Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Nano fabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Nano-Fabricator is a tier 3 crafting station. It allows the crafting of numerous new techs and EPP Augments offered by Frackin' Universe, as well as upgrades to armor and the different tiers of a more powerful resource collection device known as the Mining Laser.

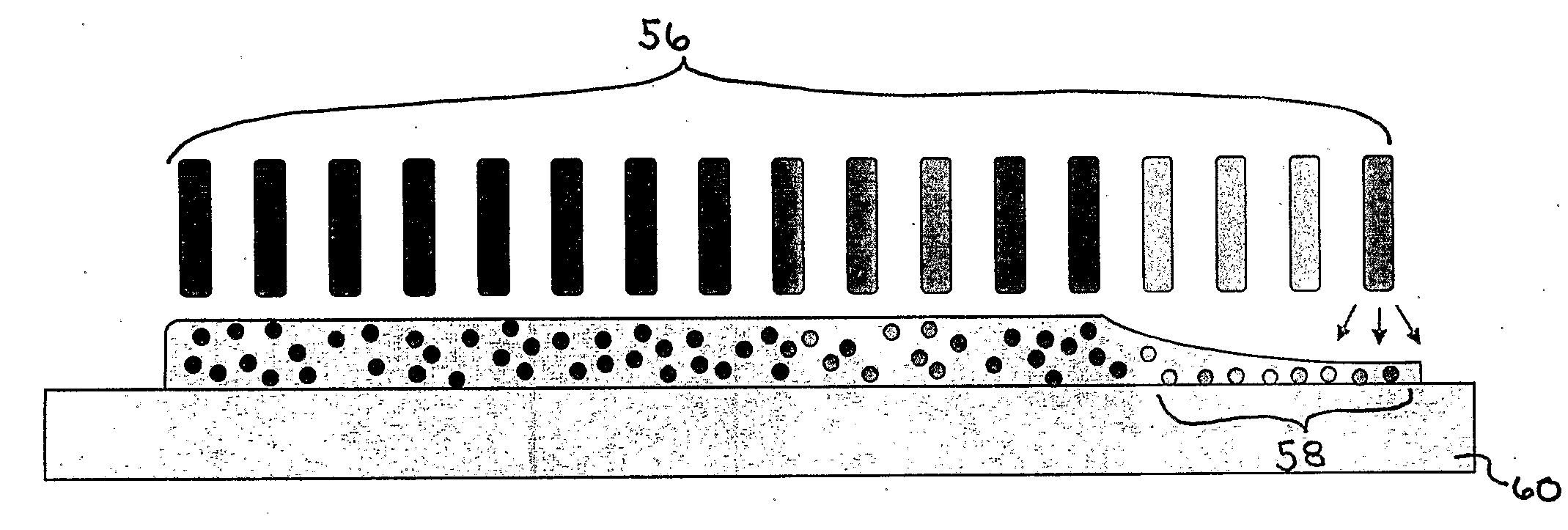

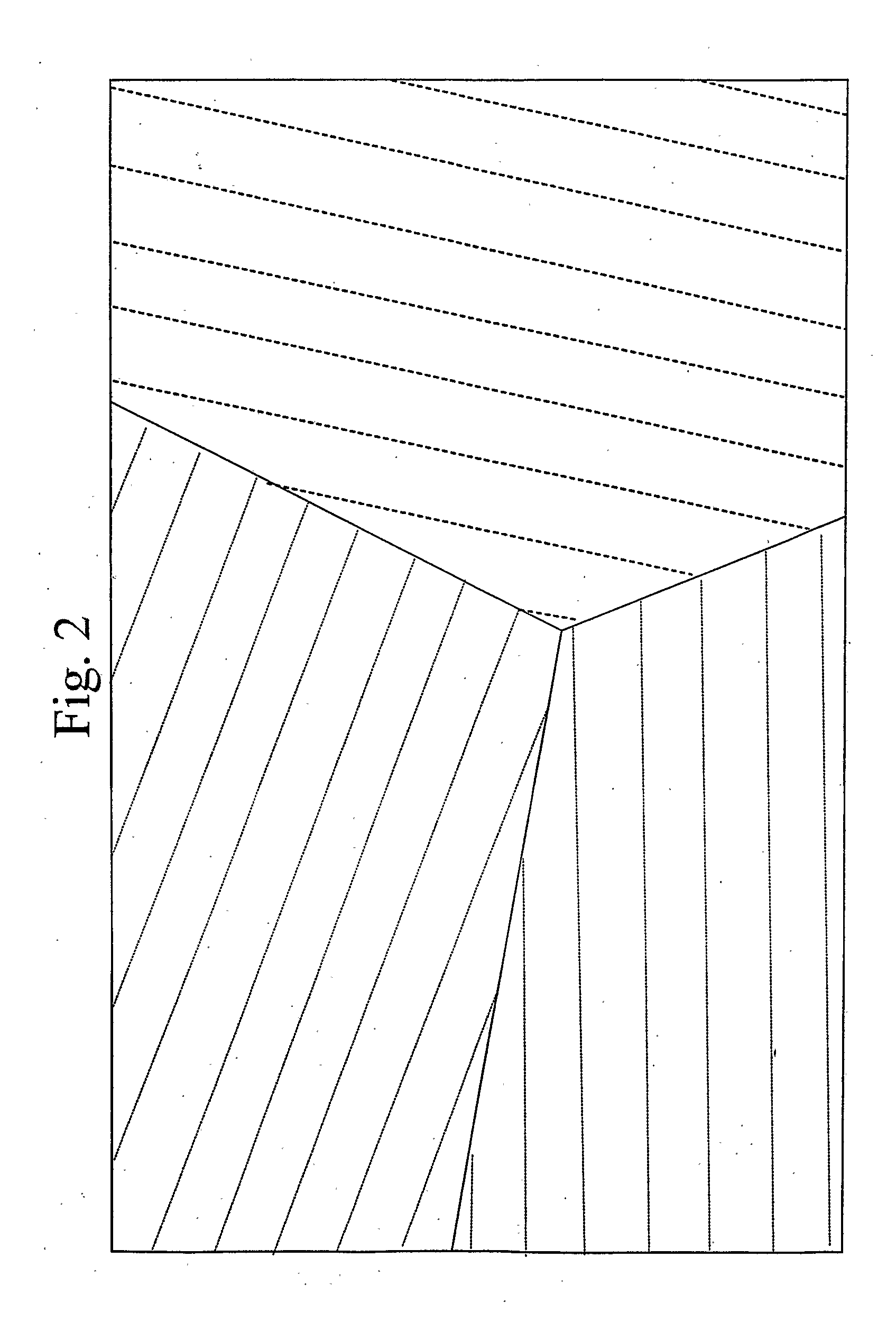

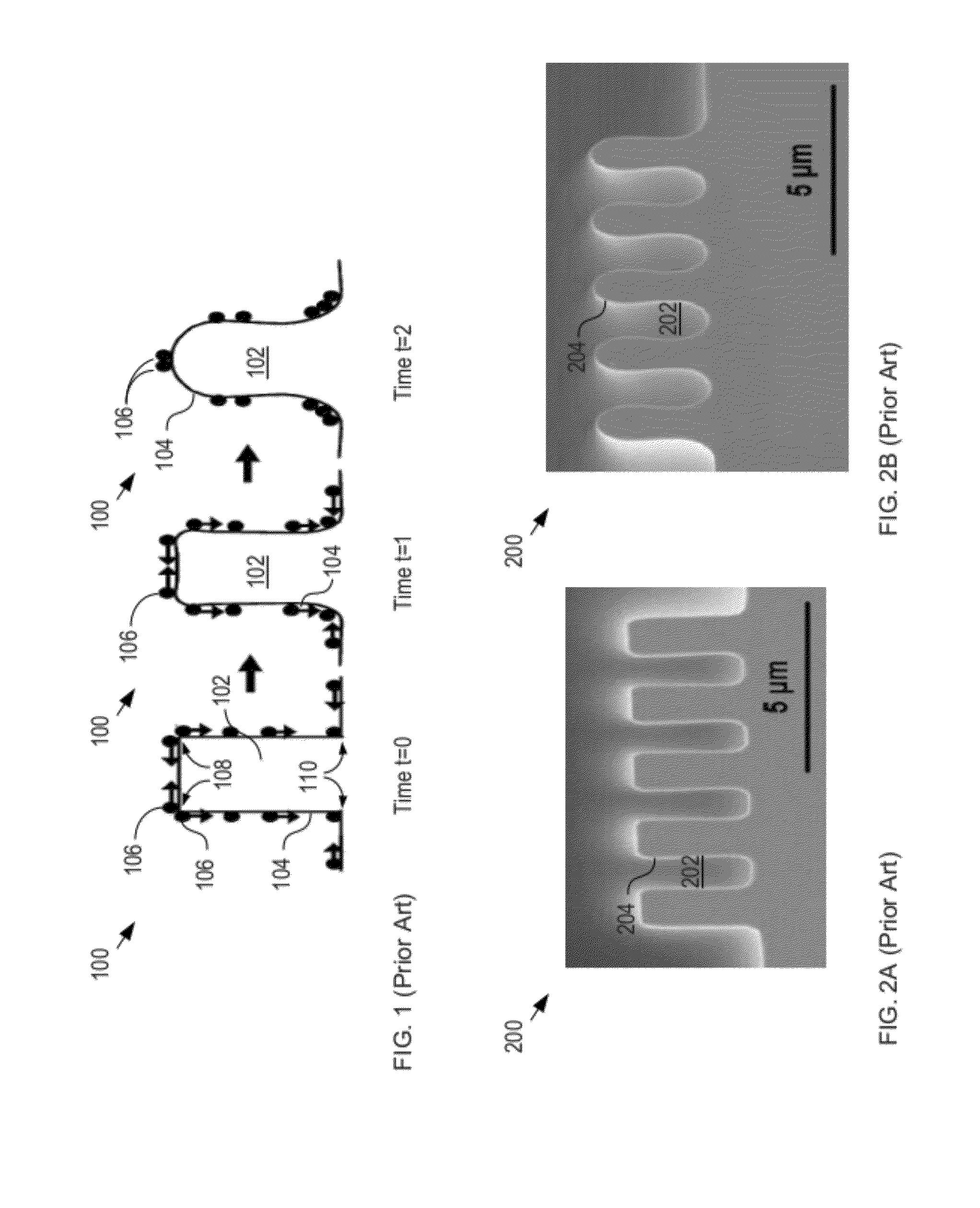

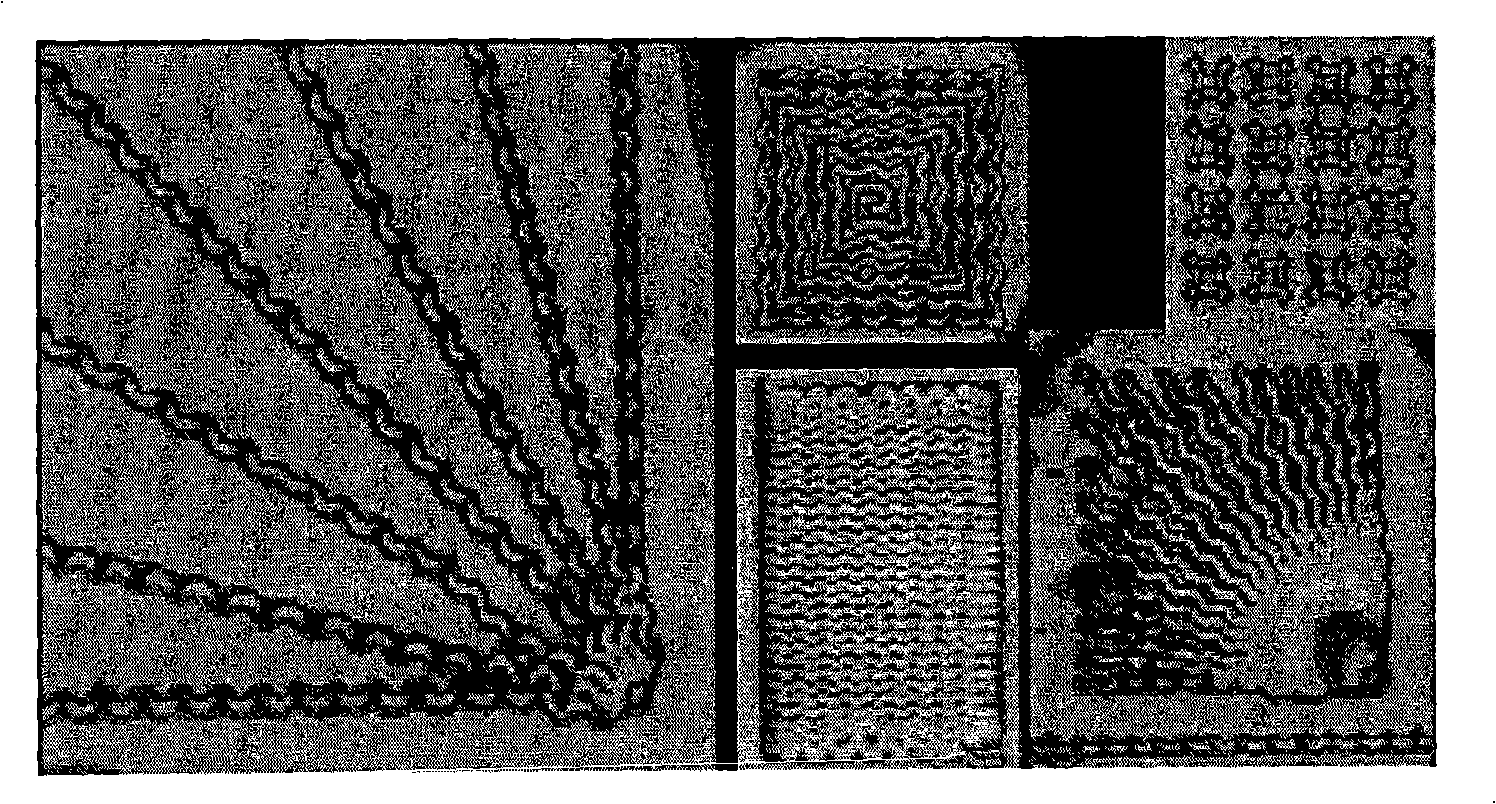

Method for Fabricating a Long-Range Ordered Periodic Array of Nano-Features, and Articles Comprising Same

