Preparation method of ferroferric oxide@silicon dioxide@zinc selenide fluorescent magnetic nanometer particles

A technology of magnetic composite nanometer and ferroferric oxide, which is applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., to achieve the effect of simple device, relatively large particle size distribution and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] (3) Preparation of zinc selenide quantum dots

[0025] Step 5: Take 0.0085g of NaBH4 and 0.0059g of Se powder respectively, and dissolve them in 2mL of distilled water under the protection of nitrogen to obtain the Se precursor; take 0.1317g of zinc acetate and dissolve them in distilled water, add an appropriate amount of TGA, and then use NaOH to adjust the pH of the solution to 9 ~11, to obtain a Zn precursor; mix the two precursor solutions, reflux in an oil bath at 90° C., and react with magnetic stirring for 1 hour. After the reaction is completed, the zinc selenide quantum dots are obtained.

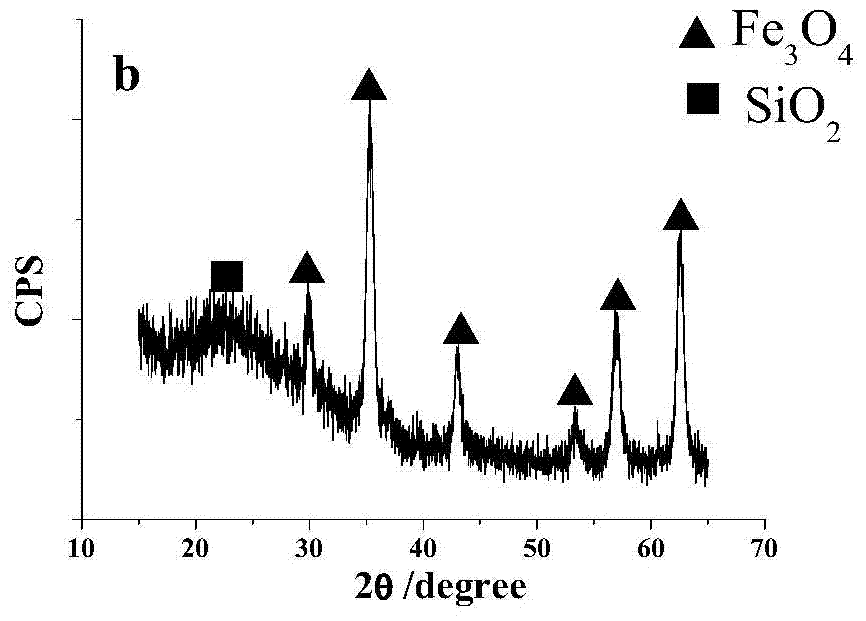

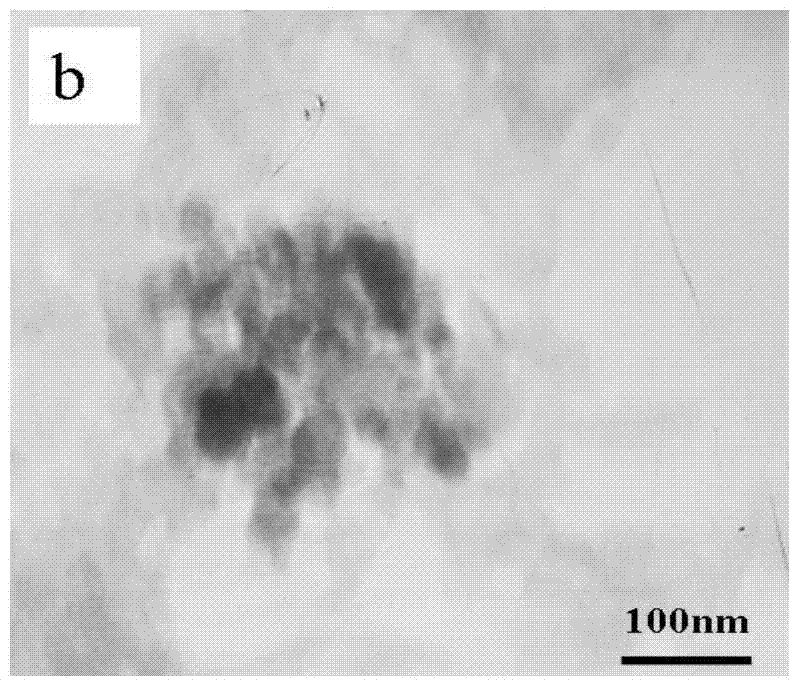

[0026] (4) Preparation of Magnetic Fluorescent Fe3O4SiO2ZnSe Composite Nanoparticles

[0027] Step 6: Take TritonX-100, n-hexanol, and cyclohexane solutions according to a certain volume ratio, put them in a beaker, and disperse them ultrasonically for 20 minutes to obtain a microemulsion system; add an appropriate amount of APTES to the freshly prepared iron ferric oxide ...

Embodiment 1

[0029] Example 1: (1) Preparation of Fe3O4 nanoparticles by hydrothermal method

[0030] Step 1. Dissolve 4.3248g of ferric chloride and 2.7802g of ferric chloride into the water-ethylene glycol mixed solution, transfer them to a four-necked flask with a water bath at 70°C under the condition of protective gas (nitrogen), and use the prepared A good NaOH is used to adjust the pH value of the solution (pH ≈ 10), and then an appropriate amount of surfactants sodium oleate and sodium dodecylbenzenesulfonate are quickly added, and mechanically stirred for 30 minutes to obtain a precursor solution of ferric oxide.

[0031] Step 2. Transfer the above precursor solution into a high-pressure reactor, react at 160-200°C for 6-10 hours, take out the product after the reaction is completed, wash with distilled water and absolute ethanol, repeat 5-6 times, and finally, put The washed reaction product is vacuum-dried to obtain ferric oxide nano-magnetic particles.

[0032] (2) Preparation...

Embodiment 2

[0039] Embodiment 2: The method and steps are the same as those of Embodiment 1, the only difference is that the temperature of the water area in Step 1 is changed to 65° C. in the process of preparing ferric oxide nanoparticles by the hydrothermal method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com