Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82 results about "Silicon nanostructures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

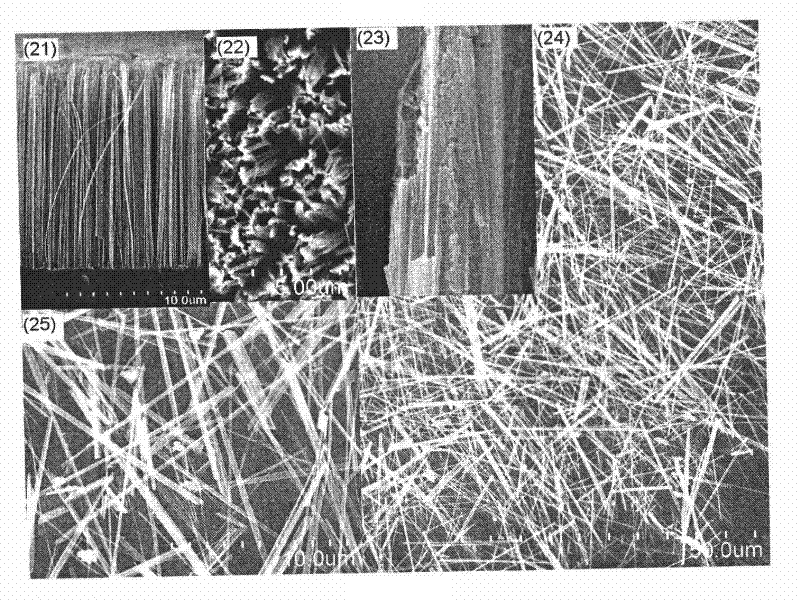

Silicon nanoparticles (SiNPs) and silicon nanowires (SiNWs) are well known as the most important zero- and one-dimensional silicon nanostructures. In the past three decades, scientists have made great strides in developing a great deal of fabrication techniques to prepare SiNPs and SiNWs.

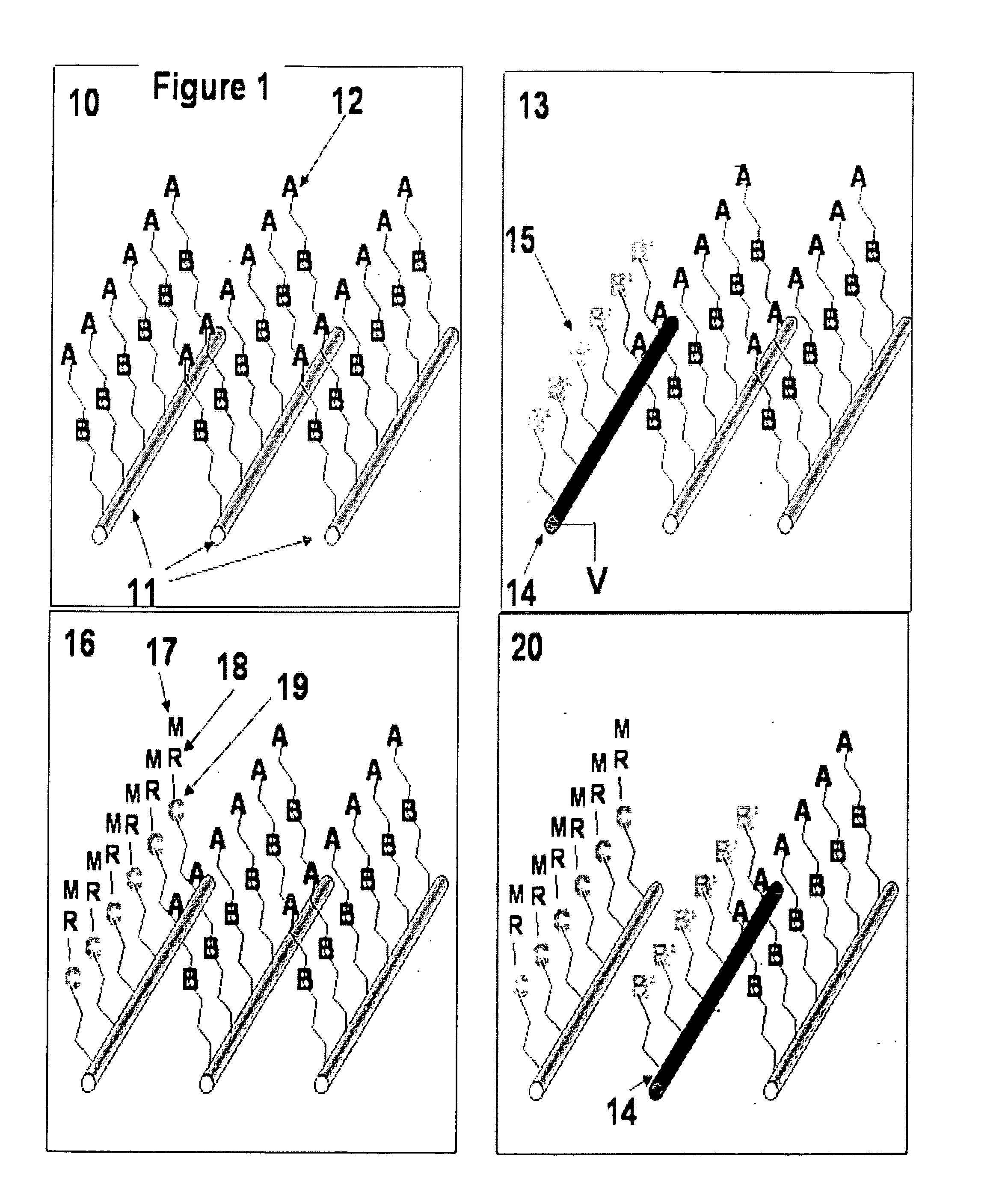

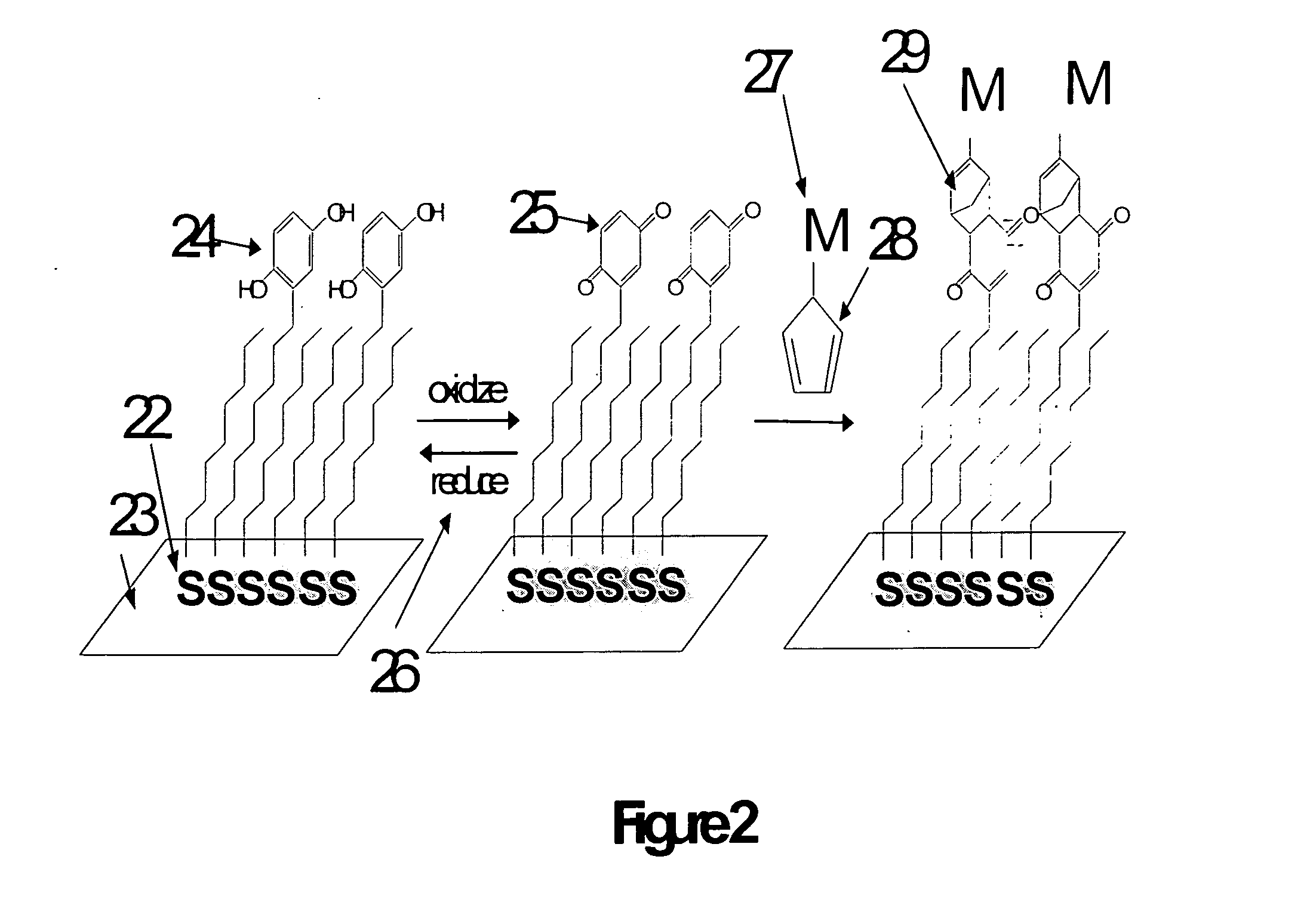

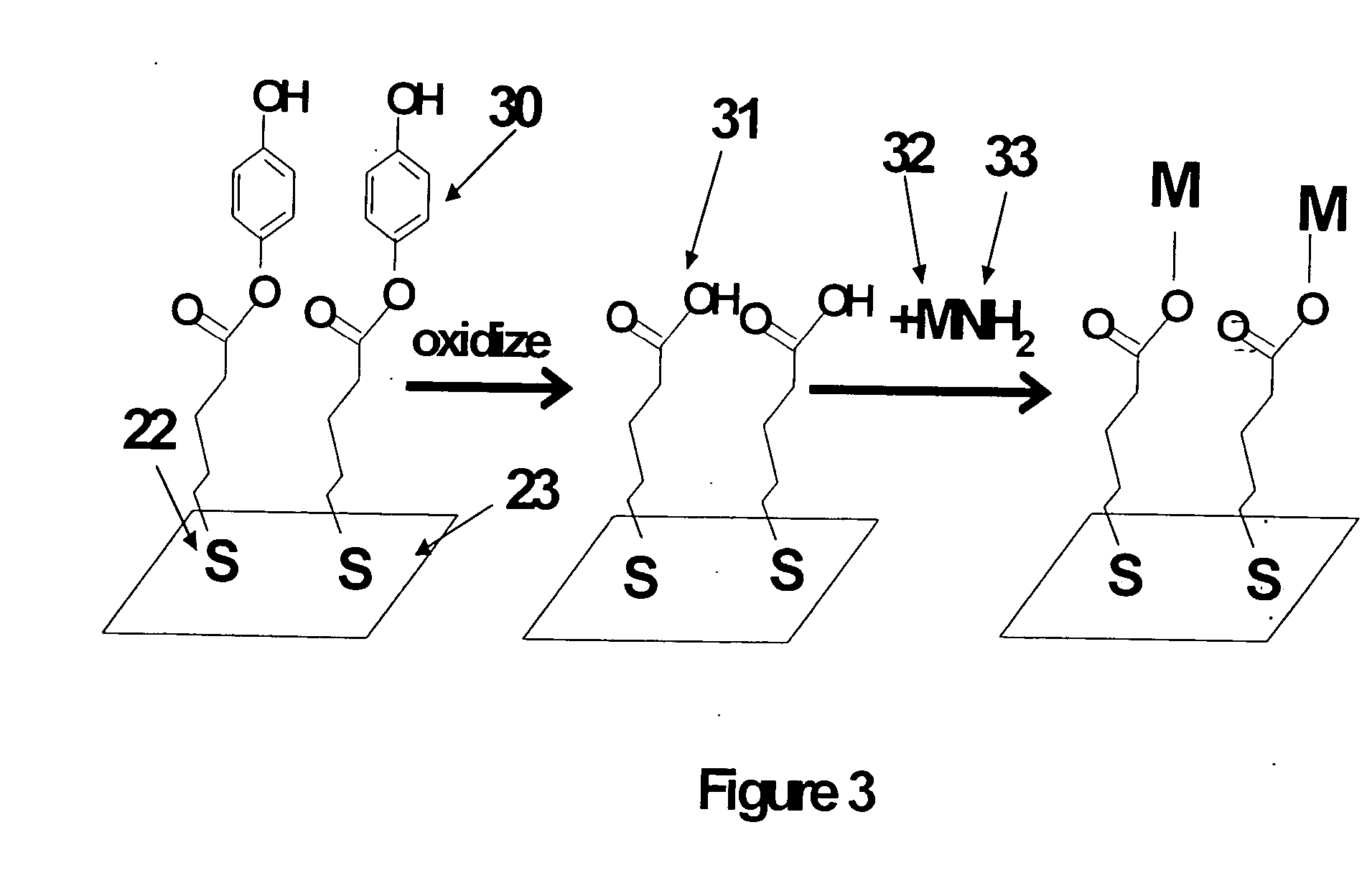

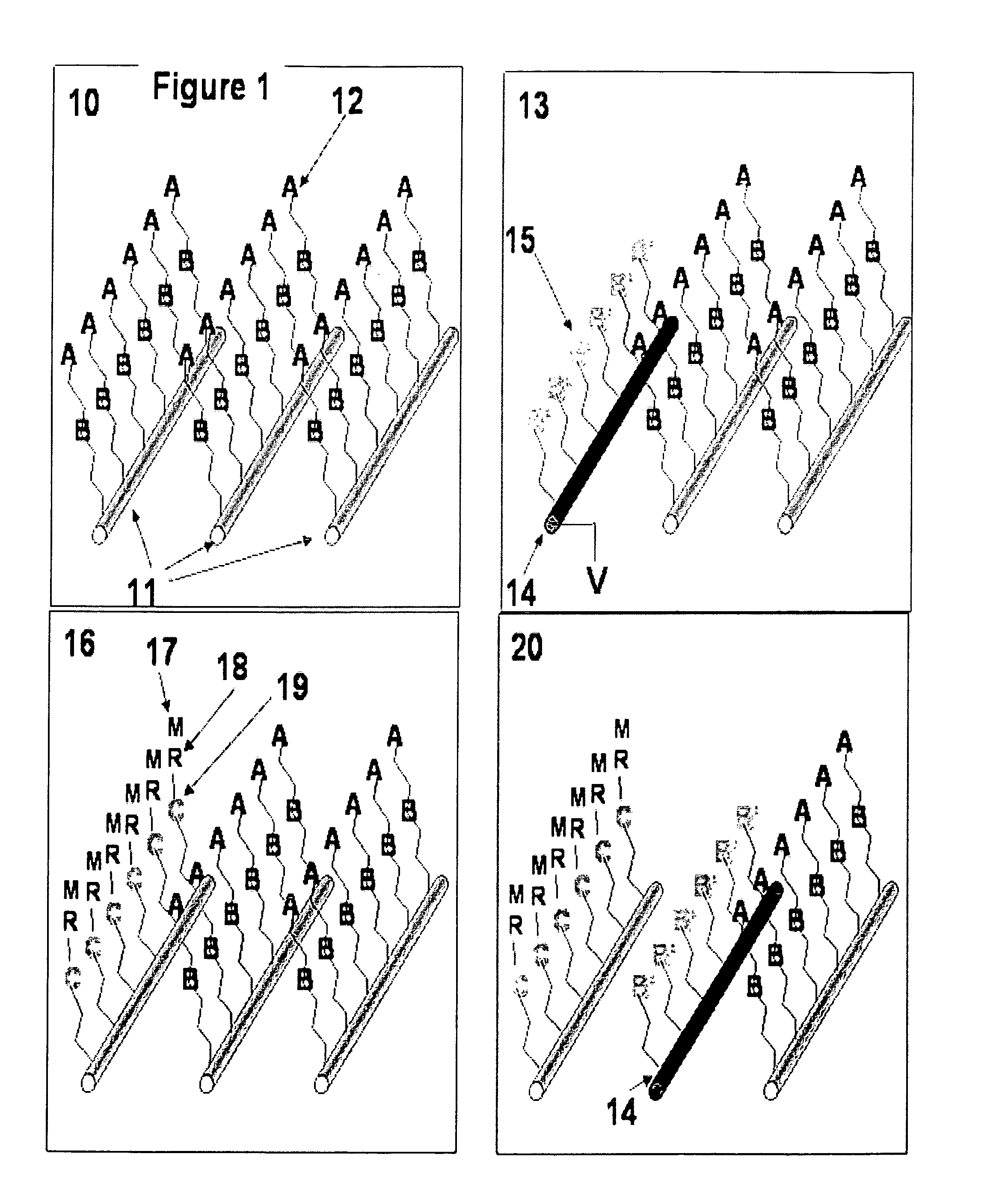

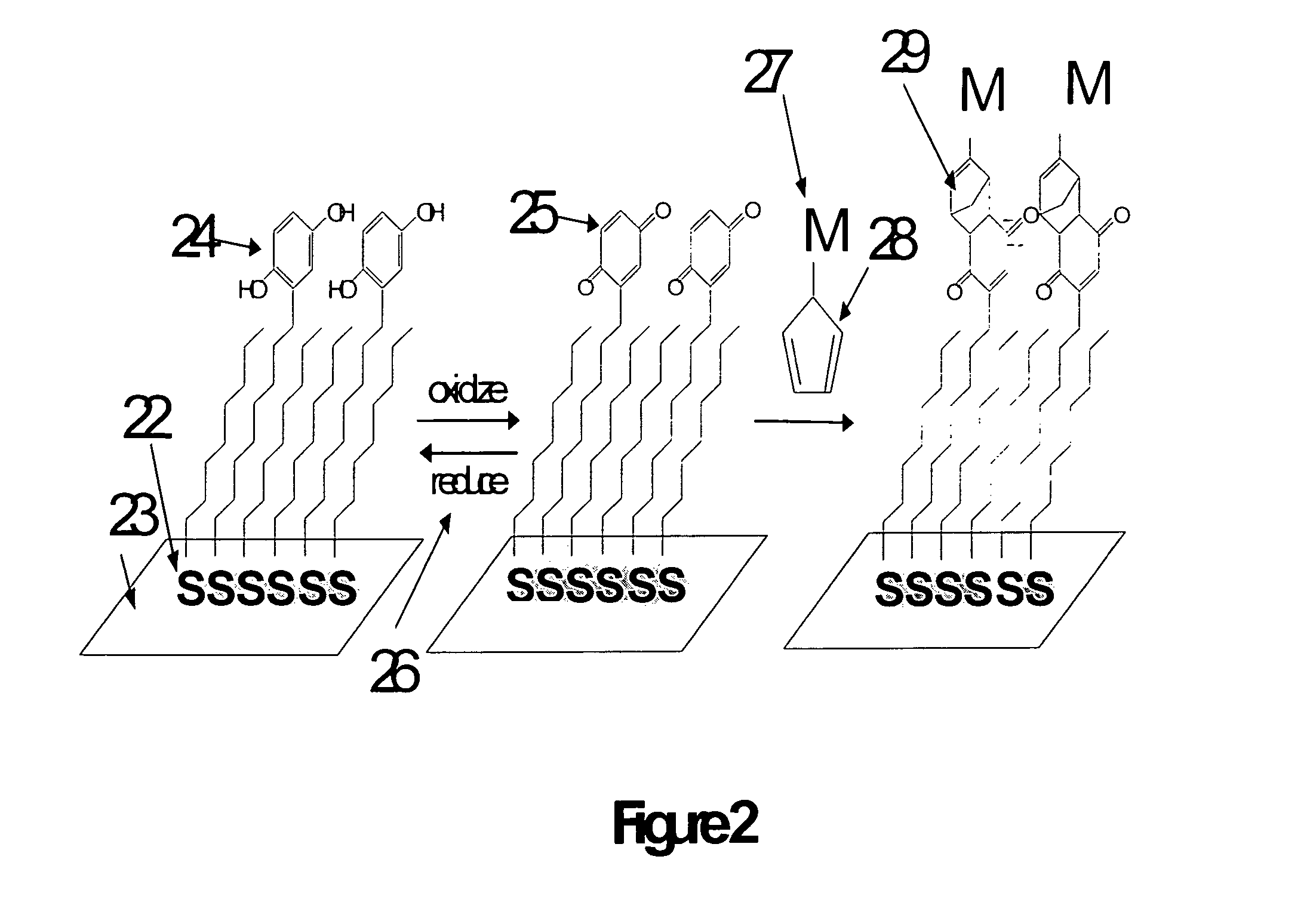

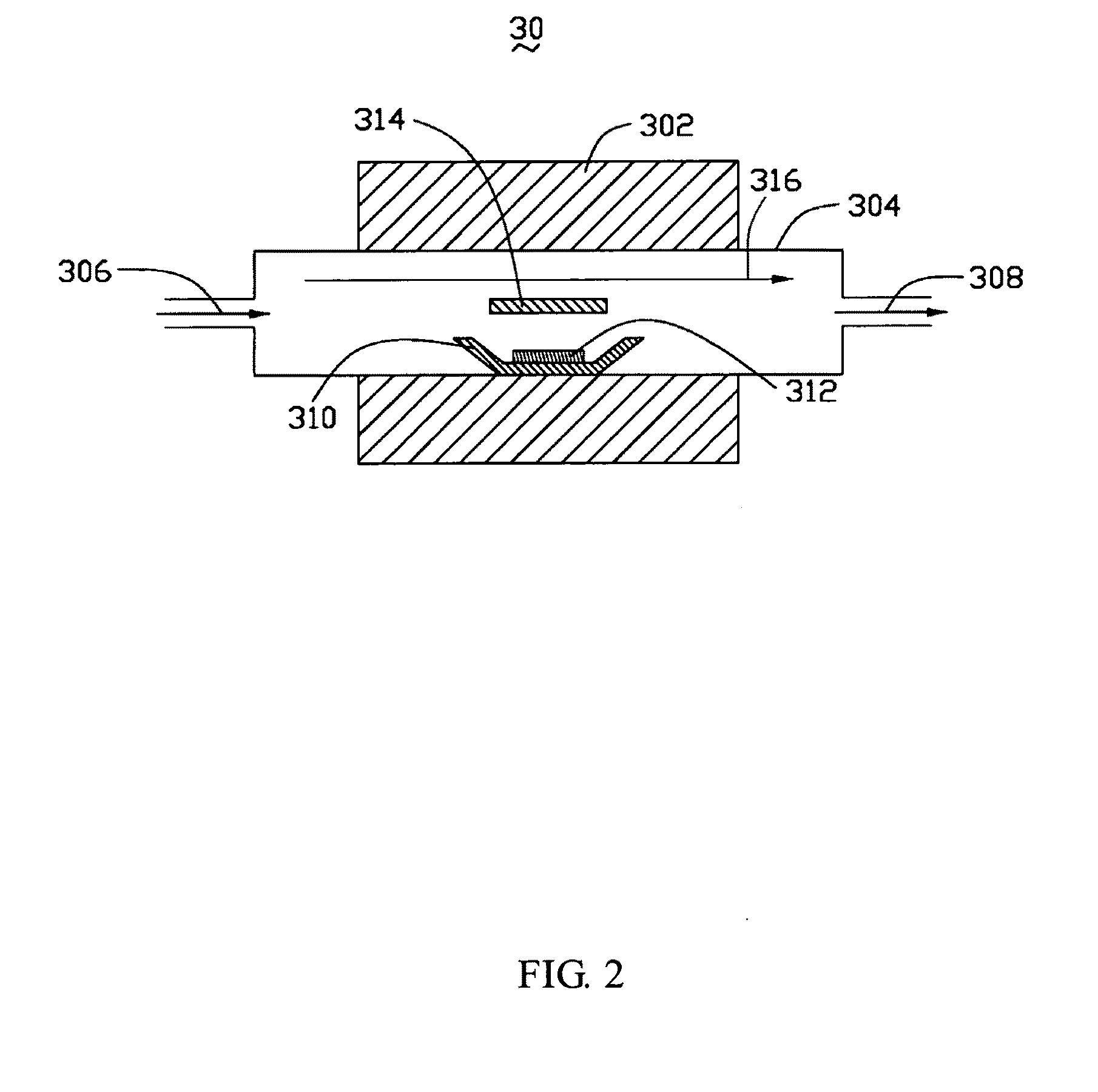

Electrochemical method and resulting structures for attaching molecular and biomolecular structures to semiconductor micro and nanostructures

InactiveUS20050032100A1Material nanotechnologyBioreactor/fermenter combinationsNanometreElectrochemical cell

A method by which silicon nanostructures may be selectively coated with molecules or biomolecules using an electrochemical process. This chemical process may be employed as a method for coating many different nanostructures within a circuit, each with a different molecular or biomolecular material. The density of devices within a circuit of devices that can be coated with different molecules is limited only by the ability to electronically address each device separately. This invention has applications toward the fabrication of molecular electronic circuitry and toward the fabrication of nanoelectronic molecular sensor arrays.

Owner:CALIFORNIA INST OF TECH

Electrochemical method for attaching molecular and biomolecular structures to semiconductor microstructures and nanostructures

InactiveUS7416911B2Bioreactor/fermenter combinationsMaterial nanotechnologyElectrochemistryNanometre

A method by which silicon nanostructures may be selectively coated with molecules or biomolecules using an electrochemical process. This chemical process may be employed as a method for coating many different nanostructures within a circuit, each with a different molecular or biomolecular material. The density of devices within a circuit of devices that can be coated with different molecules is limited only by the ability to electronically address each device separately. This invention has applications toward the fabrication of molecular electronic circuitry and toward the fabrication of nanoelectronic molecular sensor arrays.

Owner:CALIFORNIA INST OF TECH

Silicon Nanostructure Active Materials for Lithium Ion Batteries and Processes, Compositions, Components and Devices Related Thereto

ActiveUS20140248543A1Highly controllableAvoid irreversibleElectrochemical processing of electrodesElectrode carriers/collectorsCopper electrodeGraphite particle

The present invention relates to nanostructured materials for use in rechargeable energy storage devices such as lithium batteries, particularly rechargeable secondary lithium batteries, or lithium-ion batteries (LIBs). The present invention includes materials, components, and devices, including nanostructured materials for use as battery active materials, and lithium ion battery (LIB) electrodes comprising such nanostructured materials, as well as manufacturing methods related thereto. Exemplary nanostructured materials include silicon-based nanostructures such as silicon nanowires and coated silicon nanowires, nanostructures disposed on substrates comprising active materials or current collectors such as silicon nanowires disposed on graphite particles or copper electrode plates, and LIB anode composites comprising high-capacity active material nanostructures formed on a porous copper and / or graphite powder substrate.

Owner:ONED MATERIAL INC

Method for preparing one-dimensional nanostructure in anode alumina template

InactiveCN1669920AImprove qualitySynthesis temperature is lowAnodisationPolycrystalline material growthSilanesHoneycomb structure

The invention discloses a method for preparing a one-dimensional silicon nanostructure in a anodic aluminum oxide mold, which comprises the following steps: growing the one-dimensional silicon nanostructure in low-temperature by the method of plasma chemical depositing with the spacing limited function of porous aluminium oxide, including the silicon nanowire and silicon nanotube, preparing a porous aluminum oxide mold with honeycomb structure by anodic oxidation process, wherein openings arrange ordered, apertures are coherent and vertical the surfaces of the mold, imbedding the mold into a plasma enhanced chemical depositing reaction chamber, growing the silicon nanowire or silicon nanotube at a temperature of 300 Deg. C by controlling the gas flow with the perhydrous diluting silane as the growth air supply.

