Method for preparation of one-dimensional silicon nanostructure

A silicon nanometer and nanoparticle technology, which is applied in the field of preparation of one-dimensional silicon nanostructures, can solve the problems that nanomaterials are difficult to meet the needs of application occasions, and achieve the advantages of device fabrication and assembly, compatible processing technology, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

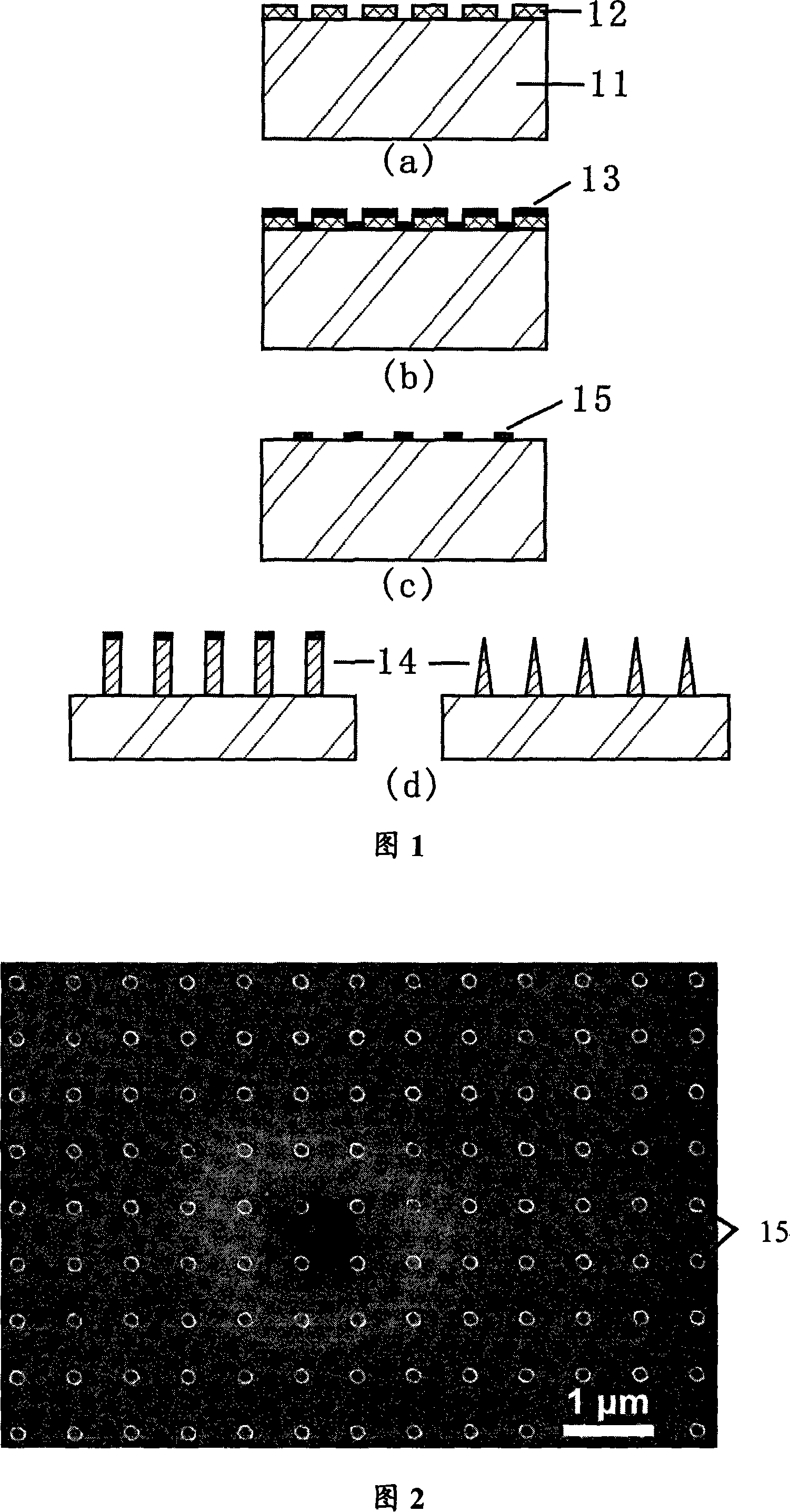

[0028] When the preparation and dispersion method of nanoparticles is used to obtain a nanoparticle mask, the process steps are as follows: first deposit a layer of metal film on the surface of the base material; then heat-treat the metal film to obtain a metal nanoparticle mask on the surface of the base material ; Finally, the base material is etched by plasma etching technology.

[0029] The present invention will be described in further detail below with different nanoparticle mask forming methods in conjunction with the accompanying drawings:

Embodiment 1

[0031] In this embodiment, electron beam lithography technology is used to form a nanoparticle mask, and single crystal silicon is used as the base material. The specific process steps are as follows:

[0032] 1. Use n-type high-conductivity single crystal silicon with crystal orientation (resistivity 2.4~3.7×10 -3 Ω·cm)11 as the substrate.

