process, then performing pre-press molding, and conducting discharge plasma sintering at 1500-1900DEG C to form a uniform three-dimensional network tungsten carbide ceramic skeleton, which can significantly improve the strength, ablation resistance and oxidation resistance of the carbon matrix, thus forming the isotropic carbon matrix composite material characterized by lowcost, low density and excellent mechanical properties, sintering performance and ablation resistance. Because of the excellent comprehensive performance, the tungsten carbide reinforced carbon matrixcomposite material can be widely applied to aerospace, national defense and other fields, and has broad application prospects.

Owner:XI AN JIAOTONG UNIV

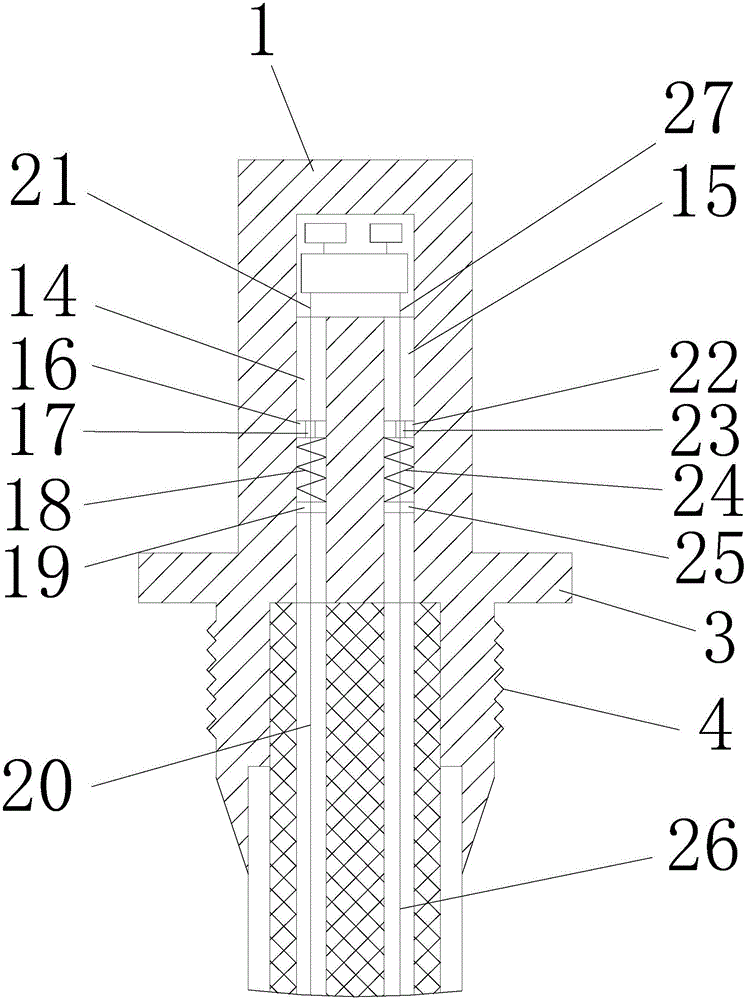

Inserted telemetering type temperature sensor

ActiveCN106482858ASimple structureReasonable designThermometer detailsThermometers using electric/magnetic elementsFiberElectricity

The invention provides an inserted telemetering type temperature sensor. A housing is composed of a mounting part and a probe part. The inside of the probe part is provided with a temperature-sensitive element and an insulating member. Heat-conductive silica gel is arranged at the periphery of the temperature-sensitive element. Probes are pressed on the electrodes of the temperature-sensitive element through springs. An infrared ray absorption film covers the lower end of the probe part. The infrared ray absorption film is arranged outside the temperature-sensitive element. The mounting part is provided with a master controller, a wireless communication module and a power supply. According to the inserted telemetering type temperature sensor, the probe part is made of a heat-conductive carbon fiber material; the heat-conductive carbon fiber material has advantages of small weight, high corrosion resistance, high strength, remarkable high-temperature resistance, remarkable low-temperature brittle rupture resistance, etc.; the heat-conductive silica gel is utilized for fixing the temperature-sensitive element and conducting heat, thereby improving sensitivity and vibration resistance; a positive probe and a negative probe are respectively pressed on a positive electrode and a negative electrode of the temperature-sensitive element through pressures of the springs; once an expansion-with-heat and contraction-with-cold of the probe occurs, the spring can adjust the pressure between the probe and the electrode at any time, thereby realizing reliable electric connection; a temperature value can be wirelessly transmitted to a remote central control terminal; and remote control without tedious wiring is realized.

Owner:江苏溢坤医疗科技有限公司

Industrial and mineral JP cabinet intelligent constant temperature system

ActiveCN106292764ABest energy saving statusObserve the temperature in real timeSubstation/switching arrangement cooling/ventilationTemperature control using electric meansEngineeringRefrigeration

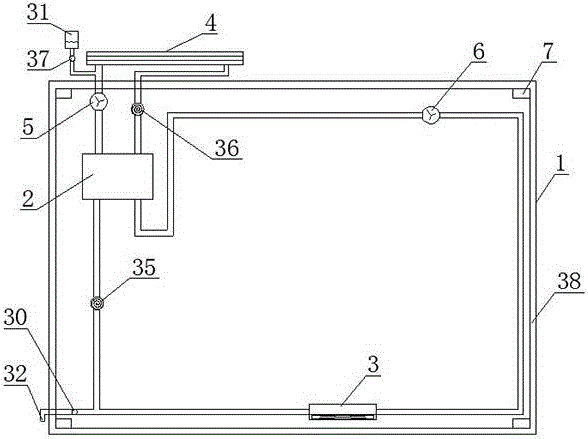

The invention discloses an industrial and mineral JP cabinet intelligent constant temperature system including a JP cabinet body, a refrigeration and heating device, an internal heat exchanger, an external heat exchanger, a first driving oil pump, a second driving oil pump, and a plurality of temperature sensors, the refrigeration and heating device, the internal heat exchanger, the first driving oil pump, the second driving oil pump, and the plurality of temperature sensors are arranged in the JP cabinet body, an external heat exchanger is arranged at the outer side of the JP cabinet body, and the refrigeration and heating device includes a heating device, a refrigerator, a controller, a plurality of groups of semiconductor refrigeration sheets, and a casing. The industrial and mineral JP cabinet intelligent constant temperature system acquires the temperature signal in the JP cabinet through the temperature sensors, the controller controls the on and off of the first driving oil pump and the second driving oil pump based on the temperature signal, and moreover, the controller controls the flow direction of the oil medium in the interface pipe and the switching of the semiconductor refrigeration sheets according to the temperature signal and reliably ensures the constant temperature in the JP cabinet.

Owner:江苏苏能机械有限公司

Silicon carbide reinforced carbon matrix composite material and preparation method

The invention discloses a silicon carbide reinforced carbon matrix composite material and a preparation method. Mesocarbon microbeads are adopted as the matrix, and silicon carbide ceramic is adoptedas the reinforcement phase and is evenly distributed among the carbon microbeads so as to form a three-dimensional network silicon carbide skeleton reinforced isotropic structure. Technically, siliconpowder particles and the mesocarbon microbeads are taken as the raw materials to prepare uniform and thickness controllable silicon carbide coating coated mesocarbon microbead powder by molten salt method, after pre-press molding, discharge plasma sintering is carried out at 1600-1900DEG C to form a uniform three-dimensional network silicon carbide ceramic skeleton, while the strength, ablation resistance, oxidation resistance and thermal shock resistance of the carbon matrix are improved, the thermal conductivity of the matrix is also improved, therefore the isotropic carbon matrix compositematerial characterized by low cost, low density and excellent mechanical properties, sintering properties, thermal shock resistance, ablation resistance and thermal conductivity can be formed. Because of the excellent comprehensive performance, the silicon carbide reinforced carbon matrix composite material can be widely applied to aerospace, national defense, electronic packaging and other fields, and has broad application prospects.

