Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Zinc selenite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc selenide (ZnSe) is a light-yellow, solid compound comprising zinc (Zn) and selenium (Se). It is an intrinsic semiconductor with a band gap of about 2.70 eV at 25 °C (77 °F). ZnSe rarely occurs in nature, and is found in the mineral that was named after Hans Stille called "stilleite.".

Compound polishing powder for polishing optical elements, preparation method and polishing technology

ActiveCN101362925BImprove effectivenessImprove machining accuracyOptical surface grinding machinesOther chemical processesSurface finishGranularity

The invention provides a compound polishing powder of a polishing optical element, a preparation method and a polishing process, belonging to expendable material used for polishing the optical element, the preparation method and the polishing process of the polishing powder; wherein, the polishing powder comprises 0.5-3 of Cr2O3 powder and 1 of Al2O3 according to the weight proportion; the granularity of the Cr2O3 powder is ranging from 0.05 microns to 0.10 microns and the granularity of the Al2O3 powder is ranging from 0.05 microns and 0.10 microns; the polishing process comprises the steps as follows: 1) installing polishing formworks for the optical element; 2) filling the polishing powder; 3) arranging a lens disc; 4) fixing the lens disc; 5) rubbing and polishing. The polishing formwork comprises 500 of polishing asphalt and 20-200 of Al2O3 according to the weight parts; in the polishing process, the polishing powder and the polishing formwork can be used for polishing the optical element which is made of zinc selenide, with the surface smoothness of more than 20-10.

Owner:CHENGDU Z & Z OPTOELECTRONICS TECH

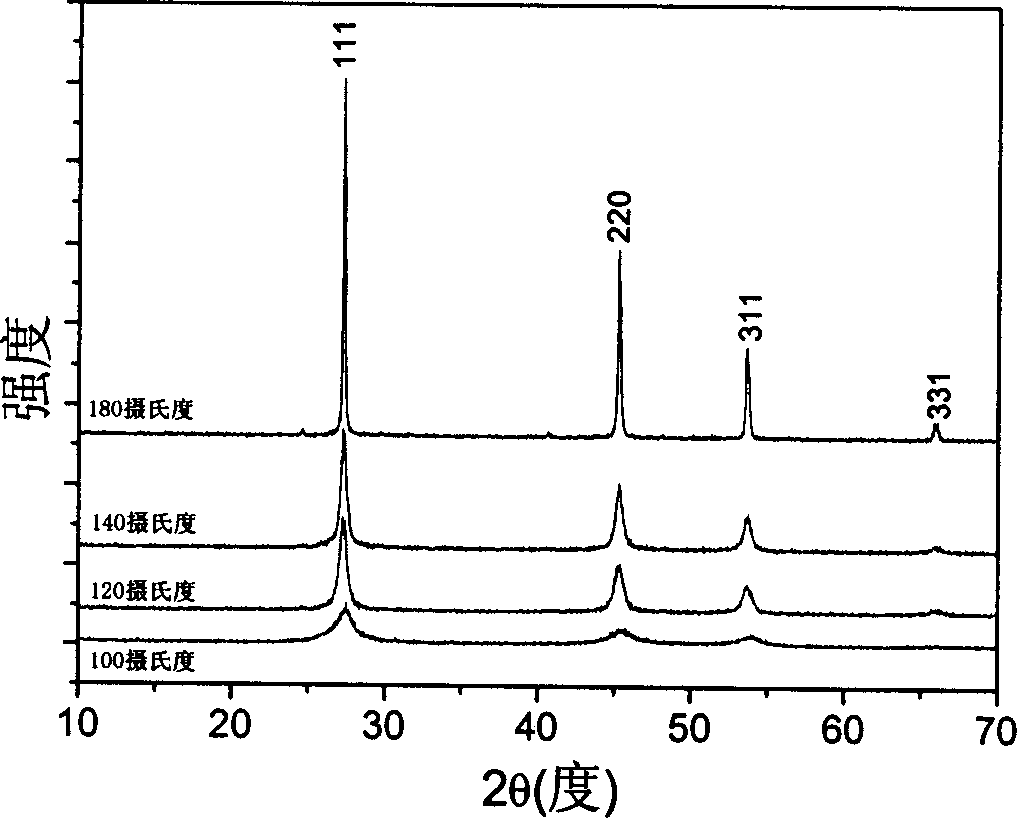

Synthesis of nano hollow balls of zinc selenide

InactiveCN1424248AOvercome the problems of high temperature, highly toxic raw materials, complicated process, etc.Low reaction temperatureZinc compoundsBinary selenium/tellurium compoundsPhotonic crystalSeleninic acid

A process for synthesizing a micro-class hollow zinc selenide sphere features that hydrothermal reduction reaction between zincic acid radical ions and seleninic acid or soluble selerate under action of hydrazine hydrate as reducer in strong alkaline condition at 100-200 deg.C in a sealed reaction. It is possible to dope it or coat it. Its advantages are low cost and high quality.

Owner:TSINGHUA UNIV

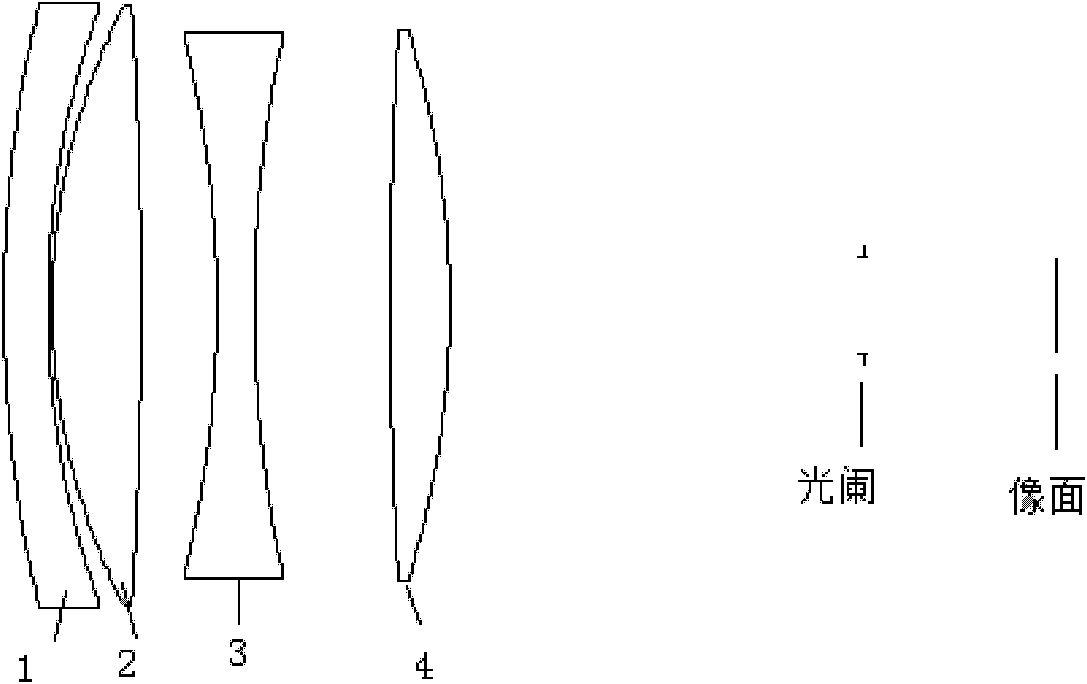

Infrared double-waveband athermalization optical lens

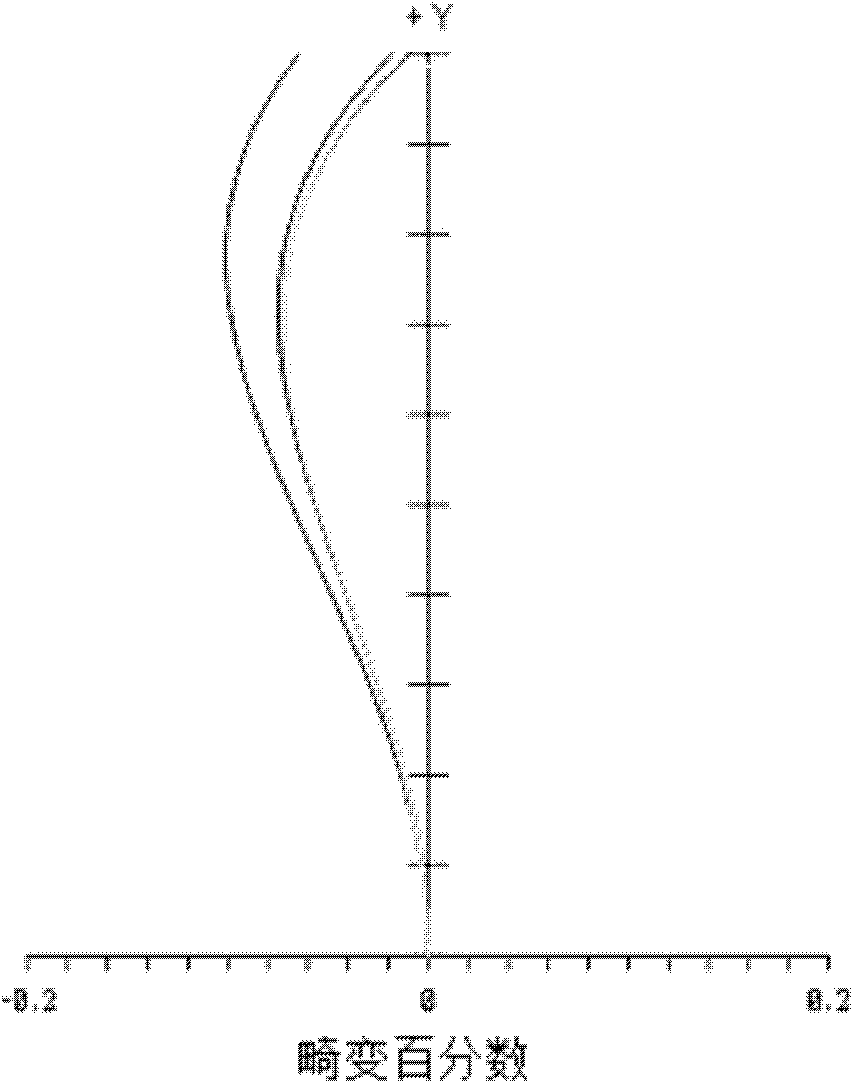

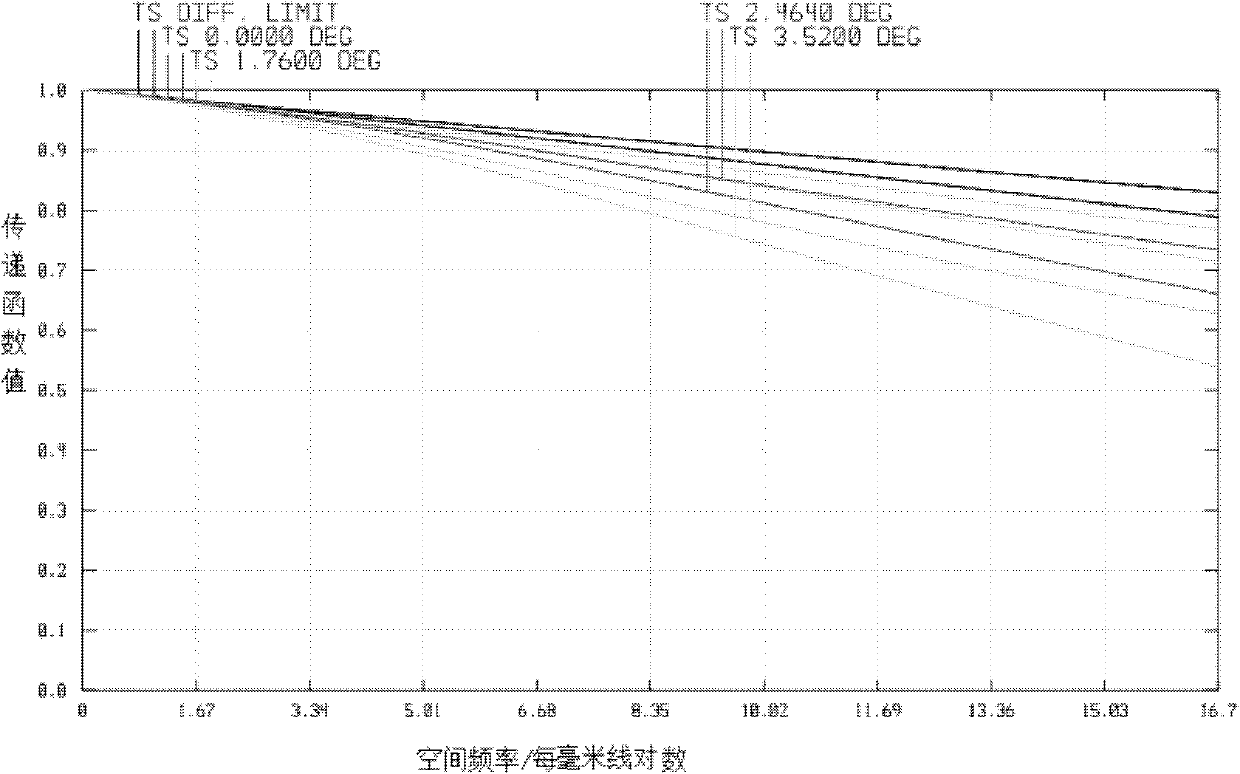

The invention discloses an infrared double-waveband athermalization optical lens, which is characterized in that working wavebands are 3-5 microns and 8-12 microns and a working ambient temperature range is from -60 DEG C to 80 DEG C. The lens is of a common optical axis Cooke triplet structure and comprises four refractor lens; an aperture diaphragm is arranged at a cold screen of an image surface; in the incidence direction of light, the back surface of a first lens [1] and the front surface of a third lens [3] are aspheric surfaces; the materials of lens are germanium, zinc selenide, zinc sulfide and zinc selenide in sequence; and when the lens focus is normalized, the value range of focal power is as follows: Phi 1 is more than or equal to -1.0 but less than or equal to -0.5, Phi 2 is more than or equal to 1.50 but less than or equal to 2.0, Phi 3 is more than or equal to -2.0 but less than or equal to -1.50, and Phi 4 is more than or equal to 1.0 but less than or equal to 1.5. The optical lens has the advantages that the structure is simple, the imaging quality is high, the athermalization effect is good, the later working distance is long, the cold aperture diaphragm efficiency is 100%, and the like. The infrared double-waveband athermalization optical lens can be used as an infrared double-color guiding head and has wide application prospect in both military and civil fields.

Owner:SUZHOU UNIV

Visible near-infrared spectrum band reflection and infrared multispectral band transmission color separation filter and preparation method

The invention relates to a visible near-infrared spectrum band reflection and infrared multispectral band transmission color separation filter and a preparation method, and belongs to the field of surface technology. The color separation filter comprises a zinc selenide base and a film system on one side of the base; the structure of the film system is (0.3h 0.6l0.3 h) ^ 10 (0.38h 0.76 l0.38 h) ^ 10 (0.5 h l0.5 h) ^ 12, and the central wavelength is 890 nm, wherein h and l refer to zinc sulfide and yttrium fluoride film respectively; and the color separation filter is prepared through the following steps: heating the base in vacuum, using ion beam to bombard the base, using ion beam to assist electronic gun evaporation to deposit the film system on two sides of the base, and cooling. The reflectivity of the color separation filter is high at 0.43-0.90 micron; the transmittance of the color separation filter is high at 1.55-1.75 microns, 2.08-2.35 microns, 3.5-5.5 microns, 7.8-10 microns, and 11.08-12.55 microns; and the color separation filter meets beam split operating requirement of a remote sensing detection system.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

ZnSe scintillators

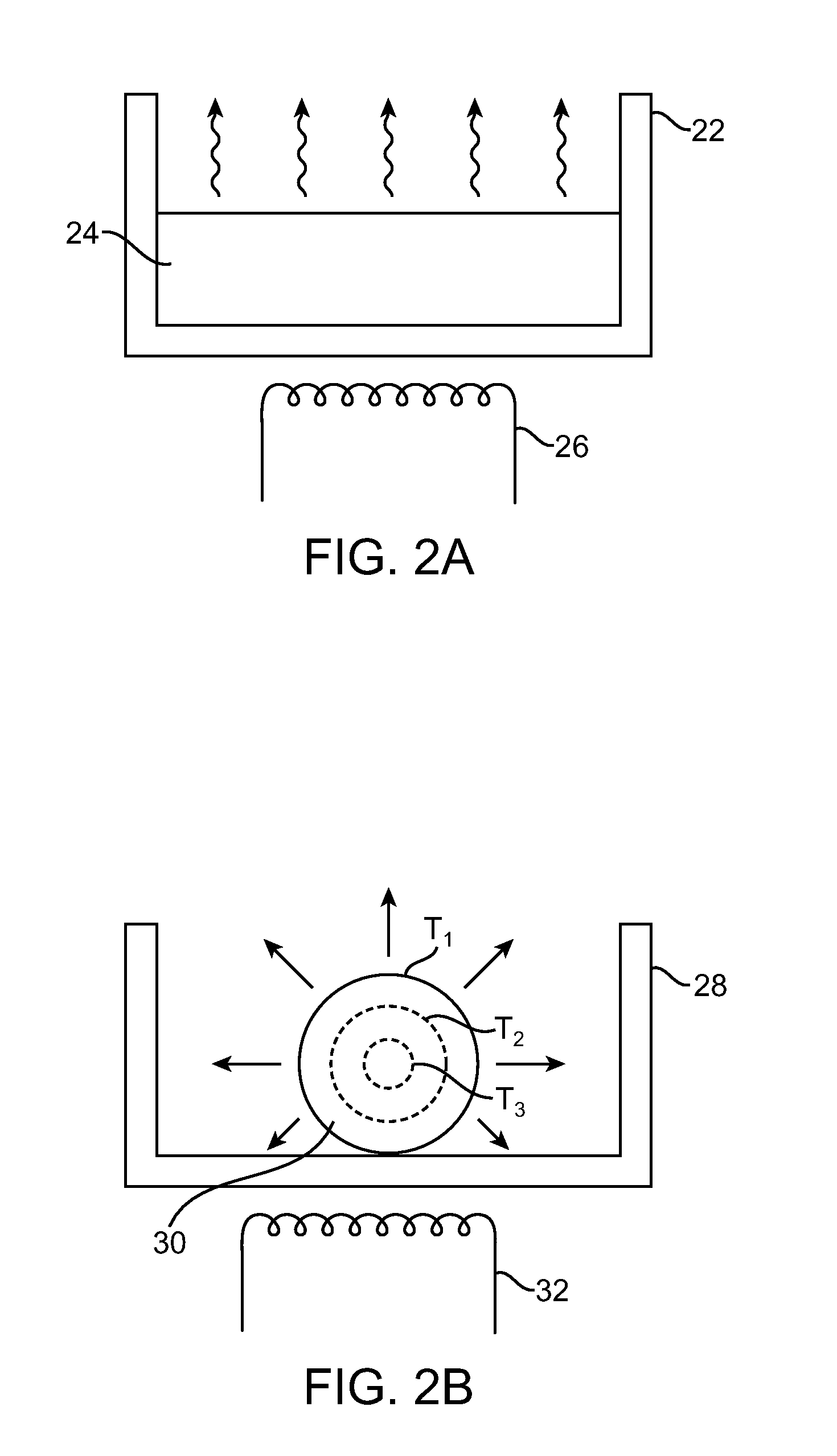

ActiveUS20090050810A1Convenient lightingImprove resolutionHandling using diaphragms/collimetersMaterial analysis by optical meansDopantHigh spatial resolution