[0033] 2. Use a KW-4AH hot plate to bake the silicon substrate at a temperature of 180°C before gluing for 30 minutes.

[0034] 3. Using a Karl Suss RC8 coating machine, evenly spin-coat a layer of electron beam photoresist PMMA (950K C4) 12 on the surface of the baked silicon substrate, the coating speed is 3000rpm, and the acceleration is 10000rpm / s, The time is 30 seconds, and the glue thickness is 380nm.

[0035] 4. Use the KW-4AH hot plate to pre-bake the coated sample, the baking temperature is 180°C, and the baking time is 90s.

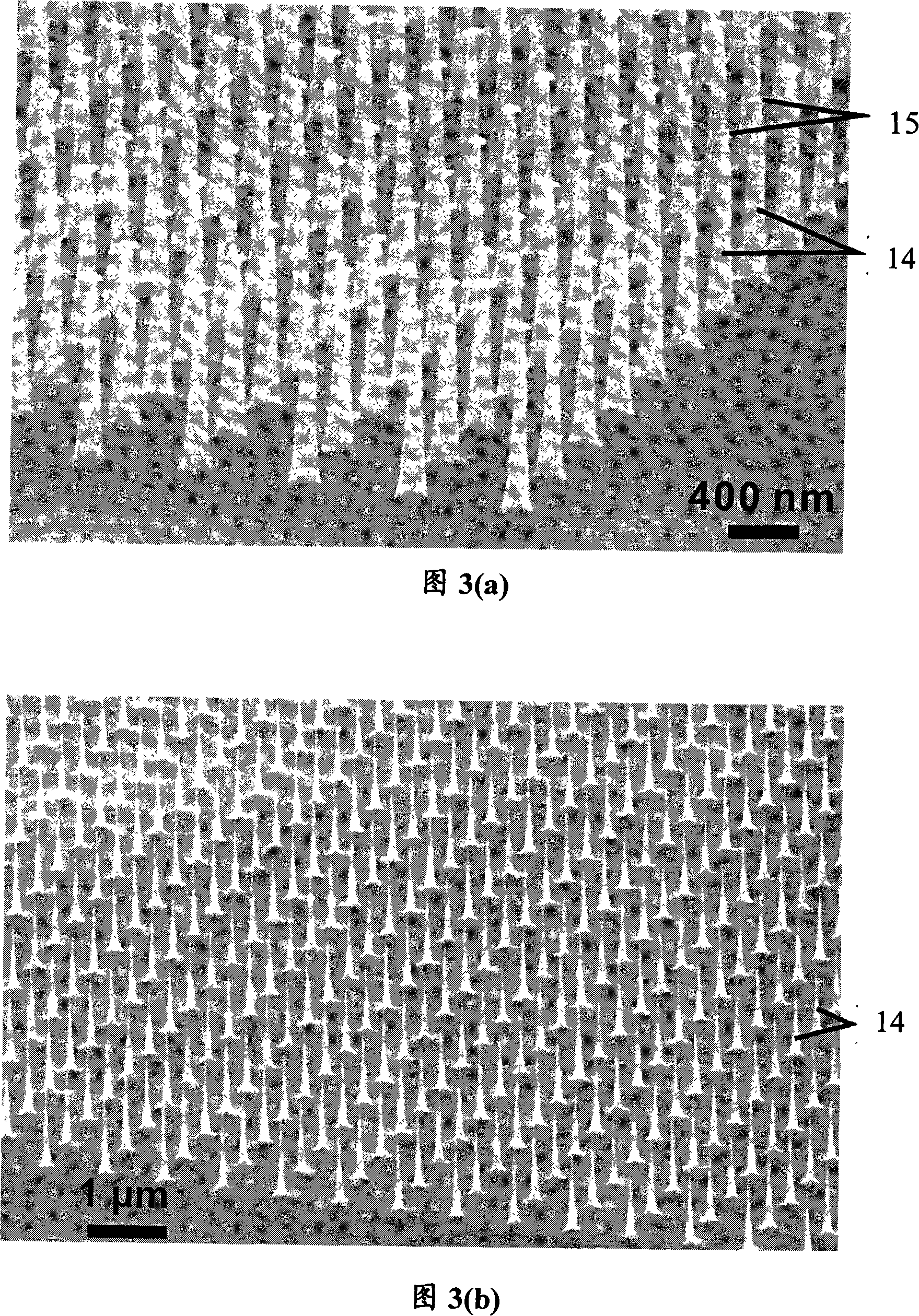

[0036] 5. Using the Raith E-line electron beam exposure system, on the PMMA-coated sample, expose t...