Owner:XI AN JIAOTONG UNIV

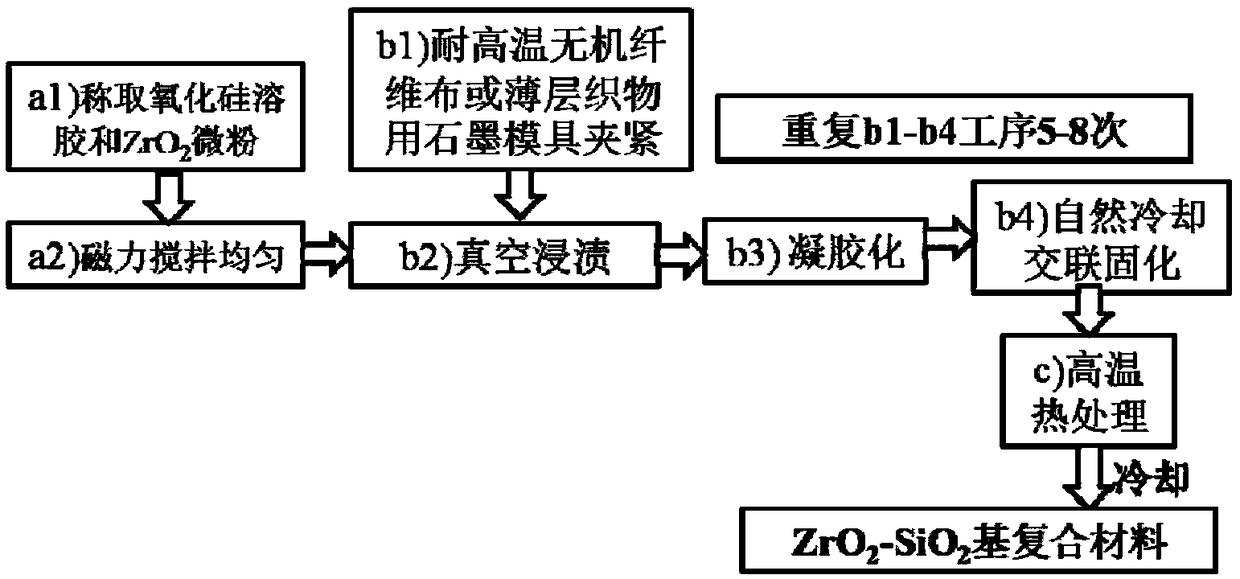

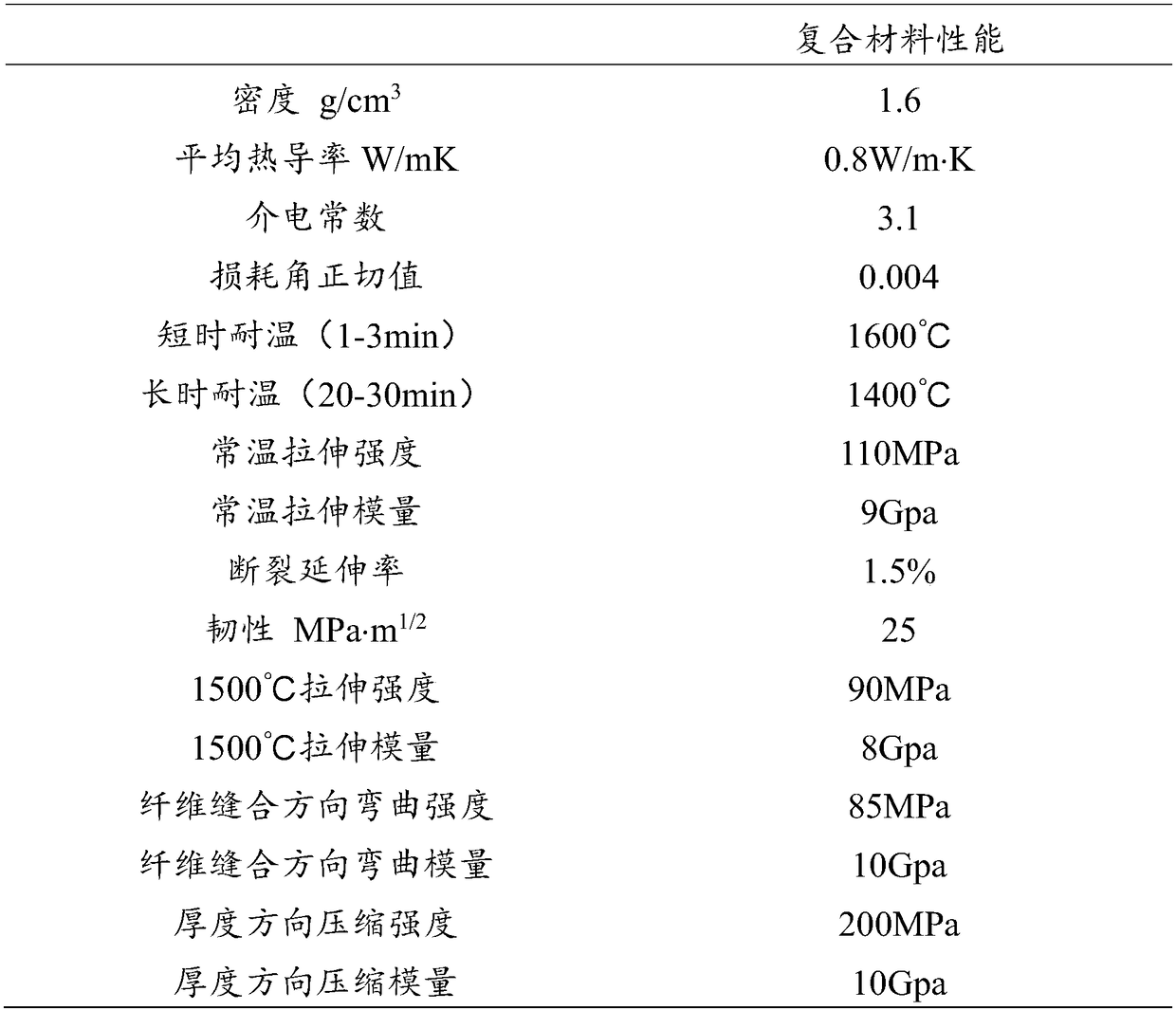

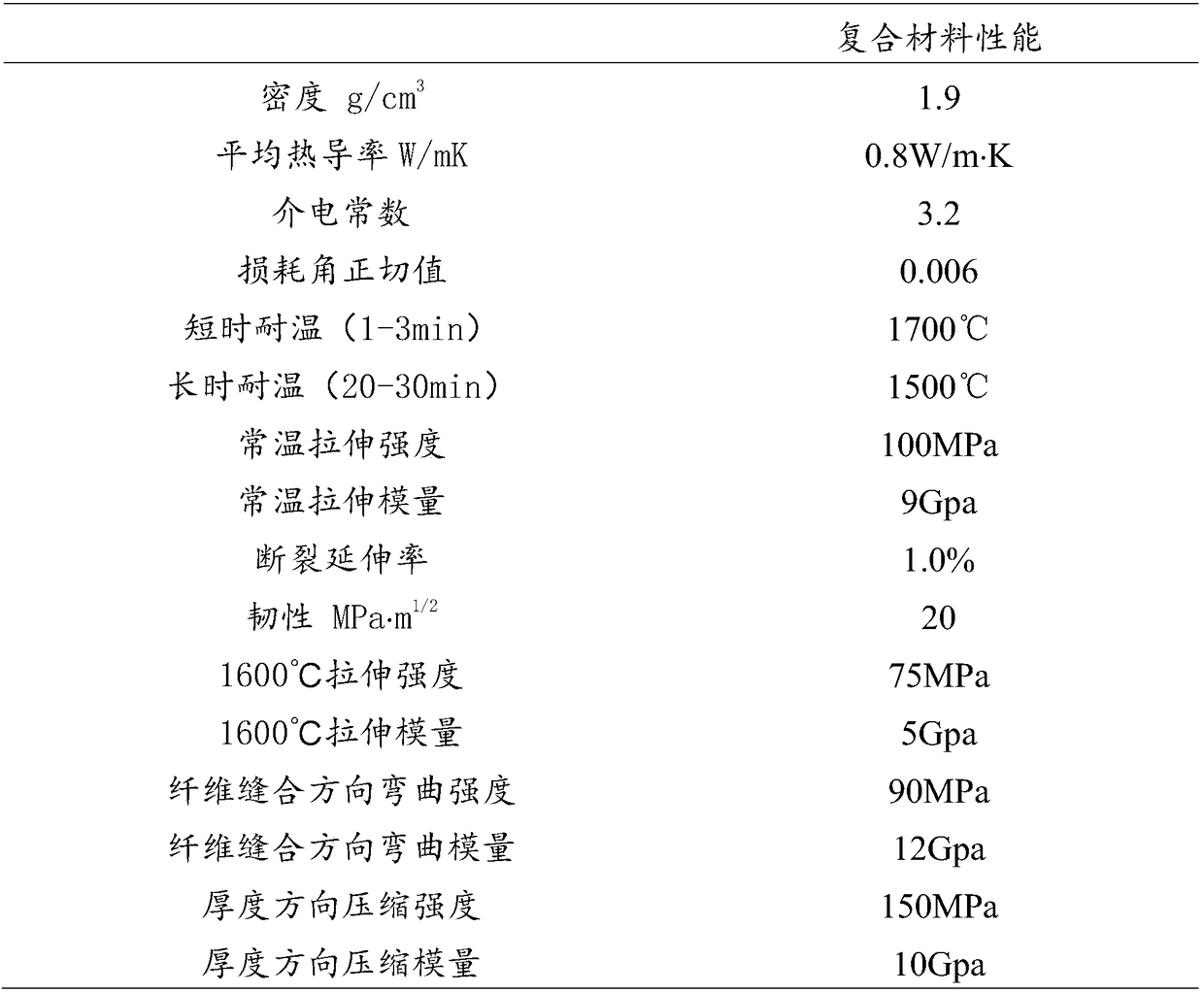

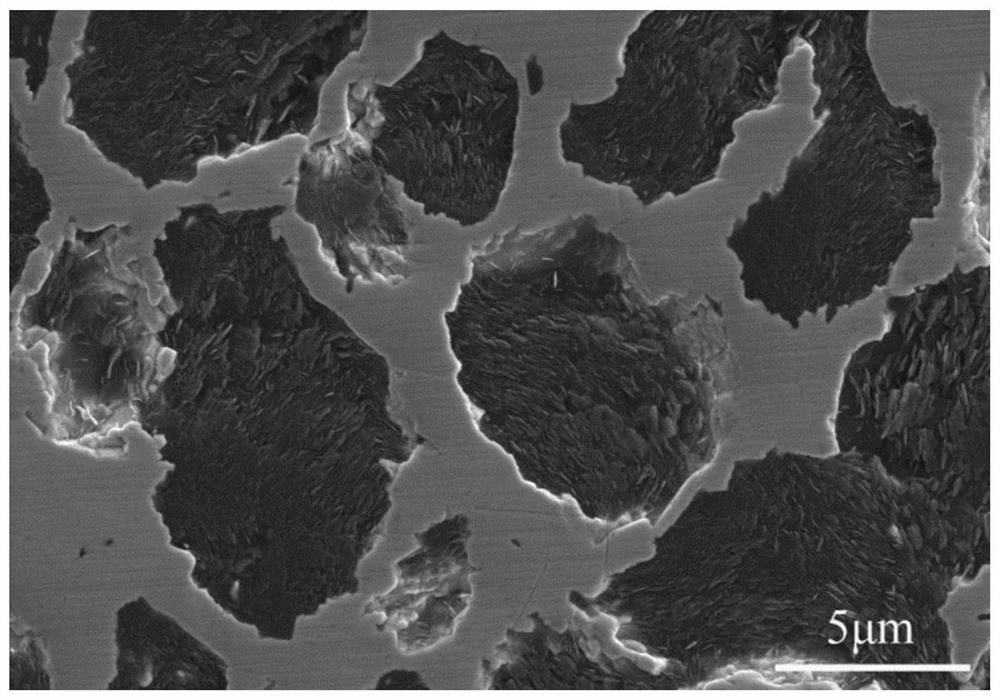

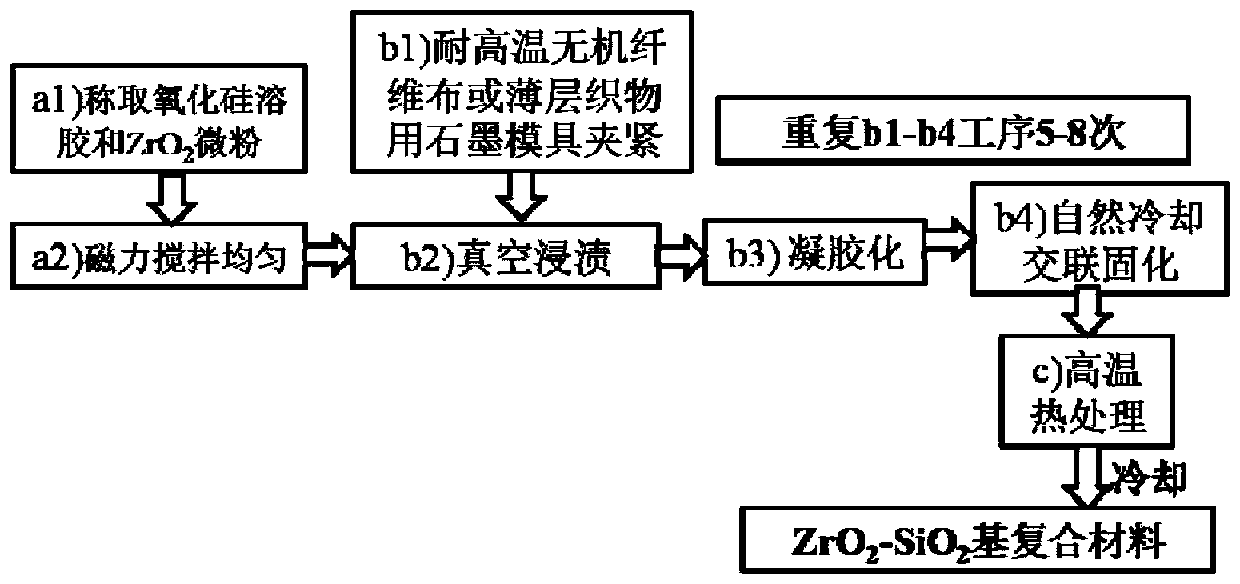

Low-temperature rapid preparation method of ZrO2-SiO2-based composite material

The invention provides a low-temperature rapid preparation method of a ZrO2-SiO2-based composite material. The method comprises the following steps: (a) weighing silicon oxide sol and ZrO2 micropowderaccording to a certain ratio, adding the ZrO2 micropowder into the silicon oxide sol and magnetically stirring for six or more hours to form suspension liquid of the silicon oxide sol doped with theZrO2 micropowder; (b) clamping a high-temperature-resistant inorganic fiber cloth or a thin-layer fabric by using a graphite die, putting the high-temperature-resistant inorganic fiber cloth or the thin-layer fabric in a vacuum container and vacuumizing, then sucking the suspension liquid obtained in the step (a) and completely dipping the high-temperature-resistant inorganic fiber cloth or the thin-layer fabric; then rapidly transferring the dipped high-temperature-resistant inorganic fiber cloth or thin-layer fabric into a drying oven for carrying out heat treatment for gelatinizing, naturally cooling to room temperature and solidifying, repeatedly carrying out overall dipping, gelatinizing and naturally cooling for 5-8 times; and (c) putting the obtained hard solid in a muffle furnace for carrying out high-temperature heat treatment under the treatment temperature being lower than 800 DEG C, finally cooling to the room temperature to obtain the ZrO2-SiO2-based composite material.