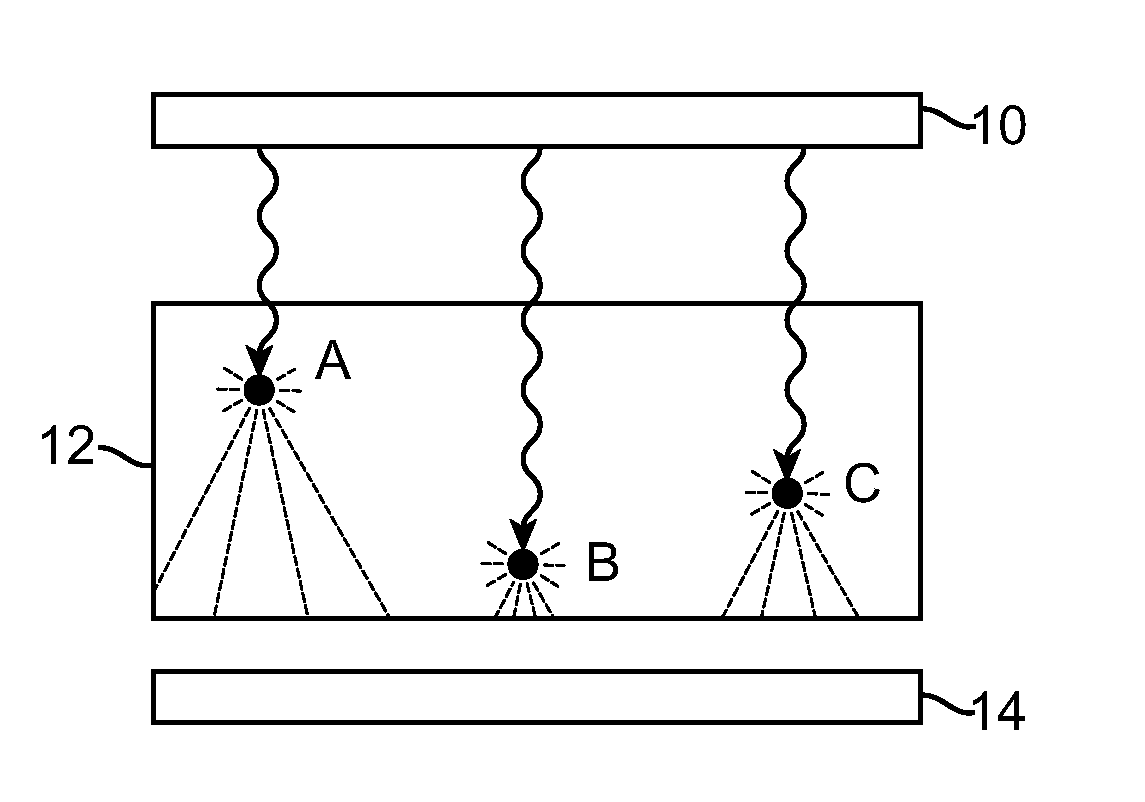

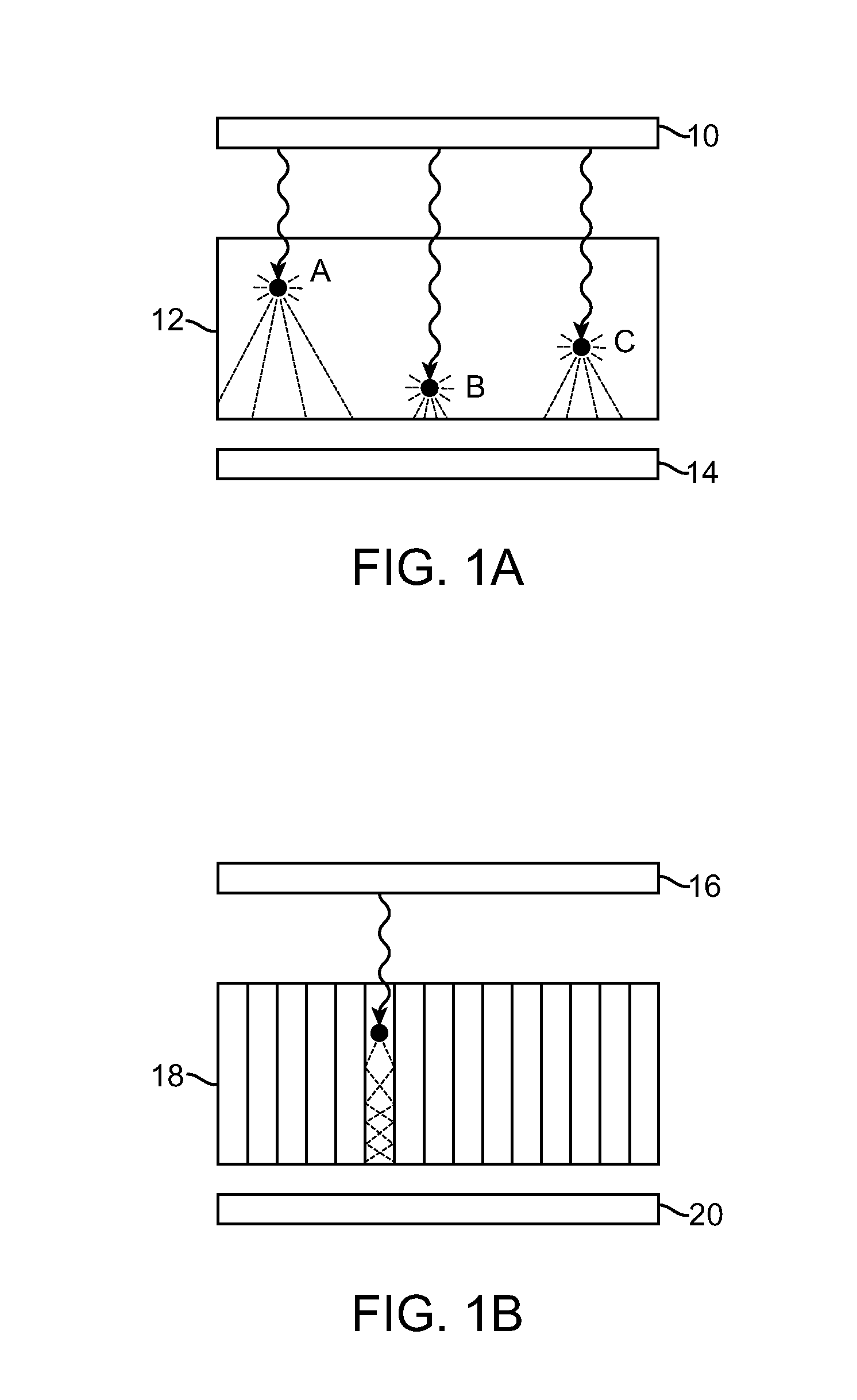

The present invention relates to a microcolumnar zinc selenide (ZnSe) scintillator and uses thereof, and methods of fabrication of microcolumnar scintillators using sublimation-based deposition techniques. In one embodiment, the present invention includes a scintillator including a microcolumnar scintillator material including zinc selenide (ZnSe) and a dopant. The microcolumnar scintillators of the present invention provide improved light channeling and resolution characteristics, thereby providing high spatial resolution, highly efficient scintillators.

Owner:RADIATION MONITORING DEVICES

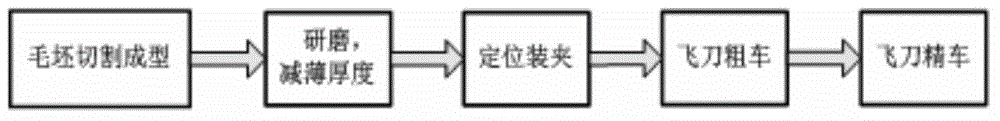

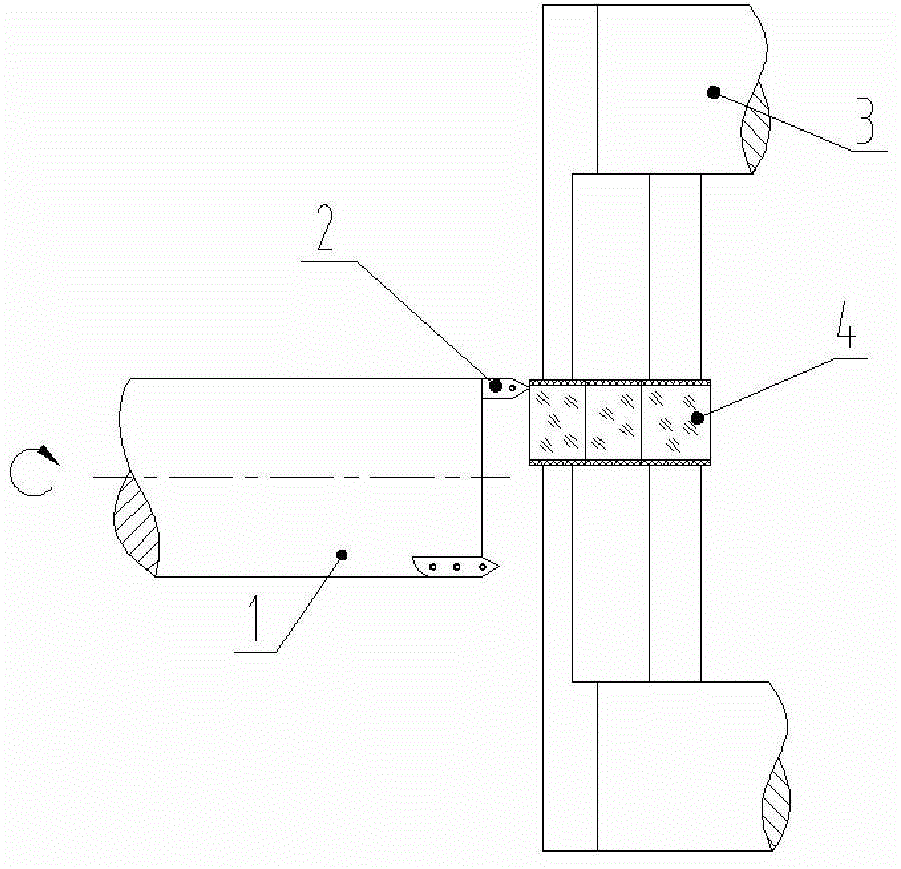

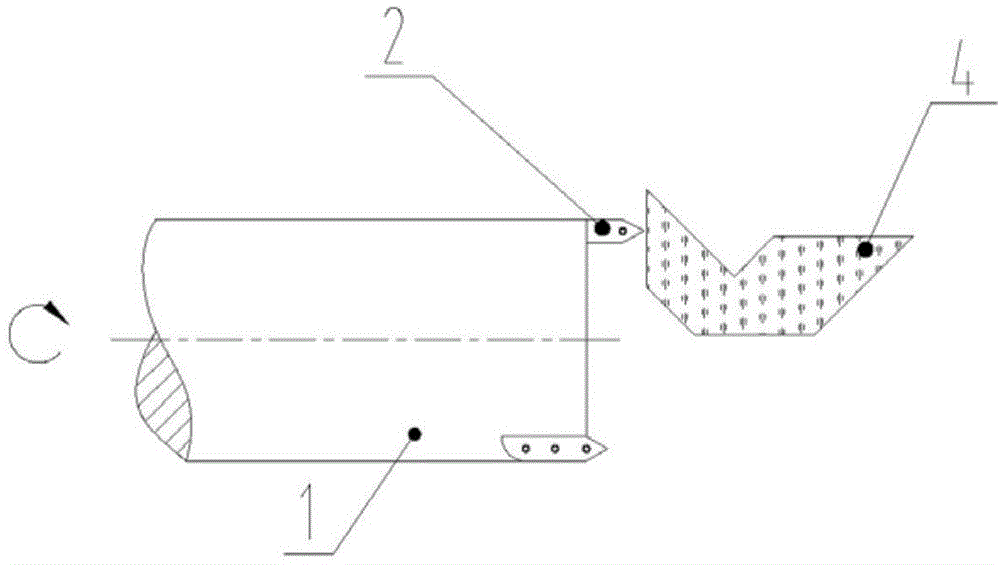

Processing method of L-shaped ZnSe (zinc selenide) turning prism

InactiveCN104551894AGuaranteed sizeGuaranteed angular accuracyEdge grinding machinesPrismsOptical processingPrism

The invention belongs to the field of precision processing and manufacturing of optical elements, and relates to a processing method of an L-shaped ZnSe (zinc selenide) turning prism, which solves the problem of the classical optical processing method that the polyhedron prism with complicated structure is difficultly processed. The processing method mainly comprises the following steps of according to the completing size of the prism, calculating the initial structure of a blank, and using an abrasive wire sawing machine to cut the initial structure; grinding the upper end surface and the lower end surface of the blank, and reducing the thickness; manufacturing a fixture and a flying cutter disc, wherein the fixture is used for fixing the prism, and the flying cutter disc is used for clamping a diamond cutter; positioning and fixing the blank and the fixture of the turning prism on a precision turntable of a lathe, and forming a diamond flying cutter turning type turning prism processing system; designing and implementing a turning processing path, and adopting a rough turning and precision turning two-step processing method to form. The processing method has the advantage that under the condition of guaranteeing of the part accuracy, the production efficiency is improved, and the labor intensity is decreased.

Owner:THE 3RD ACAD 8358TH RES INST OF CASC

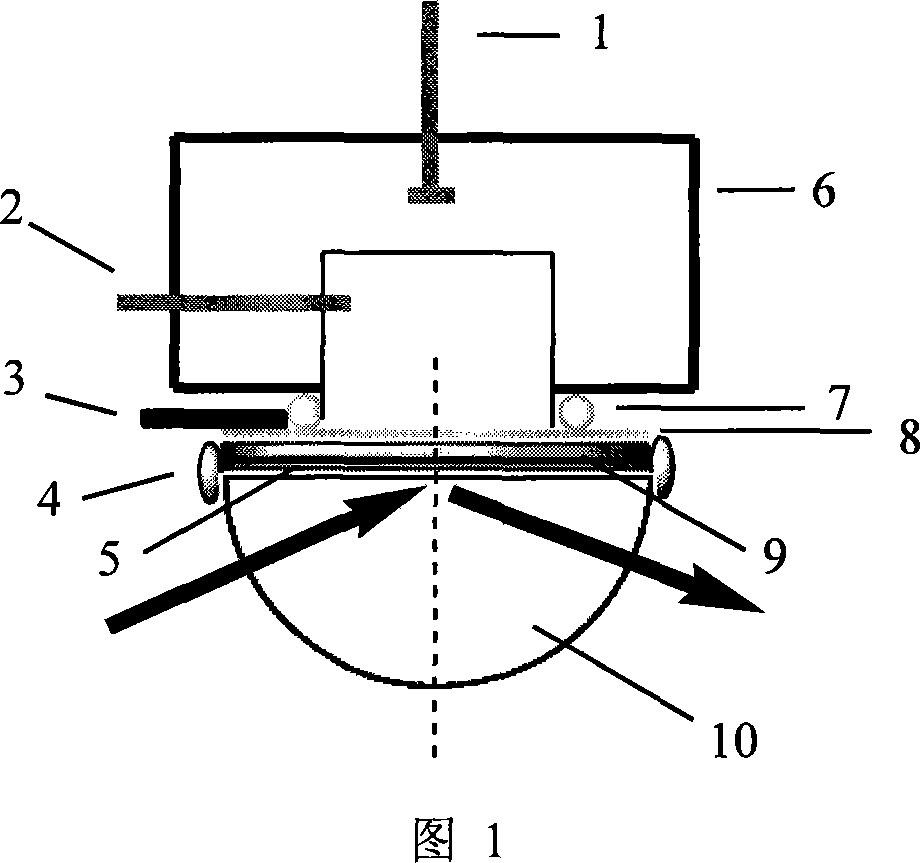

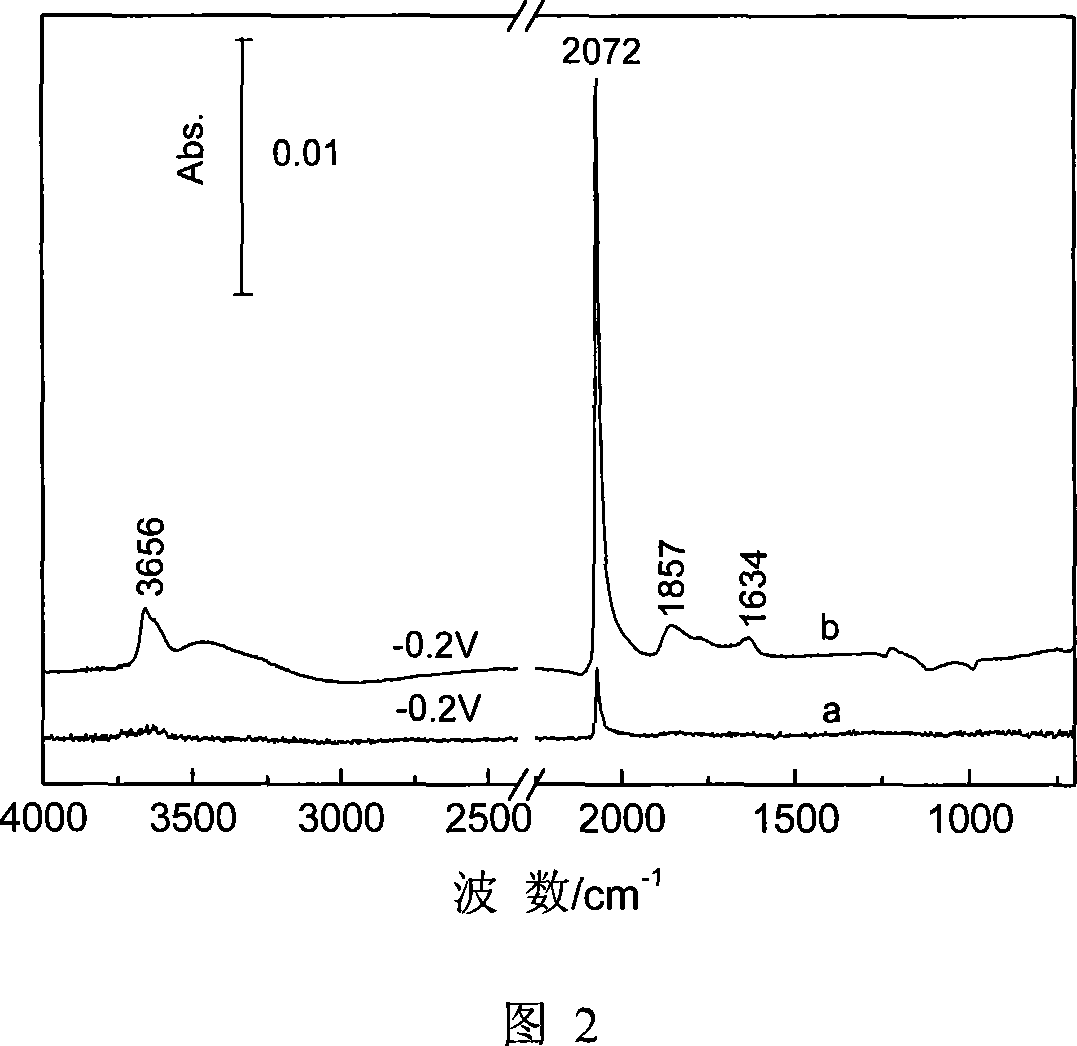

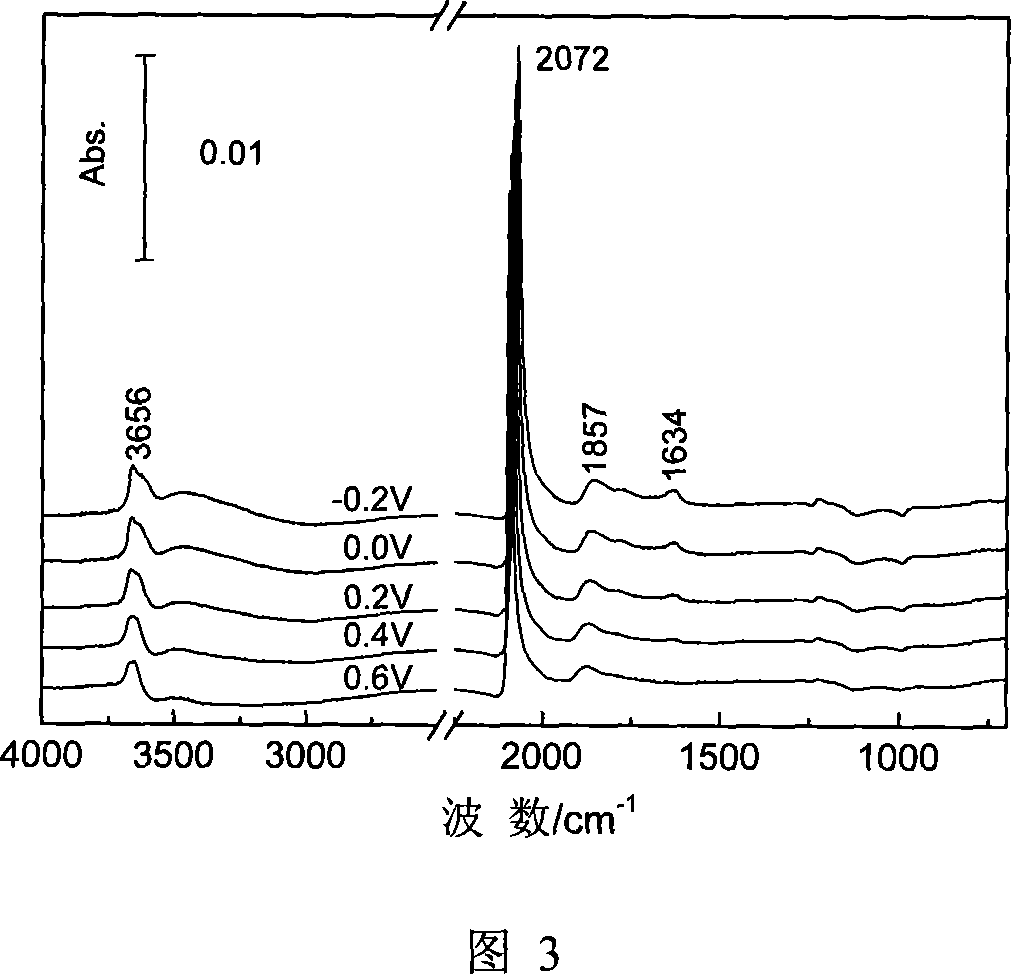

Surface-reinforced infrared spectrum optical device

InactiveCN101029867AStable structureColor/spectral properties measurementsParaffin waxMaterials science

An infrared spectrum optical device of surface intensification type is prepared as plating metal nanofilm electrode on top surface of wafer and setting water membrane layer between bottom-side surface of water and semi-cylindrical zinc selenide as well as using paraffin wax to seal peripheral seam of water membrane layer to from operation electrode, arranging electrolyzer on metal nanofilm and sealing intermediate by silicon rubber ring, using wire copper membrane to lead out metal nanofilm and setting pair electrode and reference electrode in electrolyzer to from electrode system of electrochemical spectrum test.

