Preparation method of sulfur dioxide and epoxide copolymer

A technology of epoxy compounds and sulfur dioxide, which is applied in the field of polymer material preparation, can solve the problems of harsh reaction conditions, low catalytic activity, and low molecular weight of copolymers, and achieve less catalyst consumption, shorter reaction time, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

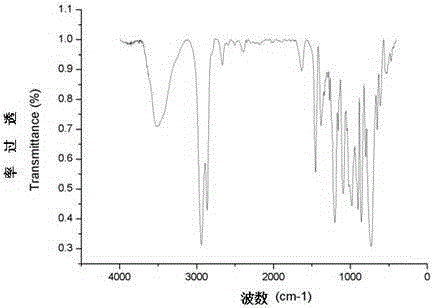

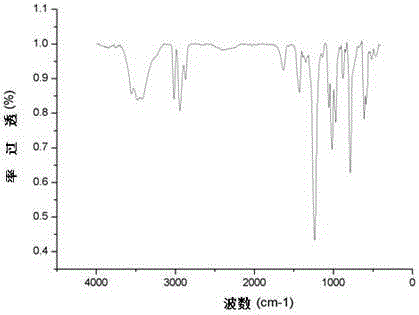

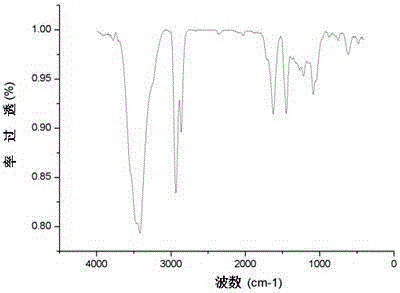

Image

Examples

Embodiment 1

[0024] (1) Add 20mL of epoxycyclohexane and 118.6mg of SalenCr into a 50ml autoclave Ⅲ Cl catalyst;

[0025] (2) Introduce 99.0% nitrogen into the sealed autoclave, and after repeating the nitrogen twice, then inject sulfur dioxide with a purity of 99.0% into the autoclave, and the pressure of sulfur dioxide is 0.1MPa;

[0026] (3) Close the inlet and outlet valves after feeding, set the speed to 280r / min, the temperature to 50°C, and the reaction time to 6h;

[0027] (4) Dissolve the obtained product in chloroform, add hydrochloric acid methanol mixture (volume ratio, methanol / hydrochloric acid = 6) for precipitation, obtain an amber precipitate after filtration, wash with methanol for 3 times, and place the washed precipitate in a vacuum In a drying oven, vacuum dry at room temperature for 8 hours to obtain a copolymer of sulfur dioxide and epoxy compounds. The number-average molecular weight determined by gel permeation chromatography was 6320 g / mol, and the yield was 5.6...

Embodiment 2

[0029] (1) Add 30mL of epoxycyclohexane and 177.9mg of SalenMn into a 50ml autoclave Ⅱ Cl catalyst;

[0030] (2) Introduce 99.0% nitrogen gas into the sealed autoclave, repeat nitrogen gas three times, and then inject sulfur dioxide with a purity of 99.0% into the autoclave, and the pressure of sulfur dioxide is 0.3MPa;

[0031] (3) Close the inlet and outlet valves after the feeding is completed, set the speed at 280r / min, the temperature at 60°C, and the reaction time at 8h;

[0032] (4) Dissolve the obtained product in chloroform, add hydrochloric acid methanol mixture (volume ratio, methanol / hydrochloric acid = 6) for precipitation, obtain an amber precipitate after filtration, wash with methanol for 3 times, and place the washed precipitate in a vacuum In a drying oven, vacuum-dry at room temperature for 12 hours to obtain a copolymer of sulfur dioxide and epoxy compound. Its number-average molecular weight measured by gel permeation chromatography is 4400g / mol, and the...

Embodiment 3

[0034] (1) Add 20mL of epoxycyclohexane and 59.3mg of SalenCo into a 50ml autoclave Ⅱ Cl catalyst;

[0035] (2) Introduce 99.0% nitrogen into the sealed autoclave, repeat nitrogen 3 times, then inject sulfur dioxide with a purity of 99.0% into the autoclave, the pressure of sulfur dioxide is 0.2MPa;

[0036] (3) Close the inlet and outlet valves after feeding, set the speed to 280r / min, the temperature to 70°C, and the reaction time to 10h;

[0037] (4) Dissolve the obtained product in chloroform, add hydrochloric acid methanol mixture (volume ratio, methanol / hydrochloric acid = 6) for precipitation, obtain an amber precipitate after filtration, wash with methanol 4 times, and place the washed precipitate in a vacuum In a drying oven, vacuum dry at room temperature for 24 hours to obtain a copolymer of sulfur dioxide and epoxy compound. The number-average molecular weight determined by gel permeation chromatography was 5850 g / mol, and the yield was 8.35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com