Owner:ZHEJIANG UNIV

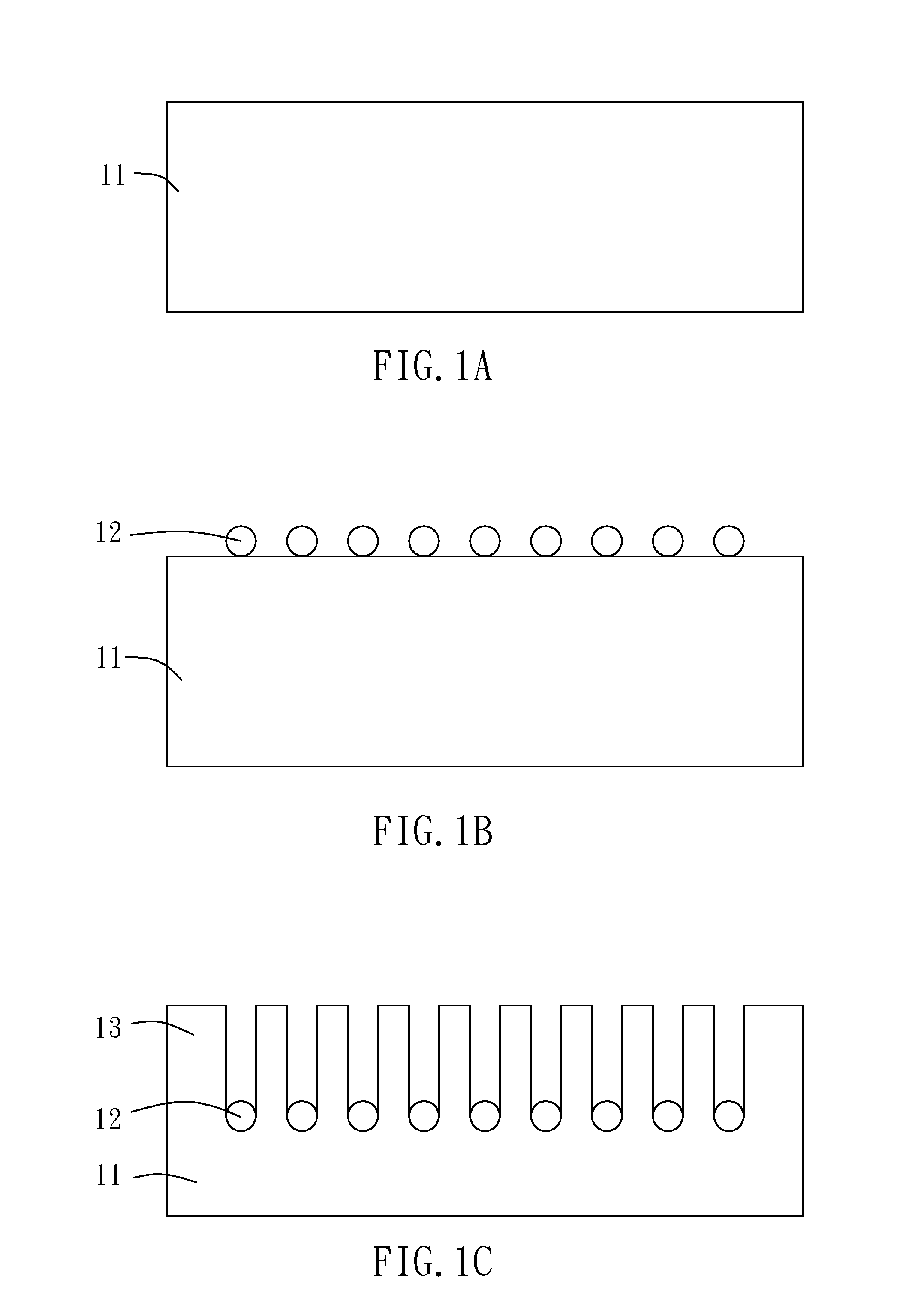

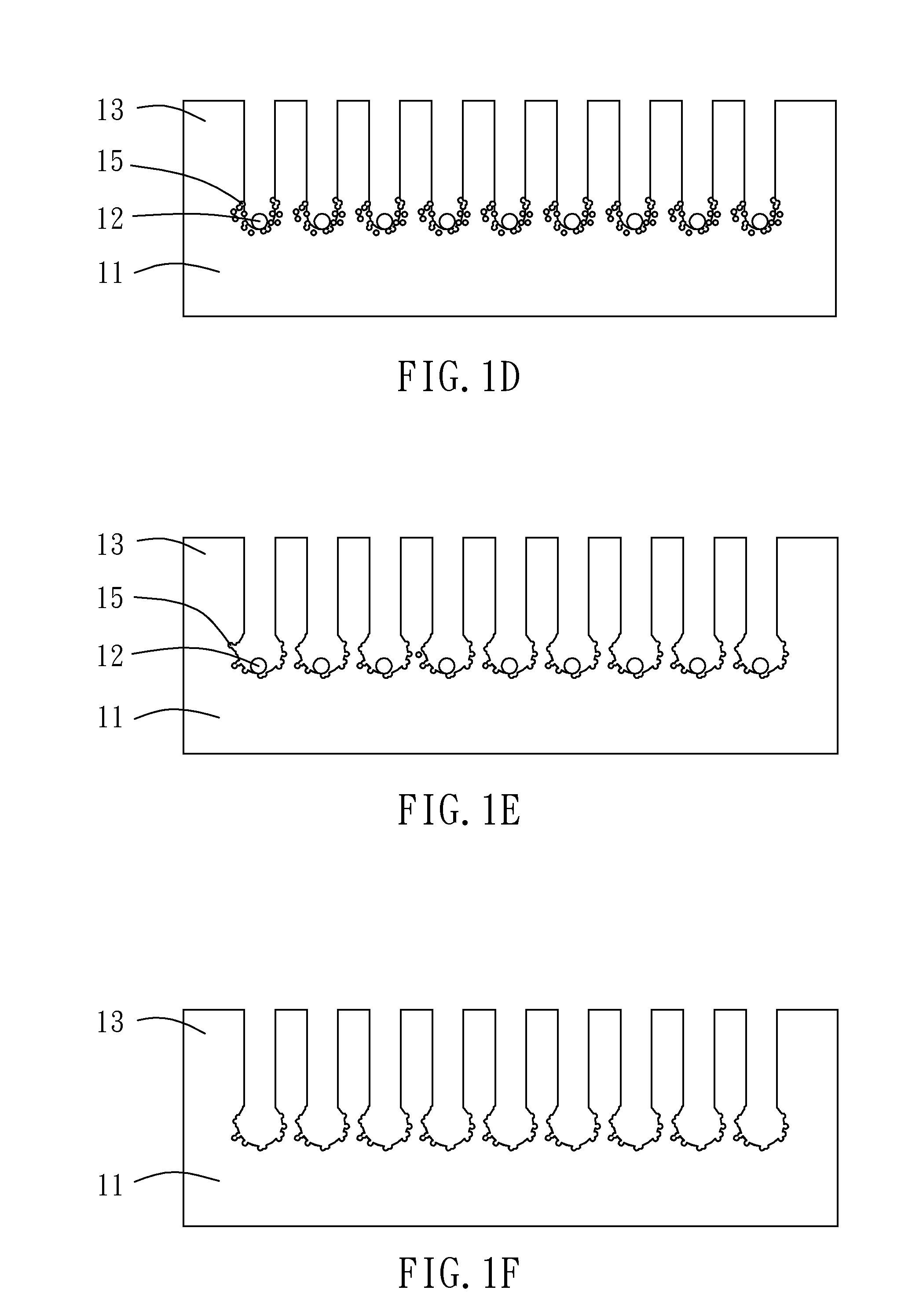

Method for preparation of one-dimensional silicon nanostructure

InactiveCN101117208APosition is easy to controlEasy to manufactureNanostructure manufactureNanoparticleSilicon nanowires

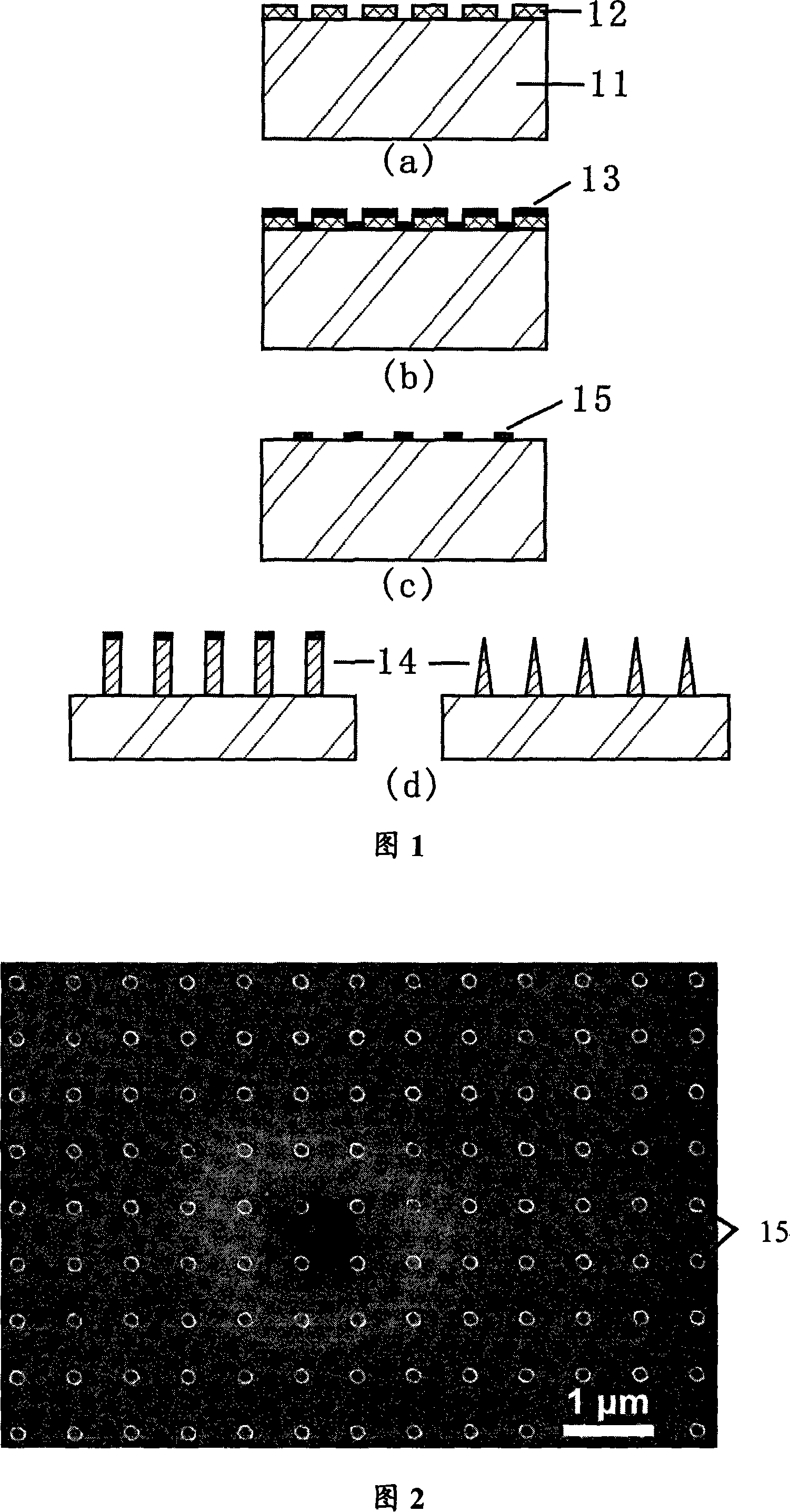

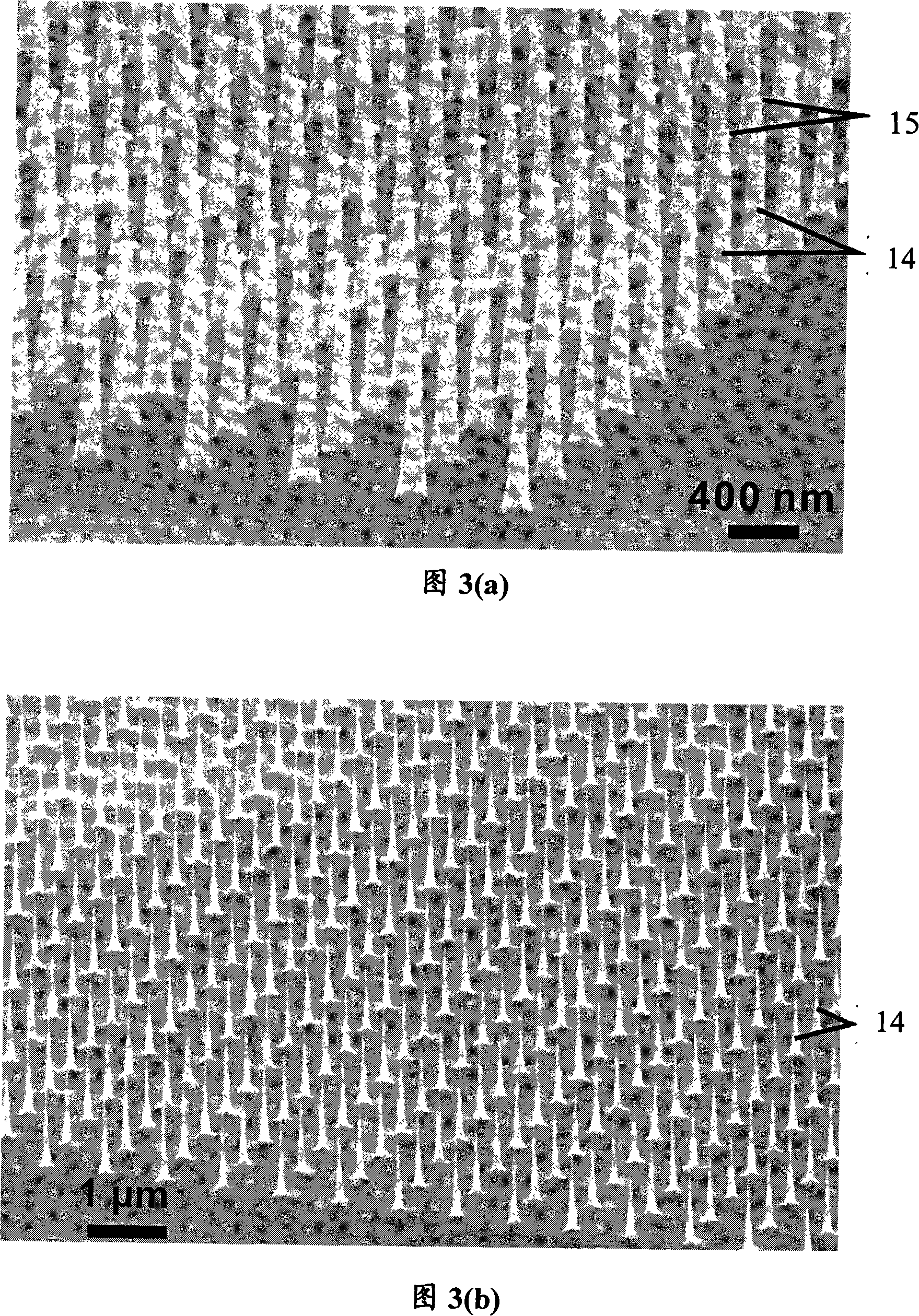

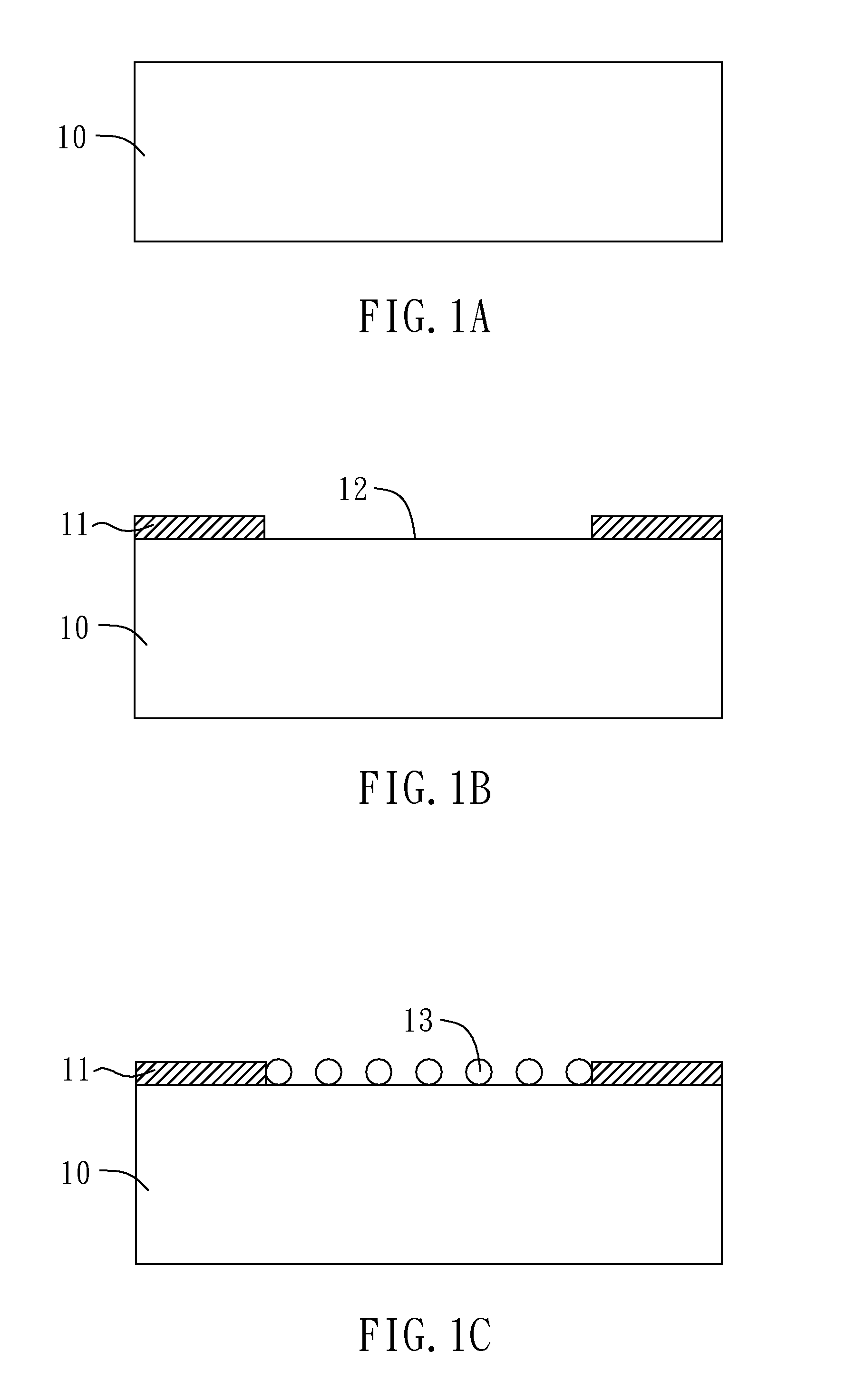

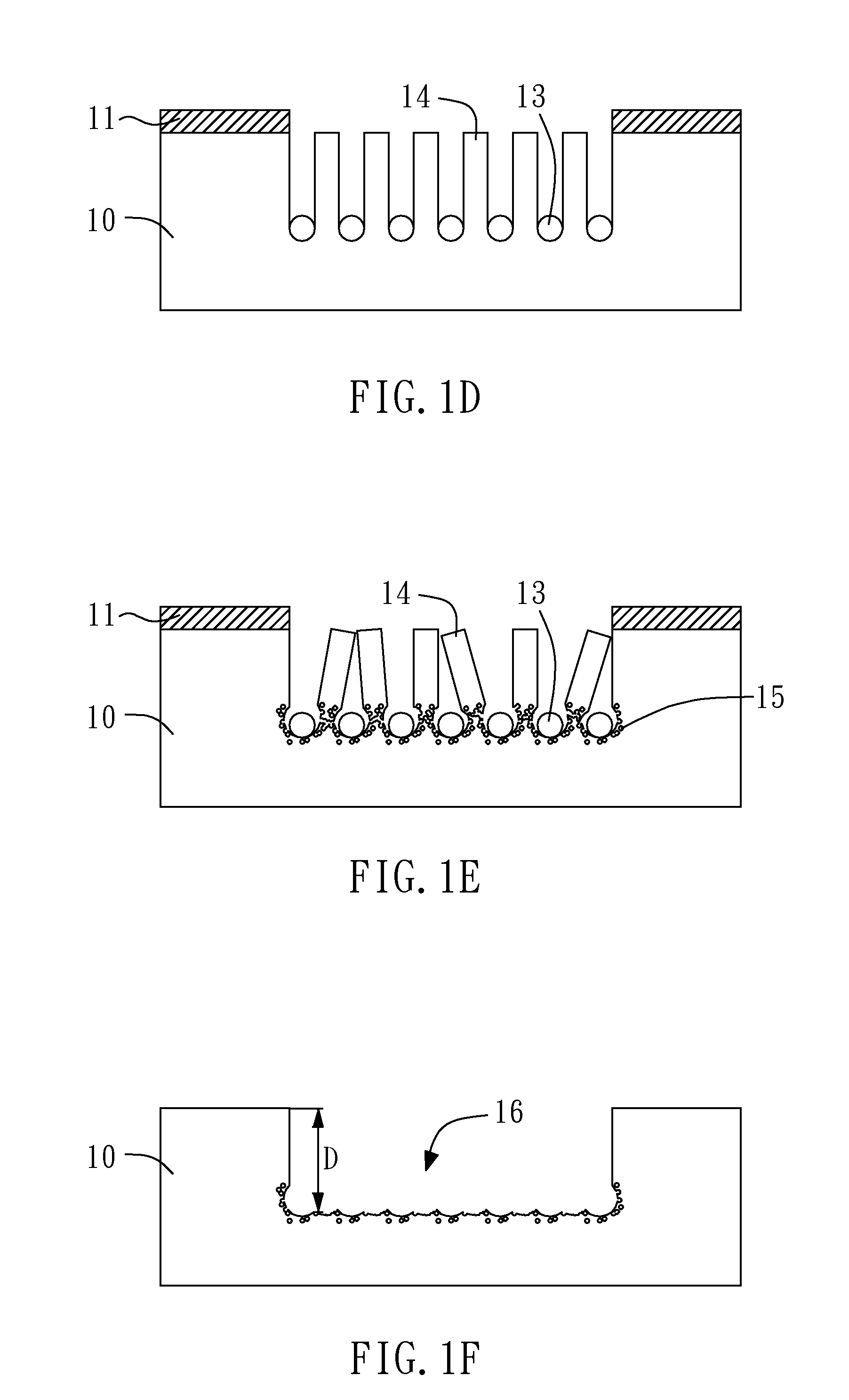

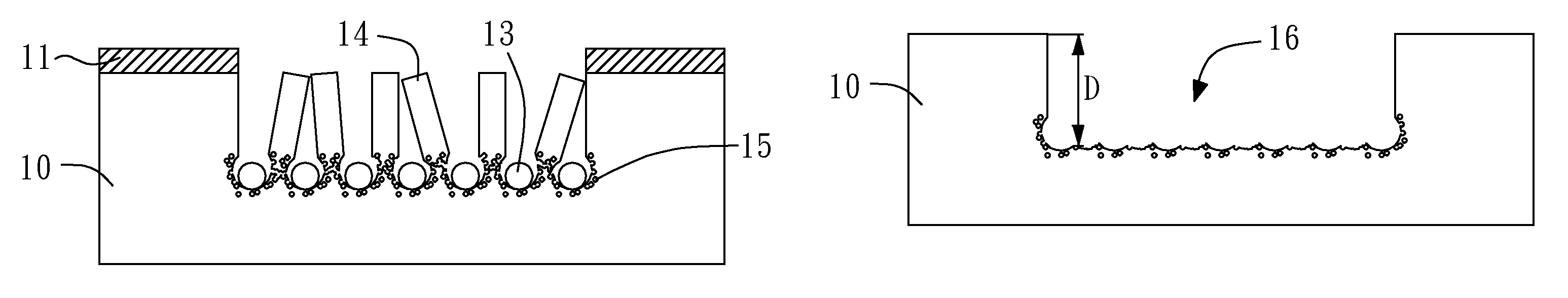

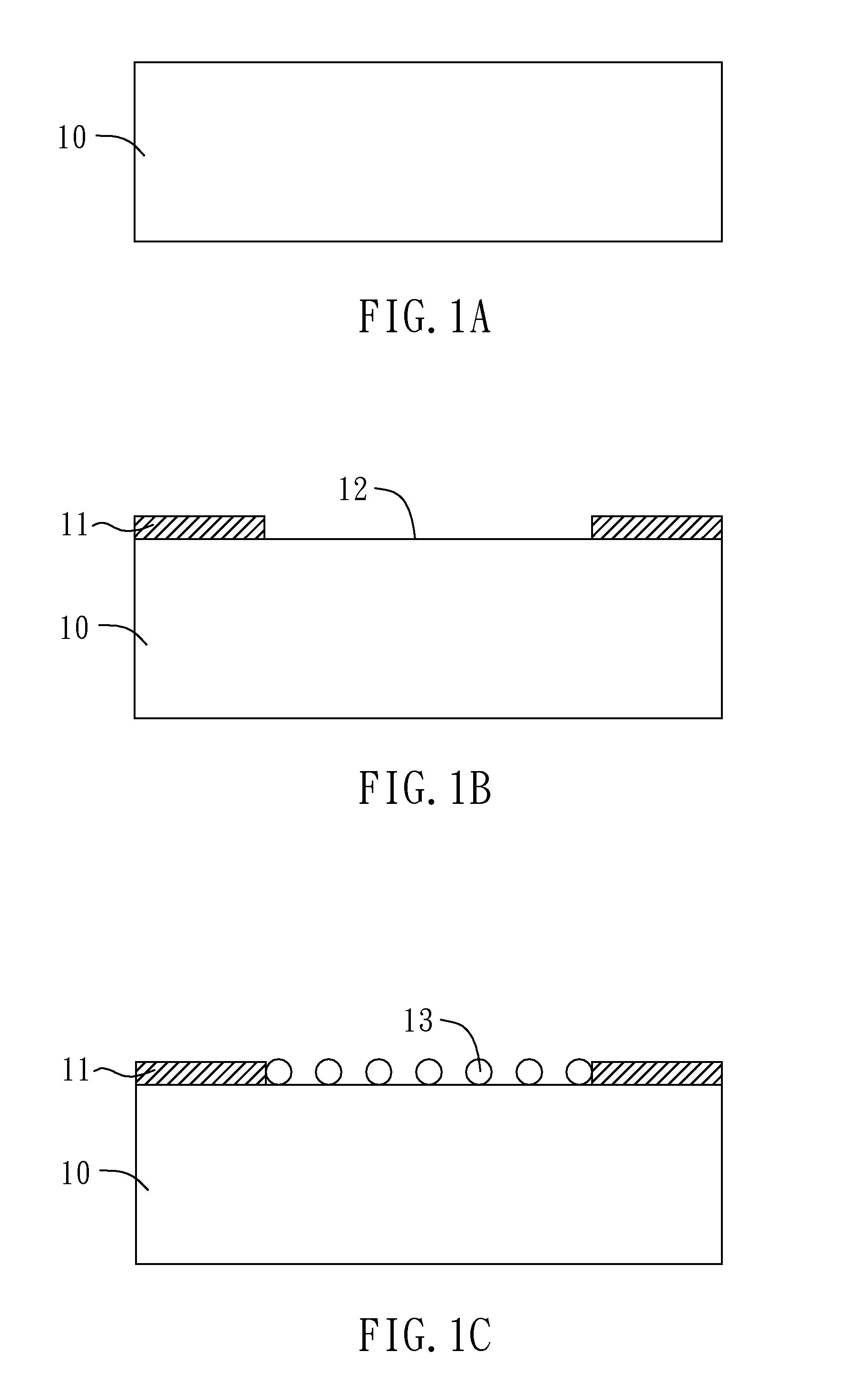

The invention discloses a method for preparing one-dimensional silicon nanostructure. The order of the processing steps adopted by the invention is as follows: (A) nanometer particle mould is prepared on the surface of backing material; (B) etching of the backing material is completed by use of plasma etching technology. The step (A) includes the following procedures: (i) the surface of backing material is coated with one layer of photoresist through spin coating at first, and then micropores are formed at the surface of backing material through adopting electronic photoetching technique; (ii) one layer of mask film is deposited on the surface of backing material; (iii) photoresist peeling-off of the surface of backing material deposited with the mask film is completed so as to form the nanometer particle mask at the micropores of procedure (i). In addition, step (A) can also be as follows: one layer of metallic film is firstly deposited on the surface of backing material and then heat treatment of the metallic film is completed to obtain metallic nanometer particle mask on the surface of backing material. The silicon nano wire / tip prepared by the invention is characterized in erection, order and controllable position and diameter etc., thereby being particularly favorable to manufacture and assembly of device.

