Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79 results about "Micro drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

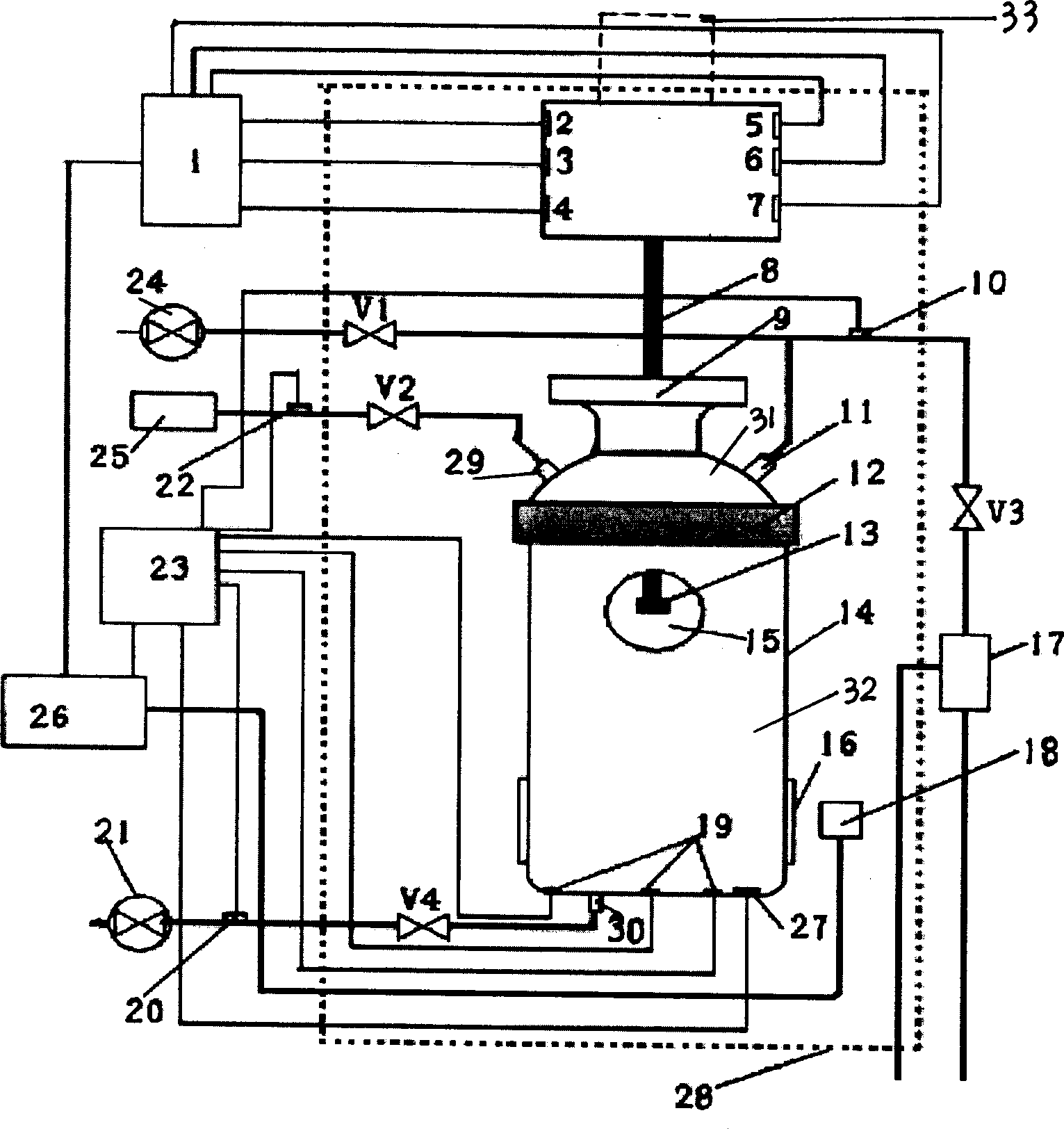

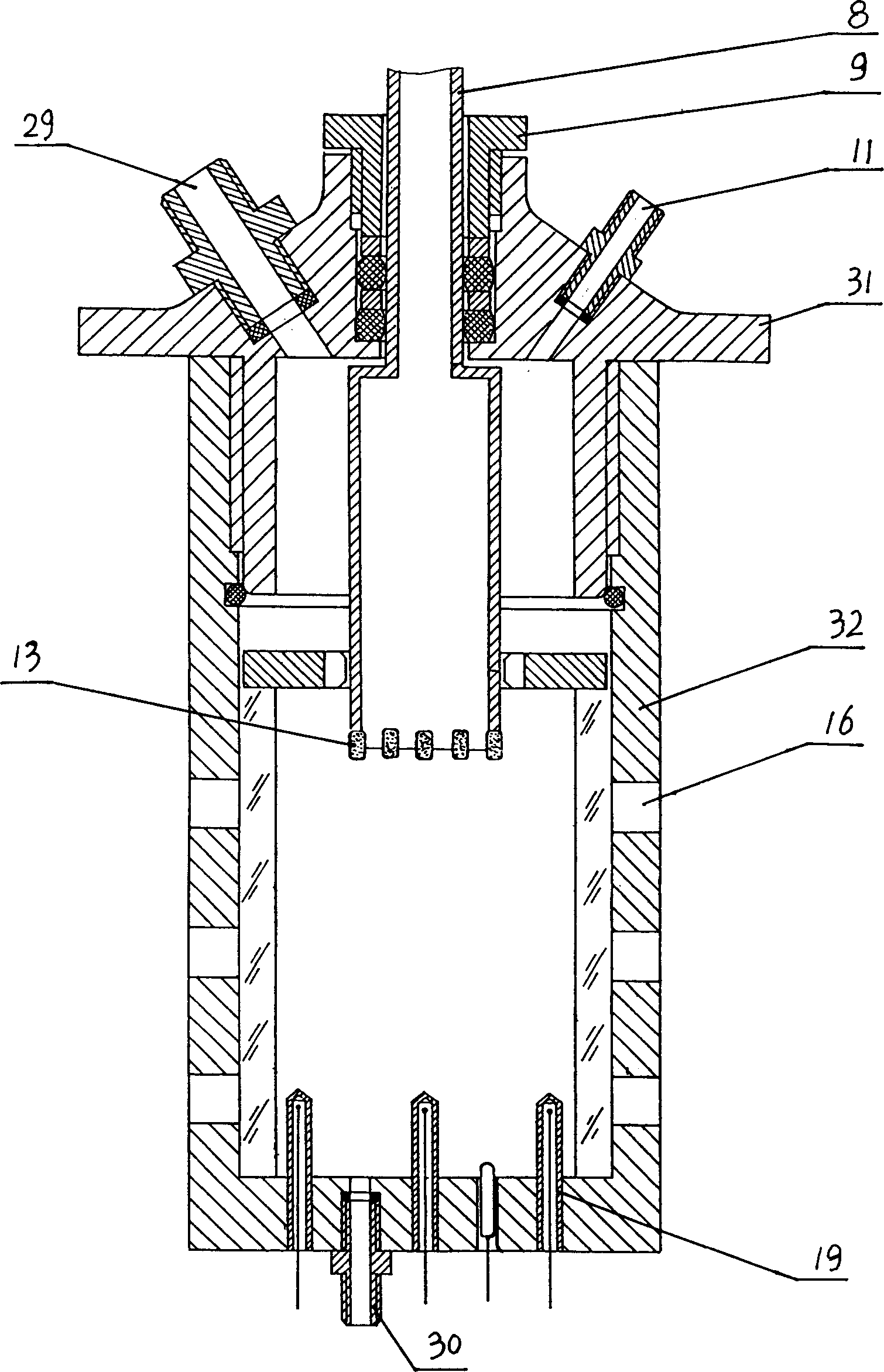

Comprehensive test equipment for natural gas hydrate

InactiveCN1440832AVersatileHigh degree of automationChemical/physical/physico-chemical processesData acquisitionVacuum pump

The comprehensive test equipment for natural gas hydrate consists of gas supplying and pressurizing unit, vacuum pump and gas / liquid separating and collecting unit, reactor, high and low temperature test box, mini drilling system with mini drilling machine and drilling rod, detection system, microphotography system, data collecting system, microcomputerized data processing system connected together. The equipment may be used in simulating synthesis research and decomposing test research as well as in the research of drilling control and exploiting method, etc.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

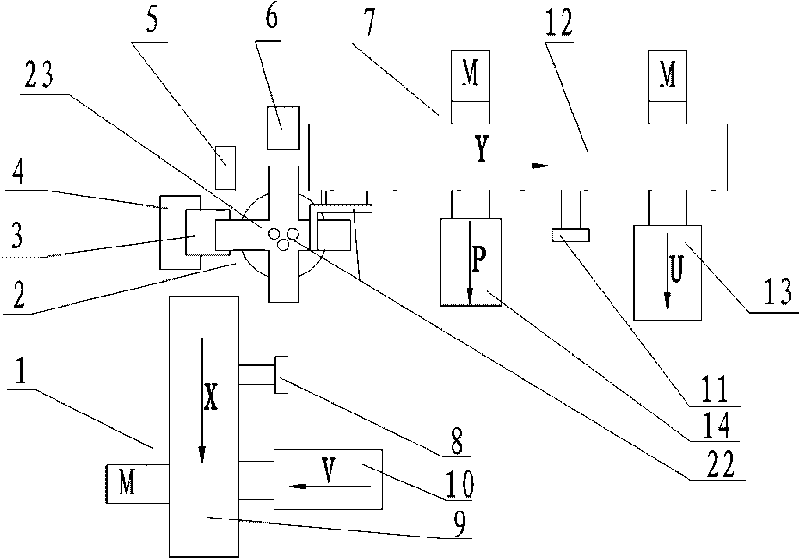

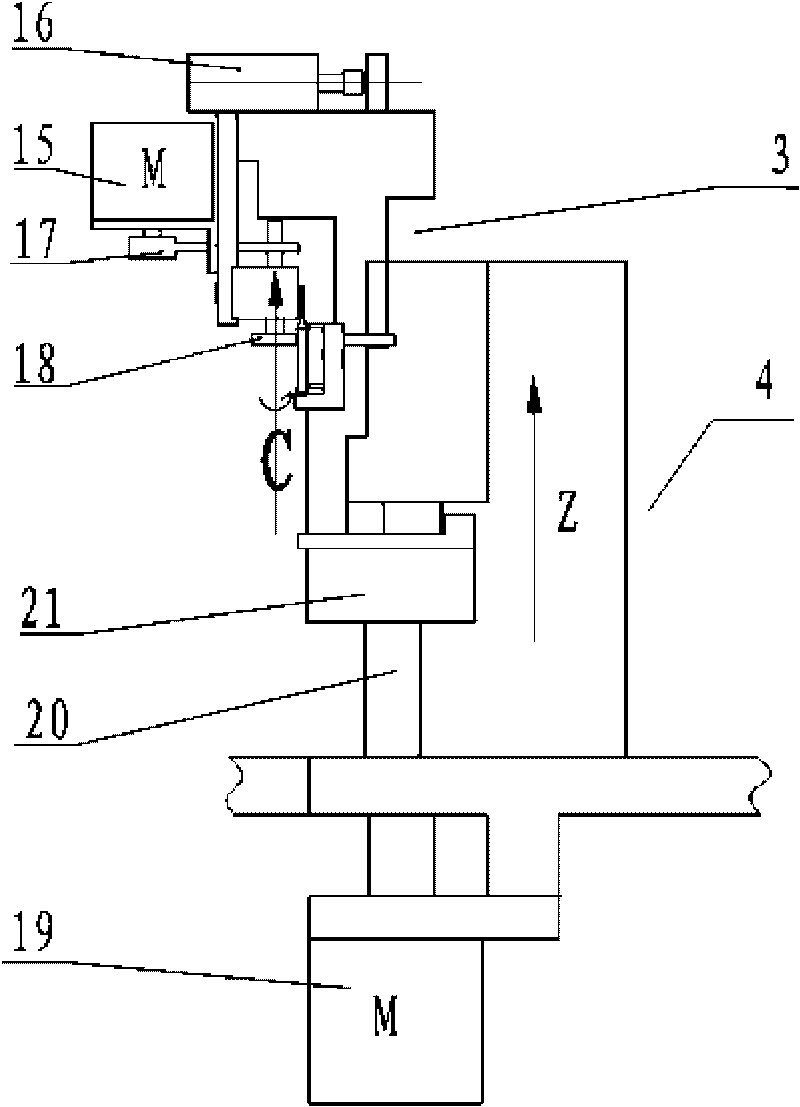

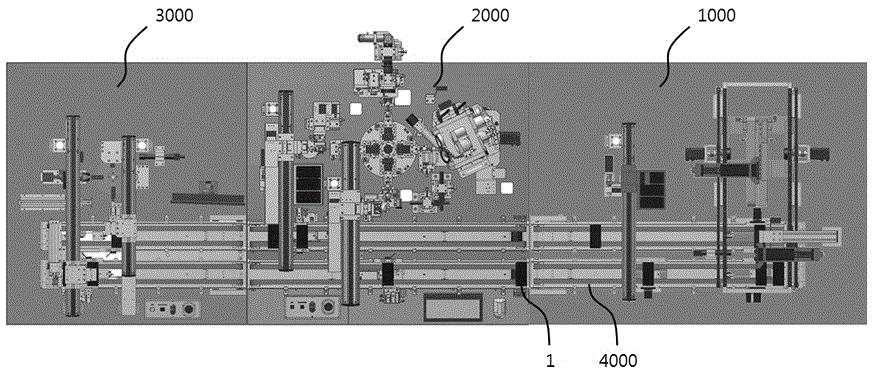

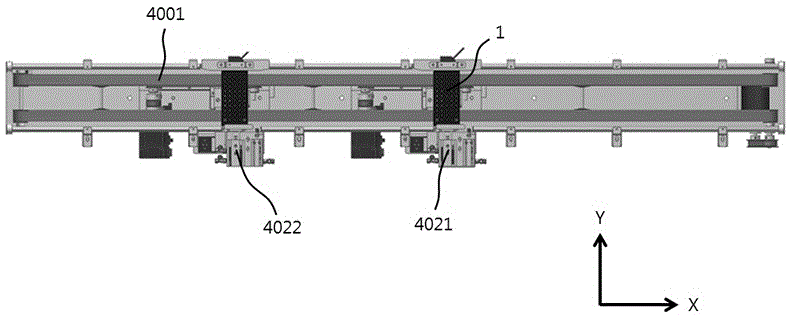

Full-automatic quality detection device of micro drill point for drilling PCB

InactiveCN101706256AReal-time precise axial positioning heightGuaranteed stabilityUsing optical meansImaging qualityEngineering

The invention relates to a full-automatic quality detection device of a micro drill point for drilling a PCB in the technical field of tool detection, which comprises a feeding mechanism, a rotary worktable, a micro drill rotary mechanism, a height adjusting mechanism, a vision detection device and a discharging mechanism, wherein the feeding mechanism, the rotary worktable and the discharging mechanism are respectively and correspondingly arranged at a feeding station, a rotary station and a discharging station of a working platform, the micro drill rotary mechanism and the height adjusting mechanism are sequentially arranged at the side face of the rotary table, the vision detection device is arranged at a vision detection station of the working platform, the feeding station and the rotary station are arranged at the same side, the discharging station and the feeding station are positioned at two ends of the working platform, and the vision detection station and the discharging station are positioned at the same side. The micro drill rotary mechanism and the height adjusting mechanism can enable a micro drill to simultaneously realize the circumferential rotation and the axial real-time precise adjustment, can fine adjust the axial positioning height of the micro drill in real time, and ensure the imaging quality of a blade surface and the measurement precision of geometric parameters.