Embodiment 2

[0046]In this embodiment, the preparation and dispersion method of nanoparticles is used to obtain a nanoparticle mask, and the substrate deposited with an amorphous silicon film is used as the base material. The specific process steps are as follows:

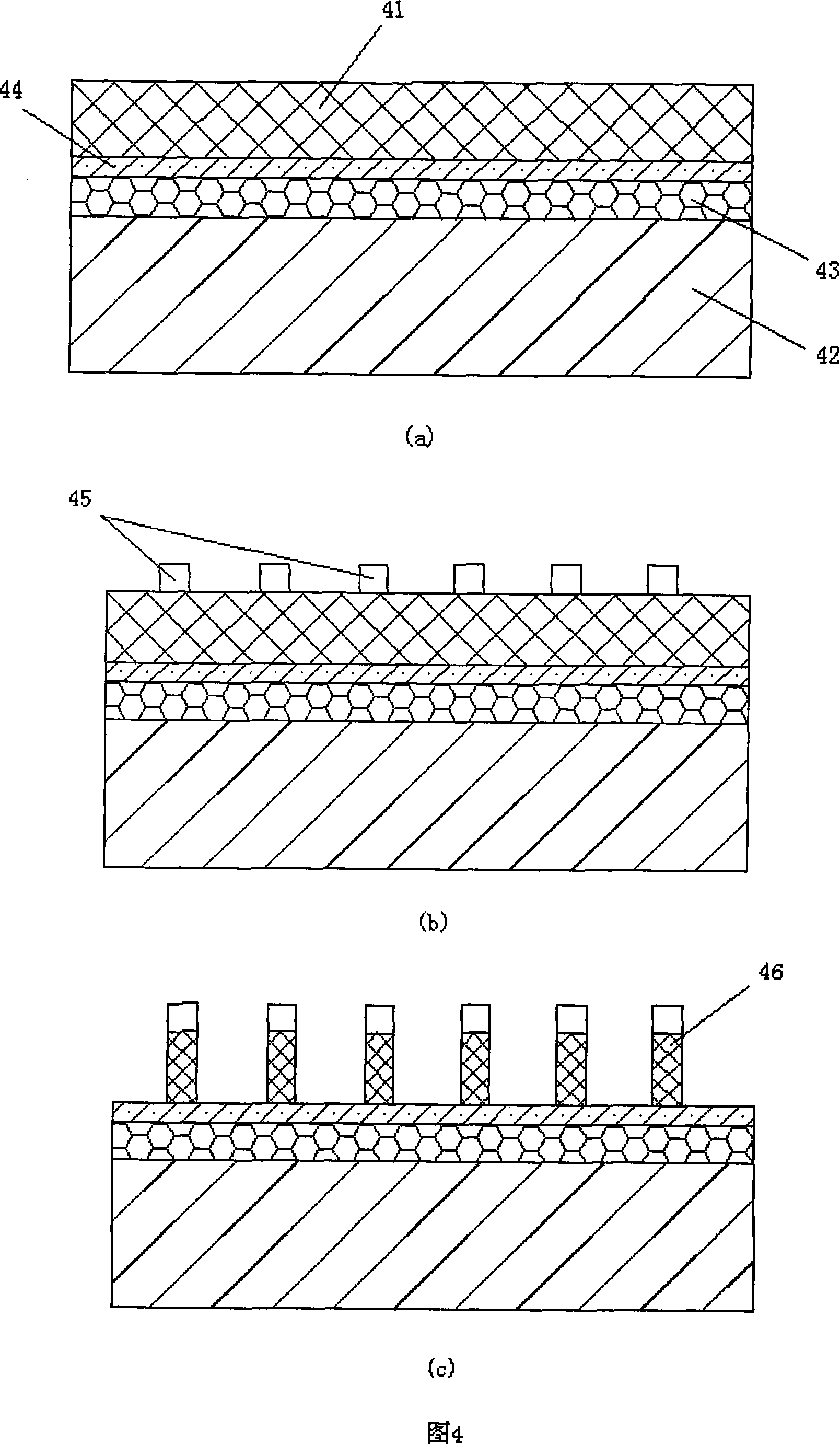

[0047] 1. as shown in Figure 4 (a), deposit one layer of 0.5 μm silicon dioxide (SiO 2 ) layer 43 and a 0.2 μm metal chromium (Cr) layer 44 as a substrate, wherein the metal chromium (Cr) layer 44 is on top of the silicon dioxide layer 43 .

[0048] 2. Place the substrate in a plasma-enhanced chemical vapor deposition system (PECVD) to deposit the amorphous silicon film 41 , as shown in FIG. 4( a ). where the reaction gas is SiH at 400 sccm 4 (5%) / Ar(95%), the radio frequency source (RF) power is 40W, the reaction pressure is 60Pa, the deposition time is 60 minutes, and the corresponding film thickness is about 1.2 μm.

[0049] 3. Deposit a layer of gold film with a thickness of several nanometers by DC sputtering on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com