Owner:FUDAN UNIV

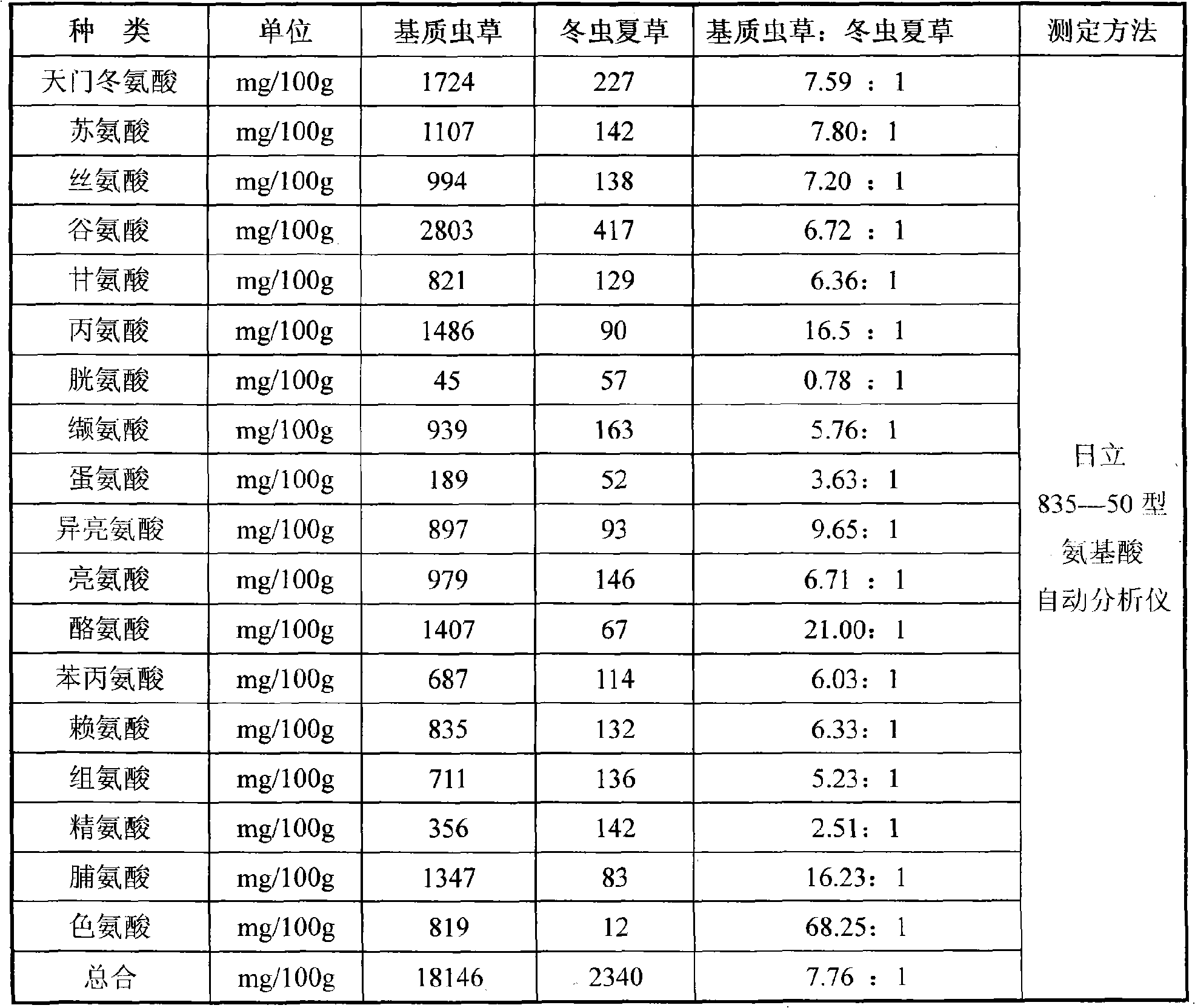

Chinese caterpillar fungus liquid bacterial cultivating matrix

InactiveCN101260368AReduce dosageNo reduction in efficacyFungiMicroorganism based processesPotassium iodineCalcium hypochlorite

The invention relates to a cordyceps liquid spawn culture medium, which is mixed and prepared by 30 to 100 gram glucose, 3 to 10 gram peptone, 0.5 to 1.1 gram multiplex vitamin, 5 to 12 gram multiplex mineral matters and 961.5 to 876.9 gram water, wherein, the vitamin mainly comprises VA, VB1, VB2, VB5, VB12, VC and VE which are prepared according to the ratio of 1 to 1; the mineral matters mainly comprise calcium hypochlorite, green vitriol, zinc selenides, sodium chlorides, potassium nitrates, magnesium sulphates, manganese sulphates, ammonia sulphates and potassium iodides which are prepared according to the ratio of 1 to 1 or are mixed and prepared by 2 gram calcium hypochlorite, 0.2 gram green vitriol, 0.2 gram zinc selenides, 0.5 to 1 gram sodium chlorides, 3 gram potassium nitrates, 3 gram magnesium sulphates, 0.2 gram manganese sulphates, 0.3 gram potassium iodides and 2 gram ammonia sulphates. The invention concentrates effective nutrition and medicinal compositions in cordyceps, and reduces the dosage but does not reduce the effect. The cordyceps liquid spawn culture medium can save 90 percent labor and save 90 percent energy, is environment-friendly without refuses; moreover, the seed production technology is simplified, which contributes to the popularity and promotion of cordyceps seed production and culture technologies and is favorable for the development of cordyceps project and simultaneously avoids large-area pollution loss due to various reasons of liquid spawn.

Owner:董亚贤

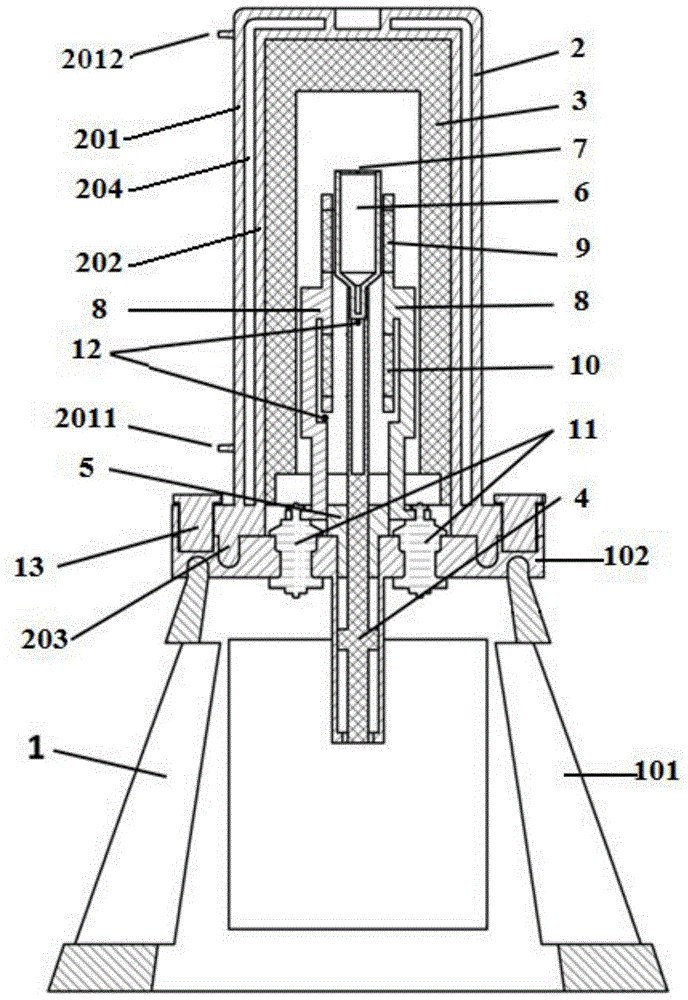

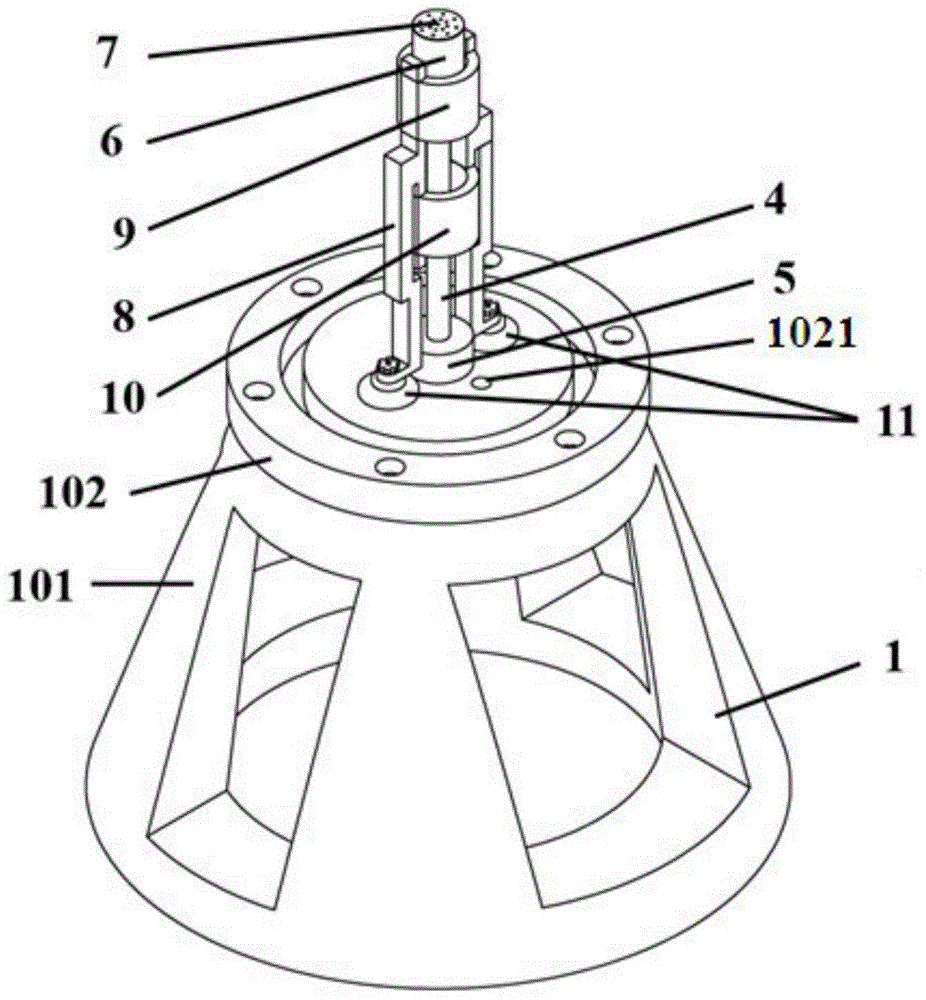

Chromium-doped zinc selenide monocrystal Bridgman growth device and method

ActiveCN104532353AGuaranteed pureStable physical and chemical propertiesPolycrystalline material growthFrom frozen solutionsCrucibleSingle crystal

The invention discloses a chromium-doped zinc selenide monocrystal Bridgman growth device and method, belonging to the technical field of crystal material preparation. The invention solves the technical problem of gradient doping density in the Cr:ZnSe crystal. The chromium-doped zinc selenide monocrystal Bridgman growth device comprises a base, a furnace mantle, a graphite felt, a transmission rod, a lockpin, a crucible, a crucible cover, two brackets, an upper heater, a lower heater, two heating electrodes and two thermocouples, wherein the transmission rod, lockpin, crucible, crucible cover, upper heater and lower heater are respectively made from graphite. The device can implement mixing and smelting of chromium powder and zinc selenide powder together, and can be used for preparing the large-volume uniform-crystalline-phase Cr:ZnSe crystal.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