Owner:NAT UNIV OF DEFENSE TECH

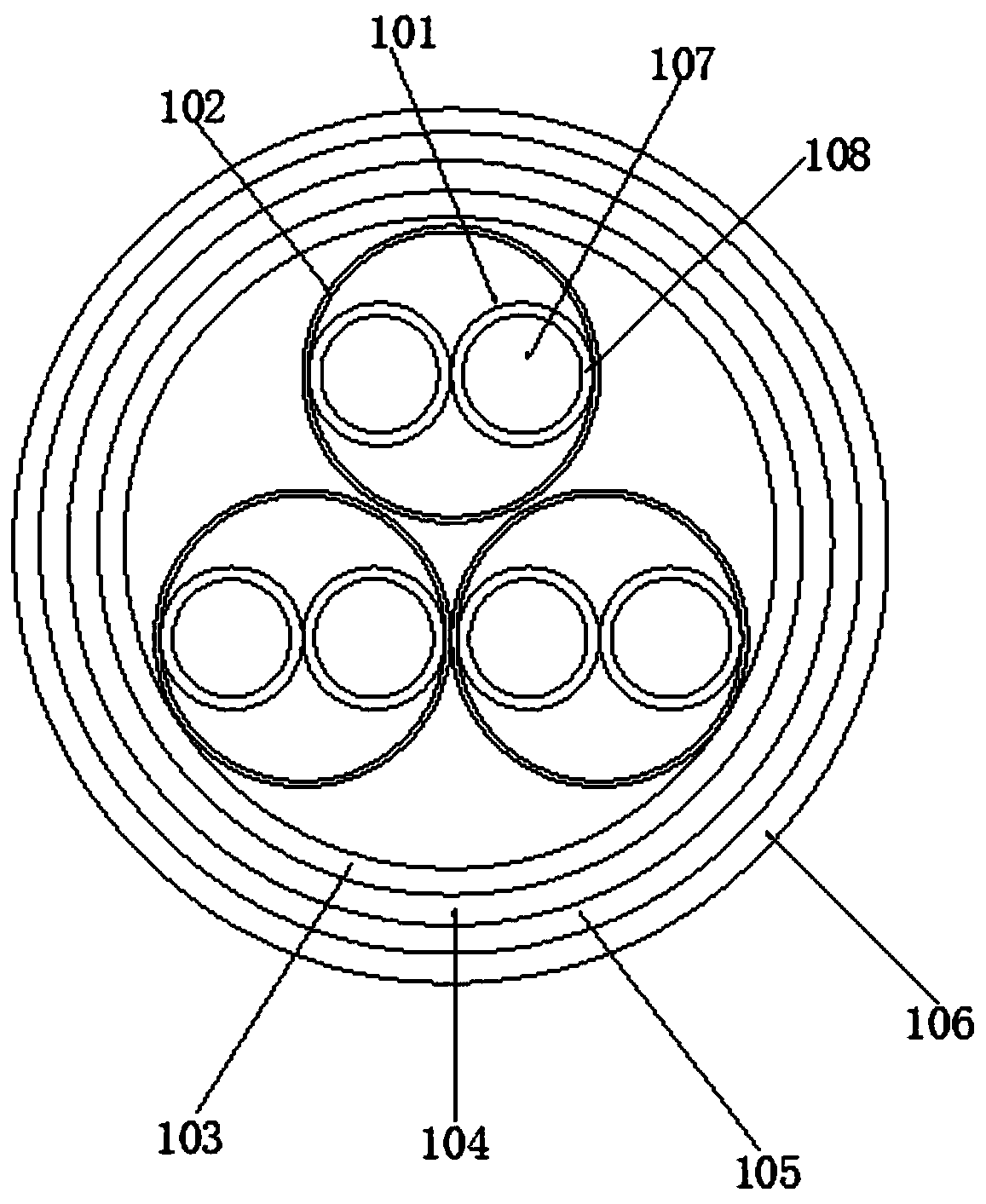

Flame-retardant and high-temperature-resistant computer cable and preparation process thereof

ActiveCN110364294AFlame retardantWith high temperature insulationInsulated cablesInsulated conductorsElectrical conductorCombustion

The invention discloses a flame-retardant and high-temperature-resistant computer cable. The cable comprises core wires, first wrapping layers, a second wrapping layer, a shielding layer, an armor layer and a sheath layer. Each core wire comprises tinned copper core conductors and insulating layers; the outer side of each tinned copper core conductor is wrapped with the corresponding insulating layer; every two core wires are twisted to form a pair wire set; and the outer side of each pair wire set is wrapped with the corresponding first wrapping layer. According to the invention, the quartz fiber maintenance sleeve layer on the outer side of the cable has the advantages of flame retardance, high-temperature resistance, insulationresistance, ablation resistance, corrosion resistance, heatinsulation ability, wave transmission ability, excellent dielectric property and the like; the cable can be protected from combustion in case of a fire; compared with polyethylene insulation, the performance of the the cross-linked polyethylene insulation is greatly improved after cross-linking modification; the comprehensive performance such as the mechanical performance, the environmental stresscracking resistance, the chemical corrosion resistance, the creep resistance and the electrical performance is remarkably improved; and the temperature resistance level is remarkably improved.