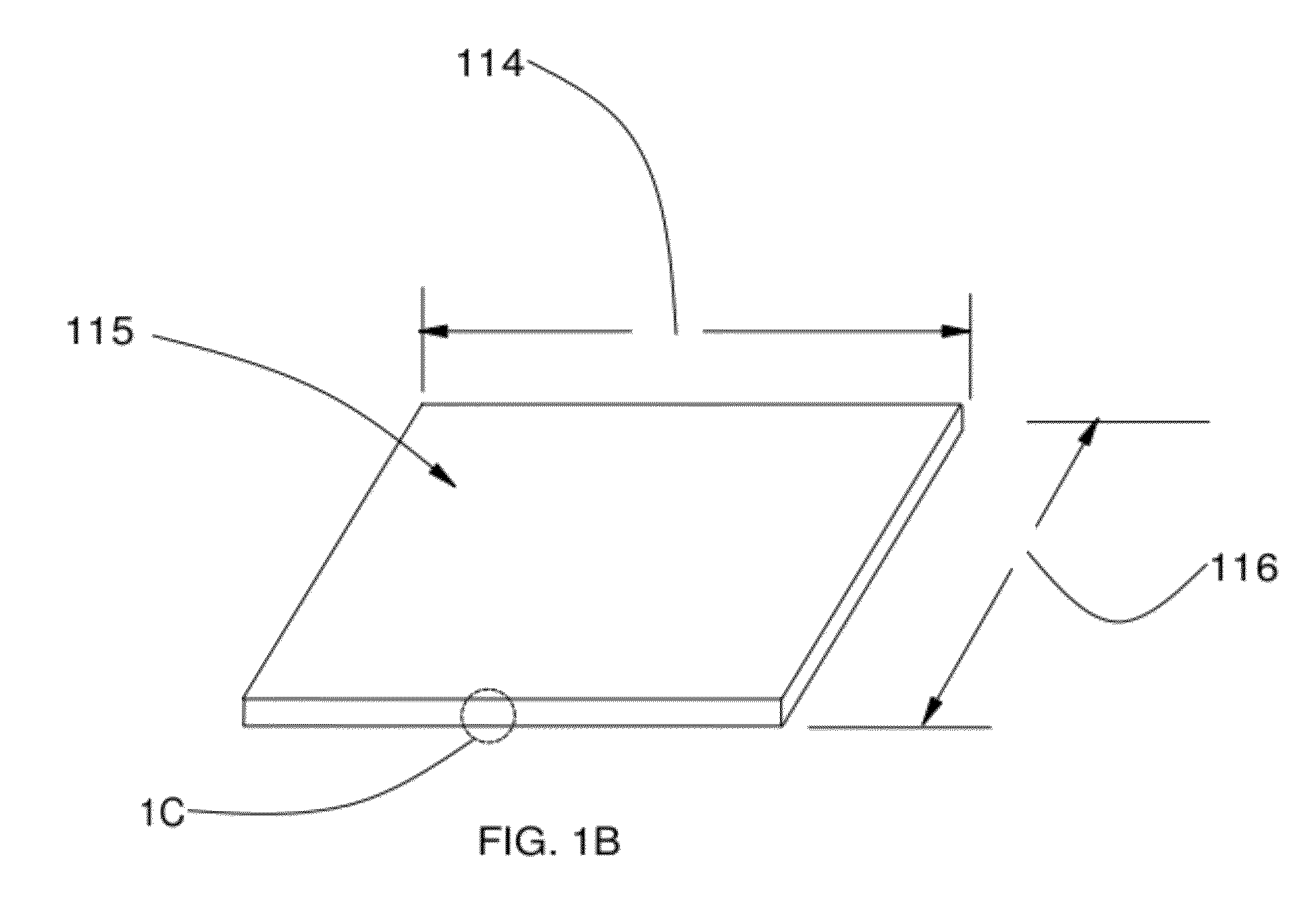

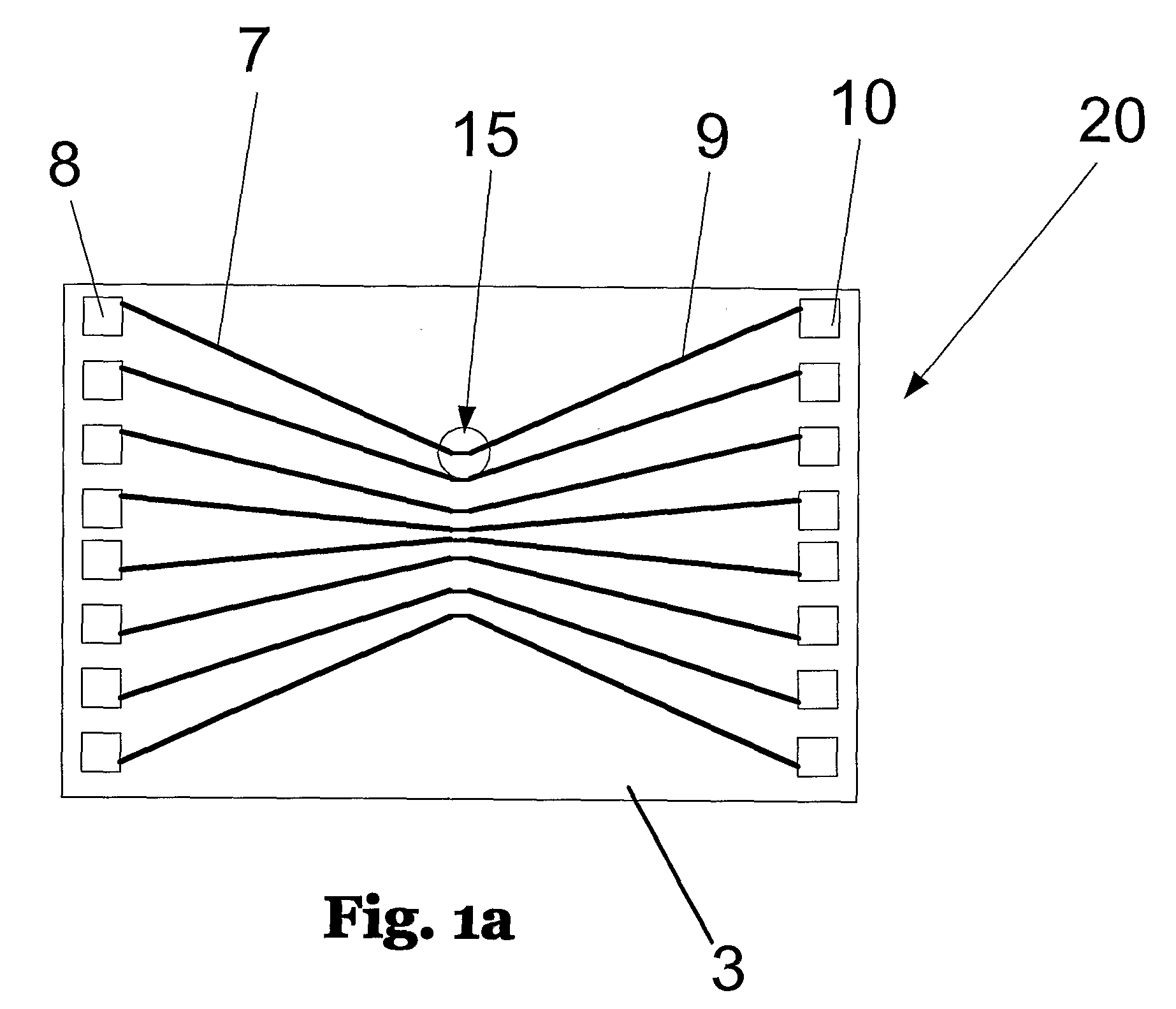

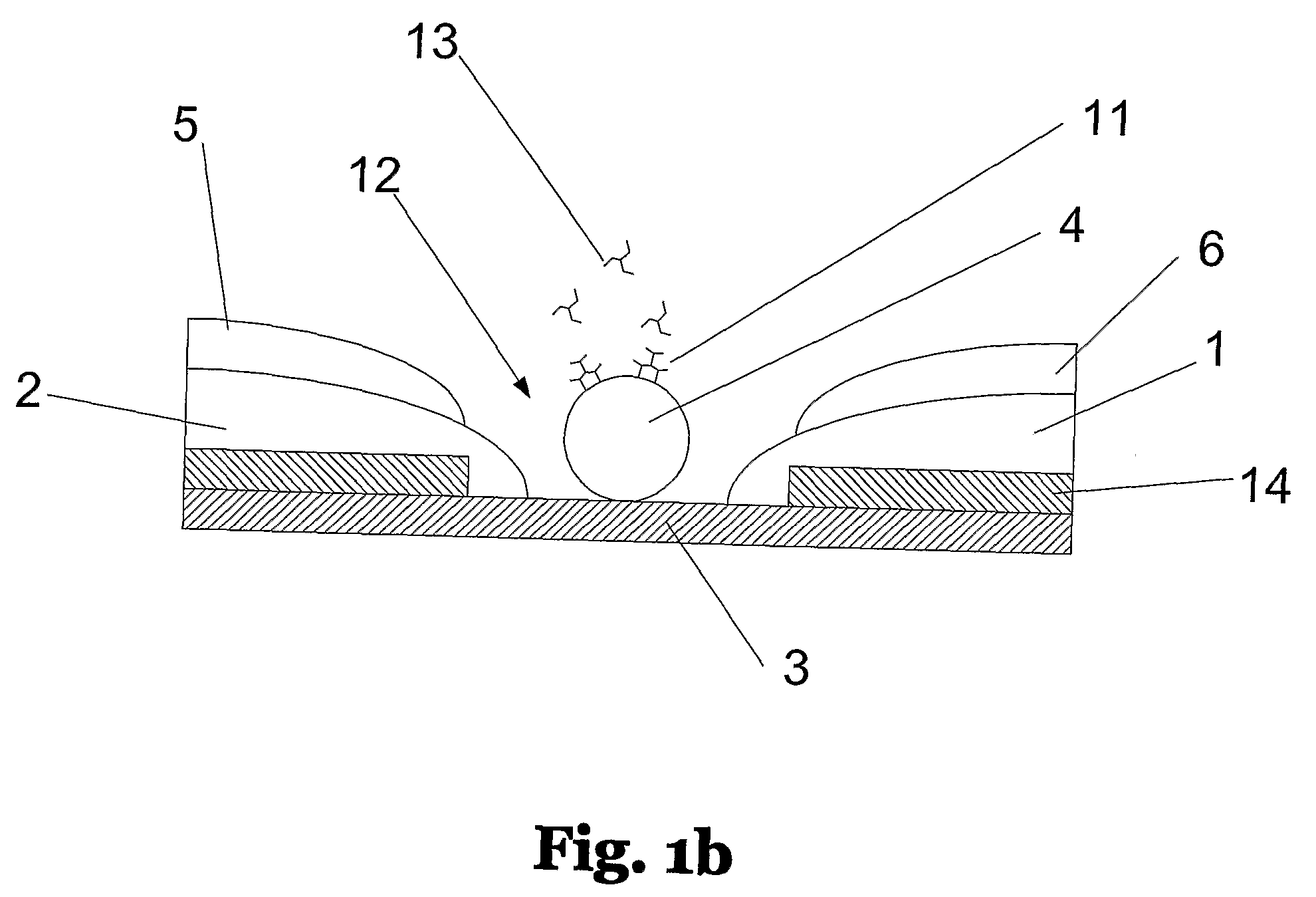

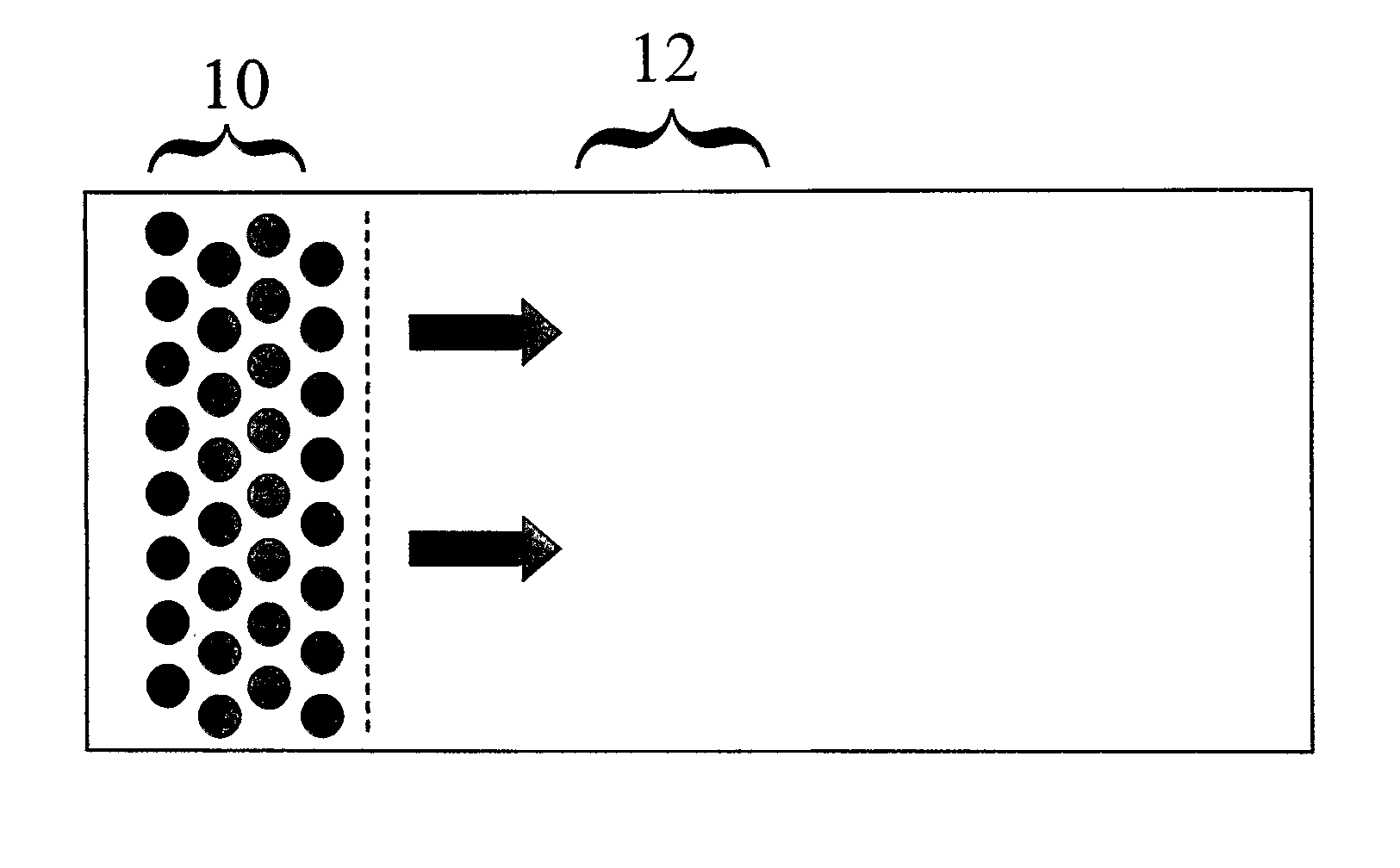

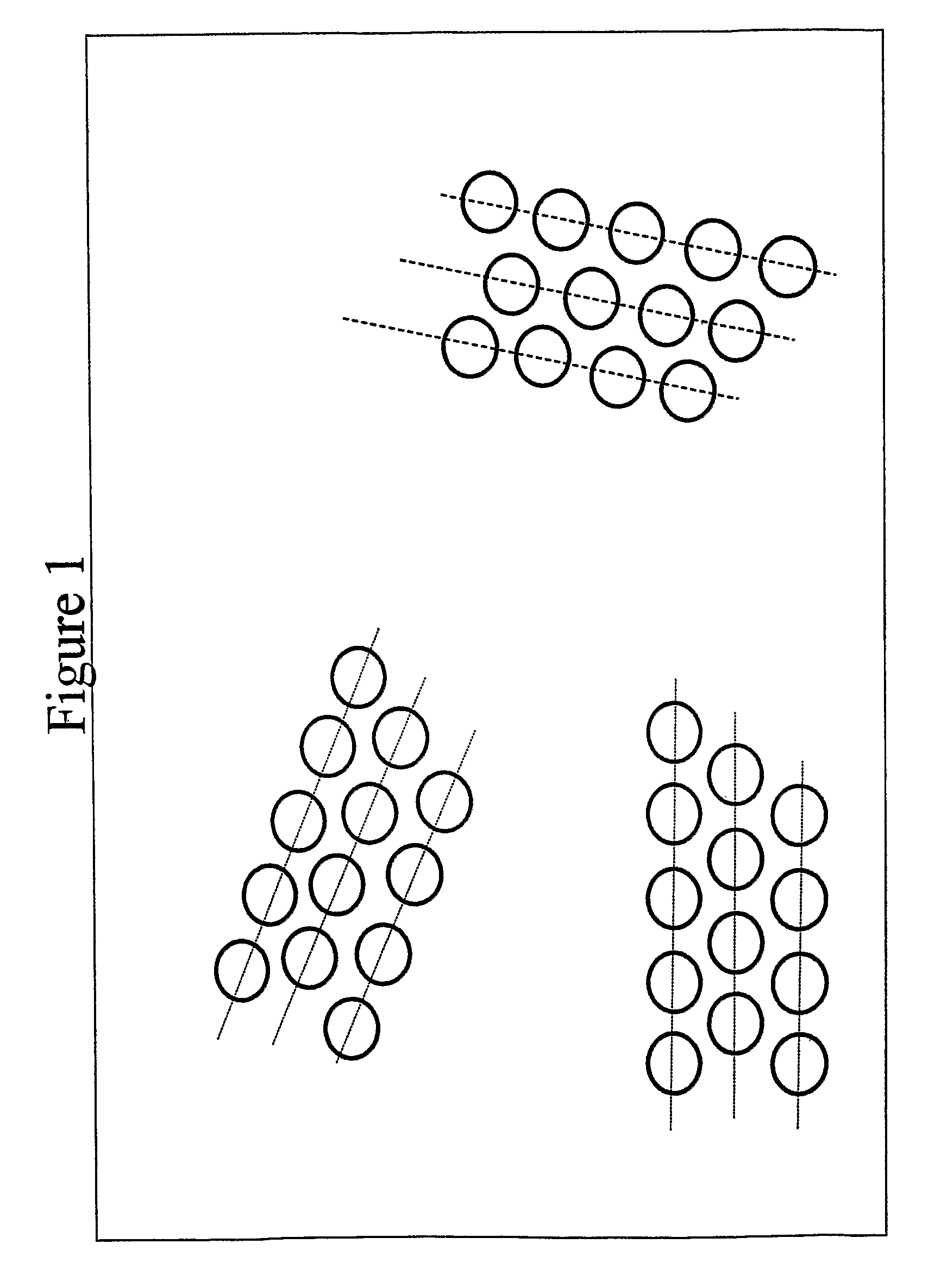

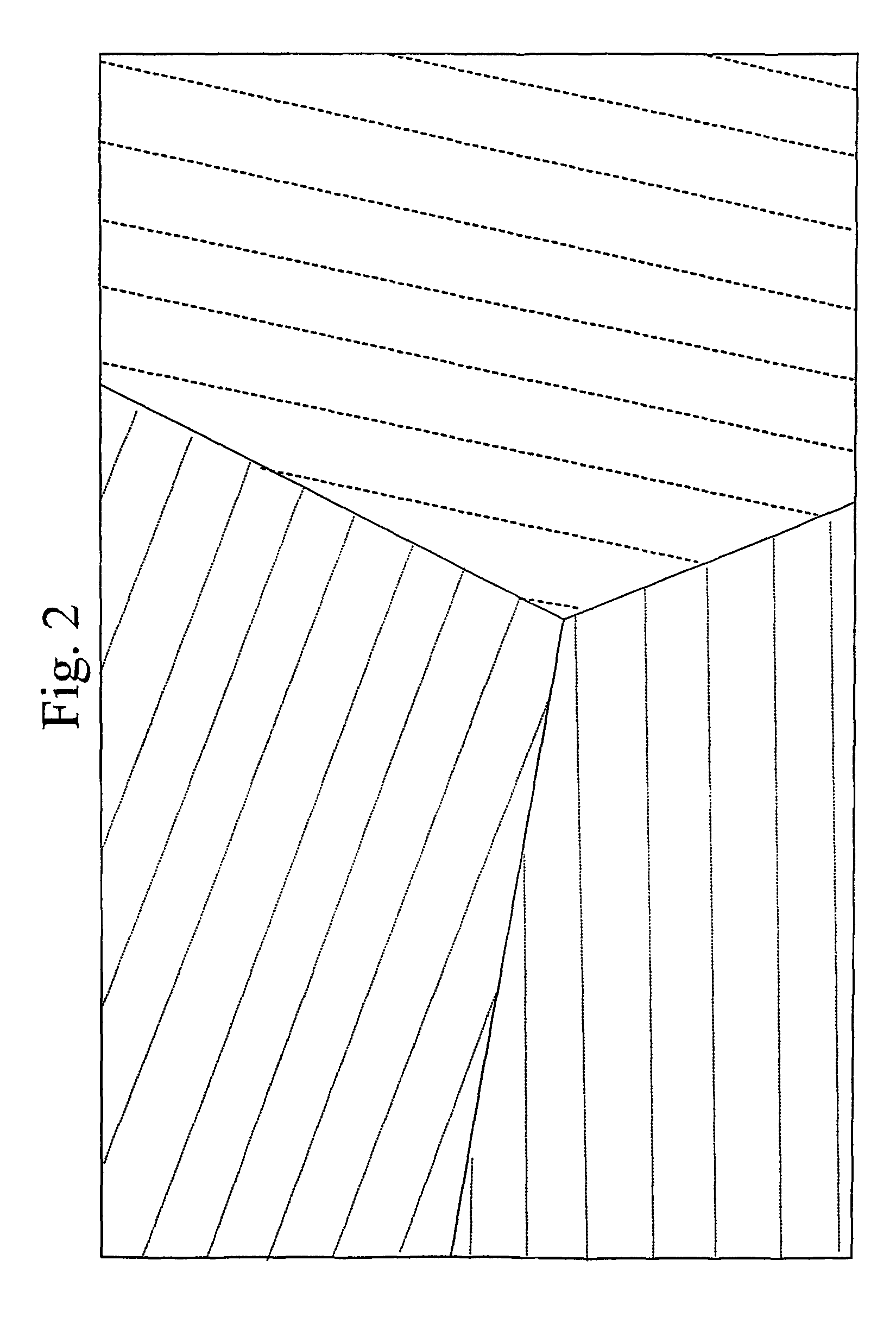

A long range, periodically ordered array of discrete nano-features (10), such as nano-islands, nano-particles, nano-wires, non-tubes, nano-pores, nano-composition-variations, and nano-device-components, are fabricated by propagation of a self-assembling array or nucleation and growth of periodically aligned nano-features. The propagation may be induced by a laterally or circularly moving heat source, a stationary heat source arranged at an edge of the material to be patterned (12), or a series of sequentially activated heaters or electrodes. Advantageously, the long-range periodic array of nano-features (10) may be utilized as a nano-mask or nano-implant master pattern for nano-fabrication of other nano-structures. In addition, the inventive long-range, periodically ordered arrays of nano-features are useful in a variety of nanoscale applications such as addressable memories or logic devices, ultra-high-density magnetic recording media, magnetic sensors, photonic devices, quantum computing devices, quantum luminescent devices, and efficient catalytic devices.

Owner:RGT UNIV OF CALIFORNIA

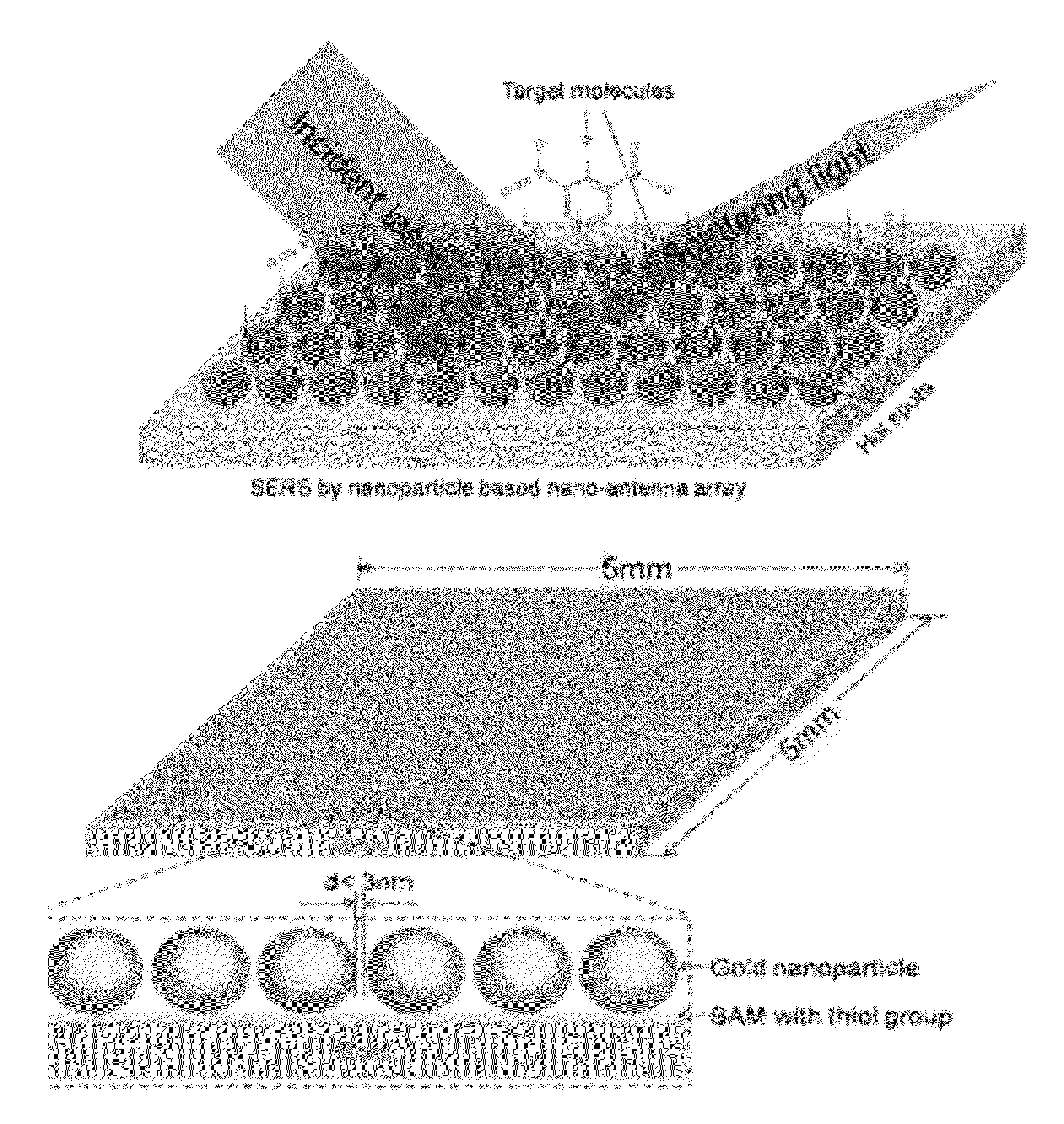

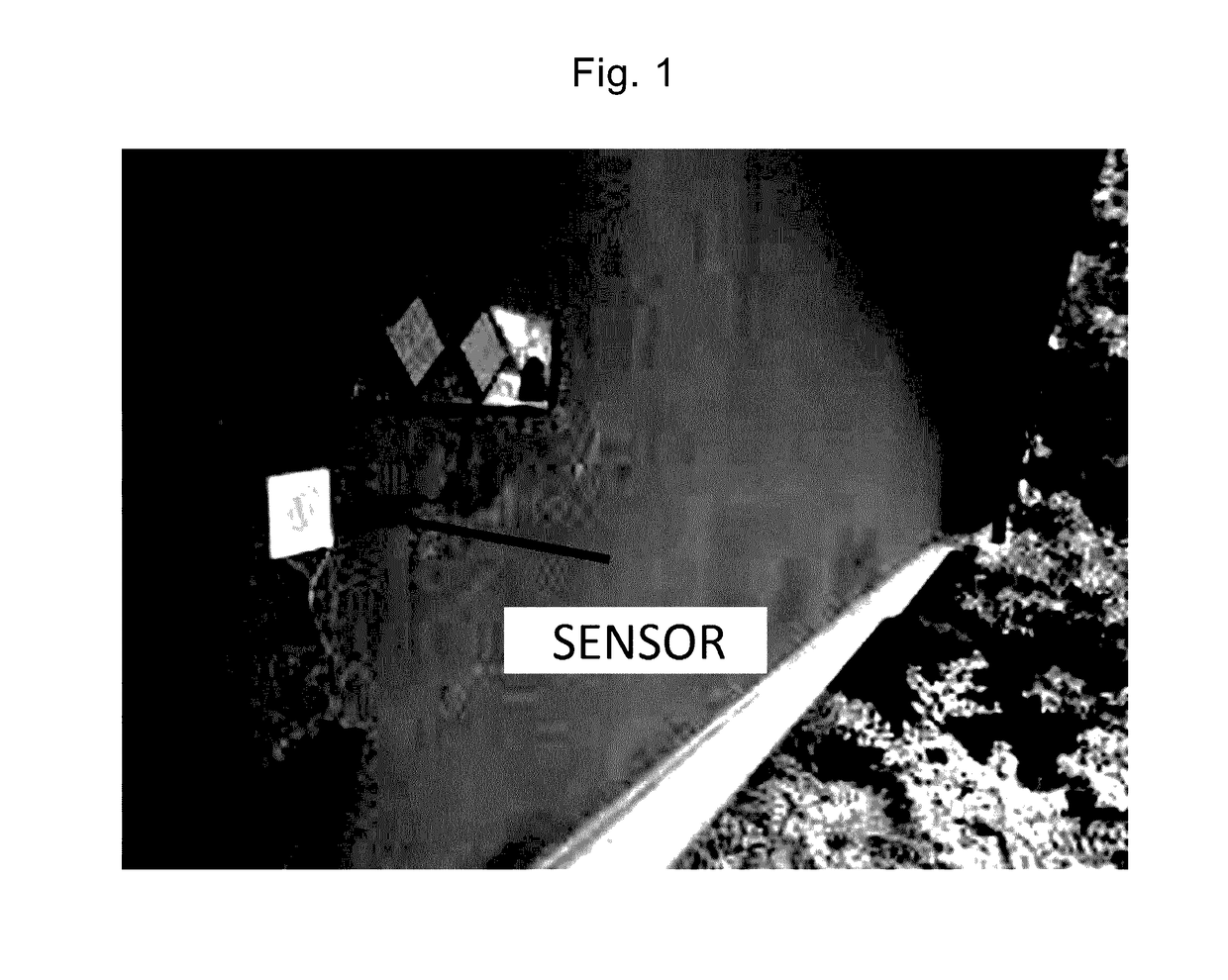

Sensor system with plasmonic nano-antenna array

ActiveUS20120050732A1Increase heightRapid and sensitive chemical/biological agent detectionMaterial nanotechnologyRadiation pyrometrySystems designEngineering

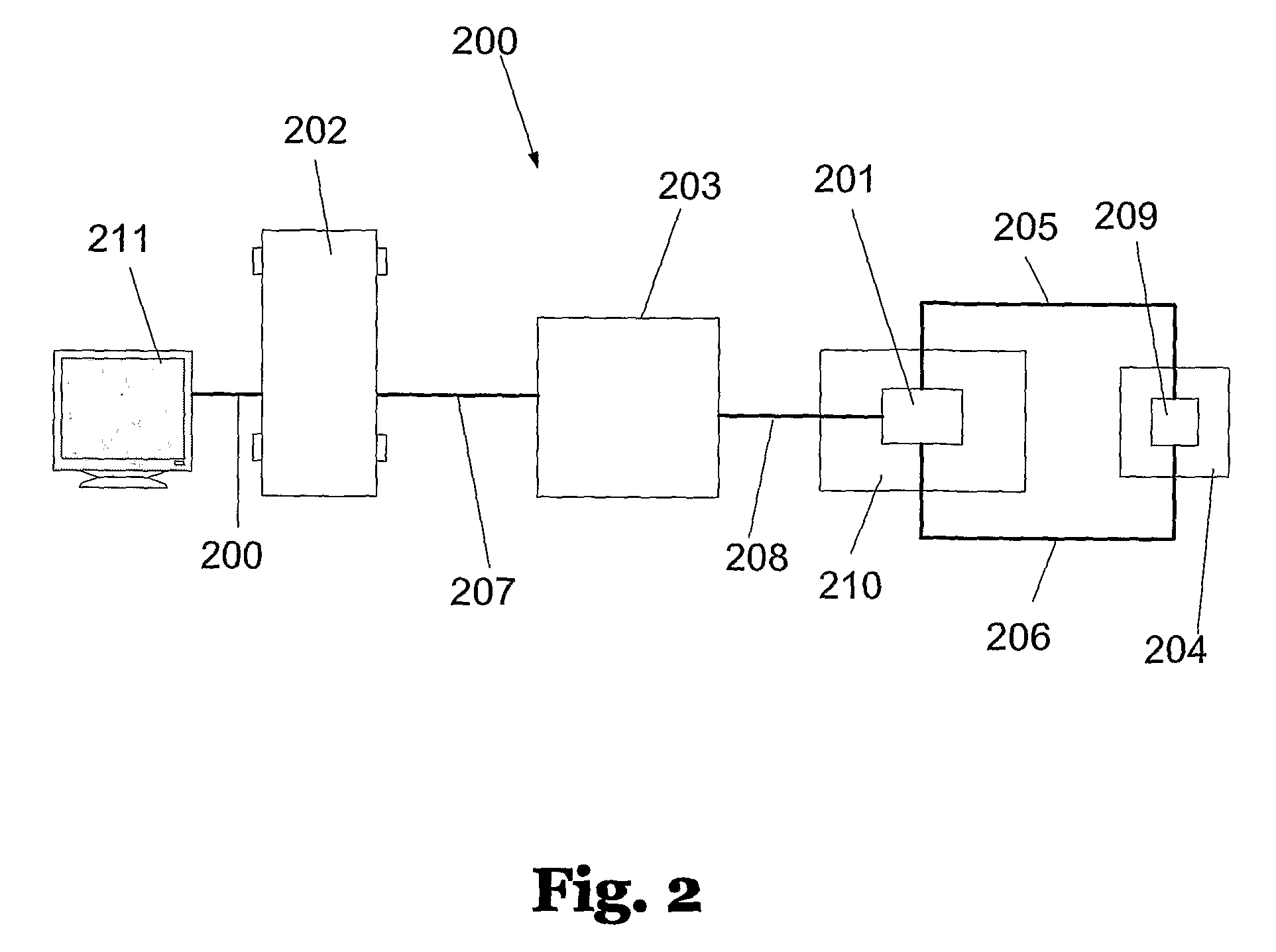

In order to provide the high sensitivity SERS active substrates needed for rapid and sensitive chemical / biological agent detection, the present invention provides a Plasmonic Nano-antenna Array (PNA) substrate with large local electromagnetic field enhancements; a controllable and repeatable nano-fabrication process for creating the PNA surface; and a system design for a compact, portable device capable of using the PNA technology to acquire and analyze target molecular samples. Both 2D and 3D systems are provided.

Owner:LU WEIXING +1

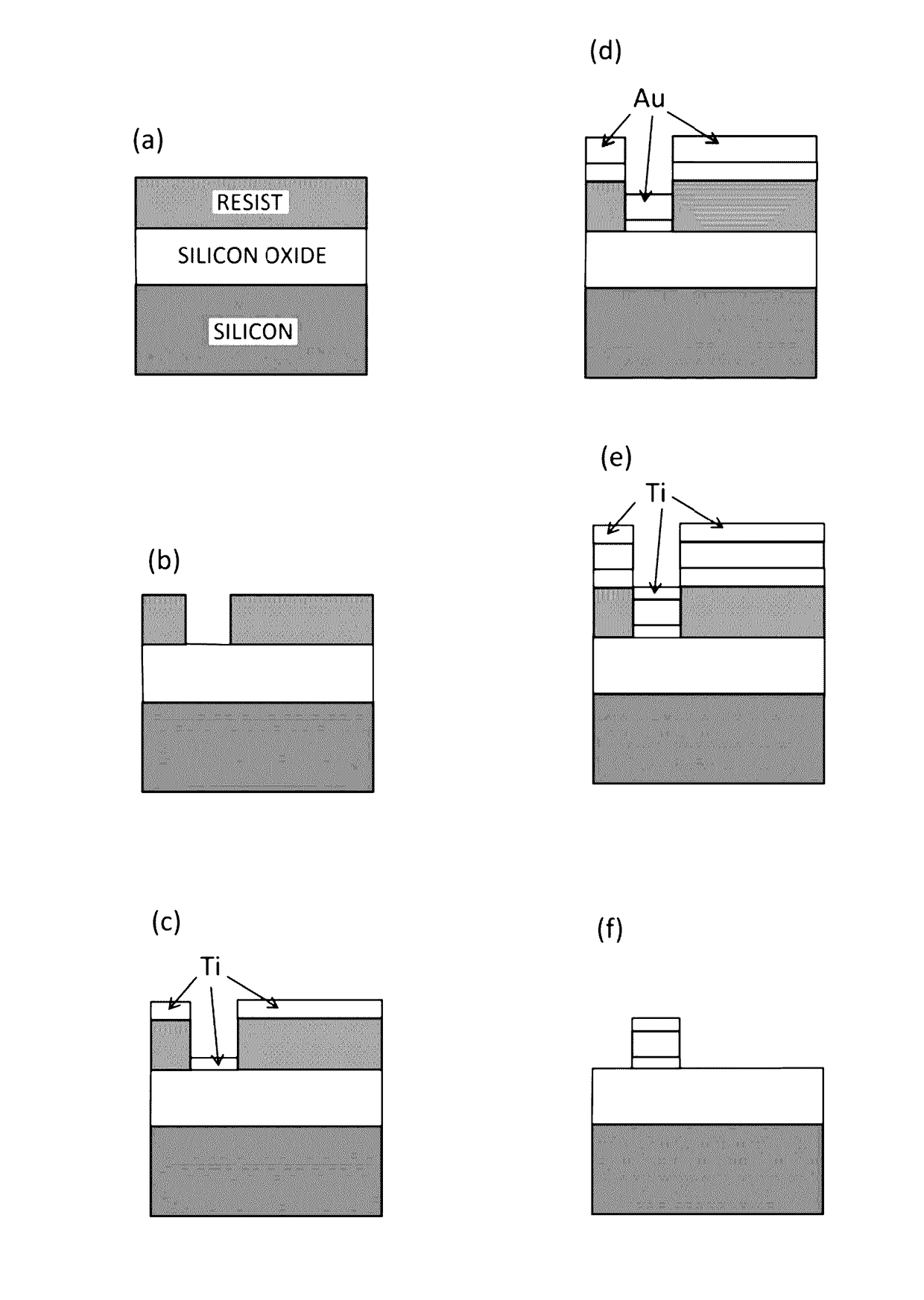

Sensor for Detection of Single Molecules

InactiveUS20080149479A1High sensitivityReduce distortion problemsImmobilised enzymesMaterial nanotechnologySingle electronNano manufacturing

A single electron transistor device for sensing at least one particle, includes at least two electrodes positioned with a gap formed between the electrodes and an activation object positioned in the gap with an insulating layer between the activation object and each electrode. The activation object which is able to transfer electrons is arranged with at least one binding structure bonded to it for receiving the at least one particle. The electrodes are formed with an inter distance of less than 50 nm and the electrodes are connectable directly or indirectly to a signal acquisition system. The sensing device is arranged to allow a tunnelling current proportional to the presence of the at least one particle in the binding structure, to flow through the activation object. A method, and system using a single electron transistor device fabricated with micro / nano fabrication methods are also disclosed.