Owner:SHANGHAI JIAO TONG UNIV

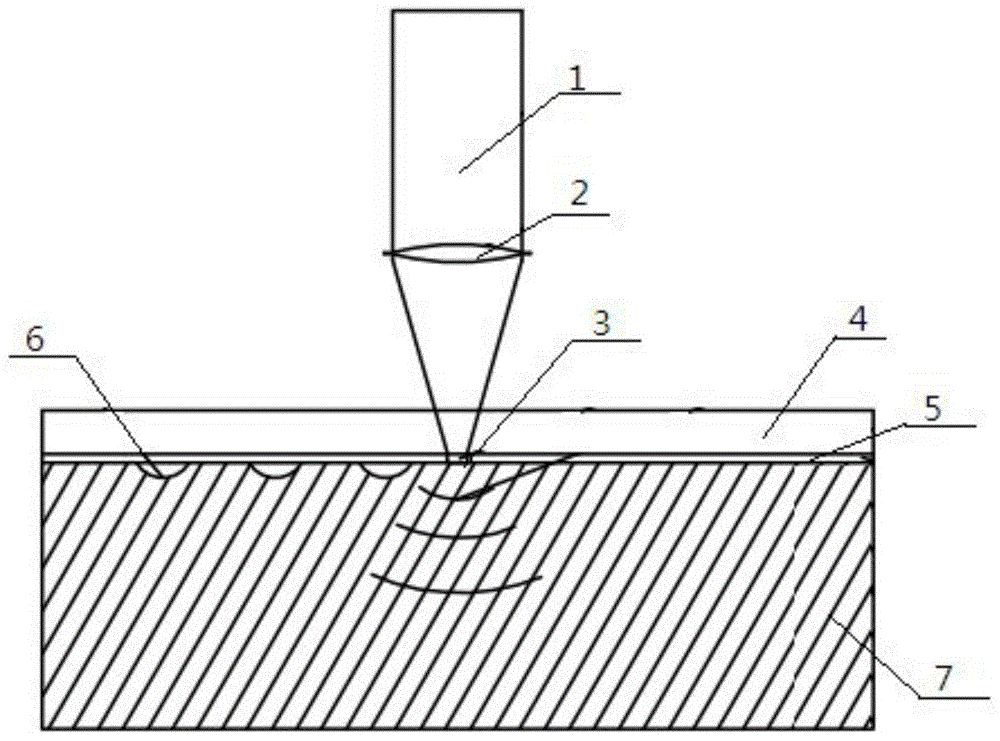

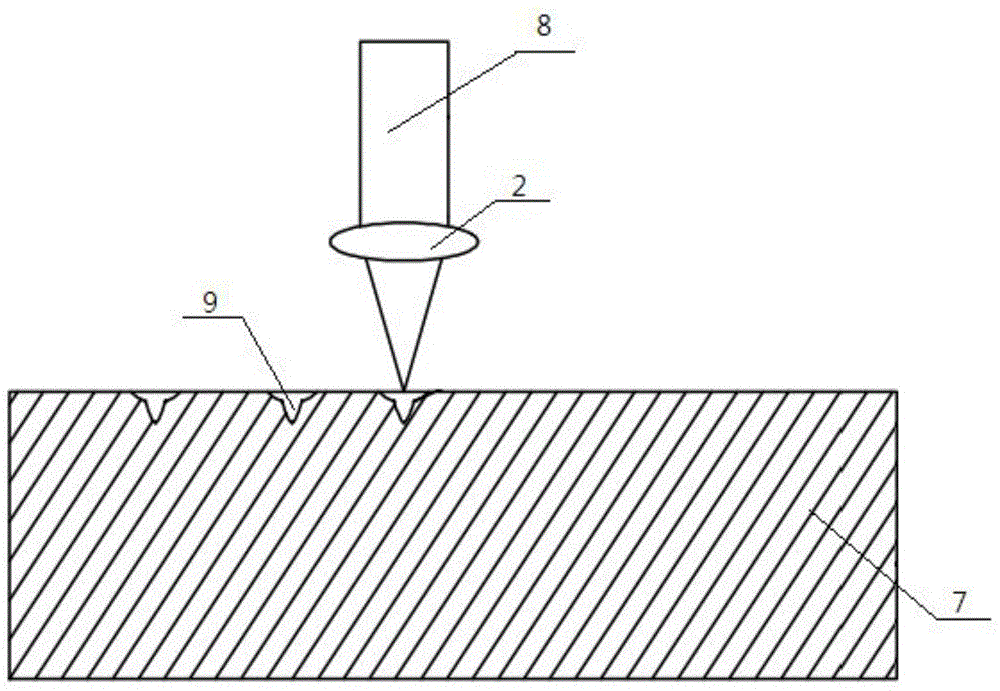

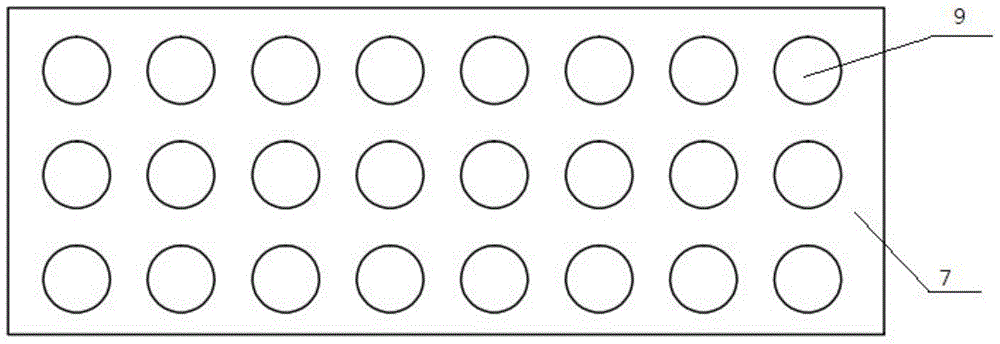

Method for obtaining antifriction and wear-resistant workpiece surface through lasers

InactiveCN105033461AImprove fatigue lifeReduce wearLaser beam welding apparatusWear resistantLight beam

The invention provides a method for obtaining an antifriction and wear-resistant workpiece surface through lasers. The method comprises the steps that laser micro-impact treatment is carried out, wherein the workpiece surface is coated with an absorption layer, the absorption layer is covered with a restraint layer, the technological parameters of a laser device are adjusted, laser beams irradiate the workpiece surface for impacting after being focused by a lens, and micro pits are obtained; laser micro drilling treatment is carried out, wherein the absorption layer and the restraint layer on the workpiece surface are removed, the laser device is replaced, laser drilling light beams are adjusted to be aligned to the centers of the micro pits, the technological parameters of the laser device are adjusted to carry out micro drilling treatment on a workpiece, then micro holes are obtained, and the relation between the laser spot diameter c in the micro drilling treatment process and the laser spot diameter C in the micro impacting process is c=(0.15-0.25)C; and the antifriction and wear-resistant workpiece surface is machined according to the number and distance of the obtained micro holes needed by the workpiece surface. The micro holes with the large diameter and large depth are machined, a lubricant is placed in the micro holes to reduce friction and wear of the contact surface of a friction pair, and then the wear resisting performance of the surface of the friction pair is improved.