Owner:TIANCHANG HUILING ELECTRIC APPLIANCE METER FACTORY

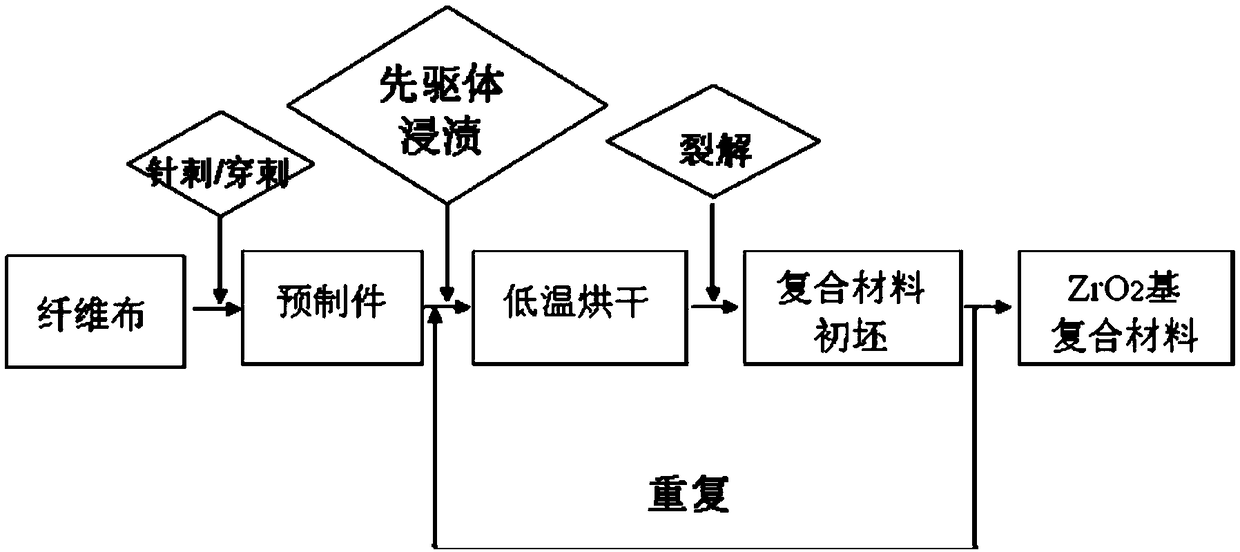

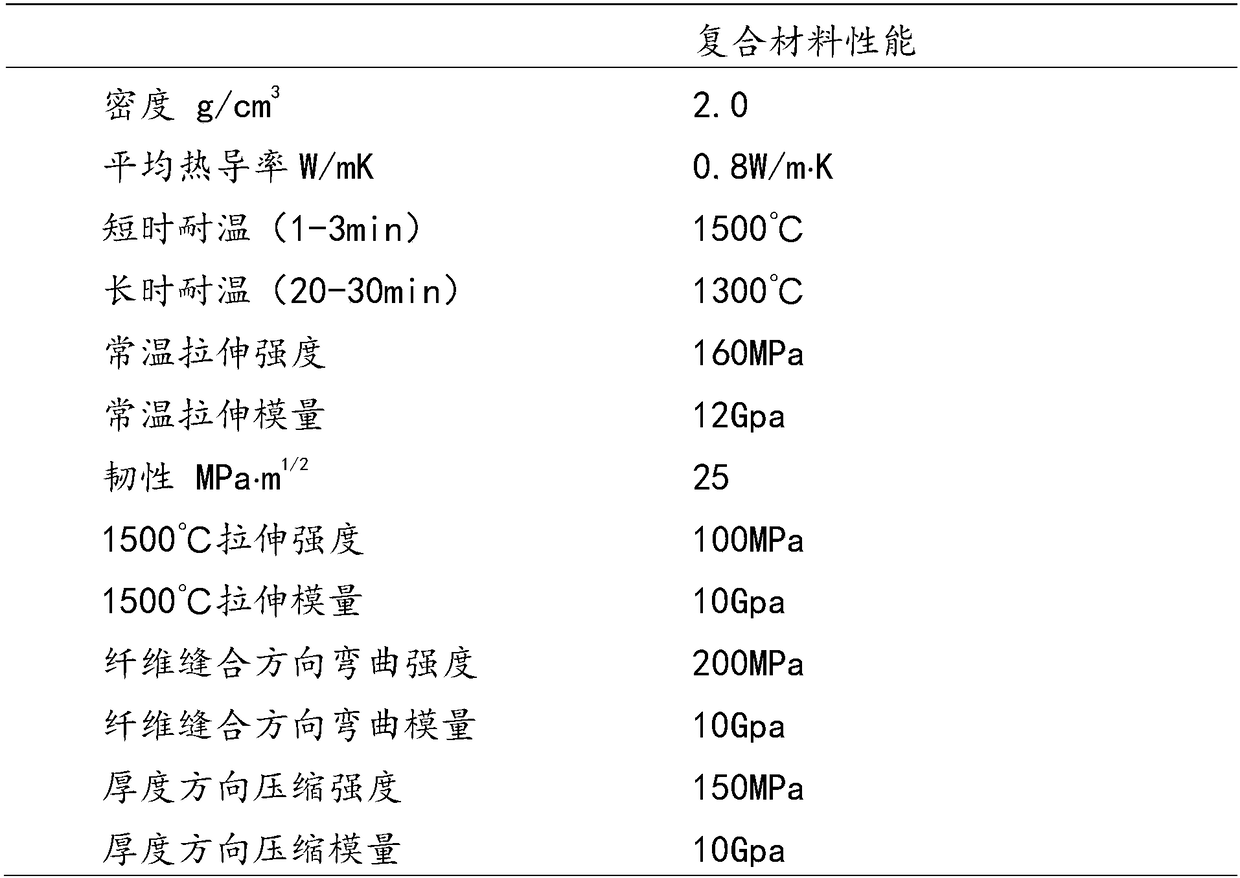

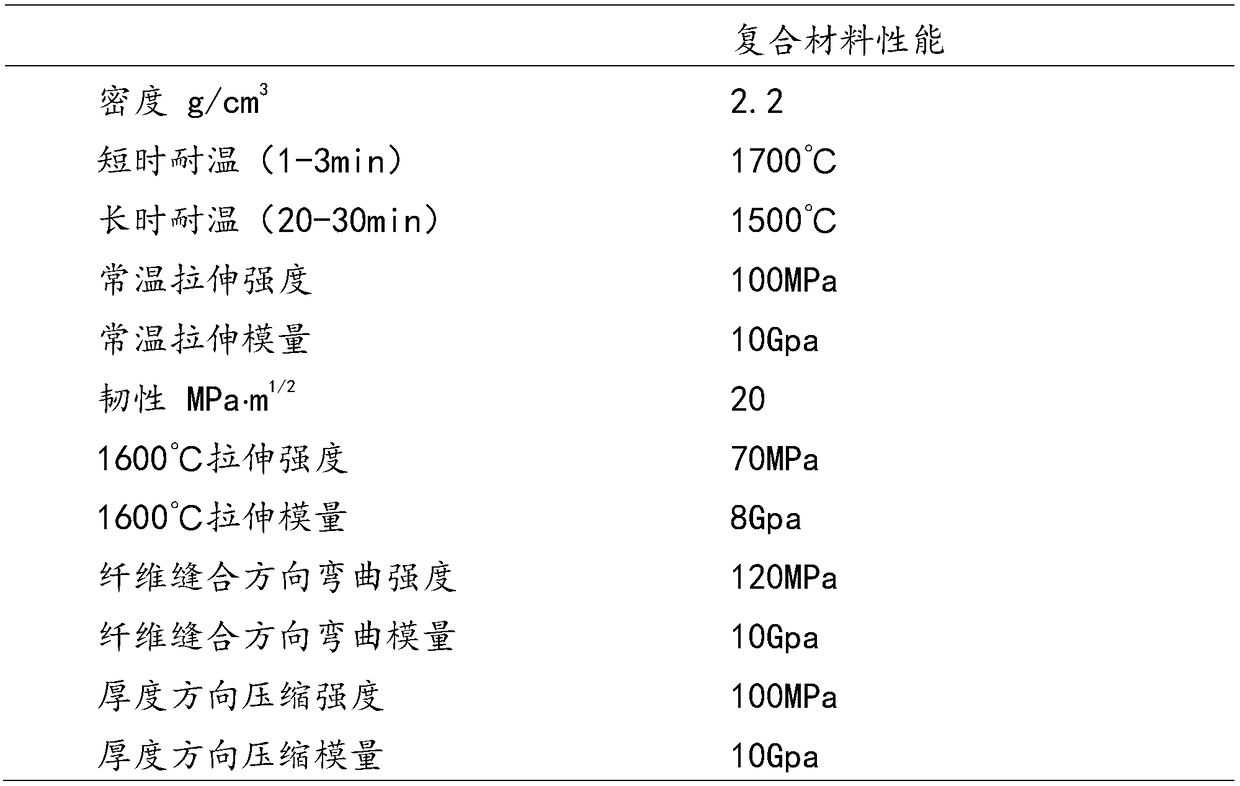

Preparation method of ZrO2-based composite material resistant to high temperature

The invention provides a method for preparing a ZrO2-based composite material resistant to high temperature. The method comprises the following steps: a) inorganic fiber cloth or thin fabric which isresistant to high temperature is tightly clamped by a graphite mould and positioned in a vacuum container which is then vacuumed, and a ZrO2 precursor is absorbed for overall impregnation; b) after overall impregnation, the inorganic fiber cloth or thin fabric which is resistant to high temperature is transferred and dried at room temperature; c) after dried, the inorganic fiber cloth or thin fabric which is resistant to high temperature is transferred to a drying oven for heat treatment and then naturally cooled to room temperature for solidification; d) after the heat treatment, the inorganic fiber cloth or thin fabric which is resistant to high temperature is put into a high temperature cracking furnace for pyrolyzing at high temperature and then cooled to room temperature; and e) the processes a)-d) are repeated by circulating in turn for 10-15 times, thereby obtaining the ZrO2-basedcomposite material. The ZrO2-based composite material provided by the invention has the performancesof being high in density, high in temperature resistance, strong in bearing capacity, and the like, and has the advantages of being easy to obtain raw materials, mature in preparation process and suitable for large-scale industrial production.

Owner:NAT UNIV OF DEFENSE TECH

Remote-transmission ventilated temperature sensor

ActiveCN106482857ASimple structureReasonable designThermometer detailsThermometers using electric/magnetic elementsElectricityComputer module

The invention provides a remote-transmission ventilated temperature sensor. A shell has a mounting part and a probe part. A thermosensitive element and an insulating element are arranged at the inner side of the probe part; the space around the thermosensitive element is filled with thermal conductive silicone; and probes are pressed on thermosensitive element electrodes by springs. An infrared absorbing film covers the outer side of the lower end of the probe part and is arranged at the periphery of the thermosensitive element. Besides, the mounting part is provided with a main controller, a wireless communication module and a power supply; and ventilation holes are formed in the side wall of the mounting part. The remote-transmission ventilated temperature sensor provided by the invention has advantages of light weight, excellent corrosion-resistant, high-temperature-resistant, and low-temperature-embrittlement-resistant performances, and high rigidity and the like. The thermosensitive element is fixed by the thermal conductive silicone and heat conduction is realized by the thermal conductive silicone, so that sensitivity and anti-vibration performances are improved. The positive probe and the negative probe are pressed on the positive electrode and the negative electrode of the thermosensitive element under pressing by the springs; when thermal expansion and cold contraction phenomena occur at the probes, the pressures between the probes and the electrodes can be adjusted at any time by the springs, thereby realizing reliable electrical connection. A temperature value can be transmitted to a remote central control terminal wirelessly; remote monitoring can be realized; and tedious wiring is avoided.