Owner:MIDORION

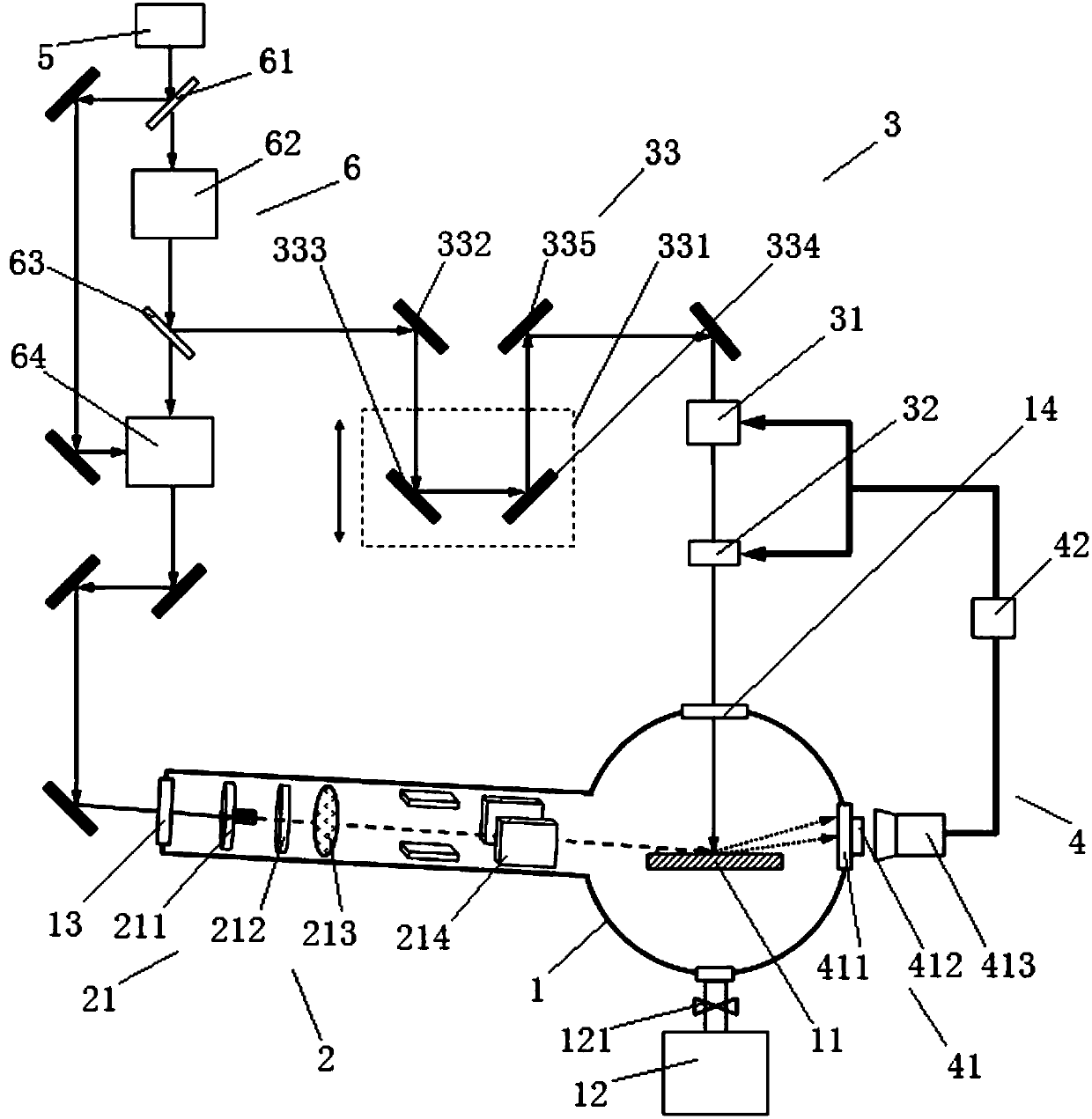

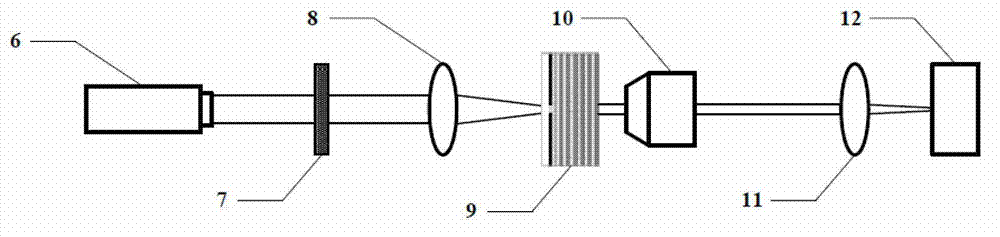

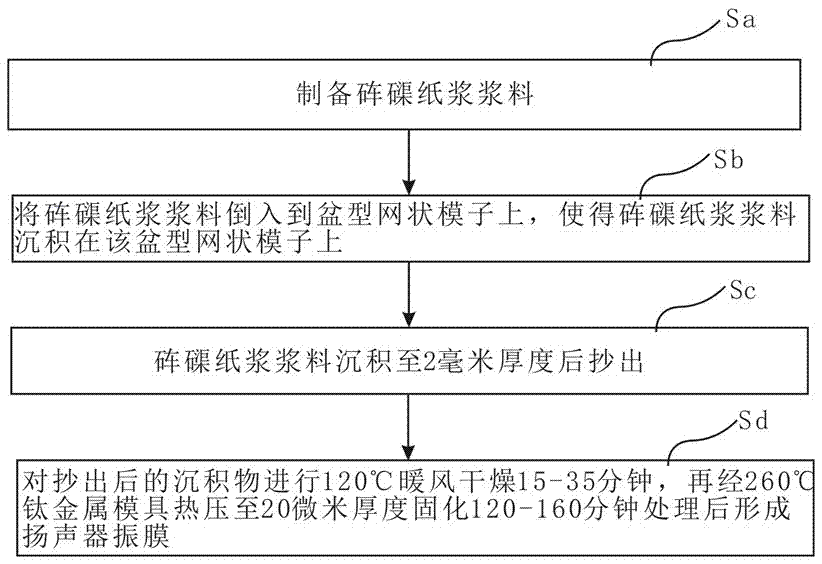

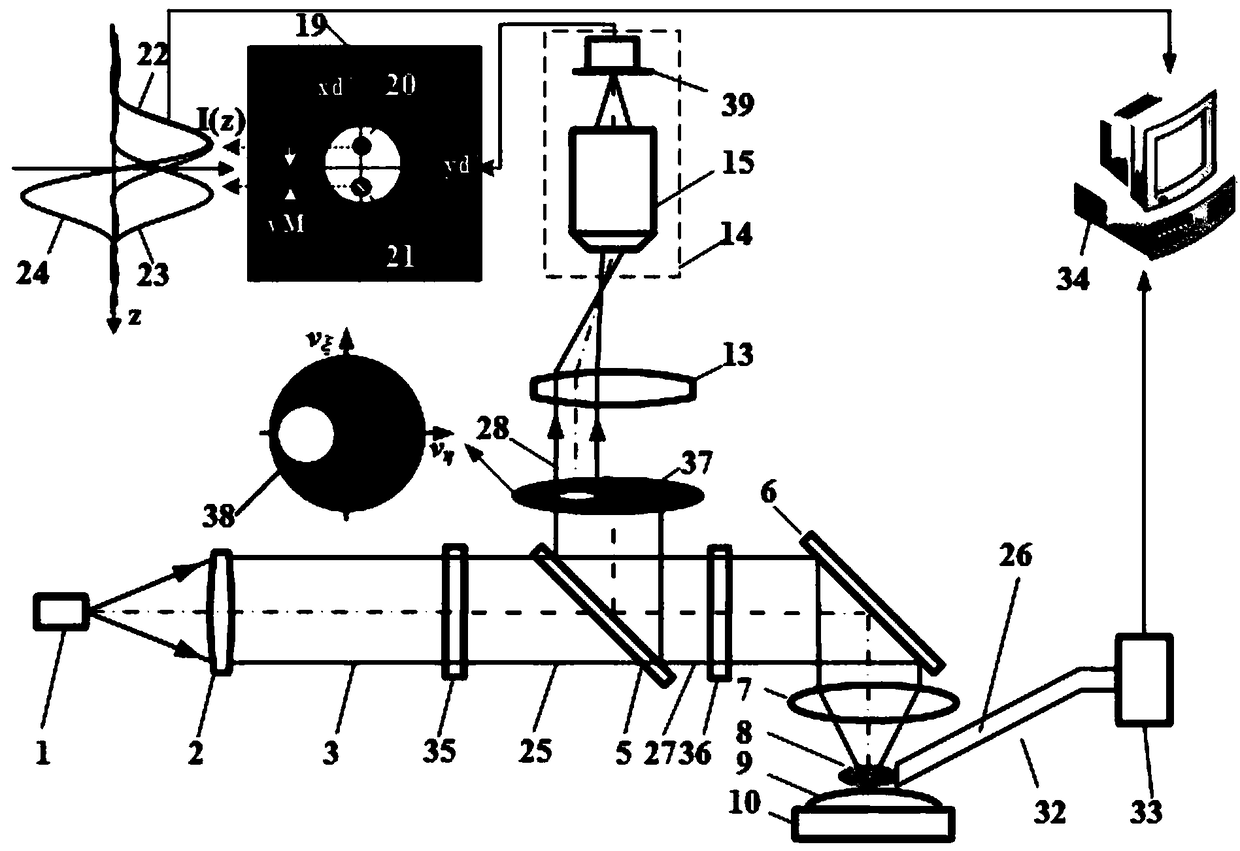

Laser differential confocal LIBS, Raman spectrum-mass spectrum imaging method and Raman spectrum-mass spectrum imaging device

InactiveCN105136750AImplement focus detectionRealize functionMaterial analysis by electric/magnetic meansRaman scatteringLaser-induced breakdown spectroscopyMass spectrometry imaging

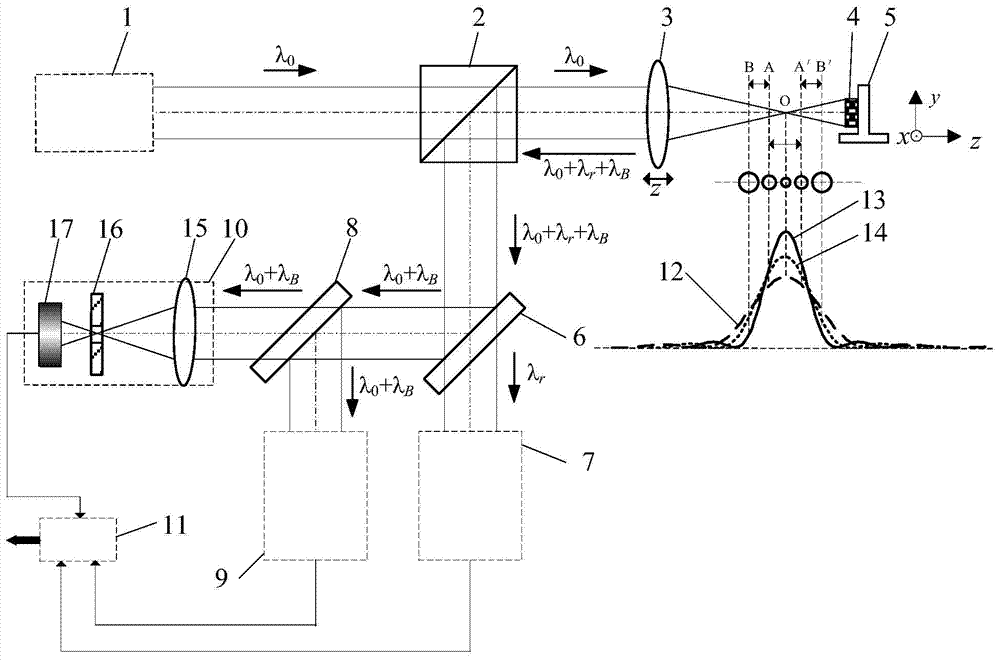

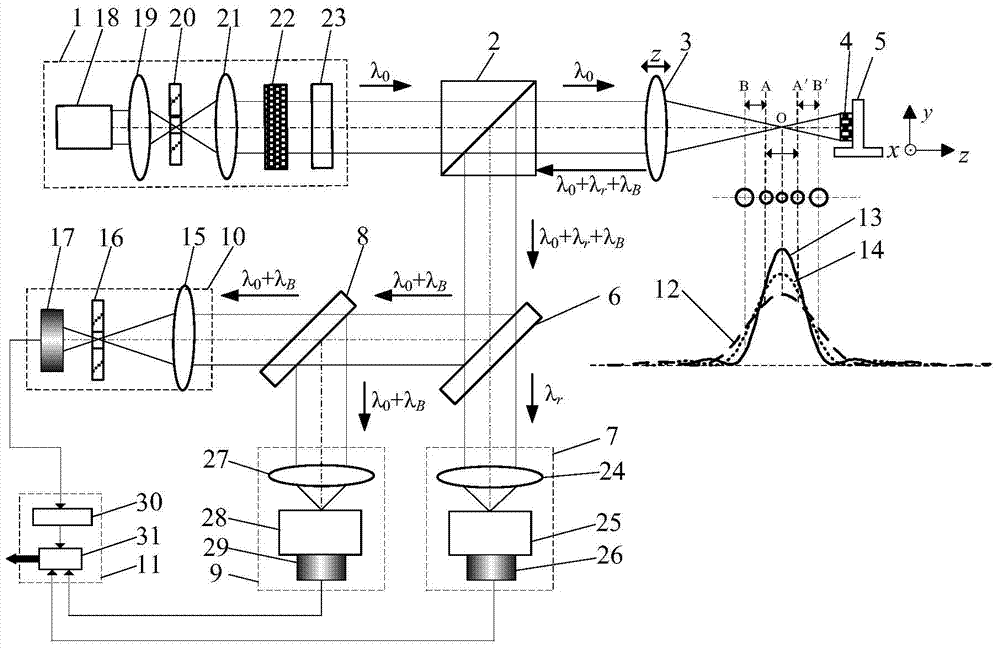

The invention relates to a laser differential confocal LIBS, a Raman spectrum-mass spectrum imaging method and a Raman spectrum-mass spectrum imaging device and belongs to the technical fields of confocal microscopy imaging, mass spectrum imaging and spectral measurement. In the invention, the differential confocal microscopy imaging technology is combined with a spectrum and mass spectrum detection technology; a high-spatial-discrimination differential confocal system is used for axially focusing and imaging a sample; a mass spectrum detection system is used for performing mass spectrum detection to charged molecules and atoms in a sample microcell; and a spectral detection system is used for performing microcell spectrum detection to focal spot excitation spectrums (Raman spectrum and induced breakdown spectrum) of a differential confocal microscopy system, thereby achieving high-spatial discrimination and high-sensitivity imaging and detection of complete component information and configuration parameters of the sample microcell. The invention achieves advantage complement and structure and function fusion of laser poly-spectrum component imaging detection (mass spectrum, Raman spectrum and laser-induced breakdown spectrum). The method and the device have wide application prospect in the fields of biology, physical chemistry, micro-fabrication and nano-fabrication and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

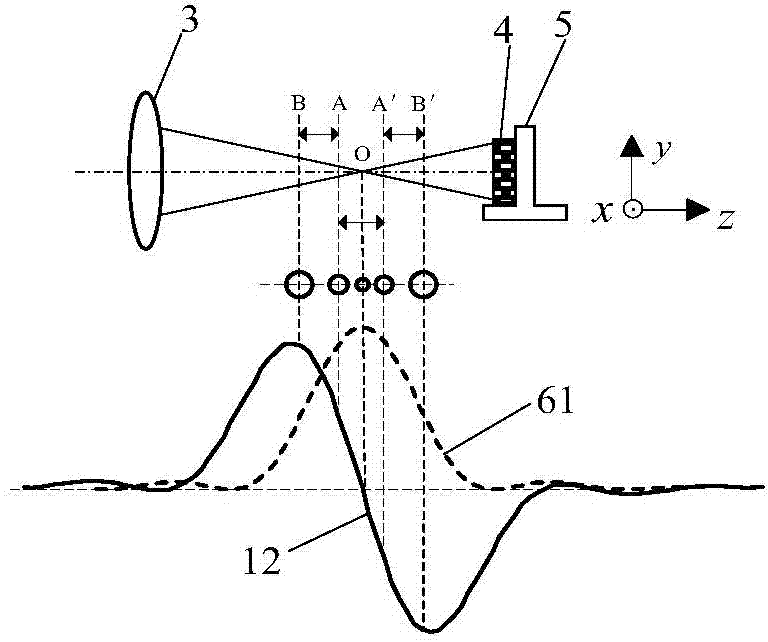

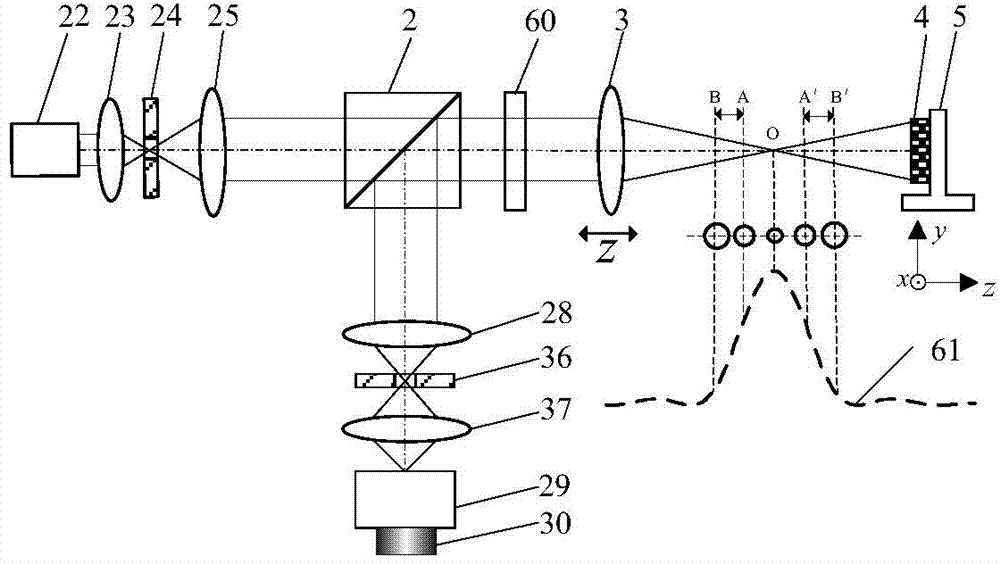

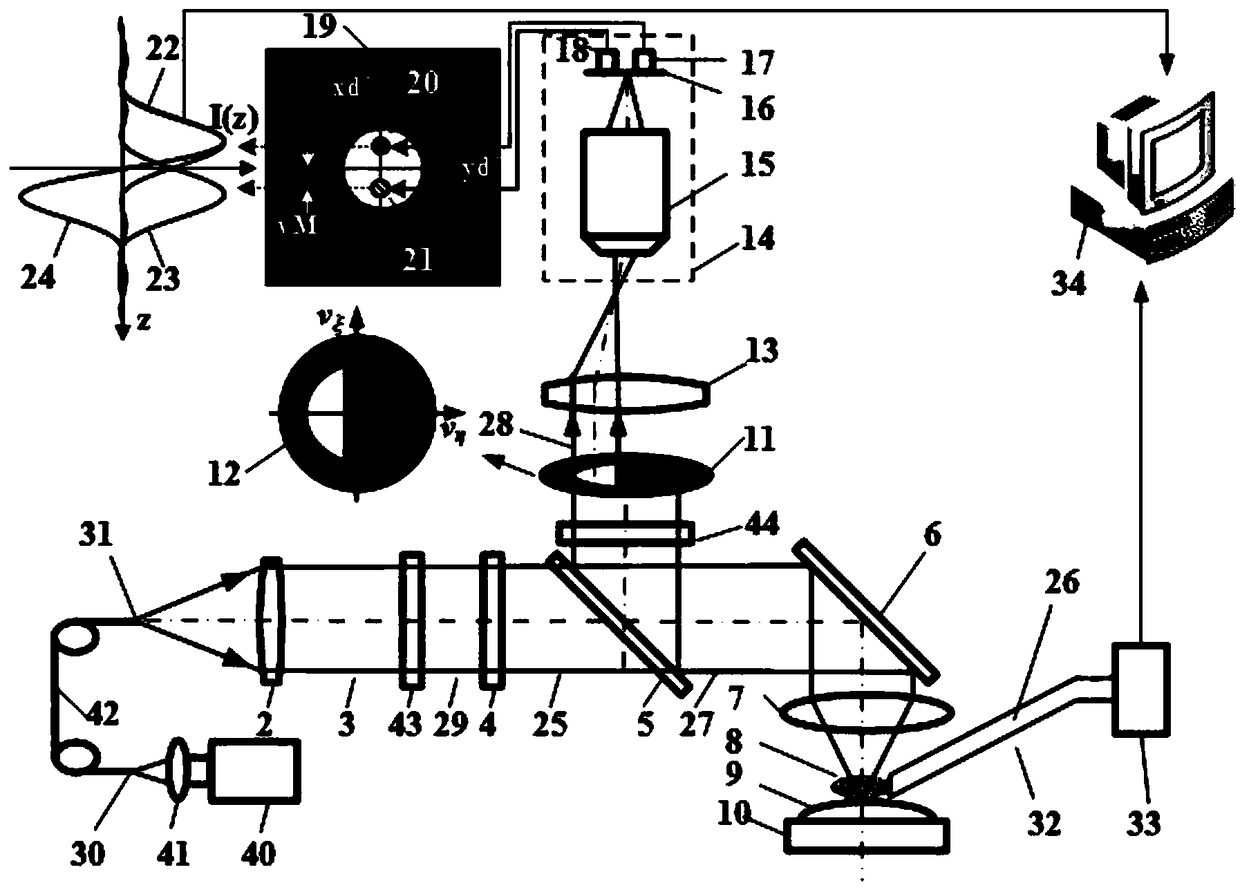

Laser confocal Brillouin-Raman spectral measurement method and apparatus

ActiveCN103940800AGood size controlEasy to testRaman scatteringElectricityThree dimensional morphology

The invention belongs to the technical field of microscopic imaging and spectral measurement and relates to a high resolution spectral imaging and detection method and apparatus which combine confocal microscopic technology and spectral detection technology together, realize integration of images and spectrums and are used for three dimensional morphology reconstruction and micro-area morphological performance parameter measurement of a variety of samples. The method and apparatus utilize Rayleigh light abandoned by a traditional confocal Raman system and confocal technology for detection of the position of a sample, employs a spectral detection system for spectral detection and uses Brillouin diffusion light abandoned by a traditional confocal Raman detection technology to test properties like elasticity and piezoelectricity of a material, thereby realizing measurement of micro-area high spatial resolution morphological parameters of a sample. The method and apparatus provided by the invention have the advantages of accurate positioning, high spatial resolution, high spectral detection sensitivity, controllable measured spot size, etc. and have wide application prospects in fields like biomedicine, evidence collection of court, micro and nano-fabrication, material engineering, engineering physics, precise metering and physical chemistry.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Laser differential confocal Brillouin-Raman spectroscopy measuring method and device thereof

InactiveCN103926233ASuppress measurement effectsHigh measurement accuracyRaman scatteringElectricityHigh resolution imaging

The invention belongs to the field of a microimaging and spectral measurement technology and relates to a laser differential confocal Brillouin-Raman spectroscopy measuring method and a device thereof which can be used in micro-area morphological parameter comprehensive test and high-resolution imaging of a sample. According to the method and the device, a differential confocal technology is incorporated into spectrum detection. Sample position detection is performed by the differential confocal technology; spectrum detection is conducted by a spectrum detection system; and properties, such as elasticity, piezoelectricity and the like, of a material are tested by the use of brillouin scattering light abandoned by a traditional confocal Raman spectrum detection technology. Thus, micro-area high-spatial resolution morphological parameter measurement of a sample is realized. The method and the device have advantages of accurate positioning, high spatial resolution, high spectrum detection sensitivity, controllable measured focusing spot size and the like, and have a wide application prospect in fields of biomedicine, evidence obtaining in court, micro and nano-fabrication, materials engineering, engineering physics, precision metrology, physical chemistry and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Electron beam aligning mark based on hafnium oxide and manufacturing method of mark

InactiveCN102969302AReduce manufacturing costHigh melting pointSemiconductor/solid-state device detailsSolid-state devicesElectron resistsResist

The invention discloses an electron beam aligning mark based on hafnium oxide, which belongs to the field of micro and nano fabrication of a semi-conductor device. The electron beam aligning mark based on hafnium oxide comprises a substrate and a hafnium oxide thin film mark plated on the substrate. The invention further provides a manufacturing method which specifically comprises the steps of: (1) cleaning the substrate; (2) carrying out spin coating of an electronic resist on the substrate and forming a pattern array with an aligned mark in the electronic resist through an electron beam photolithography technique; (3) evaporating hafnium oxide thin films on the electronic resist and the substrate; and (4) peeling the hafnium oxide thin films attached to the positive electronic resist to obtain the hafnium oxide mark. The aligned mark obtained by the electron beam lithography is prepared by using hafnium oxide which is high temperature resistive, good in adhesion and low in cost. Compared with the conventional 'titanium+gold' marks, the process cost is reduced, the problem that the gold mark and the Si substrate are not adhered well is solved, the adhesion and high temperature bearing capacity of the aligned mark to the substrate are improved, and the higher aligning precision is maintained.