Owner:JIANGSU UNIV

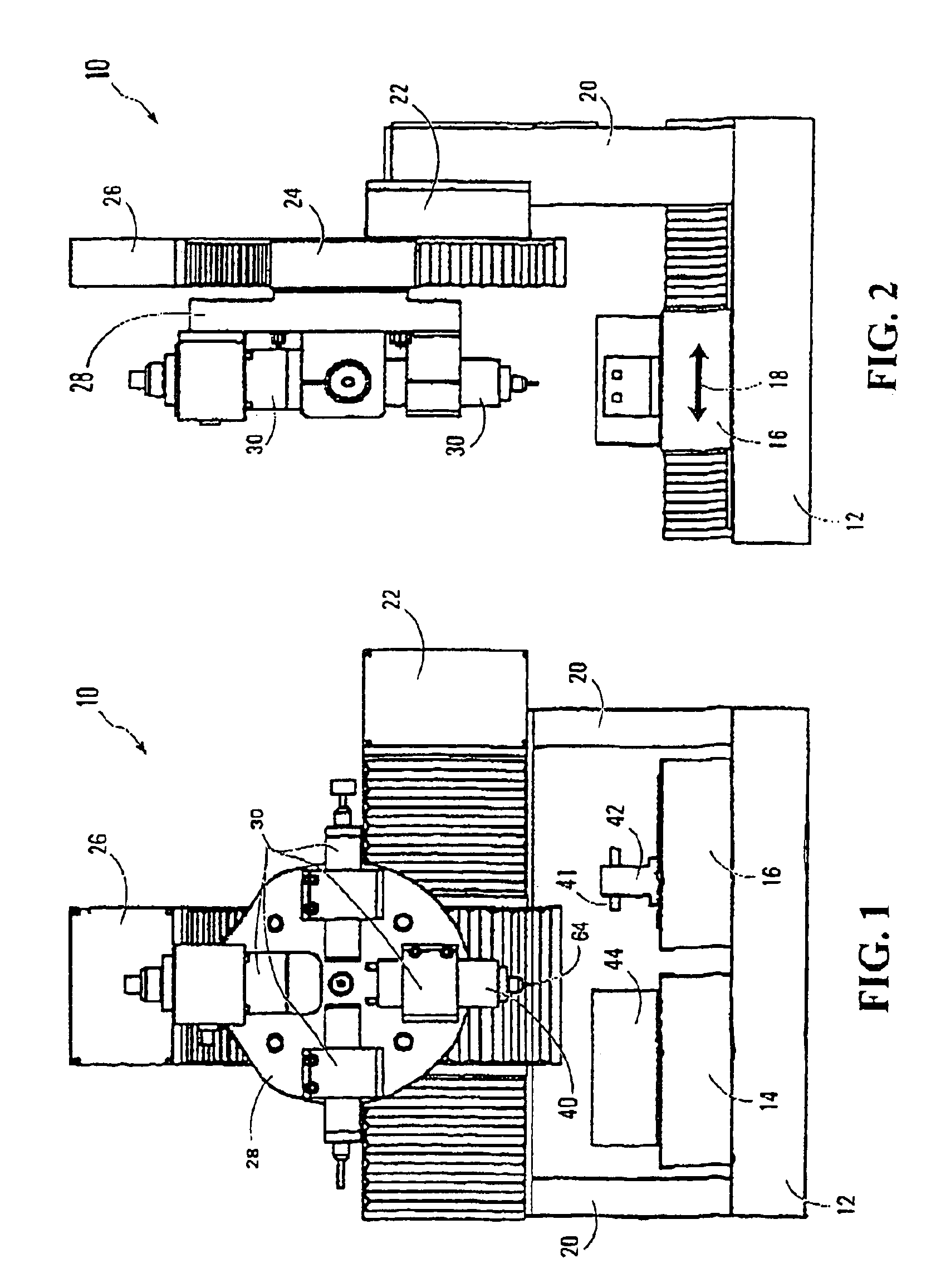

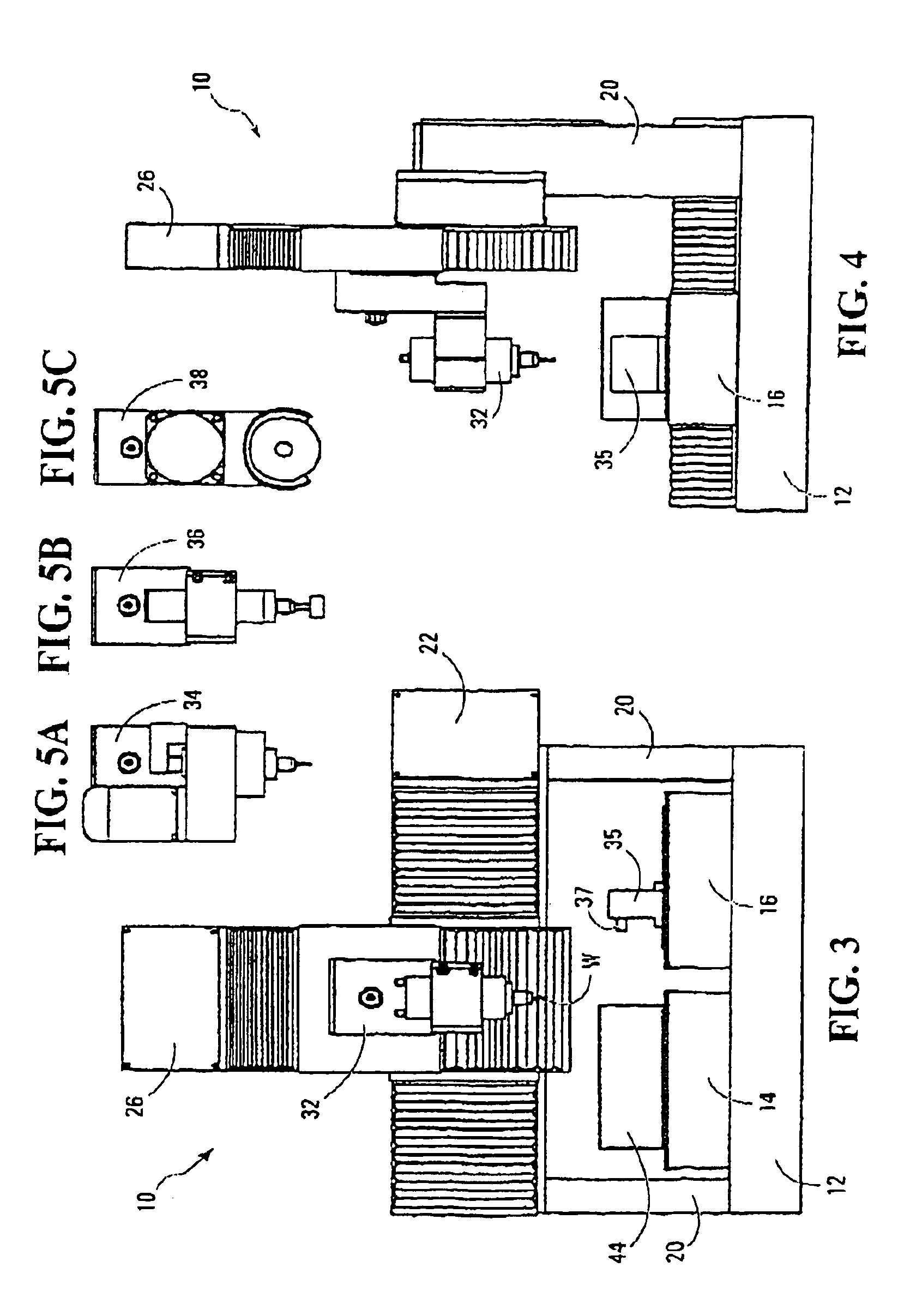

Compound fabrication process and apparatus

InactiveUS6935003B2Speed up the processHigh dimensional accuracyAutomatic/semiautomatic turning machinesElectrolysis componentsEngineeringMachine tool

A miniature machine tool for micro-machining is capable of performing on a workpiece at least one conventional mechanical machining operation and another micro-machining operation such as electrochemical machining (ECM), electro deposit machining (EDM), micro-milling or micro-turning or micro-drilling. The machine tool includes a holder in which the workpiece is clamped during all successive machining operations so that the machining operations may be performed in succession without intervening reclamping of the workpiece. This increases dimensional accuracy when micro-machining high-precision components.

Owner:NAT UNIV OF SINGAPORE

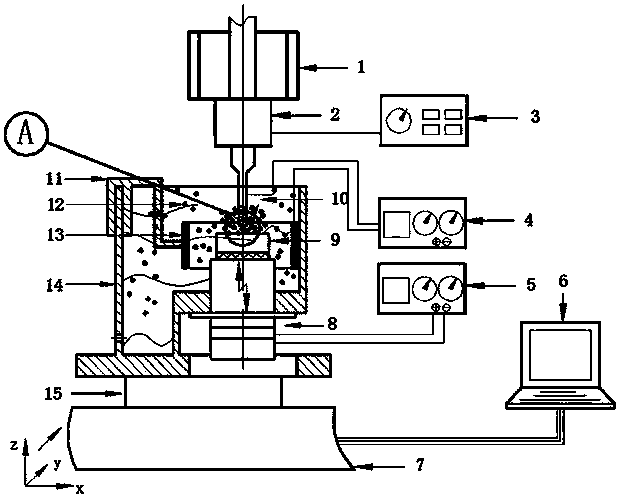

Electrophoretic assisted ultrasonic mechanical composite micro-drilling machining device

InactiveCN103909288APlay a grinding roleRealize Microhole MachiningBoring/drilling machinesElectrophoresisEngineering

The invention discloses an electrophoretic assisted ultrasonic mechanical composite micro-drilling machining device comprising a vertical slider, a micro ultrasonic spindle, a micro ultrasonic spindle power generator and a control panel thereof, an electrophoretic assisted power supply, a micro ultrasonic platform power generator and a control panel thereof, a micro three-dimensional motion platform, a micro ultrasonic operating platform, a drilling bit and an electrophoretic assisted electrode. In the ultrasonic vibration assisting micro-drilling machining process, the solution with supermicro abrasive particles is added, the micro drilling bit is provided with the assisting voltage through the electrophoretic circular assisting electrode, the assisting electric field is generated between the solution and the micro drilling bit to drive the micro abrasive particles to move or absorb the micro abrasive particles to the micro drilling bit, the binding force of the micro abrasive particles on the drilling bit can be regulated indirectly by regulating the voltage to allow the abrasive particles to grind workpieces, consolidated abrasive particles protect the drilling bit, cutter wearing is reduced, the abrasive particles are driven by ultrasonic vibrations to impact the workpieces, material removing efficiency is improved, and drilling machining efficiency is improved.

Owner:GUANGDONG UNIV OF TECH

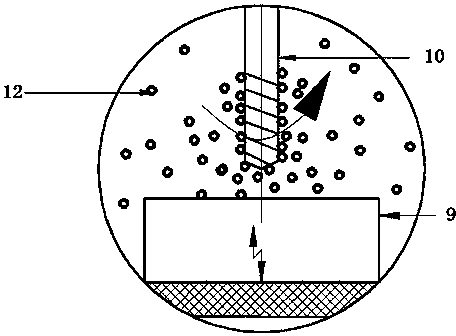

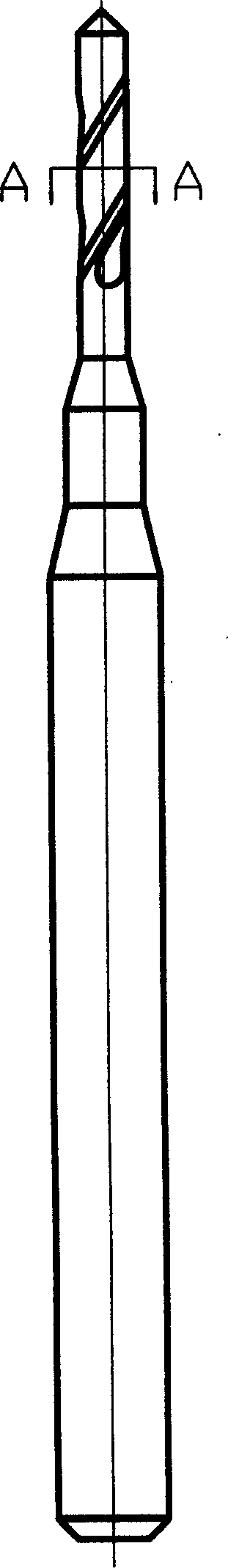

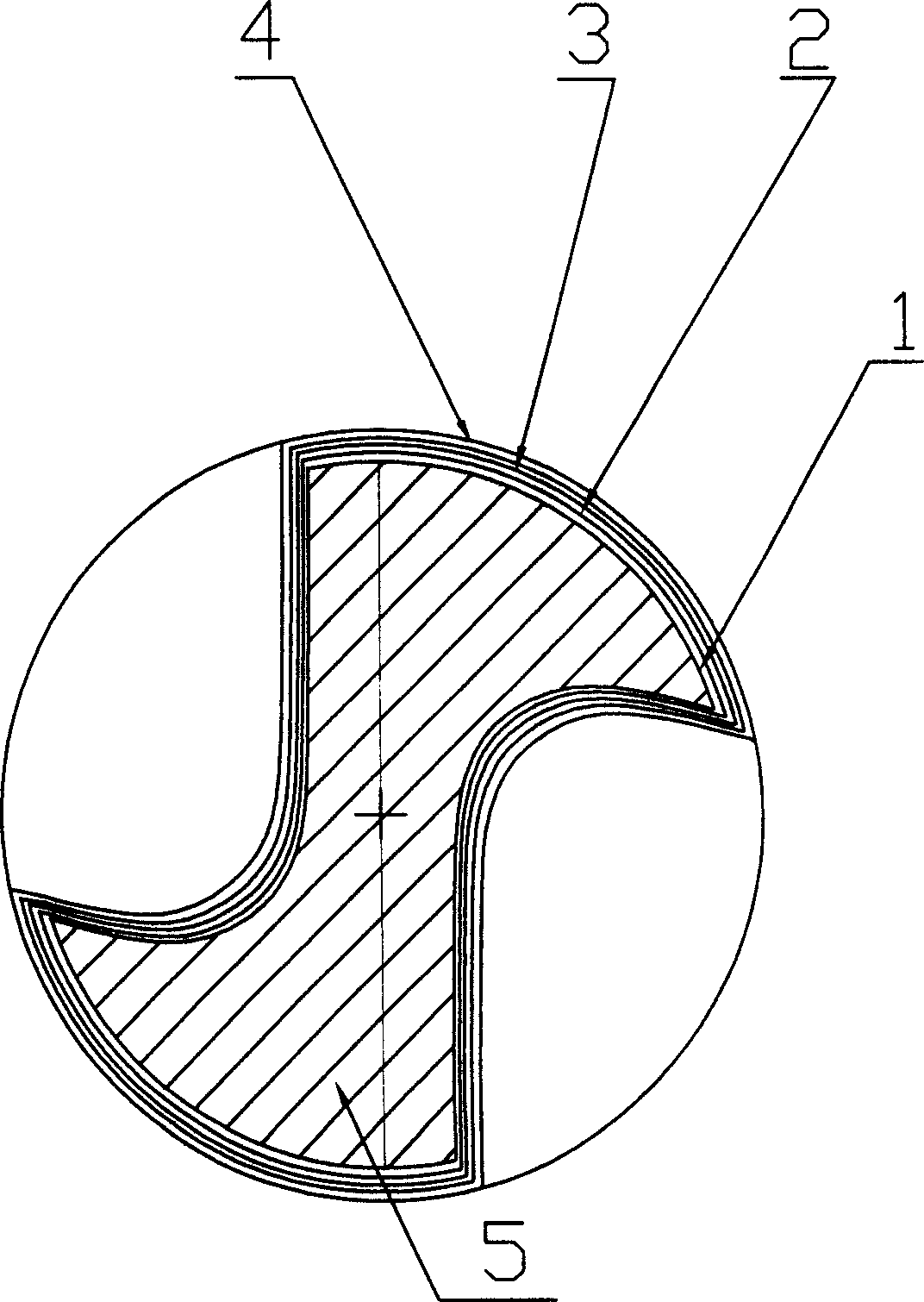

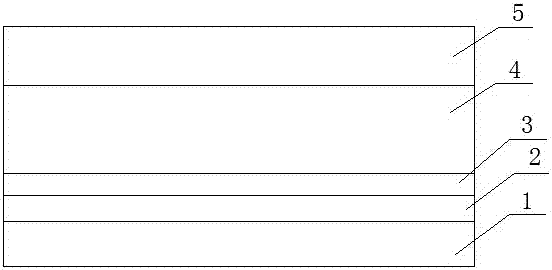

Superhard multi-layer composite diamond-like coating and preparation method thereof

InactiveCN107022740AReduce stressImprove adhesionVacuum evaporation coatingSputtering coatingChromiumDiamond

The invention discloses a superhard multi-layer composite diamond-like coating. The coating is sequentially composed of a micro drilling base body, a bottom bonding layer, a middle transition layer and a surface layer. The bottom bonding layer is a metallic titanium or metallic chromium layer, the middle transition layer is a low-hardness diamond-like film, and the surface layer is a composite diamond coating. The composite diamond coating is a titanium or titanium doped diamond-like coating. According to a preparation method of the superhard multi-layer composite diamond-like coating, the cathode filter electric arc technology, the ion beam technology and the vacuum sputtering technology are combined, and super-thick diamond-like composite coating deposition is achieved on a sample base. The obtained superhard diamond-like coating has the beneficial effects of being high in film base combination strength, low in internal stress, low in friction coefficient and long in service life.

Owner:GUANGDONG NAISENSE COATING TECH LTD

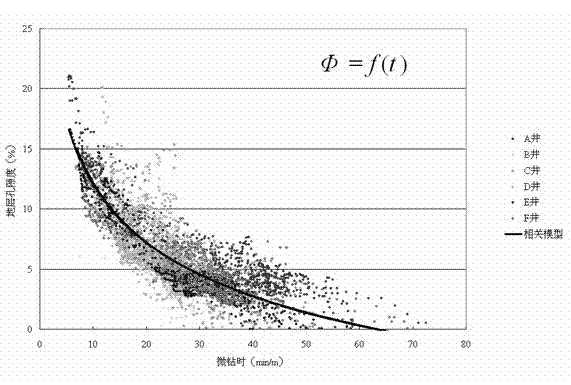

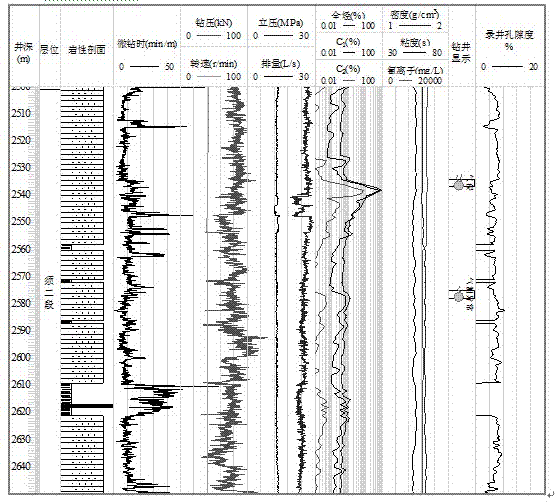

Method for reservoir assessment by calculating logging porosity while drilling by utilizing data during micro drilling

ActiveCN102900432AAchieving Quantitative InterpretationEffective evaluationBorehole/well accessoriesLower limitPorosity

The invention discloses a method for reservoir assessment by calculating logging porosity while drilling by utilizing data during micro drilling. The method comprises the following steps of: (a) collecting data during the micro drilling of drilled wells; (b) establishing a correlation model of the data during the micro drilling and formation porosity data by combining the data during the micro drilling of the drilled wells and the corresponding formation porosity data; (c) according to the established correlation model of the data during the micro drilling and the formation porosity data, calculating the logging porosity while drilling by utilizing data during the micro drilling of a well drilled at present; and (d) setting a formation porosity of a conventional dense lithological section to be a default which is lower than the lower limit standard of the formation porosity by combining with cutting logging data to finish the reservoir assessment. According to the method, the calculation of the logging porosity during drilling is realized, the real-time evaluation of reservoir during drilling is strengthened, steps are simple and easy to apply, and the logging porosity can be quantitatively calculated for carrying out the reservoir assessment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Intelligent micro drilling machine

ActiveCN103758453AEasy constructionImprove construction qualityDerricks/mastsDrilling machines and methodsPower stationMoment of inertia

The invention discloses an intelligent micro drilling machine, and belongs to the field of engineering machines. According to the intelligent micro drilling machine, a walking mechanism is provided with a main machine platform, the main machine platform is provided with a control box and a turning pair, the turning pair is connected with a stretching mechanism, and the stretching mechanism is connected with a mast. The main machine platform is connected with a power station through a connecting bridge, and the power station is communicated with the control box through a connecting pipeline. A turning pair front-mounted structure is arranged at the front end of the main machine platform, and a clamping offset mechanism is arranged on the mast. According to the intelligent micro drilling machine, the wing span of a drilling machine arm can be moved forward for a distance, construction in narrow areas is facilitated, the rotational inertia of a revolute pair when the revolute pair rotates is lowered, the drilling machine is made to be more stable and save more energy, the interference between a steel wire rope and a power head when a drilling pipe is hung is avoided, the drilling pipe can be mounted conveniently, working efficiency can be improved, selection on energy supply by the drilling machine is increased, and construction is facilitated.