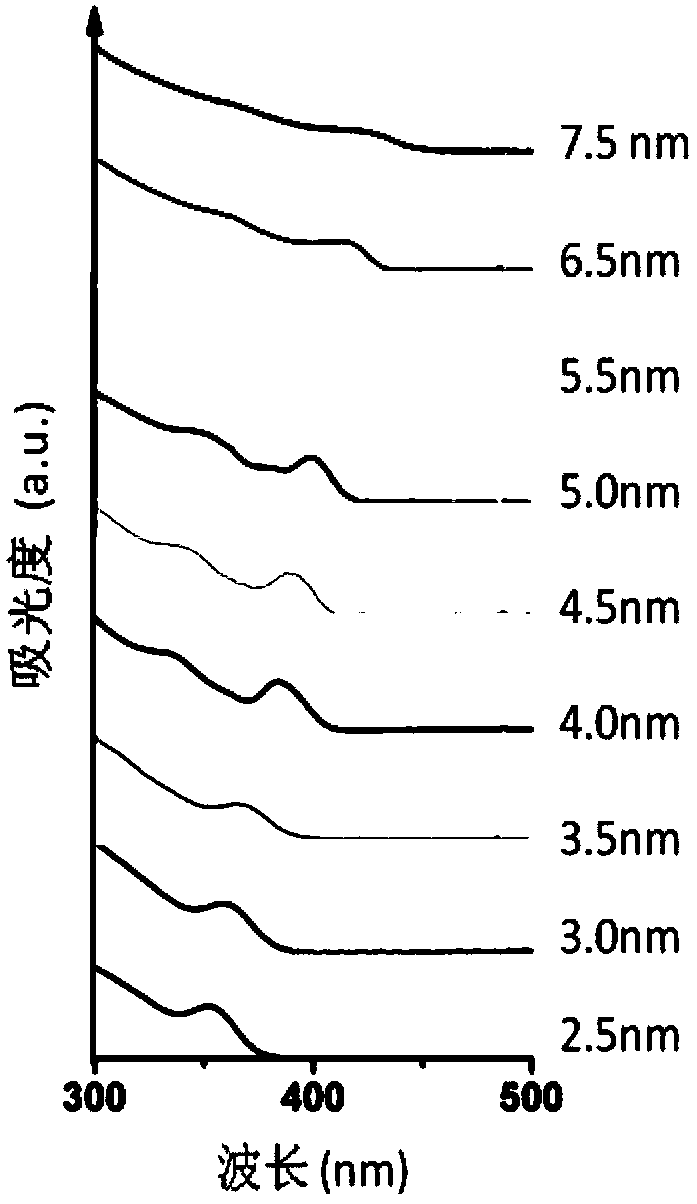

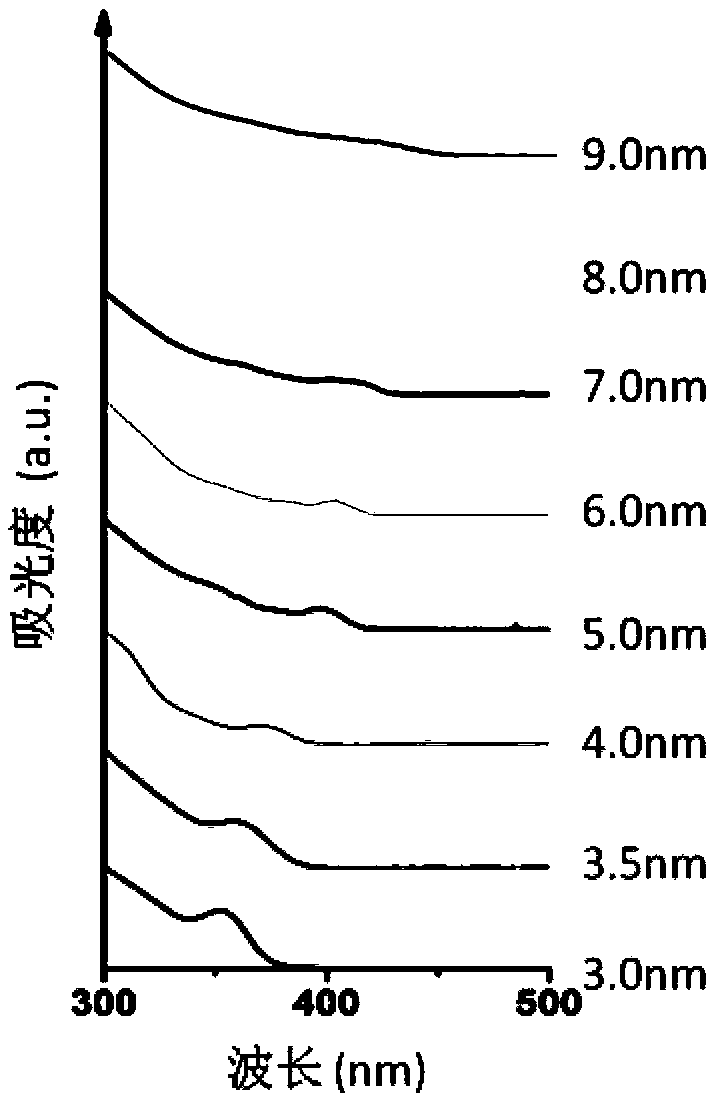

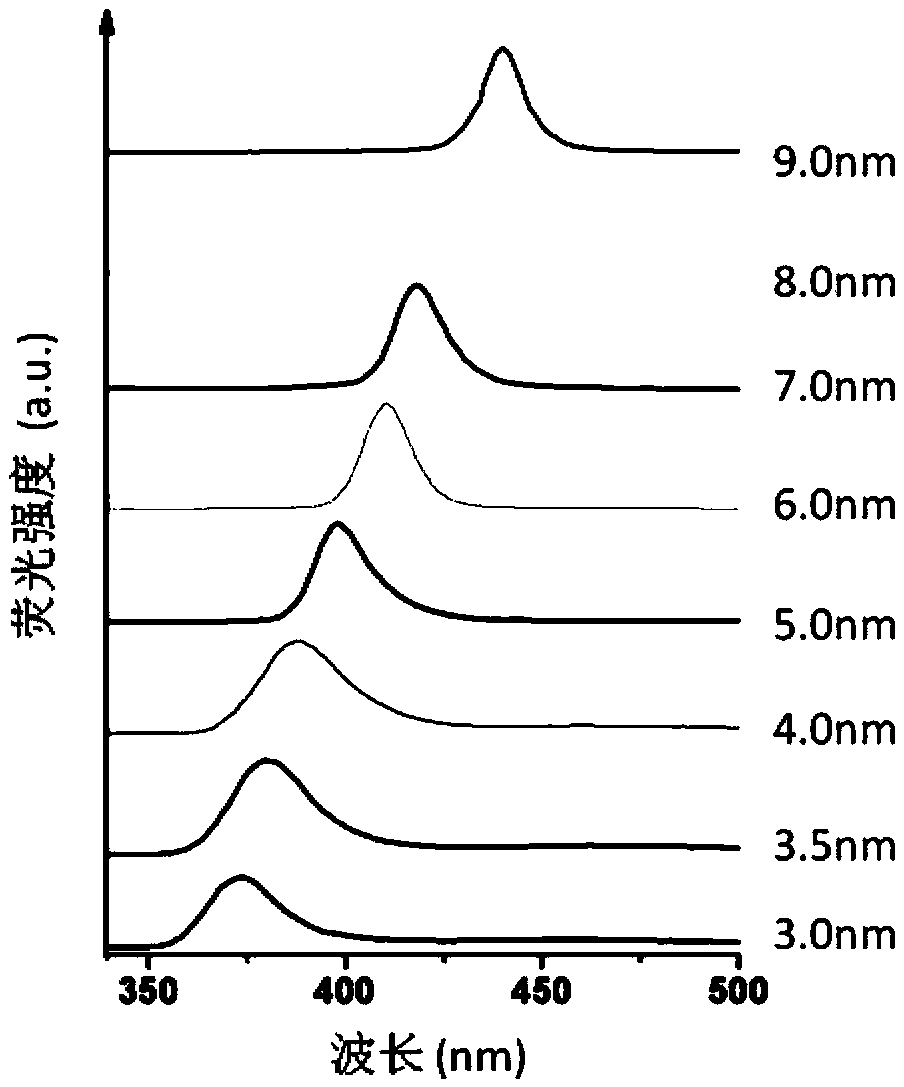

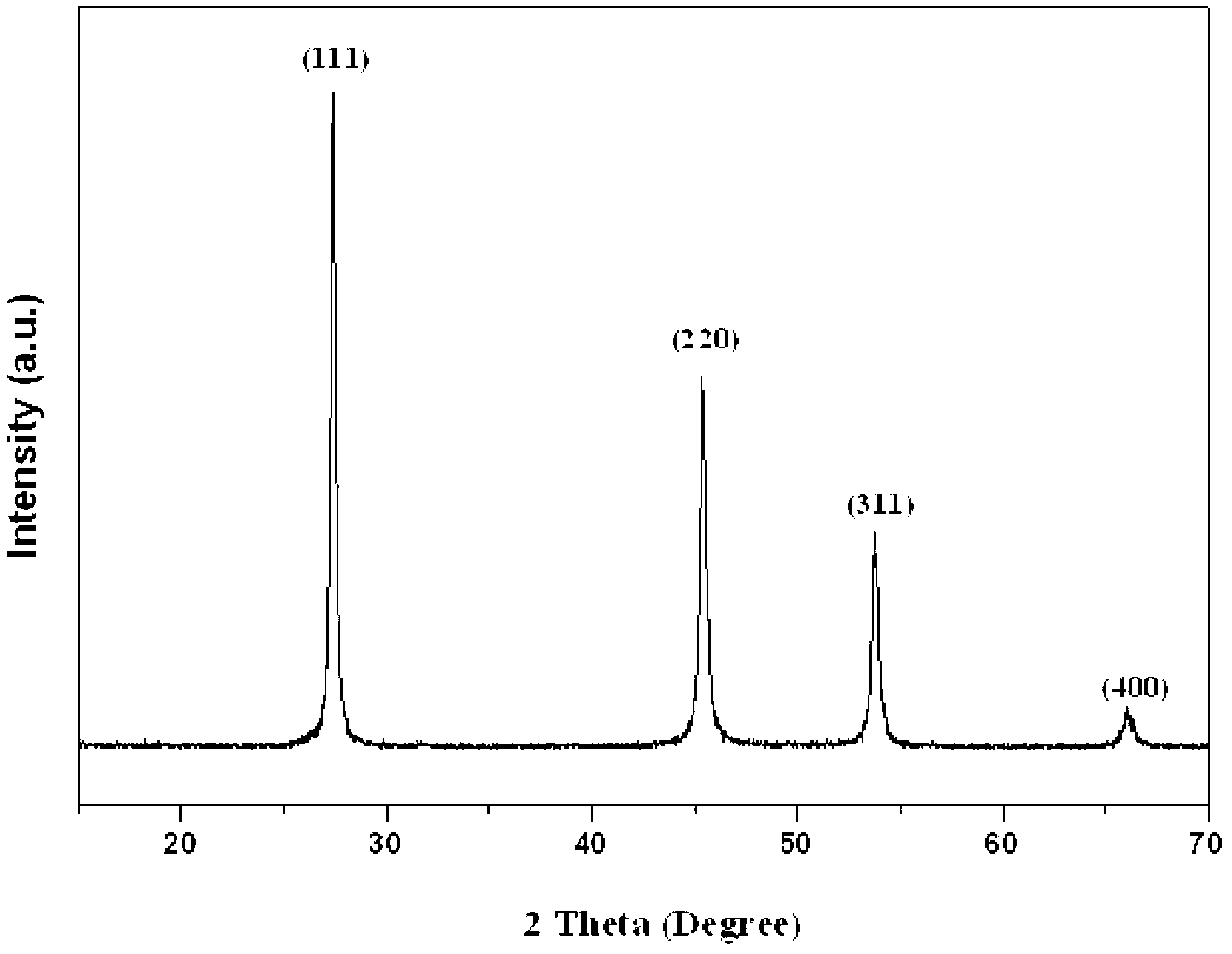

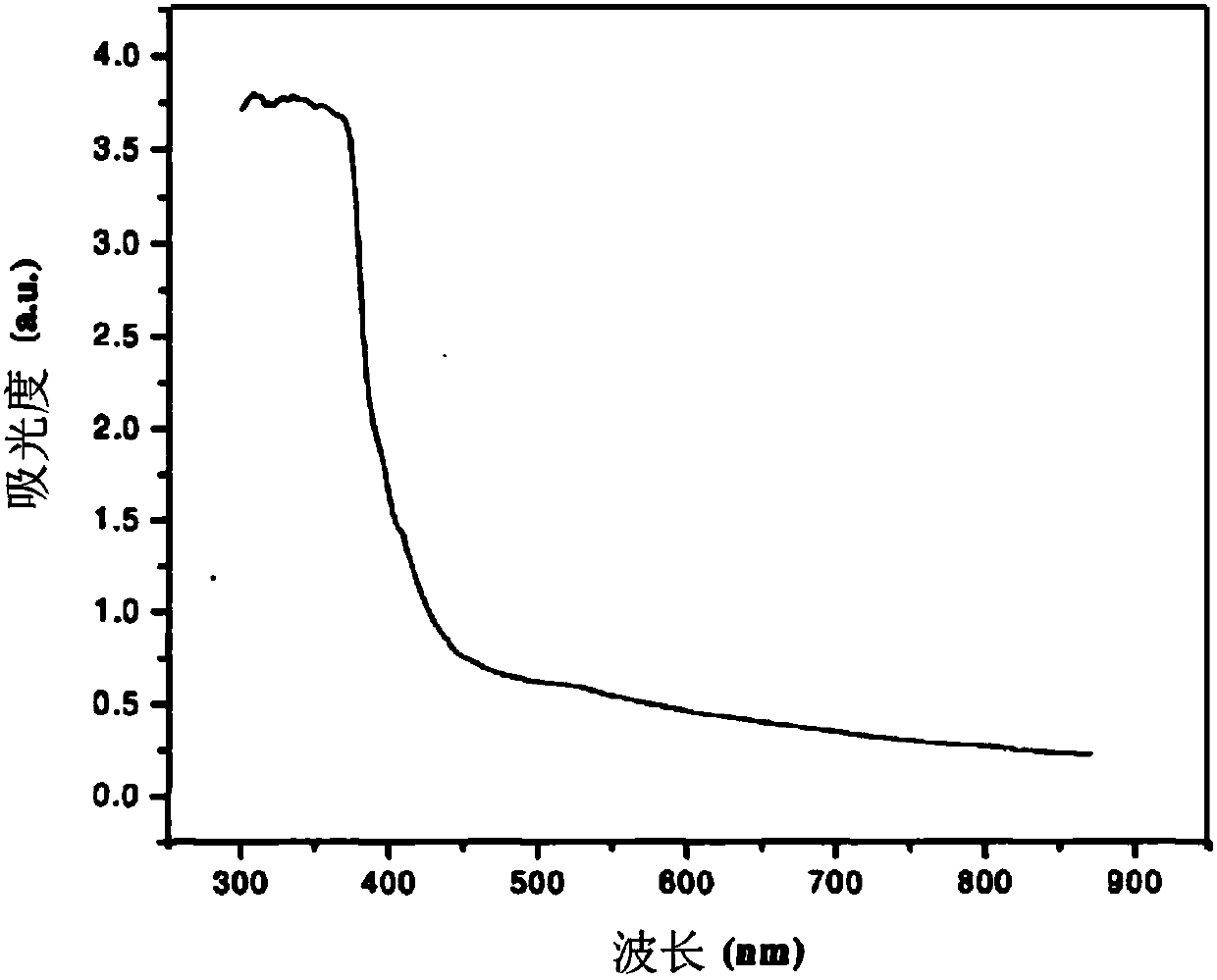

Quantum dot and preparation method thereof

ActiveCN108795412AFluorescence enhancementImprove stabilityNanotechnologyLuminescent compositionsFluorescencePhotoluminescence

The invention discloses a quantum dot and a preparation method thereof. Compared with the prior art, the quantum dot has the advantages that the synthesized precursor and steps are environment-friendly, any heavy metal element is not contained in the product, and the photoluminescence spectrum is particular and excellent; specifically, the range of fluorescence transmission peak is 370 to 450nm, the semi-height width of the fluorescence transmission peak is 10.8 to 20nm, and the efficiency of fluorescence quantum is 47 to 88%; the size of the prepared nanometer crystal is 1.5 to 9mm, and the deviation is smaller than 10%; the quantum dot specifically comprises ZnSe (zinc selenide), ZnSe / ZnS (zinc sulfide) and ZnSe / ZnSeS / ZnS.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

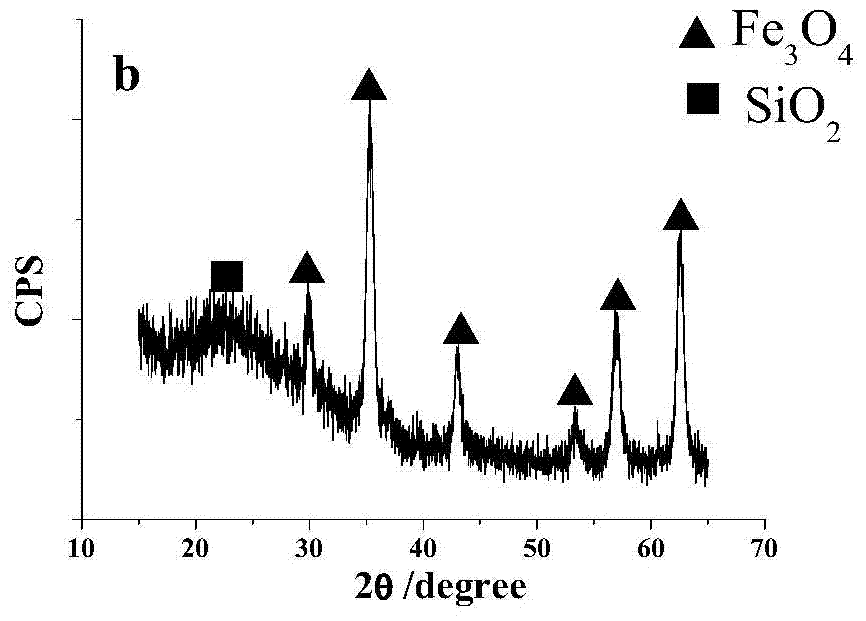

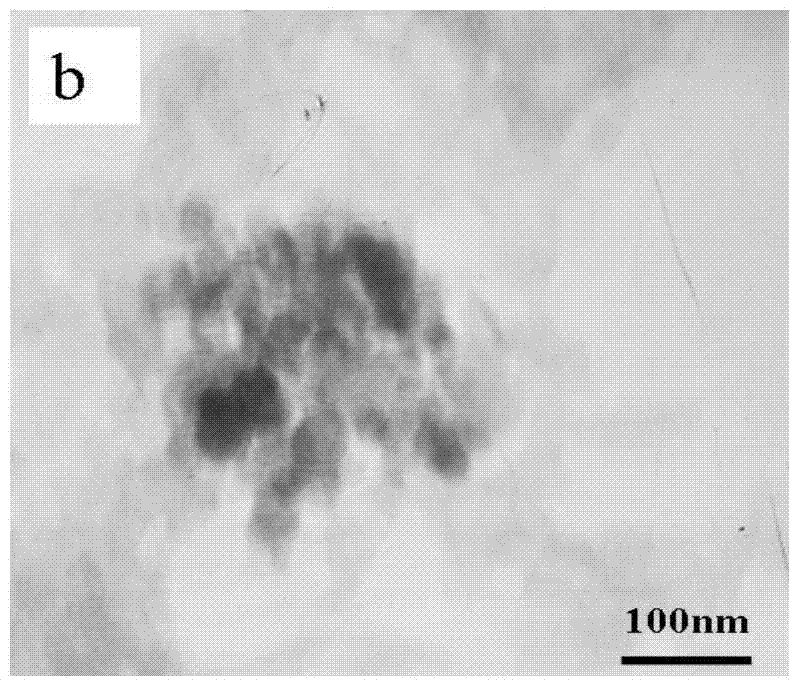

Preparation method of ferroferric oxide@silicon dioxide@zinc selenide fluorescent magnetic nanometer particles

InactiveCN103614143AMild reaction temperatureEasy to implementMaterial nanotechnologyInorganic material magnetismEmulsionFluorescence

The invention discloses a preparation method of ferroferric oxide@silicon dioxide@zinc selenide fluorescent magnetic nanometer particles. The preparation method is characterized in that the silicon dioxide grows on ferroferric oxide nano particles in situ, obtained ferroferric oxide@silicon dioxide particles are composited with quantum dots, and the ferroferric oxide@silicon dioxide@zinc selenide fluorescent magnetic nanometer particles are prepared by adopting a reverse micro-emulsion method. A device needed in the preparation method is simple, the preparation method is easily realized, the nanometer particles obtained through the method are unlikely to aggregate, and the granularity distribution is uniform.

Owner:TIANJIN UNIV

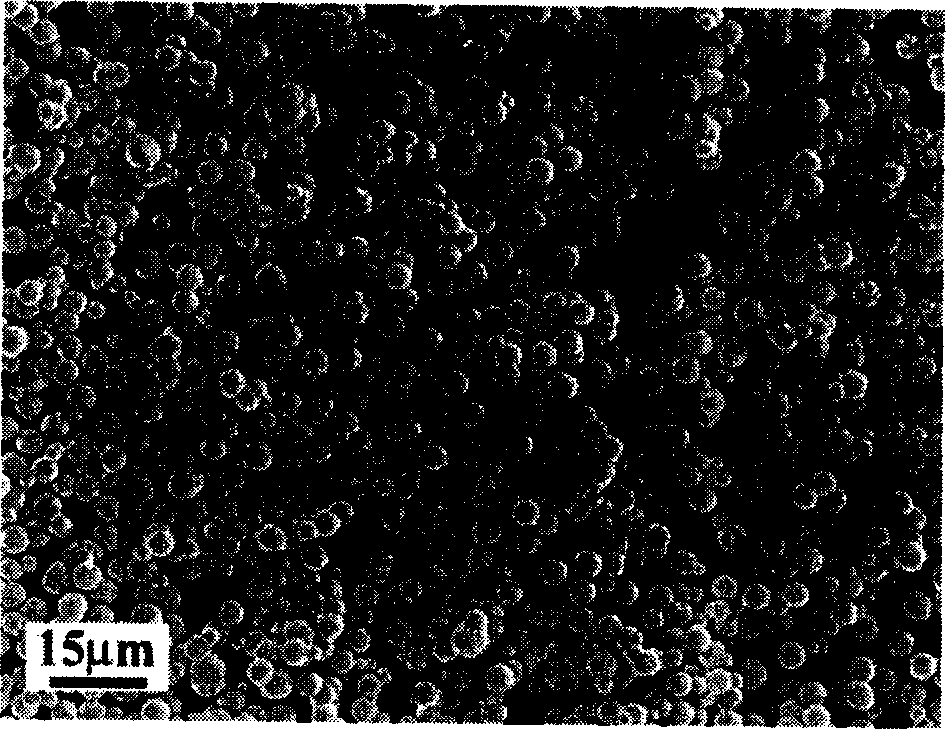

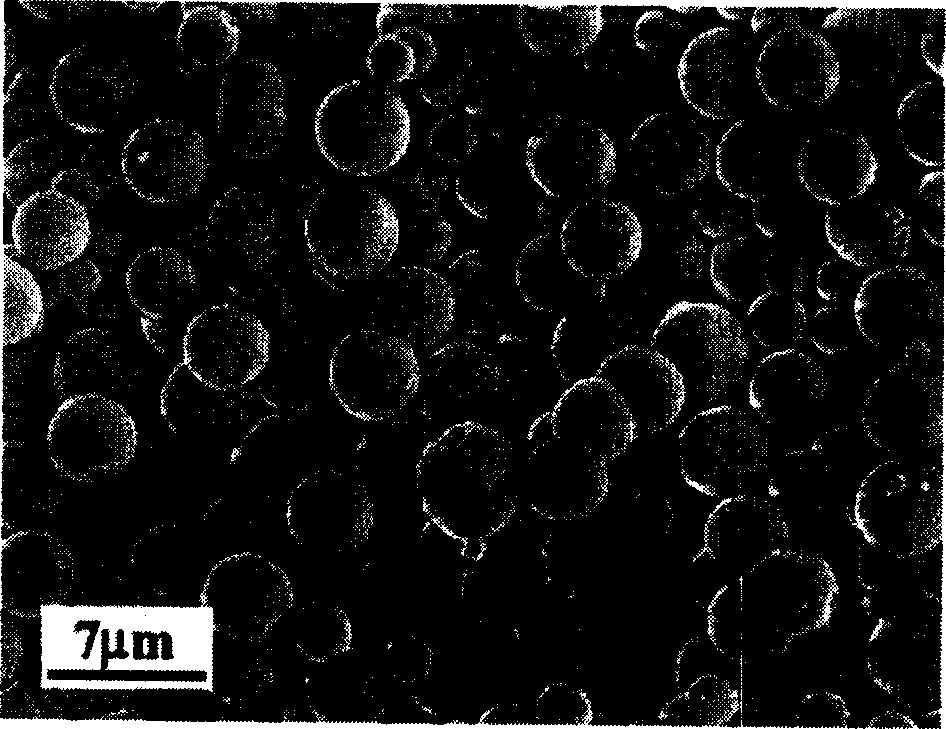

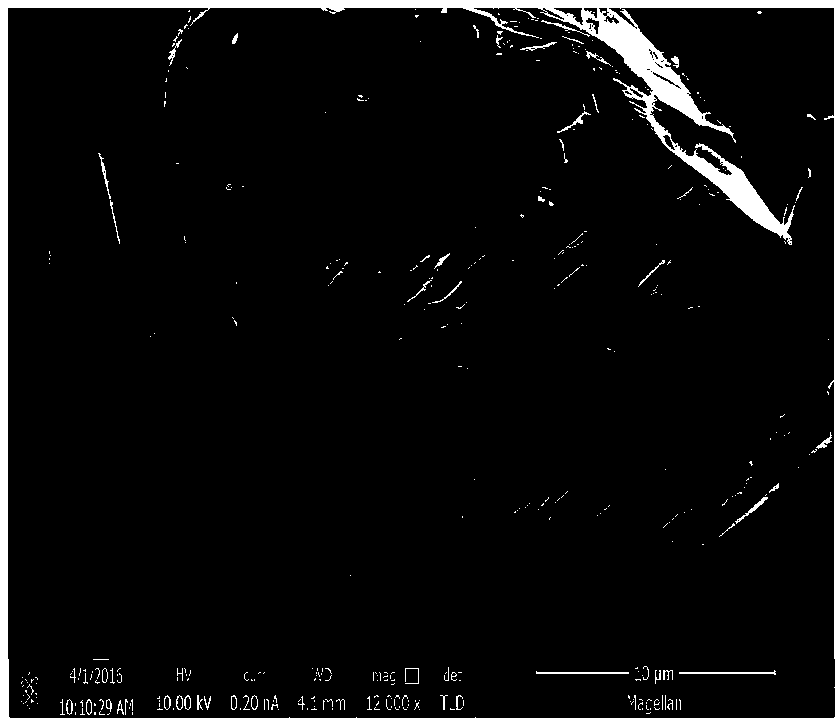

Synthesis method of ZnSe hollow microspheres by alcohol thermal reduction

InactiveCN103159189AReduce usageEasy to operateMaterial nanotechnologyBinary selenium/tellurium compoundsMicrosphereActive agent

The invention discloses a method for preparing hollow ZnSe microspheres by an alcohol thermal reduction route. By using sodium selenite as a selenium source, ethylene glycol (EG) as a reducer and ethylene diamine tetraacetic acid (EDTA) as a complexant, one-step alcohol thermal reduction reaction is carried out in an EG-water mixed solution to prepare the hollow ZnSe microspheres. In the reaction process, no surfactant or any other template is needed, and the 140-220 DEG C hydrothermal reaction is carried out for 6-24 hours to obtain the zinc selenide hollow microspheres of which the diameter is 1-3 mu m and the wall thickness is 100-200 nm. The coordination of the EDTA with metallic ions in an alkaline environment has an important action on the formation of the hollow microspheres. The method has the characteristics of simple technical route and the like, is convenient to operate and is environment-friendly.

Owner:NANJING UNIV OF SCI & TECH

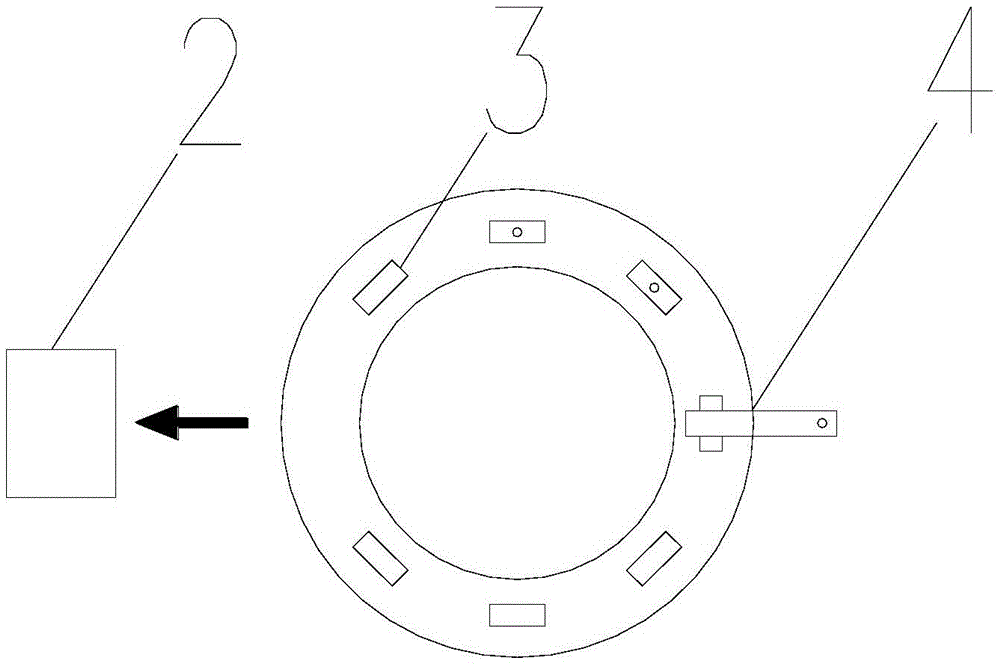

High performance liquid chromatography and Fourier transform infrared spectroscopy combined interface device

InactiveCN105606718ARealize complementary advantagesMake up for the lack of qualitative analysisComponent separationRotary stageBatch processing

The invention discloses a high performance liquid chromatography (HPLC) and Fourier transform infrared spectroscopy (FTIR) combined interface device, and belongs to the field of environmental studies. The device is composed of seven components: an optical table, a zinc selenide (ZnSe) crystal, a round drive rotary table, a heating casing pipe, an atomizer, a cleaning device and a drying device. A target pollutant enters a heating casing pipe and atomizer integrated device after being separated by a chromatography column, is heated and atomized, and then is evenly sprayed on the surface of the ZnSe crystal, and the ZnSe crystal is rotated to the optical table from the round drive rotary table. Infrared light enters the ZnSe crystal at a certain angle through the optical table, is reflected, then enters an FTIR detector and is subjected to atlas analysis. The ZnSe crystal having testing completed is transferred to the cleaning device and the drying device successively, is washed and dried respectively and then is re-used. The round rotary table carries the crystal and a sample for reciprocating detection by means of rotation, and sample batch processing and on-line detection are realized.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