Owner:SUN YAT SEN UNIV

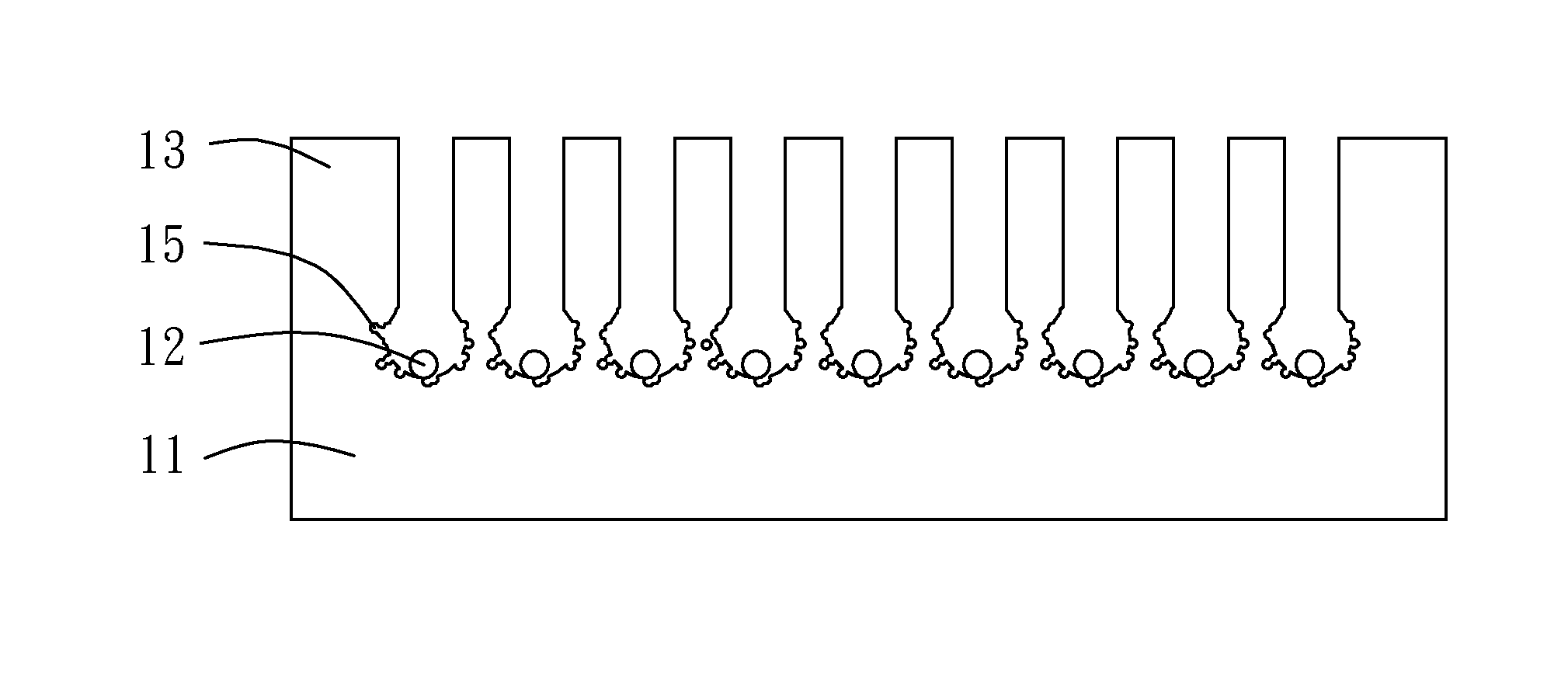

Method for producing silicon nanostructures

ActiveUS8334216B2Improve performanceReduce manufacturing costMaterial nanotechnologyNanoinformaticsEtchingMaterials science

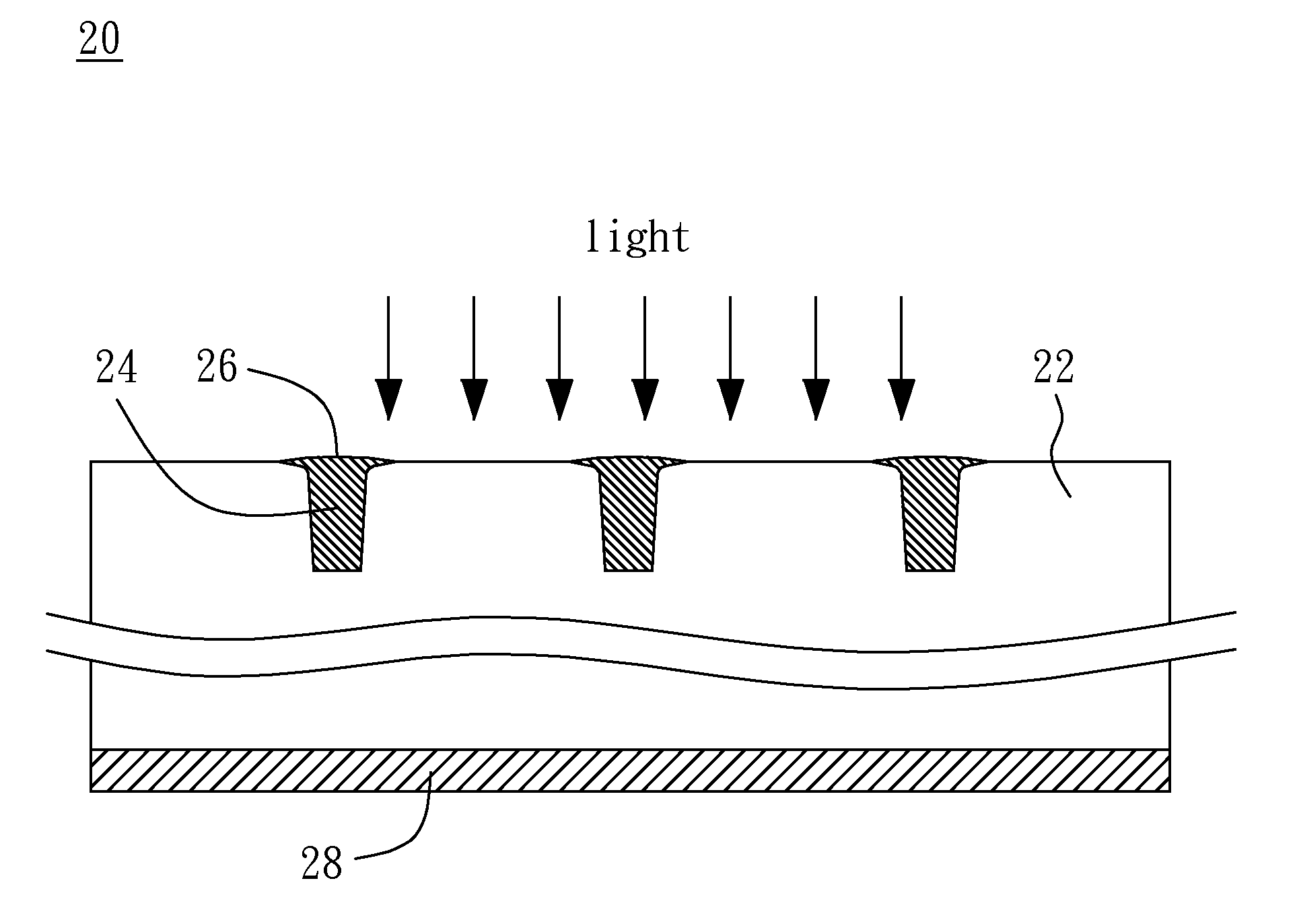

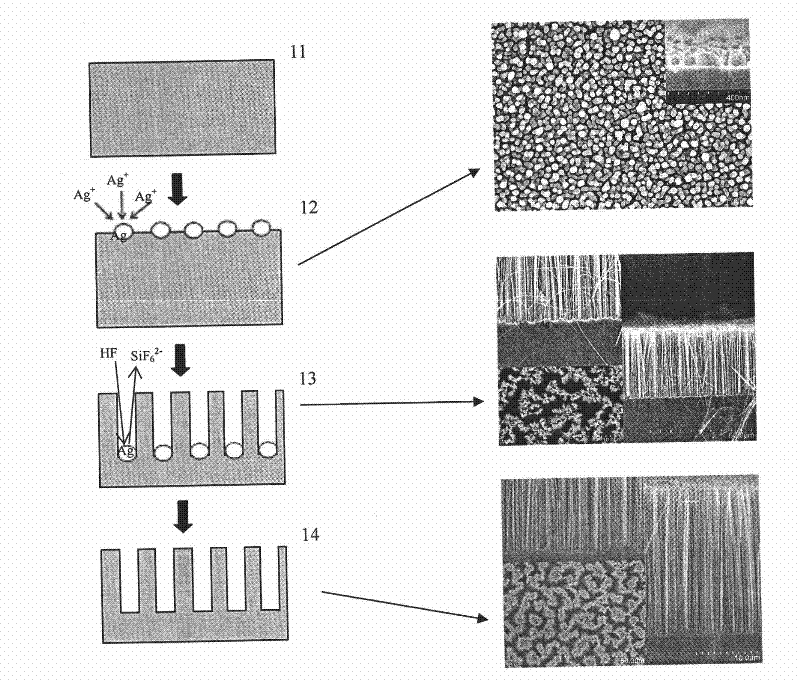

The present invention provides silicon nanostructures and their producing method. By employing a metal-assisted chemical etching method, the bottom of the produced silicon nanostructures, connected to the silicon substrate, is porous and side etched, such that the silicon nanostructures can be easily transferred to a hetero-substrate by a physical manner.

Owner:NAT TAIWAN UNIV

Method for forming silicon trench

ActiveUS20110294255A1Low costFinal product manufactureNanoinformaticsMetal catalystMaterials science

A method for forming a silicon trench, comprises the steps of: defining an etching area at a silicon substrate; forming metal catalysts at the surface of the etching area; immersing the silicon substrate in a first etching solution thereby forming anisotropic silicon nanostructures in the etching area; immersing the silicon substrate in a second etching solution thereby resulting in the silicon nanostructures being side-etched and detached from the silicon substrate, thus forming the silicon trench.

Owner:NAT TAIWAN UNIV

Method for forming silicon trench

ActiveUS8193095B2Low costFinal product manufactureNanoinformaticsMetal catalystSilicon nanostructures

Owner:NAT TAIWAN UNIV

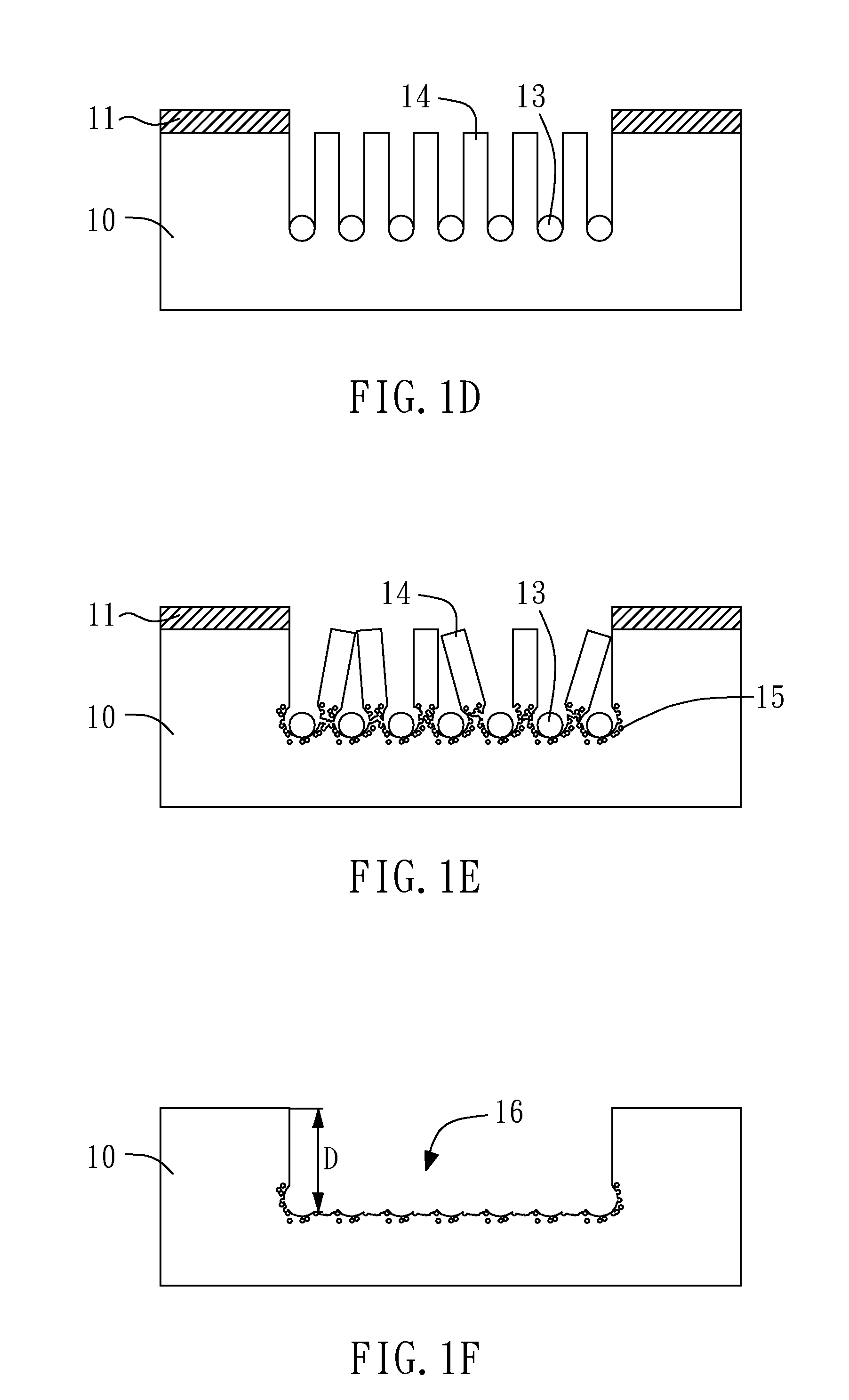

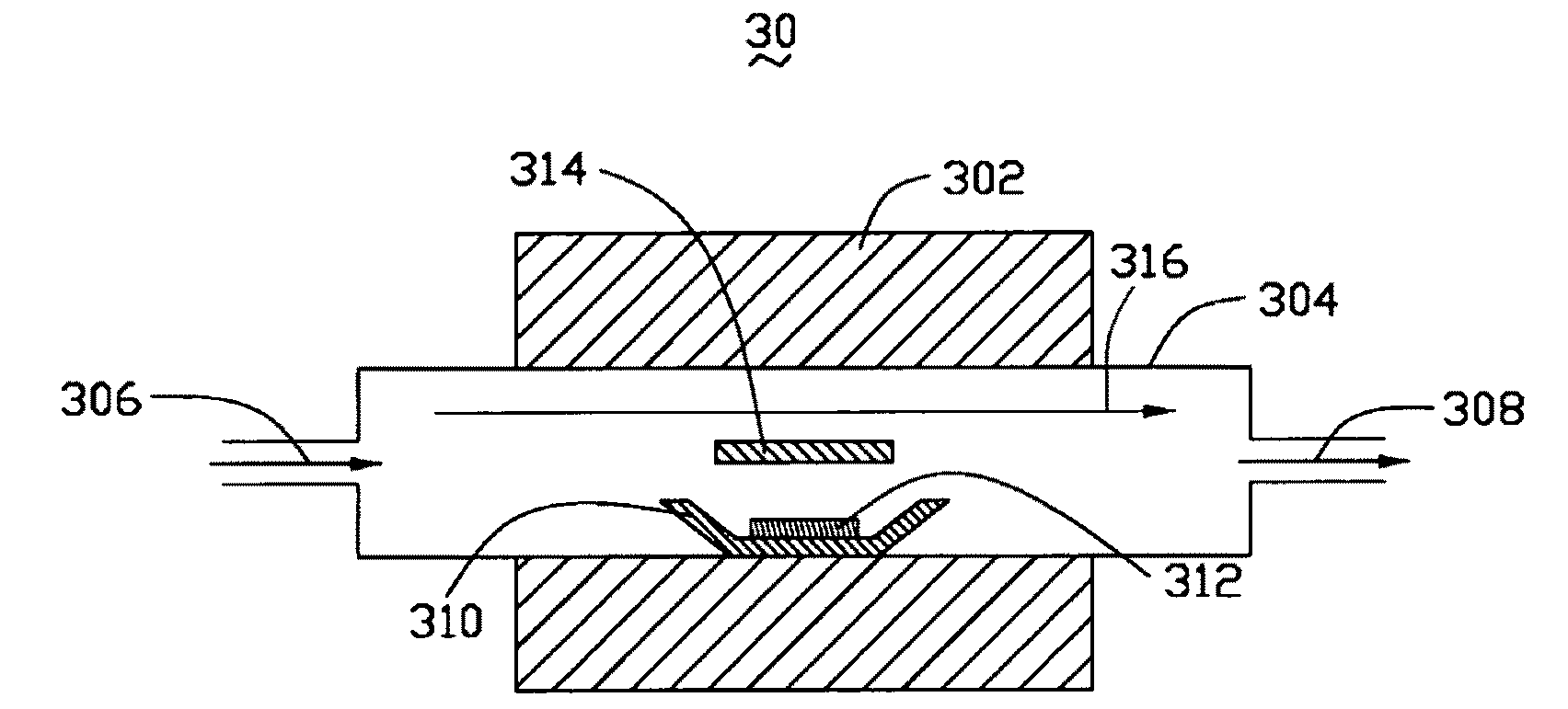

Method of manufacturing silicon nano-structure

A method for making silicon nano-structure, the method includes the following steps. Firstly, providing a growing substrate and a growing device, the growing device comprising a heating apparatus and a reacting room. Secondly, placing the growing substrate and a quantity of catalyst separately into the reacting room. Thirdly, introducing a silicon-containing gas and hydrogen gas into the reacting room. Lastly, heating the reacting room to a temperature of 500˜1100° C.

Owner:TSINGHUA UNIV +1

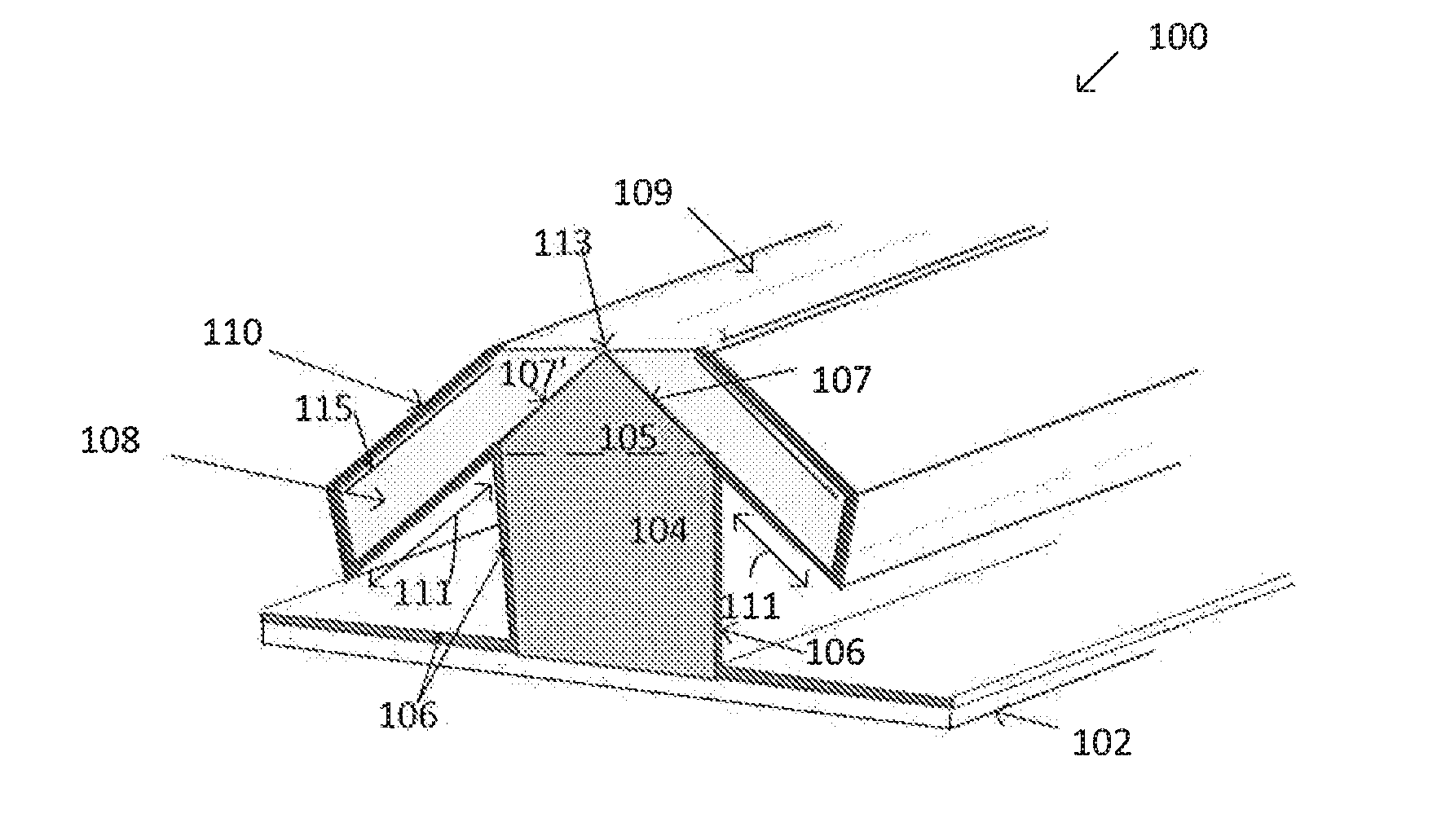

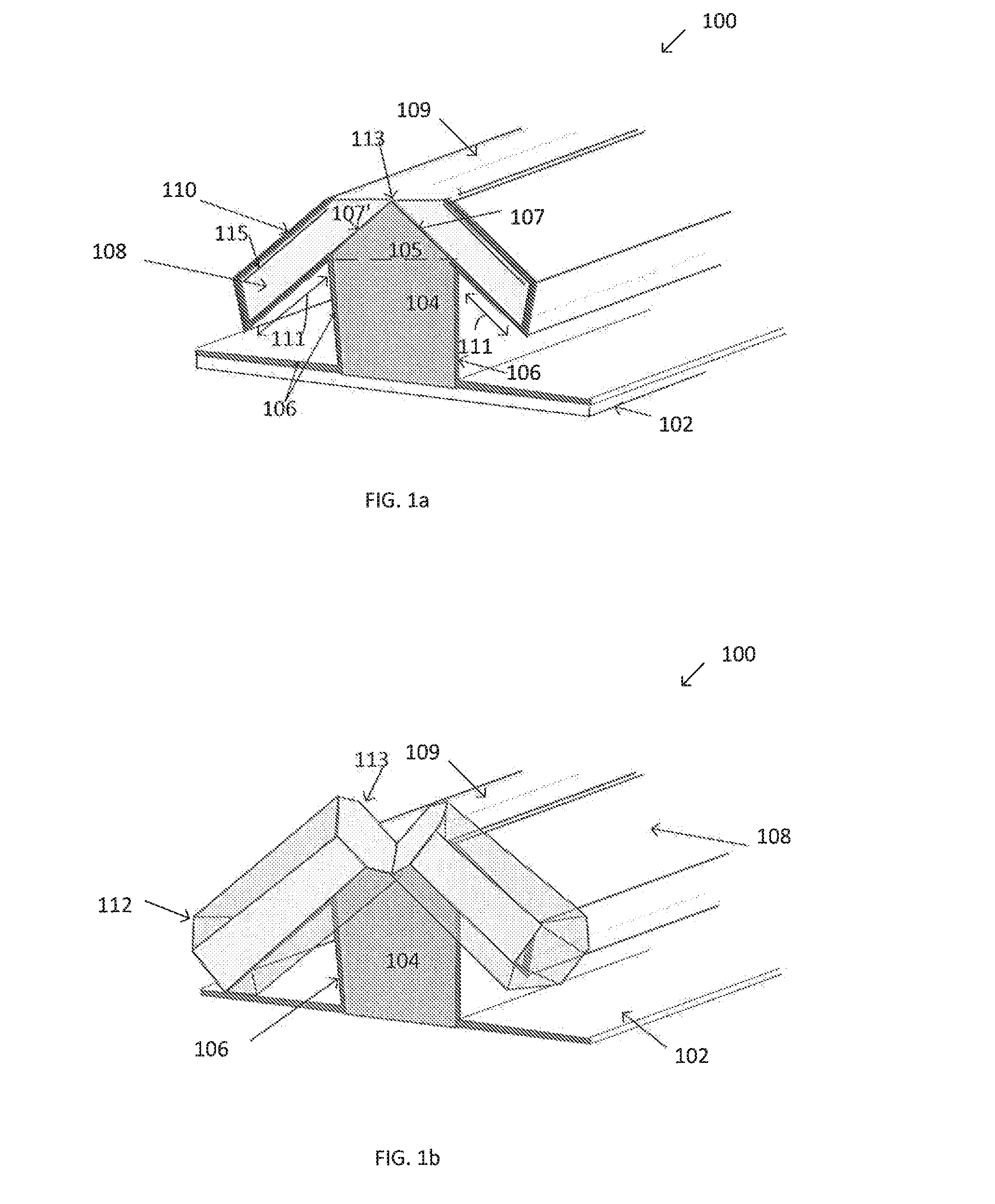

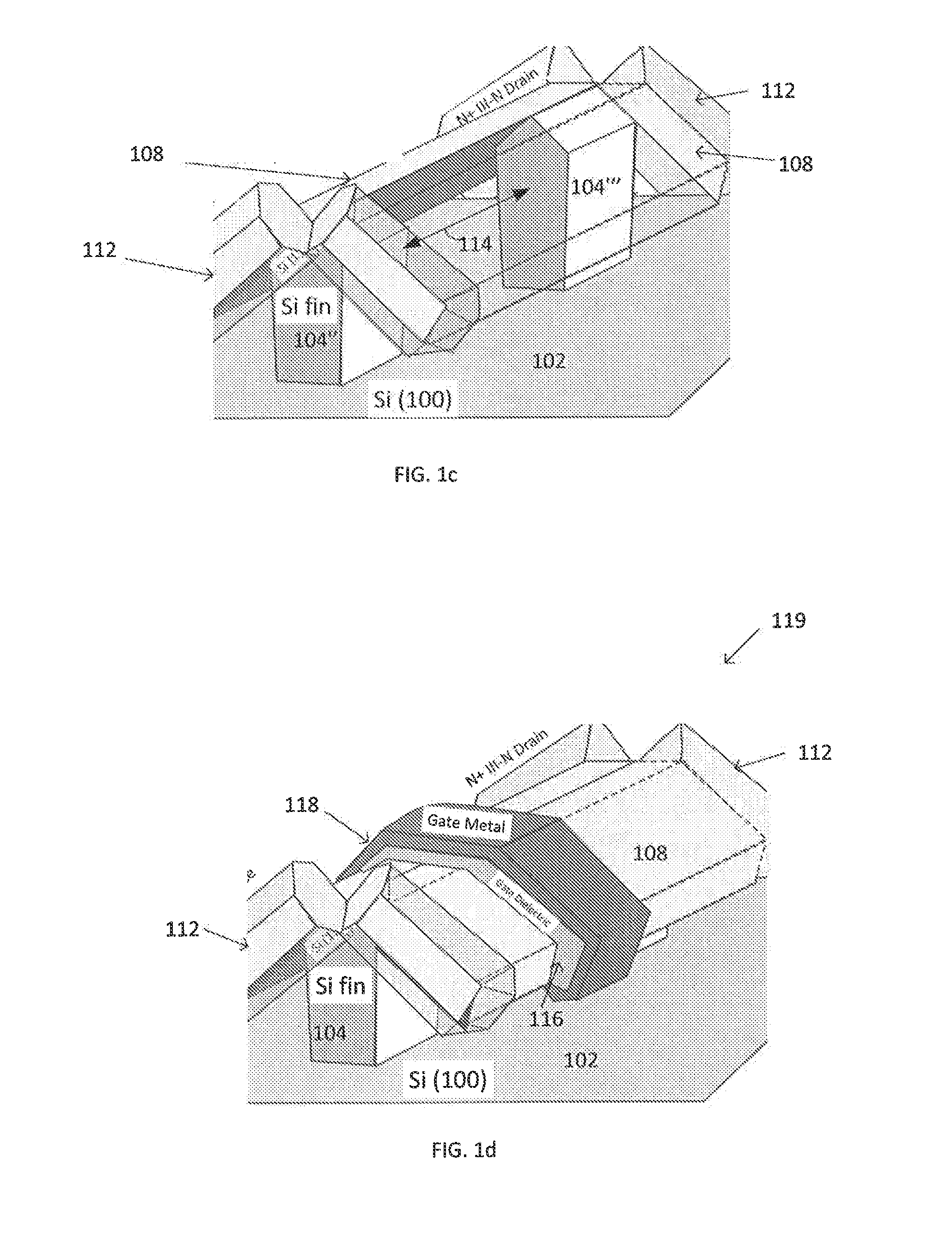

Forming iii-v device structures on (111) planes of silicon fins

Methods of forming high voltage (111) silicon nano-structures are described. Those methods and structures may include forming a III-V device layer on (111) surface of a silicon fin structure, forming a 2DEG inducing polarization layer on the III-V device layer, forming a source / drain material on a portion of the III-V device layer on terminal ends of the silicon fin. A middle portion of the silicon fin structure between the source and drain regions may be removed, and backfilled with a dielectric material, and then a gate dielectric and a gate material may be formed on the III-V device layer.

Owner:INTEL CORP

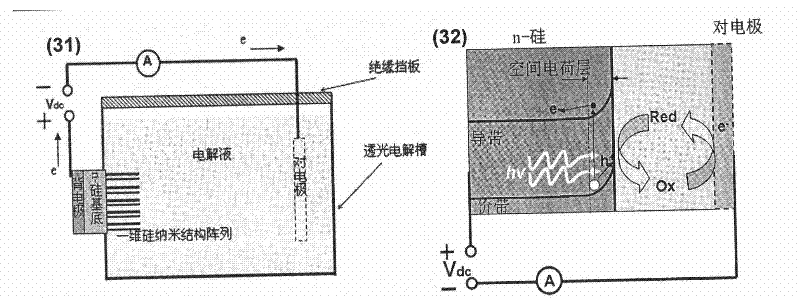

Visible photoelectrochemical detector based on one-dimensional silicon nanostructure array

ActiveCN102226715AEasy transferEasy to makeDecorative surface effectsCoupling light guidesControllabilityVacuum evaporation

The invention, which belongs to the nanometer material performance and application field, discloses a visible photoelectrochemical detector based on a one-dimensional silicon nanostructure array. The detector is characterized in that: the detection of visible lights is allowed by utilizing response characteristic of photoelectrochemistry of the one-dimensional silicon nanostructure array that has good light absorption performance. The manufacturing process of the detector and required equipment are relatively simple. And the detector has good controllability and high optical responsivity. The construction process of a detector comprises the following steps: (1), preparing a one-dimensional silicon nanostructure array by utilizing a metal-catalyzed anisotropy chemical etching method; (2), depositing a conducting layer on the back of the one-dimensional silicon nanostructure array by utilizing a magnetron sputtering technology or a vacuum evaporation technology and carrying out annealing process to form a photoelectrode of the one-dimensional silicon nanostructure array; (3), constructing a visible photoelectrochemical detector based on the photoelectrode of the one-dimensional silicon nanostructure array. According to the invention, the visible photoelectrochemical detector is constructed by utilizing the high response characteristic of photoelectrochemistry of the one-dimensional silicon nanostructure array, thereby expanding the application field of semiconductor nanometer materials.