Owner:KIMTEK IND

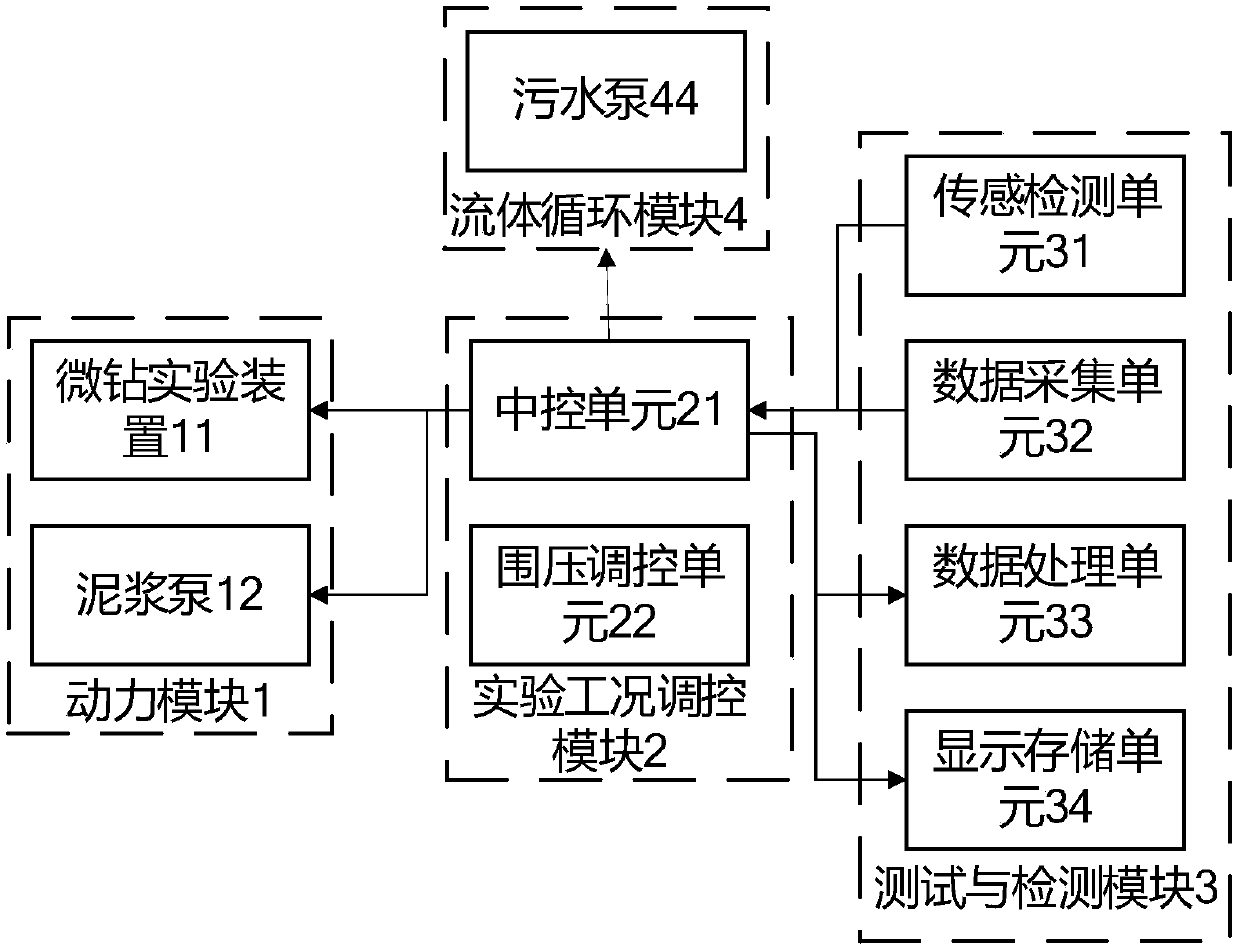

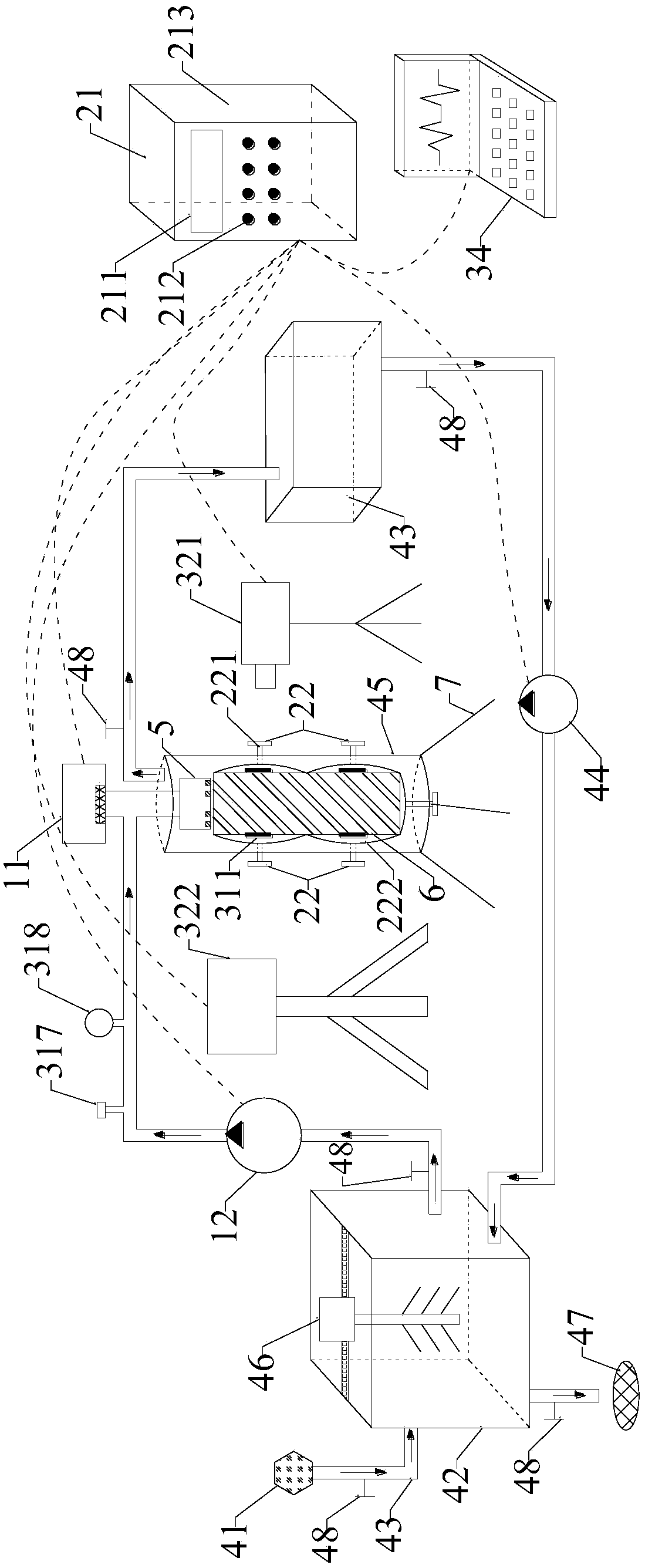

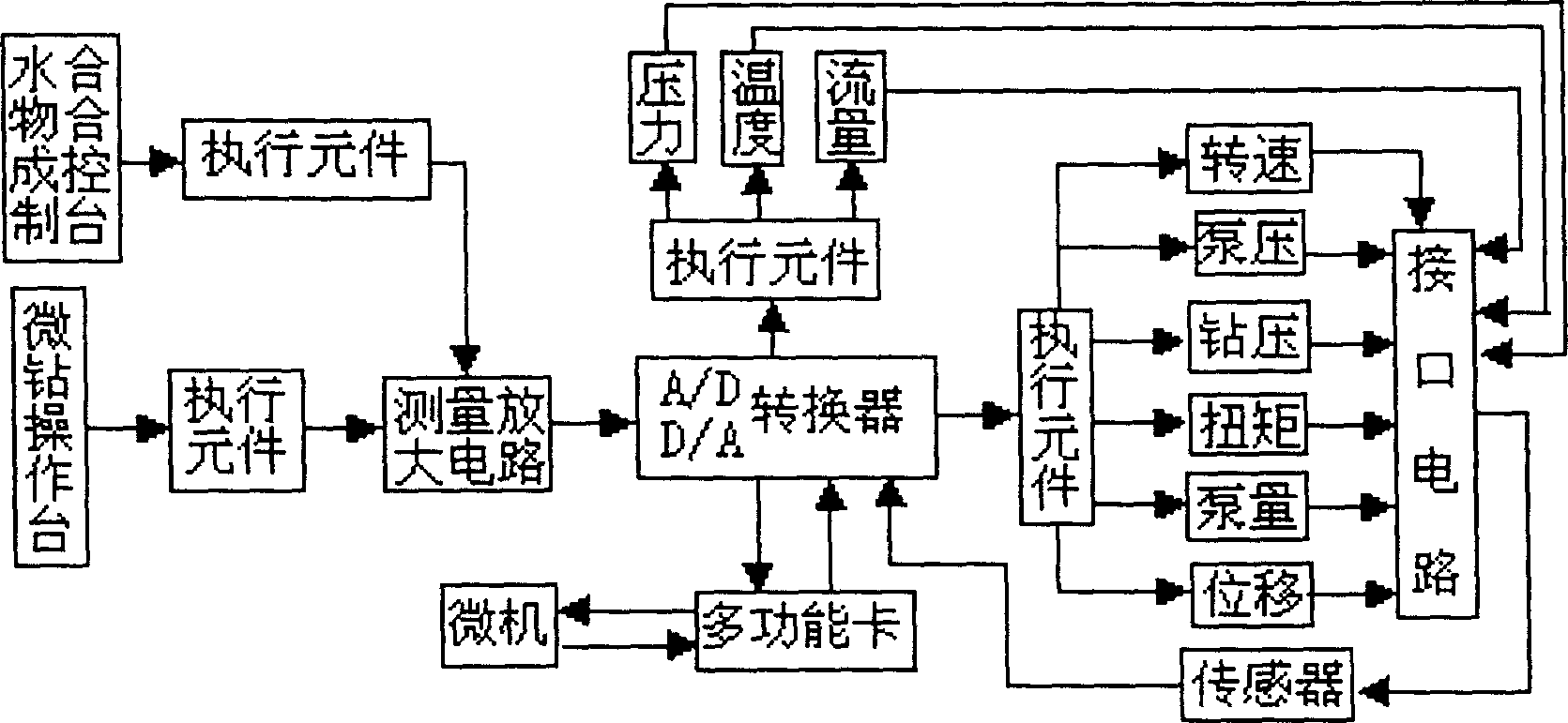

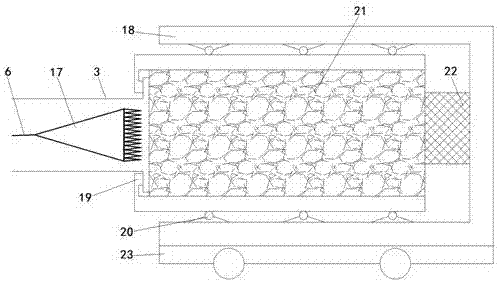

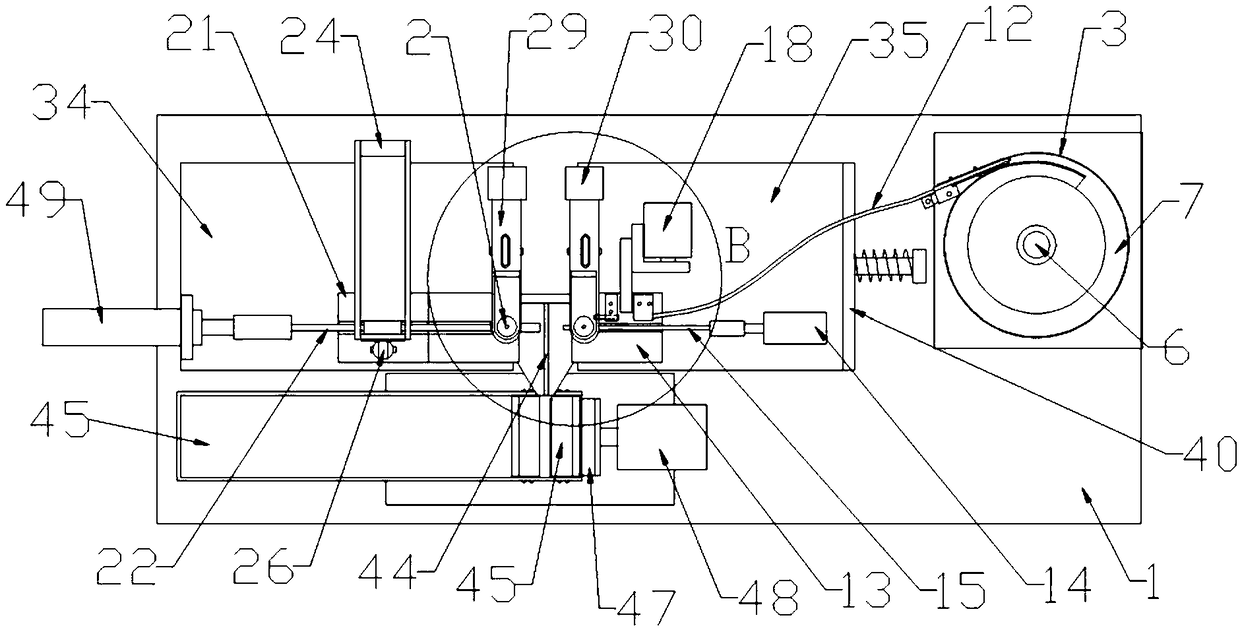

Multifunctional test and experiment platform for desk research of jet drilling

PendingCN107893634ARealize automatic controlReasonable optimization of jet drilling parametersLiquid/gas jet drillingEngineeringScientific study