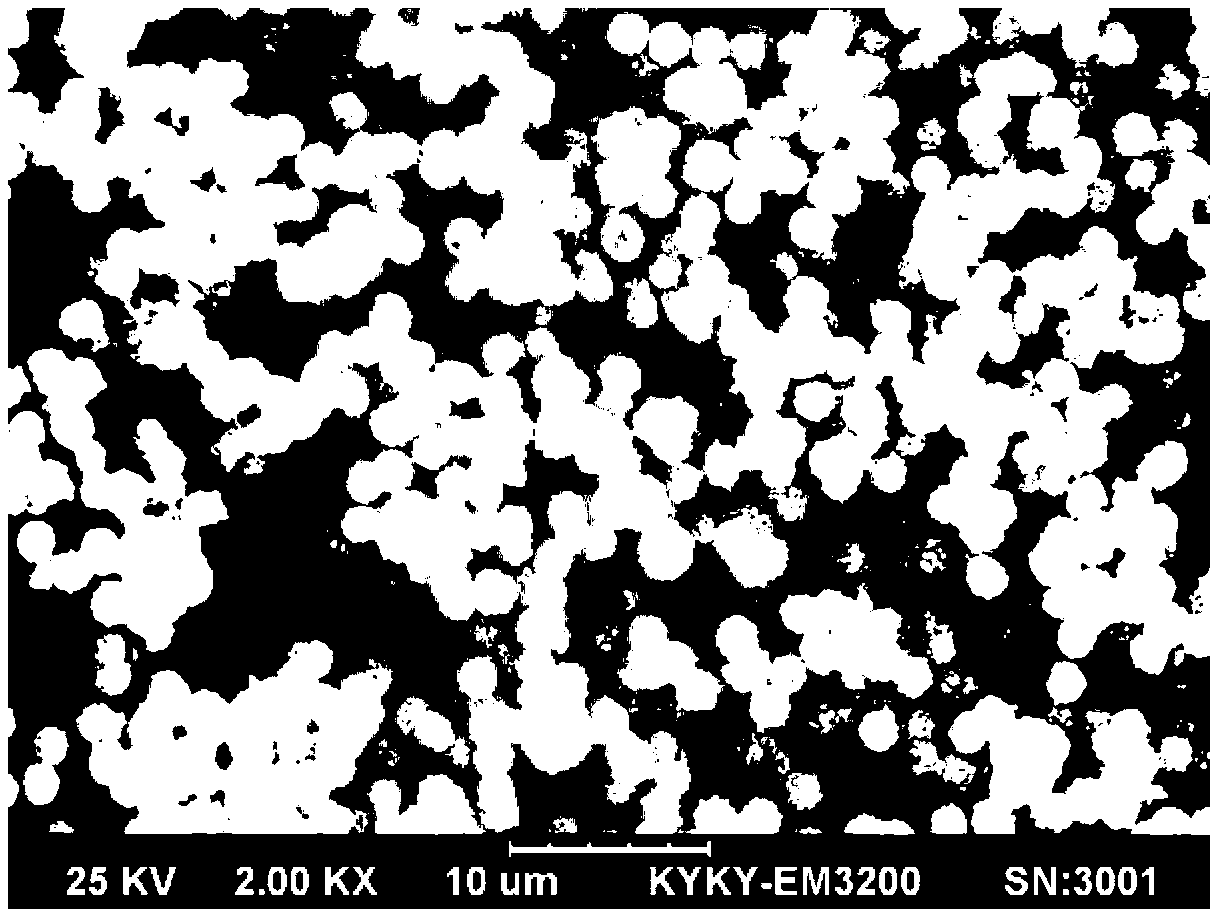

Preparation method of zinc selenide nanometer powder

InactiveCN102659084AUniform shapeUniform sizeNanotechnologyBinary selenium/tellurium compoundsChemical synthesisSolution treatment

The invention provides a preparation method of zinc selenide nanometer powder, belonging to the technical field of a hydrothermal chemical synthesis nanometer material process. According to the preparation method provided by the invention, the zinc selenide nanometer powder is prepared by using two kinds of solid powder of ZnCl2*2H2O and SeO2 as raw materials and using hydrazine as a reducing agent through steps of reacting, heating, washing, drying and the like. The zinc selenide powder obtained from the invention has the advantages of high purity, uniform size, good dispersibility, safe technical process, easiness of auxiliary solution treatment, easiness of product treatment, no pollution and the like. Accordingly, the preparation method provided by the invention has very wide application prospect.

Owner:SHANDONG JIANZHU UNIV

Production process of zincium selenious acid

InactiveCN101172584AIncrease profitSimple production processSelenium/tellurium compundsZinc compoundsSelenious AcidAqueous solution

The invention discloses a zinc selenite production method, which comprises the following steps: step one, 500 to 700 g of selenium dioxide is weighed, added into 1.5 to 2.5 L of water, and stirred to lead the selenium dioxide to be completely dissolved in the water; step two, the selenium dioxide water solution obtained in step one is added with 400 to 500 g of zinc oxide, and is stirred to be completely dissolved; step three, the deposited matter obtained in step two is cleaned, filtered, dried and crushed, and then the zinc selenite product is produced.

Owner:FIRST RARE MATERIALS CO LTD

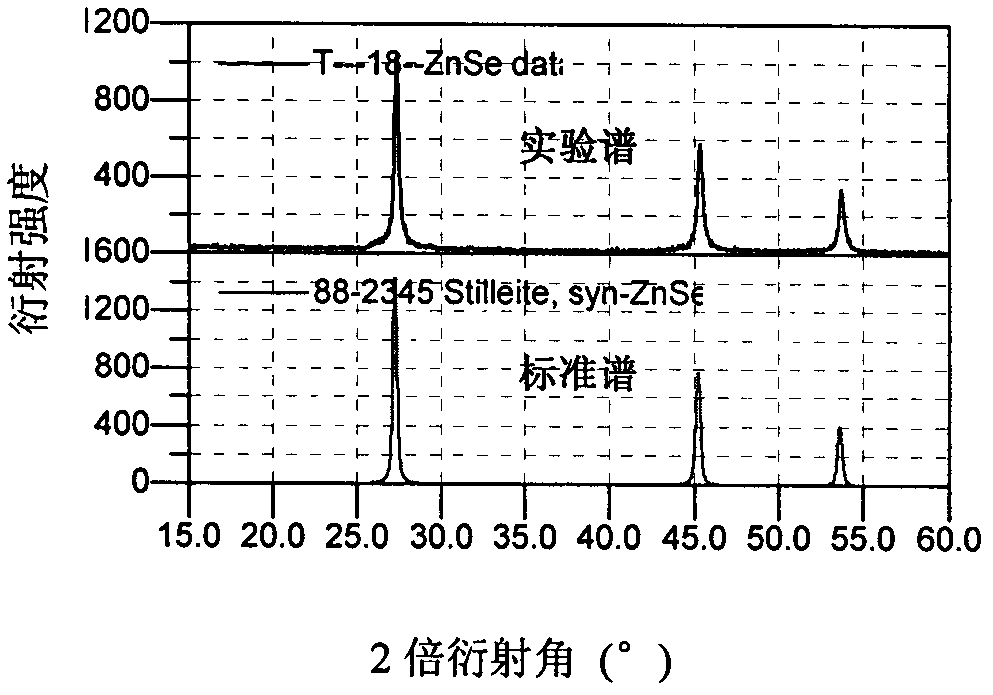

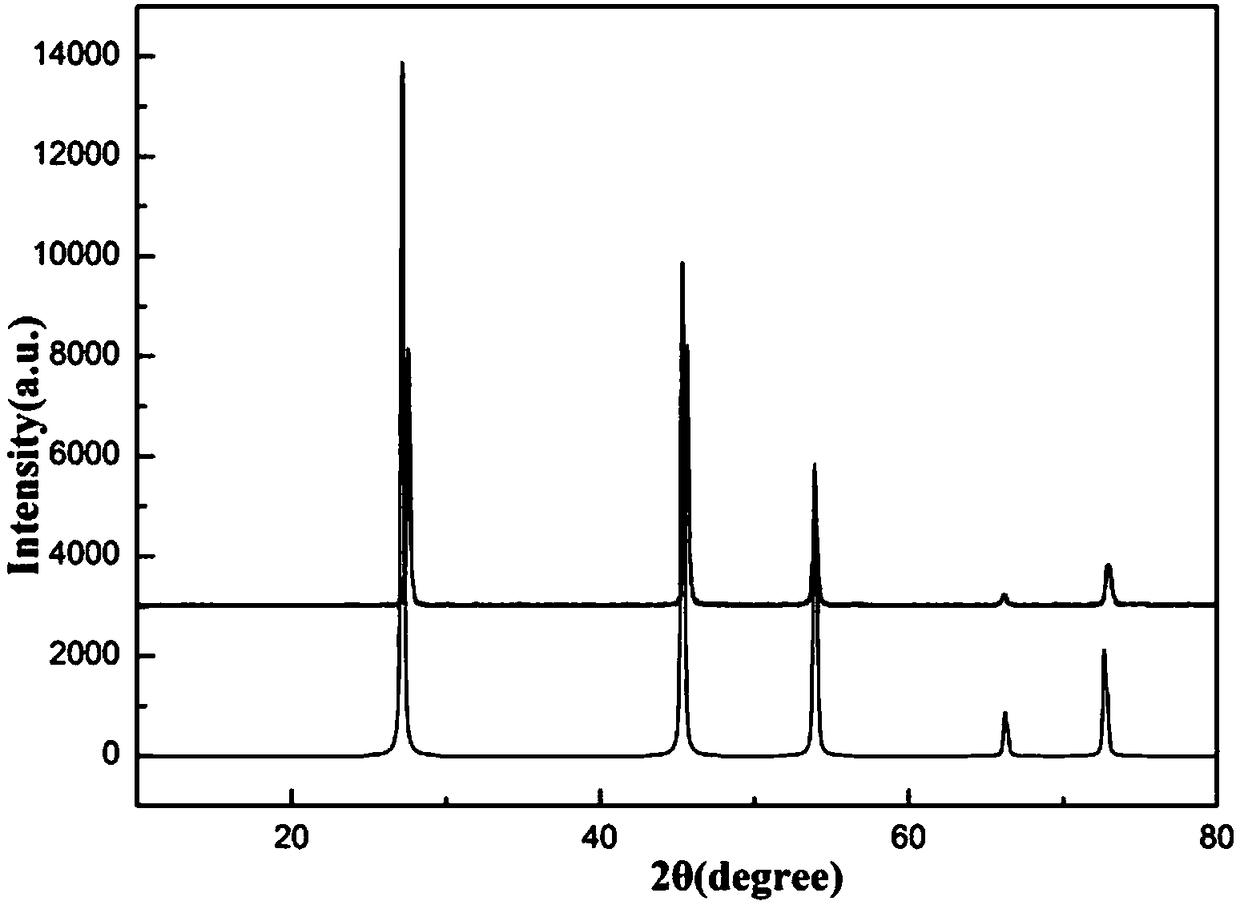

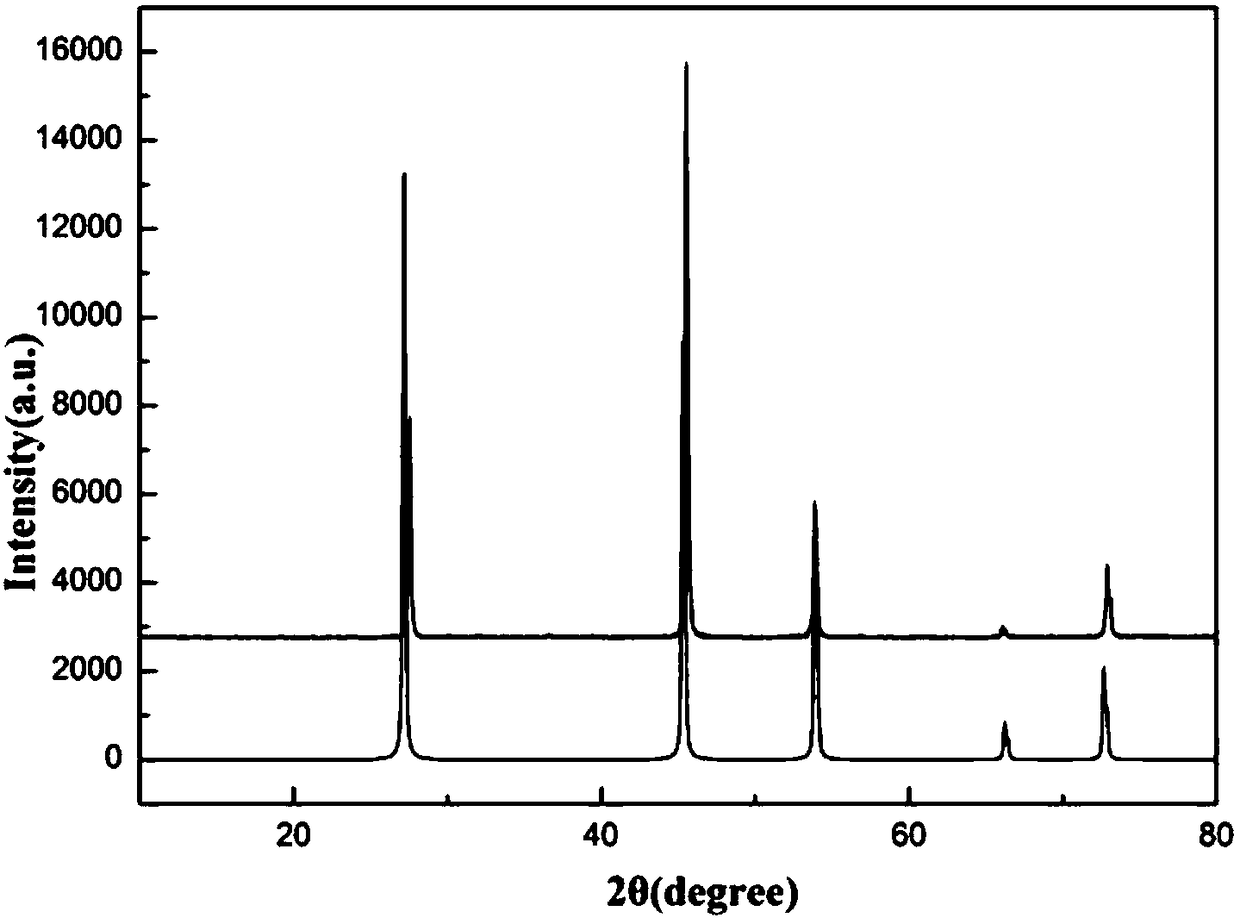

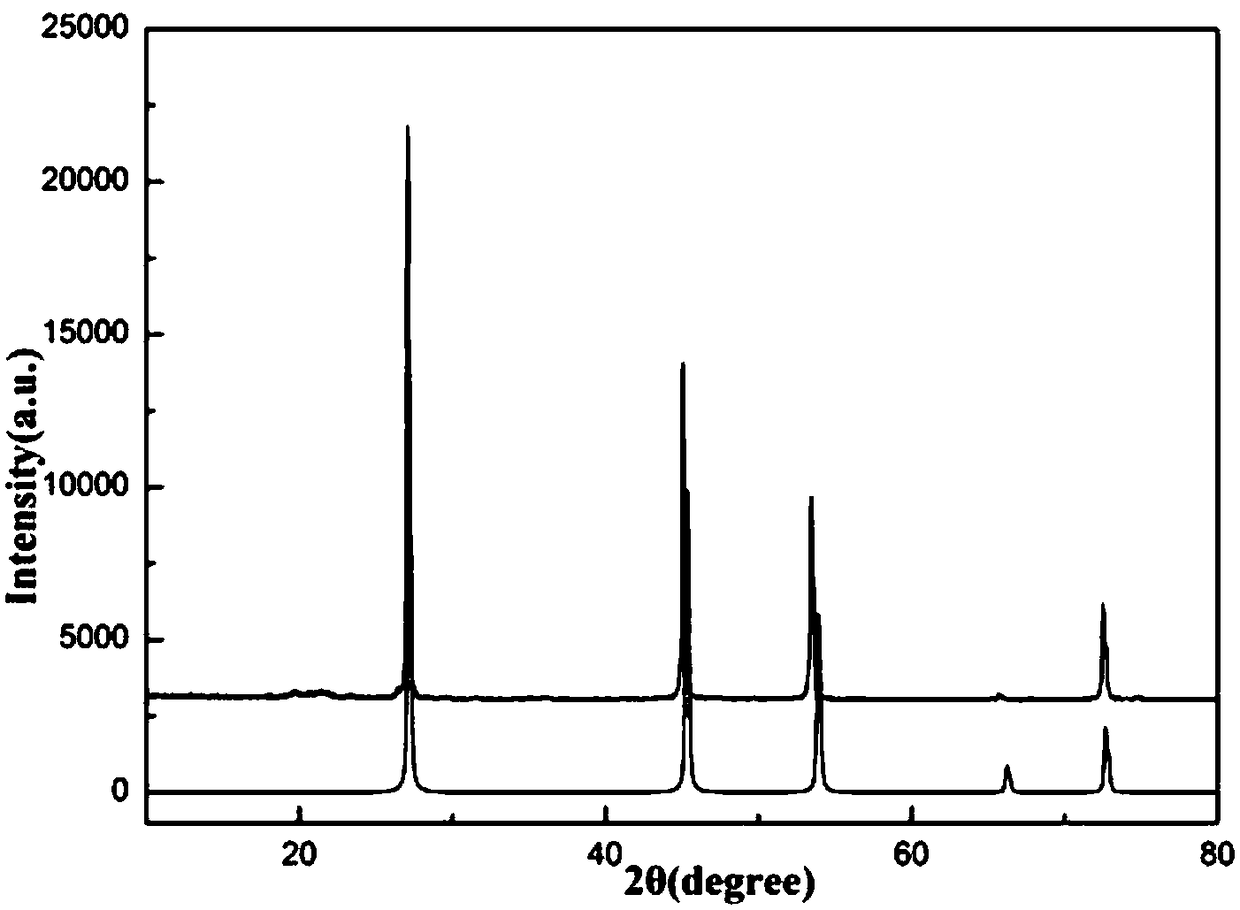

High-temperature high-pressure preparation method of zinc selenide polycrystalline bulk material

InactiveCN108358177AHigh purityShorten cycle timePolycrystalline material growthMetal selenides/telluridesSynthesis methodsHigh pressure

The invention provides a high-temperature high-pressure preparation method of a zinc selenide polycrystalline bulk material. According to the method, two kinds of elementary substances of selenium (Se) powder and zinc (Zn) powder are used as raw materials; through the technological processes of raw material mixing, briquetting, assembling, high-temperature high-pressure pressing and cooling pressure release, a molybdenum tungsten bicarbonate bulk material is prepared. A zinc selenide optical material with high purity and high transmission rate is prepared by a high-temperature high-pressure synthesis method; the material ingredient and purity of zinc selenide are regulated by optimizing the mass proportion and regulating the synthesis temperature and pressure; the high-purity bulk zinc selenide optical material is prepared. The technological process is simple; zinc oxides and sulfides do not need to be used as raw materials; the zinc selenide purity is improved by regulating the simplesubstance raw material proportion, temperature and pressure; the bulk zinc selenide material with high purity is prepared. In addition, the preparation period and the sintering time of a traditionalhot pressing sintering method are greatly shortened; the synthetized bulk material is favorable for optimizing the optical performance.

Owner:MUDANJIANG NORMAL UNIV

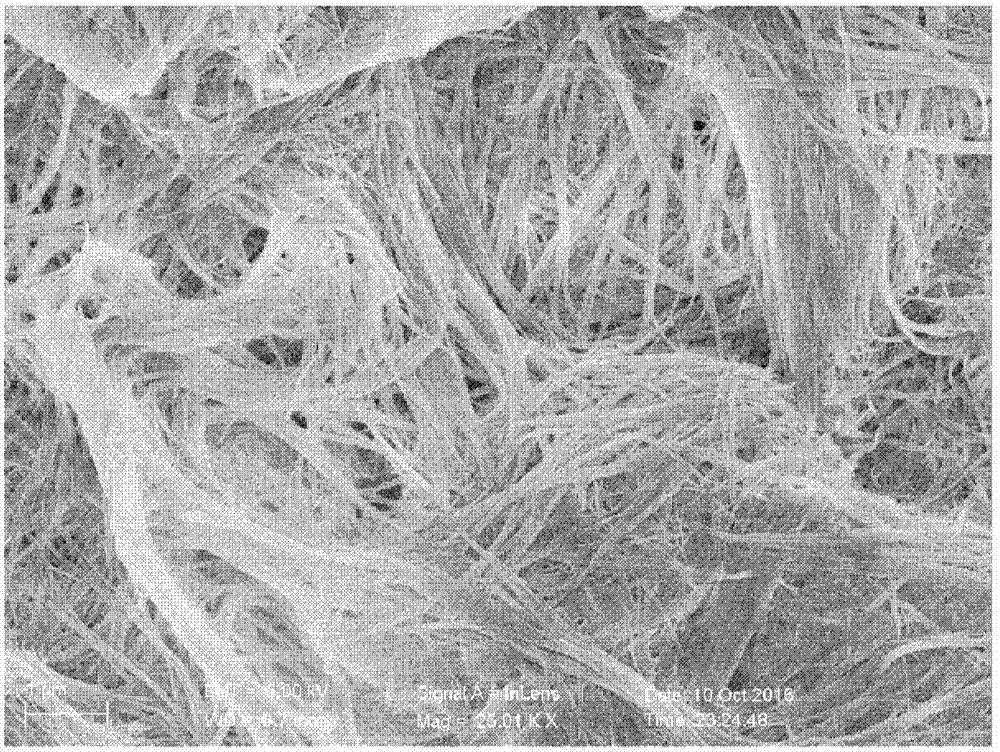

Carbon nanotube-modified electrode and preparation method thereof

InactiveCN105911119AImprove catalytic performanceHigh selectivityMaterial electrochemical variablesInfrared lampCarbon nanotube

The invention discloses a carbon nanotube-modified electrode and a preparation method thereof. The preparation method comprises modifying a glassy carbon electrode (GCE) through carbon nanotubes (MWNTs) and zinc selenide quantum dots (ZnSe QDs), wherein the carbon nanotubes, zinc selenide quantum dots and glassy carbon electrode are pre-treated before modification, mixing the treated carbon nanotubes, zinc selenide quantum dots and Nafion solution, carrying out ultrasonic treatment to obtain a uniform black mixed solution, dip-coating the treated glassy carbon electrode with the mixed solution and drying the glassy carbon electrode through an infrared lamp to obtain a ZnSe QDs / MWNTs-Nafion / GCE-modified electrode. The carbon nanotube-modified electrode has good catalytic activity and high selectivity to an object to be detected, improves a response current signal, is simple, fast, nontoxic and environmentally friendly and builds a novel method for simultaneous determination of pyrocatechol, resorcinol and hydroquinone.