Owner:HUAZHONG UNIV OF SCI & TECH

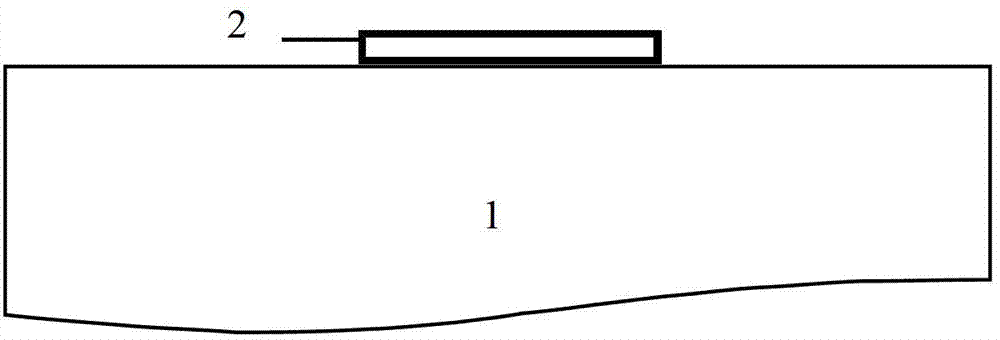

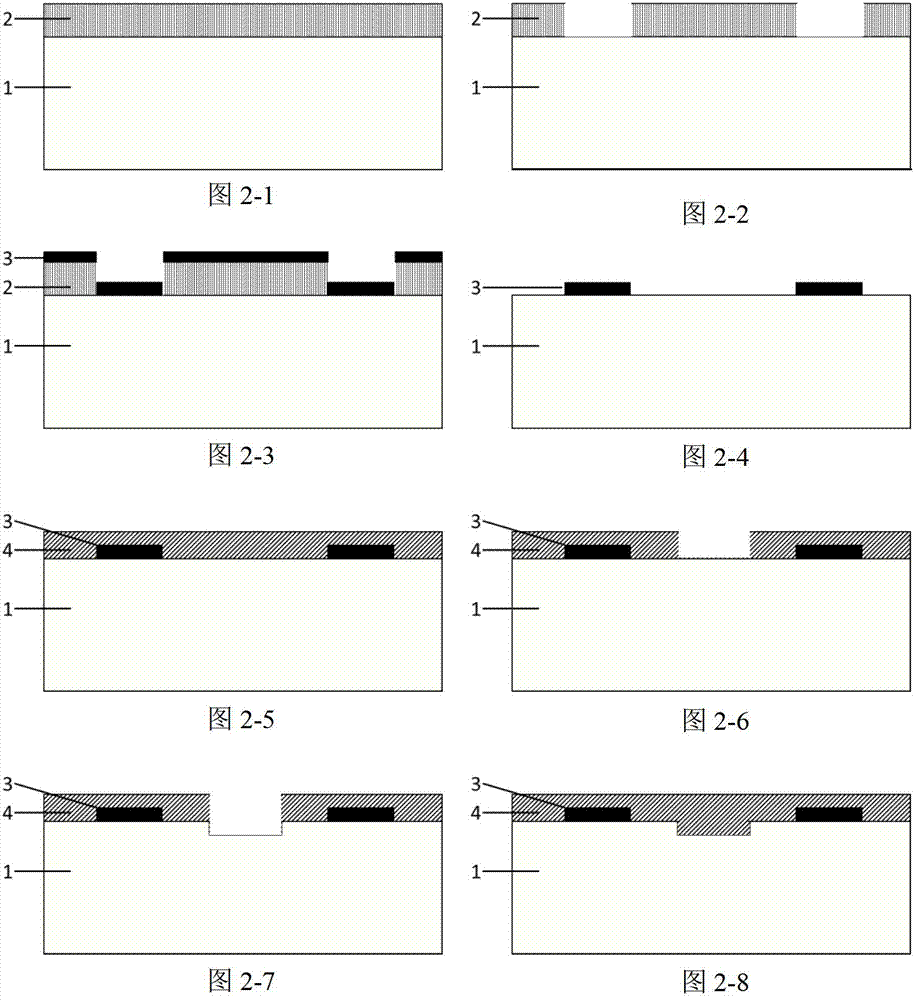

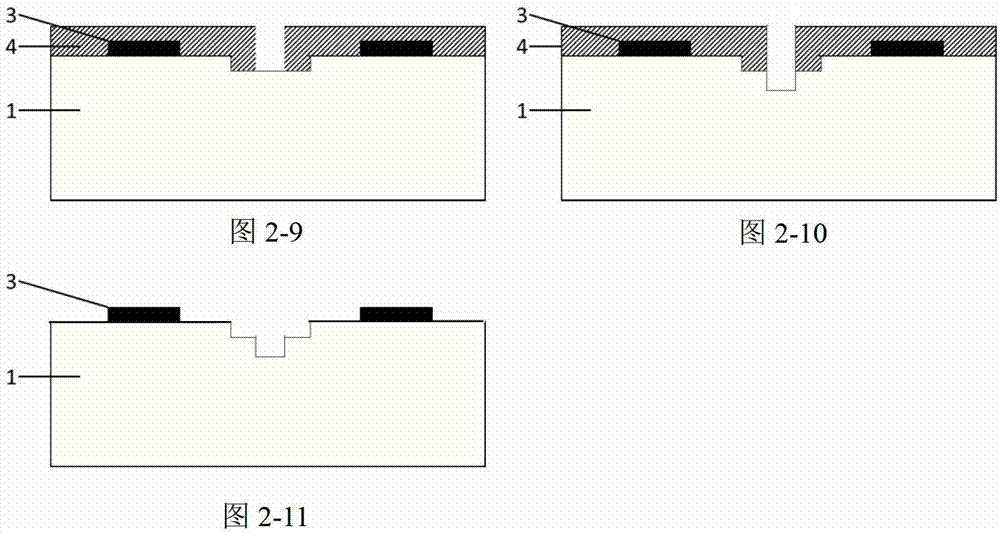

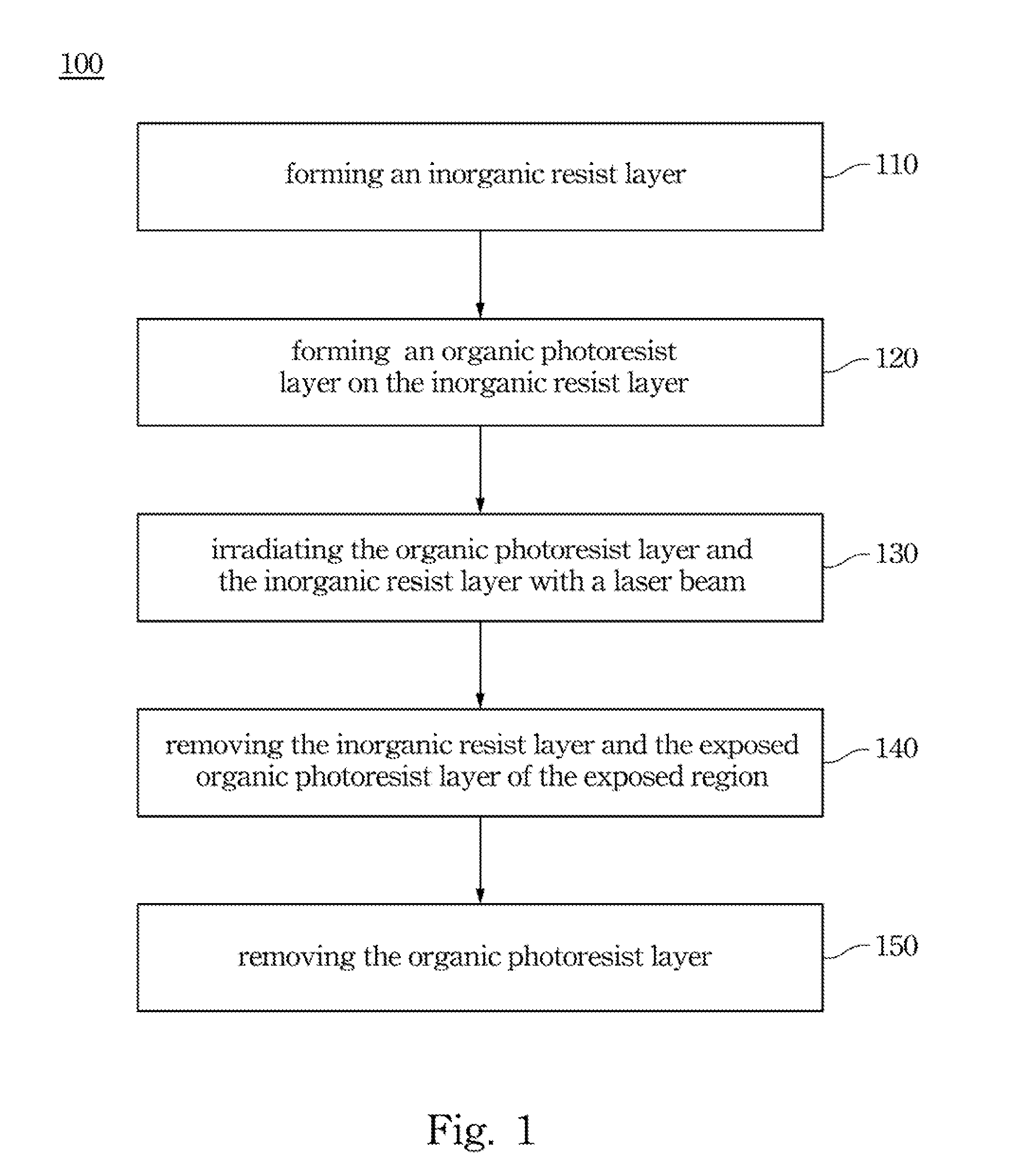

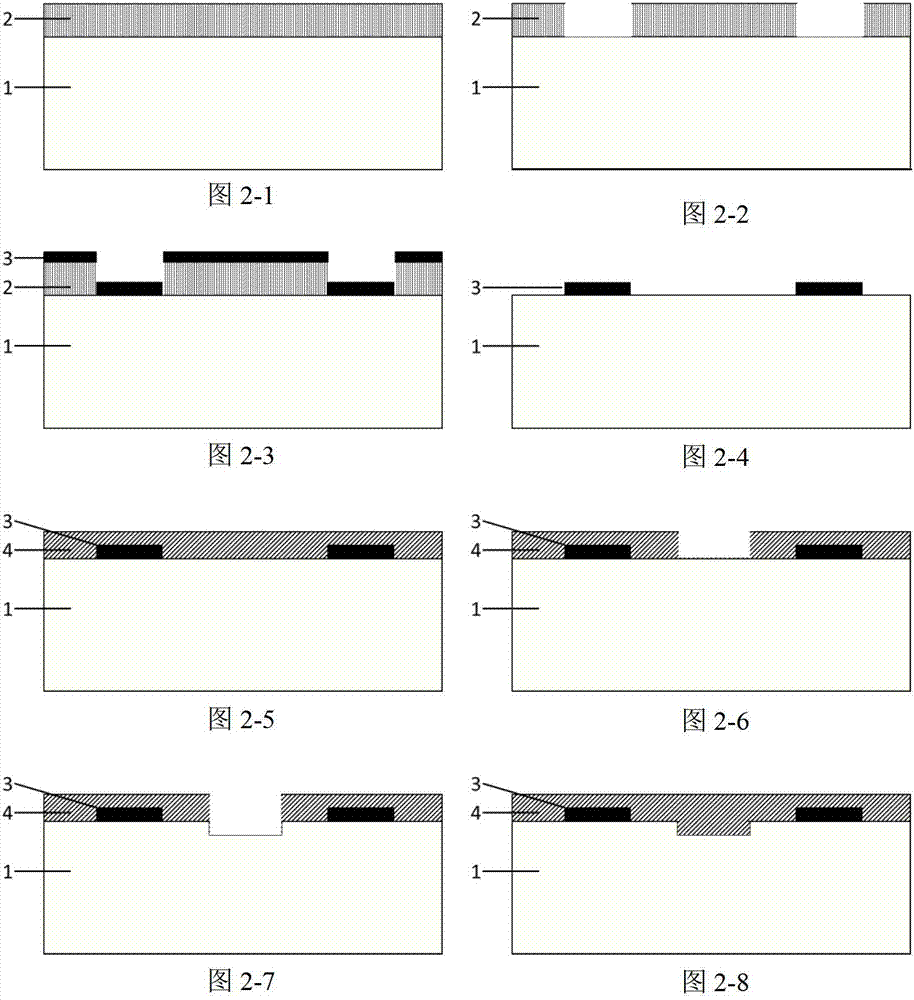

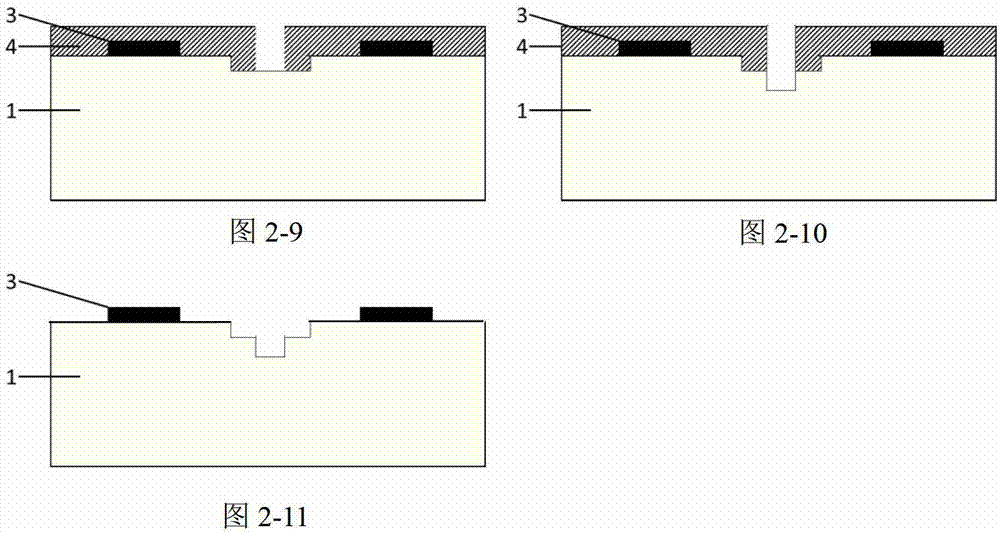

Nano-fabrication method

Disclosed herein is a nano-fabrication method, which includes the step of: (a) forming an inorganic resist layer on a substrate; (b) forming an organic photoresist layer on the inorganic resist layer; (c) irradiating both the organic photoresist layer and the inorganic resist layer with a laser beam to form a first exposed region of the inorganic resist layer and a second exposed region of the organic photoresist layer; (d) removing the inorganic resist layer of the first exposed region and the organic photoresist layer of the second exposed region to form a patterned inorganic resist layer and a patterned organic photoresist layer; and (e) removing the patterned organic photoresist layer from the patterned inorganic resist layer.

Owner:RYTEC CORP

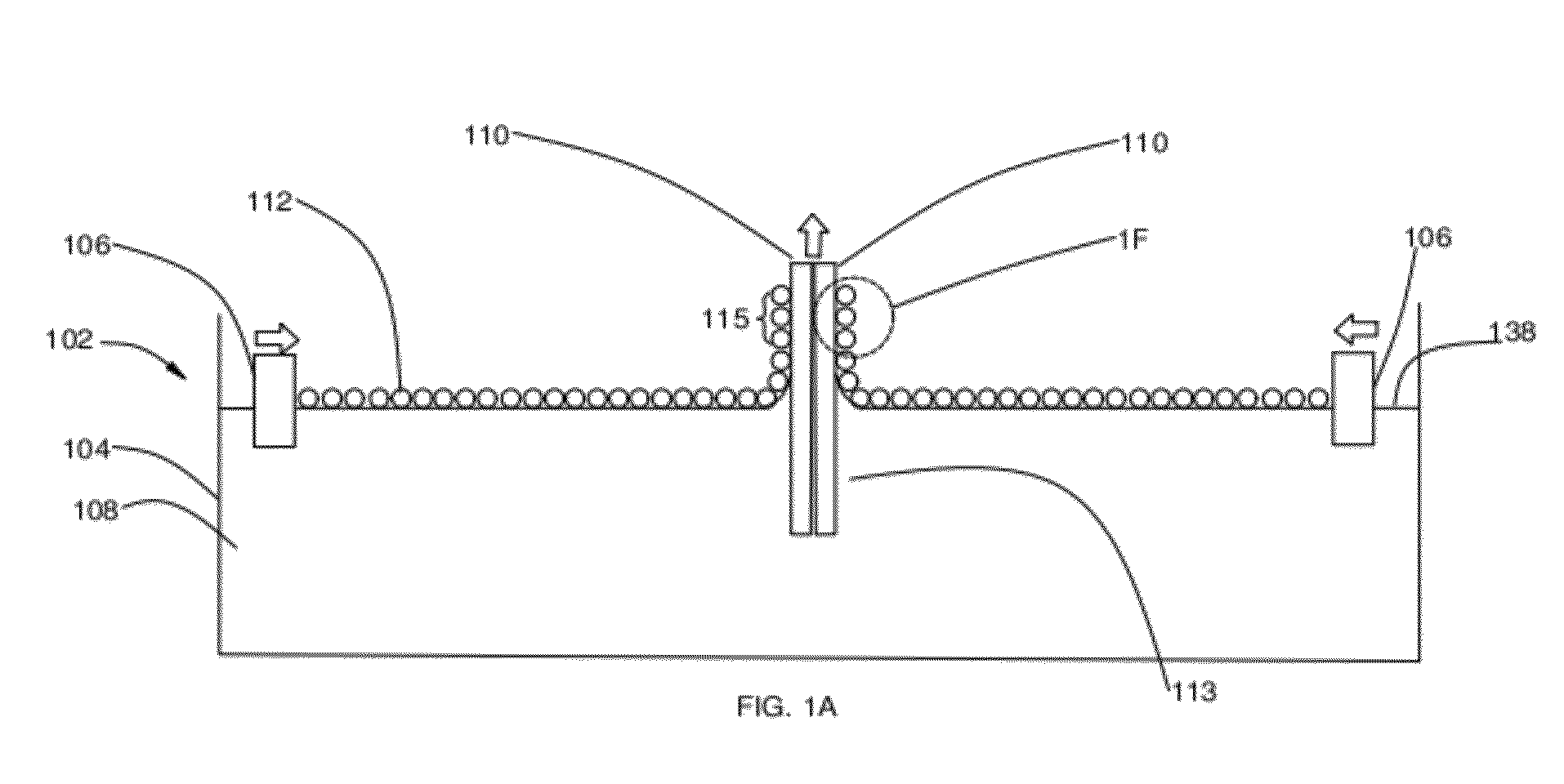

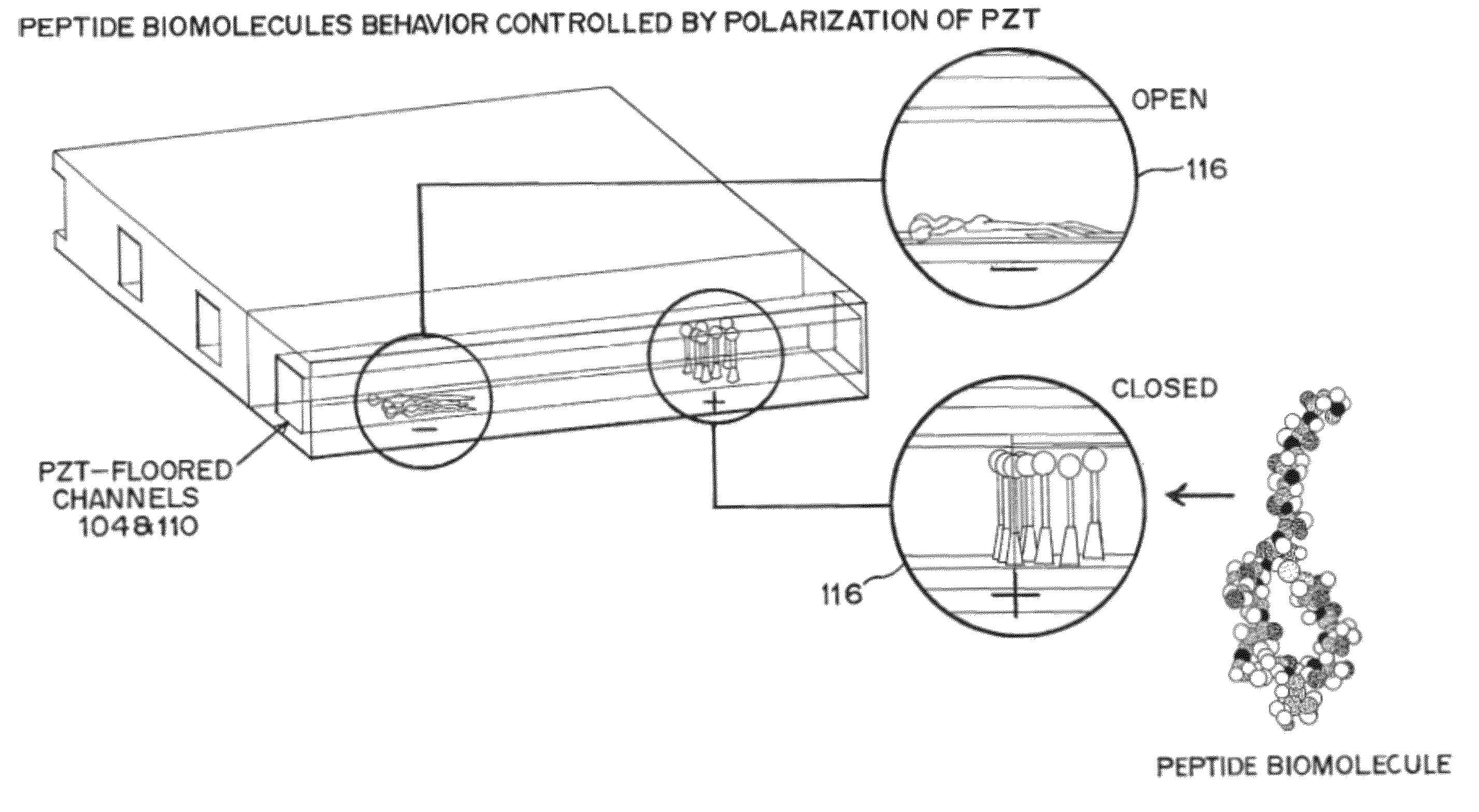

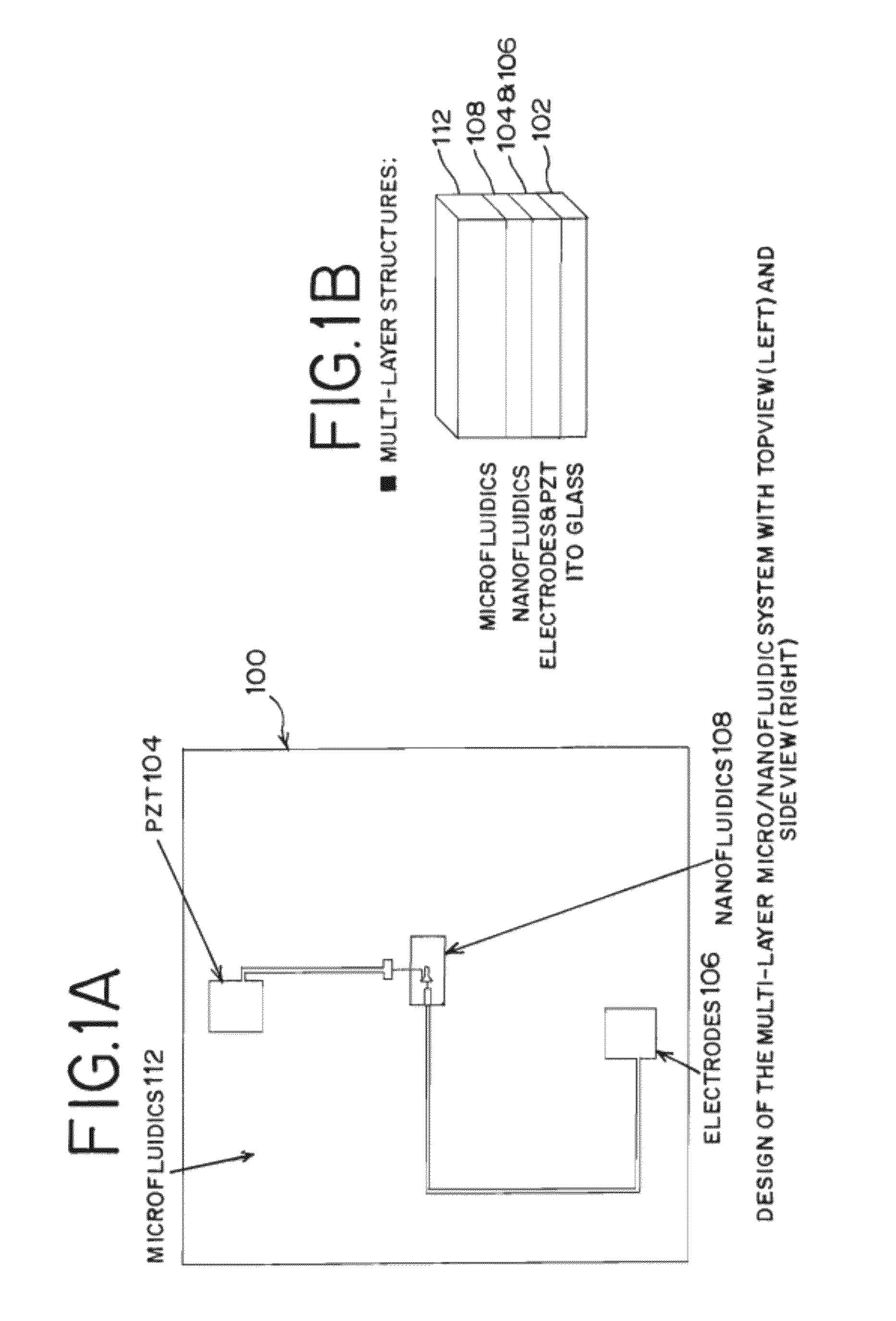

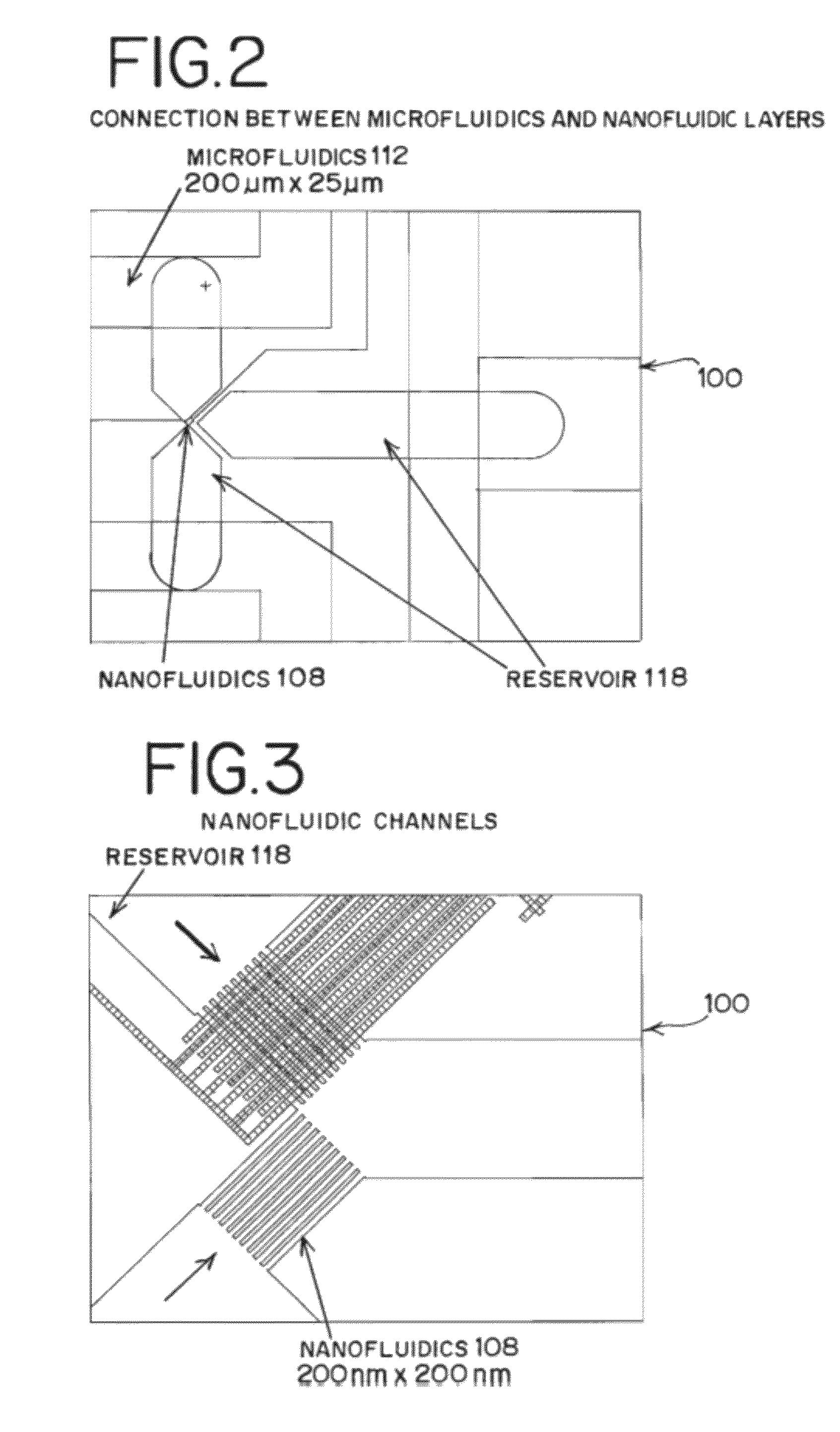

Multi-layer micro/nanofluid devices with bio-nanovalves

InactiveUS8343425B1Economical and effective and efficientPromote resultsRadiation applicationsCircuit elementsLead zirconate titanateMicrofluidics

A user-friendly multi-layer micro / nanofluidic flow device and micro / nano fabrication process are provided for numerous uses. The multi-layer micro / nanofluidic flow device can comprise: a substrate, such as indium tin oxide coated glass (ITO glass); a conductive layer of ferroelectric material, preferably comprising a PZT layer of lead zirconate titanate (PZT) positioned on the substrate; electrodes connected to the conductive layer; a nanofluidics layer positioned on the conductive layer and defining nanochannels; a microfluidics layer positioned upon the nanofluidics layer and defining microchannels; and biomolecular nanovalves providing bio-nanovalves which are moveable from a closed position to an open position to control fluid flow at a nanoscale.

Owner:UCHICAGO ARGONNE LLC

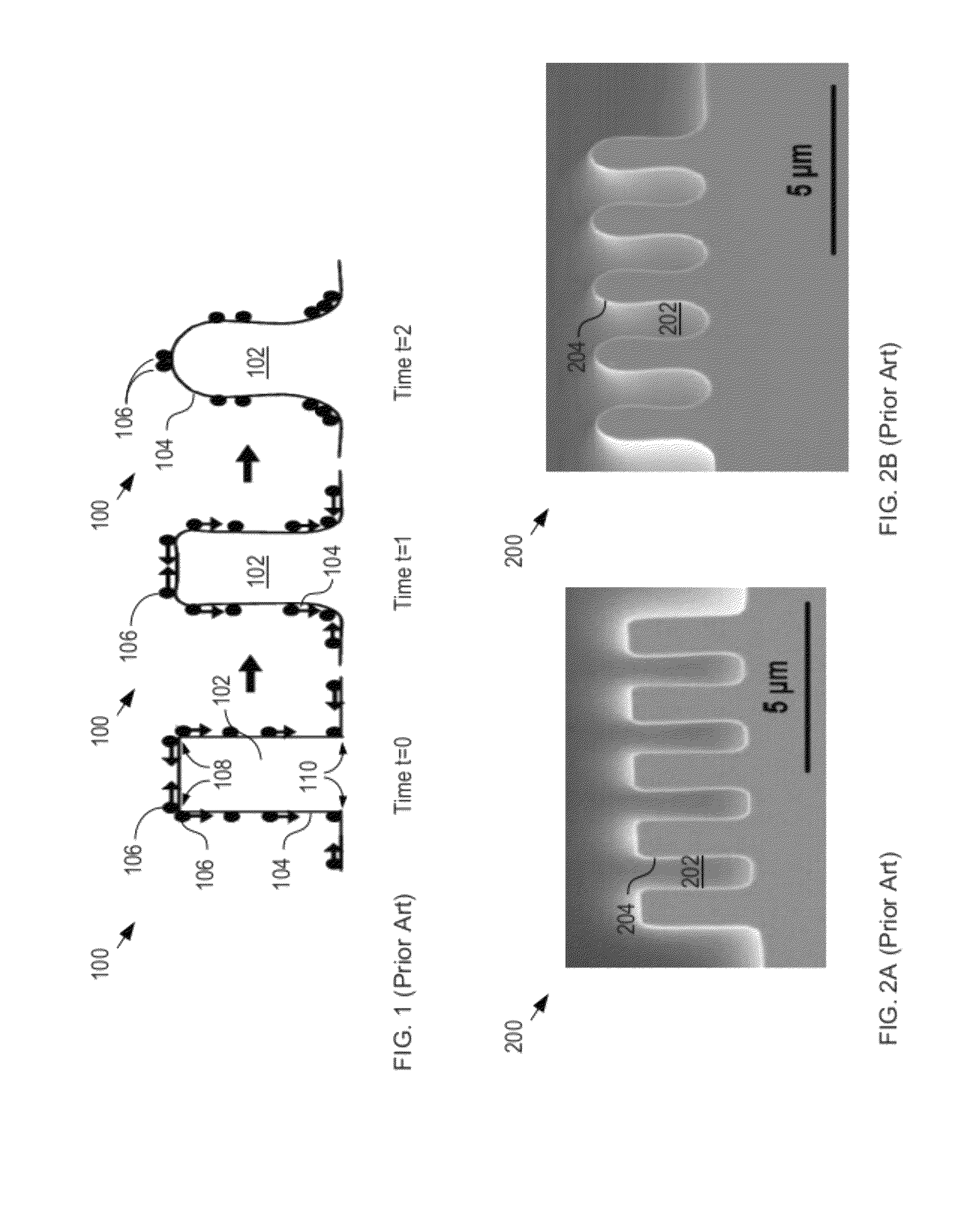

Method for fabricating a long-range ordered periodic array of nano-features, and articles comprising same

A long range, periodically ordered array of discrete nano-features (10), such as nano-islands, nano-particles, nano-wires, non-tubes, nano-pores, nano-composition-variations, and nano-device-components, are fabricated by propagation of a self-assembling array or nucleation and growth of periodically aligned nano-features. The propagation may be induced by a laterally or circularly moving heat source, a stationary heat source arranged at an edge of the material to be patterned (12), or a series of sequentially activated heaters or electrodes. Advantageously, the long-range periodic array of nano-features (10) may be utilized as a nano-mask or nano-implant master pattern for nano-fabrication of other nano-structures. In addition, the inventive long-range, periodically ordered arrays of nano-features are useful in a variety of nanoscale applications such as addressable memories or logic devices, ultra-high-density magnetic recording media, magnetic sensors, photonic devices, quantum computing devices, quantum luminescent devices, and efficient catalytic devices.

Owner:RGT UNIV OF CALIFORNIA

Electron diffractometer capable of realizing automatic defect regulation

ActiveCN107655909AAchieving Regulatory RepairQuantity is easy to controlMaterial analysis using wave/particle radiationDiffractometerPulse energy

The invention relates to an electron diffractometer and provides an electron diffractometer capable of realizing automatic defect regulation. The electron diffractometer comprises a vacuum sample room, and also comprises a testing optical path, a detect regulation optical path and a processing unit. Frequency tripled laser of the testing optical path is transmitted from a first incidence window into the vacuum sample room. Frequency doubled laser of the defect regulation optical path is transmitted from a second incidence window into a sample stage inside the vacuum sample room. An electronicgun is also arranged inside the vacuum sample room. A cathode of the electronic gun is positioned on the testing optical path. The defect regulation optical path is provided with a laser pulse energyregulator and a laser pulse scanning device. The processing unit comprises a receiving component and a control center. The electron diffractometer of the invention can achieve in-situ real-time nondestructive measurement of the micro- and nano-fabrication process and realize growth while testing. In addition, sample surface defect information is obtained through processing of diffraction images, and femtosecond laser pulse energy and scanning position are regulated according to the invention so as to repair defects, thus achieving the purpose of testing while regulating.