Owner:BEIJING NORMAL UNIVERSITY

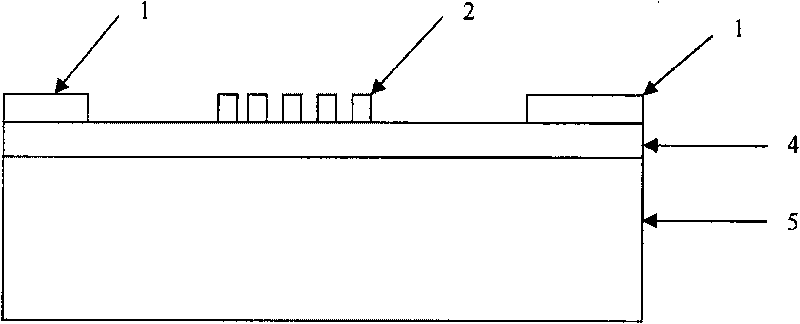

Material with metal silicide nanostructure and method for making the same

InactiveCN101207137AEliminates latch-upImprove integration densitySolid-state devicesSemiconductor/solid-state device manufacturingMetal silicideSilicon thin film

The invention relates to a material with metal silicide nanometer structure and the preparation method thereof. The material comprises a metal silicide nanometer structure which is produced on an SOI substrate; the thickness of an insulation medium layer of the SOI substrate is 100 to 1000 nanometers, and the thickness of silicon thin film is 50 to 500 nanometers. The preparation method comprises the following steps: a required mask feature structure of nanometer structure is produced on the silicon thin film surface of the SOI substrate after cleaning, drying, spin coating positive photoresist, exposing, developing, and fixing; the silicon thin film of the SOI substrate is etched to the required nanometer structure by adopting a reactive ion etching, the etching depth is equal to the thickness of the silicon thin film, a metal thin film which is required by the metal silicide is deposited on the isolation layer which contains the silicon nanometer structure, then high temperatures anneal is performed to ensure that soild phase reaction is reacted between the metal and the silicon, thus to generate the metal silicide, the unreacted metal is removed through chemical etch, and then the metal silicide nanometer structure is formed. The method is simple, and the position and the dimension of the nanometer structure can be controlled.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Silicon substrate having nanostructures and method for producing the same and application thereof

ActiveUS20110204489A1Improve anti-reflection effectReduce areaSemiconductor/solid-state device detailsSolid-state devicesIonSilicon nanostructures

A method for forming a silicon substrate having a multiple silicon nanostructures includes the steps of: providing a silicon substrate; forming an oxidization layer on the silicon substrate; immersing the silicon substrate in a fluoride solution including metal ions, thereby depositing a plurality of metal nanostructures on the silicon substrate; and immersing the silicon substrate in an etching solution to etch the silicon under the metal nanostructures, the unetched silicon forming the silicon nano structures.

Owner:NAT TAIWAN UNIV

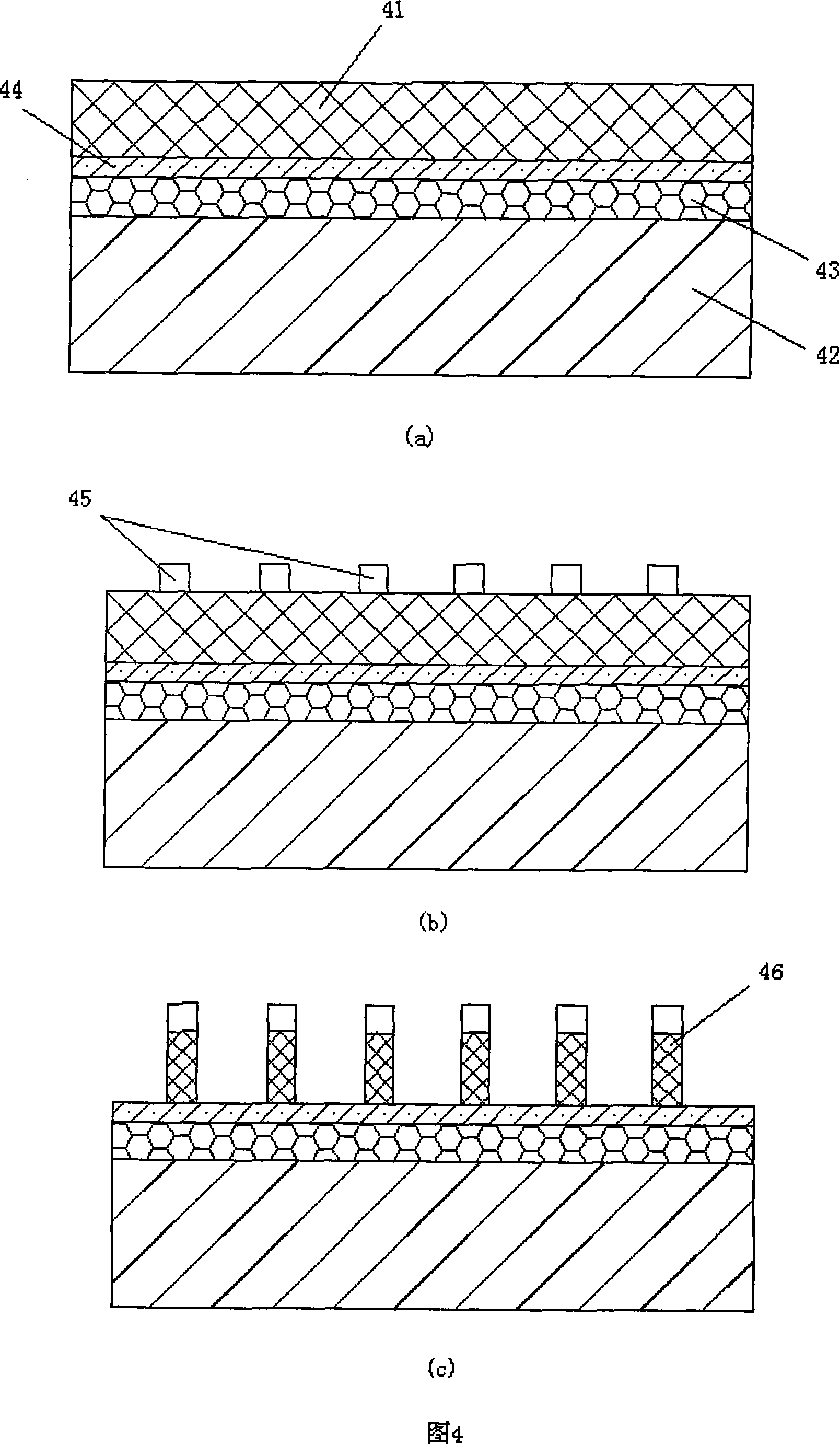

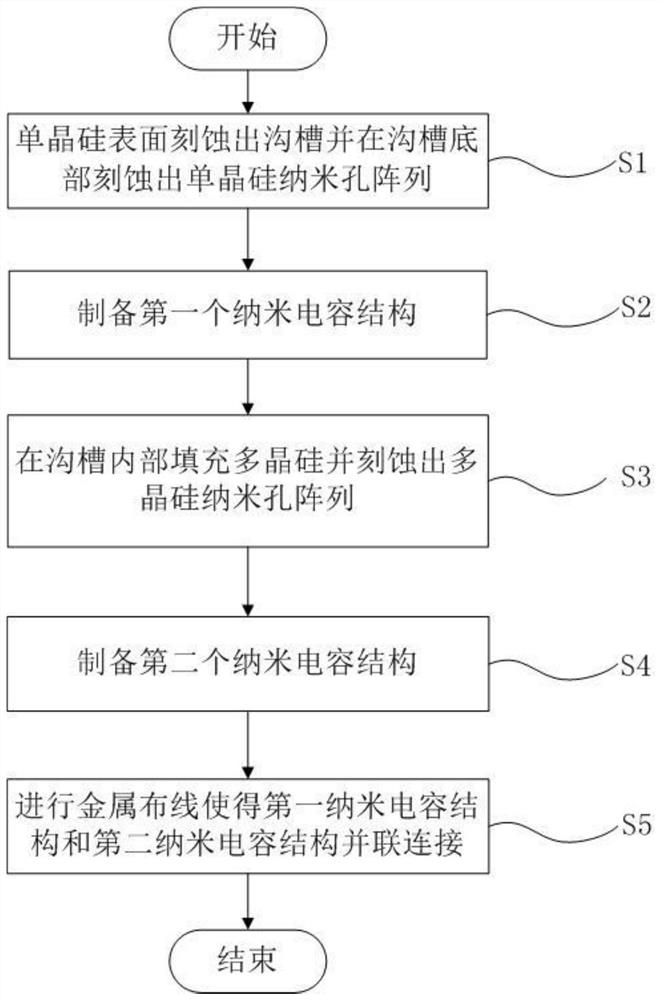

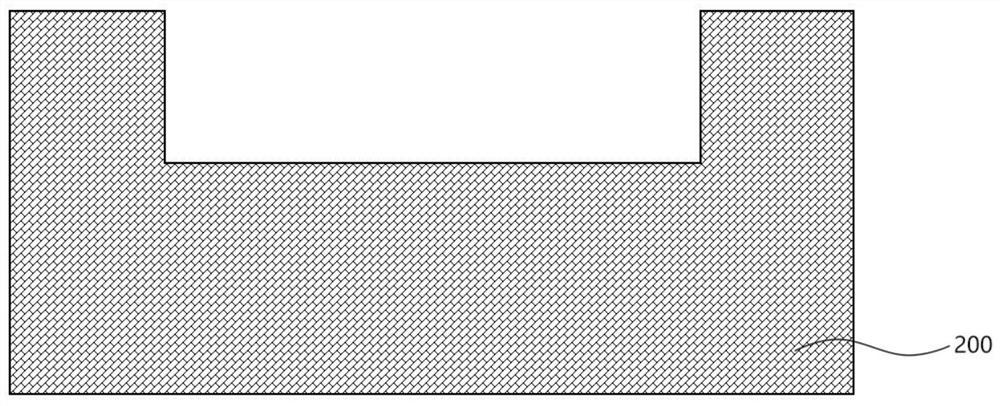

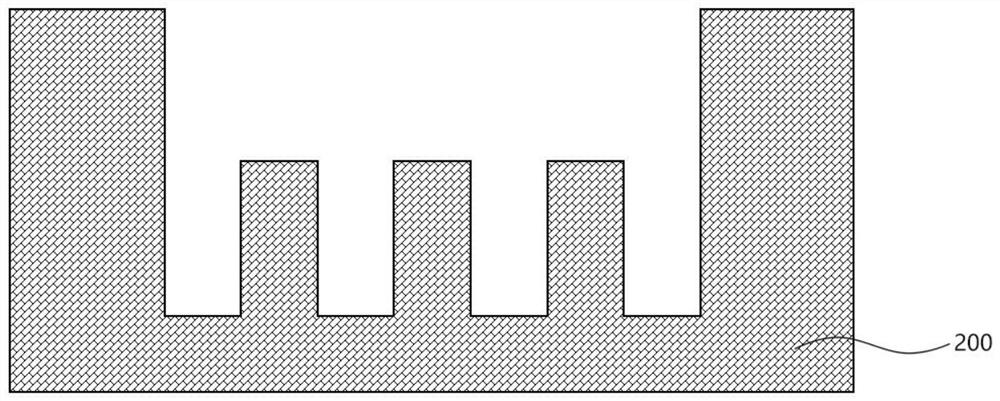

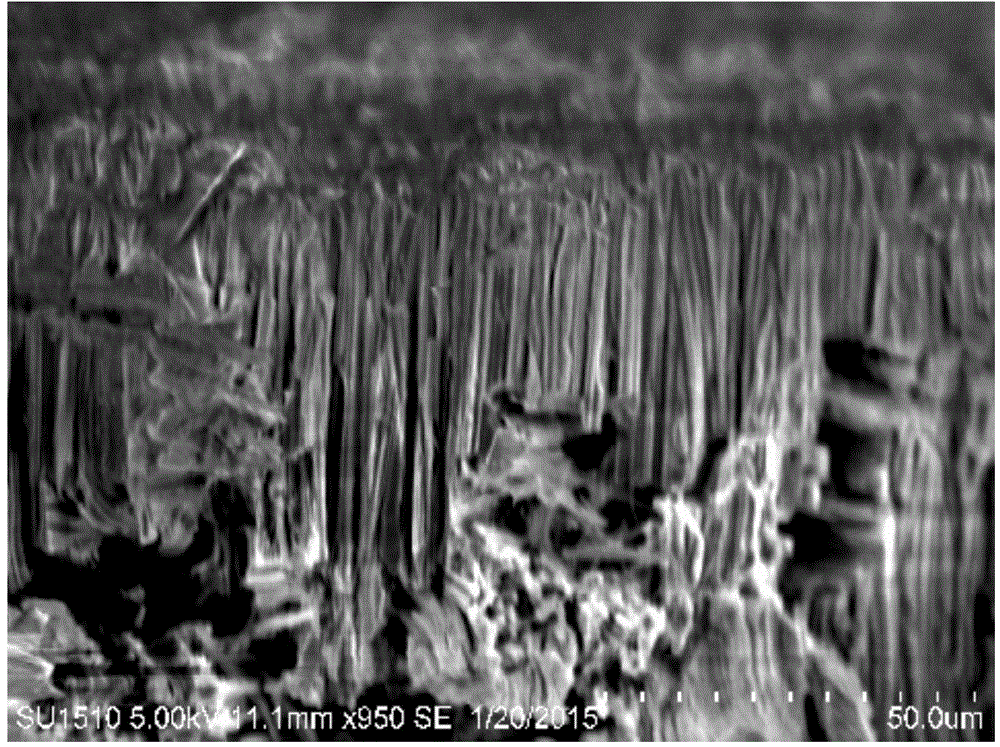

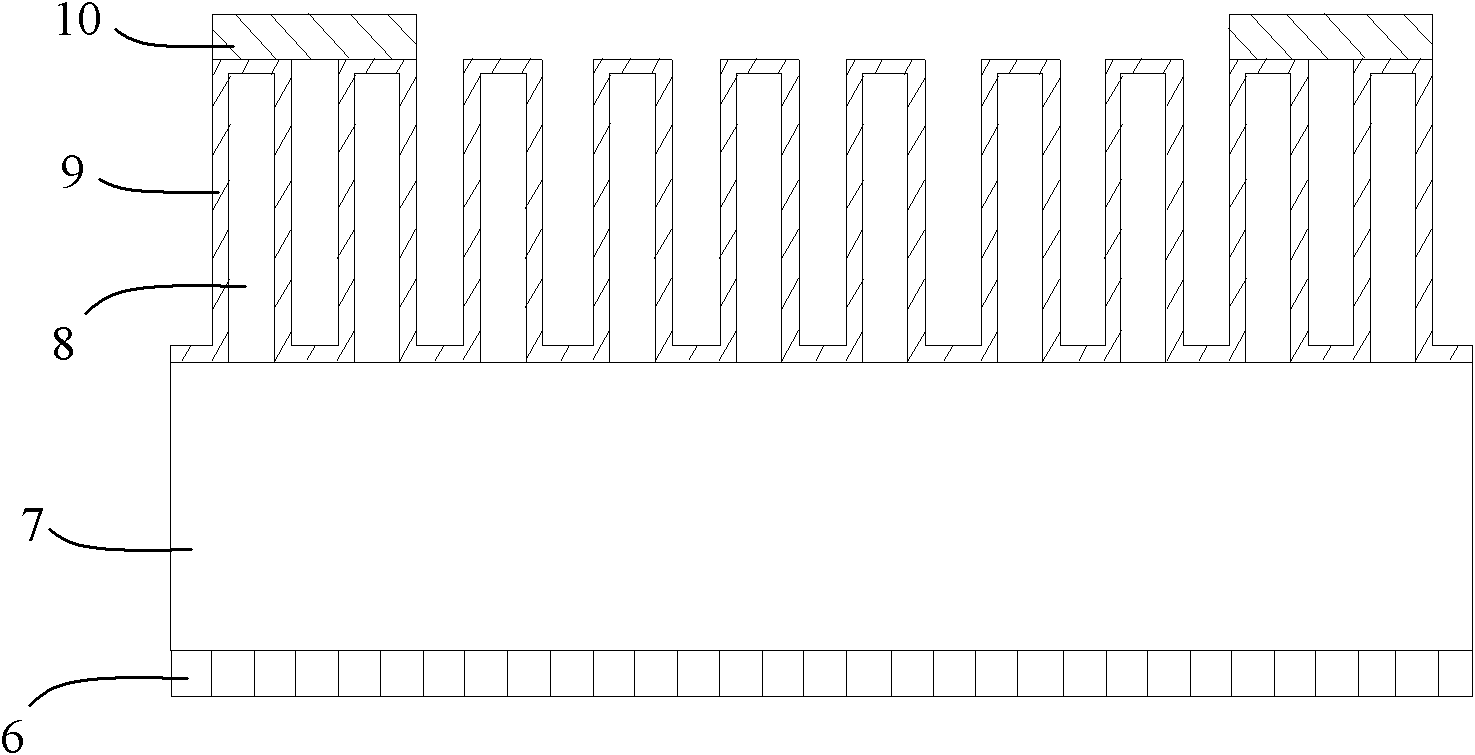

Nano-capacitor three-dimensional integrated structure and preparation method thereof

ActiveCN112018070ASemiconductor/solid-state device detailsSolid-state devicesCapacitanceManufacturing cost reduction

The invention discloses a nano-capacitor three-dimensional integrated structure and a preparation method thereof. The nano-capacitor three-dimensional integrated structure comprises a first nano-capacitor structure and a second nano-capacitor structure which are vertically stacked and formed in a groove of a silicon substrate, and the first nano-capacitor structure and the second nano-capacitor structure are connected in parallel. The high aspect ratio silicon nanostructure etched at one time is changed into the high aspect ratio silicon nanostructure etched at two times, so that the requirement on the precision of etching equipment can be reduced, and the manufacturing cost can be reduced. Due to the fact that the aspect ratio of a single silicon nanostructure is reduced, the step coverage rate of the thin film can be increased, the conformality of the thin film can also be enhanced, and therefore holes of the thin film in the deposition process can be reduced. And traditional sputtering equipment can be adopted to deposit a metal material, so that a metal electrode with relatively low resistivity can be obtained. Moreover, the overall capacitance density of the nano capacitor canbe improved, and the planar area occupied by the capacitor is reduced, so that a small-size energy buffer device can be obtained.