Owner:江苏溢坤医疗科技有限公司

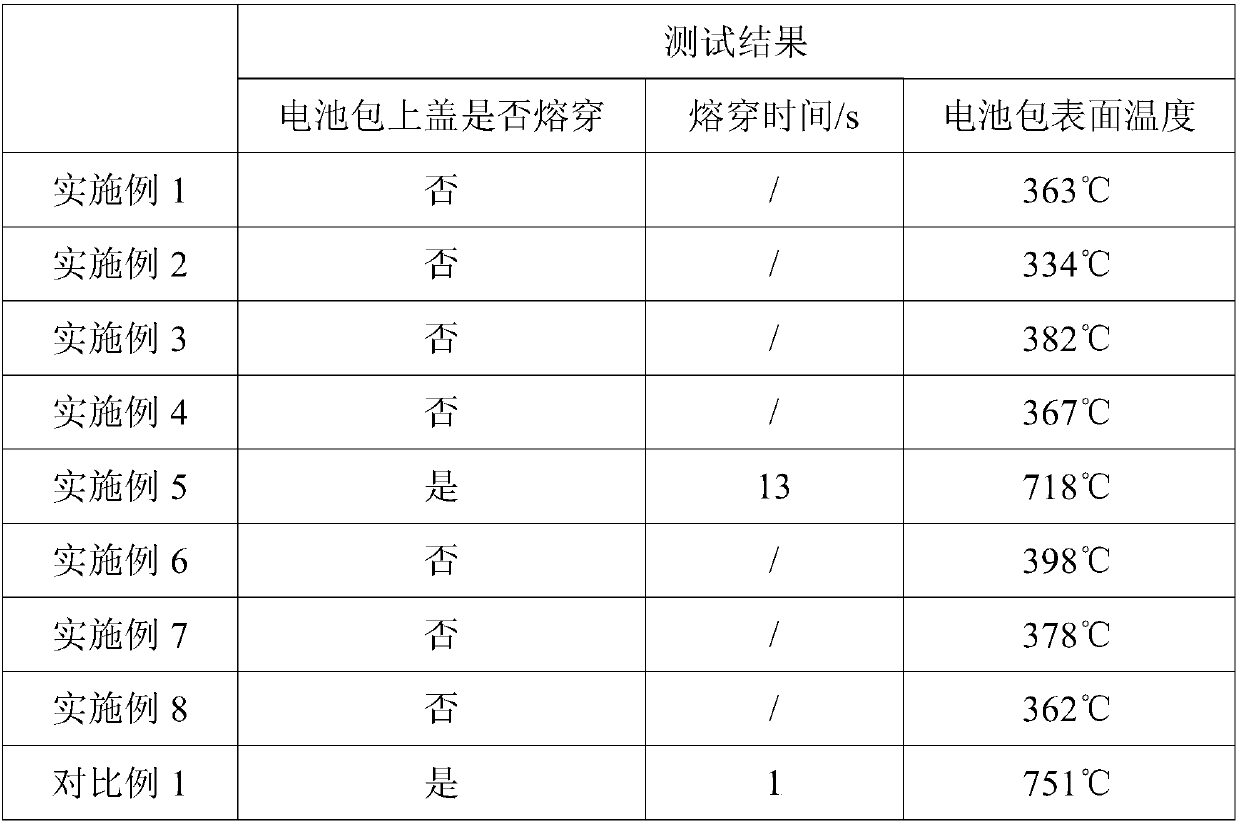

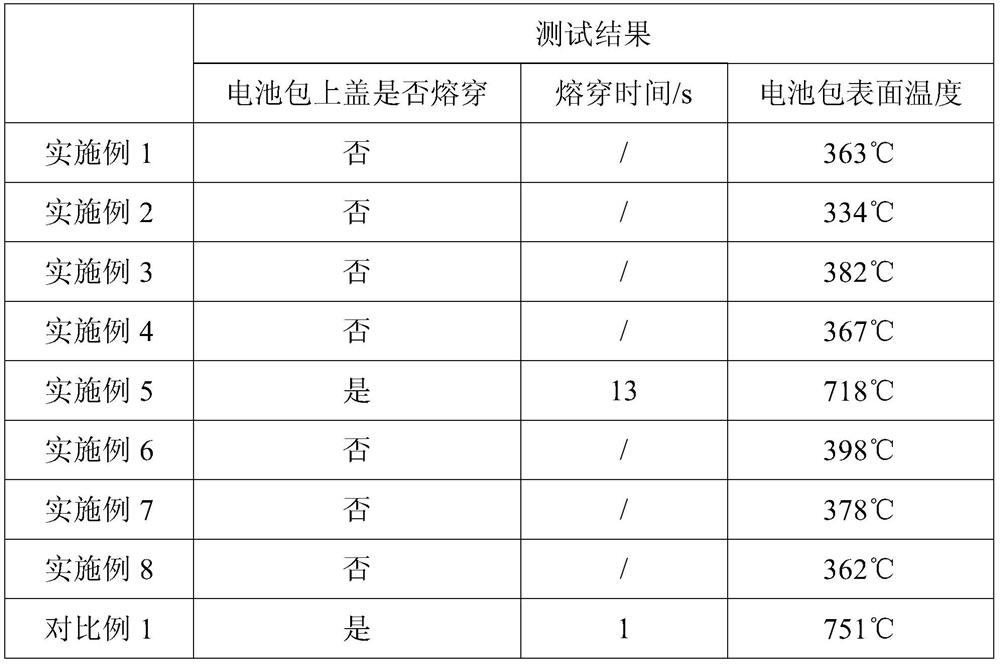

Protective layer for batteries, preparation method of protective layer and application of protective layer in battery pack

ActiveCN110815993AAvoid fireAvoid explosionBattery isolationSynthetic resin layered productsPhysical chemistryFirming agent

The invention provides a protective layer for batteries, a preparation method of the protective layer and an application of the protective layer in a battery pack. The protective layer for the batteries includes a fireproof cloth and a functional layer arranged on the fireproof cloth, and the functional layer is a thermosetting resin layer formed by performing curing on an epoxy resin substrate, an epoxy resin curing agent, a reinforcing filler, a flame retardant and a silane coupling agent. The protective layer for the batteries provided by the invention has the characteristics of high strength, ablation resistance, thermal shock resistance and flame retardancy, and can withstand explosive impact, block sparks and inhibit combustion diffusion, effectively avoid battery fire or explosion,and improve safety during use of the batteries.

Owner:CONTEMPORARY AMPEREX TECH CO

Preparation method of novel high temperature anti-oxidation C/C composite coating

The invention relates to a preparation method of a novel high temperature anti-oxidation C / C composite coating. A C / C composite material is adopted as the substrate, metal W is taken as the transition layer, platinum group metal Ir is employed as the coating, and the three layers of materials are compounded in order to obtain the composite coating. The C / C composite material has carbon fiber in transverse distribution and a density of 1.2-1.6g / cm, and is an ideal ultrahigh temperature thermal structure material in the aerospace field. The coating adopts the platinum group metal Ir with a thickness of 8microm-20microm, wherein the average crystal grain size of the coating is 1microm-2microm, and a double glow plasma surface alloying furnace is employed to deposit the Ir coating on the transition layer surface, Ir has a series of advantages of high strength, high melting point, good chemical stability, excellent oxidation resistance, no reaction with C at a temperature lower than 2280DEG C, and effective obstruction of C diffusion, etc. The invention brings the advantages of the composite structure and the excellent properties of all materials into play to make up for the shortcomings of insufficient oxidation under high temperature, high making cost and the like of the C / C composite coating, and realizes long-term, safe and stable work of the C / C composite material in a high temperature environment.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

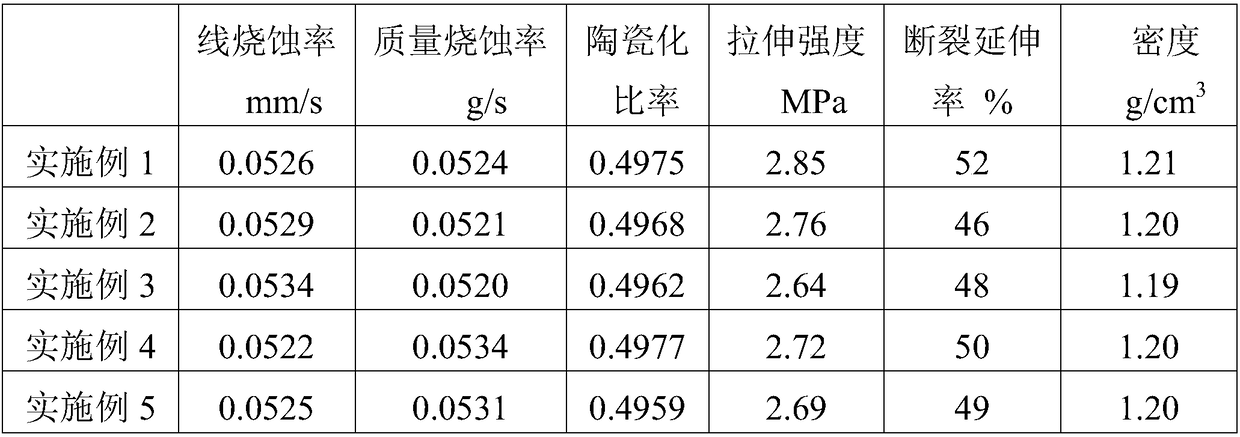

Silicon rubber thermal insulation material and preparation method thereof

InactiveCN109206919AGood elasticityStrong resistance to small molecule migrationChemistryCarbon black

The invention discloses a silicone rubber thermal insulation material and a preparation method thereof, and belongs to the technical field of thermal insulation materials, and the silicone rubber thermal insulation material is prepared from the following raw materials: 40-60 parts of methyl vinyl silicone rubber, 40-60 parts of methyl vinyl phenyl silicone rubber, 20 to 30 parts of white carbon black, 2 to 15 parts of nano calcium carbonate, 10 to 15 parts of carbon fiber, and 0.5 to 1.5 parts of a vulcanizing agent. The silicone rubber thermal insulation material can form a high melting pointceramic-like layer in the process of smelting erosion, and has the advantages of high temperature resistance, ablation resistance, good elasticity and strong resistance to migration of small molecules.