Owner:WUHAN UNIV

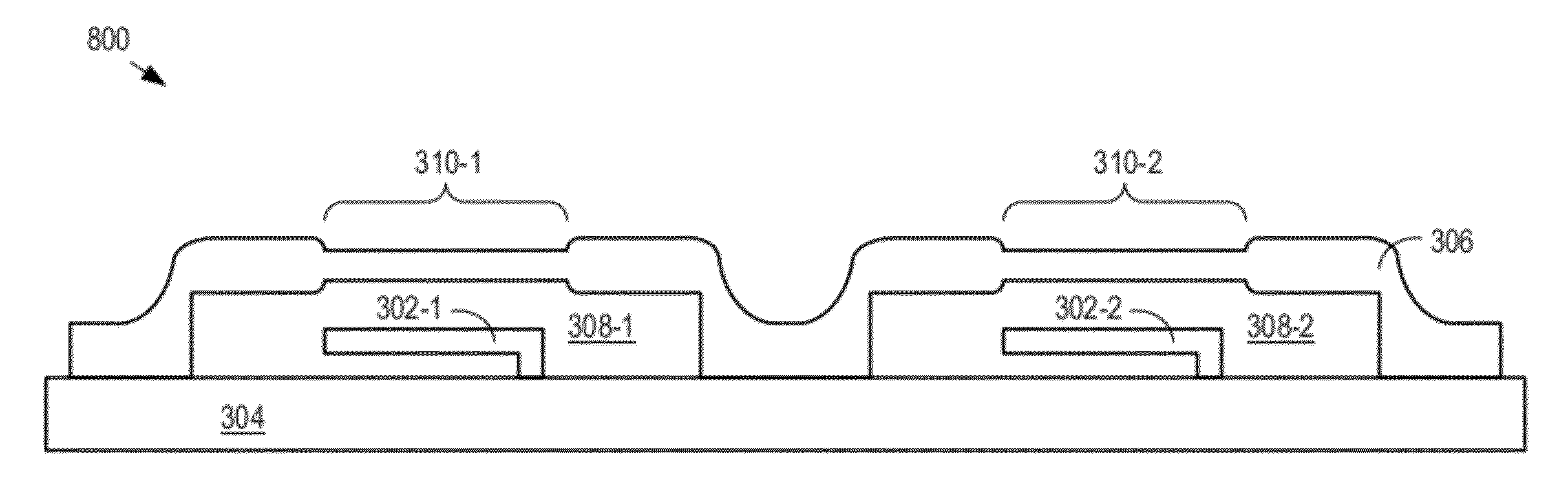

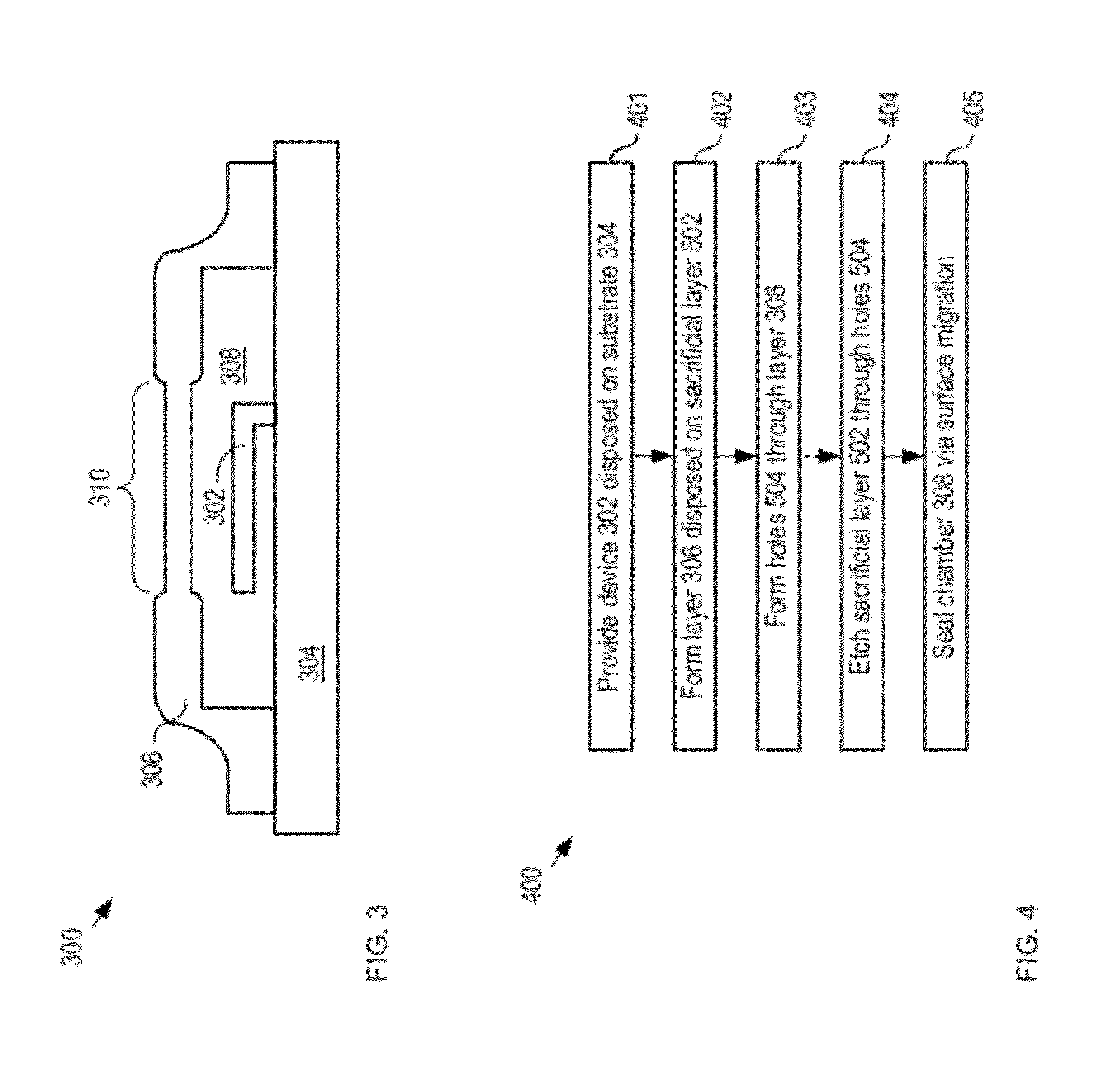

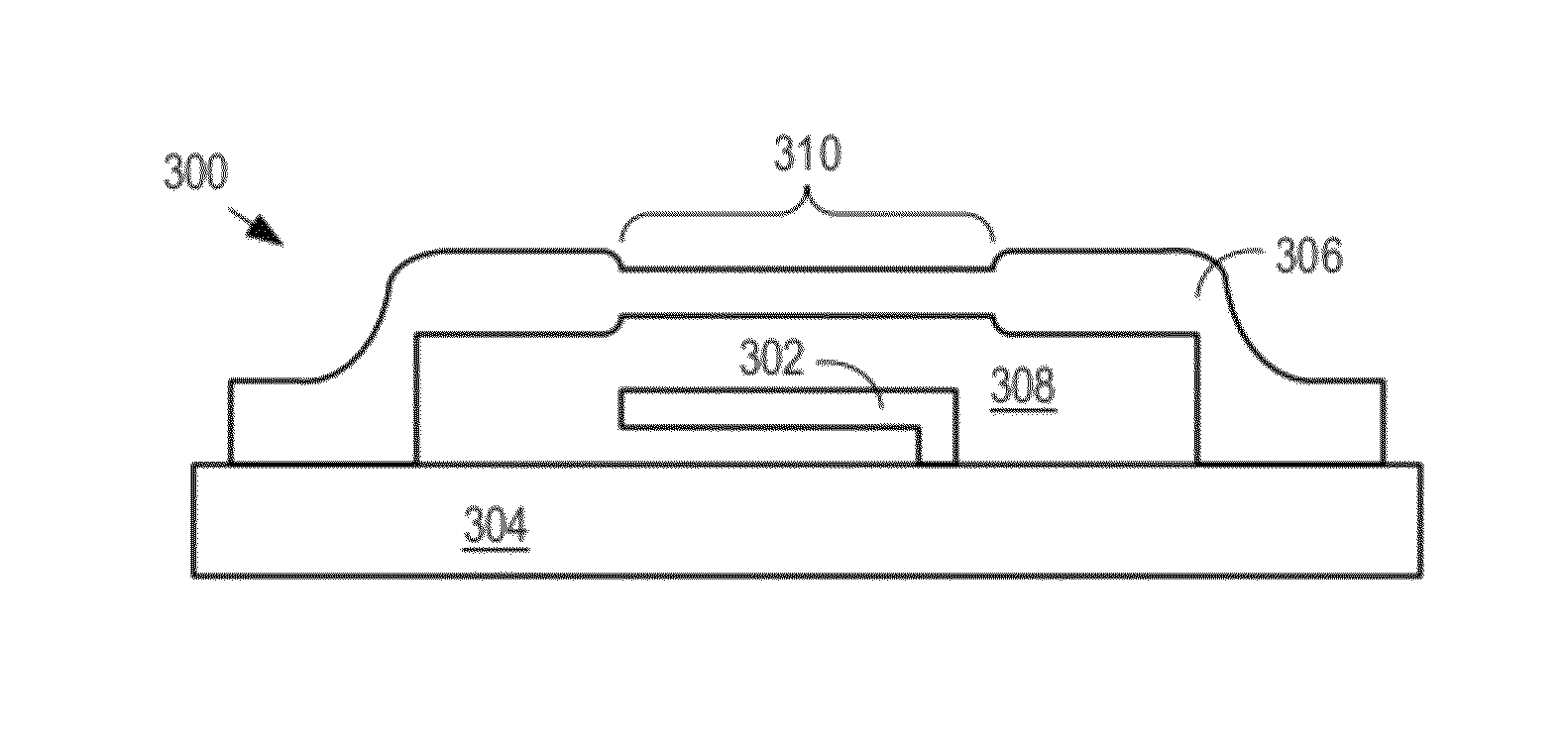

Deposition-free sealing for Micro- and Nano-fabrication

InactiveUS20120104589A1Lower average energyIncrease surface potentialSemiconductor/solid-state device detailsSolid-state devicesNano manufacturingSealant

A method for sealing through-holes in a material via material diffusion, without the deposition of a sealant material, is disclosed. The method is well suited to the fabrication and packaging of microsystems technology-based devices and systems. In some embodiments, the method comprises forming sacrificial material release through-holes through a structural layer, removing the sacrificial material via an etch that etches the sacrificial material through the release through-holes, and sealing of the release through-holes via material diffusion.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

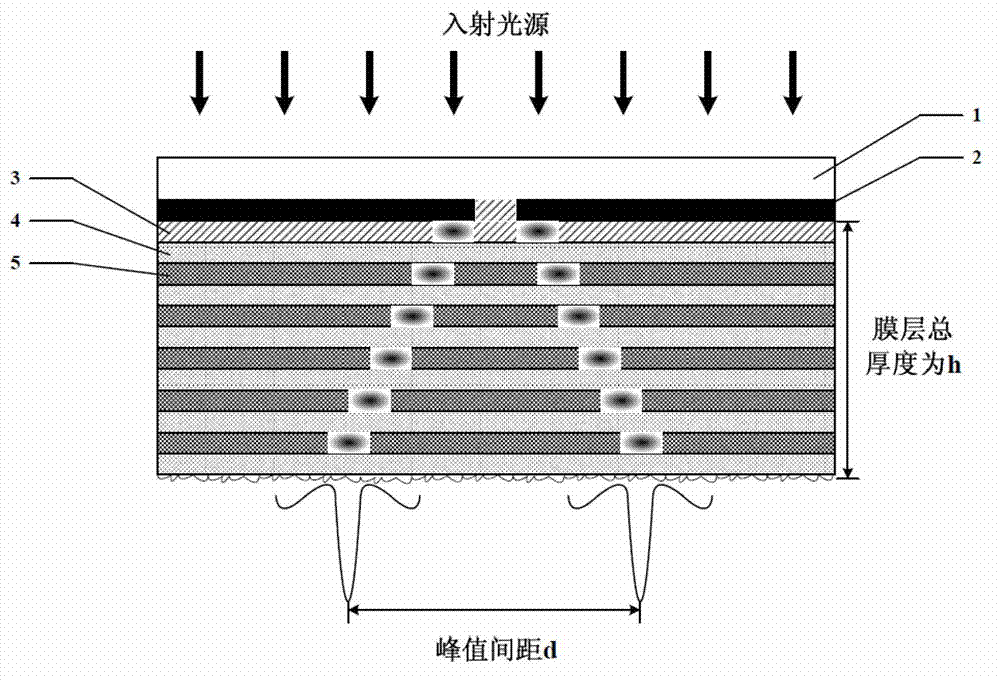

Test analysis method for manufactured super-diffraction directional transmission material structure

ActiveCN102879360ASimple test and analysis methodLittle external interferencePreparing sample for investigationAnalysis by material excitationFilm materialCharge couple device

The invention discloses a test analysis method for a manufactured super-diffraction directional transmission material structure. The test analysis method comprises the following steps of: obtaining a nano slit or pore structure mask on a transparent substrate by a nano-fabrication method; depositing a metal medium alternate multi-layer film structure material on the flattened nano slit or pore structure mask; roughening a surface film material through an etching or grinding method, and finishing structure manufacture; illuminating the slit or pore through a light source, exciting a surface plasma evanescent wave light field, and alternately coupling the light field into the multi-layer metal medium film material, wherein the surface plasma light field is specifically distributed on the outermost layer of a metal medium film layer material, is scattered to a far field by the roughened surface and is observed and recorded through an objective lens and a charge coupled device (CCD); and finally, calculating a directional transmission angle theta of the super-diffraction material. By the test analysis method, the high-frequency evanescent wave energy is conveyed to the far field and then detected and analyzed in the far field, and the quantitative analysis and characterization requirements of the optical properties of the super-diffraction material can be met in a far field range.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

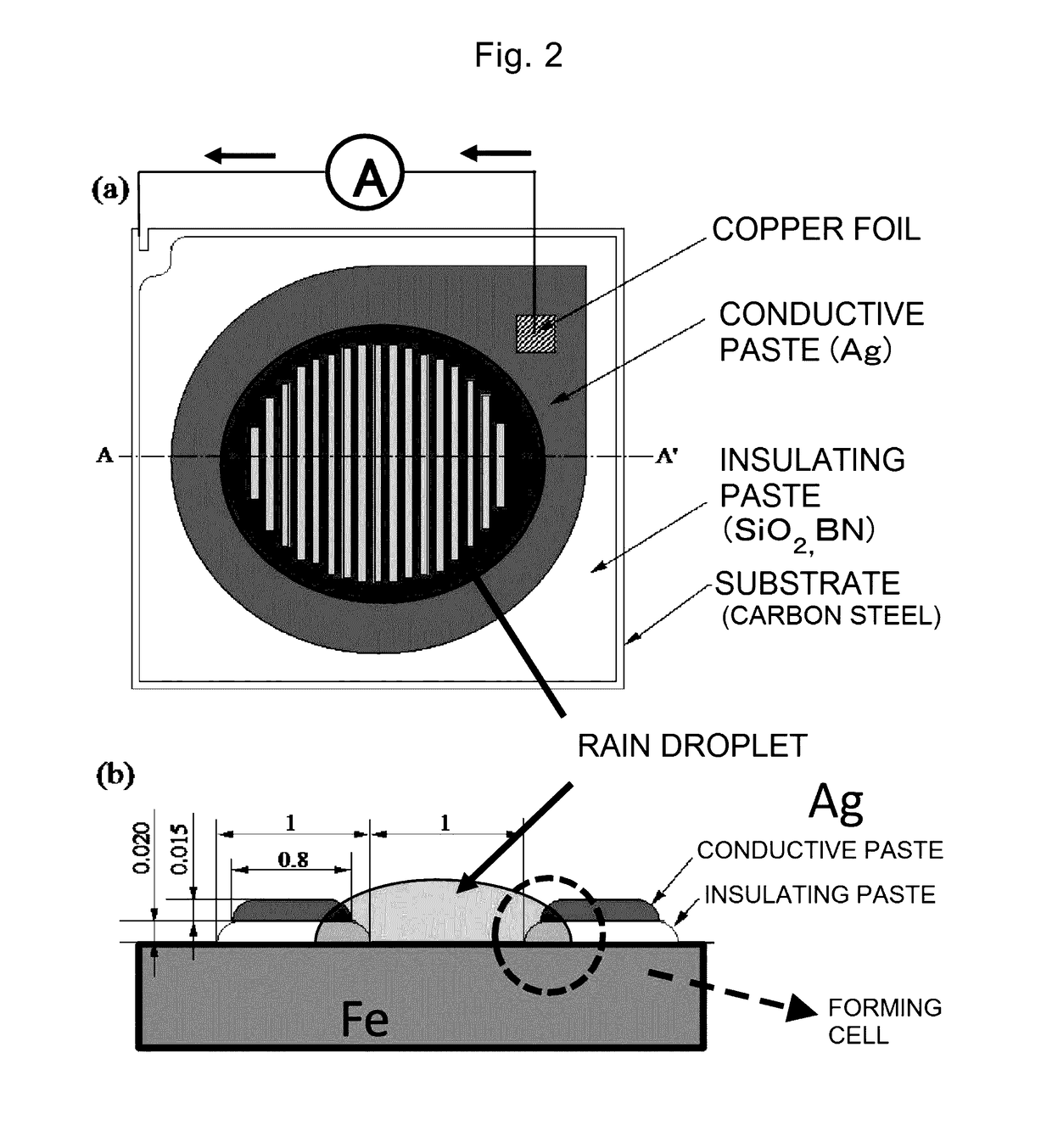

High-speed response/high-sensitivity dryness/wetness responsive sensor

ActiveUS20170167995A1Small sizeAddress rising pricesWeather/light/corrosion resistanceMaterial resistancePower flowEngineering

The present invention improves the sensitivity and the responsiveness of a dryness / wetness responsive sensor utilizing a galvanic current, allowing for downsizing of the dryness / wetness responsive sensor. Instead of the conventional structure in which an anode electrode and a cathode electrode are stacked with an intervening insulator, the present invention employs a structure in which both electrodes run in juxtaposition with each other on an insulating substrate in the form of, for example, a comb-shaped electrode as shown in the drawing. By utilizing a semiconductor manufacturing process or any other micro / nano-fabrication technology, an inter-electrode distance can be extremely shortened as compared with the conventional sensors, allowing enhancing the sensitivity per unit footprint of the electrodes. Accordingly, a decrease in the size of the dryness / wetness responsive sensor can be easily achieved.

Owner:NAT INST FOR MATERIALS SCI

Deposition-free sealing for micro- and nano-fabrication

InactiveUS8735286B2Lower average energyIncrease surface potentialSemiconductor/solid-state device detailsSolid-state devicesNano manufacturingSealant