The invention relates to a multifunctional test and experiment platform for a desk research of jet drilling. The multifunctional test and experiment platform for the desk research of the jet drillingcomprises a power module, an experimental condition control module, a test and detection module, a fluid circulation module, and a drilling assembly. The power module comprises a micro-drilling experiment device and a mud pump; the experimental condition control module comprises a center control unit and a confining pressure control unit; the test and detection module comprises a sensing detectionunit, a data acquisition unit, a data processing unit, and a display storage unit; and the fluid circulation module comprises a water faucet, a water tank, a sedimentation and a filtration ditch, a sewage pump, and a simulation wellbore with an opened upper end and a sealed and transparent lower end. According to the multifunctional test and experiment platform for the desk research of the jet drilling, a practical jet drilling process can be simulated in a laboratory, and necessary conditions can be created for carrying out the laboratory experiment of the jet drilling; and automatic controlcan be achieved in an experiment process, the non-visual jet drilling process in the underground can be visualized, and a semi-empirical research is transferred into a scientific and quantified research.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY +1

Hard film layer dedicated for micro-bore of flexible printed circuit board

InactiveCN1864900AImprove machining accuracyImprove processing efficiencyTransportation and packagingCeramic layered productsEngineeringTitanium

The invention relates to a right film of micro drilling head used to drill the soft board of printed circuit board. It is characterized in the improvement of micro drilling special rigid film. Wherein, said film should have better abrasion and high-temperature resistant properties, to improve the quality and service life of drilling hole, and improve the processing efficiency of printed circuit board and reduce the producing cost. The preparation comprises: its base material is the general drilling head, whose surface has at least three films as transition layer that contains chrome, nitride transition layer that contains chrome and nitride chrome, nitride rigid abrasion resistant layer that contains nitride chrome, from inner to outer. Said transition layer, nitride transition layer and nitride rigid abrasion resistant layer can be added with titanium and aluminum, while the nitride transition layer comprises the inner mixed layer and the outer mixed layer.

Owner:浙江汇锦梯尔镀层科技有限公司

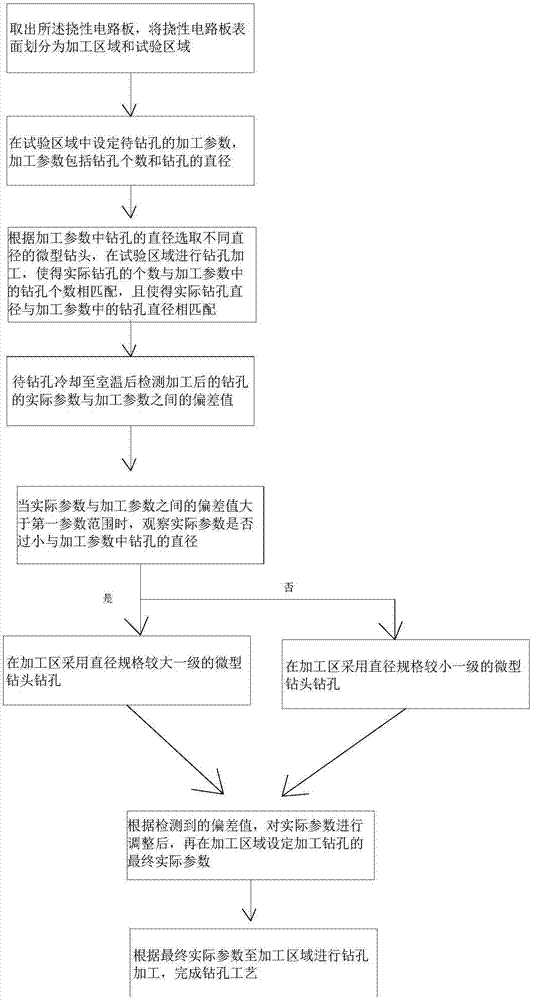

Micro-drilling method for flexible circuit board

InactiveCN107889357AImprove effectivenessHigh precisionPrinted circuit manufactureBoring/drilling machinesFlexible circuitsRoom temperature

The invention relates to a micro-drilling method for a flexible circuit board, and the method comprises the steps: taking out the flexible circuit board, and dividing the surface of the flexible circuit board into a processing region and a test region; setting the processing parameters of a to-be-drilled hole in the test region, wherein the processing parameters comprise the number of drill holesand the diameters of the drill holes; selecting miniature drill bits with different diameters according to the diameters of the drill holes in the processing parameters, carrying out the processing ofthe drill holes in the test region, enabling the number of actual drill holes to be matched with the number of the drill holes in the processing parameter, and enabling the diameters of the actual drill holes to be matched with the diameters of the drill holes in the processing parameter; detecting the deviation between the actual parameters of the processed drill holes and the processing parameters after the drill holes are cooled to room temperature; carrying out the adjustment of the actual parameters according to the detected deviation, and then setting the final actual parameters for theprocessing of the drill holes in the processing regions; carrying out the drill hole processing in the processing region according to the final actual parameters, and completing the drilling technology.

Owner:TAIZHOU BOTAI ELECTRONICS

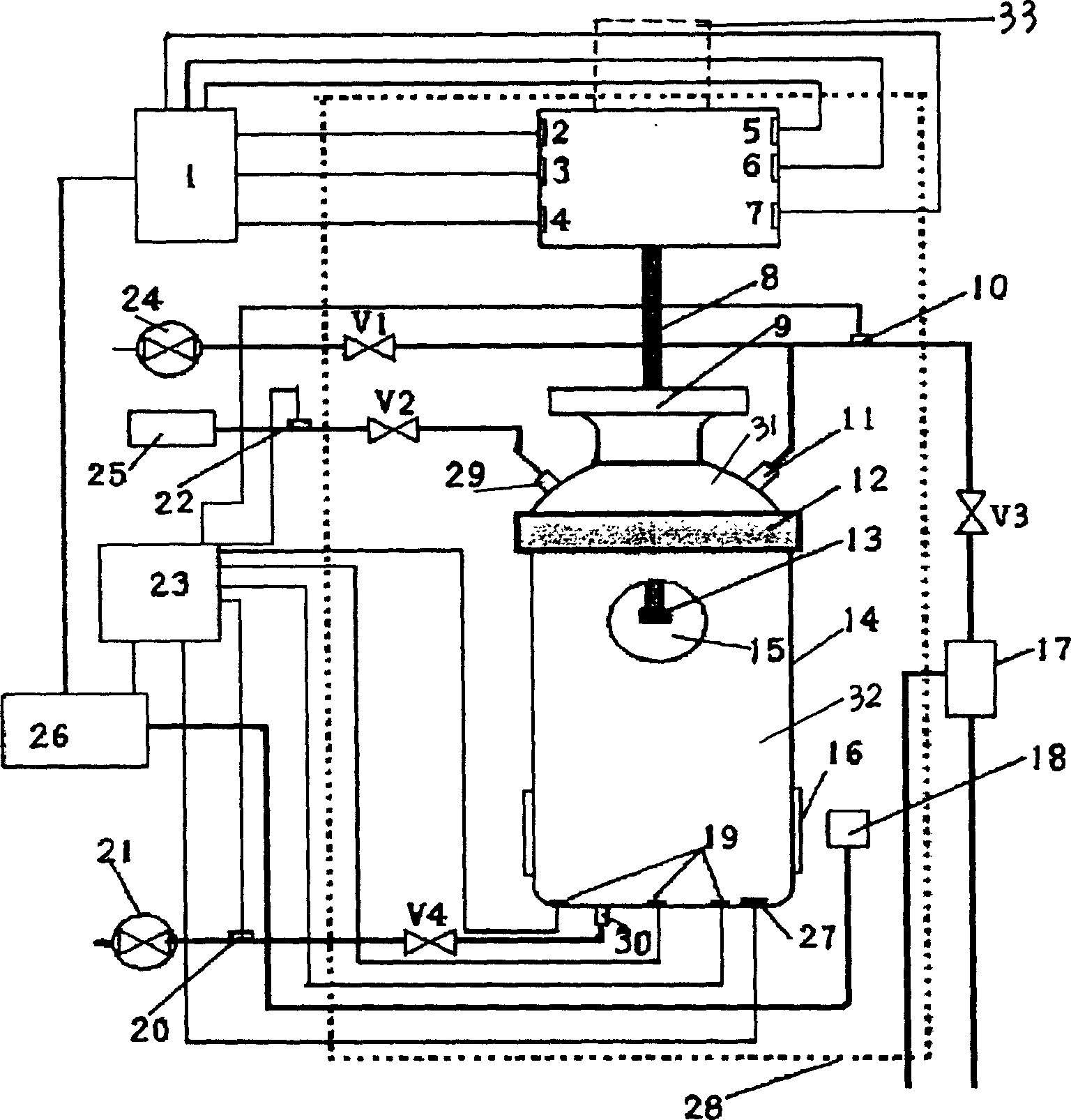

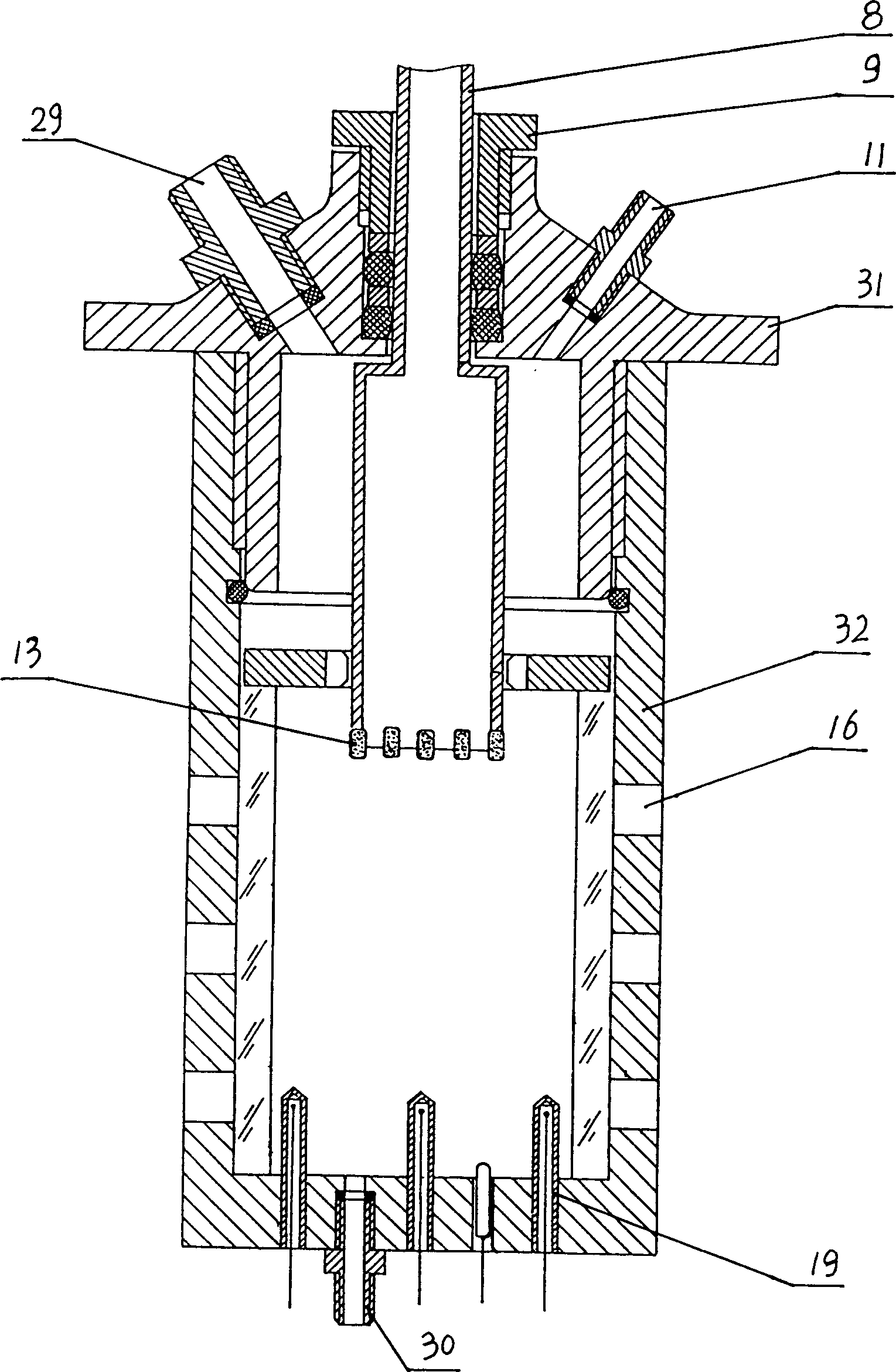

Comprehensive test equipment for natural gas hydrate

InactiveCN1176741CVersatileHigh degree of automationChemical/physical/physico-chemical processesData acquisitionVacuum pump