Owner:芜湖市颂晖商贸有限公司

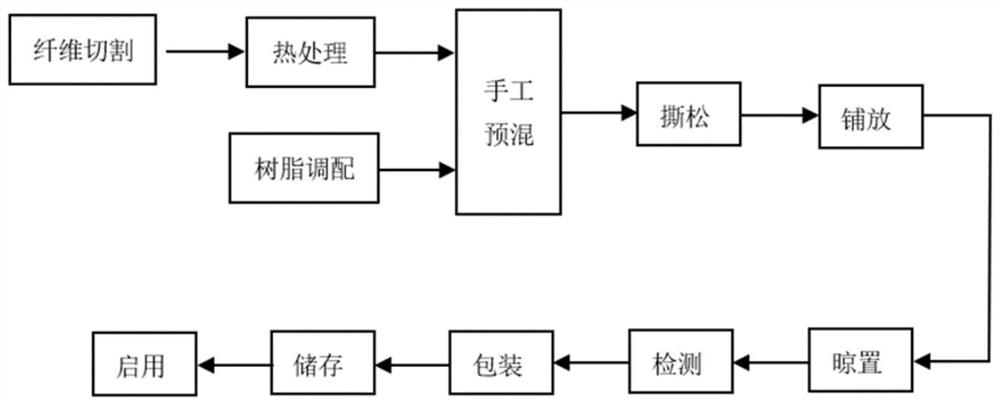

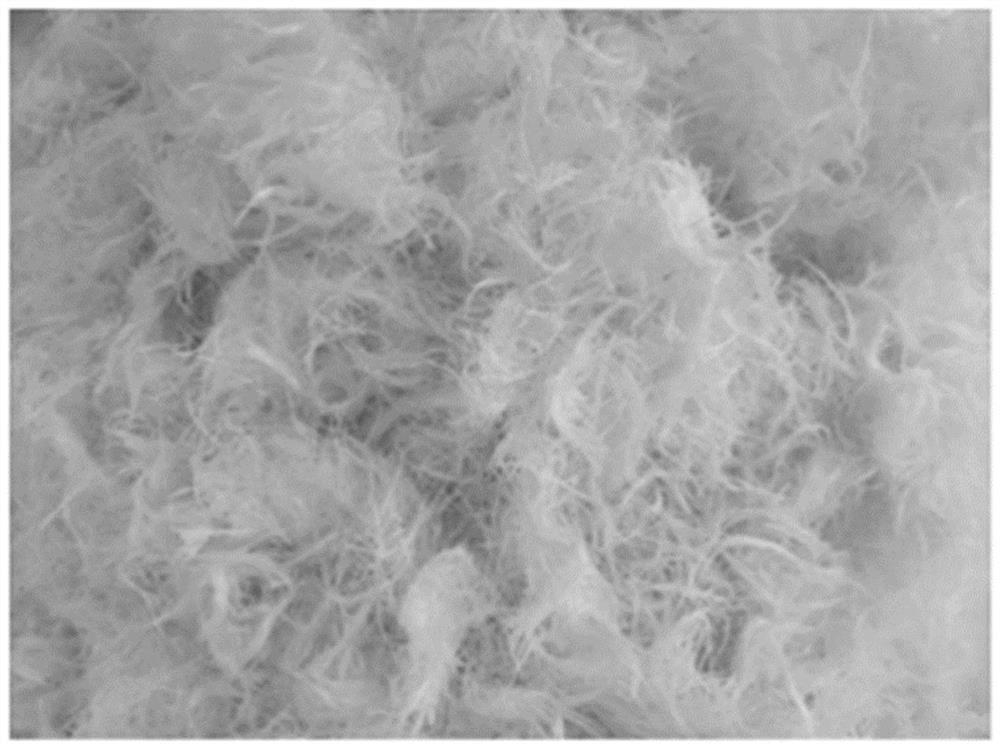

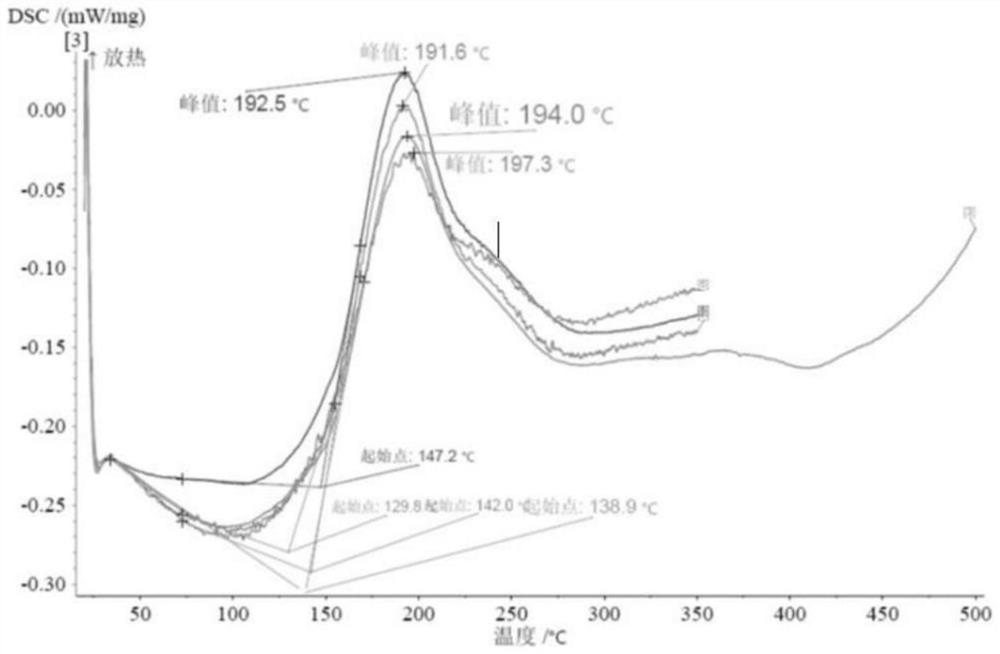

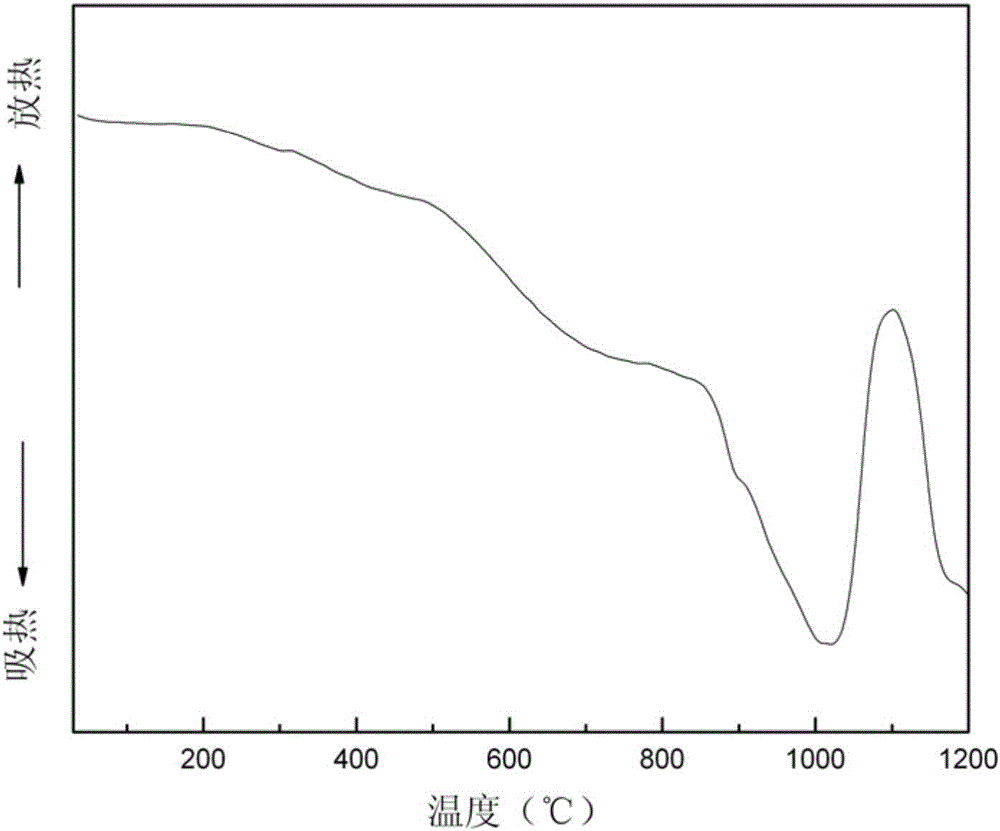

Spaceflight ablation heat-proof chopped fiber/phenolic aldehyde high-density premix, manual premixing preparation method and composite material thereof

InactiveCN113637287AOvercome the disadvantage of weak interlaminar shear strengthIncreased shear strengthYarnFiber

The invention provides a spaceflight ablation heat-proof chopped fiber / phenolic aldehyde high-density premix, a manual premixing preparation method and a composite material thereof The spaceflight ablation heat-proof chopped fiber / phenolic aldehyde high-density premix is prepared from high-temperature-resistant chopped fibers and high-residual-carbon phenolic aldehyde under the action of an auxiliary agent by adopting a manual premixing process, and is prepared by the steps of cutting yarns, drying the yarns, preparing glue, manually premixing, tearing, laying, airing, drying, testing, packaging, storing, starting and the like to prepare an intermediate material which has a certain pre-curing degree, is in a scattered state and has no certain direction of fibers. Then the spaceflight ablation heat-proof composite material is prepared from the chopped fiber / phenolic aldehyde high-density premix in a closed mold at a certain temperature and pressure through the mold pressing process. The resin content of the premix is (33-55)%, and the density of the composite material formed by the premix through the mold pressing process is (1.45-1.85) g / cm < 3 >. The premix prepared by the manual premixing method has the manufacturability advantages of being good in mold pressing fluidity, suitable for manufacturing composite material products with complex structures, high in resin content precision, capable of forming composite materials in net size and the like; and the composite material formed by the premix through a mold pressing process has excellent characteristics of ablation resistance, high temperature resistance, heat insulation, flame retardance and the like, has certain mechanical strength, and can be applied to the fields of aerospace ablation heat protection, civil use and the like.

