Battery protective layer, preparation method and application in battery components

A technology for battery components and protective layers, which is applied in the field of preparation and battery protective layers, can solve problems such as restricting the rapid development of new energy vehicles, and achieve the effects of avoiding fire or explosion, improving safety, and inhibiting combustion diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

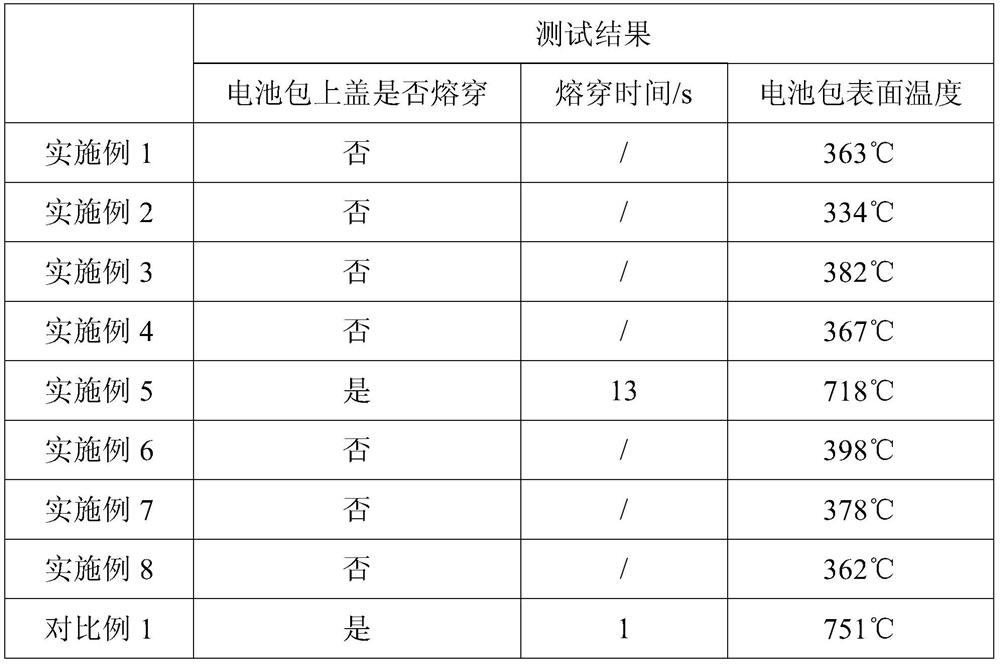

Examples

preparation example Construction

[0030] Next, the preparation method of the battery protection layer according to the present invention will be described.

[0031] The preparation method of the battery protection layer of the present invention comprises the steps: (1) dissolving the epoxy resin matrix in a solvent to obtain an epoxy resin matrix solution; (2) then adding reinforcing fillers and flame retardants to the epoxy resin matrix solution , mix evenly, then add silane coupling agent, mix evenly again, add epoxy resin curing agent and stir evenly to obtain a mixed solution; (3) fully impregnate the mixed solution into the fireproof cloth, then cover the fireproof cloth on the main material, and let it stand at room temperature Place or heat treatment to cure the epoxy resin matrix in the mixed solution to form a thermosetting resin layer, and complete the preparation of the battery protective layer.

[0032] In the preparation method of the battery protective layer, the type of solvent is not particular...

Embodiment 1

[0043] Dissolve 40 parts by mass of silicone-modified epoxy resin in acetone, then add 25 parts by mass of glass fiber reinforced filler and 10 parts by mass of phosphate flame retardant, mix well and then add 0.5 parts by mass of silane coupling agent γ-ammonia Propyl triethoxysilane, mix again and add 25 parts by mass of imidazole curing agent, stir evenly to obtain a mixed solution; brush the mixed solution on the surface of the glass fiber cloth and make the mixed solution fully impregnate the glass fiber cloth, and then put The glass fiber cloth is covered on the inner side of the upper cover of the battery pack, and heated and cured at 80°C for 2 hours to form a battery protective layer with a thickness of 2mm.

Embodiment 2

[0045] Dissolve 80 parts by mass of phenolic modified epoxy resin in diethylene glycol monomethyl ether, then add 40 parts by mass of carbon fiber reinforced filler and 25 parts by mass of ammonium polyphosphate flame retardant, mix well and then add 1 part by mass of silane Joint agent γ-(2,3-glycidoxy) propyltrimethoxysilane, mix again evenly, add 40 parts by mass of anhydride curing agent, stir evenly to obtain a mixed solution; brush the mixed solution on the basalt fiber cloth and fully impregnate the basalt fiber cloth with the mixed liquid, then cover the inner side of the battery pack cover with the basalt fiber cloth, and heat and cure at 100°C for 6 hours to form a battery protective layer with a thickness of 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com