Tungsten carbide reinforced carbon matrix composite material and preparation method

A carbon-based composite material and composite material technology are applied in the field of tungsten carbide reinforced carbon-based composite materials and their preparation, which can solve the problems of uneven microstructure, poor anti-oxidation and anti-ablation performance, and low mechanical properties, and achieve enhanced bonding strength. , The effect of reducing the sintering temperature and enhancing the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

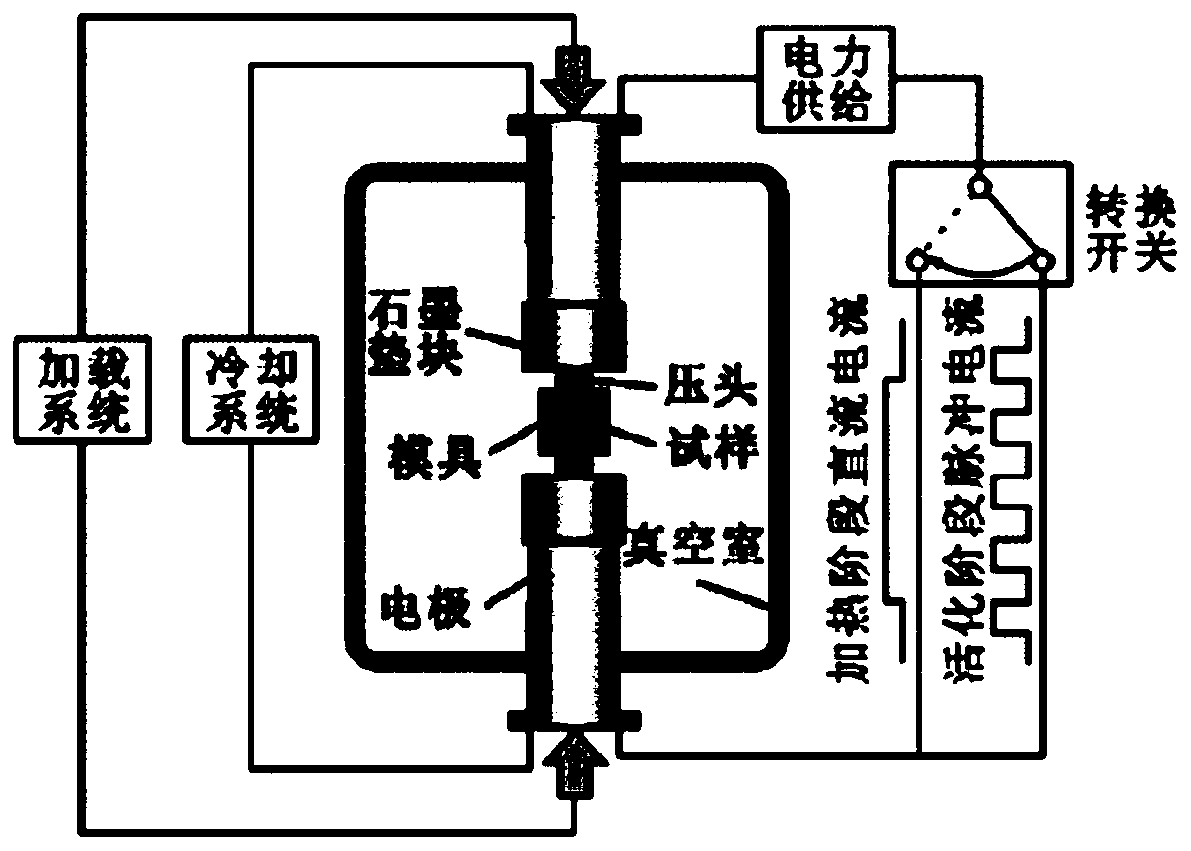

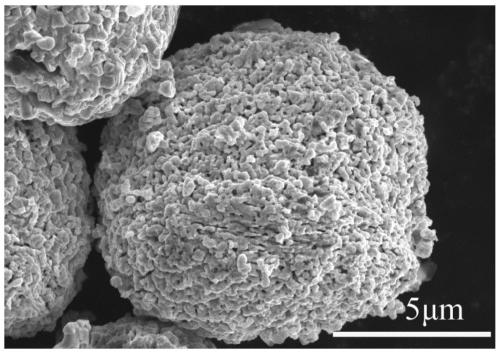

[0035] Weigh tungsten oxide and mesophase carbon microspheres with a molar ratio of 1:40 as raw material powder, and 1:1 sodium chloride and potassium chloride as medium, wherein the mass ratio of raw material powder and medium is 1:7, and the powder is in Mechanically stir in an agate mortar for 20 minutes to mix well. Put the mixed powder into an alumina crucible, under vacuum or protective atmosphere, raise the temperature of the mixed powder to 600°C at a rate of 10°C / min, keep it warm for 30 minutes; then raise the temperature to 1100°C at a rate of 5°C / min , keep warm for 1 hour, rinse with hot water at 80-100°C for 30-50 times, and dry to obtain tungsten carbide-coated mesophase carbon microsphere powder. Take part of the composite powder and put it into a carbon mold. The upper and lower pressure heads and the inner wall of the mold are pre-laid with a layer of carbon paper, which is pre-pressed to form a sample, and then the carbon mold is placed in the figure 1 spa...

Embodiment 2

[0038] The process of this example is the same as that of Example 1, except that some process parameters are changed: the holding time in vacuum atmosphere is 2.5 hours, and the final sintering temperature is 1800°C.

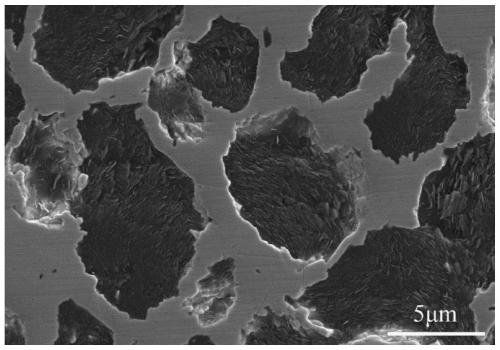

[0039] Carry out the performance test identical with embodiment 1 to the sintered sample of present embodiment, the result is as follows: density reaches 3.87g / cm 3 , the relative density reaches 94.45%, and the apparent porosity is 2.98%. Form a three-dimensional network ceramic skeleton and image 3 Similar; microstructure and figure 2 Similar; the flexural strength of the composite material reaches 124MPa.

Embodiment 3

[0041] The process of this embodiment is the same as that of Example 1, except that some process parameters are changed: the holding time in vacuum atmosphere is 5 hours, and the final sintering temperature is 1850°C.

[0042] The same performance test as in Example 1 is carried out on the sintered sample of this embodiment, and the results are as follows: the density reaches 3.98g / cm 3 , the relative density reaches 95.95%, and the apparent porosity is 2.74%. Form a three-dimensional network ceramic skeleton and image 3 Similar; microstructure and figure 2 Similar; the flexural strength of the composite material is 182MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com