The comprehensive test equipment for natural gas hydrate consists of gas supplying and pressurizing unit, vacuum pump and gas / liquid separating and collecting unit, reactor, high and low temperature test box, mini drilling system with mini drilling machine and drilling rod, detection system, microphotography system, data collecting system, microcomputerized data processing system connected together. The equipment may be used in simulating synthesis research and decomposing test research as well as in the research of drilling control and exploiting method, etc.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for preparing superfine hard alloy

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

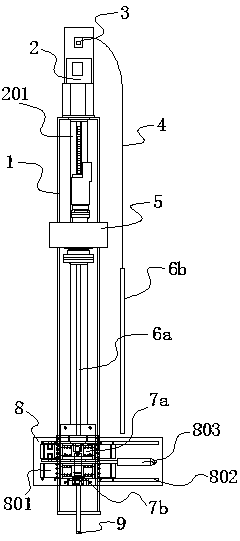

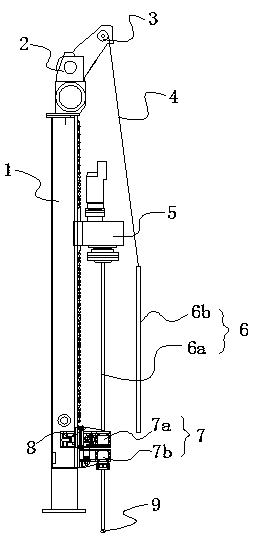

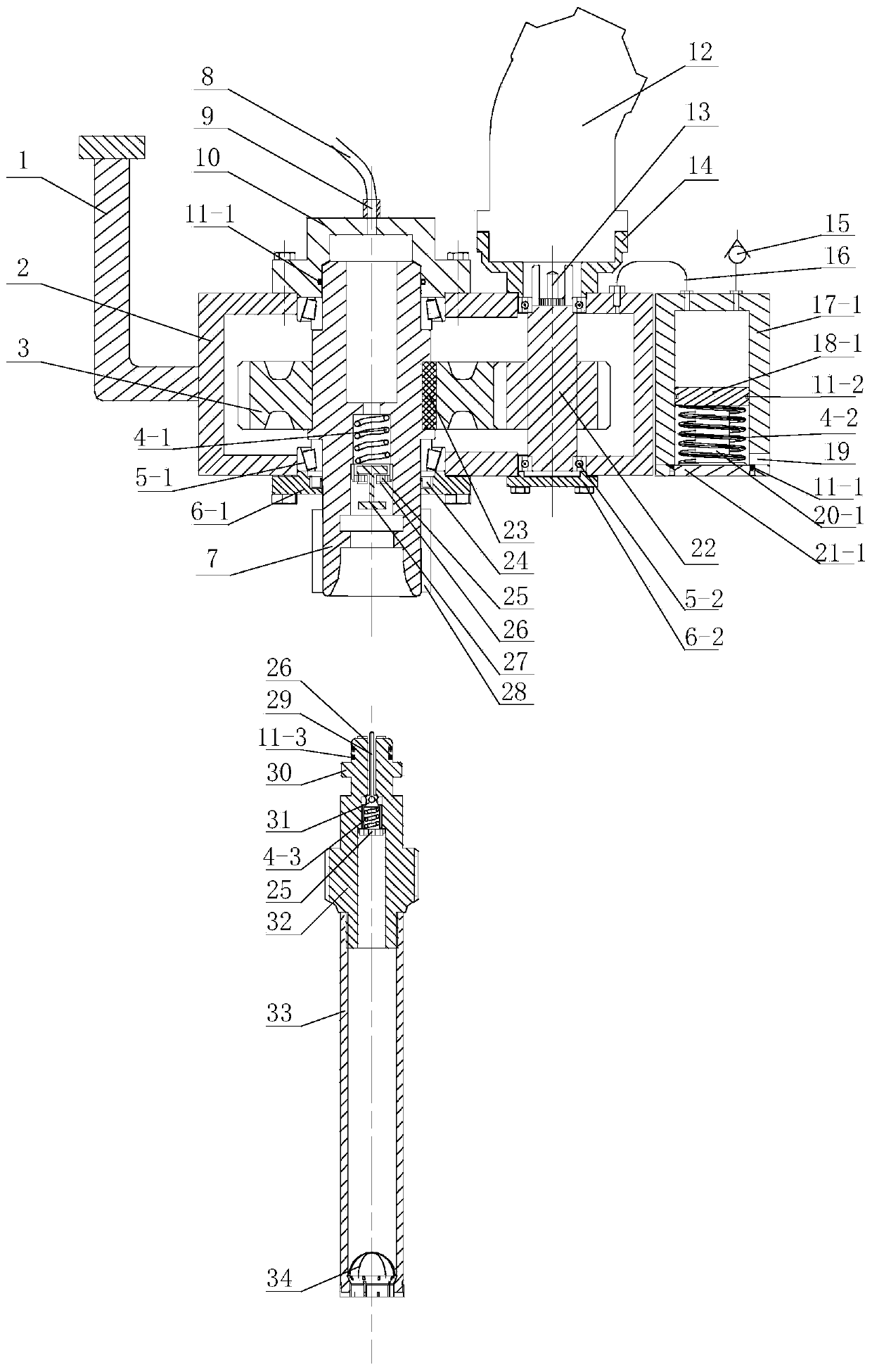

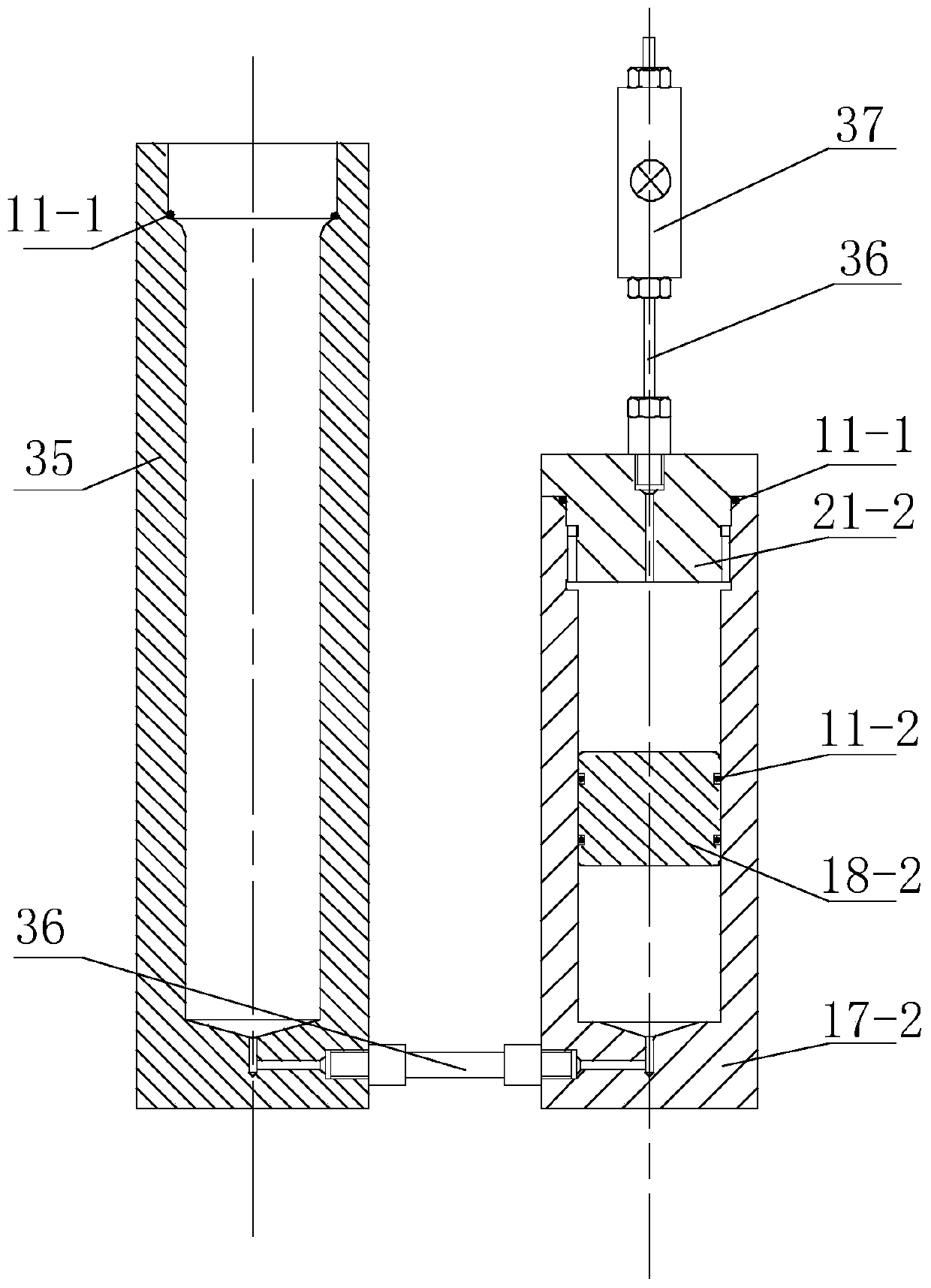

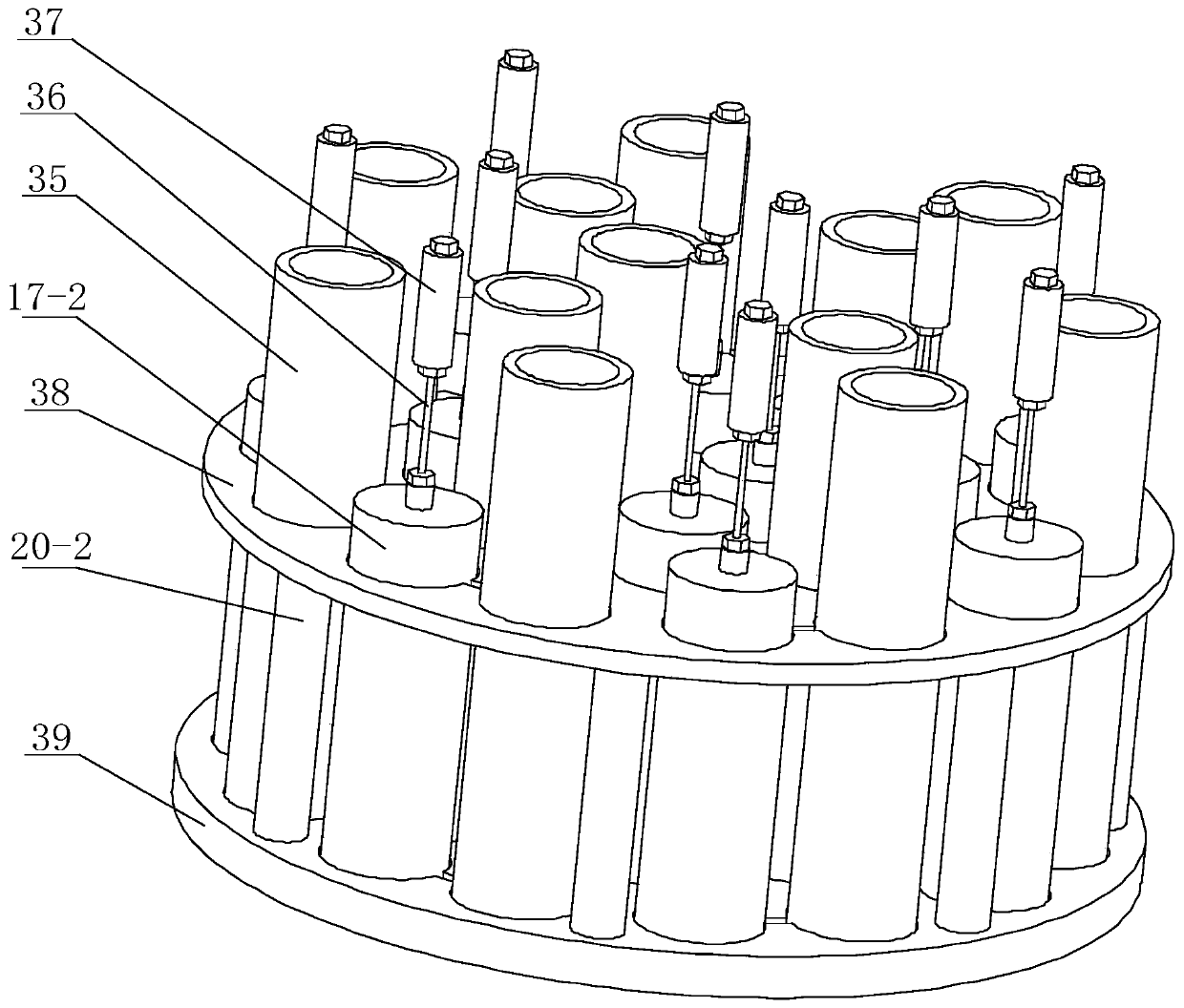

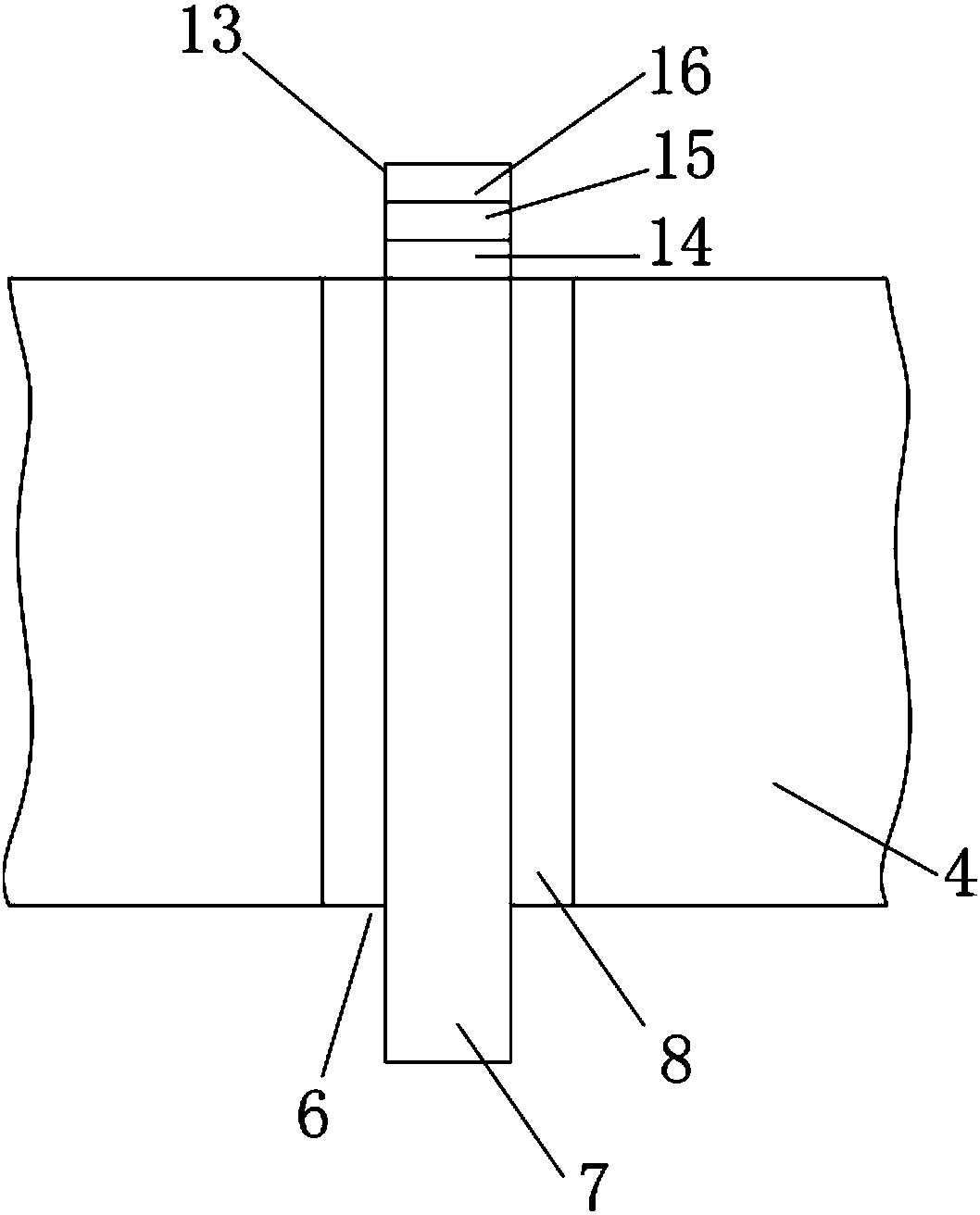

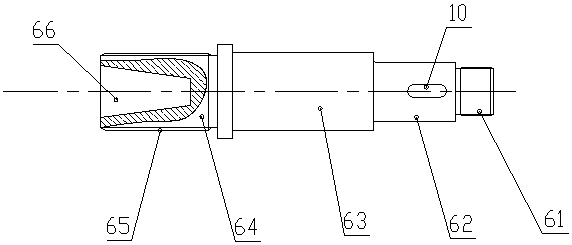

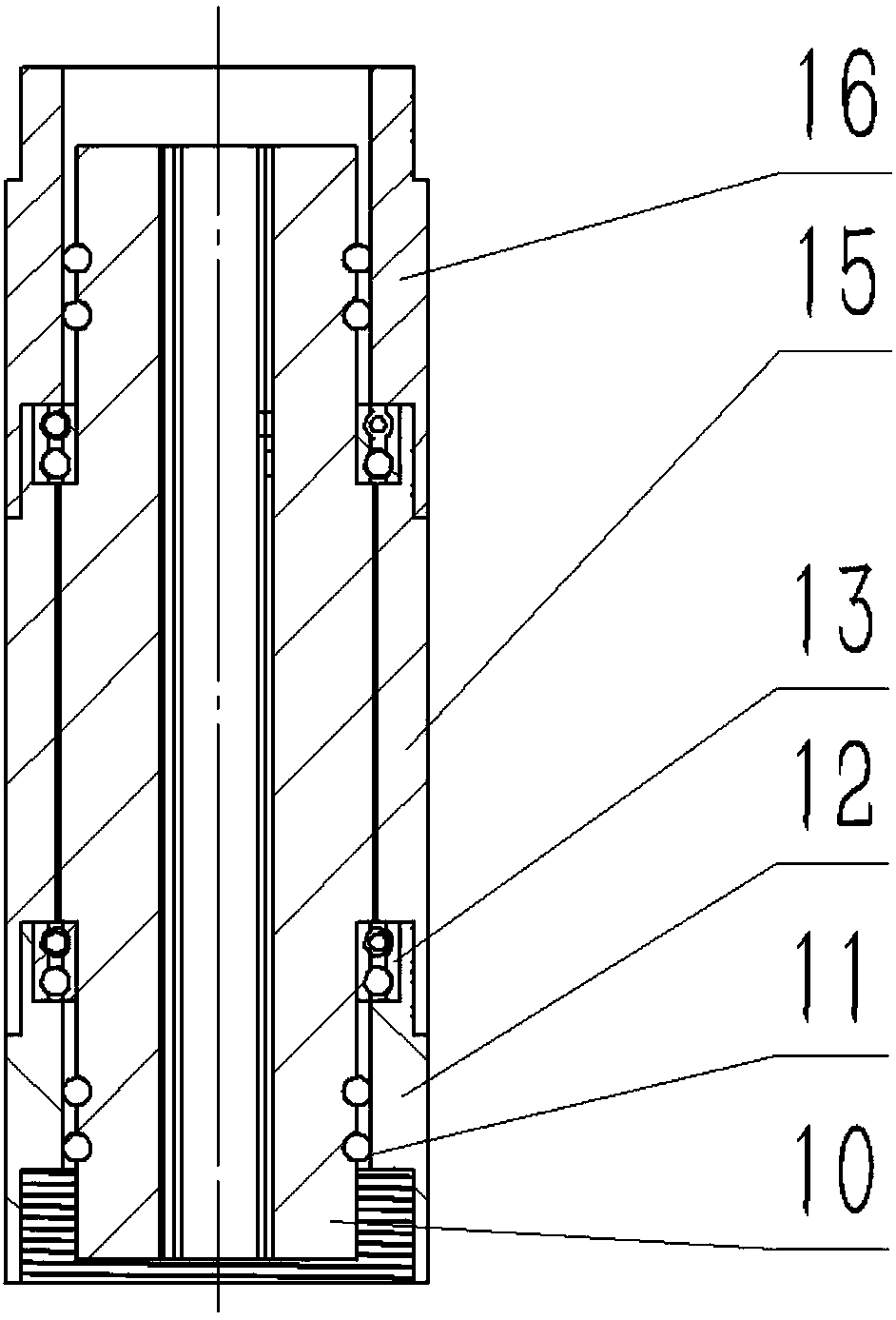

Seabed hard rock multi-point pressure-maintaining coring micro drilling machine

PendingCN111119737AEnsure safetyRealize pressure-holding coringUnderwater drillingCore removalMining engineeringMicro drilling

The invention discloses a seabed hard rock multi-point pressure-maintaining coring micro drilling machine. The seabed hard rock multi-point pressure-maintaining coring micro drilling machine comprisesa handle, a power head, a reduction gearbox, a drilling tool discarding device, a drilling tool, a pressure compensator, a rock placing rack and a rock core pressure maintaining device; a water supply joint and the power head are installed on the top plate of the reduction gearbox, the output shaft of the power head is connected with the input shaft of the reduction gearbox, a central hole is formed in the output shaft of the reduction gearbox, and the central hole communicates with a water inlet hole of the water supply joint; and a lower inner cavity is provided with a hanging clamp groove,and is connected with a drill through a discardable connecting