Owner:FUDAN UNIV +1

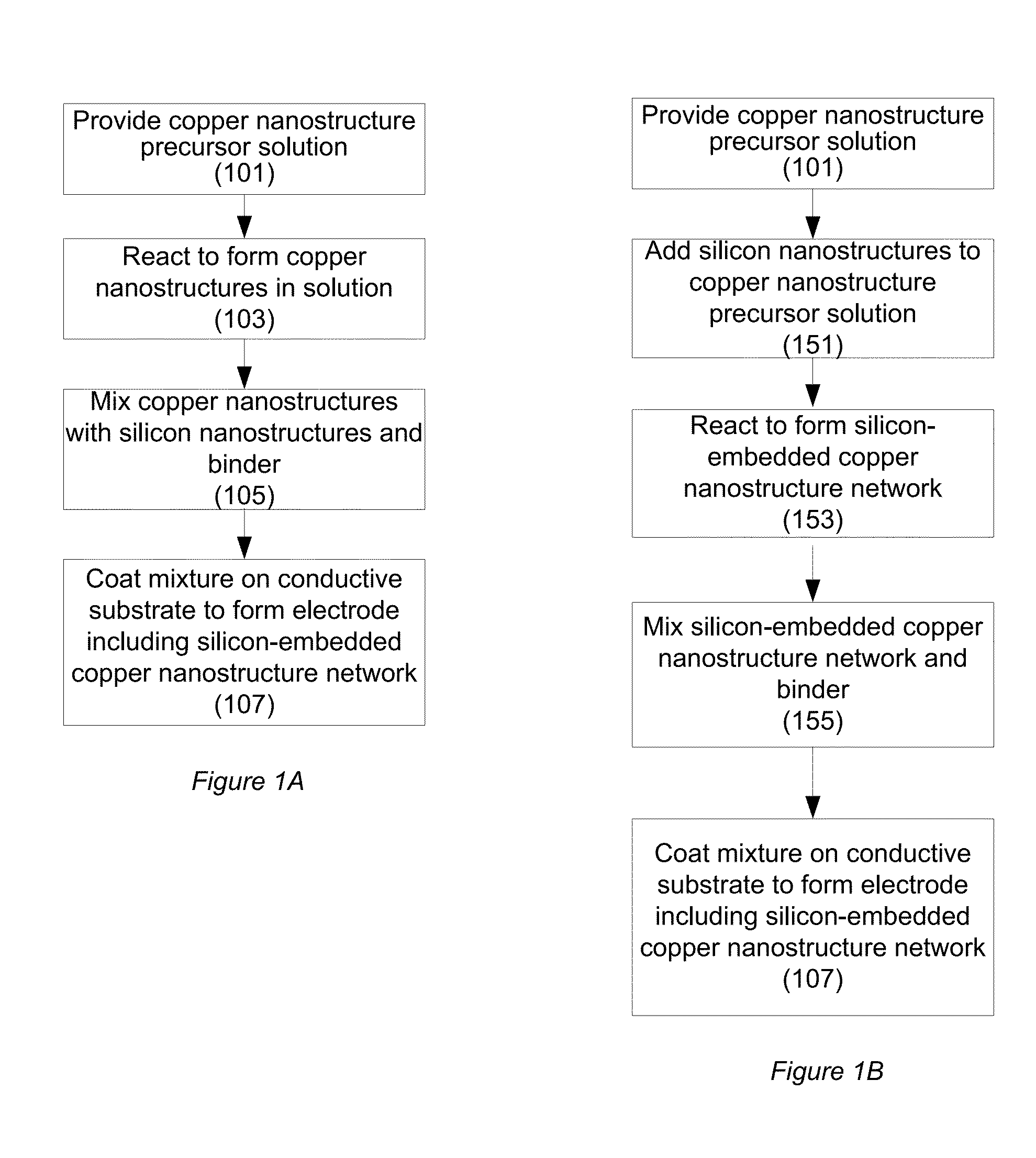

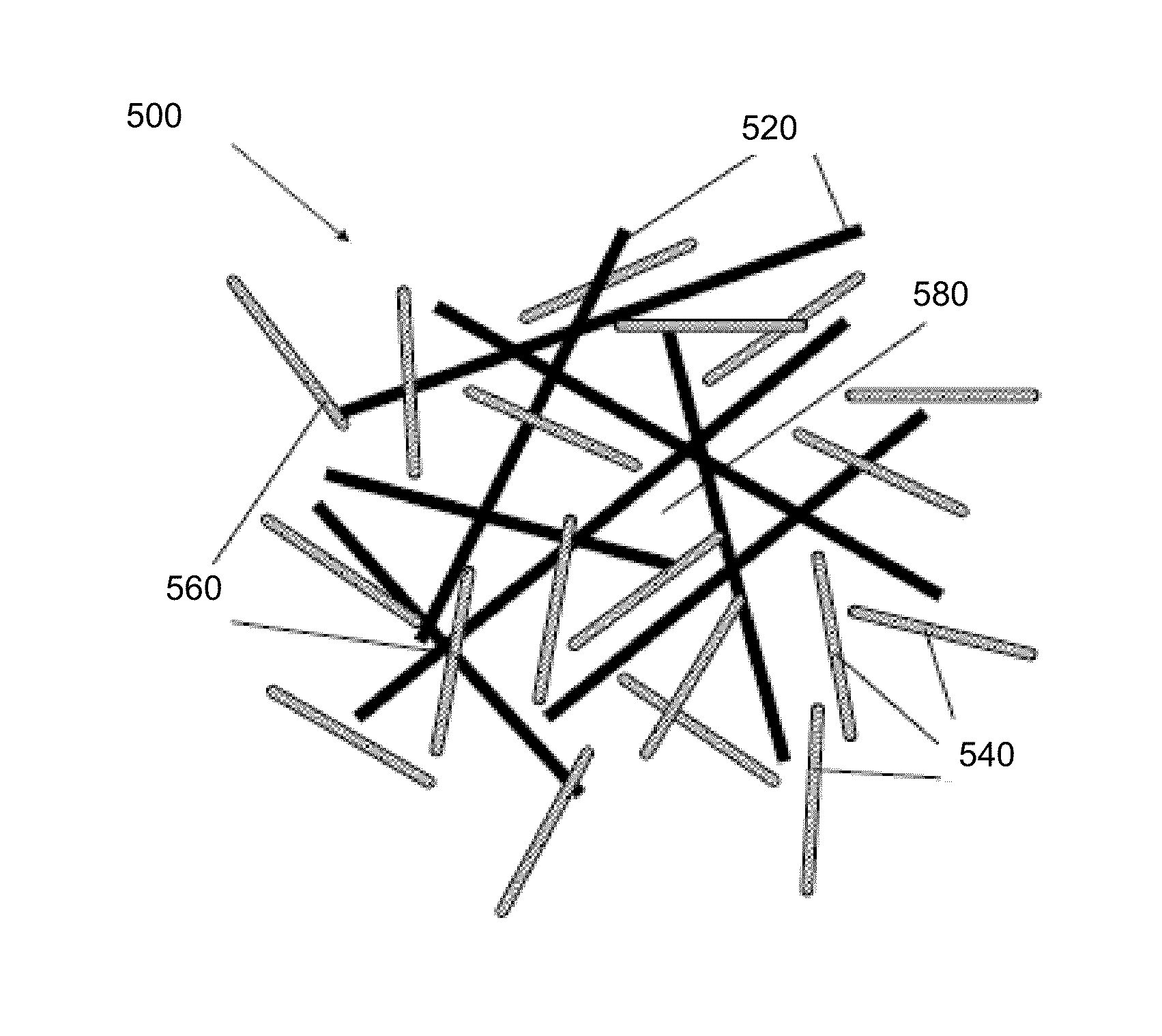

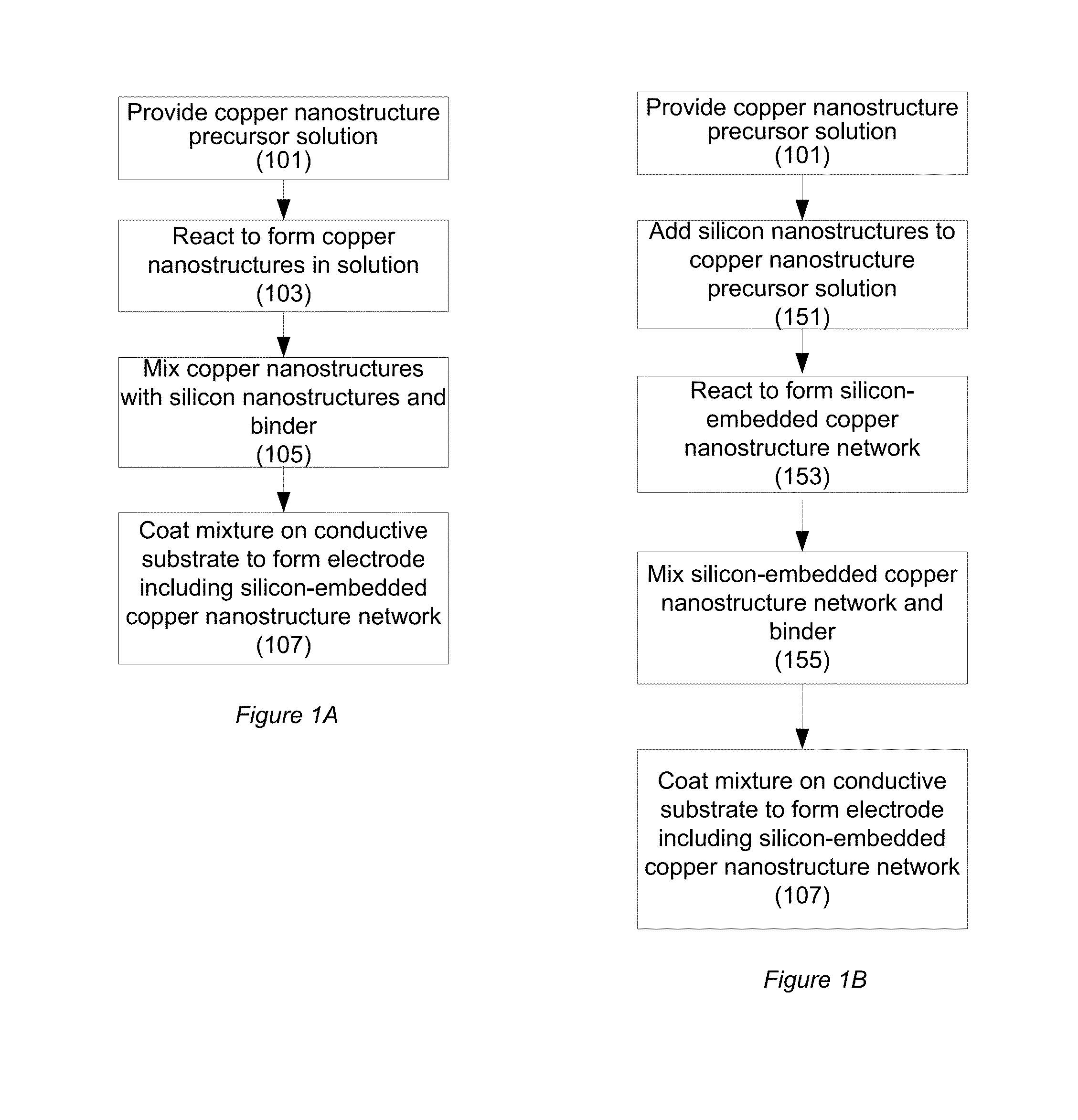

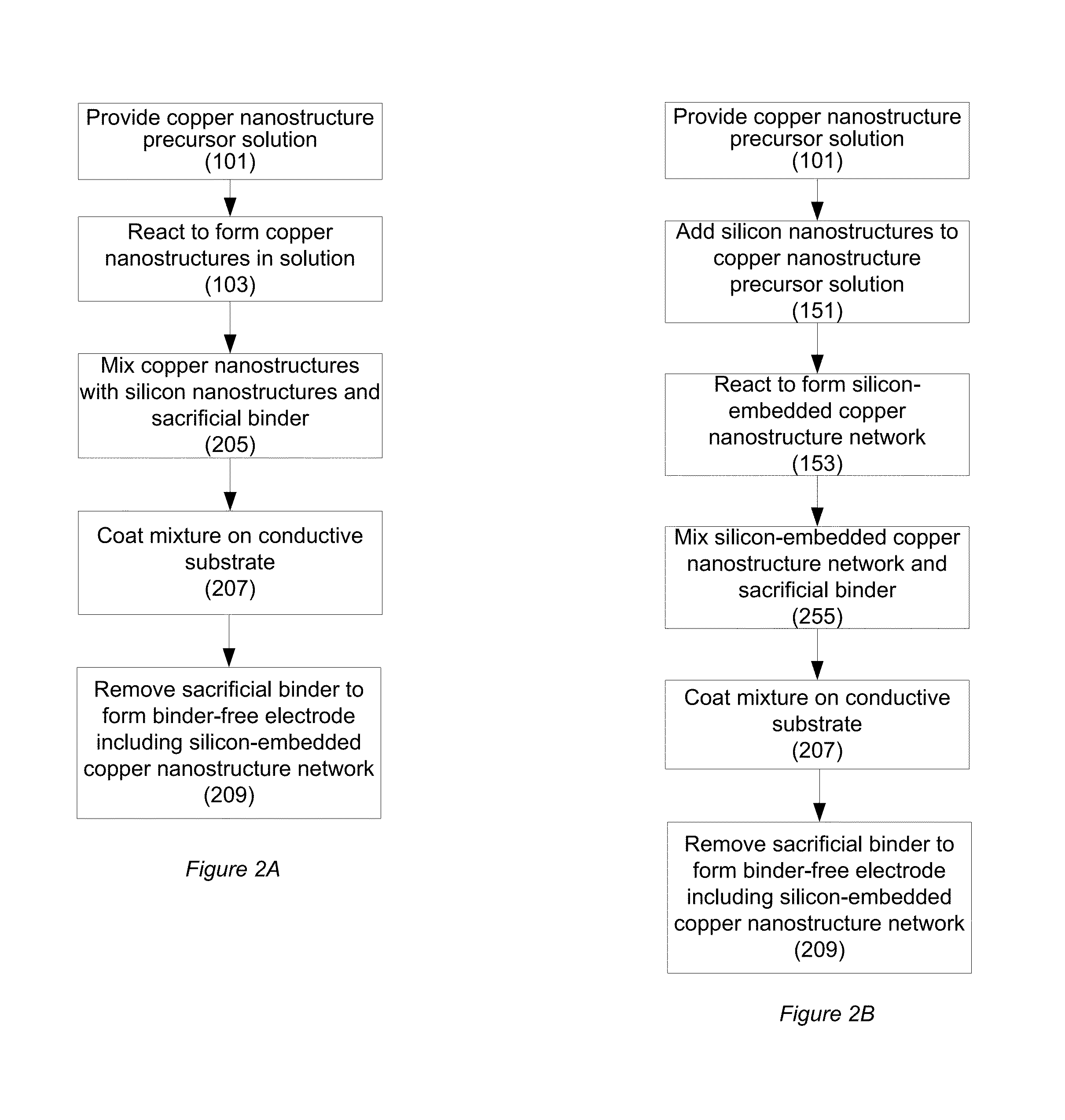

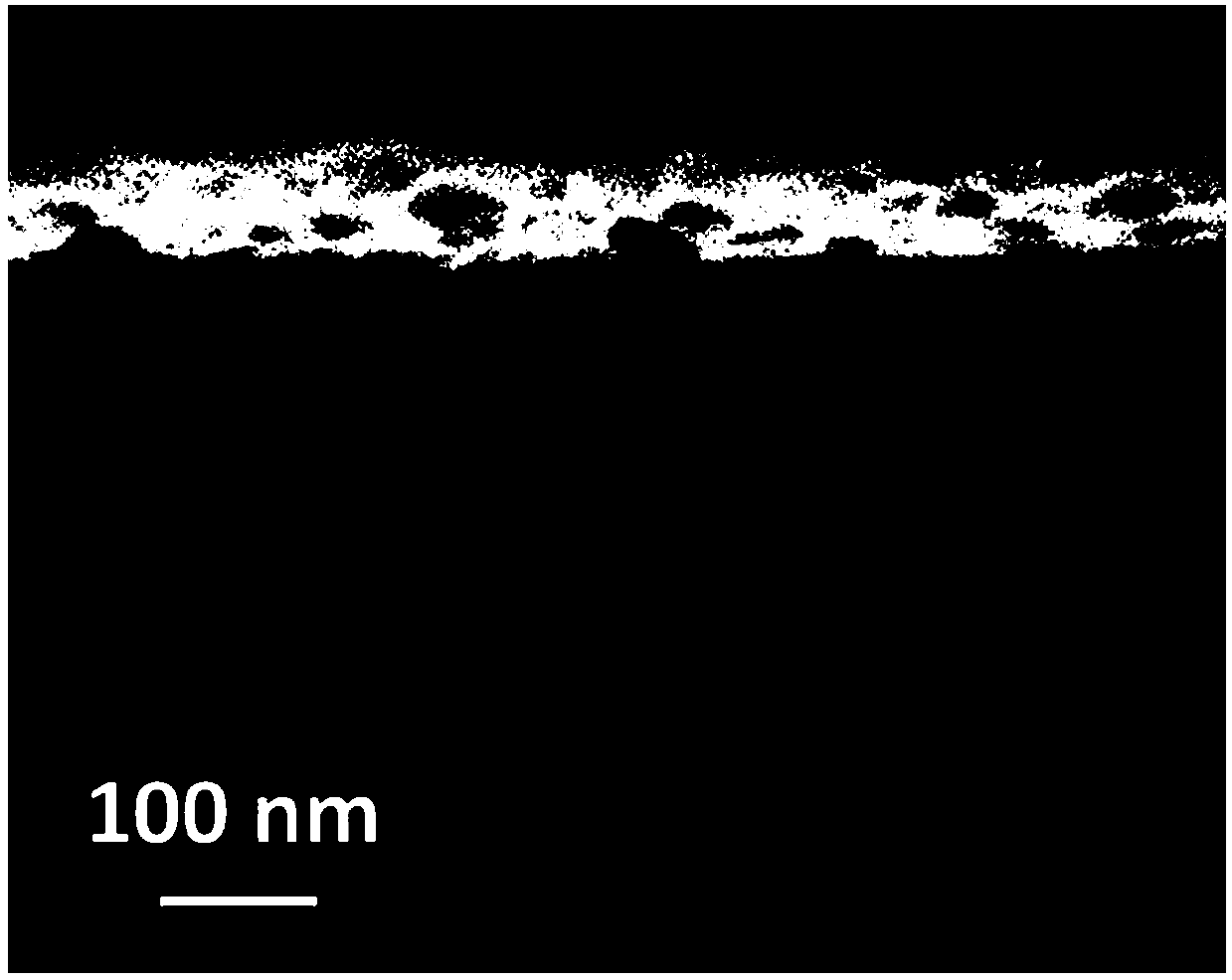

Silicon-embedded copper nanostructure network for high energy storage

Provided herein are nanostructure networks having high energy storage, electrochemically active electrode materials including nanostructure networks having high energy storage, as well as electrodes and batteries including the nanostructure networks having high energy storage. According to various implementations, the nanostructure networks have high energy density as well as long cycle life. In some implementations, the nanostructure networks include a conductive network embedded with electrochemically active material. In some implementations, silicon is used as the electrochemically active material. The conductive network may be a metal network such as a copper nanostructure network. Methods of manufacturing the nanostructure networks and electrodes are provided. In some implementations, metal nanostructures can be synthesized in a solution that contains silicon powder to make a composite network structure that contains both. The metal nanostructure growth can nucleate in solution and on silicon nanostructure surfaces.

Owner:AMPRIUS TECH INC

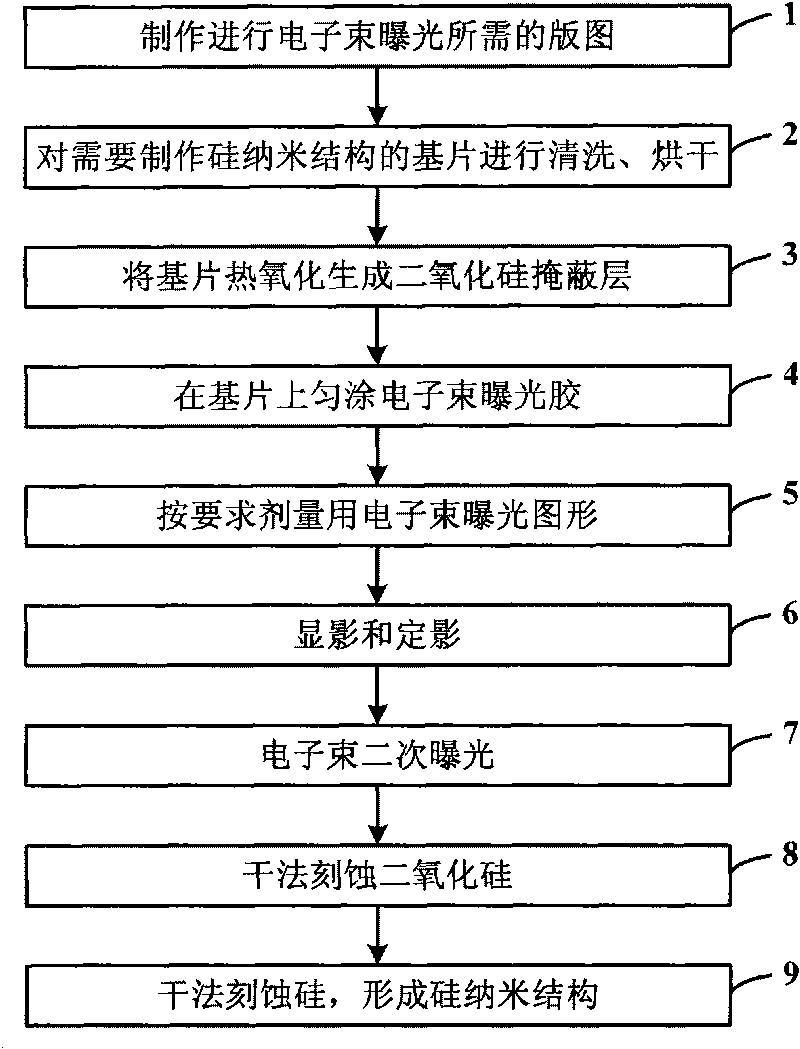

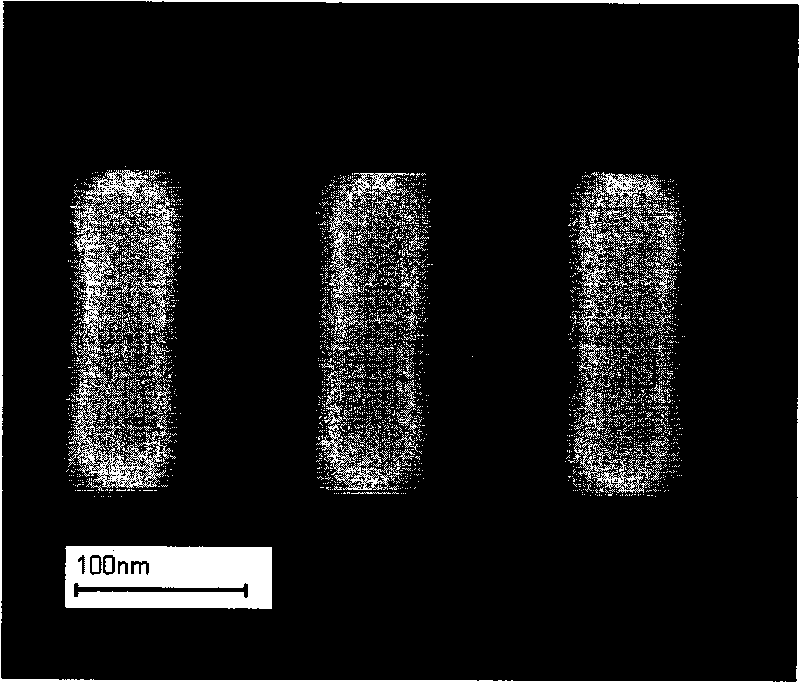

Method for manufacturing silicon nano structure

InactiveCN101759140AIncreased etch resistanceSmooth edgesNanostructure manufactureMicro nanoAdhesive

The invention discloses a method for manufacturing silicon nano structure, which relates to the technical field of semiconductor micro-nano processing in nano electron technology. The method comprises the following steps of: manufacturing a board pattern required by electron beam exposure; cleaning and drying a substrate which needs manufacturing the silicone nano structure; thermally oxidizing the substrate to produce a silicon dioxide masking layer; evenly coating the substrate with an electron beam exposure adhesive; exposing the pattern using electron beams as required dosage; developing and fixing; using electro beams for secondary exposure; carrying out dry etching on silicon dioxide; and carrying out dry etching on silicone to form the silicone nano structure. The method can manufacture the silicone nano structure smaller than 100 nm by using electron beam exposure and the dry etching technology; moreover, the silicone nano structure has regular shape, smooth edges and compact arrangement, and the finest part of the silicone nano structure can reach 30 nm.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Silicon solar cell and manufacturing method thereof

ActiveCN104051580AEnhanced charge transport capabilityImprove stabilityFinal product manufacturePhotovoltaic energy generationHeterojunctionSilicon solar cell

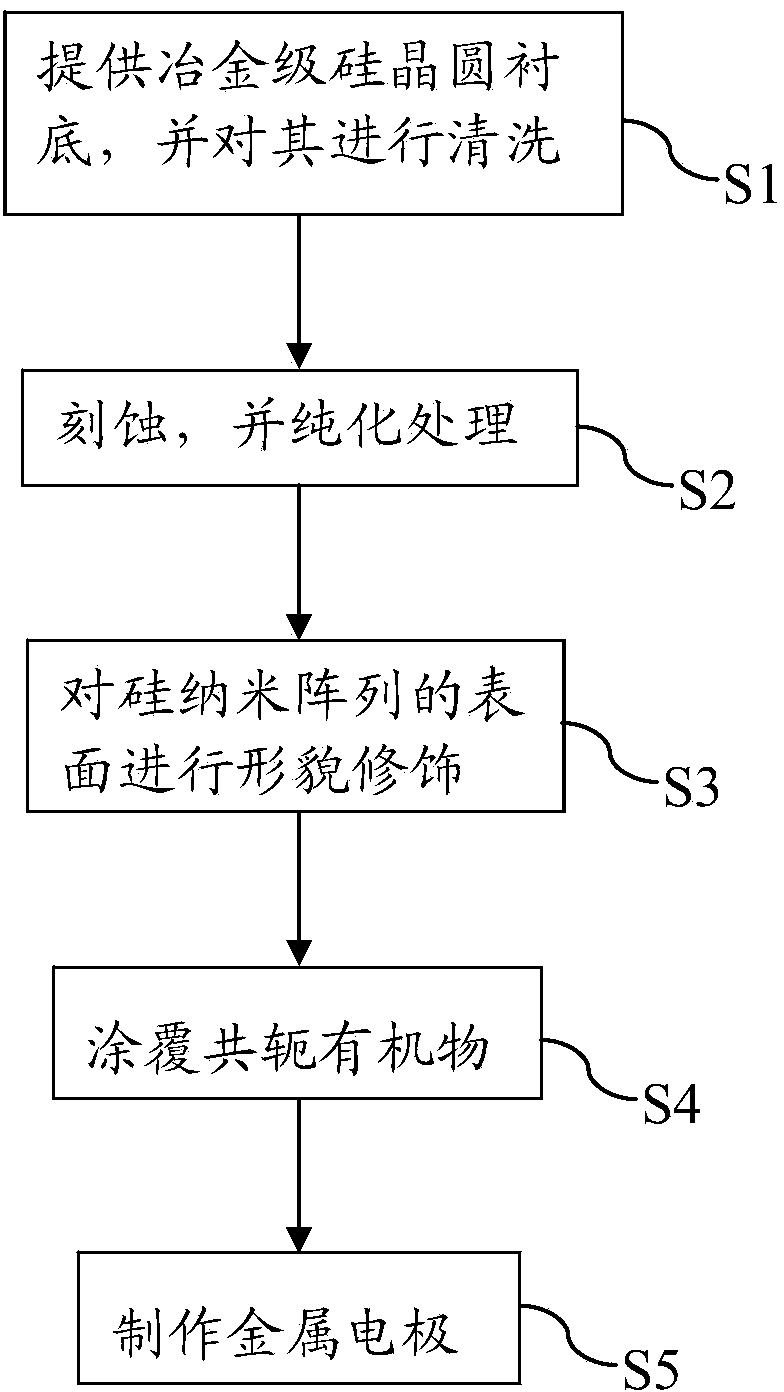

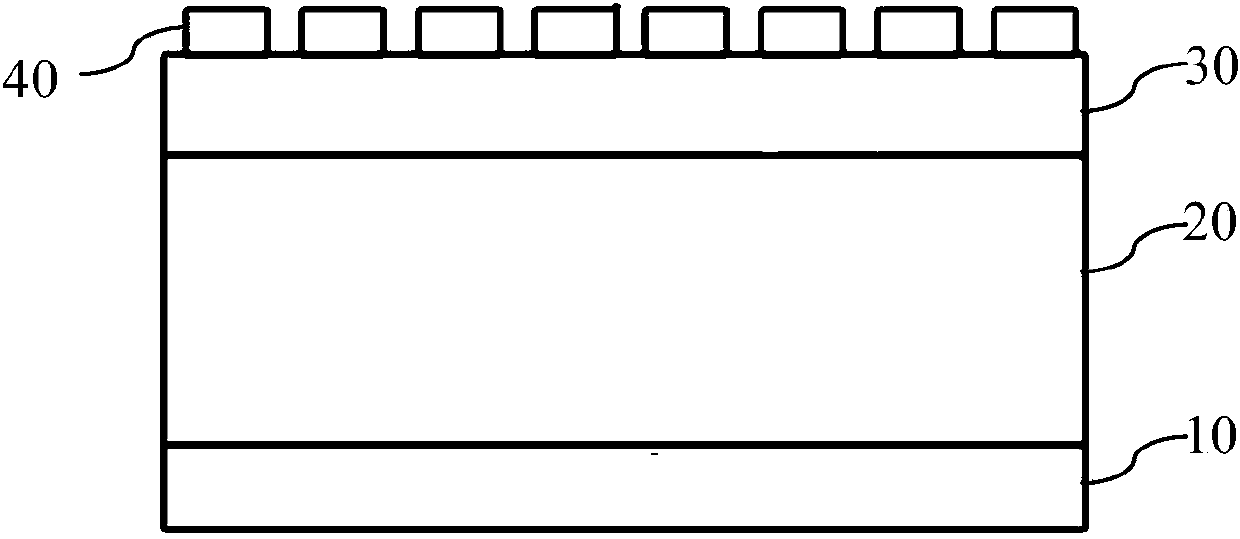

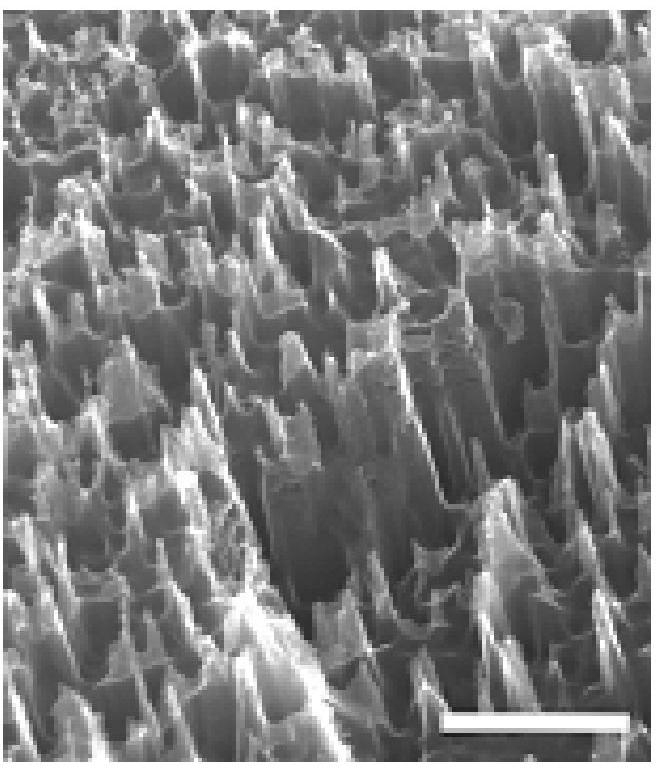

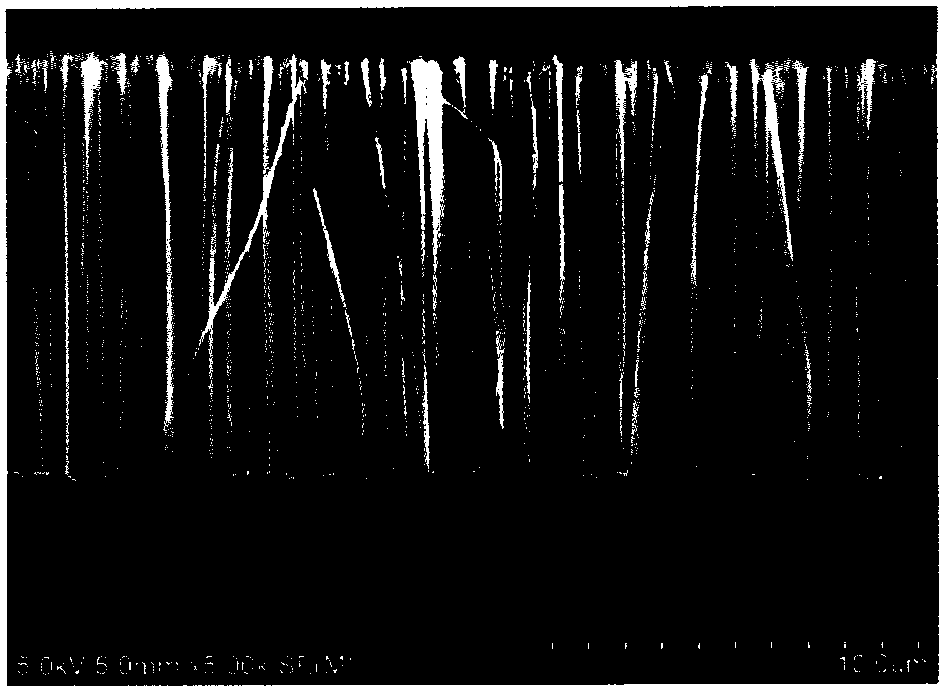

The invention discloses a silicon solar cell and a manufacturing method of the silicon solar cell. The manufacturing method of the silicon solar cell includes the following steps of firstly providing a metallurgical grade silicon wafer substrate and cleaning the metallurgical grade silicon wafer substrate, secondly etching the metallurgical grade silicon wafer substrate and conducting purification on the metallurgical grade silicon wafer substrate, thirdly conducting morphology modification on the surface of a silicon nanometer array, fourthly conducting morphology modification on the surface of the silicon nanometer array again, and fifthly coating the silicon nanometer array with conjugated organic matter. According to the manufacturing method of the silicon solar cell, the metallurgical grade silicon materials are applied to preparation of the solar cell, surface morphology treatment and surface purification treatment are conducted on the metallurgical grade silicon materials by fully applying the wet metal auxiliary chemical etching technology, and a silicon nanometer structure is formed. Passivating treatment is conducted on organic materials and the silicon nanometer structure, electrical performance and optical performance of a metallurgical grade silicon cell are improved, and charge separation performance and charge transmission performance are improved. Stability of the cell is improved through modification to organic-inorganic hybrid heterojunction, and the charge transmission capacity of the solar cell is enhanced.

Owner:SUZHOU INAINK ELECTRONICS MATERIALS CO LTD

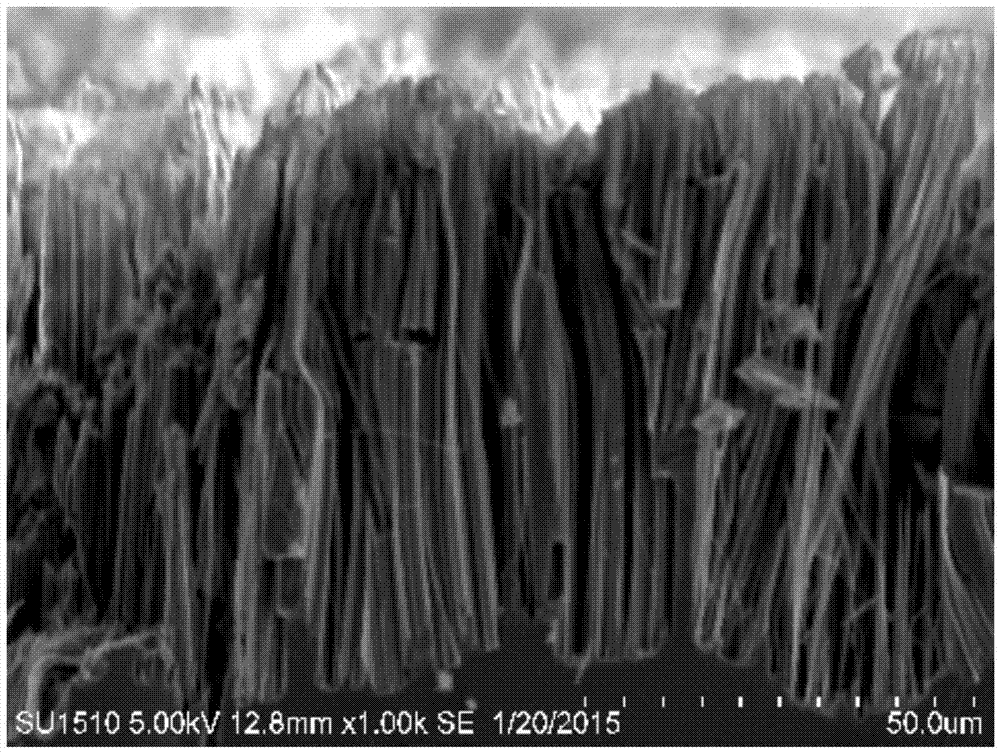

Method for preparing silicon nanostructured material

The invention discloses a method for preparing a silicon nanostructured material, belonging to the field of new materials and nano materials. According to the method, dissolved oxygen in hydrofluoric acid solution is adopted as an oxidizing agent, a silicon nanostructure is etched on the surface of a silicon wafer through a primary battery corrosion technology, so that controllable preparation of various shapes of silicon nanostructured materials can be realized. The silicon nanostructured material prepared by the method can be used as excellent solar battery and photocatalysis materials, thermoelectric material and lithium ion battery cathode material, and has wide application prospect and practical value. The method has simple technologies, has low cost, and is convenient for large scale production.

