Visible photoelectrochemical detector based on one-dimensional silicon nanostructure array

A technology of silicon nano-array and photoelectrochemistry, which is applied in the direction of photometry, optics, and optical components using electric radiation detectors, and can solve the problems of multiple and complex equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0046] 1. Fabrication of n-type one-dimensional silicon nanostructure arrays by metal-catalyzed chemical etching

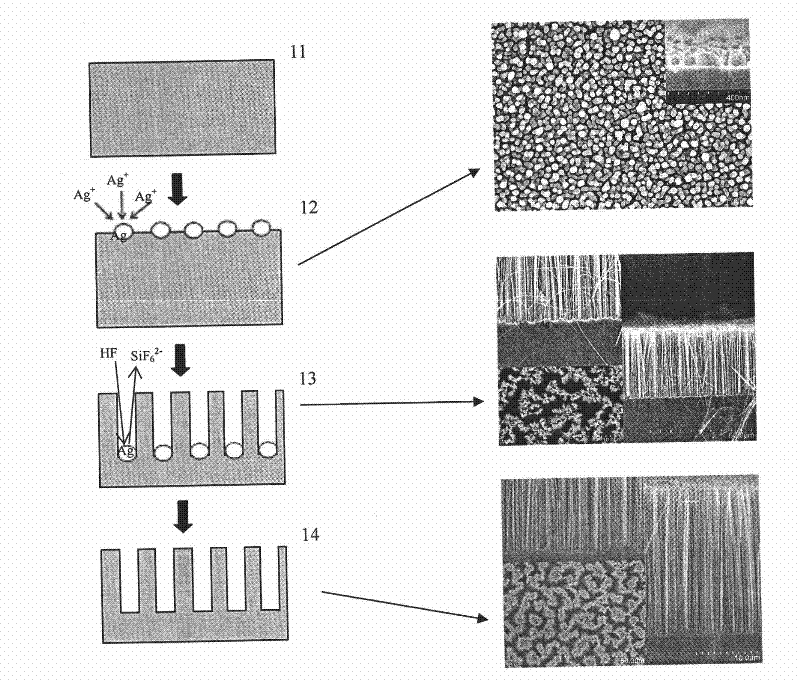

[0047] figure 1 It is a schematic diagram of the process of preparing a one-dimensional silicon nanostructure array by metal-catalyzed chemical etching on a (100) single crystal silicon substrate and a typical scanning electron microscope image of the corresponding stage. The preparation process is divided into four steps:

[0048] (1), silicon wafer cleaning: put the n-type polished silicon single wafer into acetone, alcohol and deionized water for ultrasonic cleaning for 10 to 20 minutes to remove organic matter such as dust and oil stains on the silicon surface; then immerse in sulfuric acid (H 2 SO 4 ) and hydrogen peroxide (H 2 o 2 ) (volume ratio of 4 / 1) in a mixture of 15 to 60 minutes to remove pollutants such as metal ions; rinse the n-type polished silicon wafers cleaned by ultrasonic and boiling with deionized water, and finally store them in deioniz...

specific Embodiment approach 2

[0058] 1. Fabrication of p-type one-dimensional silicon nanostructure arrays by metal-catalyzed chemical etching

[0059] figure 1 It is a schematic diagram of the process of preparing a one-dimensional silicon nanostructure array on a (100) single crystal silicon substrate and a typical scanning electron microscope image of the corresponding stage. According to the figure, the preparation process can be divided into four steps:

[0060] (1), silicon wafer cleaning: place the p-type polished silicon single wafer in acetone, alcohol and deionized water for ultrasonic cleaning for 10 to 20 minutes to remove organic matter such as dust and oil stains on the p-type polished silicon surface; then immerse in sulfuric acid (H 2 SO 4 ) and hydrogen peroxide (H 2 o 2 ) (volume ratio of 4 / 1) in a mixture of 15 to 60 minutes to remove pollutants such as metal ions; rinse the p-type polished silicon wafers cleaned by ultrasonic and boiling with deionized water, and finally store them i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dark current density | aaaaa | aaaaa |

| Photocurrent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com