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

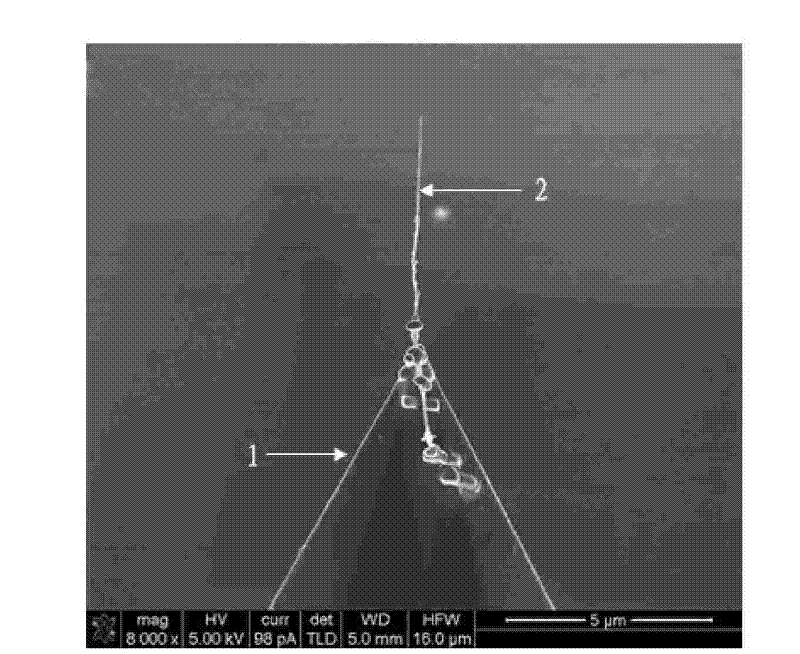

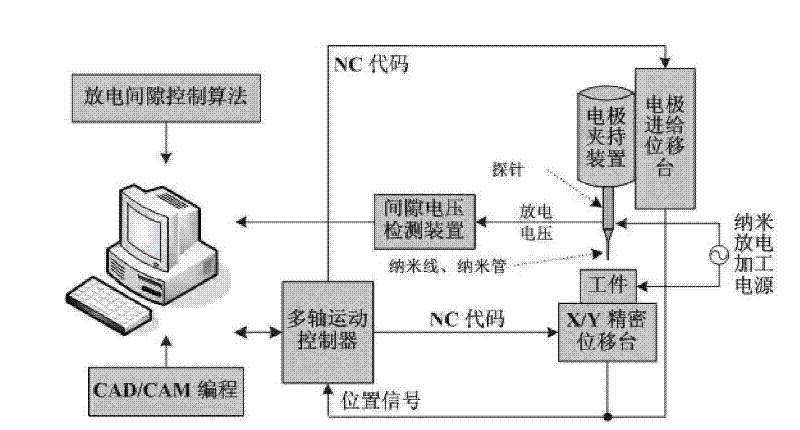

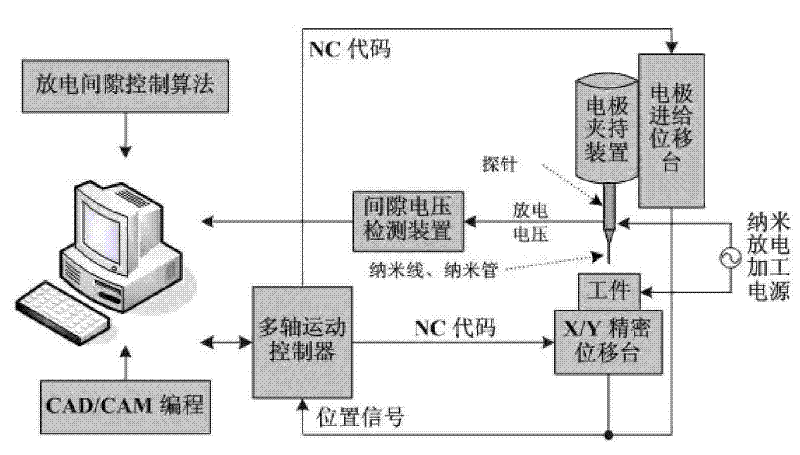

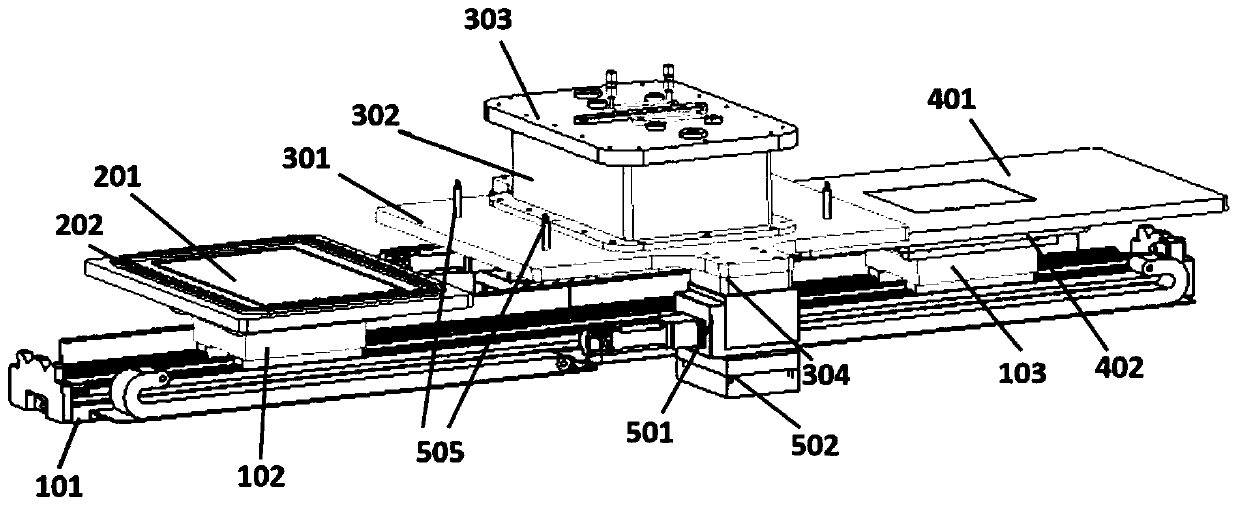

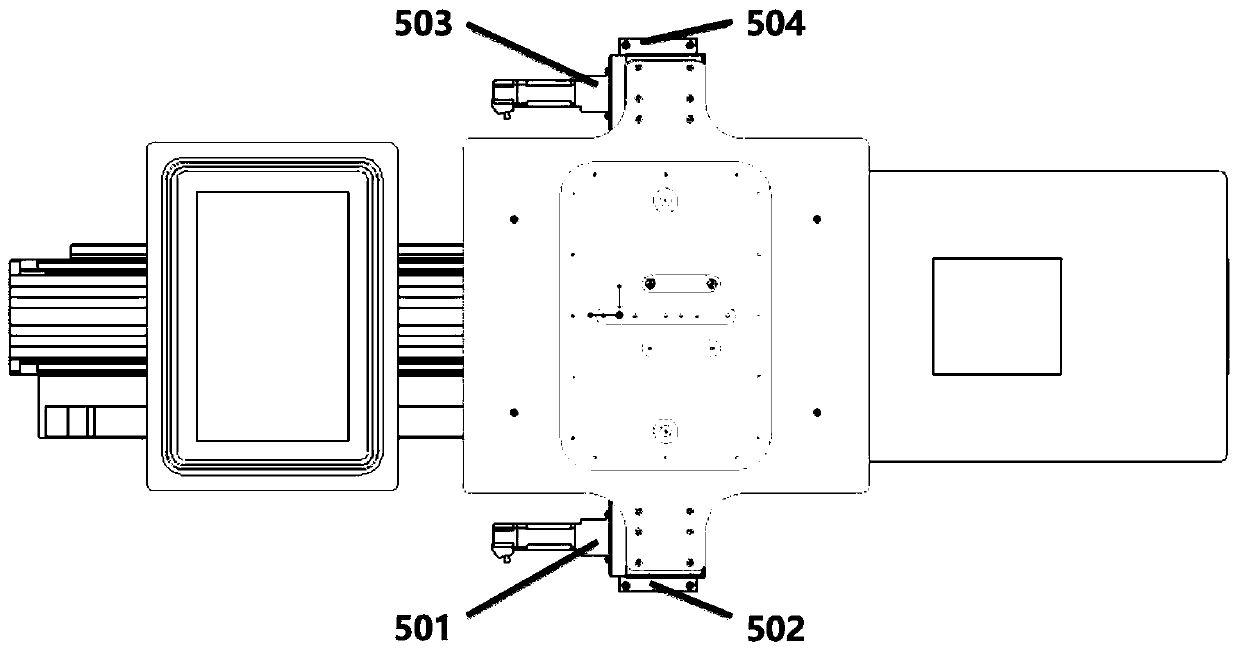

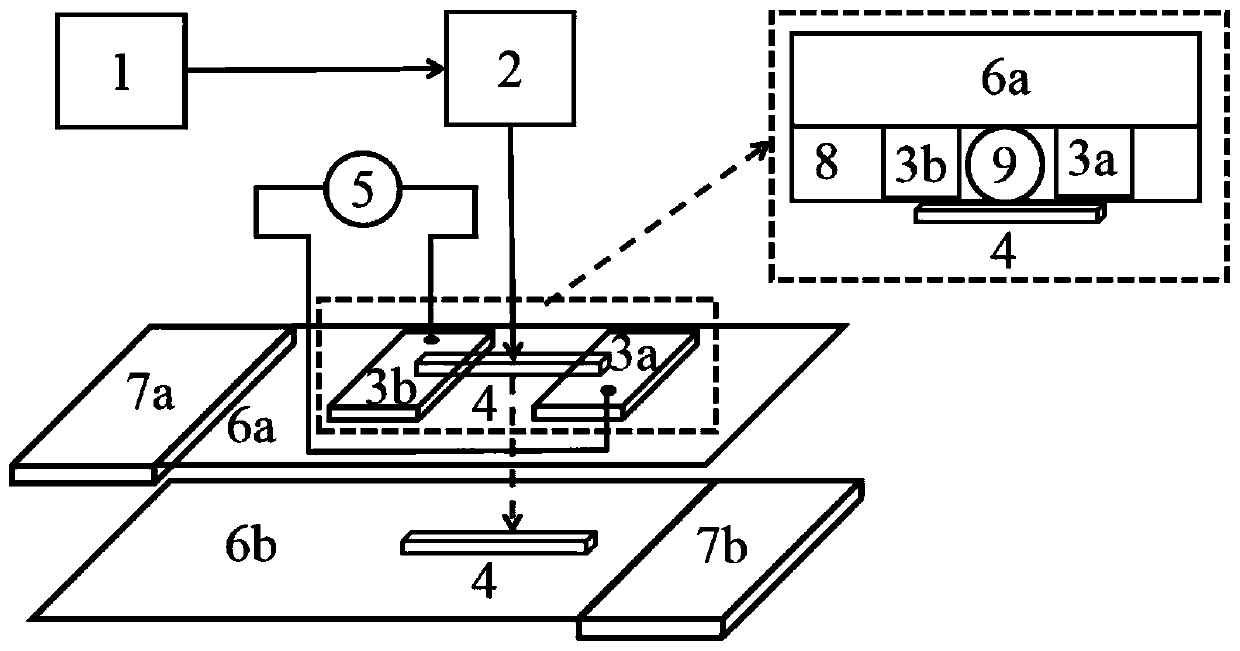

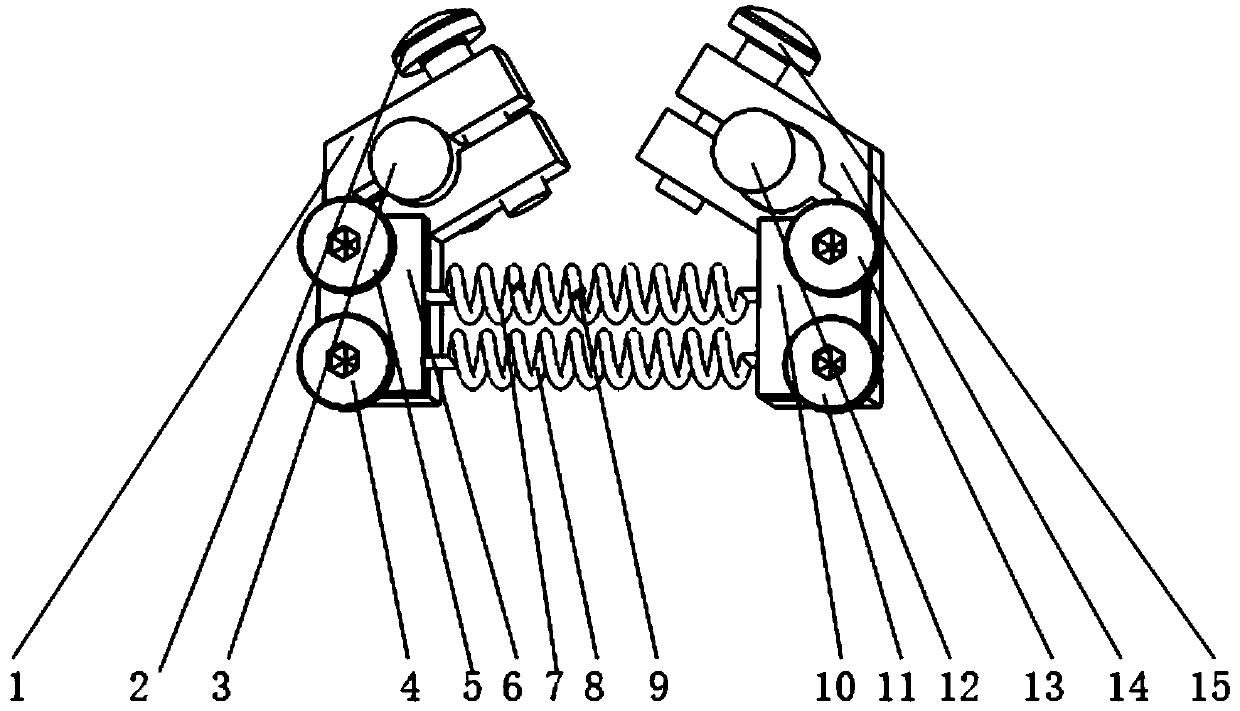

A method and system for micro-nano electrical discharge machining of micro-three-dimensional structures

InactiveCN101665238BRich technical methodsSolve the problem of chip removalSemi-permeable membranesNanostructure manufactureMicro nanoNanowire

The invention belongs to the technical field of micro-nano manufacturing, and relates to a method for micro-nano electric discharge machining of a micro-three-dimensional structure: (1) fixing conductive nanowires or nanotubes on probe tips made of conductive materials as electrodes; (2) ) place the electrode clamping device on the displacement platform, and control the movement of the displacement platform through the multi-axis motion controller; (3) place the conductive material workpiece on the X / Y precision displacement platform, and use the multi-axis motion controller to control the movement of the displacement platform; Control the movement of the X / Y precision translation stage; (4) Connect the negative pole of the pulse power supply to the probe, and its positive pole to the workpiece; (5) Use the industrial computer to send instructions to the multi-axis motion control card to control the placement of electrodes The displacement table of the clamping device is provided with the working voltage of the discharge machining by the pulse power supply, and the discharge gap voltage is collected by the gap voltage detection device, and the industrial computer controls the movement of the electrode feeding displacement table according to the gap voltage. The invention enables the size of electric discharge machining to reach micron and nanometer levels, and simultaneously solves the chip removal problem in the machining process.

Owner:TIANJIN UNIV

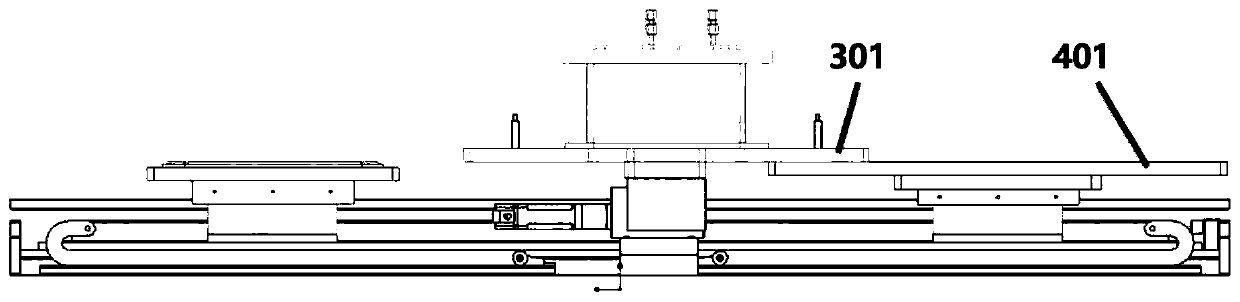

Modularized sealed device for preparing film through spatial isolation atomic layer deposition

ActiveCN110656318AGuaranteed vacuumReduce usageChemical vapor deposition coatingReciprocating motionEngineering

The invention belongs to the related field of micro and nano fabrication, and particularly discloses a modularized sealed device for preparing a film through spatial isolation atomic layer deposition.The device comprises a moving device, a spray head device, a sealing device and a reaction device, wherein the moving device is used for driving the sealing device and the reaction device to move along a horizontal rail and driving the spray head device to move in the vertical direction; a sealing cavity of the spray head device is connected with a lifting table; a sealing cavity cover plate is fixed above the sealing cavity; a modularized spray head is fixed below the sealing cavity; the sealing device and the spray head device are in sealing fit; and the reaction device is arranged below the spray head device to do reciprocating motion to realize the spatial isolation atomic layer deposition. The reaction device is arranged below the spray head device to do reciprocating motion to realize spatial isolation atomic layer deposition; and when atomic layer deposition is not performed, the sealing device is moved to a part below the spray head device to seal the spray head device to ensure the vacuum degree of the spray head device so as to realize the modularized sealing.

Owner:HUAZHONG UNIV OF SCI & TECH

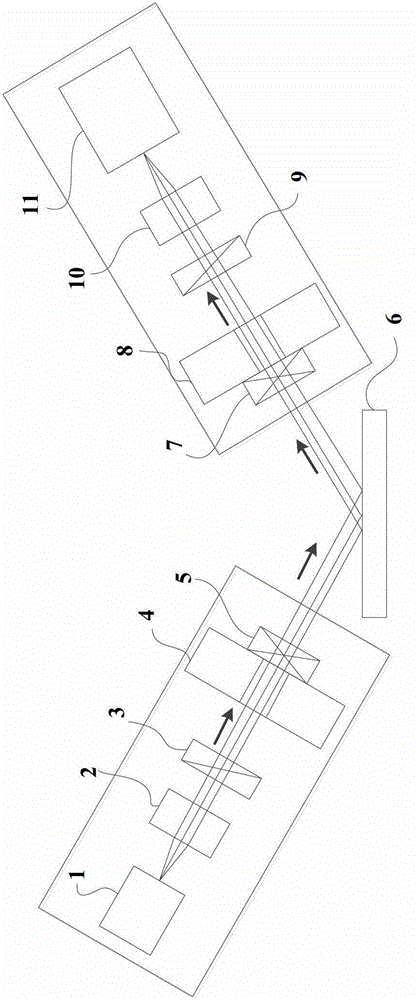

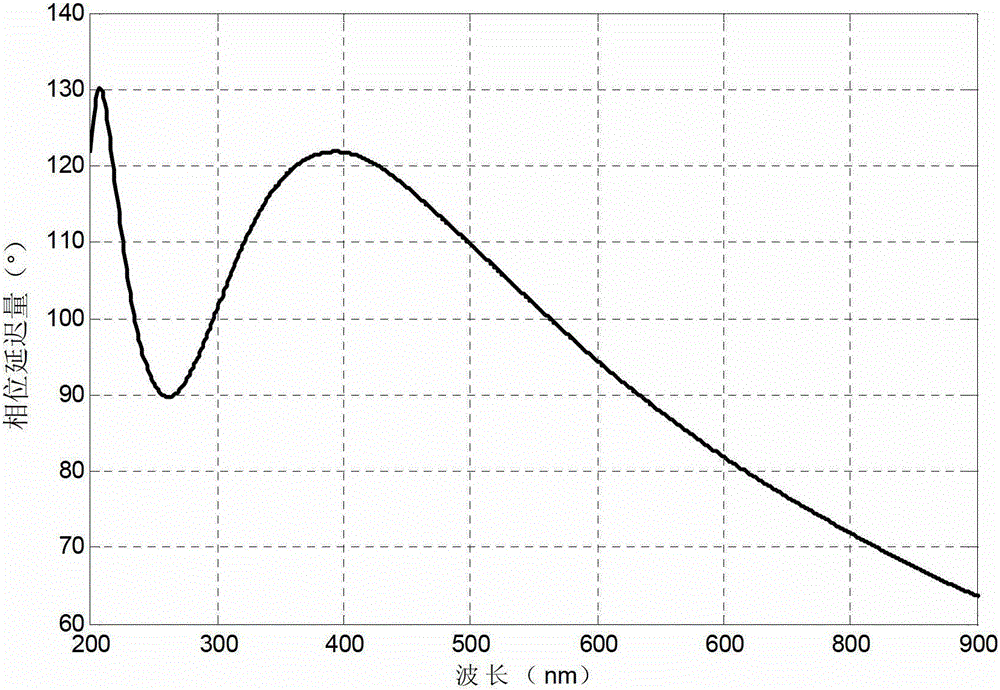

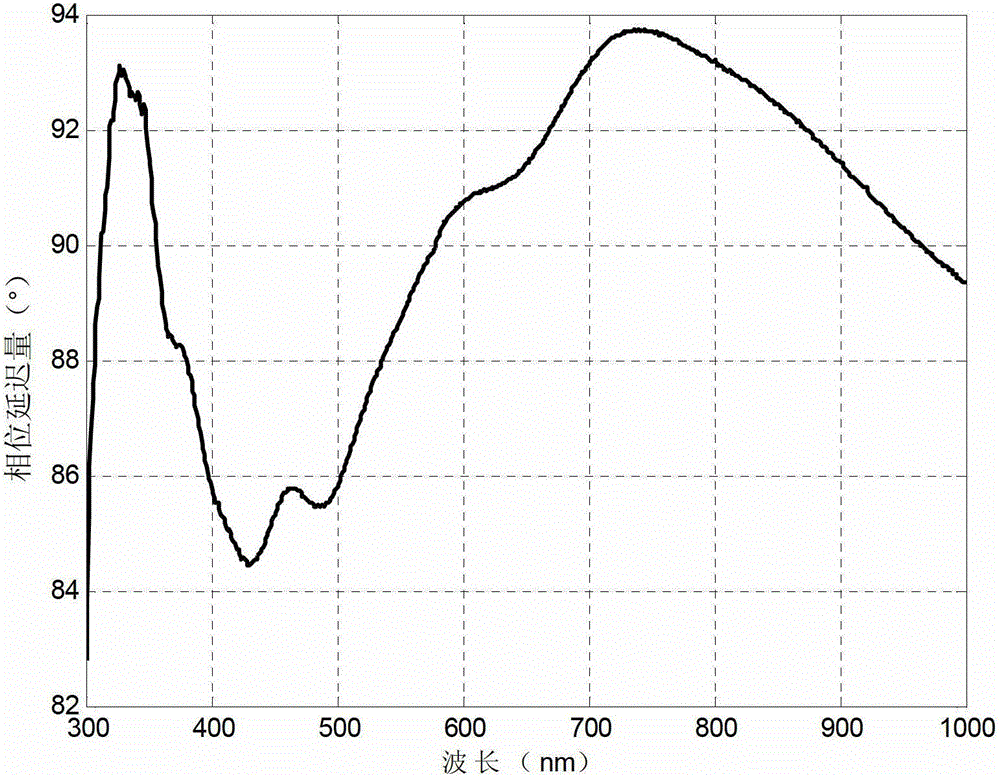

A transmission type full Muller matrix spectroscopic ellipsometer and its measuring method

ActiveCN103134592BAccurate measurementDoes not change polarization statePolarisation spectroscopyNon destructiveNano structuring

The invention discloses a transmission type Mueller matrix spectrum ellipsometer and a measuring method thereof. The transmission type Mueller matrix spectrum ellipsometer measuring method comprises the following steps: projecting modulation rays produced by a partial arm on the surface of a to-be-tested sample, a check partial arm demodulates and receives the rays reflected (or transmitted) by the to-be-tested sample, by proceeding harmonic wave analysis to a tested spectrum, computing and acquiring the full Mueller matrix information of the to-be-tested sample, further through arithmetic of nonlinear regression, liberty matching, and the like, and fitting and extracting information of an optical constant, characteristic, morphology, size and the like of the to-be-tested sample. An ellipsometer comprises the partial arm (comprises light source, a lens group, a polarizer, and a compensator driven by a servo motor),the to-be-tested sample and the check partial arm (comprises the compensator driven by a servo motor, an analyzer the lens group and a spectrograph. The transmission type Mueller matrix spectrum ellipsometer and the measuring method thereof can achieve all kinds of materials and components with information phoelectron functions, and online measurement of all kinds of nano-structures in nano-fabrication, so that transmission type Mueller matrix spectrum ellipsometer and the measuring method thereof have the advantages of being capable of possessing non-destructive property, fast, and low in cost.

Owner:WUHAN EOPTICS TECH CO LTD

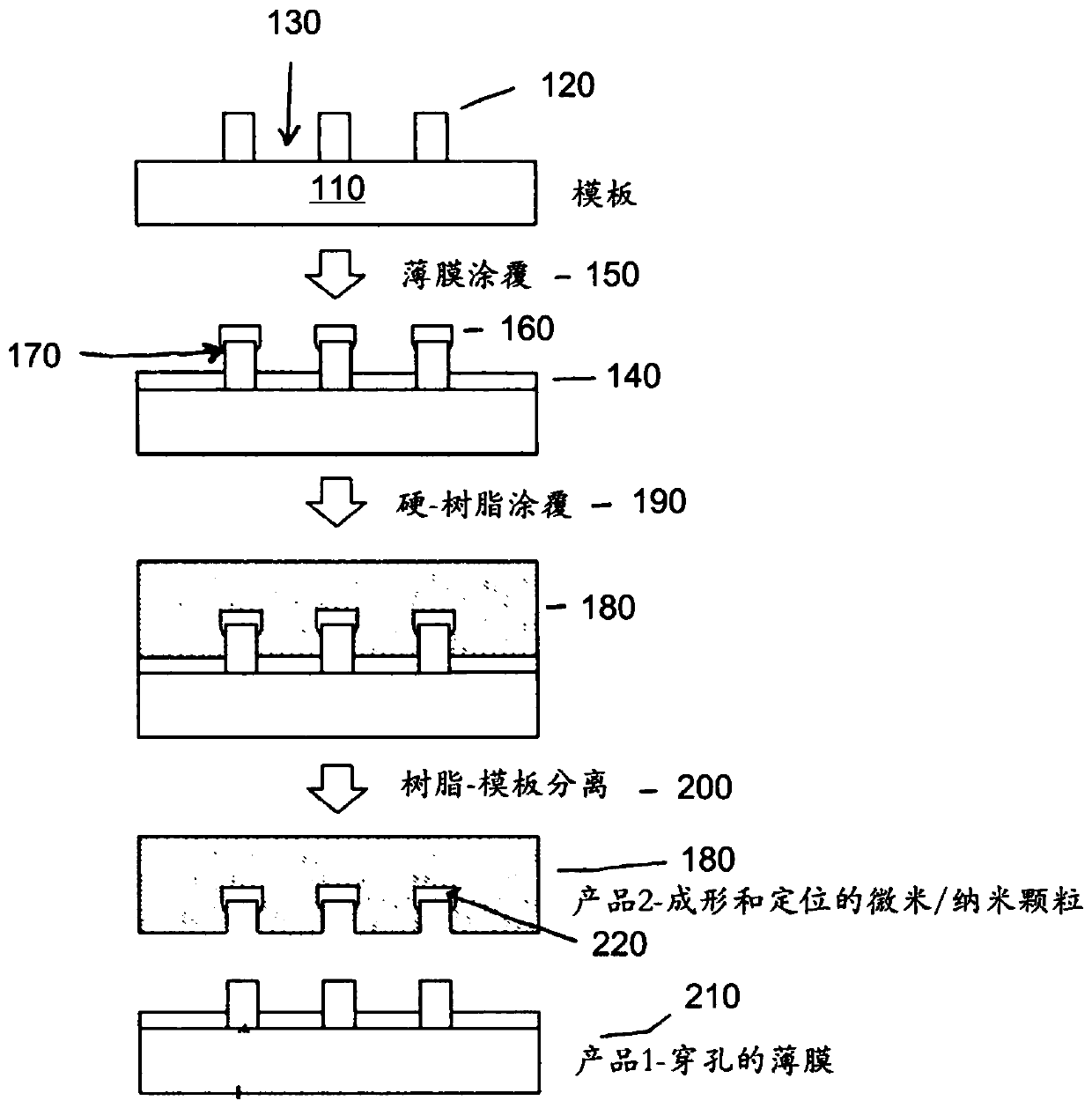

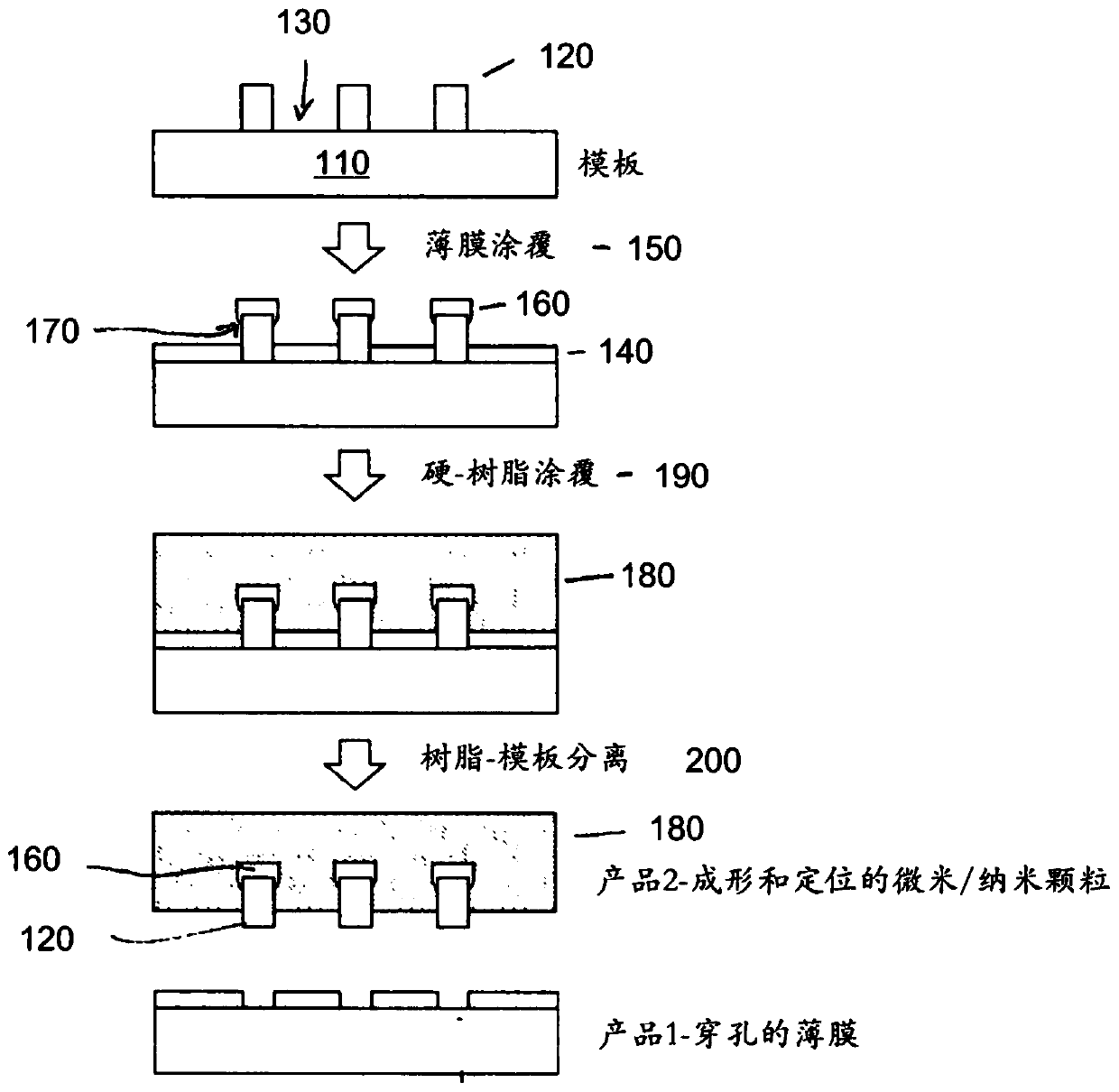

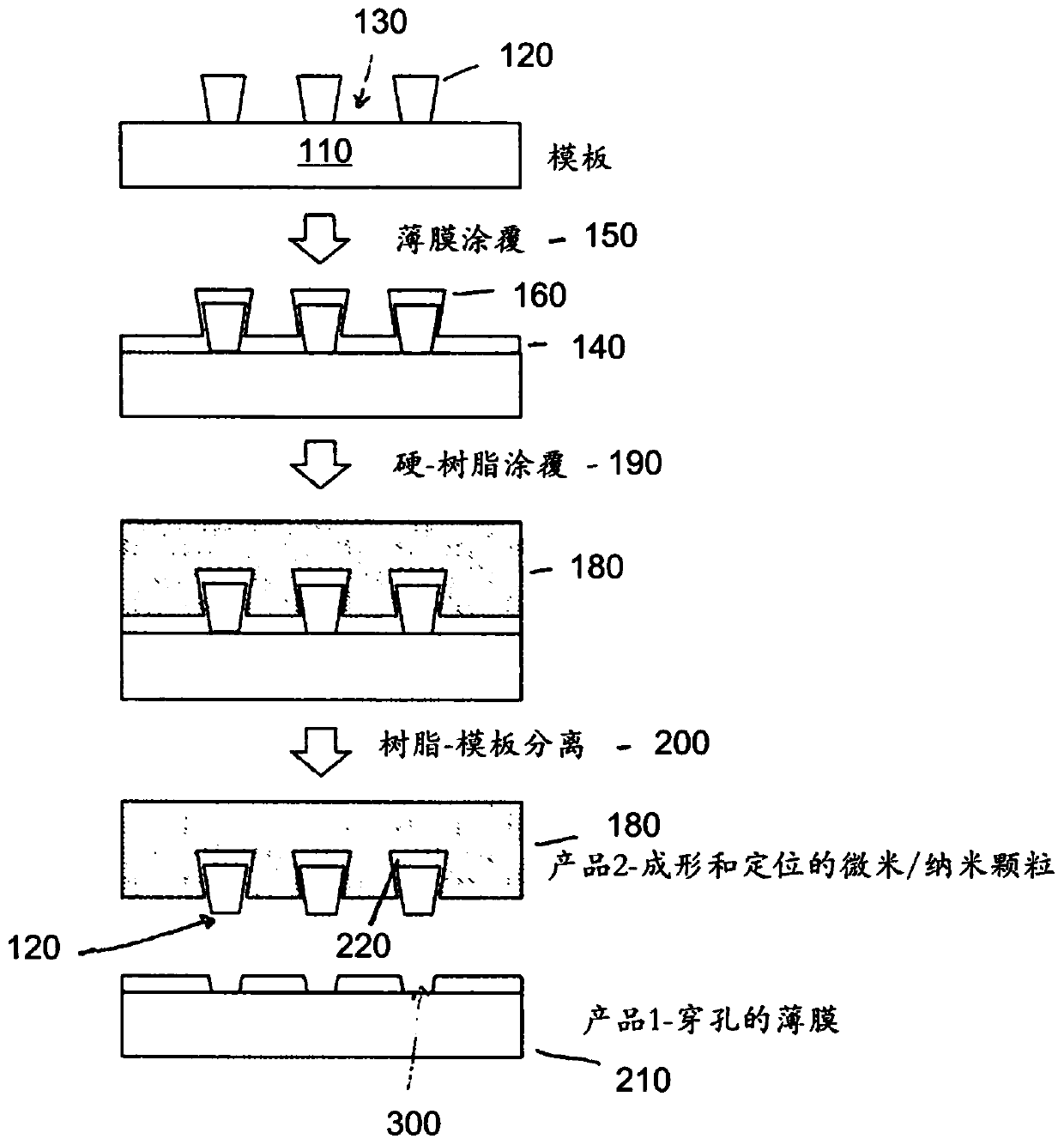

Methods for micro and NANO fabrication by selective template removal

ActiveCN110891895AHigh bonding strengthMaterial nanotechnologyVolume/mass flow by thermal effectsNano manufacturingNanohole

A method to remove selected parts of a thin-film material otherwise uniformly deposited over a template is disclosed. The methods rely on a suitable potting material to encapsulate and snatch the deposited material on apexes of the template. The process may yield one and / or two devices during a single process step: (i) thin-film material(s) with micro- and / or nano-perforations defined by the shapeof template apexes, and (ii) micro- and / or nano-particles shaped and positioned in the potting material by the design of the template apexes. The devices made from this method may find applications in fabrication of mechanical, chemical, electrical and optical devices.