Owner:BEIJING NORMAL UNIVERSITY

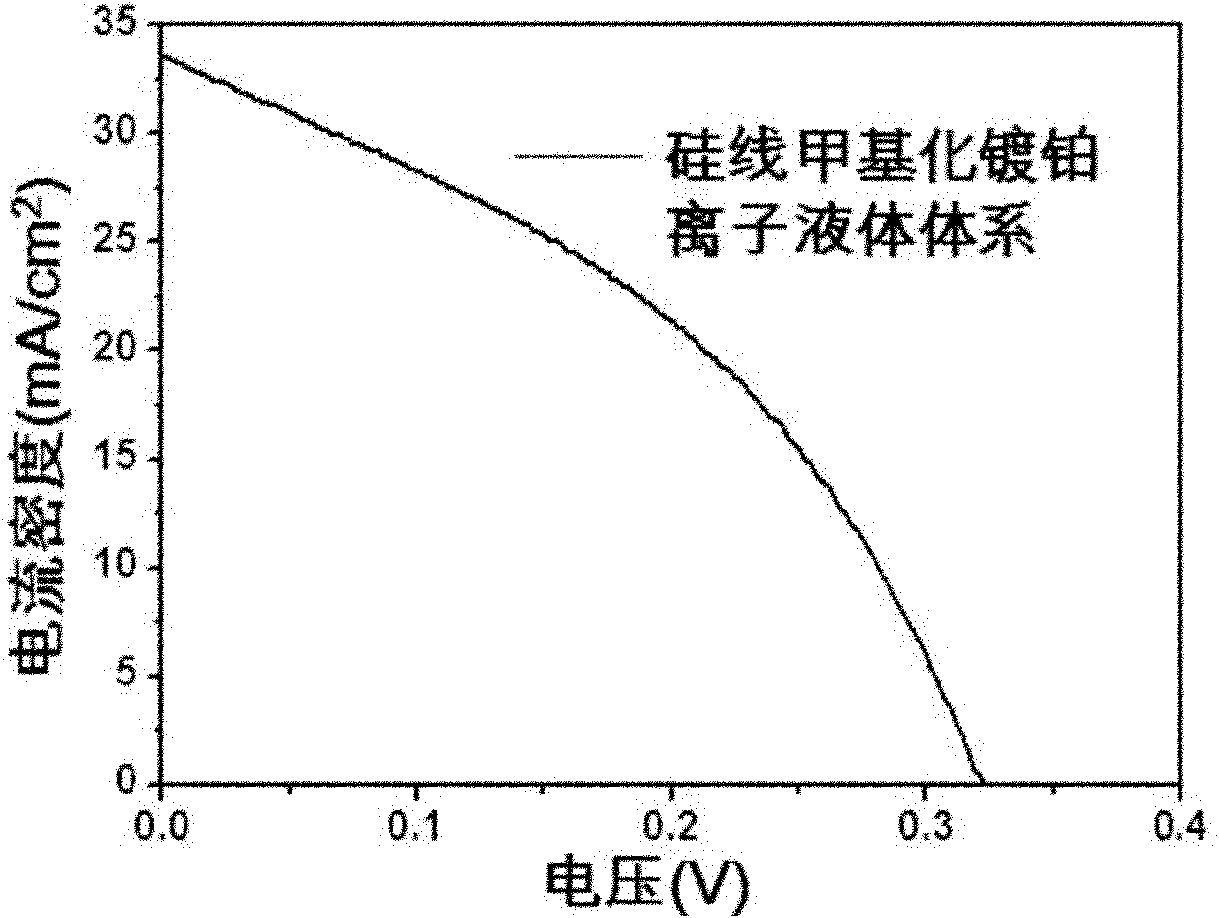

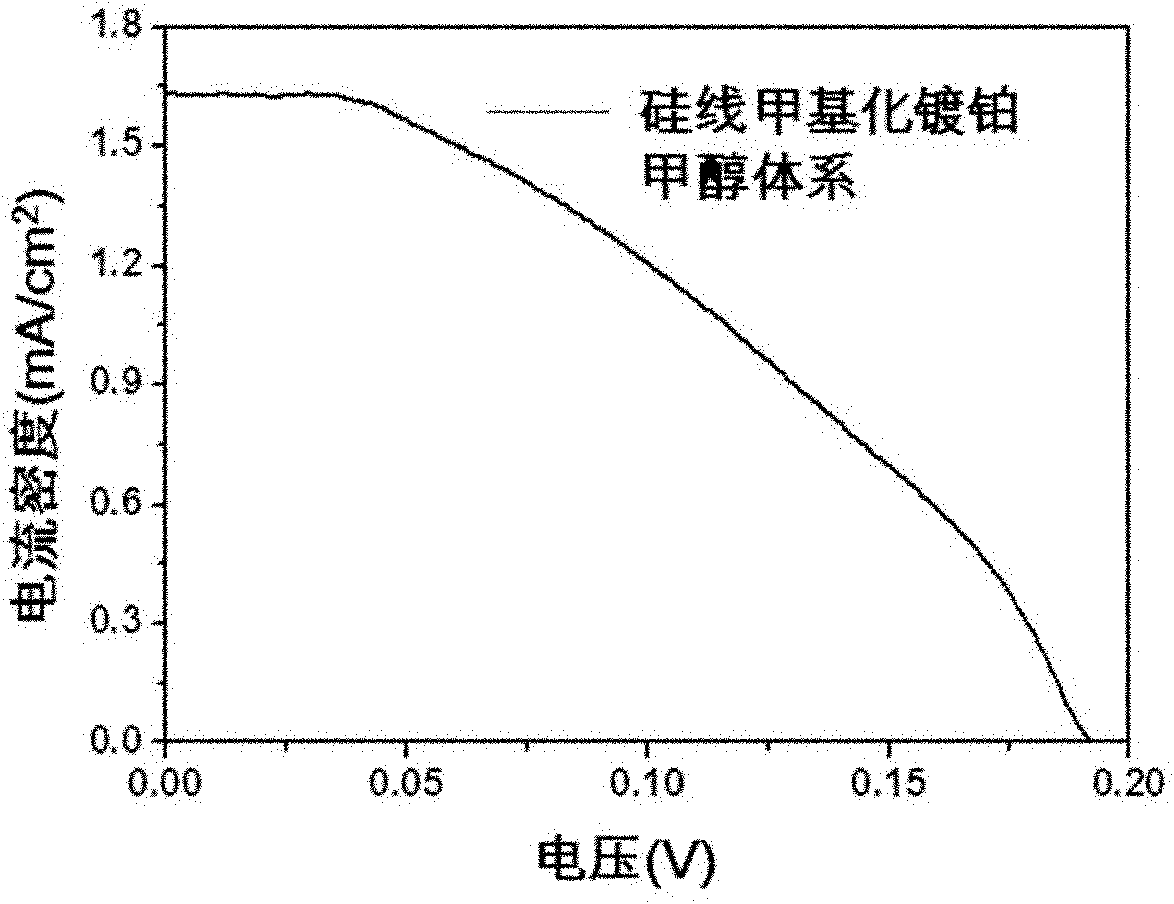

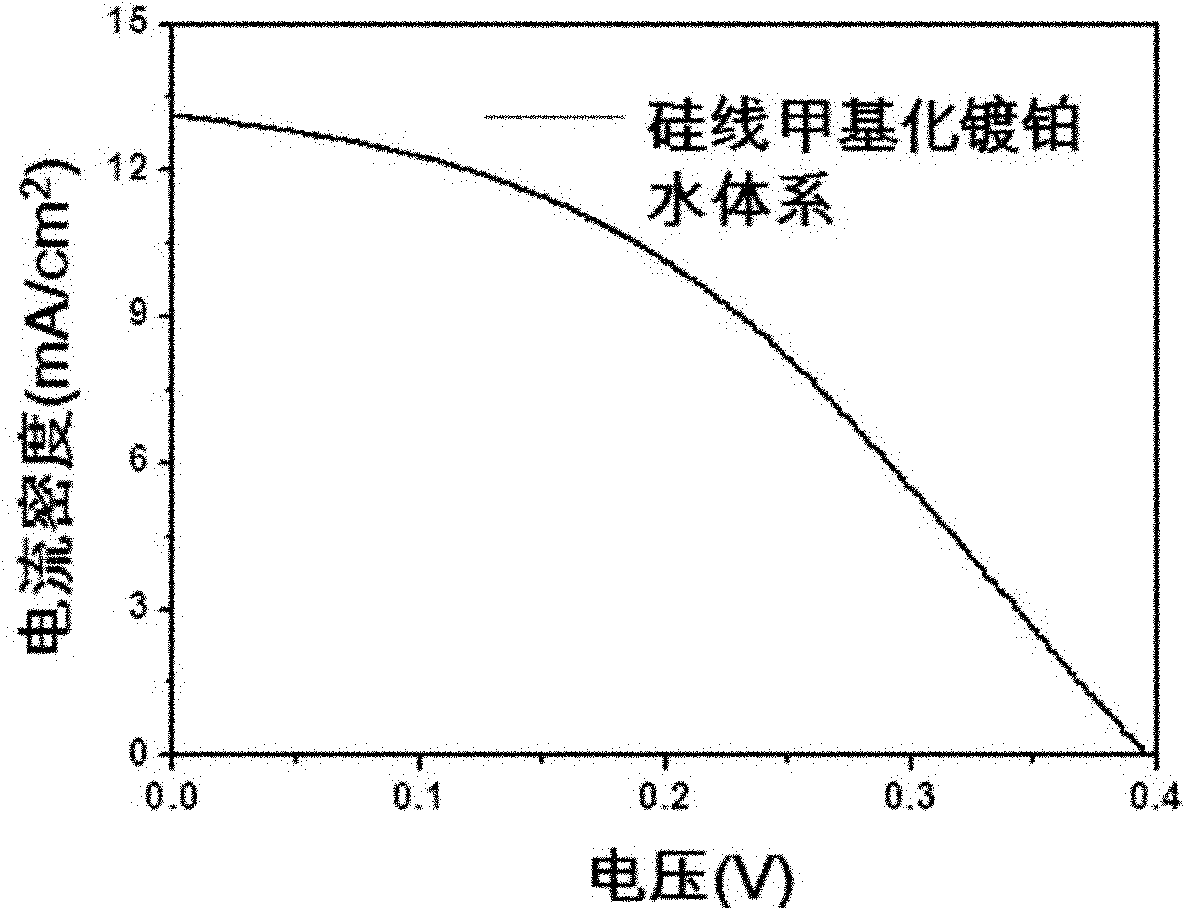

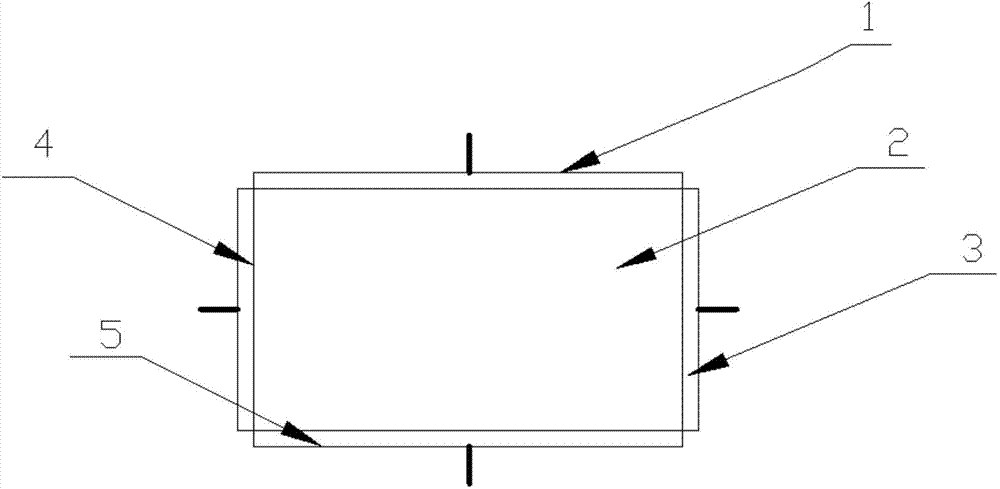

Solar battery based on silicon nano material

InactiveCN102157579ADesignableImprove conductivityLight-sensitive devicesPhotovoltaic energy generationSilicon electrodeSolar battery

The invention discloses a solar battery based on a silicon nano material. The solar battery based on the silicon nano material comprises a silicon wafer on which conductive glass is arranged; an insulation sealing layer is encircled between the conductive glass and the silicon wafer; an electrolyte chamber is formed between the conductive glass and the silicon wafer; ion liquid electrolyte is arranged in the electrolyte chamber; and lead-out electrodes are arranged on the backs of the conductive glass and the silicon wafer so as to form an ohm electrode structure. The solar battery has the characteristics of high thermal stability and chemical stability; a thinner silicon wafer can be used as a silicon electrode, the requirement for purity of the silicon is relatively low and the encapsulation requirement on the battery is reduced greatly at the same time. The invention also provides a low-cost, high-efficiency and stable technology for preparing the solar battery, which has a positive practical significance.

Owner:SUZHOU UNIV

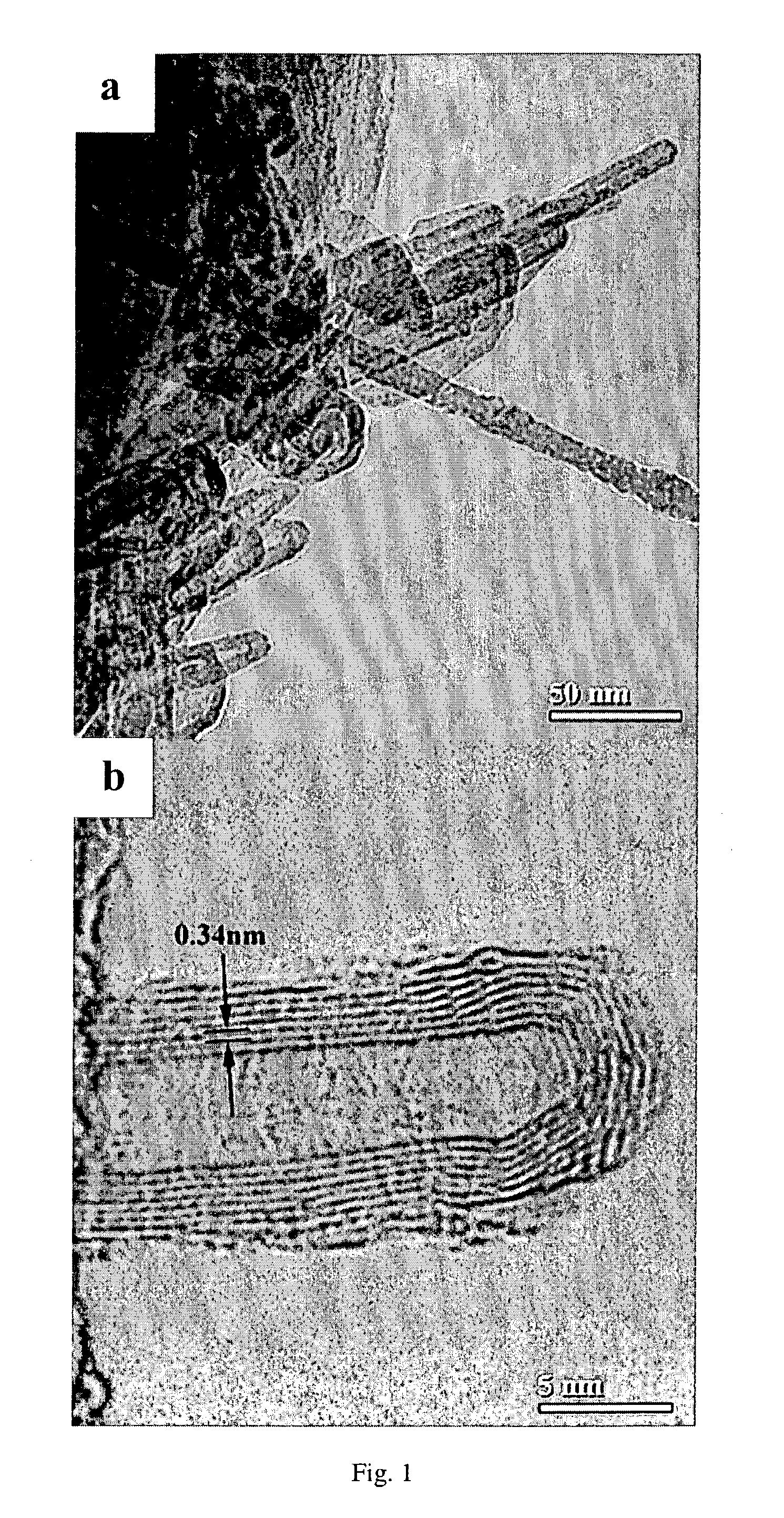

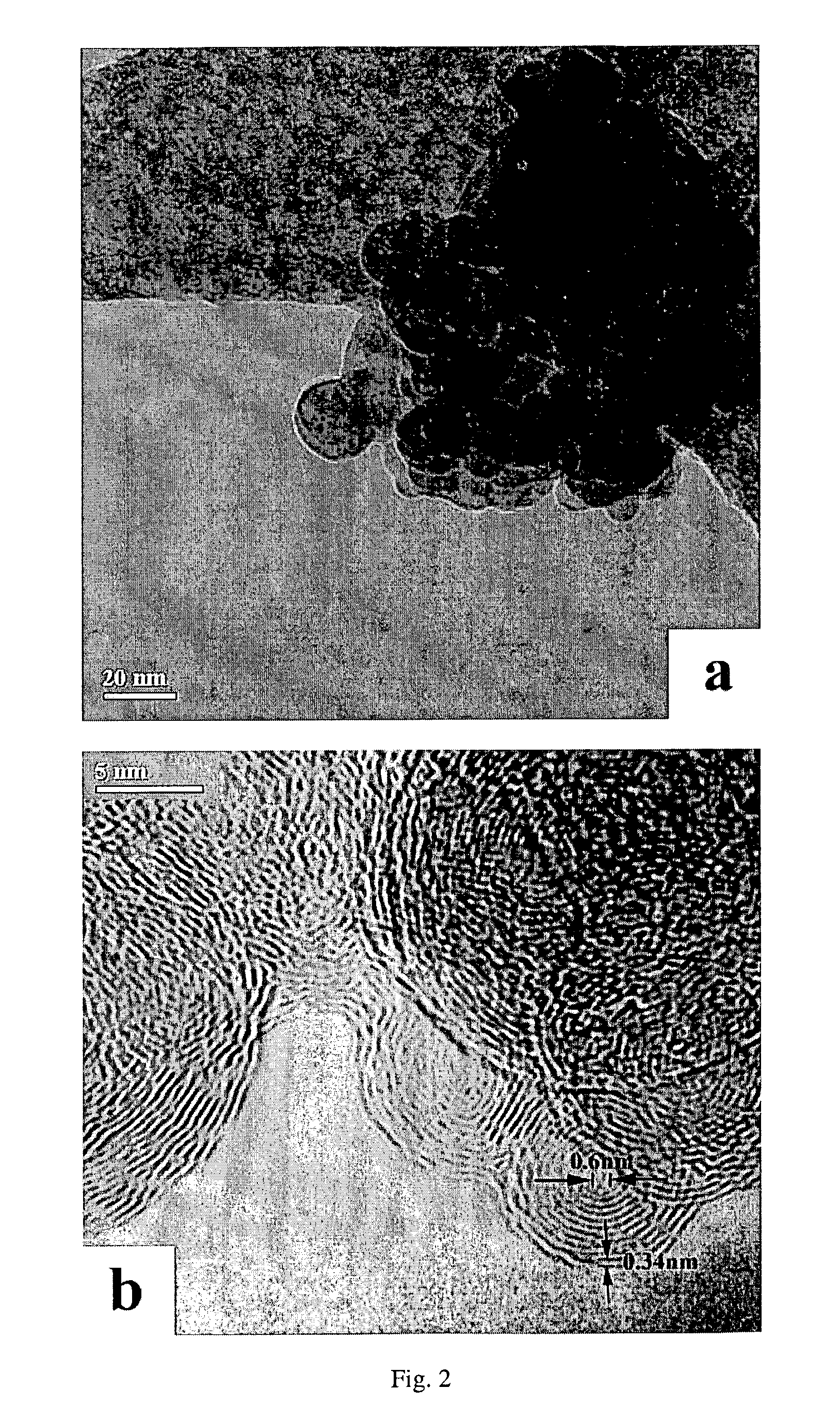

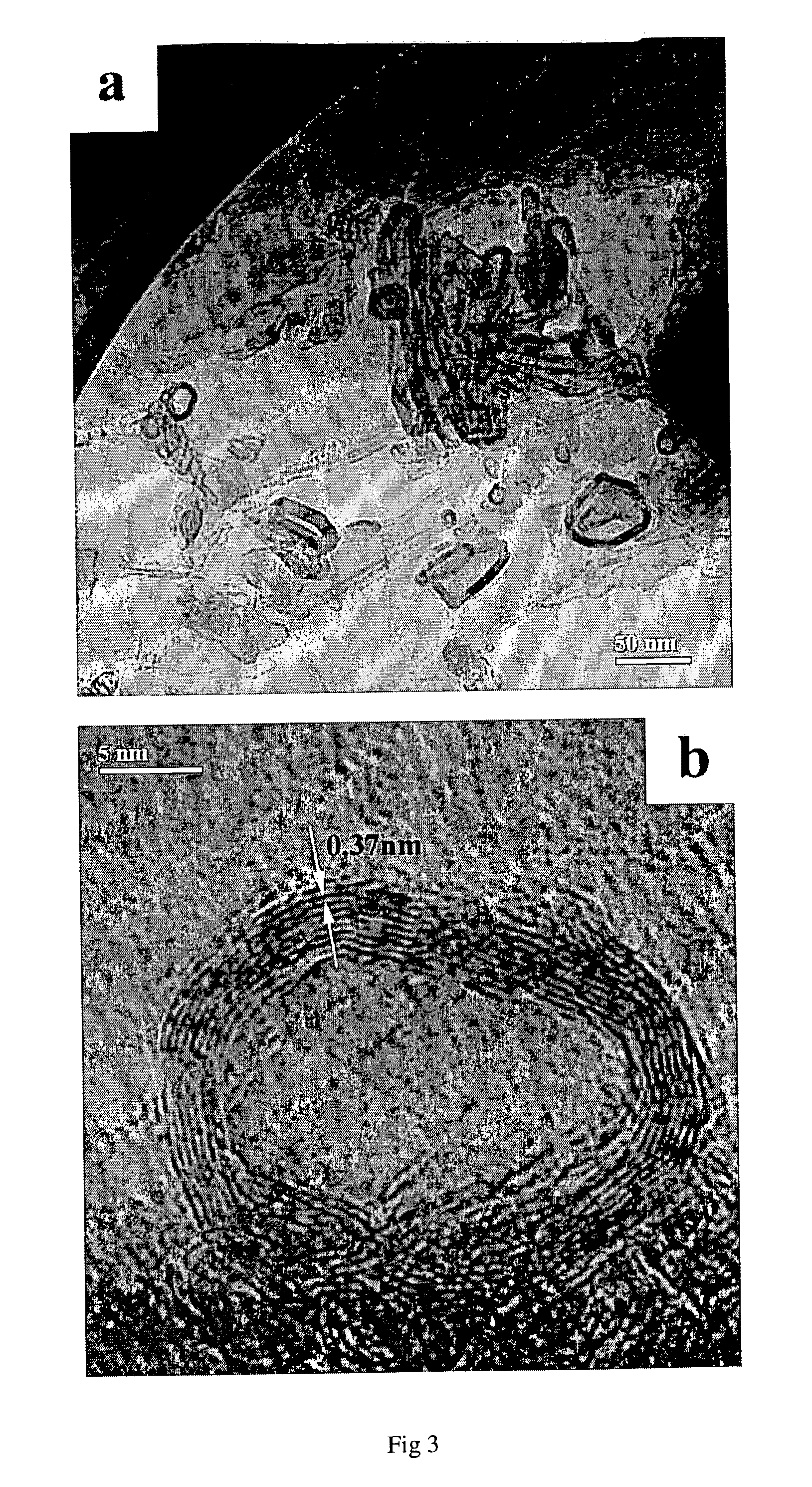

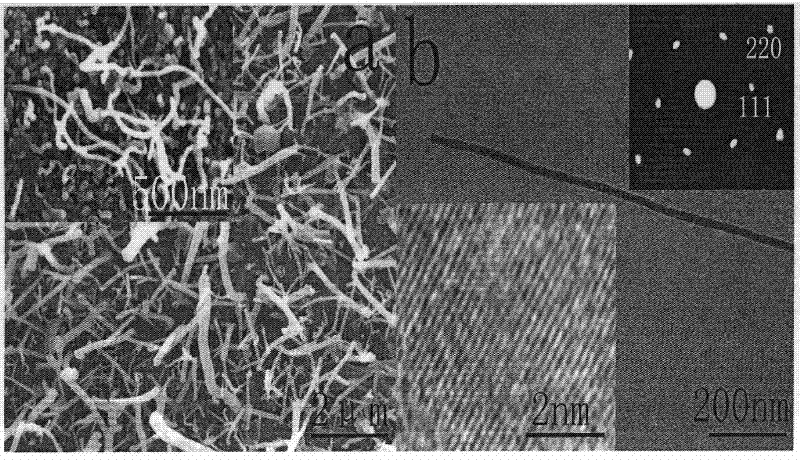

Room temperature synthesis of multiwalled carbon nanostructures

ActiveUS7132126B2Quality improvementSpeedMaterial nanotechnologyLiquid surface applicatorsNanodotNanowire

A simple chemical technique has been developed to grow large quantity of carbon nanostructures, including carbon nanotubes, hydrocarbon nanotubes and carbon nanoonions, in the organic solution at ambient (room) temperature and atmospheric pressure using silicon nanostructures (nanowires, nanodots, ribbons, and porous silicon) as starting materials. These CNT and CNO have the lattice d-spacing from 3.4 Å to 5 Å.