Owner:北京元蛋复合材料有限公司

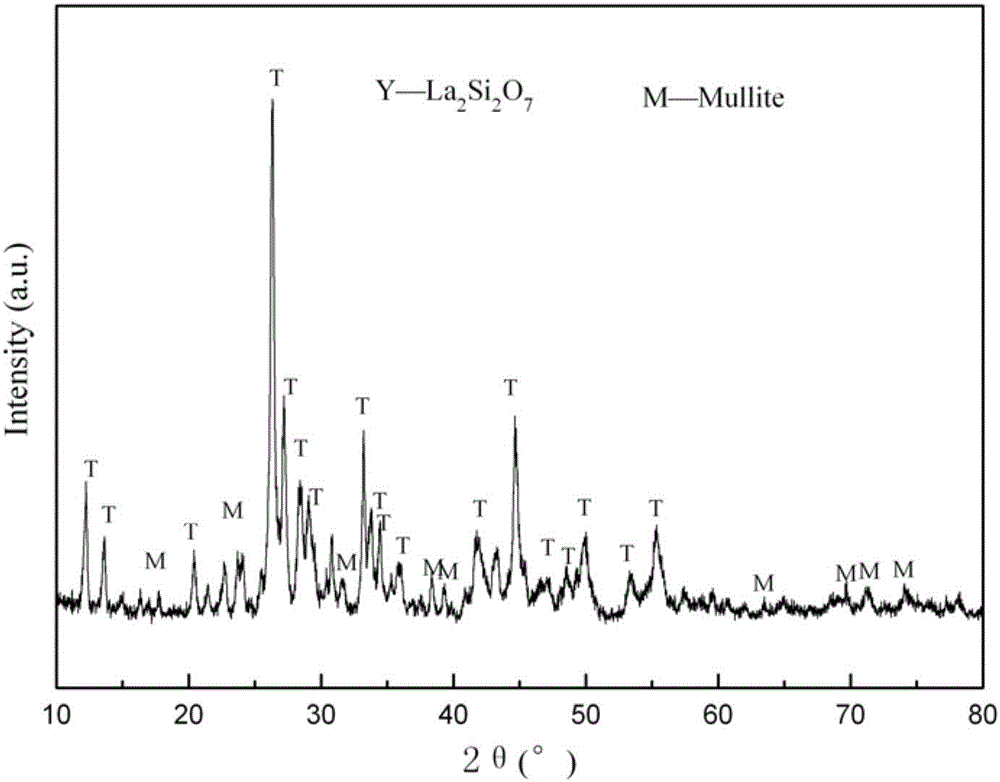

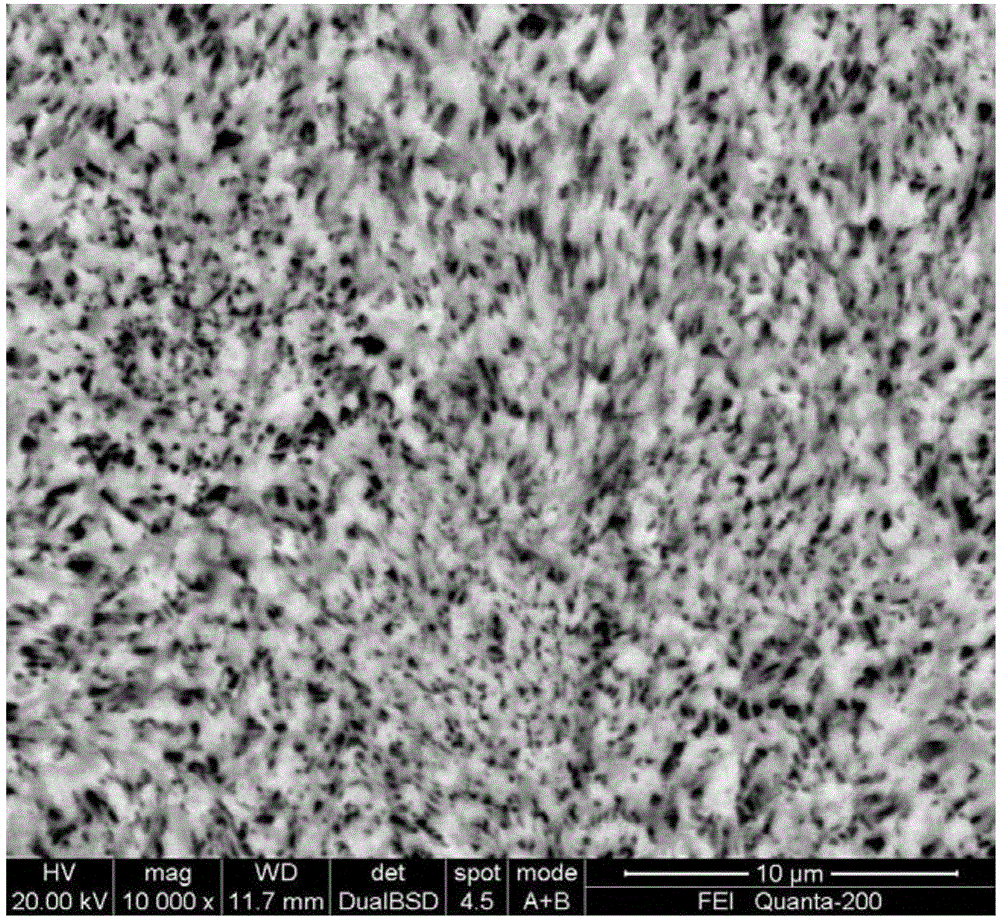

Ceramic glass with lanthanum disilicate as principal crystalline phase, preparation method and application

The invention relates to ceramic glass with lanthanum disilicate as a principal crystalline phase, a preparation method and application. The ceramic glass is obtained by carrying out nucleation and crystallization treatment on base glass. The base glass consists of the following oxides in mole percent: 22-26% of La2O3, 3-5% of MgO, 11-13% of Al2O3 and 58-62% of SiO2. The preparation method comprises the following steps: melting the various raw materials at the temperature of 1,520-1,530 DEG C; pouring melted liquid in a mold and annealing at the temperature of 650-680 DEG C to obtain the base glass; heating the base glass until the temperature of the base glass is higher than glass conversion temperature which is 40-60 DEG C, carrying out nucleation, and continuing heating to the temperature which is equal to devitrification temperature + / - 10 DEG C to obtain a ceramic glass material. The preparation method is simple, energy consumption is low, the ceramic glass is environmentally friendly, the production cost is low, and the obtained material can be used as a thermal barrier coating material, a high-temperature-structure material, an anti-friction and anti-abrasion material and the like.

Owner:CENT SOUTH UNIV

Urushiol boron resin and preparation method thereof

The invention discloses an urushiol boron resin and a preparation method thereof. The urushiol boron resin comprises the following raw materials in percentage by mass: 20-40% of urushiol, 4-8% of aldehyde compound, 0.5-1% of boron compound, 10-20% of epoxy resin, 0.5-1% of catalyst and 40-60% of thinner. The urushiol boron resin has the characteristics of high temperature resistance, alkali resistance, water resistance, oil resistance, wear resistance and strong adhesive force, and can be directly coated on an object. The varnish film has the advantages of excellent heat resistance, water resistance and strong chemical resistance. The product of the invention is suitable for aerospace, electronic information, automobile industry, household appliances and the like.

Owner:中华全国供销合作总社西安生漆涂料研究所

Modified epoxide resin adhesive with high strength and preparing method thereof

InactiveCN106336841AHigh bonding strengthIncreased durabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

The invention discloses a modified epoxide resin adhesive with high strength and a preparing method thereof. The modified epoxide resin adhesive is prepared from, by weight, 80-100 parts of epoxide resin, 3-21 parts of carboxylic acrylonitrile butadiene rubber latex, 1.1-7.7 parts of polyacrylate latex, 5-10 parts of quartz powder, 1.1-1.5 parts of aluminium silicate, 2-3 parts of anti-settling agent, 1-3 parts of aminopropyltriethoxysilan; the ratio of carboxylic acrylonitrile butadiene rubber latex to polyacrylate latex is 2.7:1; the modified epoxide resin adhesive with high strength has good properties of ablation resistance, acid and alkali resistance, moisture absorption and thermal stability, aging resistance, anti-shearing force, high insulation and high sealing, and in terms of electrical insulation property, due to quartz powder added in the formula, and the product after solidification has stronger insulation property and ablation resistance property.

Owner:穆勇华

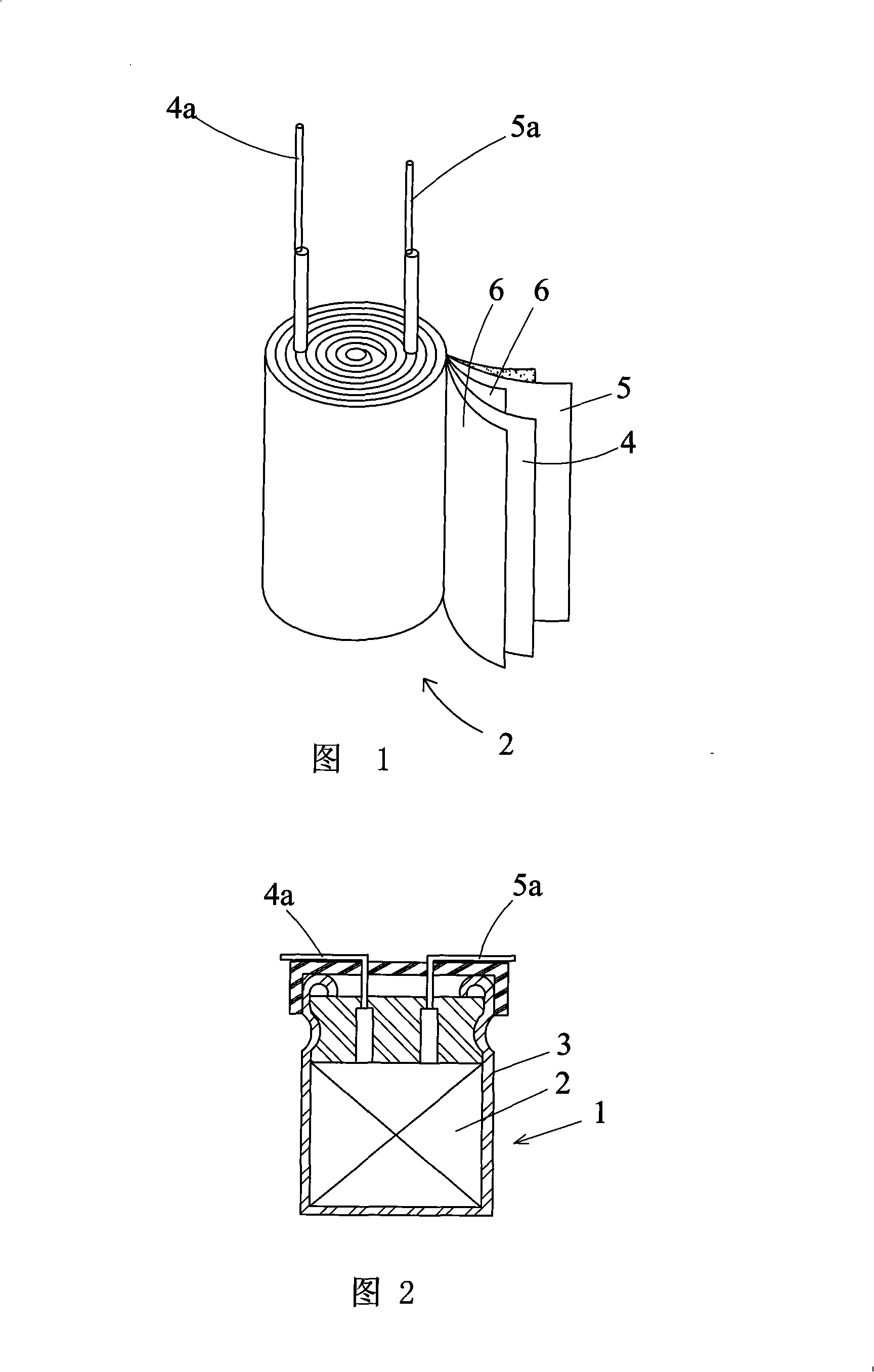

Solid electrolytic capacitor and method of processing the same

InactiveCN101320625AHigh temperature resistantAblation resistantSolid electrolytic capacitorsCapacitor electrolytes/absorbentsCapacitanceElectrolysis

The invention provides a solid electrolysis capacitor with small impedance, large electric capacity, stronger thermal endurance and weathering resistance. The product may not be broken because of transportation for high yield and strong capability for bearing external force of the product. Thus, the invention further provides a process method of capacitors, comprising: an anode film, an anode, a cathode film, a cathode and a conductivity high polymer electrolyte layer between the anode film and the cathode film. Surface of the anode film covers an oxidation electric surface layer. Carrier of the conductivity high polymer electrolyte layer is a separation layer, characterized in that the separation layer is a film containing carbon fibres. Process method of capacitors comprises steps of: regarding etched conduction metal foil as the anode film, of which the surface is treated with anode oxidation to form the oxidation electric surface layer, the anode film leading a lead form an anode; manufacturing the cathode film by using the metal foil and leading the lead to form a cathode; winding the anode film, the cathode film and the separation layer between them into a cylinder shape to complete subassemblies of the capacitor; finally, packing subassemblies of the capacitor into a box, or covering with a protection layer to obtain the solid electrolysis capacitor.