shaft with a hanging clamp. The seabed hard rock multi-point pressure-maintaining coring micro drilling machine is simple and compact instructure, small in volume and high in reliability, and can be mechanically held by hands, and the drilling tool can be discarded in an emergency; and the safety of a submersible is ensured, and thecost of fault maintenance is lowered. The obtained rock core is stored in a pressure maintaining cylinder, and the multi-point pressure maintaining coring of the surface hard rock on the seabed can beachieved.

Owner:HUNAN UNIV OF SCI & TECH

Ceramic-based vertical micro-thin probe-card connecting opening MVW structure

ActiveCN109490588AReduce volumeShort preparation cycleElectrical measurement instrument detailsElectrical testingEpoxyCopper plating

The invention discloses a ceramic-based vertical micro-thin probe-card connecting opening MVW structure. The ceramic-based vertical micro-thin probe-card connecting opening MVW structure comprises a reinforcement plate, a PCB mainboard, a grounding plate, a ceramic substrate, a power board, a micro drilling hole, a micro-thin metal wire, epoxy resin, PPS1 power contacts, PPS2 power contacts, grounding contacts, signal contacts, a contact plating, a copper plating, a nickel plating, a gold plating, a vertical probe card head, a probe and the like; the ceramic-based vertical micro-thin probe-card connecting opening MVW structure is characterized in that the vertical probe-card connecting system MVW structure is small in whole connecting base size, short in making period and low in cost; thelarge-current high-frequency test requirement can be met, and the reliability is improved. The vertical probe card head is in direct mechanical connection with the PCB mainboard, the circuit distanceis short, the transmission speed is high, the frequency is high, simple assembling is achieved, the structure can be reused, and can also be repaired after abrasion, contact portions are polished andsubjected to gold plating anew, and repairing is convenient and fast and easy and convenient; the defects of the prior art are overcome.