Owner:HONG KONG CITY UNIV OF

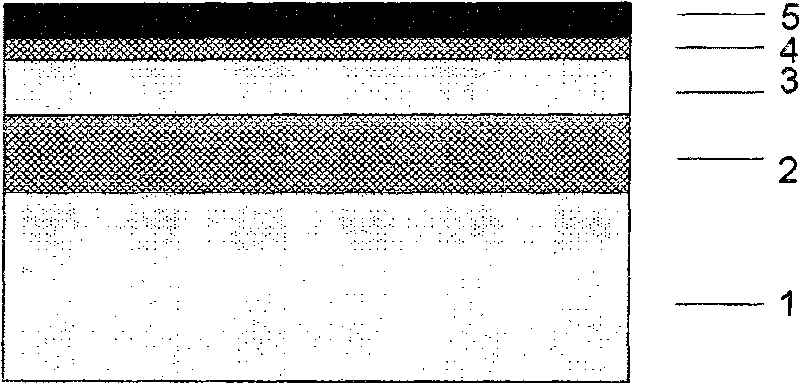

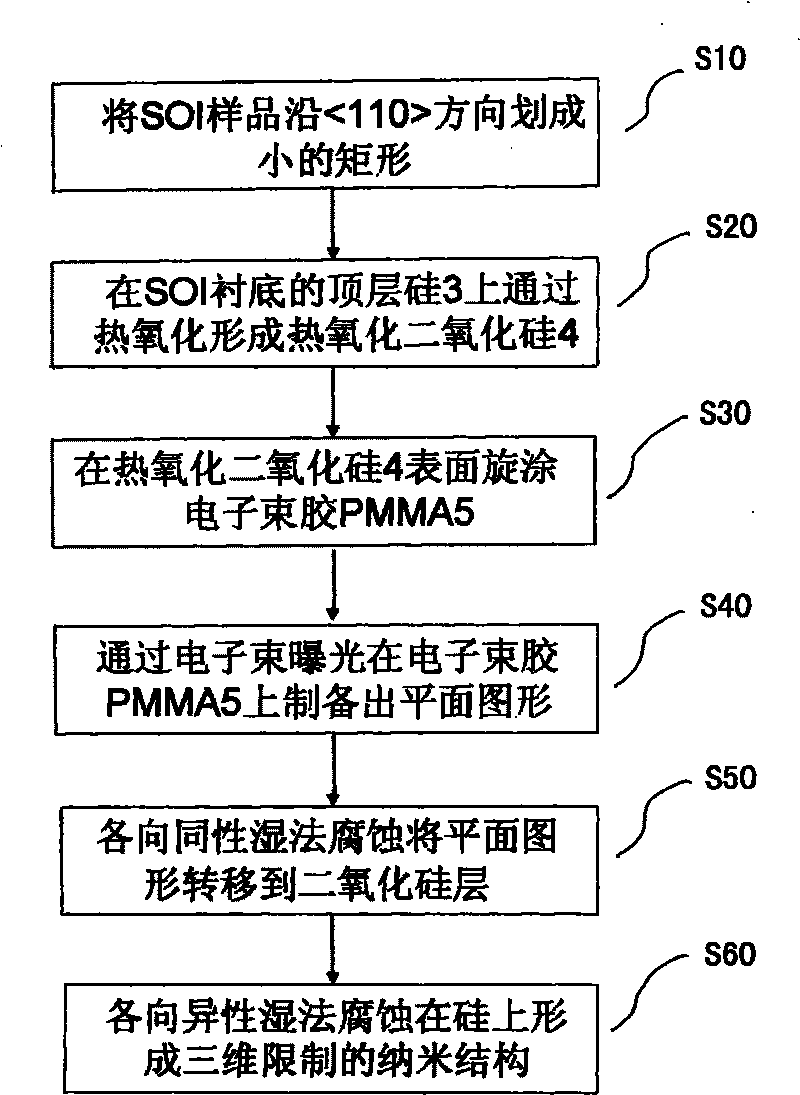

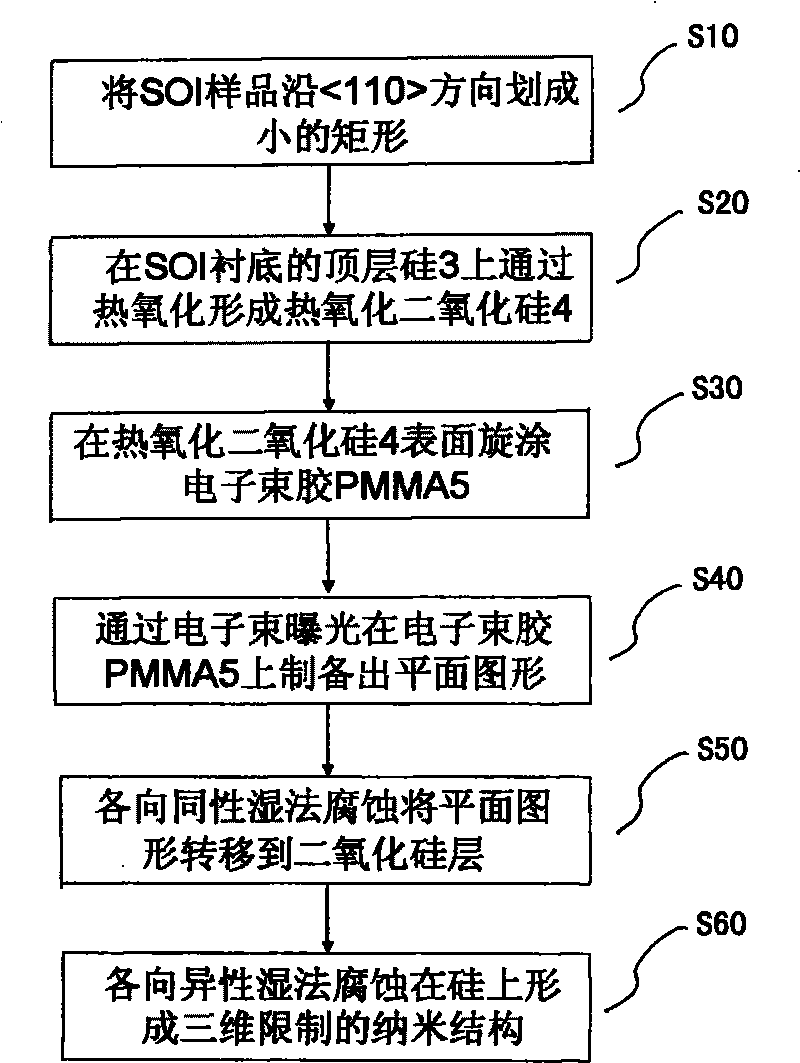

Method for preparing tri-dimension-limited crystal-facet-dependent silicon nanostructures

InactiveCN101723312AOvercoming inconsistencies in quantum electrical performanceLower resistanceNanostructure manufactureCrystal orientationSilicon dioxide

The invention provides a method for preparing a tri-dimension-limited crystal-facet-dependent silicon nanostructure, which is characterized by comprising the following steps: (a) taking silicon-on-insulator (SOI) as a substrate; (b) scribing on the substrate along the crystal orientation (110) as a reference direction for exposure; (c) performing heat oxidation on the substrate to generate a silica mask layer; (d) adopting electron-beam exposure to generate a plane figure; (e) eroding the silica mask layer by using isotropic corrosive liquids; and (f) obtaining the tri-dimension-limited crystal-facet-dependent silicon nanostructure on the silicon layer below the silica mask layer by using isotropic wet corrosion.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

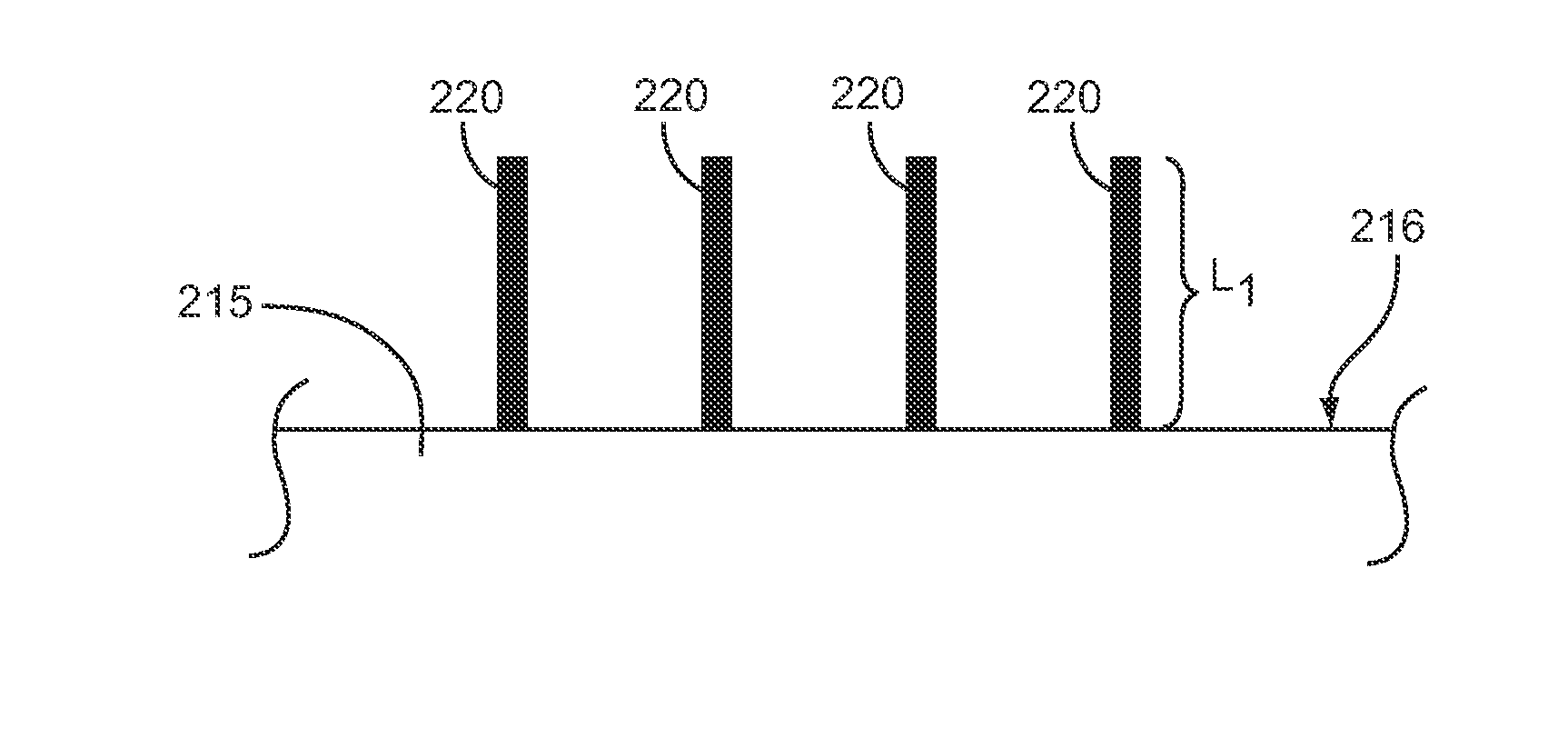

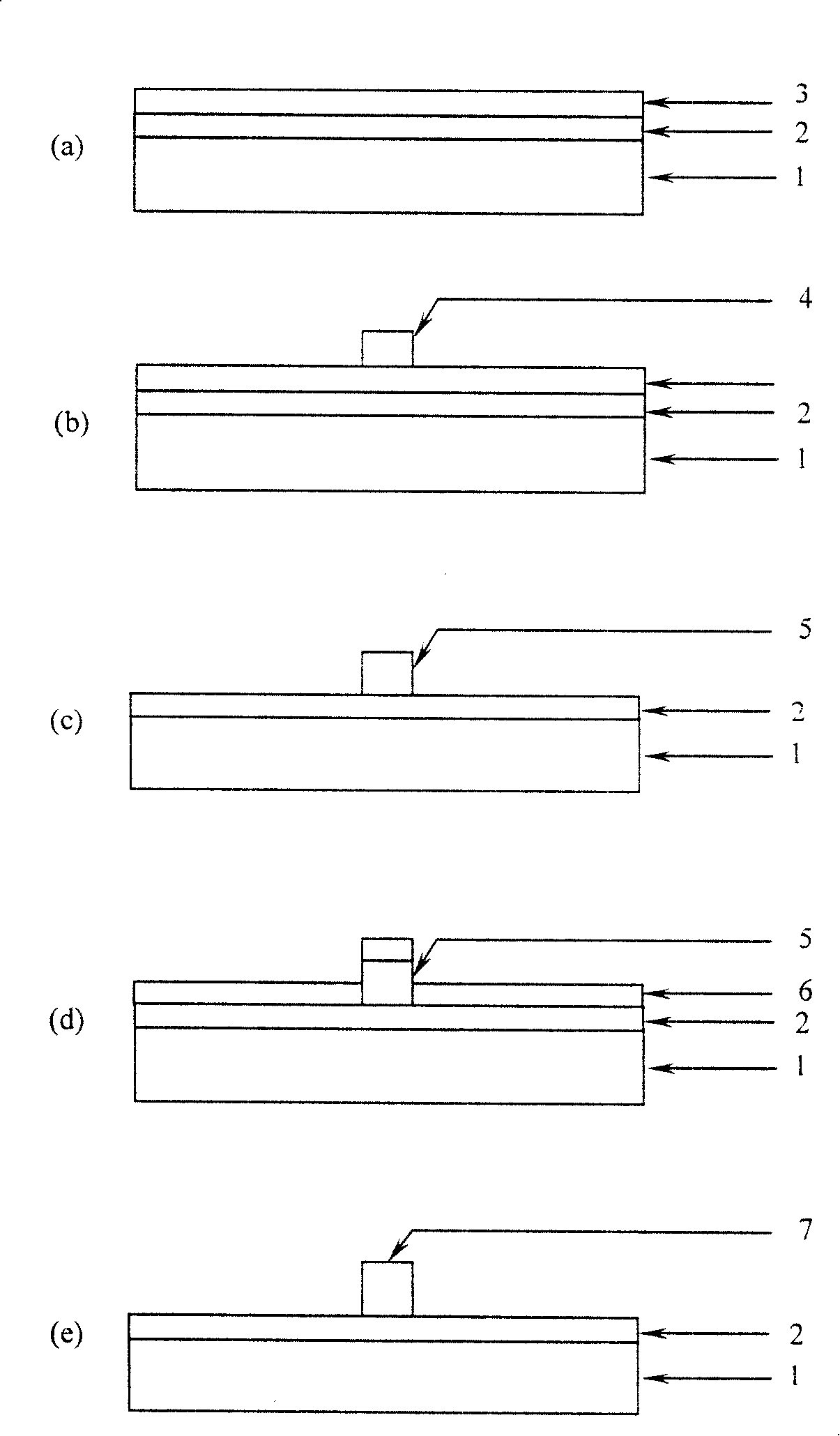

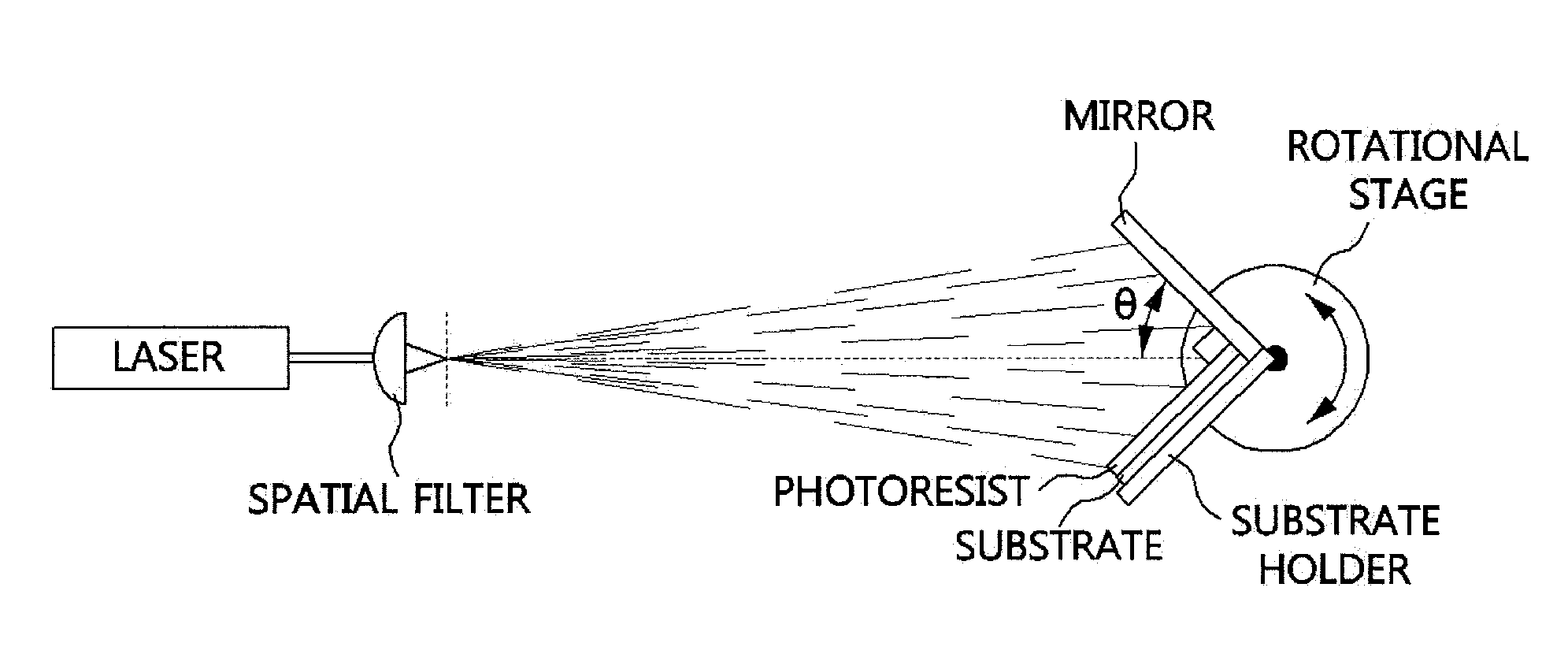

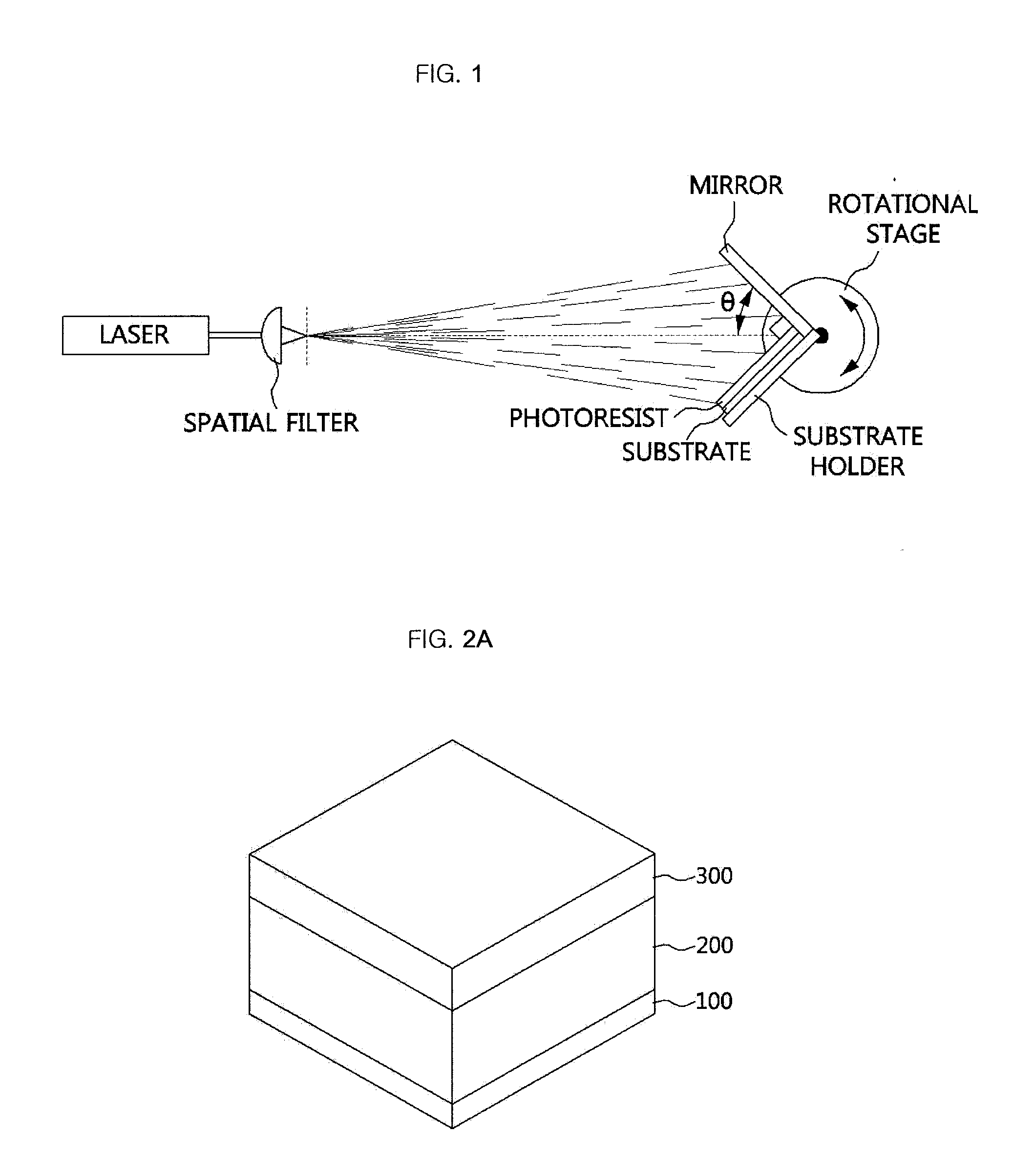

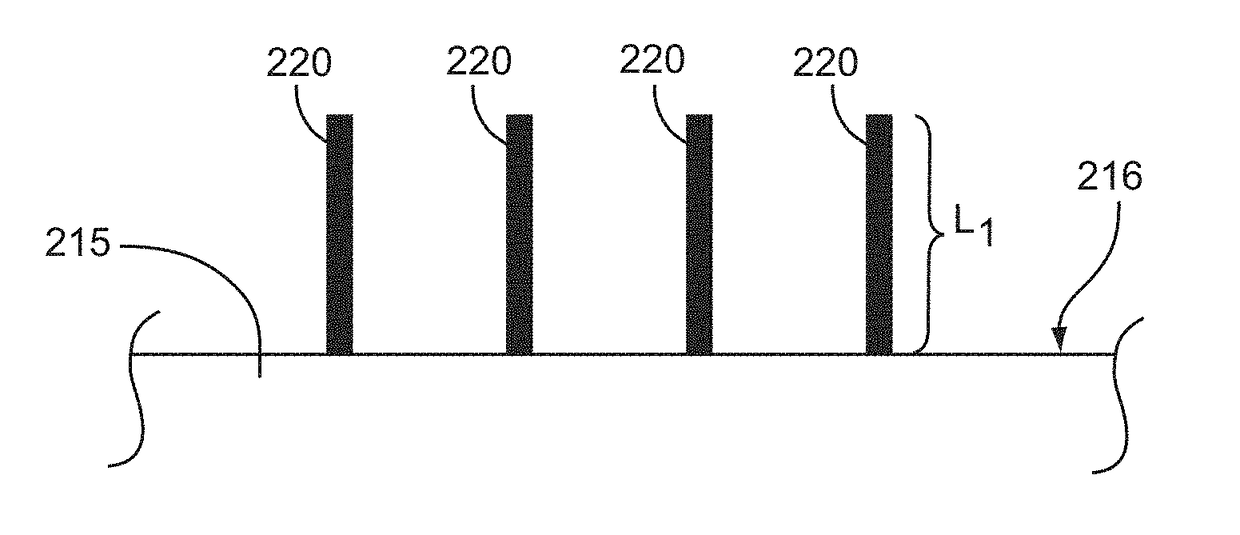

Electrode for battery and method for manufacturing thereof

InactiveUS20130052532A1Long charge/discharge cycle characteristicLarge capacityMaterial nanotechnologyNanostructure manufactureInternal resistanceEngineering

An electrode for a battery and a method for manufacturing the same are disclosed. The electrode for a battery according to the present invention comprising silicon nanostructures integrally formed on a silicon thin film and having a period array can reduce the internal resistance, have better charge transport properties, and reduce the structural stress, thereby exhibiting high storage capacity, high efficiency charge / discharge characteristics, and long charge / discharge cycle characteristics. Moreover, the method for manufacturing the electrode for a battery according to the present invention can simply and easily form a nanopattern with nanostructures on a silicon thin film using laser interference lithography (LIL) and dry etching.

