Methods for micro and NANO fabrication by selective template removal

A technology of templates and nanostructures, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as limiting the robustness and imperfection of structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

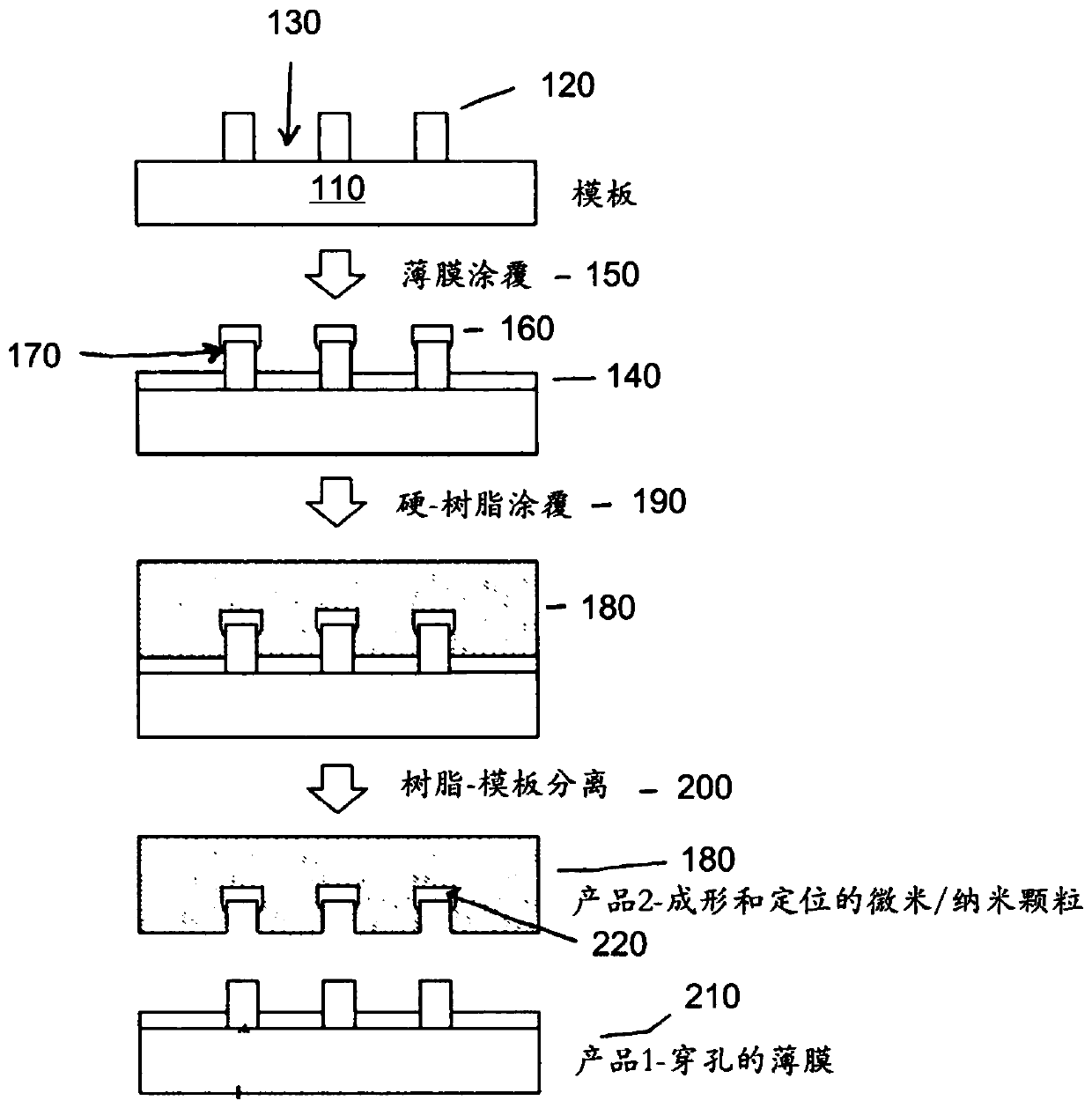

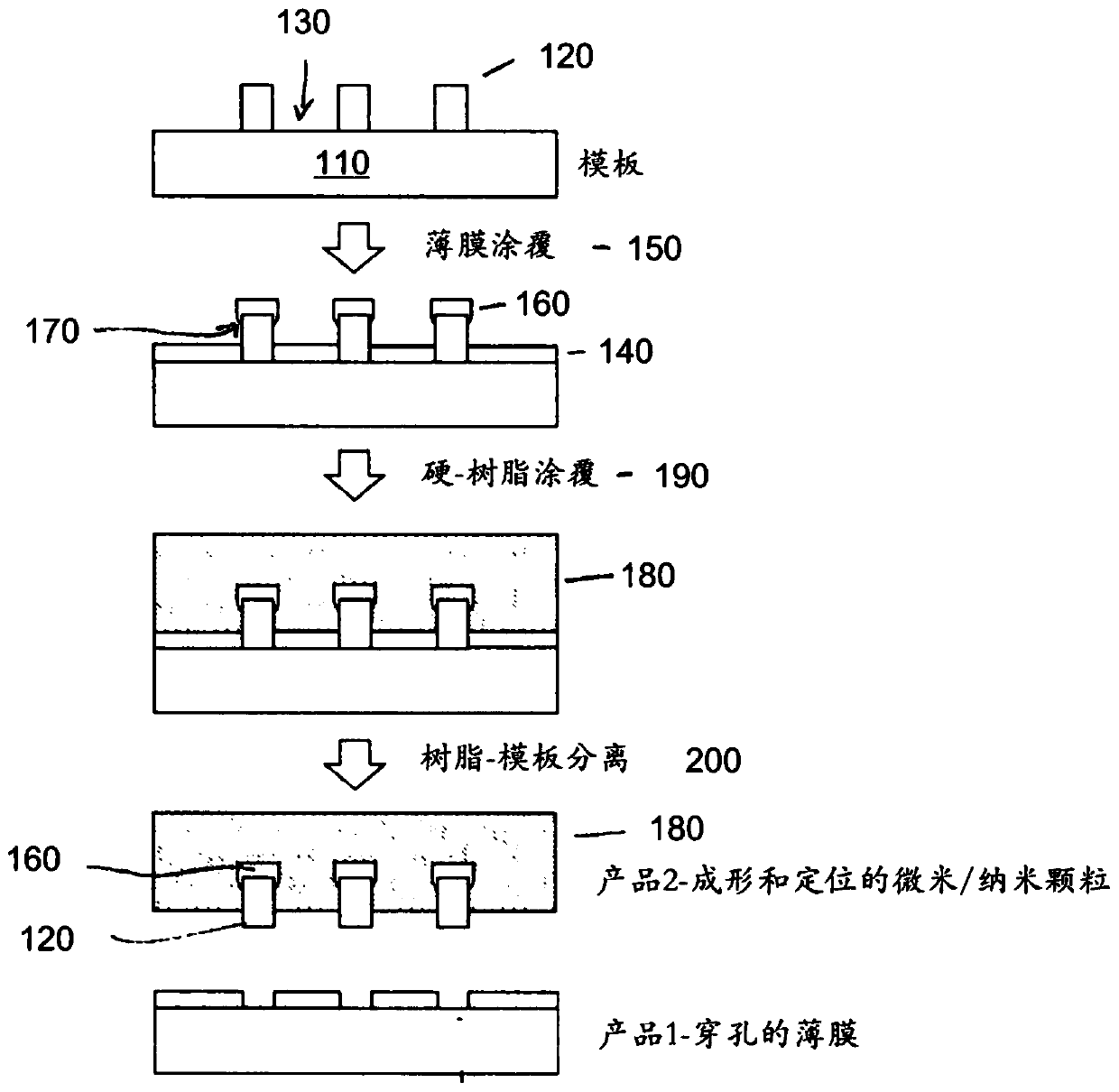

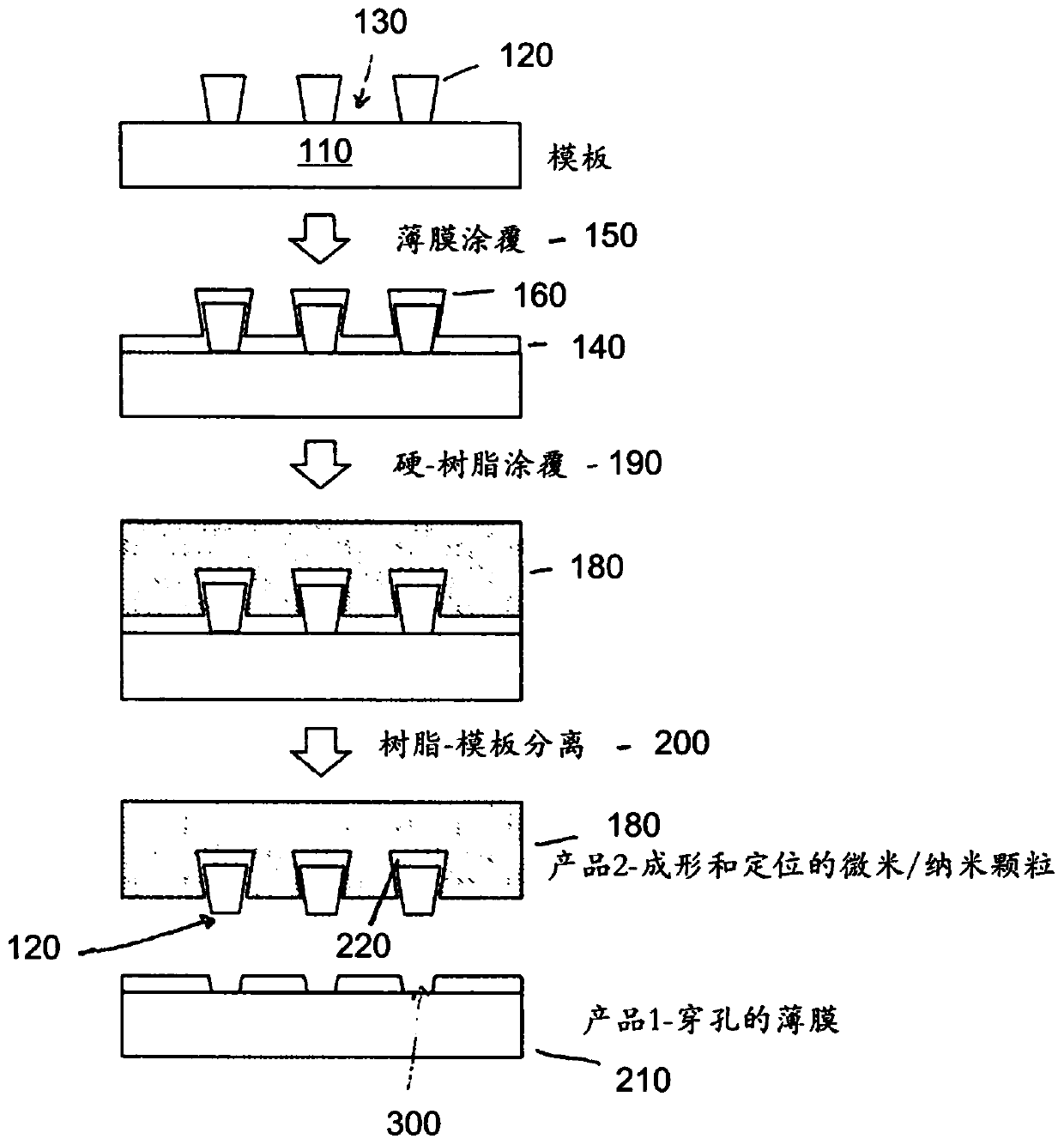

[0048] In one embodiment of the present invention, a method of fabrication is provided for fabricating (i) a perforated film having micro- or nanostructured perforations on the surface of a substrate, and (ii) encapsulating shaped and positioned Micro or nano structured particles.

[0049] In a particular embodiment of the present invention, the method of manufacturing a perforated thin film coating from a thin film layer uniformly deposited on a template substrate having raised structures, such as micro and / or nanostructured tops or vertices, may comprise the use of hardened Resin or polymer potting material to encapsulate and subsequently remove the encapsulated micro- or nanostructured thin-film cap to selectively remove the cap portion of the thin-film coating on the template.

[0050] In another embodiment of the invention, removal of the hardened resin or polymer potting material comprising the encapsulated thin film micro- and / or nanostructured caps desirably creates a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com