a zro 2 -sio 2 Low temperature rapid preparation method of matrix composites

A composite material, low temperature technology, applied in the field of rapid preparation of ZrO2-SiO2 matrix composite materials at low temperature, can solve the problems of low yield of oxide sol ceramics, decreased strength of quartz fibers, formation of cracks and pores, etc., to shorten the preparation period, reduce Preparation cost, easy to formulate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

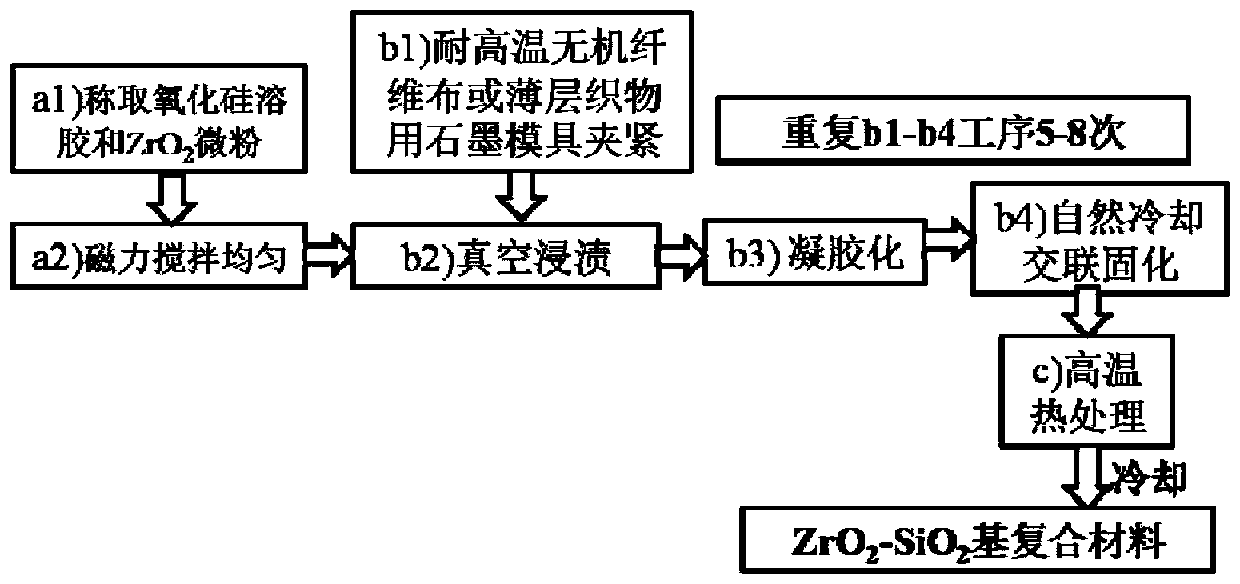

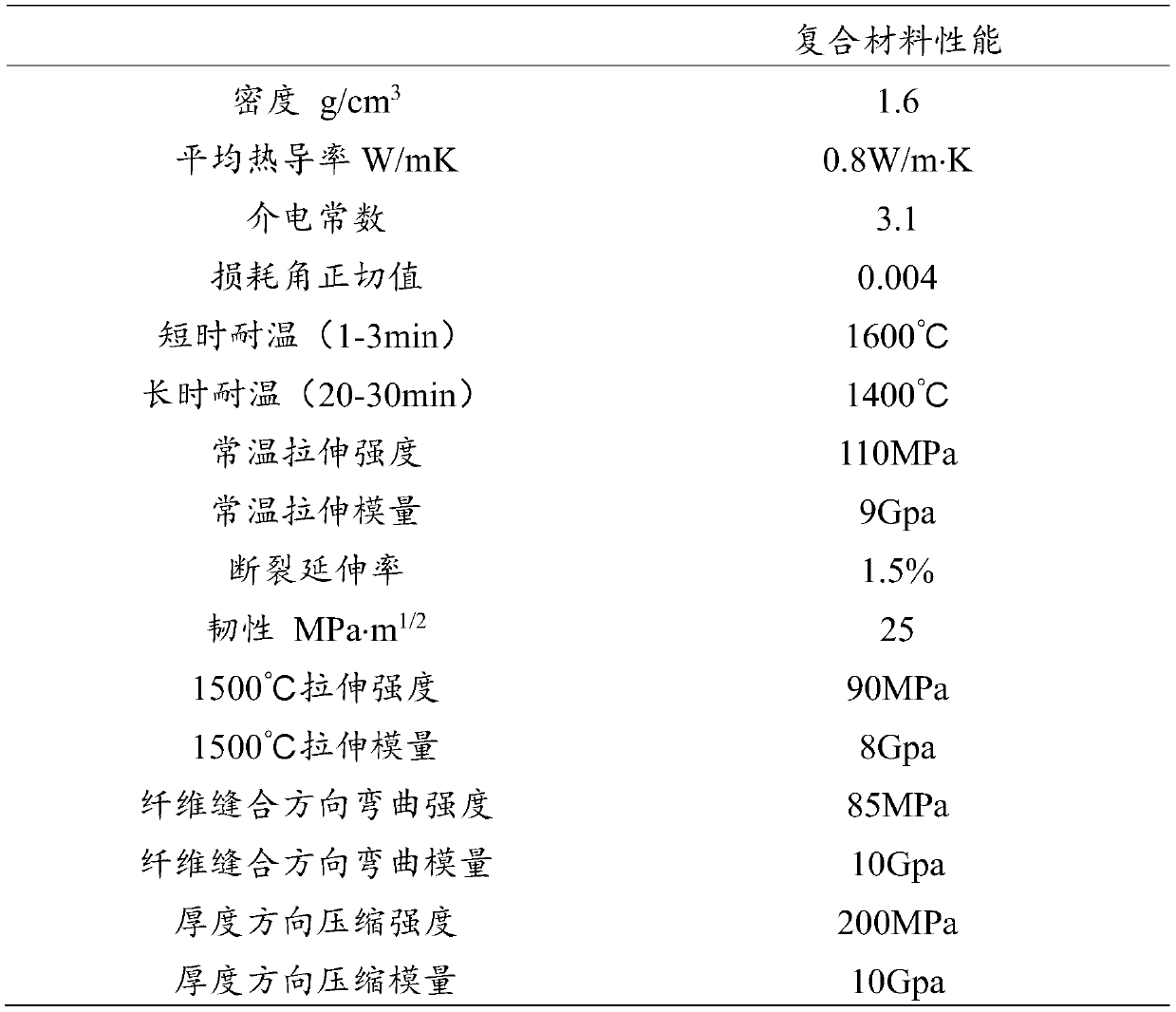

[0029] a ZrO 2 -SiO 2 Matrix composite material, high temperature resistant inorganic fiber cloth or thin layer fabric is quartz fiber cloth, the thickness of product material is 3mm, and its preparation method is as follows figure 1 As shown, the following steps are included: (1) flat lay 8 layers of 0.28mm thick quartz fiber cloth, and then perform suture processing. The fiber used for suture is commercially available common 750Tex mullite fiber, which has better flexibility , not easy to break, in order to obtain better mechanical properties, the distance between every two sutures is designed to be 10mm; (2) ZrO 2 Micropowder (200 mesh) is placed in silica sol, wherein silica sol and ZrO 2 The mass ratio of the micropowder is 5:1, stirred by magnetic force for 4h; (3) clamp the quartz fiber cloth obtained in step (1) with a graphite mold, place it in a vacuum container, vacuum inhale the sol obtained in step (2), and soak for 2h, Then make it gelatinized at a temperature o...

Embodiment 2