Owner:LUOYANG MINGLI TECH DEV

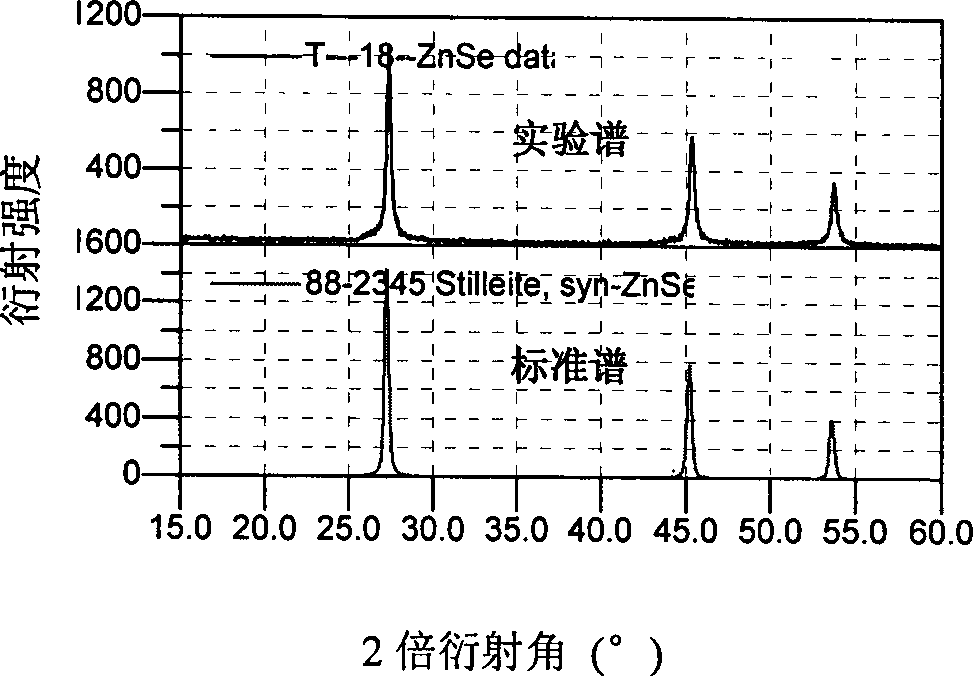

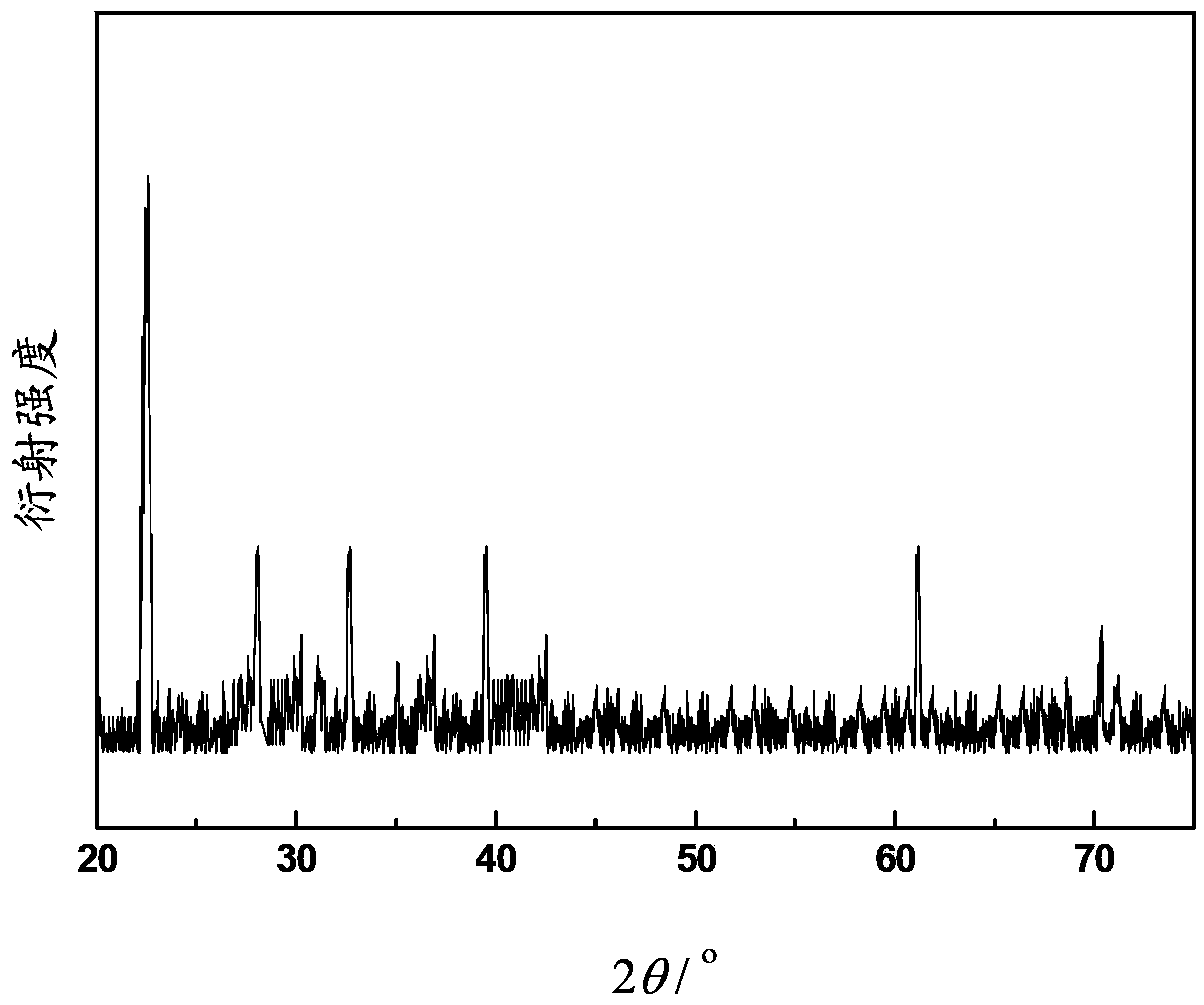

Method for preparing intermediate infrared laser transition metal ion doped-zinc selenide ceramic

The invention relates to a method for preparing intermediate infrared laser transition metal ion doped-zinc selenide ceramic. The method includes the following steps that 1, ZnSe powder and transitionmetal composition powder which are mixed evenly are subjected to impurity removal treatment, and then subjected to isostatic cool pressing forming under the pressure of 50-200 MPa; 2, a formed samplein the step1 is placed into a hexahedron ejector machine, and subjected to heat preservation and pressure maintaining for 30-180 min under the pressure of 1-6 Gpa and at the temperature of 900-1,300DEG C, and finally the ceramic is obtained. With the method for preparing the ceramic, the compactness of the ceramic is effectively improved, pores in the ceramic are eliminated, and therefore the comprehensive performance of the ceramic is greatly improved; sintering temperature is decreased, sintering time is shortened, and therefore adverse reactions, high-temperature volatilization and otherproblems are easily reduced.

Owner:SINOMA SYNTHETIC CRYSTALS CO LTD +1

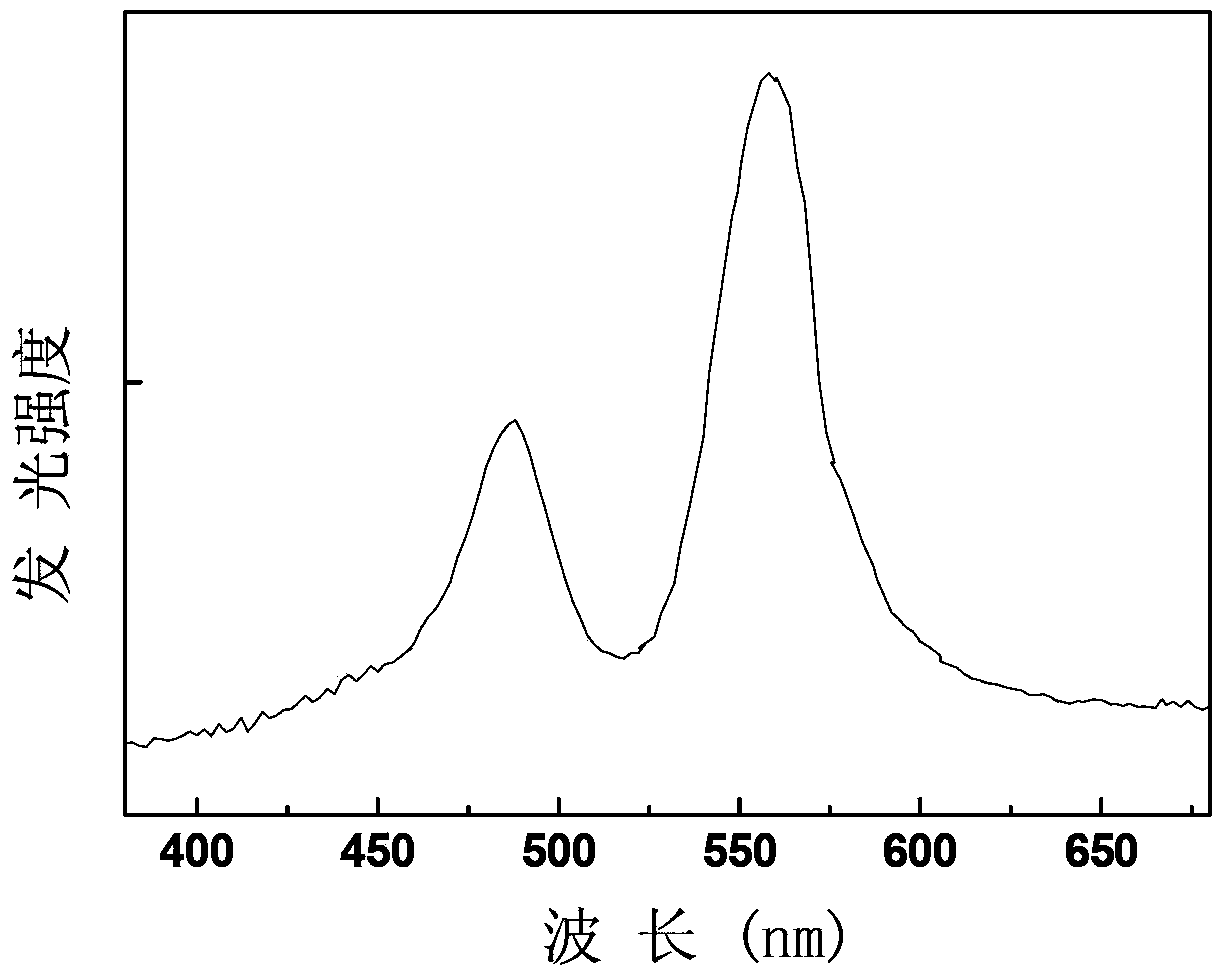

Europium-erbium double-doped zinc selenide luminescent material, and preparation method and application thereof

InactiveCN104342158AStrong luminescent peakLuminescent compositionsSemiconductor devicesElectroluminescence spectraLength wave

The invention provides an europium-erbium double-doped zinc selenide luminescent material with a chemical formula of ZnSe:xEu<3+>,yEr<3+>, wherein x is 0.01-0.05, y is 0.01-0.06, ZnSe is a matrix, and Eu<3+> and Er<3+> ions are active elements. In an electroluminescence spectrum (EL) of a luminescent thin film prepared with the europium-erbium double-doped zinc selenide luminescent material, strong luminescence peaks can be found at 490nm and 580nm wavelength zones. The material can be used in a thin-film electroluminescent display device. The invention also provides a preparation method and an application of the europium-erbium double-doped zinc selenide luminescent material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

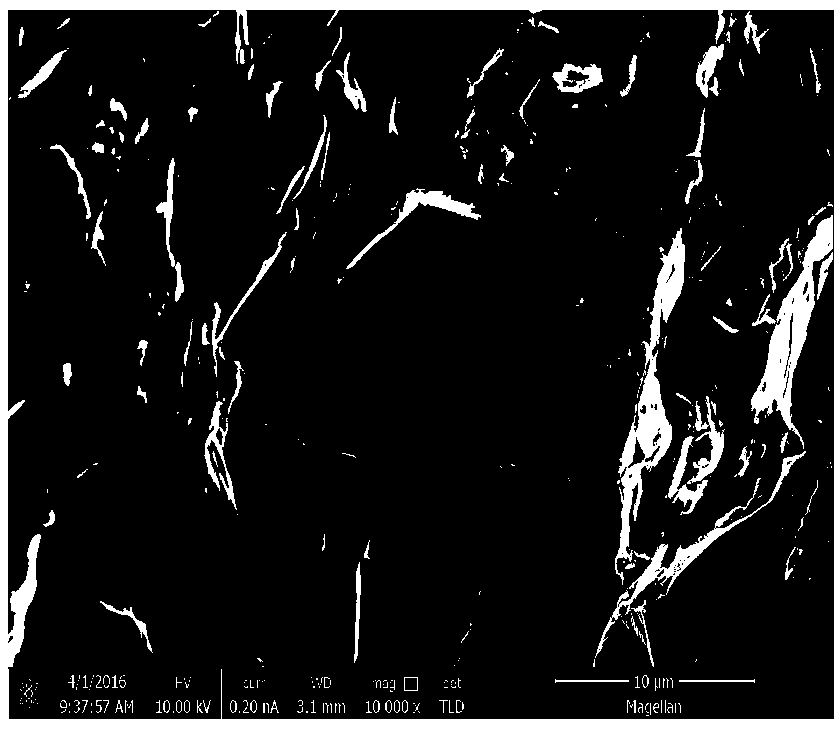

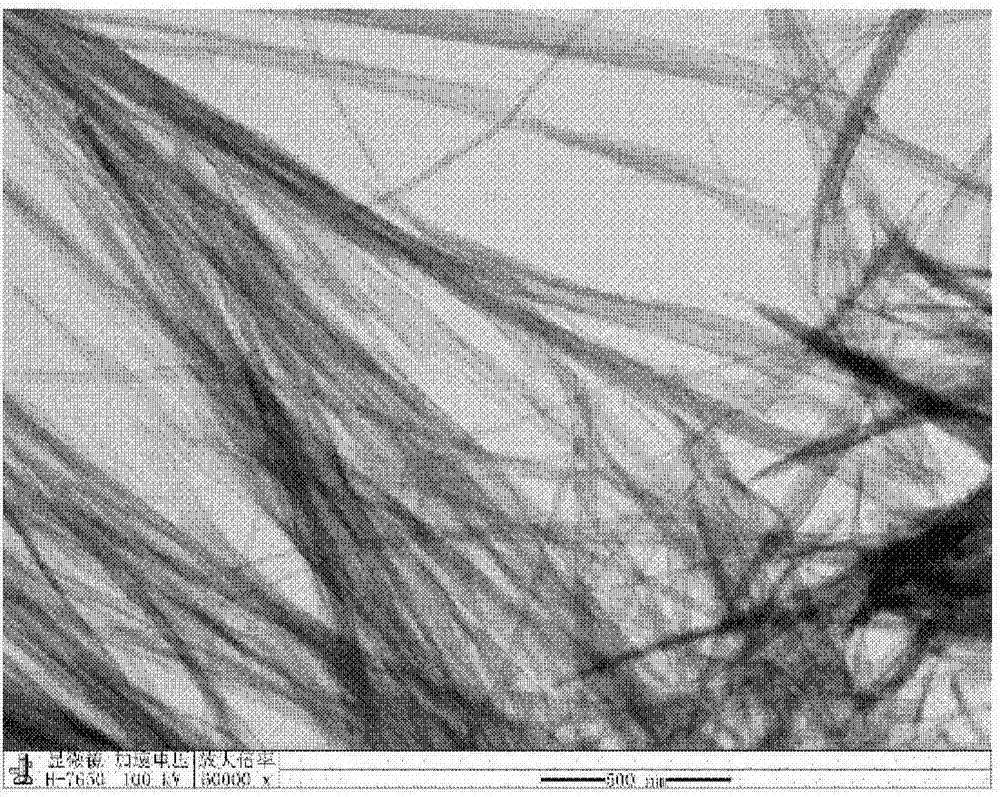

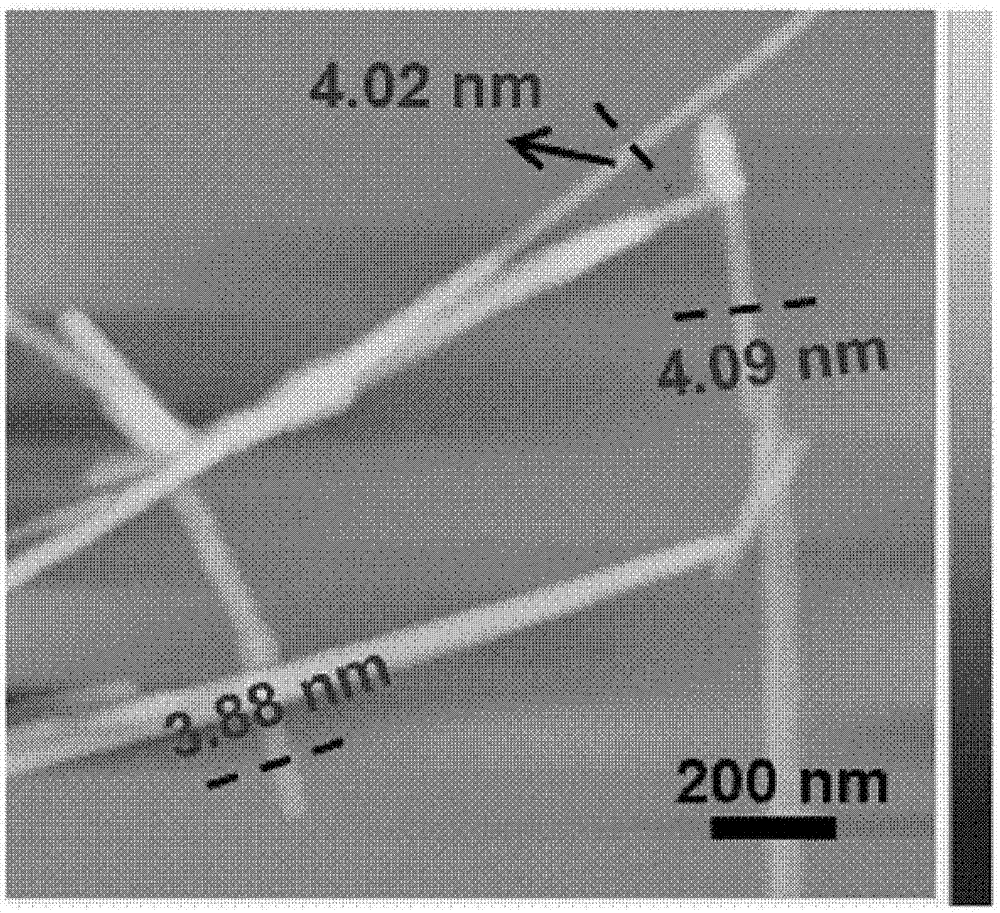

Zinc selenide ultrathin nanoribbon and anion exchange method for preparing same

ActiveCN107572489AExcellent photohydrogen production performanceGreat application potentialMaterial nanotechnologyHydrogen productionPhotonicsIon exchange

The invention provides a zinc selenide ultrathin nanoribbon and an anion exchange method for preparing the same. The zinc selenide ultrathin nanoribbon is of an ultrathin ribbon structure with the length being 5-10mu m, the width being 17-19nm and the thickness being less than 5nm, and a conspicuous porous structure is formed on the surface of the zinc selenide ultrathin nanoribbon. In addition, the invention further provides a zinc selenide / molybdenum disulfide heterogeneous nanoribbon which is prepared from the zinc selenide ultrathin nanoribbon as a raw material, and a preparation method ofthe zinc selenide / molybdenum disulfide heterogeneous nanoribbon. The zinc selenide nanoribbon provided by the invention is good in water solubility, dispersibility and photonic hydrogen production catalysis activity; and due to the heterogeneous structure molybdenum disulfide, the photocatalytic performance is further remarkably improved.