Owner:钰邦电子(无锡)有限公司

Preparation method of metal modified phenolic aldehyde based polyurethane foam

The invention provides a preparation method of metal modified phenolic aldehyde based polyurethane foam. The method comprises the steps of reacting a phenolic compound and a metallic compound under the action of a catalyst, and then reacting with an aldehyde compound to generate metal modified high-ortho thermoplastic phenolic polyhydric alcohols with low molecular weight; mixing the obtained metal modified phenolic polyhydric alcohols with a foaming agent, a catalyst, a foam stabilizer and the like to obtain a component A; mixing and reacting the component A and a component B (polyisocyanates), and then curing to obtain the metal modified phenolic aldehyde based polyurethane foam. According to the preparation method of the metal modified phenolic aldehyde based polyurethane foam providedby the invention, the metal modified phenolic polyhydric alcohols is adopted as a raw material for preparing polyurethane, so that experimental procedures are simplified, and a test cycle is shortened; a benzene ring is used for replacing a long carbon chain, and meanwhile, a metal-oxygen bond or metal carbide is introduced on a main chain, so that the thermal performance and the mechanical property are improved; through the synthesis of the metal modified high-ortho thermoplastic phenolic polyhydric alcohols, a molecular structure is improved, and the control of a cross-linked structure is facilitated.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Battery graphite anode material prepared by using nano graphite carbon powder and method of preparing same

ActiveCN106025281AHigh temperature resistantAblation resistantMaterial nanotechnologyCell electrodesGraphite carbonDischarge efficiency

The invention overcomes the defects of the prior art and provides a battery graphite anode material prepared by using nano graphite carbon powder and a method of preparing the same. Obtained is the graphite anode material featuring high quality, high reliability, high energy density, long life, high cathode utilization, high initial discharge efficiency and the like; to solve the above technical problem, a following technical scheme is used: a battery graphite anode material prepared by using nano graphite carbon powder and a method of preparing the same, wherein the graphite anode material is 30-70 nm in particle size D, > / =2.33 g / cm<2> in true density, < / =0.01% in ash content, > / =1.13 g / cm<2> in tap density, < / =1.7 g / cm<2> in specific surface area, 325-355 mAh / g in initial discharge capacity and > / =90% in initial discharge efficiency, and the desired battery graphite anode material is obtained through calcining and graphitizing; the invention is widely applicable to the field of battery graphite anode materials.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Decoration and fire prevention integrated plate and manufacturing method thereof

ActiveCN106760339AFunction as a decorative panelImprove high temperature resistanceCovering/liningsSynthetic resin layered productsFiberRefractory

Provided are a decoration and fire prevention integrated plate and a manufacturing method thereof. The decoration and fire prevention integrated plate comprises a base plate adhering to a wall and a fireproof and decorative laminboard combined on the base plate, the fireproof and decorative laminboard is formed by combining three layers of boards and comprises fireproof boards on the two sides and a decorative composite core layer clamped between the fireproof boards on the two sides, and the base plate and the fireproof and decorative laminboard are connected into a whole through buried connecting parts located at the four corners of a composite plate. The decorative composite core layer is of a double-layer structure that a decorative face layer is bonded to a high-silica refractory fiber cloth lining layer, the lining layer has the function of an underlayer relative to the decorative face layer, and phenolic resin plates on the two sides have double protection on the decorative composite core layer. The fireproof performance and decoration performance of a fireproof plate are organically combined, the fireproof plate can be directly used as a cladding panel, and the function of a decoration plate is achieved.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Plug-in vented temperature transducer

ActiveCN106556471ASimple structureReasonable designThermometers using electric/magnetic elementsUsing electrical meansInfraredCorrosion

The invention provides a plug-in vented temperature transducer. A shell is divided into a mounting part and a probe part; the inner side of the probe part is provided with a thermosensitive element and an insulating element; filling of thermal-conductive silica gel around the thermosensitive element is realized; a probe is pressed onto an electrode of the thermosensitive element through a spring; the lower end of the probe part is covered with an infrared absorption film; the infrared absorption film is located on the periphery of the thermosensitive element; and vent holes are arranged in the side wall of the mounting part. The plug-in vented temperature transducer has the advantages that the structure is simple and the design is reasonable; the thermal-conductive carbon fiber material is adopted as the probe part, and advantages of light weight, corrosion resistance, ablation resistance, high hardness, wear resistance, high temperature resistance, low temperature embrittlement resistance and the like are realized; the thermal-conductive silica gel fixes the thermosensitive element and conducts the heat, and the sensitivity and the anti-seismic performance are improved; a positive probe and a negative probe are pressed onto the positive electrode and the negative electrode of the thermosensitive element under pressure of the spring, when a thermal expansion and contraction phenomenon happens to the probe, the spring can randomly adjust the pressure between the probe and the electrode, and reliable electrical connection is realized.

Owner:江苏溢坤医疗科技有限公司

Molybdenum phenolic resin precoated sand material for instrument casting

InactiveCN106077427AImprove high temperature casting performanceAblation resistantFoundry mouldsFoundry coresFiberAlkali free

A molybdenum phenolic resin precoated sand material for instrument casting comprises, by weight, 1-2 parts of molybdenum phenolic resin, 0.02-0.06 part of a coupling agent, 0.2-0.5 part of urotropin, 0.2-0.5 part of a curing agent, 0.5-1 part of alkali-free glass fiber, 0.2-0.5 part of microcrystalline wax, 1-2 parts of montmorillonoid, 1-3 parts of manganese ore slag, 5-10 parts of emery, 5-10 parts of soldering iron ore sand and 85-95 parts of dead burnt magnesite sand. Compared with conventional precoated sand, the molybdenum phenolic resin precoated sand material for instrument casting, has the performance of reducing the gas generation speed and restraining nitrogen generation besides the performance of the conventional precoated sand, nitrogen holes of castings can be effectively reduced, and accordingly the yield of a casting instrument is increased. The universality of the precoated sand from iron castings to steel castings is improved, the production rate of the castings is increased, the cost of modeling materials of a casting enterprise is saved, and good high-temperature resisting casting performance is achieved.

Owner:无锡市三峰仪器设备有限公司

A kind of preparation method of polycarboxy metal phthalocyanine-aromatic copolyester

InactiveCN103408742BExcellent dielectric propertiesHigh temperature resistantMolecular networkPolymer science

Owner:TONGJI UNIV

A kind of tungsten carbide reinforced carbon-based composite material and its preparation method

The invention discloses a tungsten carbide reinforced carbon matrix composite material and a preparation method. Mesocarbon microbeads are adopted as the matrix, and tungsten carbide ceramic is adopted as the reinforcement phase and is evenly distributed among the carbon microbeads so as to form a three-dimensional network tungsten carbide skeleton reinforced isotropic structure. The preparation method includes: firstly taking tungsten oxide particles and mesocarbon microbeads as the raw materials to prepare uniform and thickness controllable tungsten carbide coating coated mesocarbon microbead powder by molten salt process, then performing pre-press molding, and conducting discharge plasma sintering at 1500-1900DEG C to form a uniform three-dimensional network tungsten carbide ceramic skeleton, which can significantly improve the strength, ablation resistance and oxidation resistance of the carbon matrix, thus forming the isotropic carbon matrix composite material characterized by lowcost, low density and excellent mechanical properties, sintering performance and ablation resistance. Because of the excellent comprehensive performance, the tungsten carbide reinforced carbon matrixcomposite material can be widely applied to aerospace, national defense and other fields, and has broad application prospects.

Owner:XI AN JIAOTONG UNIV

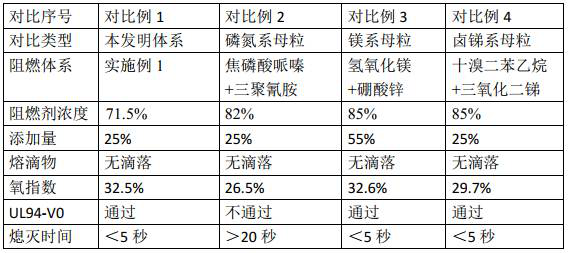

A low-temperature ceramic flame retardant functional masterbatch and its preparation method

The invention relates to a low-temperature ceramic flame-retardant functional masterbatch, which comprises the following components by mass: 10-25 parts of silicone rubber, 5-15 parts of silicone resin, 2-6 parts of aluminum hypophosphite, and 2-10 parts of glass microspheres 2-8 parts of montmorillonite, 10-25 parts of natural bone powder, 25-50 parts of synthetic ceramic bone powder, 1-2 parts of coupling agent, 1-3 parts of lubricant and 1-3 parts of dispersing agent. The invention also relates to a method for preparing low-temperature ceramicized flame retardant functional masterbatch, which improves the dispersibility and increases the carbon formation rate, so that the carbon layer with a multi-dimensional stable structure has a high precipitation rate and integrity rate. The flame retardant masterbatch prepared by the invention can be ceramicized at low temperature when the material encounters flame attack, and can form a continuous and dense ceramic oxygen barrier layer, which has the characteristics of high efficiency and environmental protection.

Owner:见喜新材料股份有限公司

a zro 2 -sio 2 Low temperature rapid preparation method of matrix composites

The invention provides a low-temperature rapid preparation method of a ZrO2-SiO2-based composite material. The method comprises the following steps: (a) weighing silicon oxide sol and ZrO2 micropowderaccording to a certain ratio, adding the ZrO2 micropowder into the silicon oxide sol and magnetically stirring for six or more hours to form suspension liquid of the silicon oxide sol doped with theZrO2 micropowder; (b) clamping a high-temperature-resistant inorganic fiber cloth or a thin-layer fabric by using a graphite die, putting the high-temperature-resistant inorganic fiber cloth or the thin-layer fabric in a vacuum container and vacuumizing, then sucking the suspension liquid obtained in the step (a) and completely dipping the high-temperature-resistant inorganic fiber cloth or the thin-layer fabric; then rapidly transferring the dipped high-temperature-resistant inorganic fiber cloth or thin-layer fabric into a drying oven for carrying out heat treatment for gelatinizing, naturally cooling to room temperature and solidifying, repeatedly carrying out overall dipping, gelatinizing and naturally cooling for 5-8 times; and (c) putting the obtained hard solid in a muffle furnace for carrying out high-temperature heat treatment under the treatment temperature being lower than 800 DEG C, finally cooling to the room temperature to obtain the ZrO2-SiO2-based composite material.

Owner:NAT UNIV OF DEFENSE TECH

Battery protective layer, preparation method and application in battery components

ActiveCN110815993BAvoid fireAvoid explosionBattery isolationSynthetic resin layered productsElectrical batteryResin matrix

The invention provides a battery protective layer, a preparation method and its application in battery components. The battery protective layer includes a fireproof cloth and a functional layer arranged on the fireproof cloth, and the functional layer is mainly composed of epoxy A thermosetting resin layer formed by curing the resin matrix, epoxy resin curing agent, reinforcing filler, flame retardant and silane coupling agent. The battery protection layer of the invention has high strength, ablation resistance, heat shock resistance and flame retardancy, can withstand explosion impact, block sparks and inhibit combustion diffusion, effectively avoid battery fire or explosion, and improve battery safety during use.

Owner:CONTEMPORARY AMPEREX TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com