[0033] a ZrO 2 -SiO 2 Matrix composite material, wherein the high temperature resistant inorganic fiber cloth or thin layer fabric is 2.5D woven alumina fiber, and the thickness of the product material is 1.0mm. Its preparation method is as figure 1 Shown, comprise the following steps: (1) ZrO 2 Micropowder (100 mesh) is placed in silica sol, wherein silica sol and ZrO 2 The mass ratio of the micropowder is 1:1, and the suspension is formed by magnetic stirring for 6 hours; (2) A layer of 2.5D alumina fiber woven piece is laid flat, and then punctured. The fiber used for acupuncture is 600Tex alumina Fiber, the distance between every two acupuncture lines is 5mm; (3) clamp the alumina fiber 2.5D braided piece with graphite mold after the puncture obtained in step (2), place it in a vacuum container, and vacuum inhale the obtained product in step (1) Slurry suspension, and then gelatinized at a temperature of 150°C, repeated dipping and gelatinization 8 times; (4) Put the a...

Embodiment 3

[0038] a ZrO 2 -SiO 2 Matrix composite material, wherein the high temperature resistant inorganic fiber cloth or thin layer fabric is silicon carbide fiber cloth, and the material thickness is 3.0mm. Its preparation method is as figure 1 Shown, comprise the following steps: (1) ZrO 2 Micropowder (200 mesh) is placed in silica sol, wherein silica sol and ZrO 2 The mass ratio of the micropowder is 2:1, and the suspension is formed by magnetic stirring for 4 hours; (2) 3 layers of silicon carbide fiber cloth with a thickness of 0.9mm are laid flat, and then punctured to form a silicon carbide fiber cloth "skin". The fiber used in the puncture is 600Tex silicon carbide ceramic fiber, and the distance between every two needle punching lines is 10mm; (3) clamp the silicon carbide fiber cloth "skin" obtained in step (2) with a graphite mold, and place it in a vacuum container , vacuum inhale the suspension obtained in step (1), then gelatinize it at a temperature of 100°C, and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com