Owner:NANOTECH SECURITY

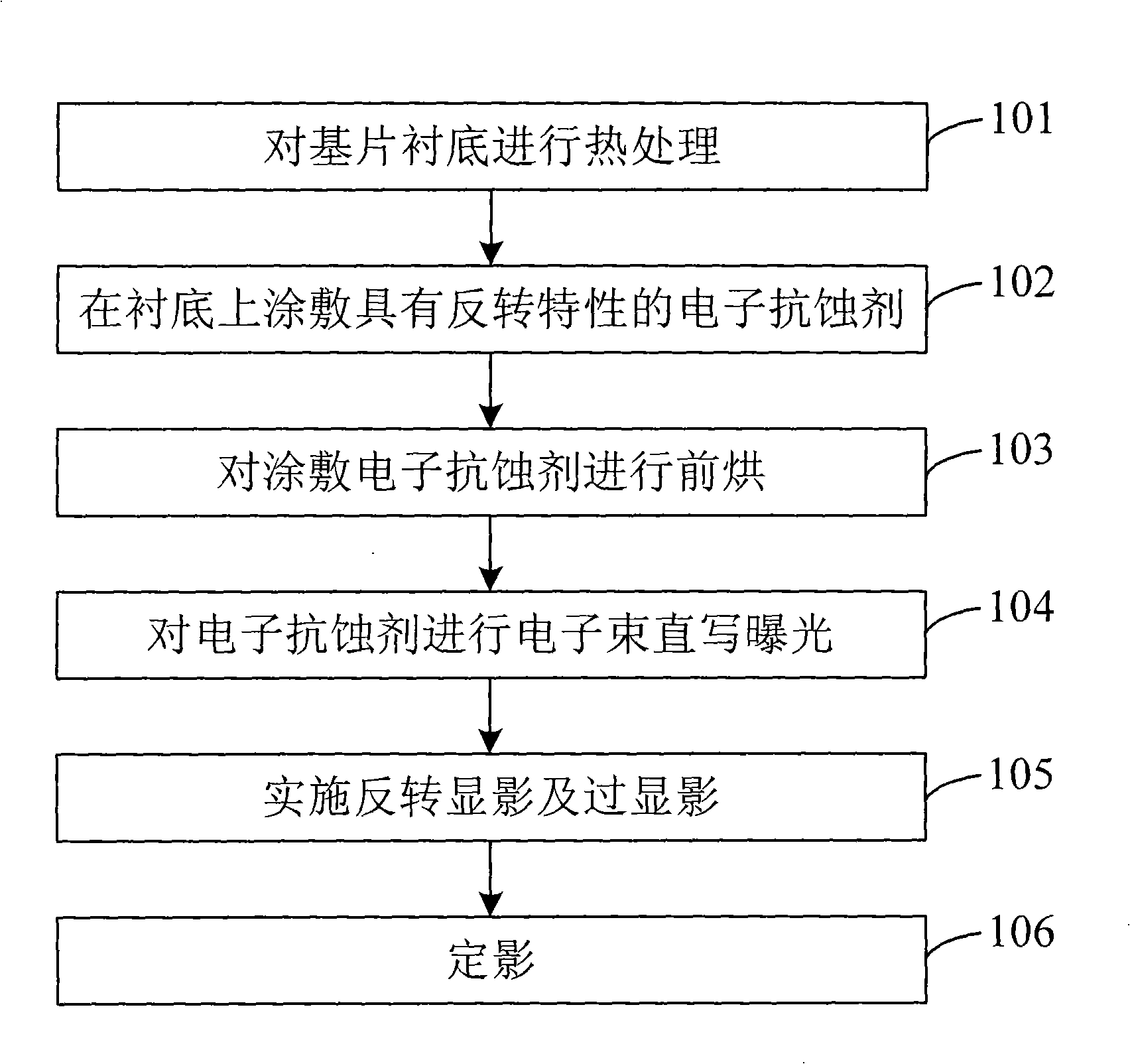

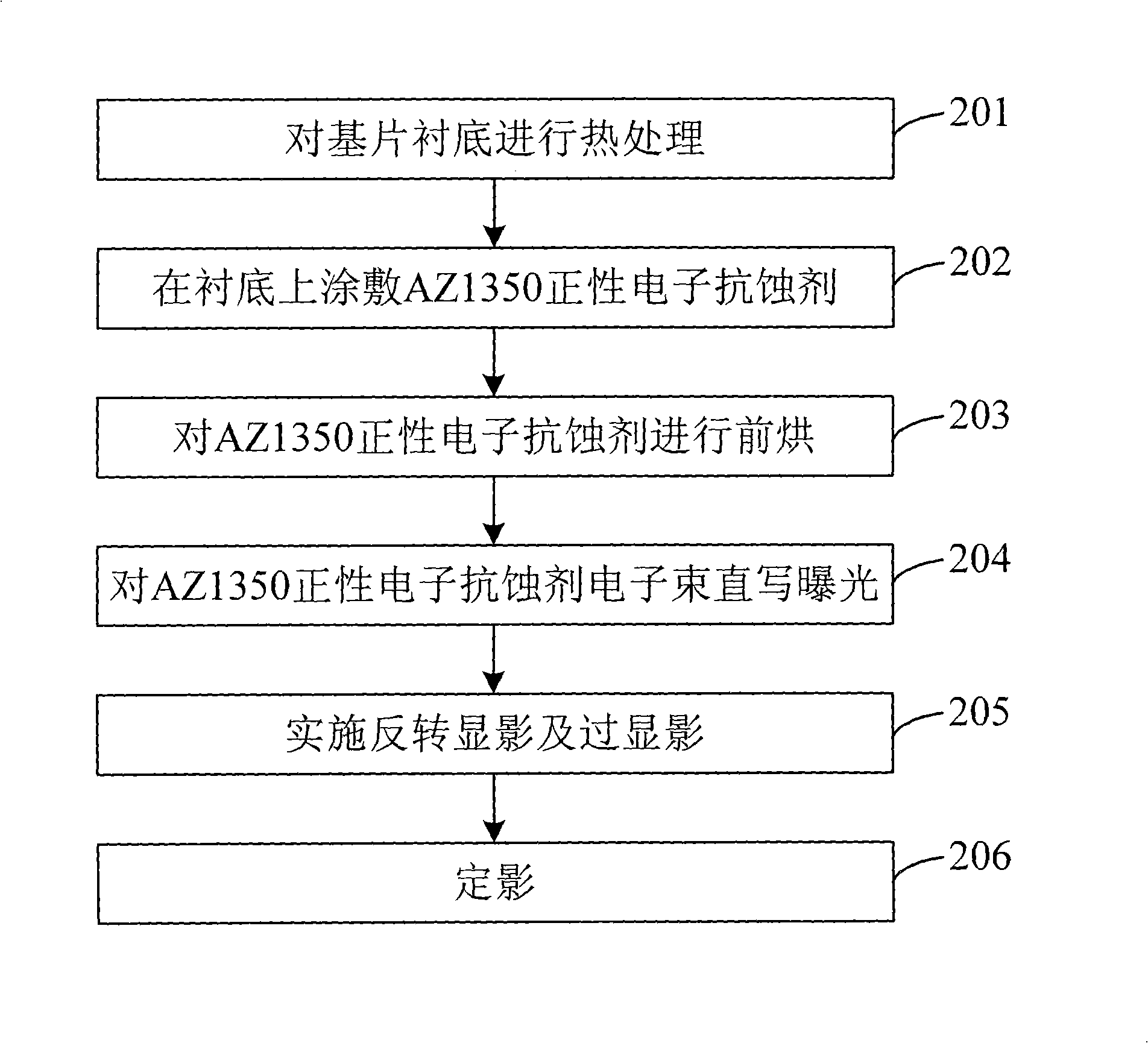

Method for manufacturing hundred nano-scale electric solenoid or net-shaped structure

InactiveCN101276149AReduce process stepsThe process steps are simpleNanostructure manufacturePhotomechanical exposure apparatusElectron resistsResist

The present invention relates to a technical field of nano fabrication, providing a method of producing hundreds nanometer level solenoid or reticular formation, the method includes: A, processing heat treatment to a substrate; B, coating an electronic resist having inversion characteristic on the substrate; C, processing prebaking to the coating electronic resist; D, processing e-beam direct-writing exposure to the electronic resist; E, implementing inversion development and over development; F, fixing. The invention simplifies the producing process, achieving the aim of obtaining a stereostructure by planar exposure.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

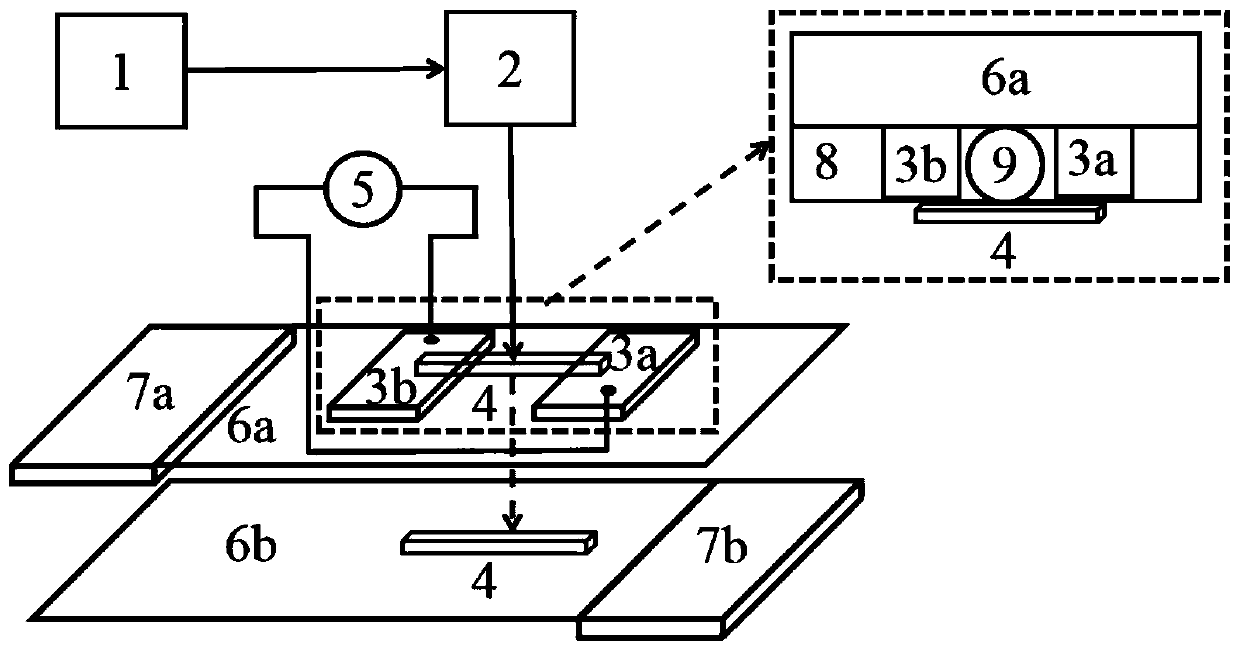

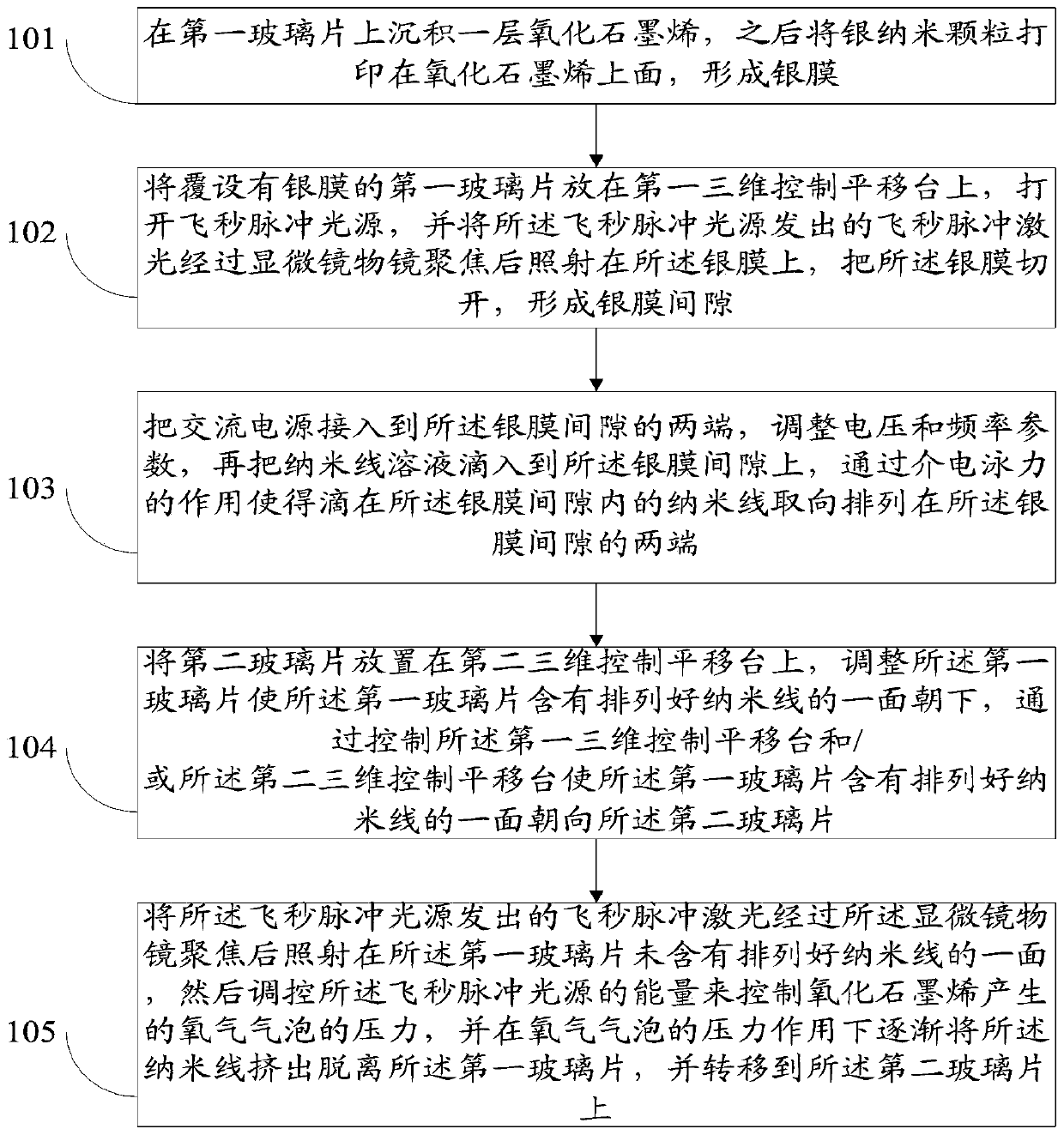

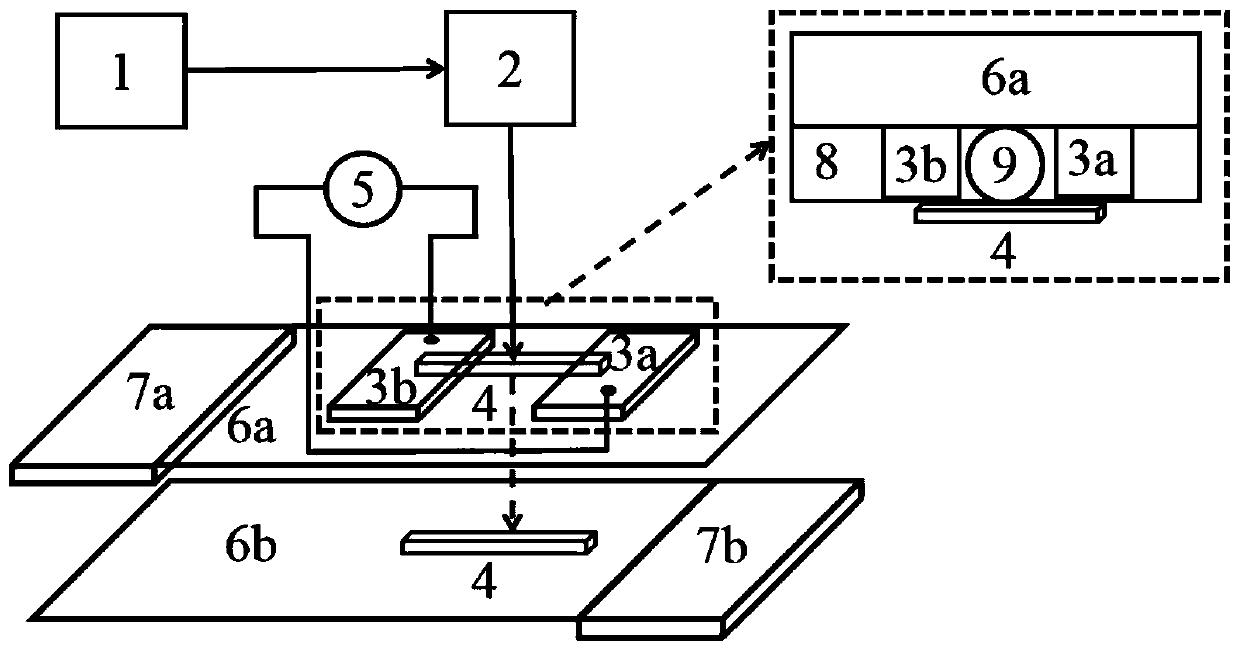

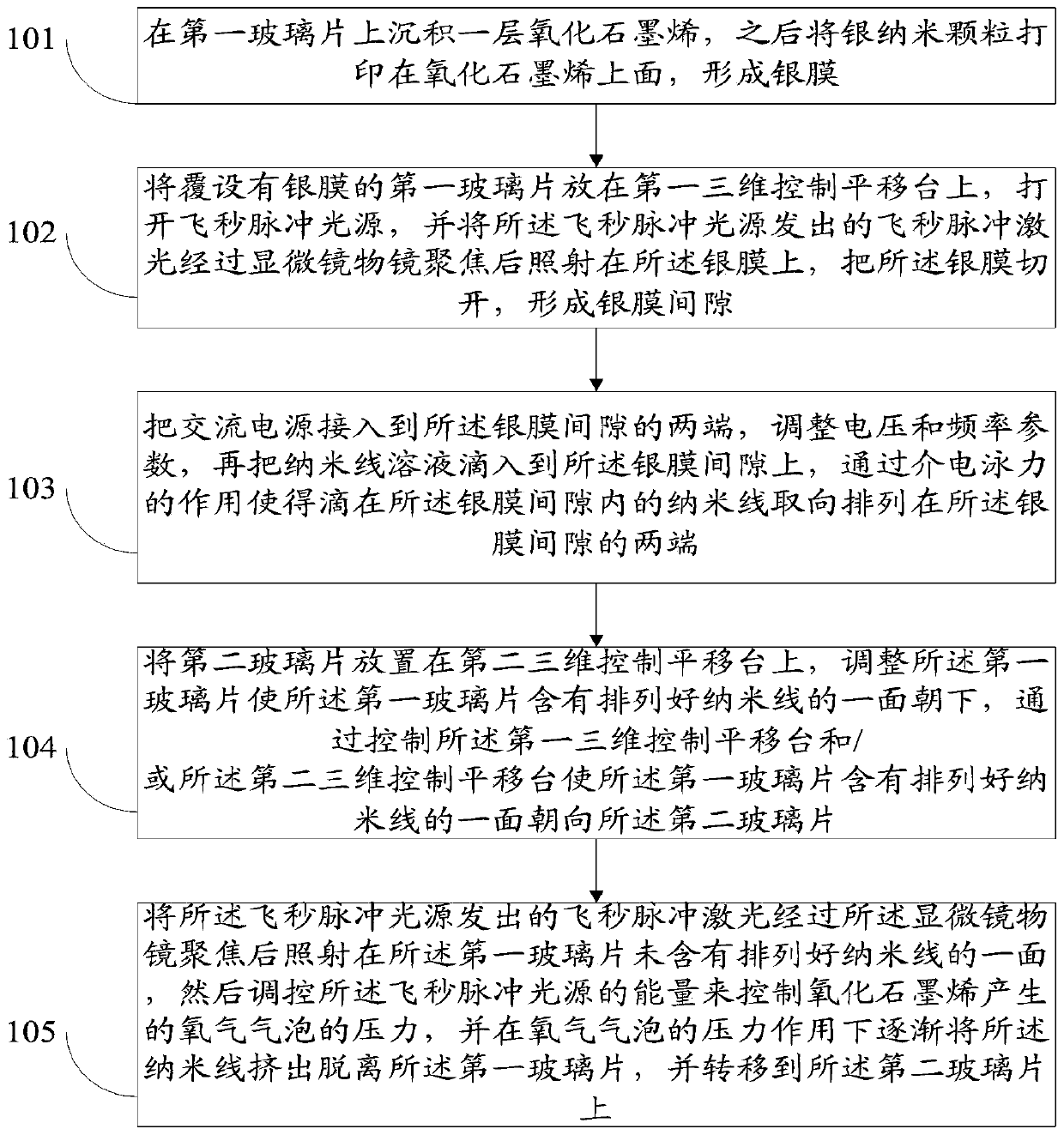

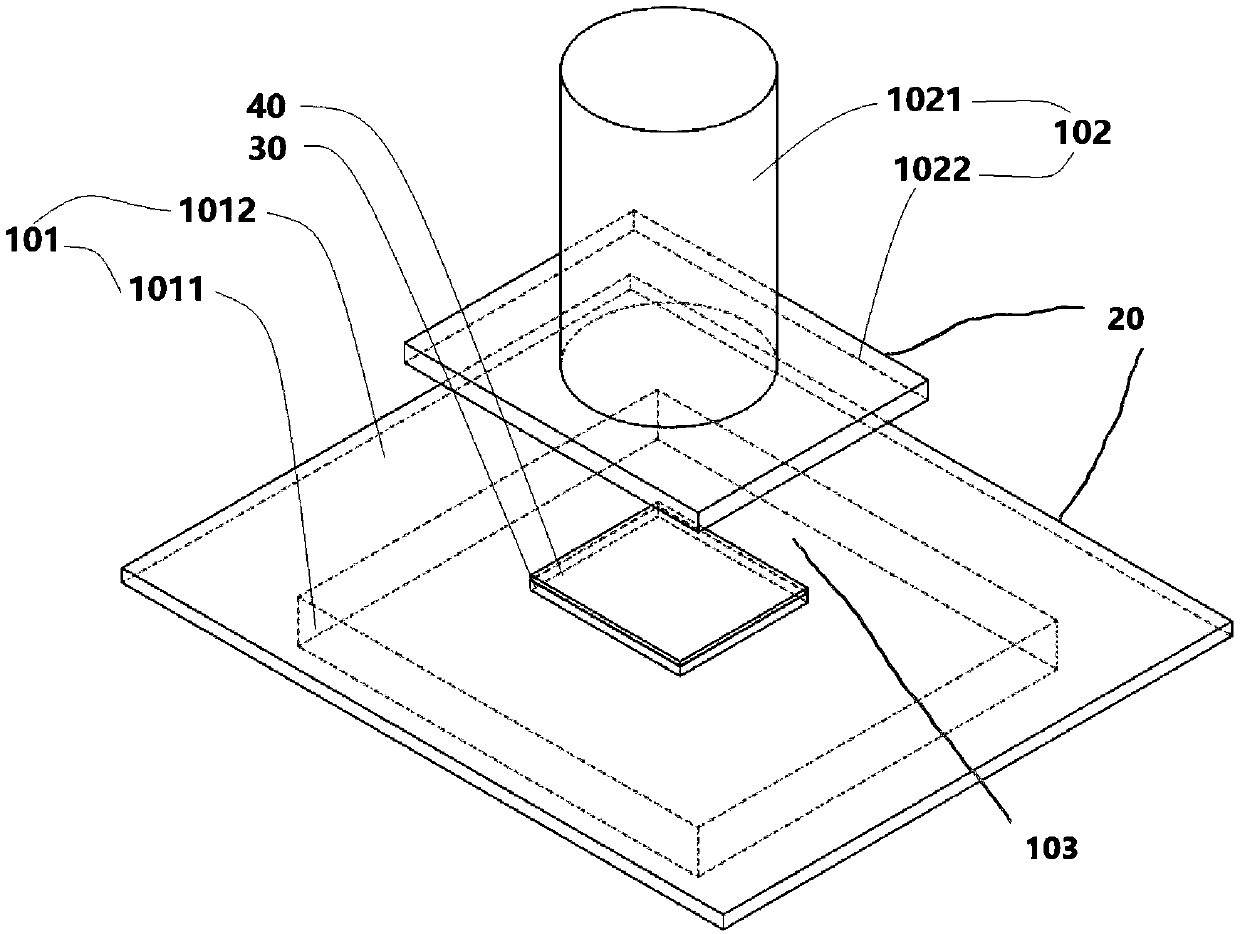

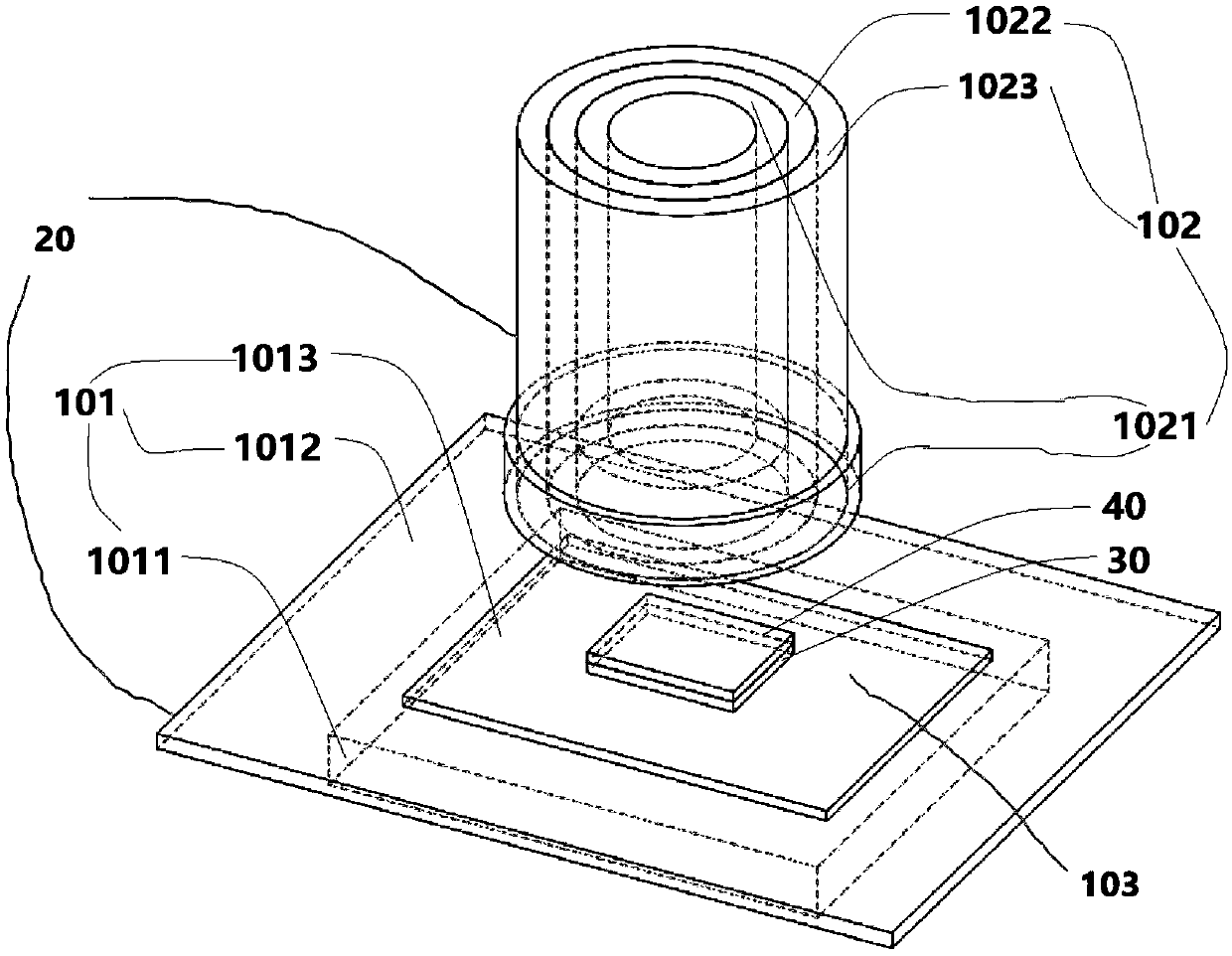

Device and method capable of precisely controlling and transmitting nanowire

ActiveCN109911848APrecision ControlPrecision transferNanostructure manufactureNanowireFemtosecond pulsed laser

The invention discloses a device and a method capable of precisely controlling and transmitting a nanowire, and relates to the technical field of micro and nano-fabrication. The device comprises a femtosecond pulse light source, a microscope objective, a silver film-coated first glass sheet, a second glass sheet and an alternating-current power supply. The method comprises the following steps: firstly, focusing femtosecond pulse laser emitted by the femtosecond pulse light source by the microscope objective and then irradiating on the silver film to form a silver film gap; secondly, connectingthe alternating-current power supply with the two ends of the silver film gap, dropping a nanowire solution on the silver film gap to orientally arrange the nanowires at the two ends of the silver film gap, and reversing the first glass sheet; and thirdly, focusing the emitted femtosecond pulse laser by the microscope objective and then irradiating on one side, without being coated with the nanowire, of the first glass sheet to transfer the nanowire from the first glass sheet to the second glass sheet. Through the combination of a dielectrophoresis technology and a laser induced forward transfer technology taking graphene oxide as a dynamic release layer, precise control and nanowire transmission can be realized simply, conveniently and rapidly.