Owner:UNIV OF SCI & TECH OF CHINA

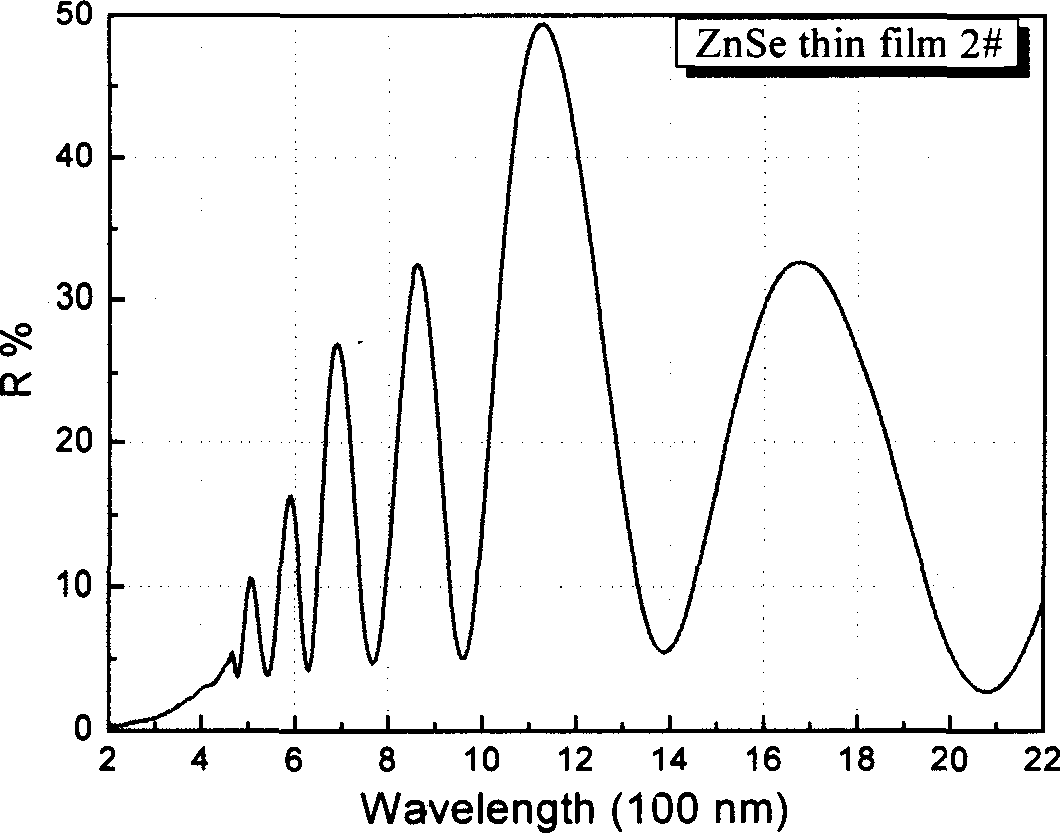

Preparation method of zinc selenide with high optical quality

ActiveCN101759161BSolve build problemsHigh infrared transmittanceBinary selenium/tellurium compoundsPhysical chemistryChemical vapor deposition

Owner:GRINM GUOJINGHUI NEW MATERIALS CO LTD +1

Zinc selenide crystal

InactiveCN104651927ATo achieve the purpose of protectionImprove qualityPolycrystalline material growthFrom condensed vaporsGas phaseSolvent

The invention discloses a zinc selenide crystal. The zinc selenide crystal is prepared by the following process: (1), screening and removing impurity from zinc selenide powder; (2), putting the treated zinc selenide powder into a physical vapor deposition furnace, and heating under a vacuum condition, so that zinc selenide vapor is solidified and deposited at the cold end from the hot end to obtain crystals; (3), checking the obtained zinc selenide crystals: cutting the zinc selenide crystals with the preset indexes of a qualified product; (4), putting the unqualified zinc selenide crystals and scraps from the cutting procedure in the step (3) into a sealed container, breaking and recycling; and (5), packaging the qualified crystals by vacuum aluminum plastic paper, and sealing the opening by utilizing a vacuum sealing machine. In the whole preparation procedure, no auxiliary materials or solvents are used, and the whole procedure is performed in a clean room; a physical vapor deposition temperature rising control operation is safe and reliable, and the internal air and the external air of the clean room are highly effectively filtered and isolated, therefore, on the one hand, the quality of products is ensured; and on the other hand, the production personnel and the external environment are protected.

Owner:XUYI XINYUAN OPTICAL SCI TECH CO LTD

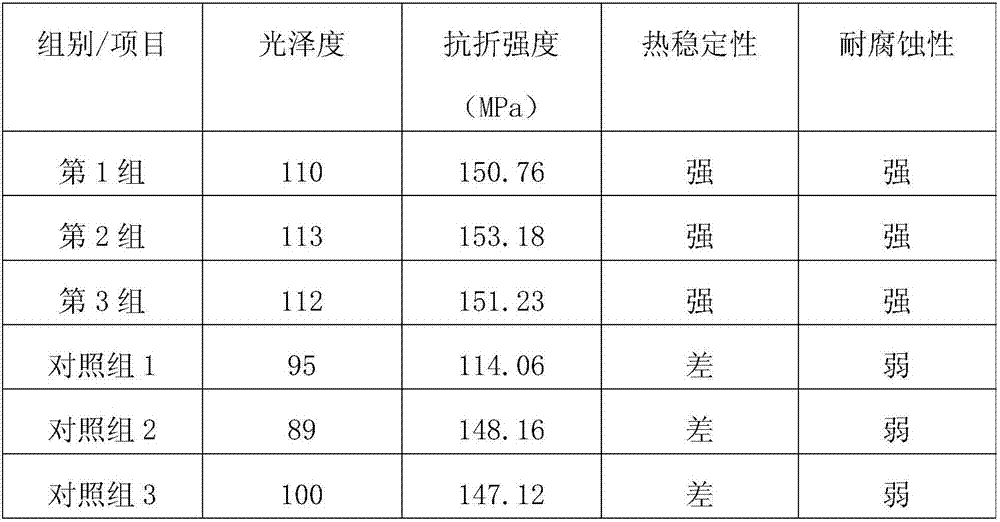

Ceramic glaze and preparation method thereof

The invention discloses a ceramic glaze and a preparation method thereof and relates to the field of ceramic glaze products. The ceramic glaze is prepared from the following raw materials: amazonite, anorthite, apatite, allophone, montmorillonite, sodium hexametaphosphate, cerium oxide, barium oxide, titanium oxide, zinc oxide, stannic oxide, zinc selenide, aluminum silicate and aluminum oxide. Through optimizing and improving the raw materials and the preparation method, the prepared ceramic glaze is capable of improving the glossiness of a ceramic product after being applied to the ceramic product; and through detection, the glossiness of the ceramic product after the ceramic glaze is used is 110-113.

Owner:韦尧天

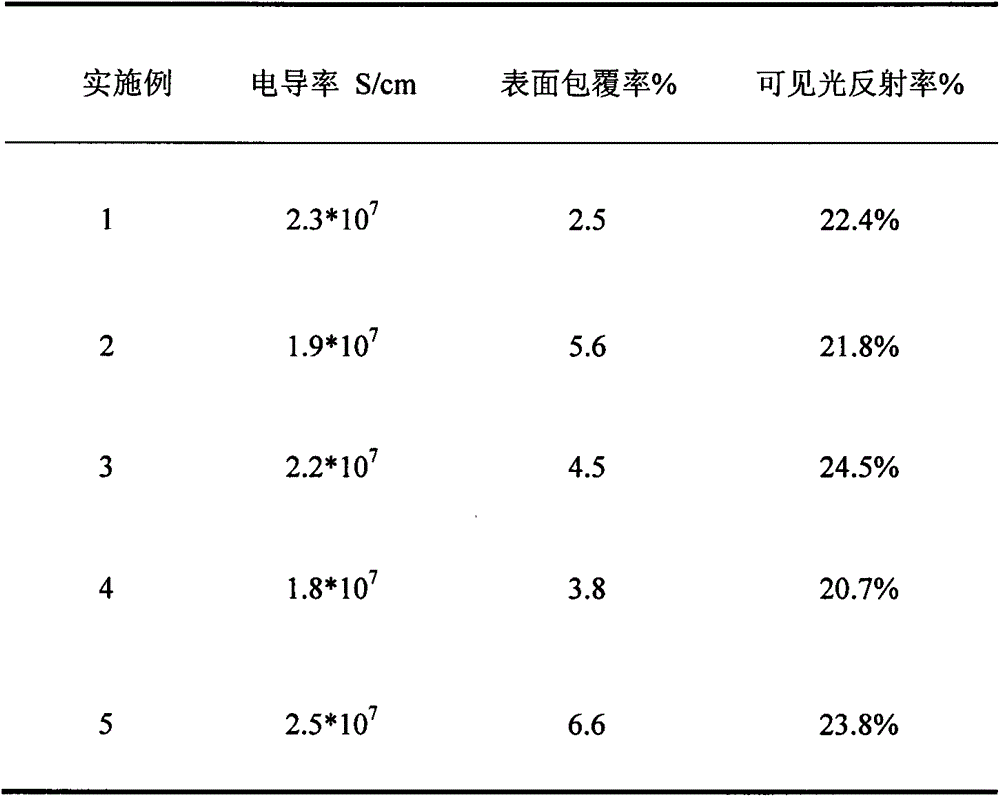

Leafing aluminum powder coated with modified film and preparing method thereof

The invention discloses leafing aluminum powder coated with a modified film and a preparing method thereof. The modified film is a zinc sulfide film or zinc selenide film which is 0.1-3 [mu]m thick. The surface of the leafing aluminum powder is coated with the zinc sulfide film or zinc selenide film which has excellent infrared transmission property, so that the obtained surface-modified leafing aluminum powder reserves the low infrared emitting ability of aluminum powder, visible light reflection is greatly reduced by means of the zinc sulfide film or zinc selenide film, and the visible light reflection ability of the leafing aluminum powder is hidden. Due to the fact that the zinc sulfide film or zinc selenide film has excellent infrared transmission property, the manufactured leafing aluminum powder coated with the modified film can be widely applied to infrared camouflage materials.

Owner:常州市武进晨光金属涂料有限公司

Method For Obtaining Polycrystal Optical Zinc Selenide

ActiveCN102400212AImprove optical qualityIncrease productionPolycrystalline material growthFrom condensed vaporsEvaporationCooling down

The invention, belonging to the optical medium technology field, provides a method for obtaining polycrystal optical material, particularly a method for obtaining polycrystal optical zinc selenide. The method comprises heating and evaporating of the raw material. The steam is condensed upon the heated substrate. The raw material carries out evaporation at a temperature ranging from 1050 DEG C to 1150 DEG C, with the steam being condensed upon the substrate while the substrate being heated to a temperature within the range of 950 to 1050 DEG C. To improve the quality of the obtained product, the speed of the steam depositing upon the substrate shall be controlled. The cultivated blank shall be cooled down via the specific technology, thereby decreasing the internal stress of the blank. The method improves the technology for obtaining large-sized optical material blanks, raises the optical quality of the material used within the visible light and infrared spectrum range, and improves the yield of the qualified products.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

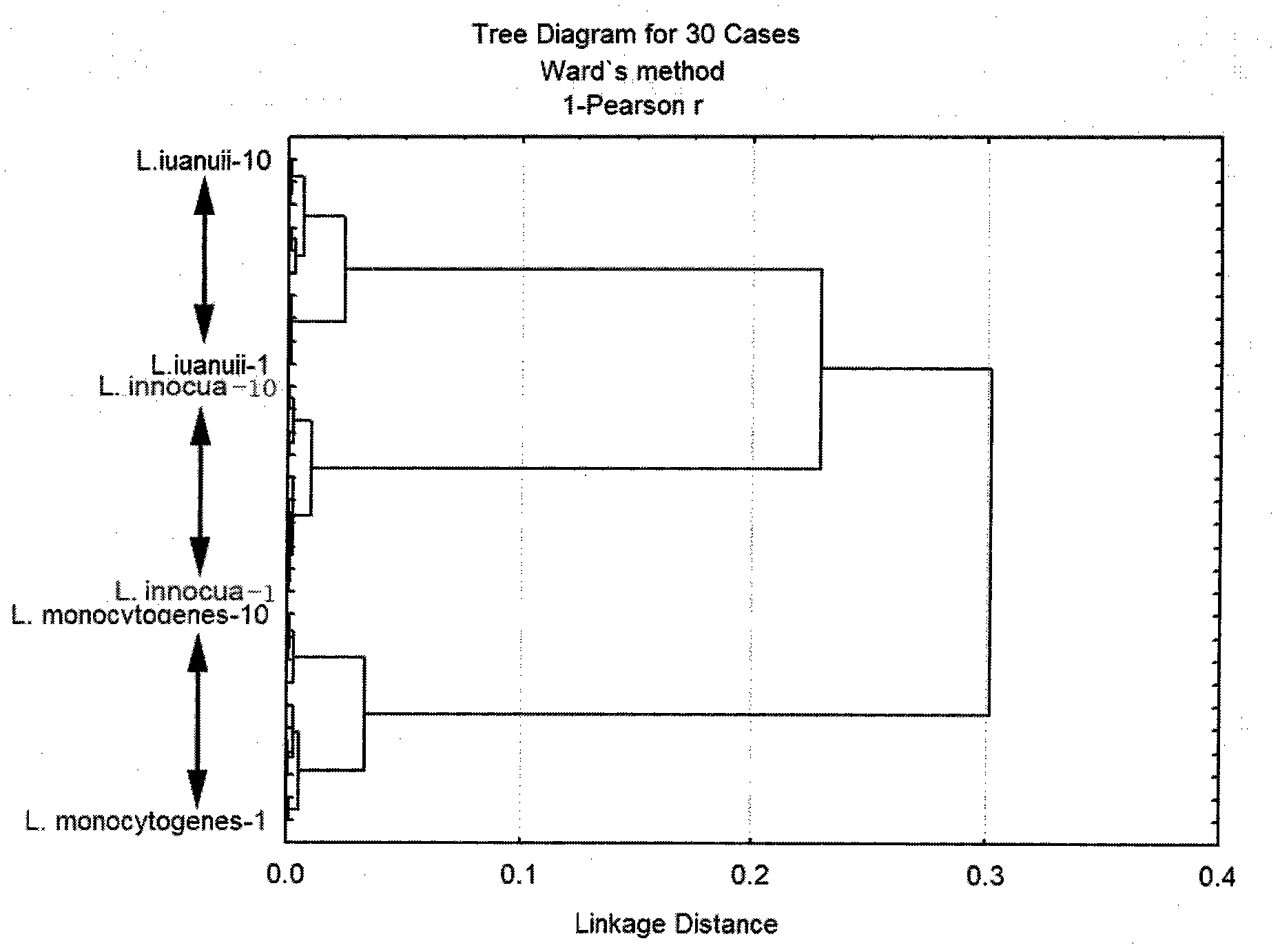

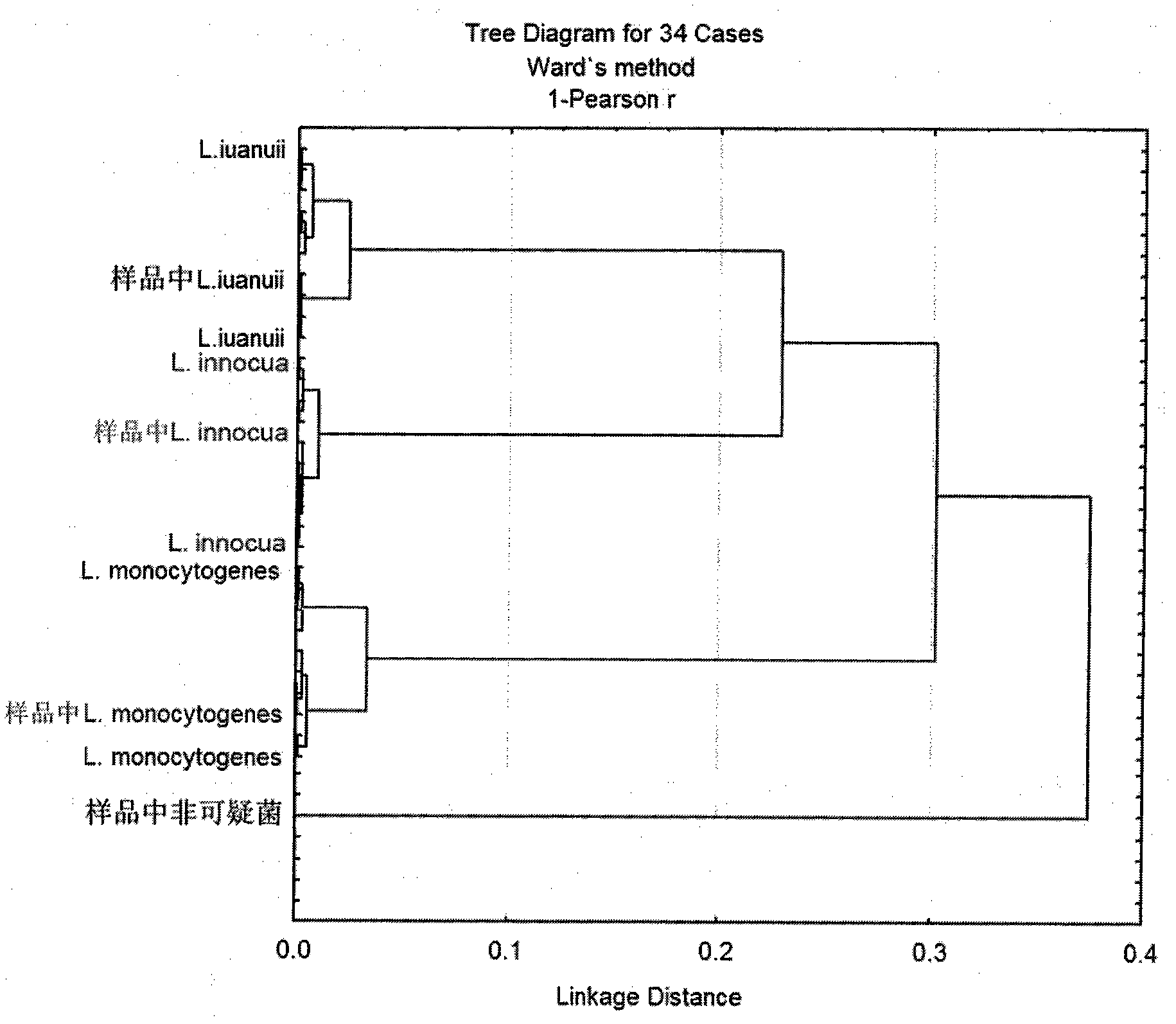

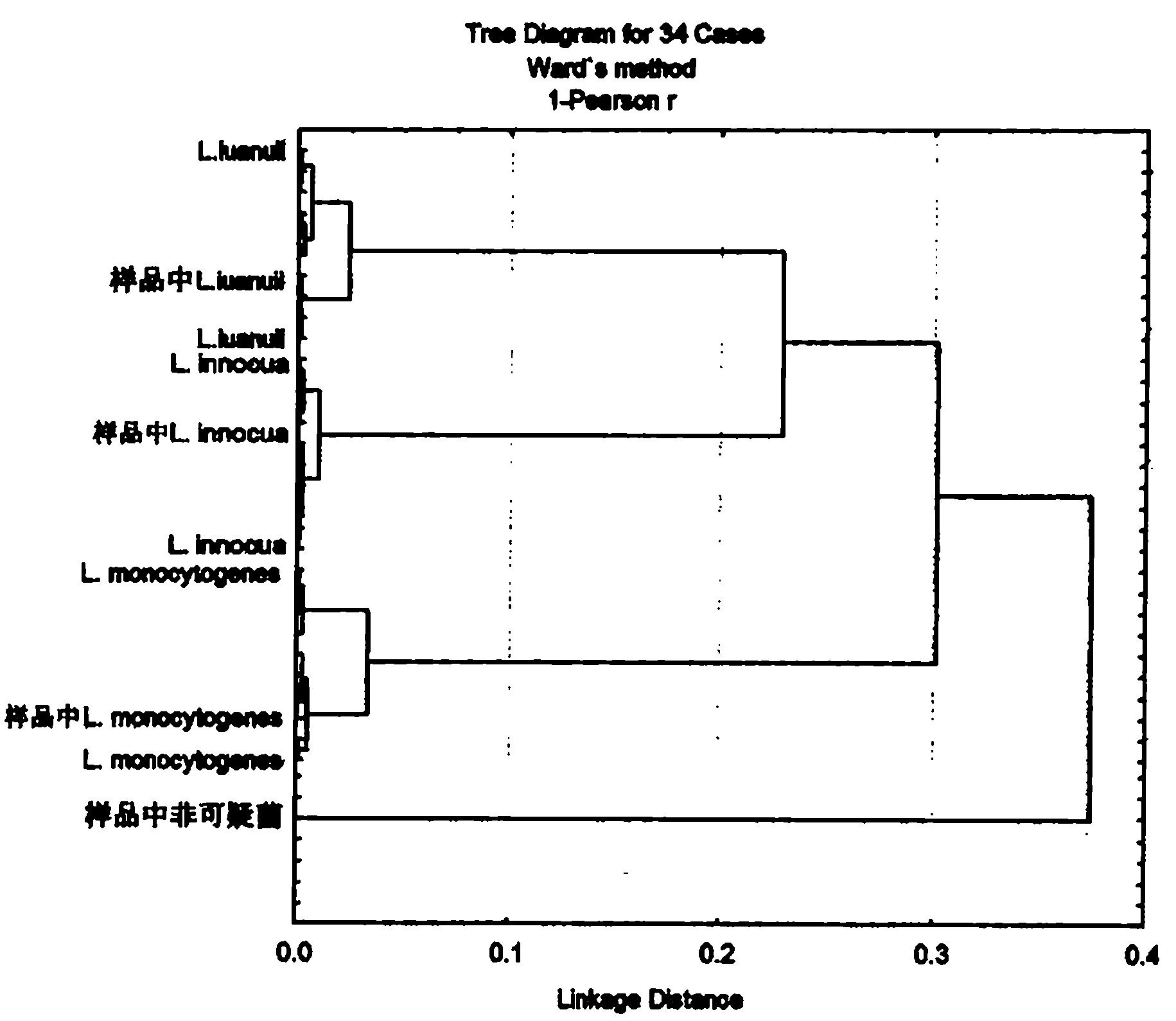

Classification and determination of Salmonella parayphi A, Salmonella parayphi B and Salmonella parayphi C through Fourier transform infrared spectrum technology

InactiveCN102564995APreparing sample for investigationColor/spectral properties measurementsImage resolutionCulture bacteria

The invention belongs to classification and determination to three Salmonella parayphis and particularly relates to classification and determination of Salmonella parayphi A (S. parayphi A), Salmonella parayphi B (S. parayphi B) and Salmonella parayphi C (S. parayphi C) by using a Fourier transform infrared spectrum (FT-IR) technology to be combined with calculation in chemometrics (hierarchical cluster analysis). The method comprises the following steps of: establishing FT-IR spectrum information databases for the three Salmonella parayphis; culturing bacteria; manufacturing a zinc selenide (ZnSe) window, collecting and pro-processing spectrums; and finally judging a result by using the hierarchical cluster analysis. The method disclosed by the invention has the advantages of high resolution ratio, fast speed, simplicity in operation and low cost.