Owner:GWANGJU INST OF SCI & TECH

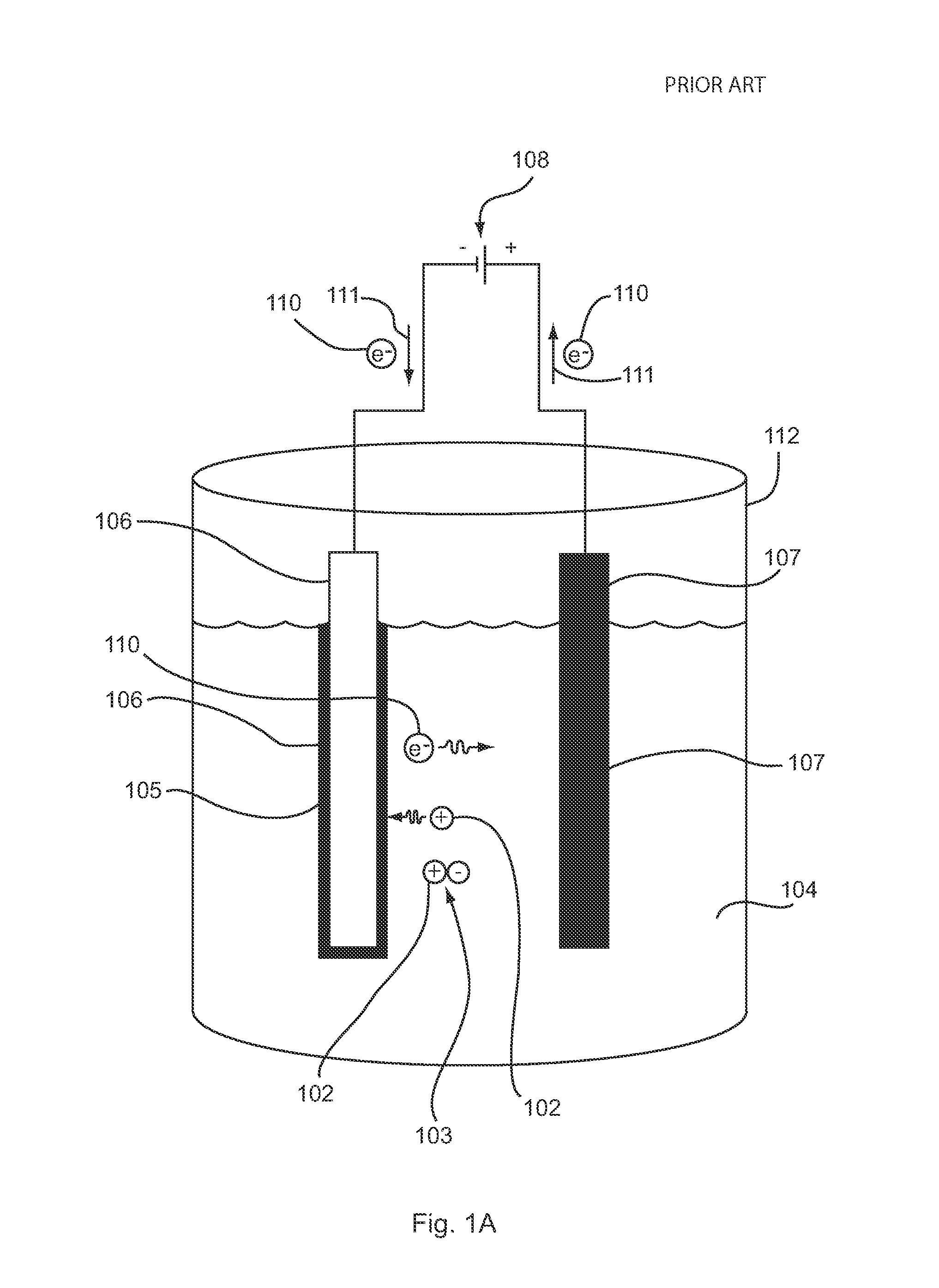

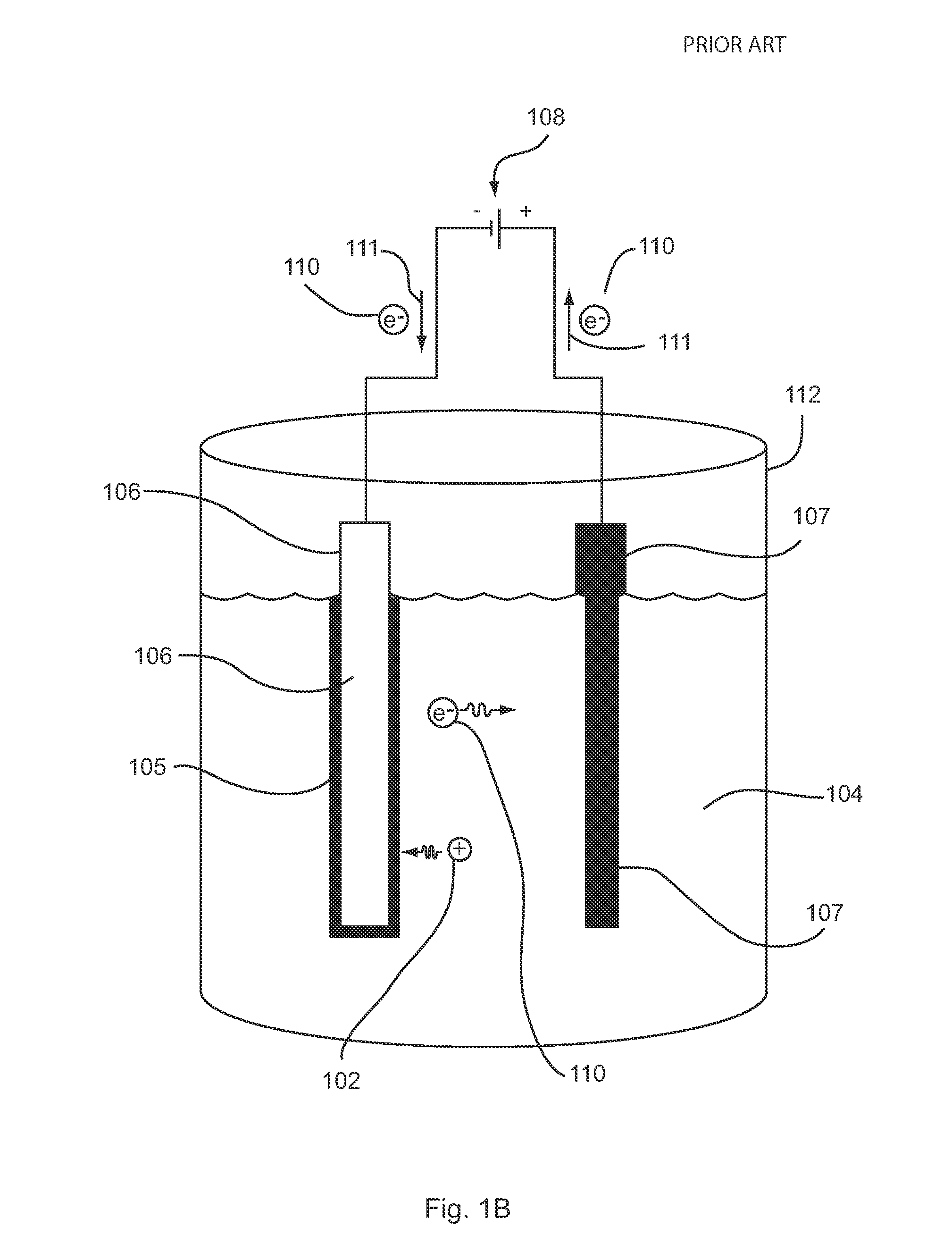

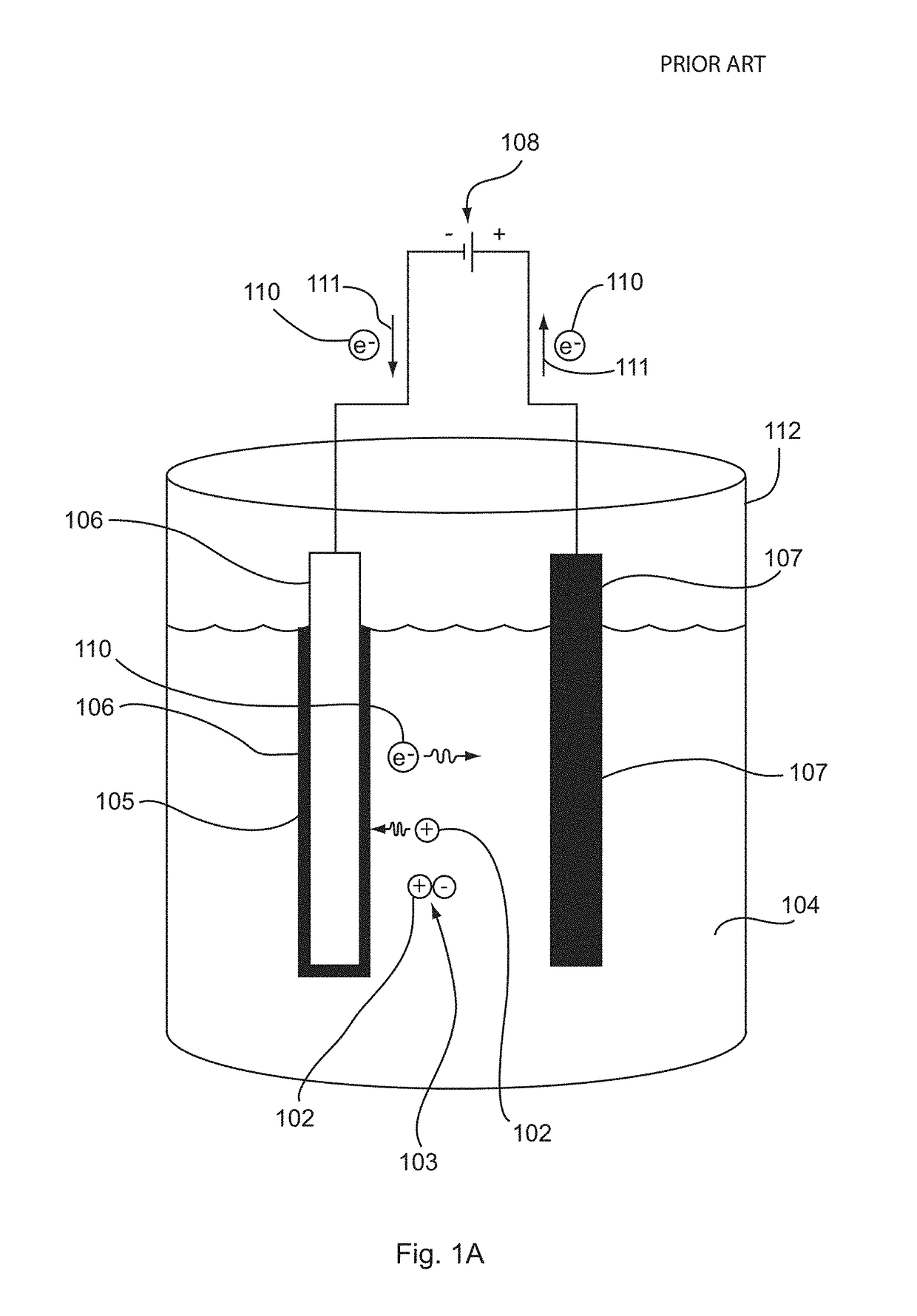

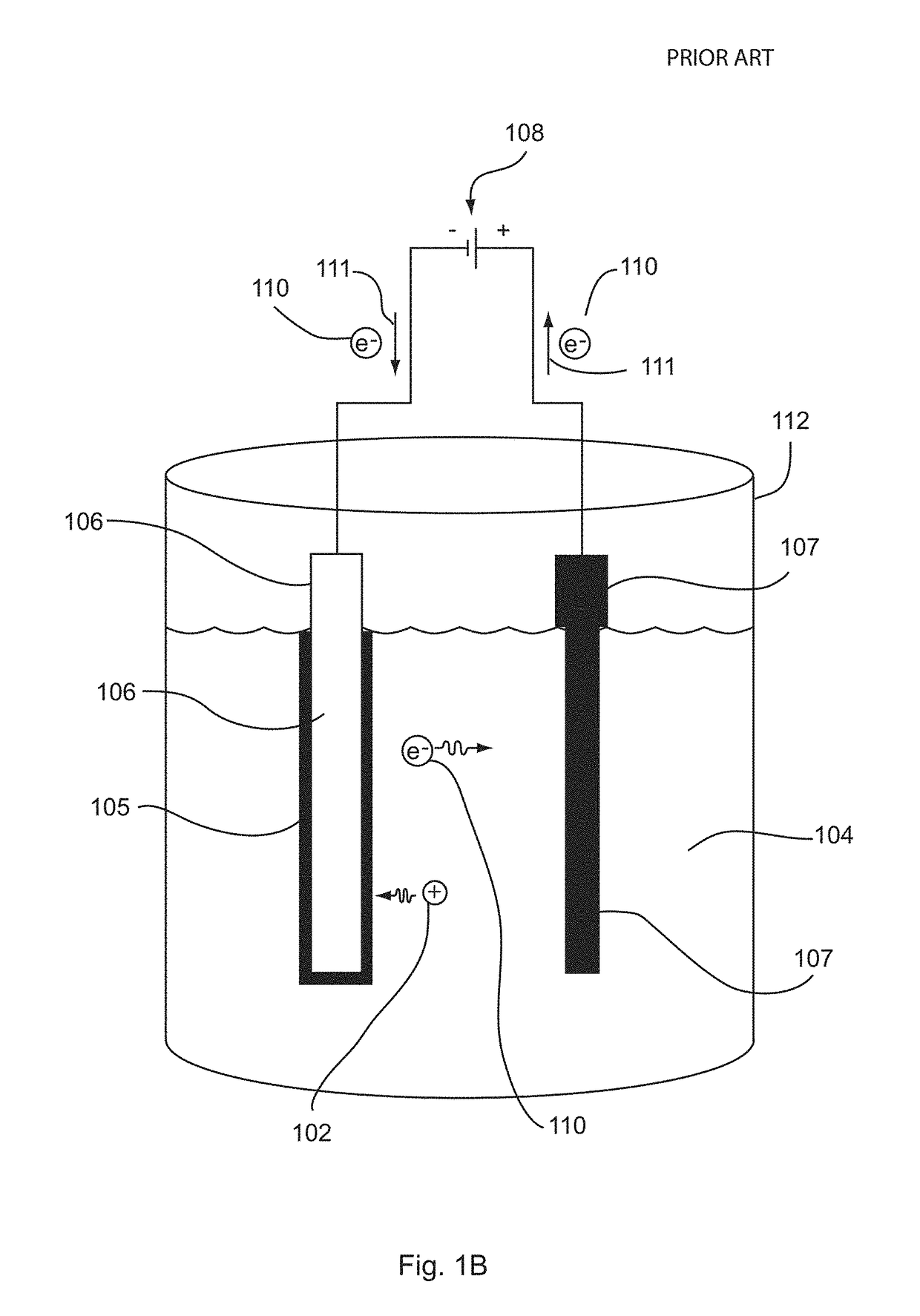

Method for preparing silicon nanostructured material based on external electric field

ActiveCN104818532AControl Corrosion PathGood application effectAfter-treatment detailsNanotechnologySolar cellLithium-ion battery

The invention discloses a method for preparing a silicon nanostructured material based on an external electric field. The method comprises the following steps: (1) putting a clean silicon wafer into a mixed solution of hydrofluoric acid and silver nitrate to deposit a layer of silver film on the surface of the silicon wafer; (2) immediately putting the coated silicon wafer from the step (1) into a corrosive liquid, wherein the corrosive liquid is contained in a container; a pair of noble electrodes are fixed to two sides of the container; and the noble electrodes are immersed in the corrosive liquid; and (3) immediately turning on a power supply of the noble electrodes after the step (2) and corroding for a period of time to obtain the silicon nanostructured material. Only by changing a single variable of electric field, corrosion path of catalyst granules can be controlled according to the method. The method is simple and easy to operate and is beneficial to large-scale production. In addition, applicability of the silicon nanostructured material in aspects of solar cells, lithium ion batteries, thermo-electric devices, precision sensors and the like is enhanced.

Owner:王颐疆

Hydrogen reservoir based on silicon nano-structures

InactiveUS20070059859A1Low costLow cost manufacturingSiliconReactant parameters controlHydrogenMedicine

Owner:CENT NAT DE LA RECHERCHE SCI +1

Silicon nanostructure active materials for lithium ion batteries and processes, compositions, components and devices related thereto

ActiveUS9812699B2Cost-effectiveHighly controllableElectrochemical processing of electrodesElectrode carriers/collectorsCopper electrodeLithium-ion battery

The present invention relates to nanostructured materials for use in rechargeable energy storage devices such as lithium batteries, particularly rechargeable secondary lithium batteries, or lithium-ion batteries (LIBs). The present invention includes materials, components, and devices, including nanostructured materials for use as battery active materials, and lithium ion battery (LIB) electrodes comprising such nanostructured materials, as well as manufacturing methods related thereto. Exemplary nanostructured materials include silicon-based nanostructures such as silicon nanowires and coated silicon nanowires, nanostructures disposed on substrates comprising active materials or current collectors such as silicon nanowires disposed on graphite particles or copper electrode plates, and LIB anode composites comprising high-capacity active material nanostructures formed on a porous copper and / or graphite powder substrate.

Owner:ONED MATERIAL INC

Silicon-embedded copper nanostructure network for high energy storage

Owner:AMPRIUS TECH INC

An electrochemical method for the controllable preparation of silicon nanostructure materials

InactiveCN102260894AAchieving controllable equipmentEasy to separateAnodisationElectrochemical responseChemical reaction

The invention discloses a method for preparing a silicon nanostructure material or an array thereof. The method of the present invention comprises the following steps: using monocrystalline silicon as an anode and an inert electrode as a cathode, placing the anode and the cathode in an electrolytic solution, and adding a water-immiscible hydrocarbon solvent to the electrolytic solution; An electric current is applied to the anode to carry out an electrochemical oxidation reaction, and the silicon nanostructure material or its array is obtained after the reaction; wherein, the electrolyte is composed of a hydrofluoric acid solution with a mass concentration of 10-30%, an organic solvent and Catalyst composition; The organic solvent is methanol, ethanol or their mixture in any proportion, and the catalyst is polyacid compound, hydrogen peroxide or their mixture; The density of the water-immiscible hydrocarbon solvent is less than that of water density. By adjusting the type of catalyst and the current density of electrochemical reaction, the method can realize the controllable preparation of various silicon nanostructures and their arrays, and is a general preparation method for silicon nanostructures, which is simple and feasible.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

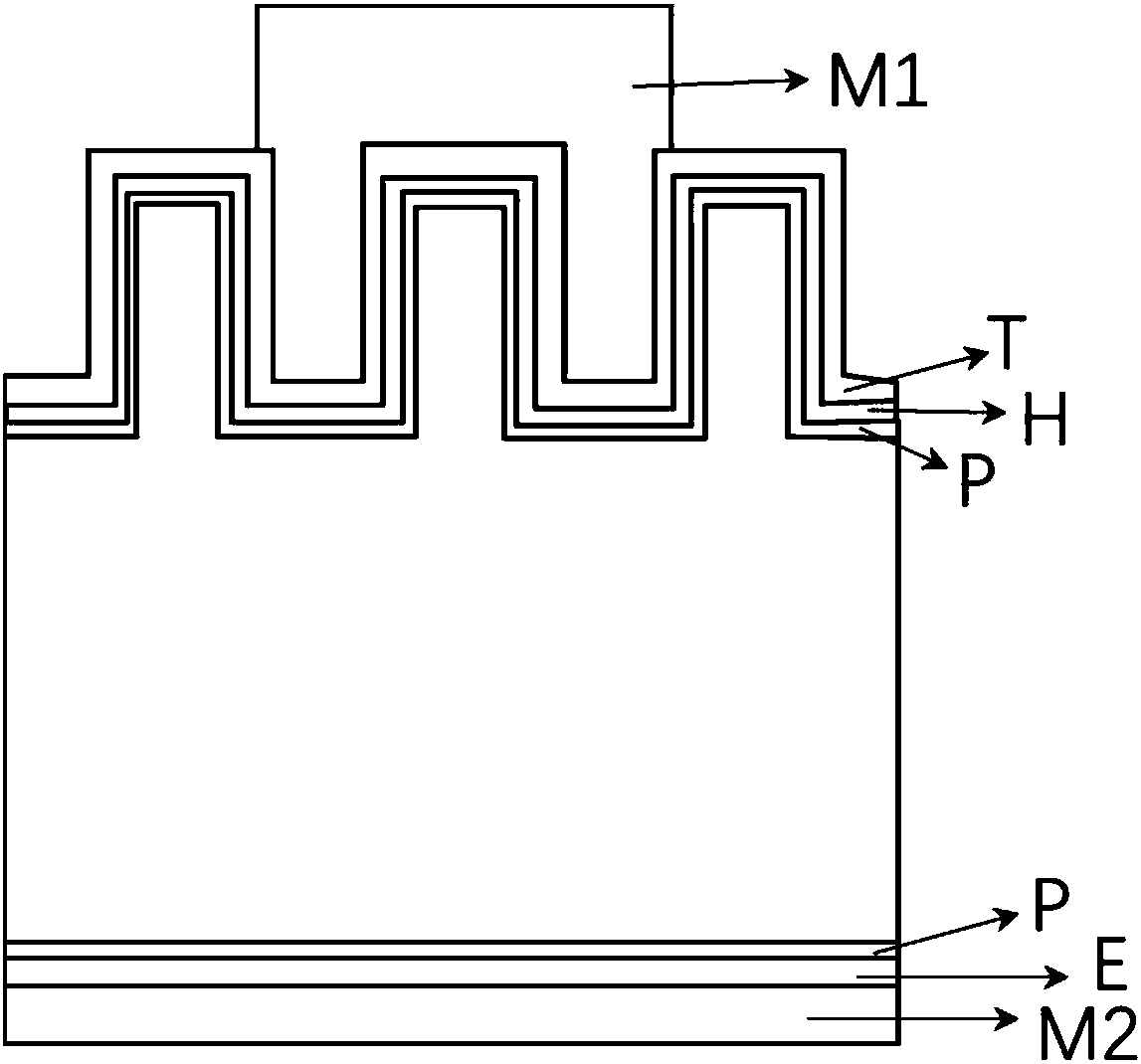

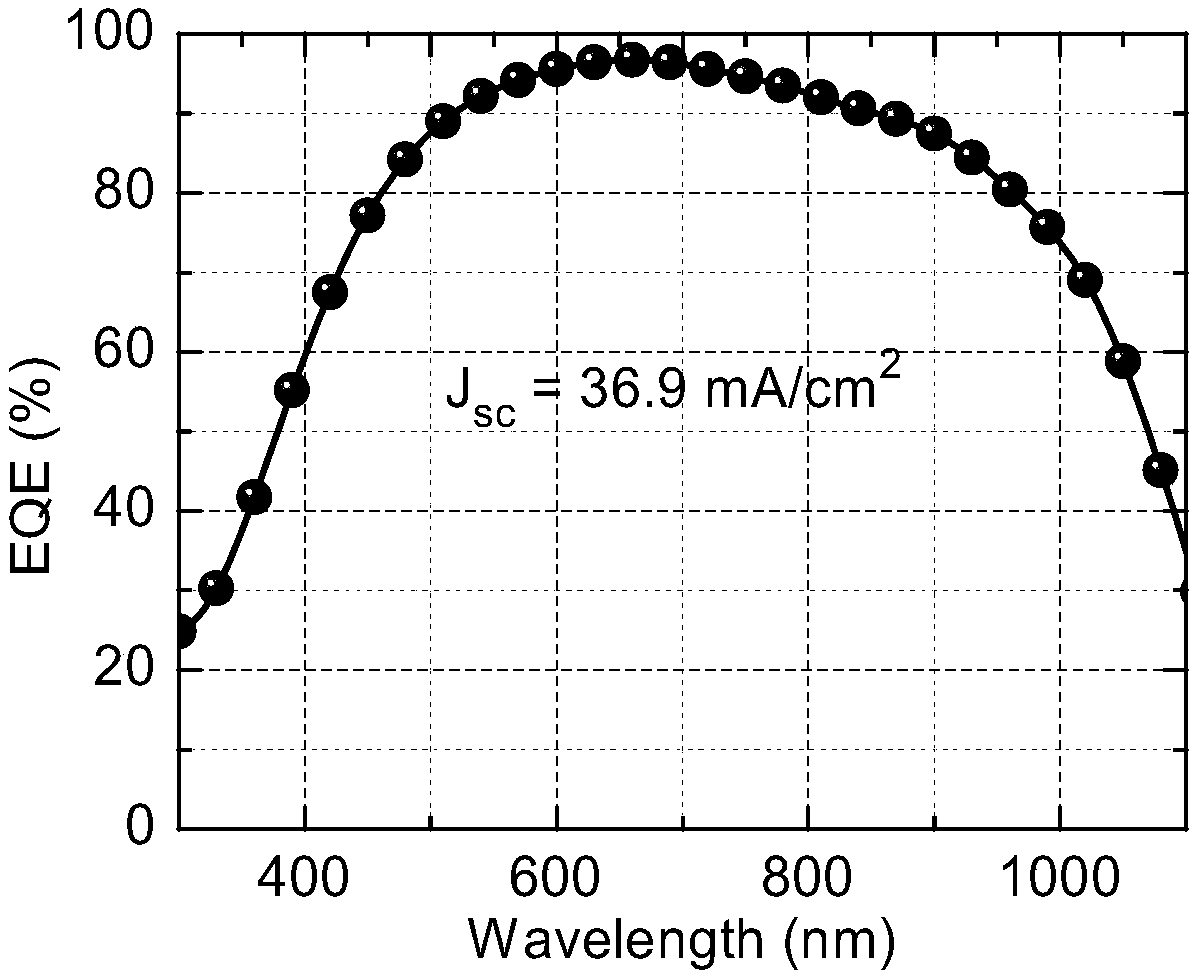

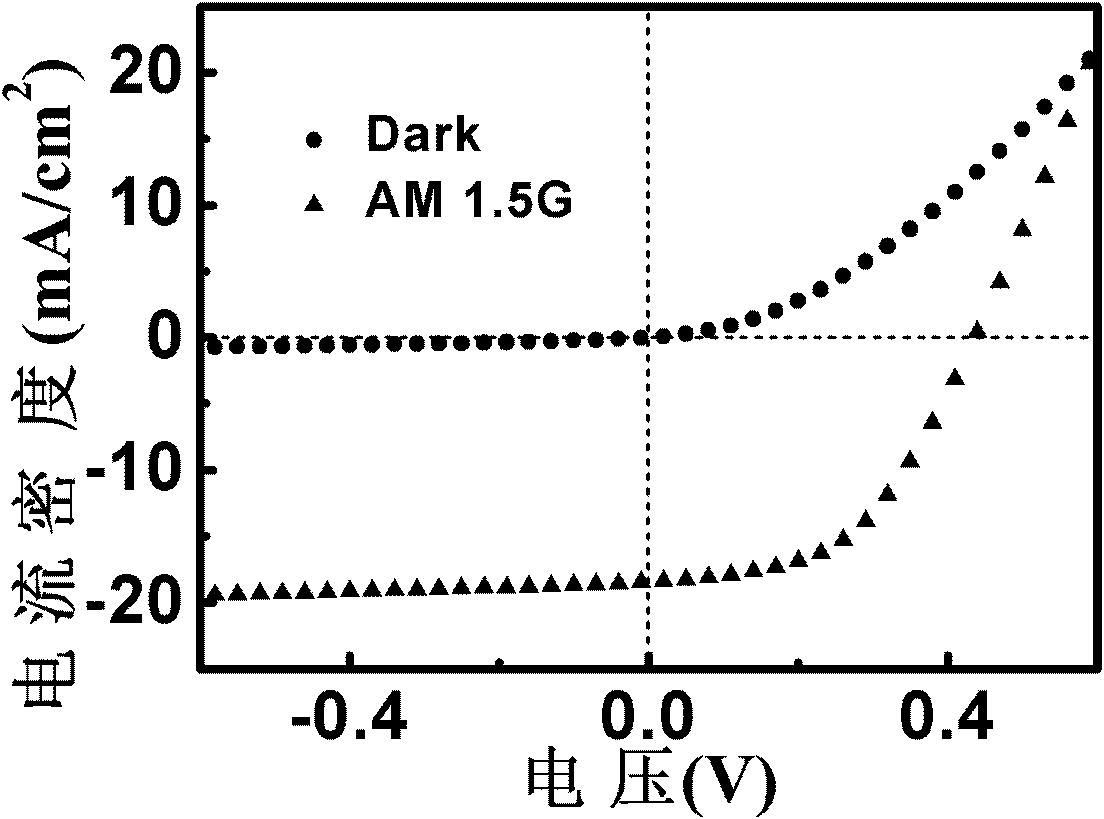

Silicon nanostructured heterojunction solar cell and preparation method thereof

InactiveCN107706248AAvoiding problems with conformal depositionGreat uniformityFinal product manufacturePhotovoltaic energy generationHeterojunctionTransport layer

The invention provides a silicon nanostructured heterojunction solar cell and a preparation method thereof, and belongs to the technical field of solar cells. The silicon nanostructured heterojunctionsolar cell is composed of a crystalline silicon nanostructured substrate S, an ultra-thin silicon oxide passivation layer P, an undoped hole transport layer H, an undoped electron transport layer E,a transparent electrode T, a metal gate line electrode M1 and a back electrode M2. The effective absorption of incident light is realized by utilizing the high trapping property of the silicon nanostructured substrate. The wide bandgap and high transmission characteristics of the non-doped electron (hole) transport layer are used to further reduce the parasitic absorption of a device and improve the photoelectric conversion efficiency. The electron (hole) transport layer of the silicon nanostructured solar cell does not involve a doping process, and both H and T have the characteristics of high transmission and low parasitic light absorption, the defect state density of the device can be effectively reduced, and the preparation method is simple and easy to implement.

Owner:JILIN NORMAL UNIV

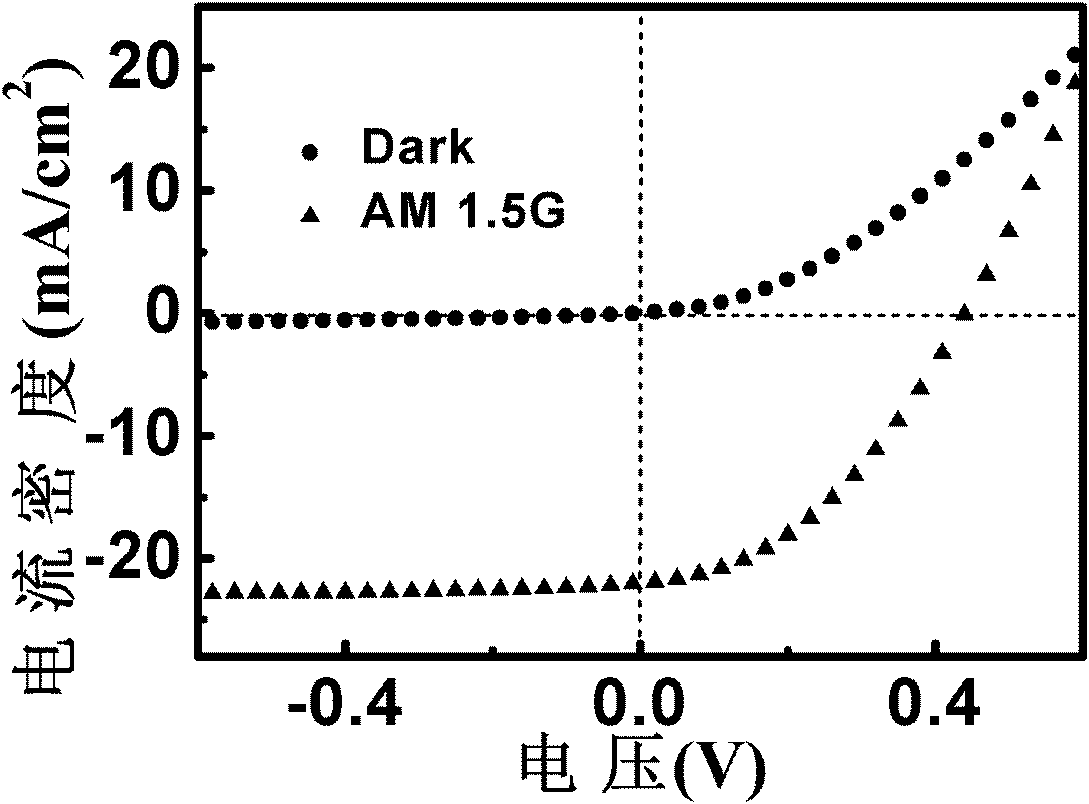

Silicon nano-wire array or silicon nano-pore array Schottky junction type solar battery and preparation method thereof

InactiveCN102569474ASimple processImprove efficiencyFinal product manufacturePhotovoltaic energy generationNano structuringSilicon nanowires

The invention discloses a silicon nano-wire array or silicon nano-pore array Schottky junction type solar battery and a preparation method thereof. the preparation method is characterized in that an Al metal membrane back electrode layer is arranged on the bottom face of a P type silicon substrate layer and serves as a back lead-out electrode; the P type silicon substrate layer is arranged on the Al metal membrane back electrode layer and serves as a base region of the solar battery; a P type silicon nano-wire array layer is arranged on the upper surface of the P type silicon substrate layer, the surface of the P type silicon nano-wire array layer is coated with Ti metal layer and the Ti metal layer and the P type silicon nano-wire array layer form a Schottky junction; a Ti grid type electrode is arranged on the Ti metal layer and serves as a front lead-out electrode; and the silicon nano-wire array also can be replaced with a silicon nano-pore array. The preparation method has simple process steps, is suitable for large-scale production, can be used for preparing a solar battery with high light absorption capability and high photoelectric conversion efficiency and lays a foundation for the application of a silicon nano structure in the solar battery.

Owner:HEFEI UNIV OF TECH

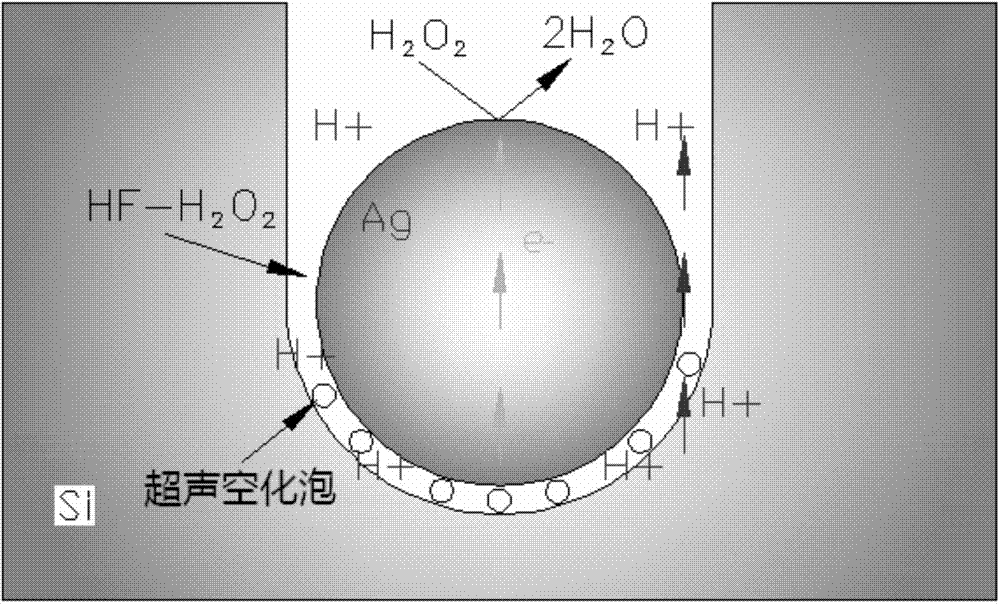

Method for preparing silicon nanostructure material under alternative electric fields

InactiveCN104711678ARealize the direction controllability of processingAchieving directional controllabilityAfter-treatment detailsNanotechnologyHydrofluoric acidStructure of the Earth

The invention discloses a method for preparing a silicon nanostructure material under alternative electric fields. The method comprises the following steps: 1, bonding six surfaces of bulk silicon with three pairs of independent inert electrodes, and drilling each of the inert electrodes with a fabrication hole, wherein the inert electrodes can generate alternative electrode fields; 2, putting the bulk silicon obtained in step 1 in a corrosive solution prepared by using hydrofluoric acid, hydrogen peroxide, a metal catalyst and deionized water; and 3, starting the inert electrodes after step 2, controlling the corrosion direction and the corrosion speed under three orthogonal alternative electric fields generated by the three inert electrodes under the frequency of the alternative electric fields of 28-40kHz, taking out the obtained bulk silicon after corrosion for a period of time, and cleaning to prepare the silicon nanostructure material. The method solves the problems of low metal assisted corrosion and low precision of the prepared silicon nanostructure, and controls the corrosion direction through the accurate control of metal catalyst particles by the alternative electric fields in order to realize accurate preparation of the three dimensional silicon nanostructure.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com