Owner:HUNAN CITY UNIV

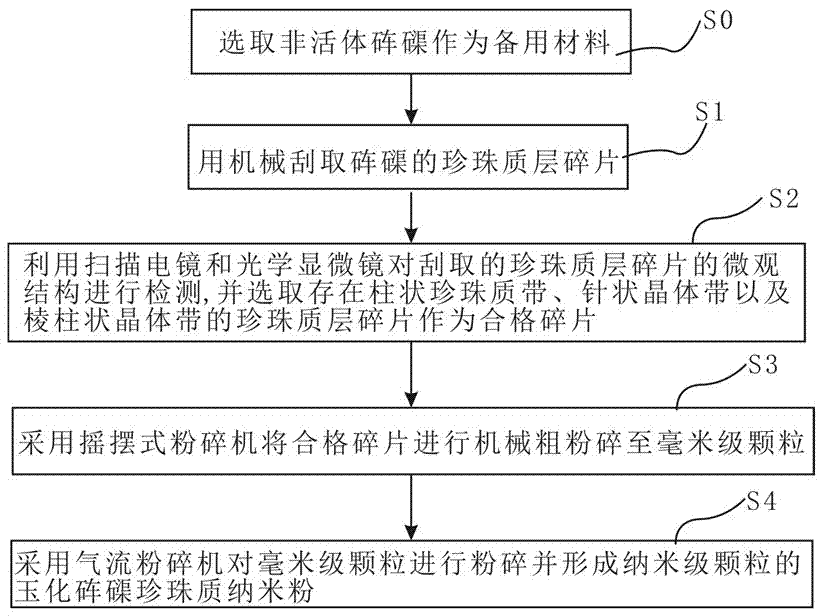

Method for making jadeized giant clam nacre nanopowder and loudspeaker diaphragm

ActiveCN104135708BExcellent fracture toughnessHigh activityElectrical transducersMicrometerResonance

The present invention discloses fabricating methods of jade tridacna nacreous nano powder and speaker diaphragm, the fabricating method of the speaker diaphragm comprises the steps of preparing tridacna paper pulp, pouring the paper pulp onto a basin-shaped net-like mold, such that the tridacna paper pulp is deposited on the basin-shaped net-like mold, papermaking after the tridacna paper pulp is deposited with a thickness of 2 mm, drying the deposits after papermaking by warm air at 120 DEG C for 15-35 minutes and forming a speaker diaphragm after hot-pressing into the thickness of 20 micrometers by a titanium metal mold at 260 DEG C and curing for 120-160 minutes. The diaphragm of the present invention is made of a combination of jade tridacna nacreous nano powder and base paper pulp. The diaphragm can rapidly absorb the energy transversely transferred by voice and also can vibrate longitudinally to make sound rapidly. The cone breakup resonance caused by the high portion of audio frequency is sufficiently reduced and the cutoff band of roll-off also becomes smooth. The speaker made of the diaphragm is penetrating and mellow in sound, clear in details of music and good in fidelity.

Owner:陈宏乔

Rear spectrophotometric pupil laser differential confocal mass-spectrum microscopic imaging method and device

InactiveCN109187720ADrift suppressionEffectively exploit the potential of high spatial resolutionMaterial analysis by electric/magnetic meansAnalysis by material excitationHigh spatial resolutionPupil

The invention discloses a rear spectrophotometric pupil laser differential confocal mass-spectrum microscopic imaging method and device, and belongs to the technical field of confocal microscopic imaging and mass-spectrum imaging measurement technologies. According to the method and the device in the invention, a rear spectrophotometric pupil laser differential confocal microscopic imaging technology and a mass-spectrum detection technology are combined; mass-spectrum detection on sample microzonal charged molecules, atoms and the like is carried out by utilization of a mass-spectrum detectionsystem; laser mass-spectrum detection and rear spectrophotometric pupil differential confocal detection structures are fused; and thus, high spatial resolution and high-sensitive imaging and detection of sample microzonal composition information and morphological parameters are realized. The invention can provide a brand-new effective technology way for morphological imaging and material composition detection in the fields, such as biomedicines, material sciences, mineral products and micro and nano-fabrication.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

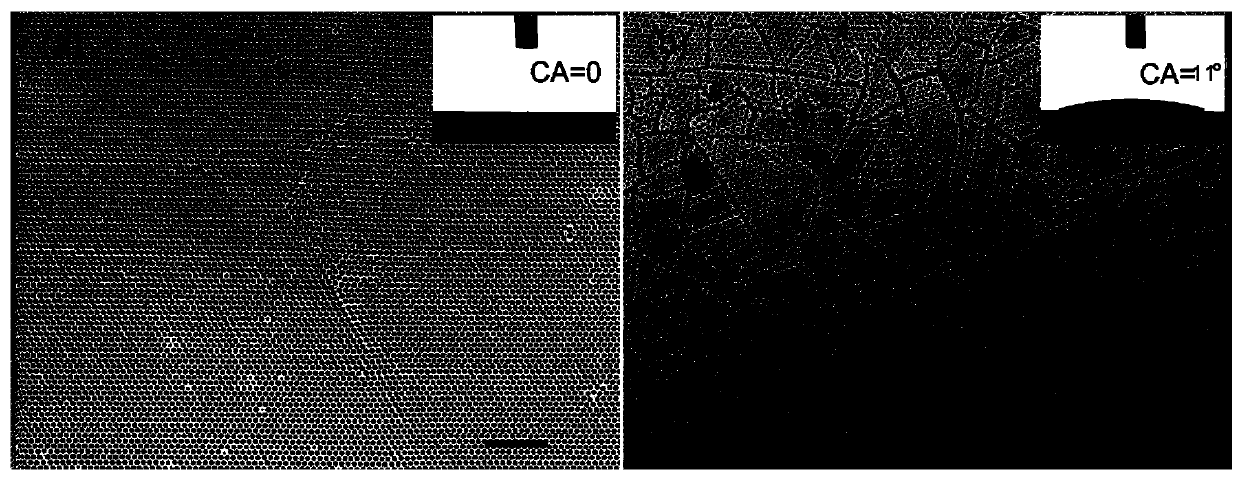

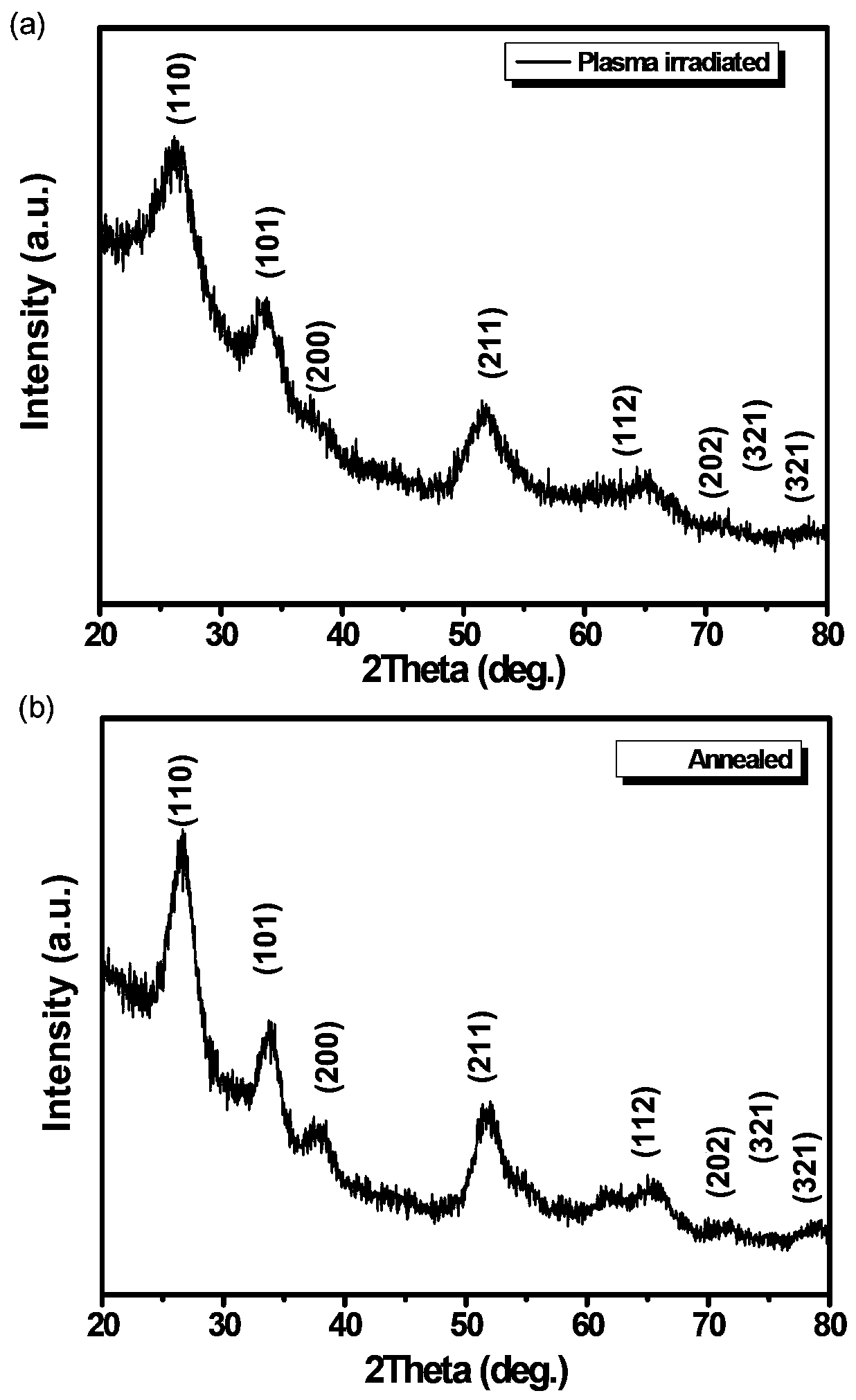

Oxygen plasma irradiation preparation method of ordered porous array of oxide micro-nano structure

The invention discloses an oxygen plasma irradiation preparation method of an oxide micro-nano structure ordered porous array. It includes a two-dimensional colloidal crystal template method and a plasma irradiation method. The specific steps are as follows: a single-layer two-dimensional colloidal crystal template is synthesized by a gas / liquid interface assembly method. In particular, the template was transferred and floated to the surface of the 0.02‑0.2mol / L precursor solution, the template immersed in the solution was picked up and placed in an 80‑120ºC oven for 15‑30 minutes, followed by a plasma cleaner Irradiated in an oxygen atmosphere for 10-60min, and the plasma power was 5.8-18W. This method does not use any expensive special instruments and surface modifiers, and the preparation process is simple and fast, low cost, high efficiency, safe and environmentally friendly, and can be widely used in photonic crystals, micro / nano processing, catalysis, surface-enhanced Raman scattering, sensing and other fields.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

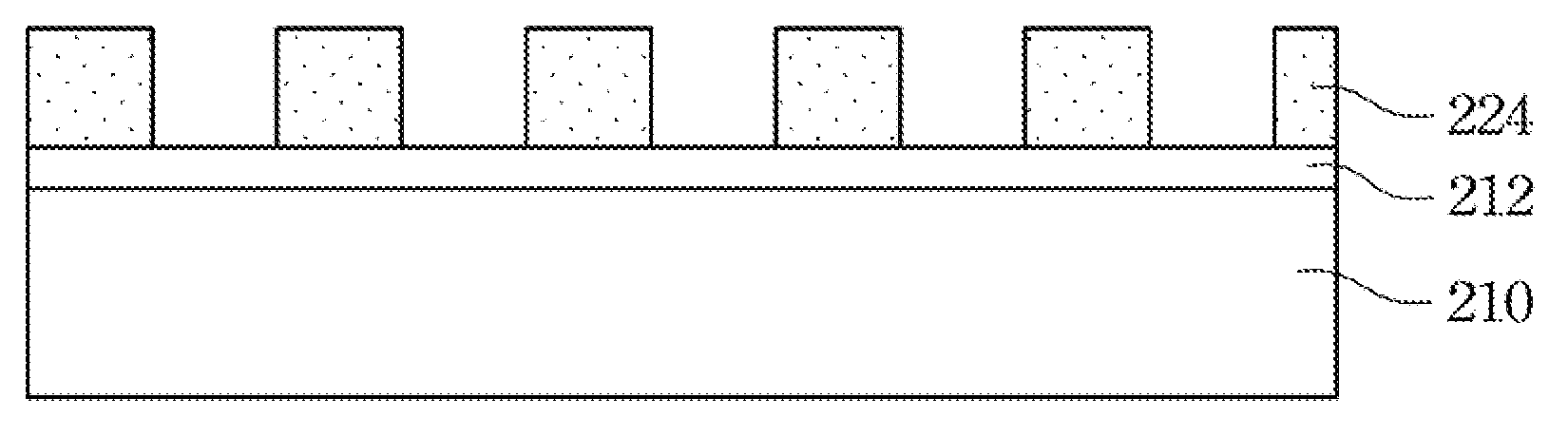

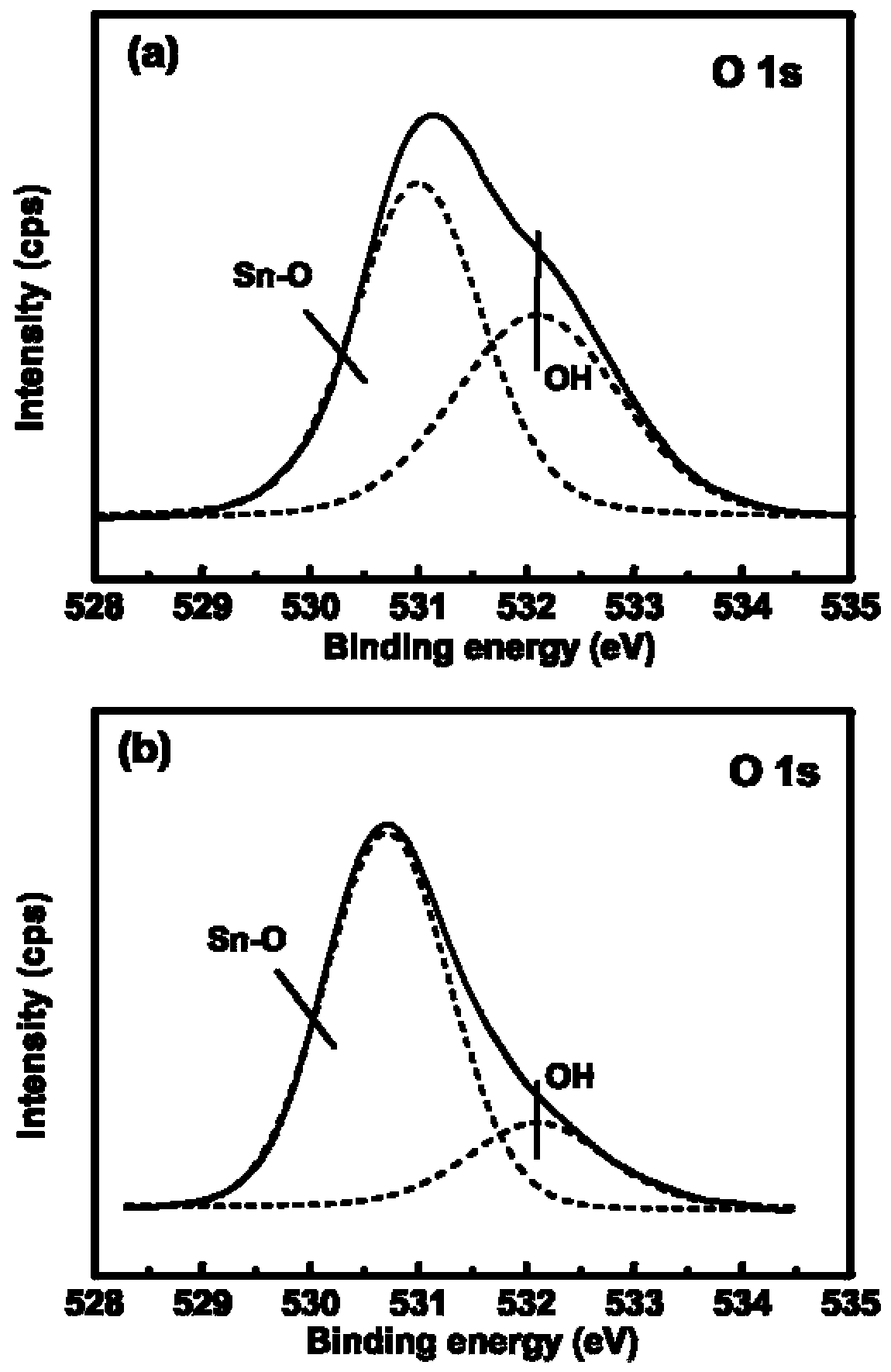

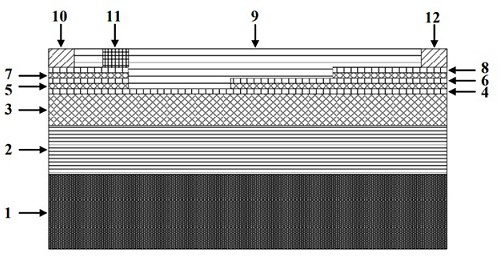

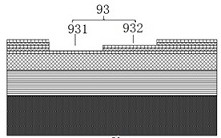

Variable channel algan/gan HEMT structure and preparation method

ActiveCN114582962BAdjust charge densityEffective modulation of electric field distributionTransistorSemiconductor/solid-state device manufacturingHeterojunctionEngineering

The invention discloses a variable channel AlGaN / GaN HEMT structure and a preparation method. A buffer layer is grown on a substrate layer, and a multi-channel layer is regrown on the buffer layer, that is, two or more layers of AlGaN / GaN heterolayers are formed. Then, the multi-channel layer is selectively etched to form a stepped multi-channel layer; then a dielectric passivation layer is deposited on the surface of the device, and chemical and physical polishing is performed to form a stepped passivation layer and top passivation Finally, the metal electrode of the device is prepared by a micro-nano fabrication process to obtain a variable multi-channel AlGaN / GaN HEMT structure.

Owner:NANJING UNIV OF POSTS & TELECOMM +1

Nano-microfiber production method

ActiveCN103572613BUniform hair feelFeel plumpSynthetic resin layered productsPolyurea/polyurethane coatingsSlurryHydrolysis

The invention discloses a nano-micro fiber making method. The method comprises the following steps: uniformly mixing 80-100 parts of a high-hydrolysis-resistance polyurethane resin with 150-280 parts of dimethyl formamide, allowing the obtained mixture to stand, uniformly mixing with a slurry formed by 5-10 parts of dimethyl formamide, 2-10 parts of a hydrolysis resistant color paste and 1-3 parts of a surfactant at 20-40DEG C, and carrying out deaeration filtering defoaming; ironing a fleece, immersing in the slurry, solidifying with an aqueous solution of dimethyl formamide, washing with water, extruding, and drying to obtain a wet base; and carrying out surface polishing of the wet base, and carrying out textured surface treatment to obtain nano-micro fibers. The method adopts the high-hydrolysis-resistance polyurethane resin to prepare the wet base and allows the surface of the wet base to undergo post-treatment buffing, and the produced nano-micro fibers have the advantages of fine surface, uniform wool feeling, certain acerbity hand feeling, ventilation, softness, full hand feeling, good elasticity and the like.

Owner:KUNSHAN XIEFU NEW MATERIALS LTD BY SHARE LTD

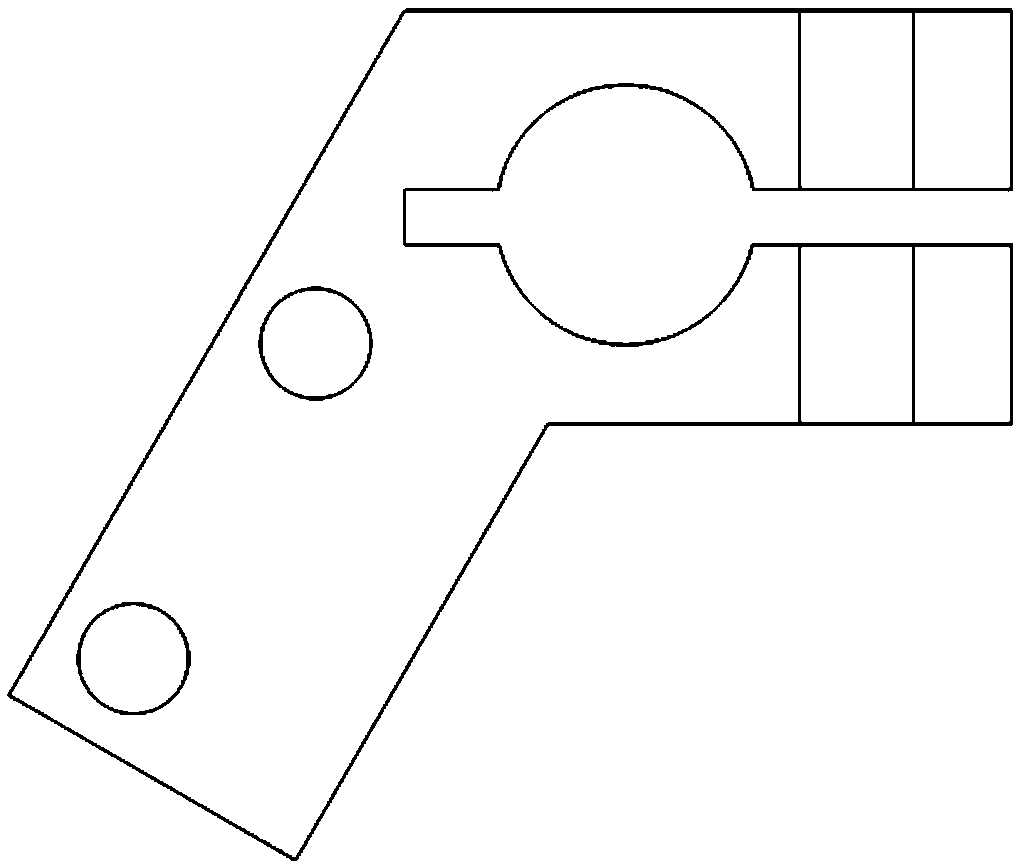

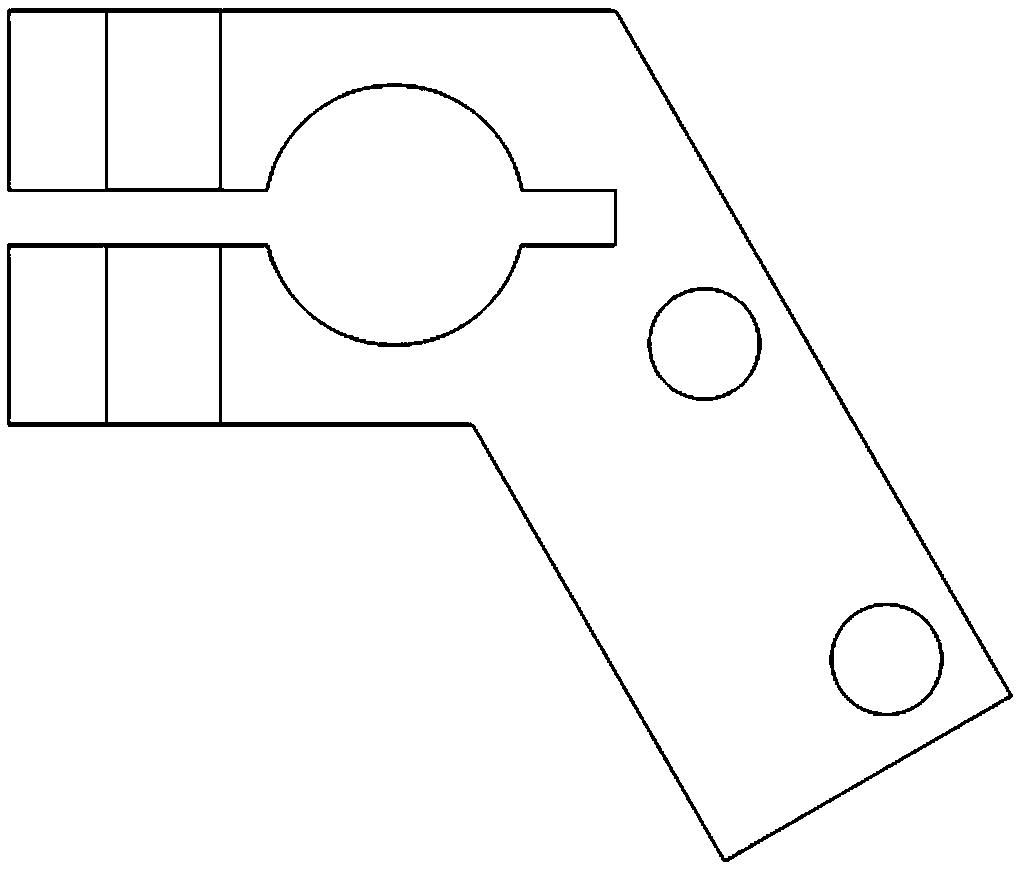

Special fixture applied to aluminum thick film resistivity method vacuum evaporation device

PendingCN109594051AUltimate Thickness ImprovementVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceManufacturing technology

The invention belongs to the technical field of micro and nano-fabrication, and provides a special fixture applied to an aluminum thick film resistivity method vacuum evaporation device. The special fixture is of a bilateral symmetry structure and comprises a left clamp, a left electrode, a first tungsten wire cover plate, a first tungsten wire, a second tungsten wire, aluminum rings, a second tungsten wire cover plate, a right electrode and a right clamp; the use amount of used evaporation source aluminum rings is 2.5 times that of aluminum rings before transformation, after the use amount ofthe evaporation source aluminum rings is increased, the limit thickness of one-time evaporation can be increased to the micrometer scale from few hundred nanometers, and through increasing of the useamount of evaporation source aluminum rings, the limit thickness of a coating film is obviously improved; when the transformed clamps and tungsten wires are used for evaporating the aluminum film, the distance between a sample and an evaporation source is increased, the included angle between the sample and the evaporation source is 71.4 degrees, at the time, the single-time aluminum film evaporation limit thickness is the micrometer scale, and the clamp can achieve the aim of evaporating the aluminum thick film.

Owner:DALIAN UNIV OF TECH

A device and method for precisely manipulating and delivering nanowires

ActiveCN109911848BAccurate transferEasy to operateNanostructure manufactureManufacturing technologyNanowire

The invention discloses a device and a method capable of precisely controlling and transmitting a nanowire, and relates to the technical field of micro and nano-fabrication. The device comprises a femtosecond pulse light source, a microscope objective, a silver film-coated first glass sheet, a second glass sheet and an alternating-current power supply. The method comprises the following steps: firstly, focusing femtosecond pulse laser emitted by the femtosecond pulse light source by the microscope objective and then irradiating on the silver film to form a silver film gap; secondly, connectingthe alternating-current power supply with the two ends of the silver film gap, dropping a nanowire solution on the silver film gap to orientally arrange the nanowires at the two ends of the silver film gap, and reversing the first glass sheet; and thirdly, focusing the emitted femtosecond pulse laser by the microscope objective and then irradiating on one side, without being coated with the nanowire, of the first glass sheet to transfer the nanowire from the first glass sheet to the second glass sheet. Through the combination of a dielectrophoresis technology and a laser induced forward transfer technology taking graphene oxide as a dynamic release layer, precise control and nanowire transmission can be realized simply, conveniently and rapidly.

Owner:HUNAN CITY UNIV

A plasma surface modification method for a nanomaterial

ActiveCN109553066ABroad spectrum adaptabilityBroad Spectrum FlexibilityMaterial nanotechnologyNanostructure manufactureRoom temperaturePhase change

The invention discloses a plasma surface modification method for a nanomaterial, and relates to the field of micro and nano fabrication in electronic, material, medicine and aerospace fields. The method includes 1) arranging a dielectric barrier discharging type plasma reactor; 2) arranging a substrate material in an air gap; 3) adding a working medium solution; and 4) exciting generation of plasma and allowing the plasma to act on the surface of the substrate material. The method combining heating, reacting and phase change deposition is provided and has advantage of wide-spectrum adaptability, flexibility and reliability. A material surface modification process can be achieved at room temperature or in a natural environment temperature range with a simple device without the need of sealing, and the method is suitable for modification of plurality of special-shape structures and large-area workpieces.

Owner:SHANGHAI JIAO TONG UNIV

Electron beam overlay marking based on hafnium dioxide and its manufacturing method

InactiveCN102969302BReduce manufacturing costHigh melting pointSemiconductor/solid-state device detailsSolid-state devicesResistElectron resists

The invention discloses an electron beam aligning mark based on hafnium oxide, which belongs to the field of micro and nano fabrication of a semi-conductor device. The electron beam aligning mark based on hafnium oxide comprises a substrate and a hafnium oxide thin film mark plated on the substrate. The invention further provides a manufacturing method which specifically comprises the steps of: (1) cleaning the substrate; (2) carrying out spin coating of an electronic resist on the substrate and forming a pattern array with an aligned mark in the electronic resist through an electron beam photolithography technique; (3) evaporating hafnium oxide thin films on the electronic resist and the substrate; and (4) peeling the hafnium oxide thin films attached to the positive electronic resist to obtain the hafnium oxide mark. The aligned mark obtained by the electron beam lithography is prepared by using hafnium oxide which is high temperature resistive, good in adhesion and low in cost. Compared with the conventional 'titanium+gold' marks, the process cost is reduced, the problem that the gold mark and the Si substrate are not adhered well is solved, the adhesion and high temperature bearing capacity of the aligned mark to the substrate are improved, and the higher aligning precision is maintained.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com