Owner:威海出入境检验检疫局检验检疫技术中心

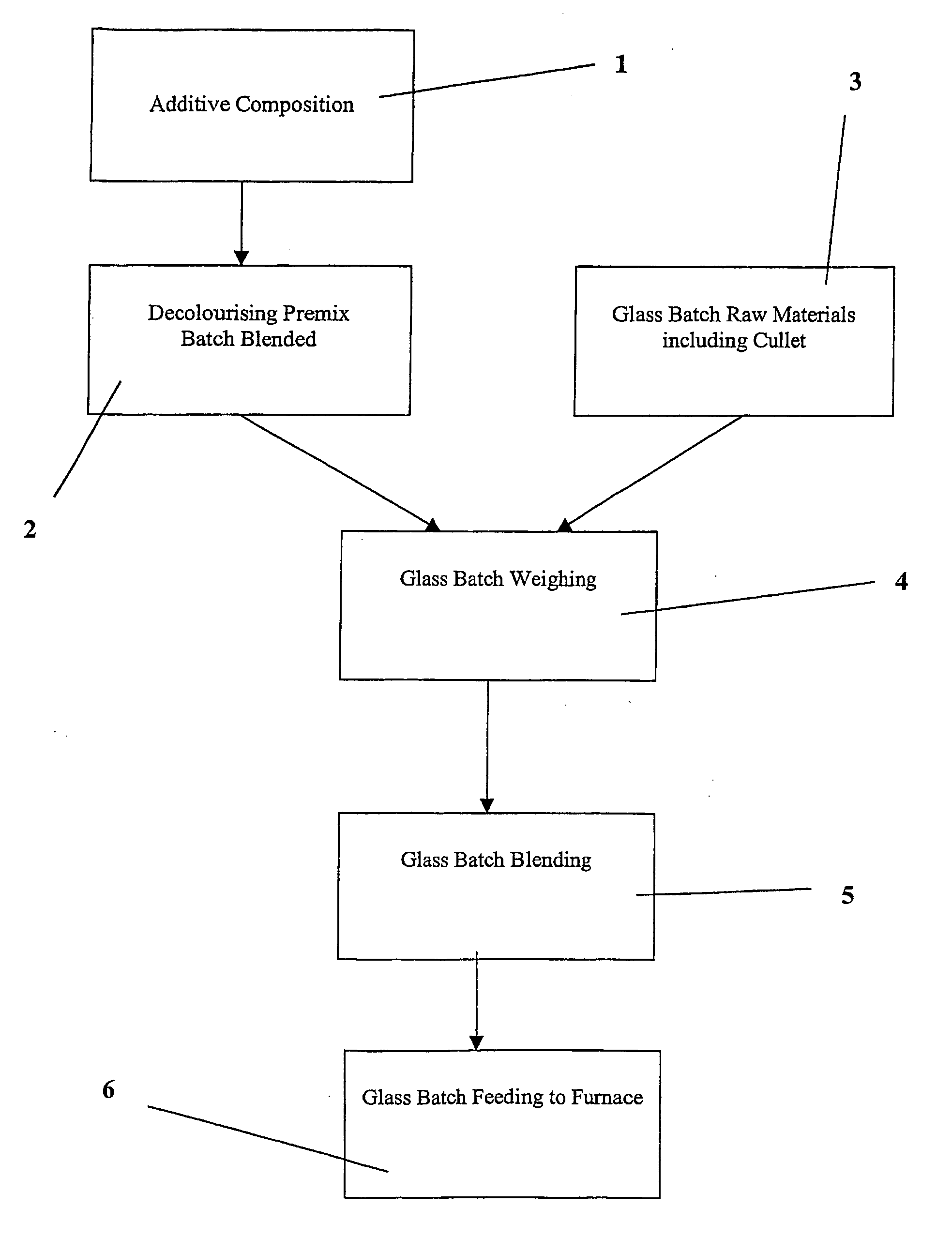

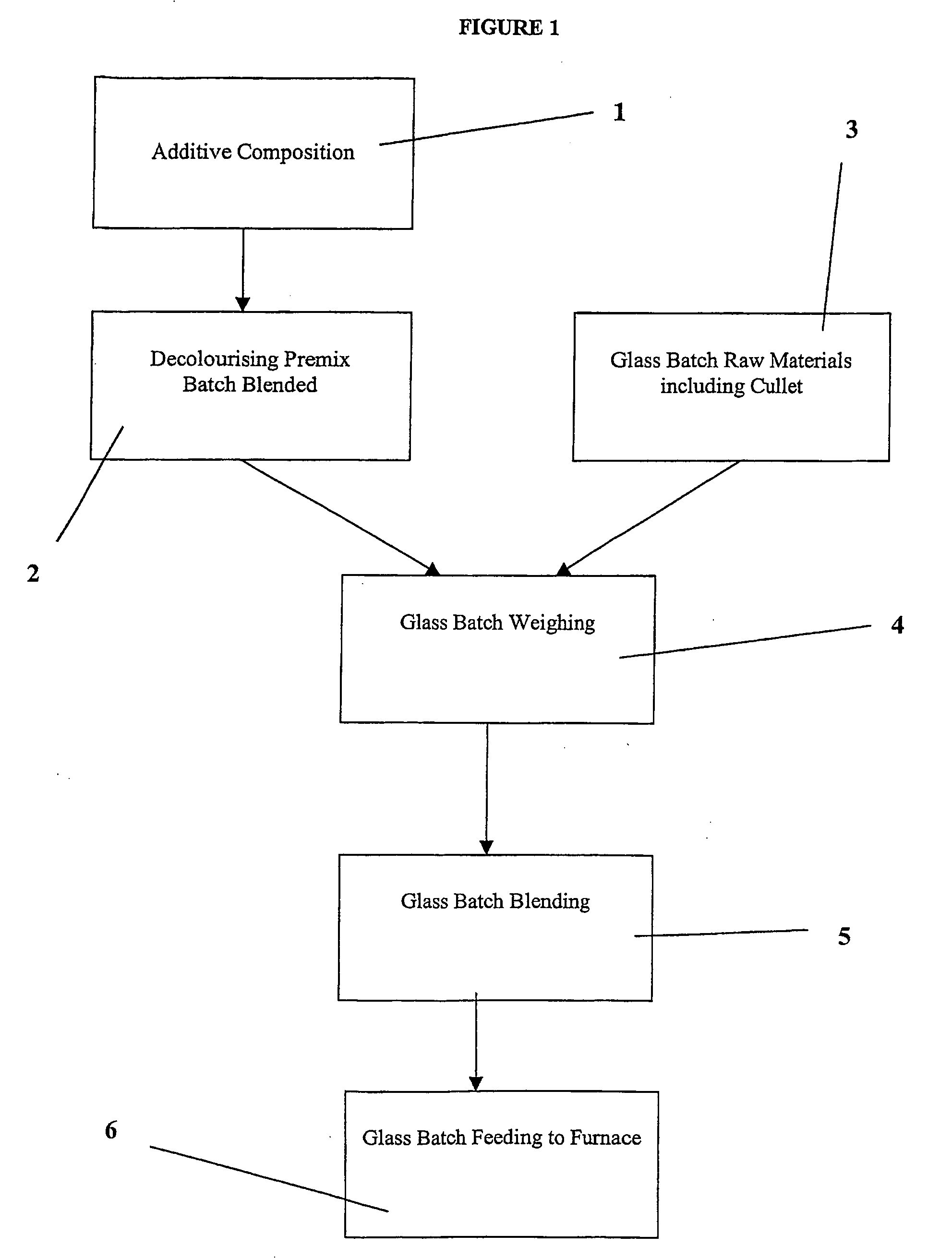

Additives for the manufacture of glass

A glass additive composition which consists of a carrier such as calcium carbonate, having an active material such as zinc selenite in combination with a surfactant and / or film forming material deposited thereon is an effective medium for introducing active materials into the glass manufacturing process and especially the manufacture of container glass.

Owner:NORFEED UK

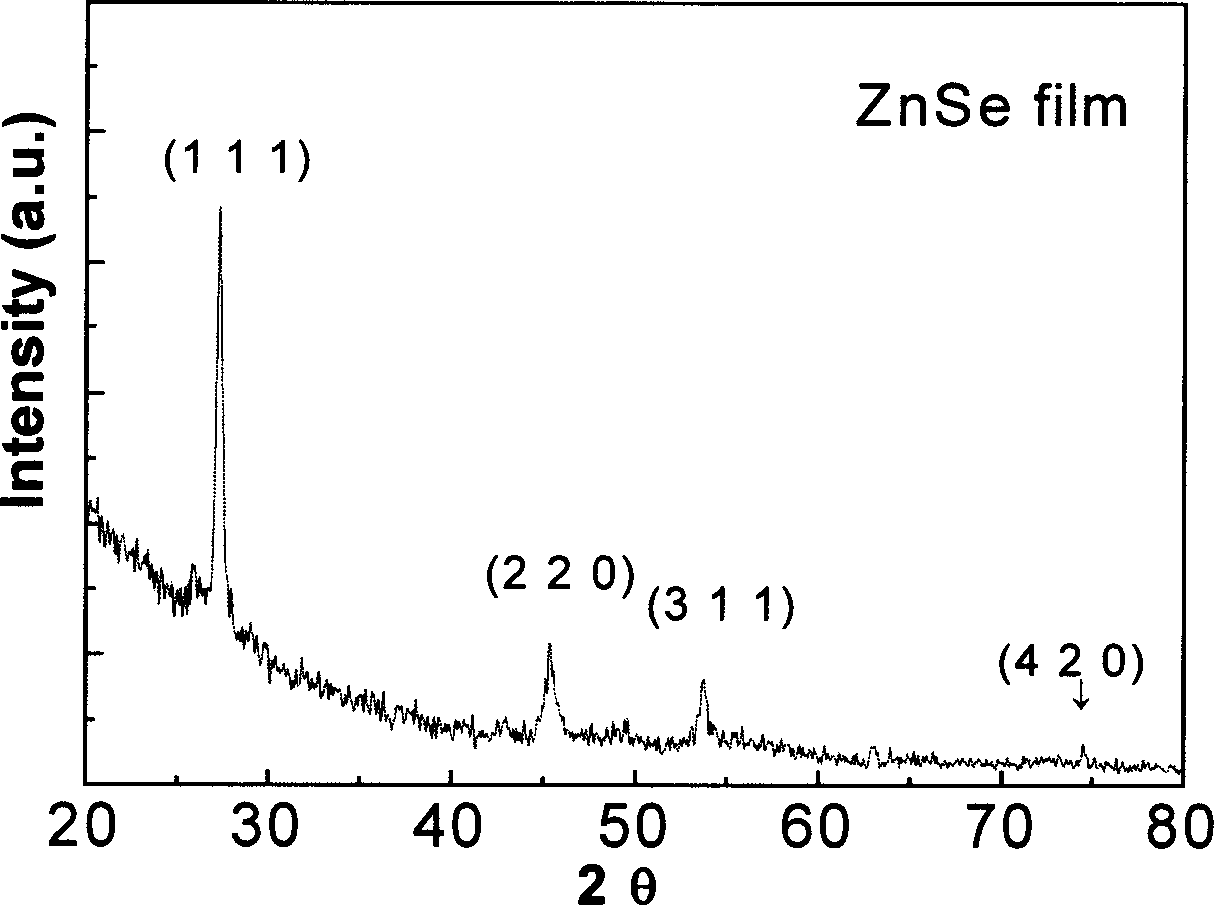

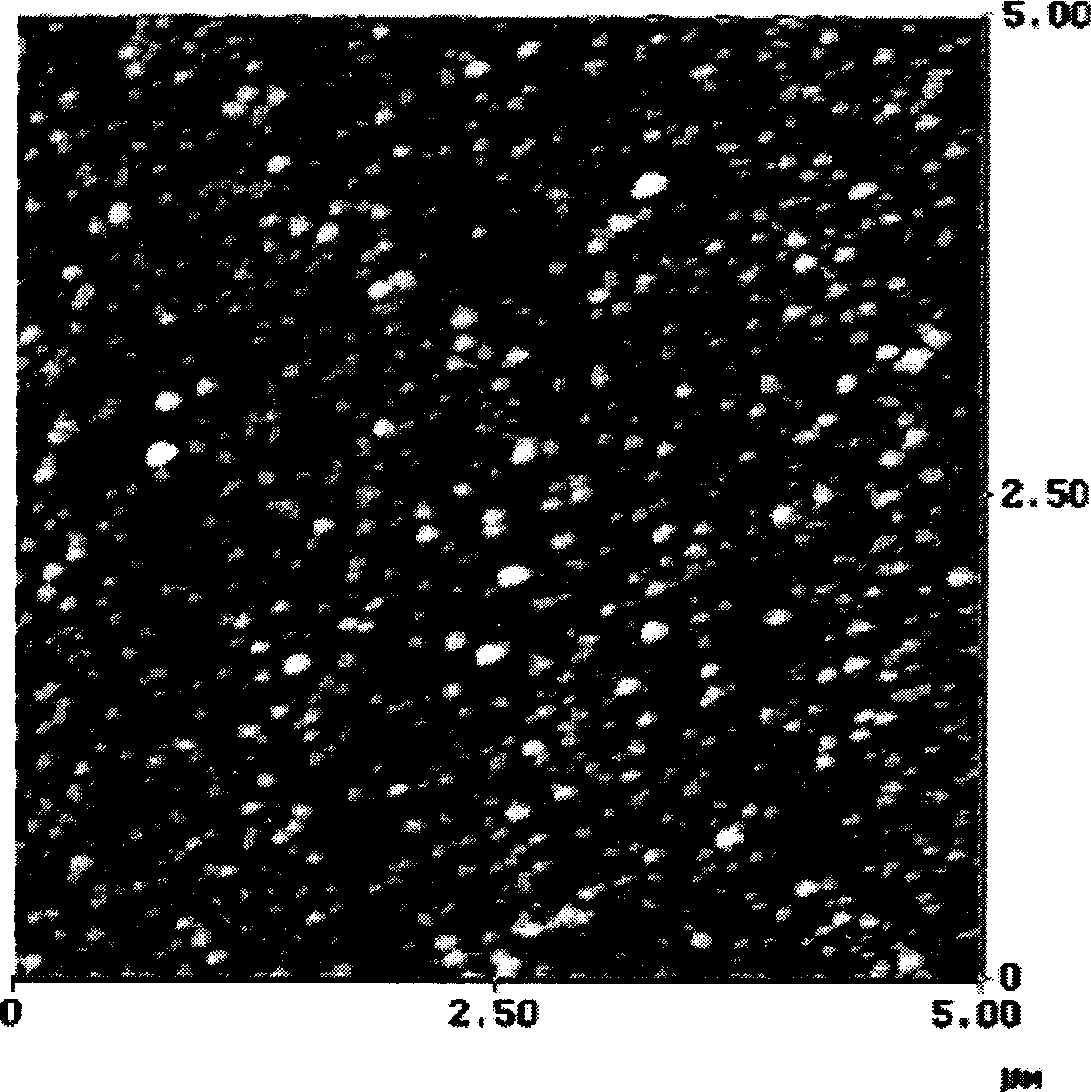

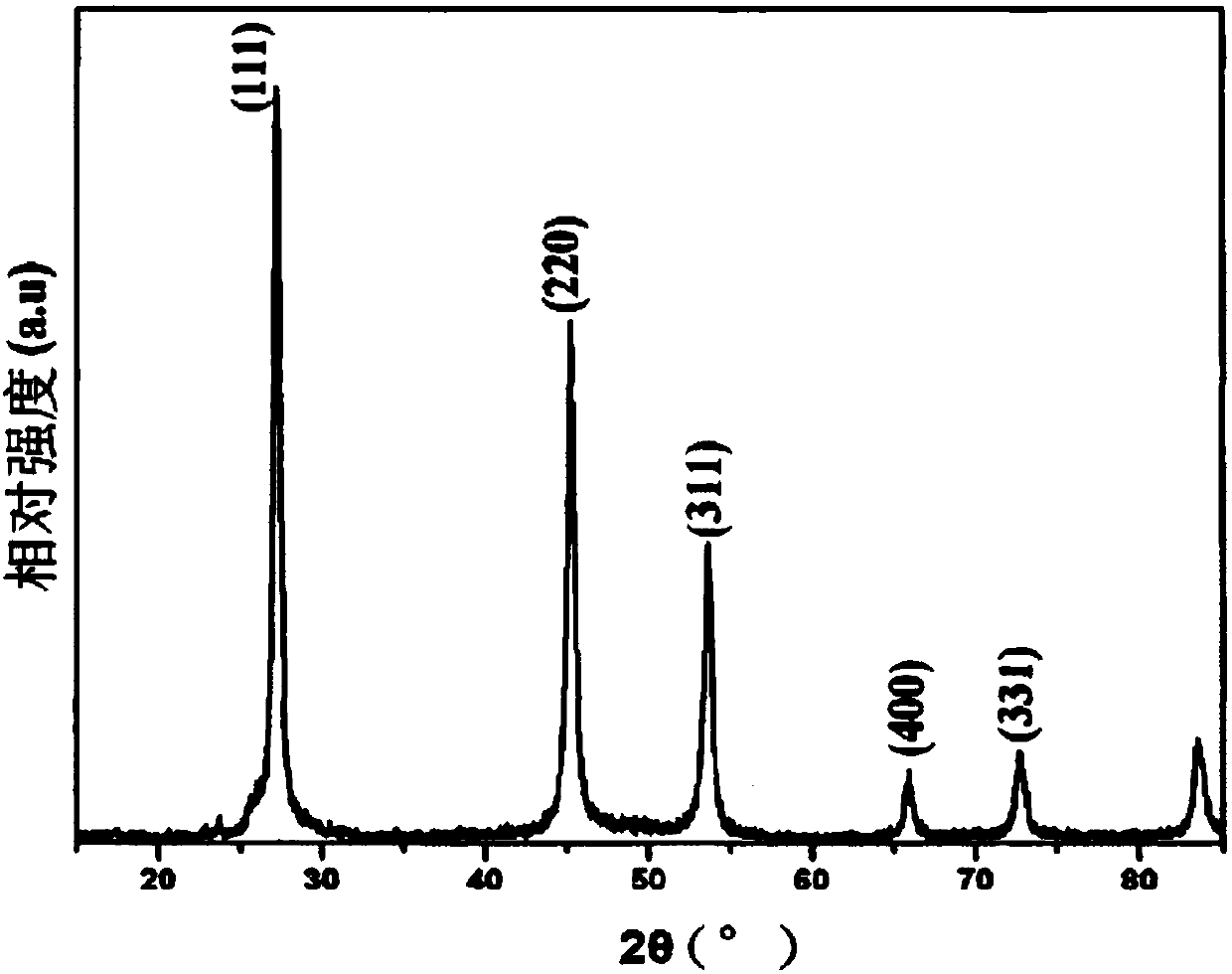

Process for rapid heating preparation of zinc selenide nano-crystal film by tubular gas furnace

InactiveCN1827528AUniform size distributionSame speedSelenium/tellurium compundsZinc compoundsTube furnaceNitrogen

This method consists of mixing elemental selenium powder and elemental zinc powder as the ratio of 1:1 and rolling them into energetic grinding tank, grinding until the dimension of zinc selenide powder reach 5-20 nanometer under the protect of nitrogen or argon gas; putting zinc selenide powder into a flute at the end of quartz boat, while putting silicon chip or quartz chip into the other flute of quartz boat; laying the quartz boat into a quartz pipe of more than 1.5 times as large as tube furnace in length, triply turning on air exhauster to eject oxygen and inflating argon; putting the cold end of quartz pipe into the tube furnace, heating zinc selenide nanometer powder stock in the quartz pipe to 800-1000 DEG C in 5 minutes. We can get zinc selenide nanocrystal film from silicon chip or quartz chip when its temperature reaches 160-240 DEG C. This invention has no strict request for the degree of vacuum, and can control the thickness of film and the dimension of nanocrystal film by technical condition.

Owner:XI AN JIAOTONG UNIV

Visible light responding sulfur-doped selenide photocatalyst and preparation method thereof

InactiveCN101947461AWater/sewage treatment by irradiationDispersed particle separationUltraviolet lightsPhotochemistry

The invention relates to a visible light responding selenide photocatalyst and a preparation method thereof, belonging to the field of inorganic nano photocatalytic materials. The catalyst comprises sulfur-doped nano-metal selenide semi-conductors including zinc selenide, cadmium selenide and bismuthous selenide. The photocatalyst has photocatalytic activity in wider wavelength range and can treat toxic and harmful chemical substances through photodecomposition and purification under radiation of ultraviolet light, visible light or natural light.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of zinc selenide membrane

ActiveCN107557834AImprove uniformityQuick responseElectrolytic inorganic material coatingPlatinumDeposition temperature

The invention discloses a preparation method of a zinc selenide membrane. The preparation method comprises the following steps of S1, clearly cleaning and drying the surface of a cathode sheet; S2, preparing a selenium and zinc containing solution, and performing deoxidization on the obtained selenium and zinc containing solution; S3, by taking the selenium and zinc containing solution obtained inthe step S2 as an electrochemical deposition liquid, the cathode sheet obtained in the step S1 as a counter electrode, a saturated calomel electrode as a reference electrode and a platinum sheet as aworking electrode, performing electrochemical deposition on the cathode sheet to form the zinc selenide membrane, wherein a deposition voltage is 0.2-(-0.4)V, a deposition temperature is 25-80 DEG C,and a deposition time is 1-20min; and S4, after electrochemical deposition is finished, taking out the zinc selenide membrane, and cleaning and drying the zinc selenide membrane to obtain the zinc selenide membrane. The method is rapid in reaction rapid, liable in industrial large scale production and low in production cost; and a product obtained through the method is good in homogeneity.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com