Owner:无锡旺矽科技有限公司

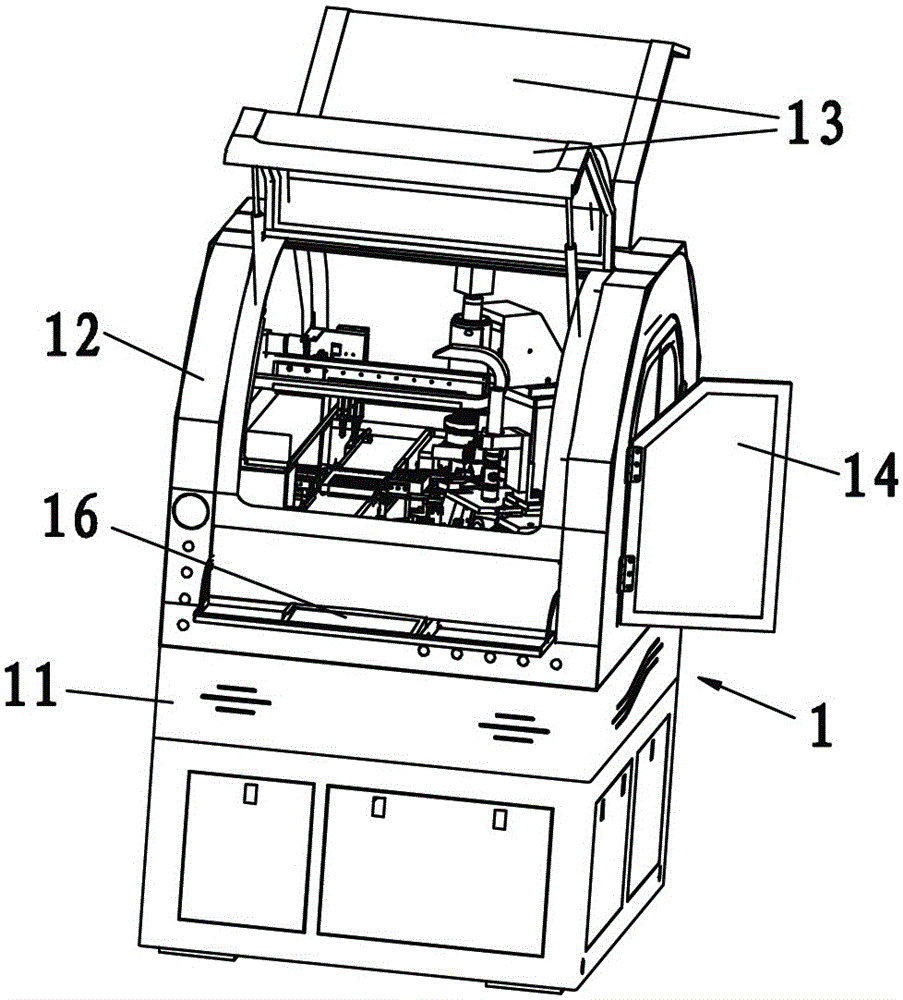

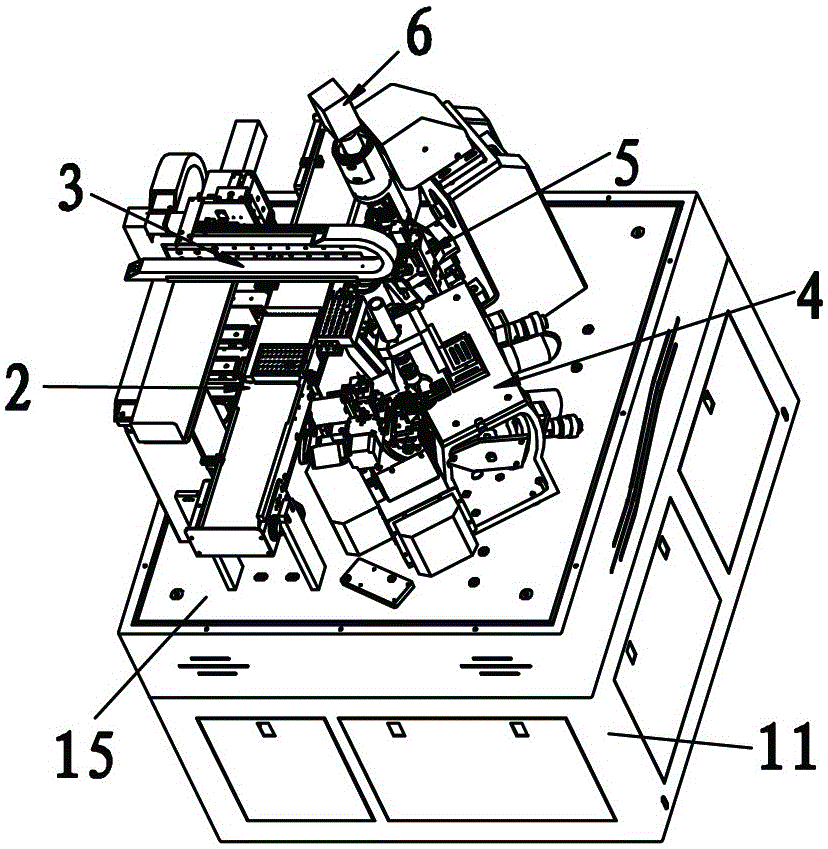

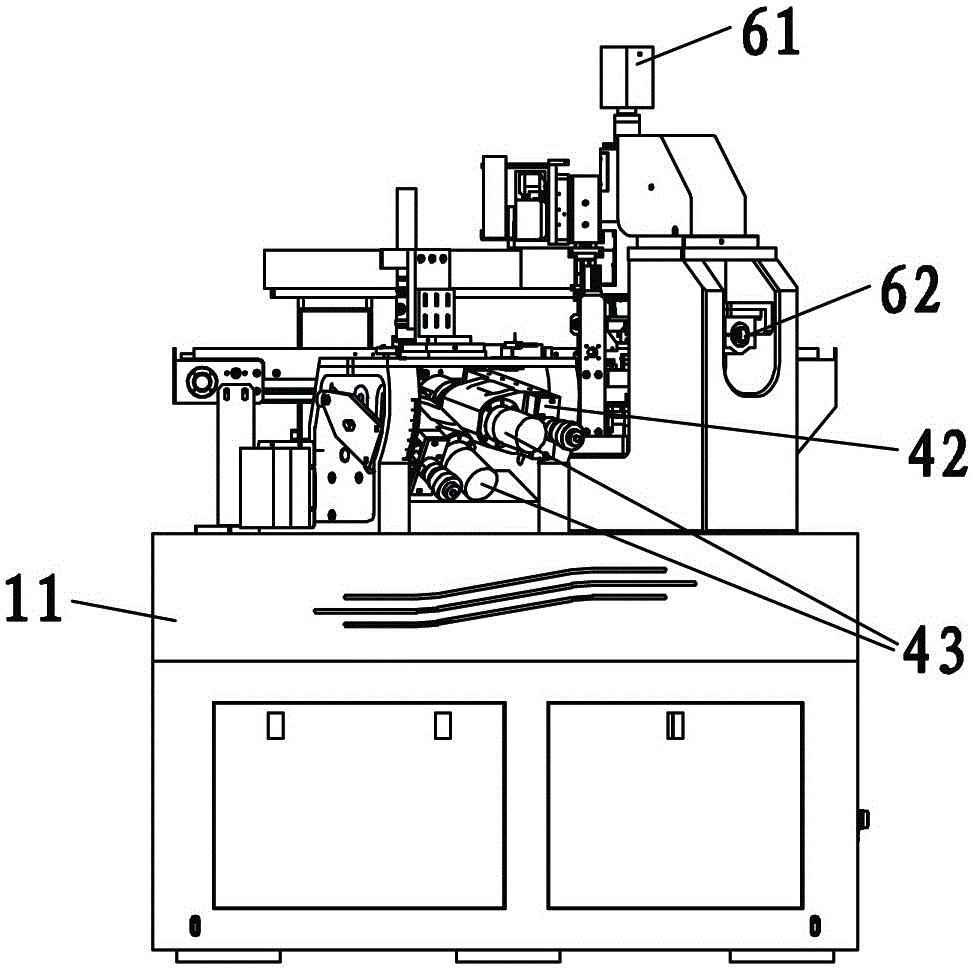

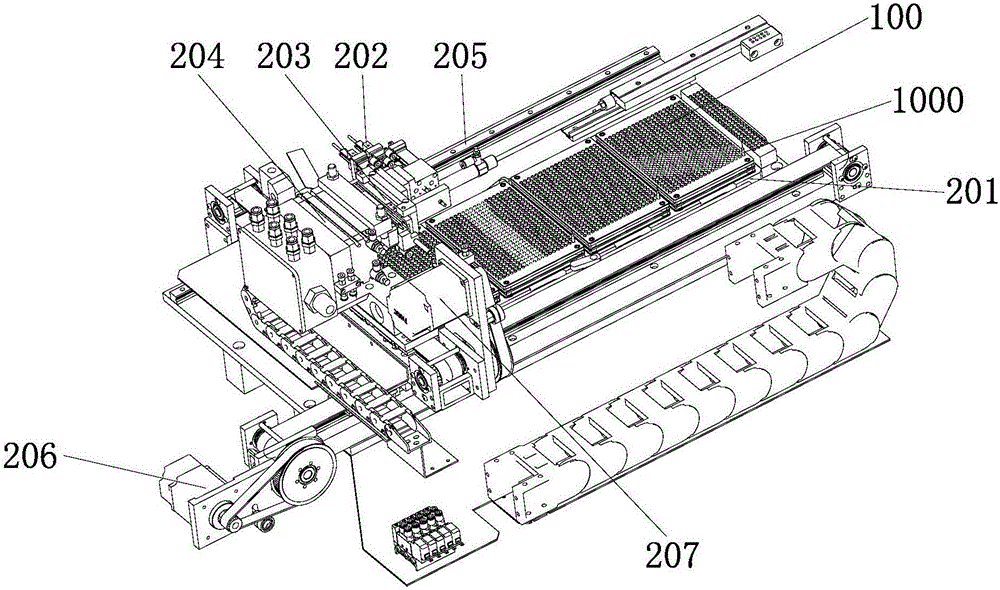

Full-automatic micro drilling grinder

ActiveCN105081899AImprove performanceSave human effortGrinding carriagesGrinding drivesBiochemical engineeringManipulator

The invention belongs to the technical field of grinders, and in particular, relates to a full-automatic micro drilling grinder. The full-automatic micro drilling grinder comprises a frame, a conveying mechanism, a manipulator mechanism, a grinding mechanism, a cleaning mechanism and a detecting mechanism, wherein the conveying mechanism, the manipulator mechanism, the grinding mechanism, the cleaning mechanism and the detecting mechanism are all arranged on the frame; the manipulator mechanism is arranged above the conveying mechanism; the grinding mechanism is corresponding to the conveying mechanism; and the cleaning mechanism and the detecting mechanism are arranged at one side of the grinding mechanism in sequence. The full-automatic micro drilling grinder is stable in performance, saves labors, improves the efficiency, reduces the production cost, improves the product pass percent, and solves the problems of great errors, low yield and high production cost in the drill point machining of the prior art.

Owner:GUANGDONG UCAN ROBOT TECH CO LTD

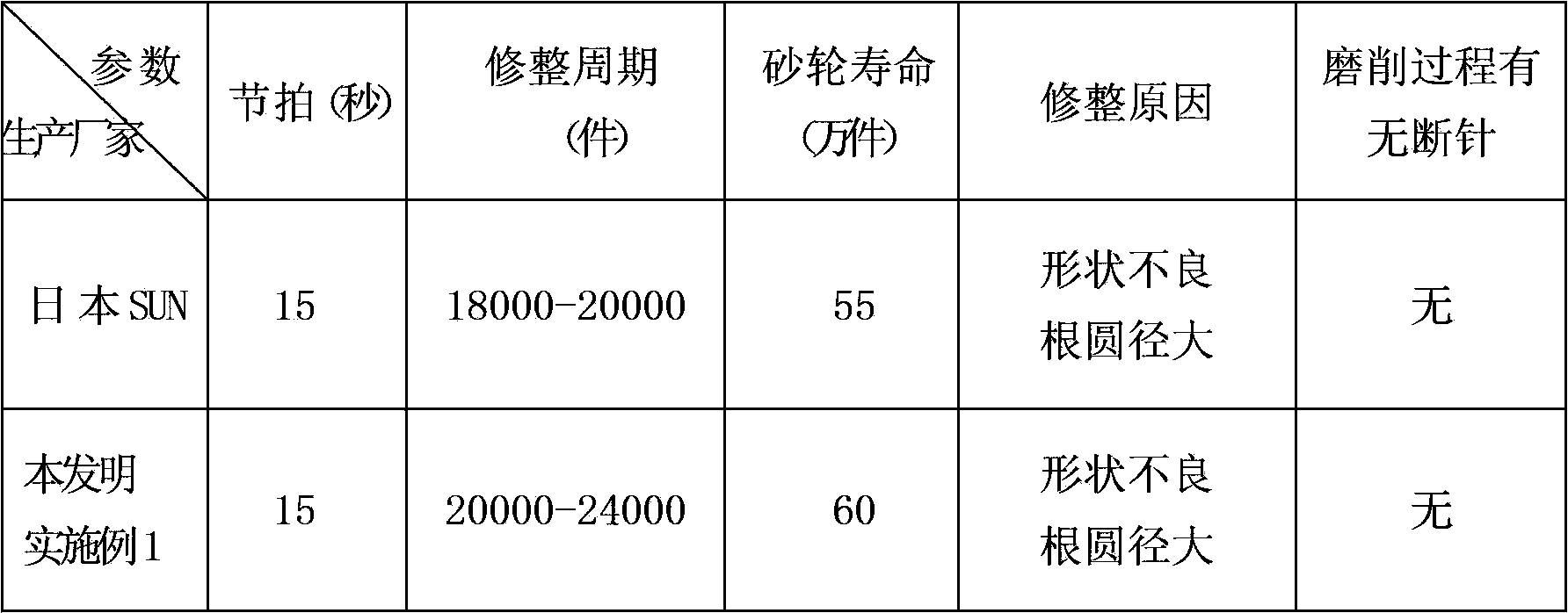

High-precision resin diamond micro-drilling excircle grinding wheel and application

ActiveCN103567889AImprove toughnessReduce needle breakageAbrasion apparatusDrilling toolsEngineeringGrinding wheel

The invention discloses a high-precision resin diamond micro-drilling excircle grinding wheel and an application. By means of the grinding wheel and the application, the problem that product machining efficiency is low, rejection rate is high, a cutting edge is not sharp and the like due to the fact that a printed circuit board (PCB) drill material is high in hardness, abrasion resistance and brittleness and small in drill edge diameter (0.10-6.50mm) and the like is solved. The grinding wheel is composed of a base body and a work grinding material layer. The work grinding material layer comprises, by weight, 50-70% of resin binder, 10-20% of white corundum, 1-5% of nanoscale MgO, 5-15% of copper powder, 1-10% of nanoscale TiO2, 10-20% of diamond and 5-10% of CBN. The grinding wheel has the advantages of being high in grinding efficiency; being good in grinding wheel shape retention and high in abrasion resistance; being low in grinding temperature and good in heat conduction; being high in ground workpiece precision and sharp in cutting edge; greatly reducing rejection rate caused by needle breaking.

Owner:沈阳中科超硬磨具磨削研究所

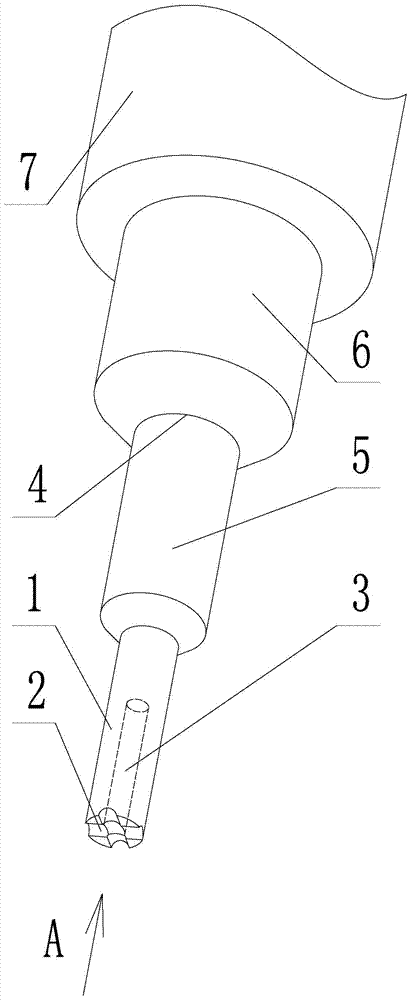

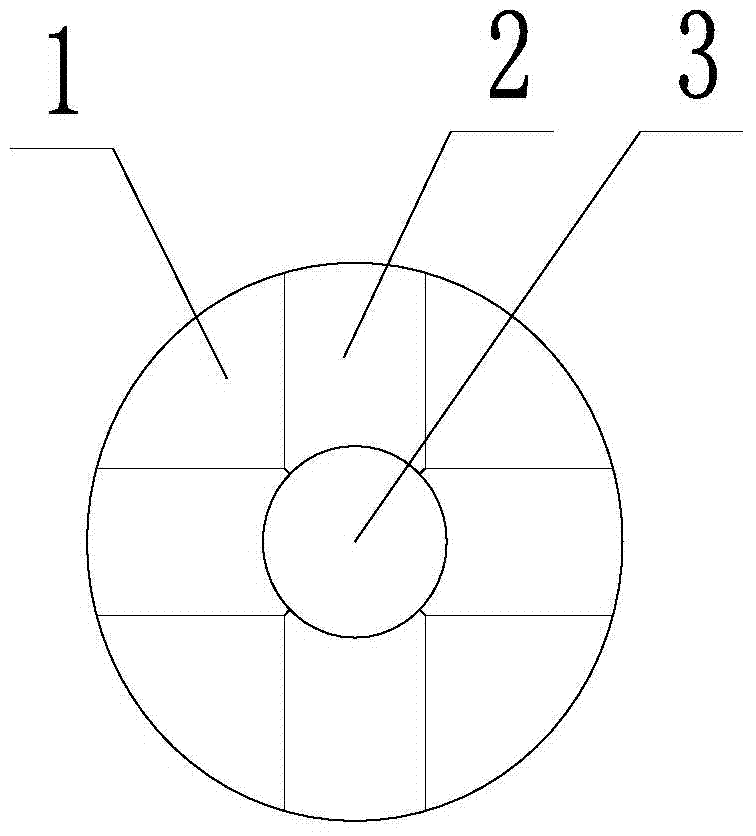

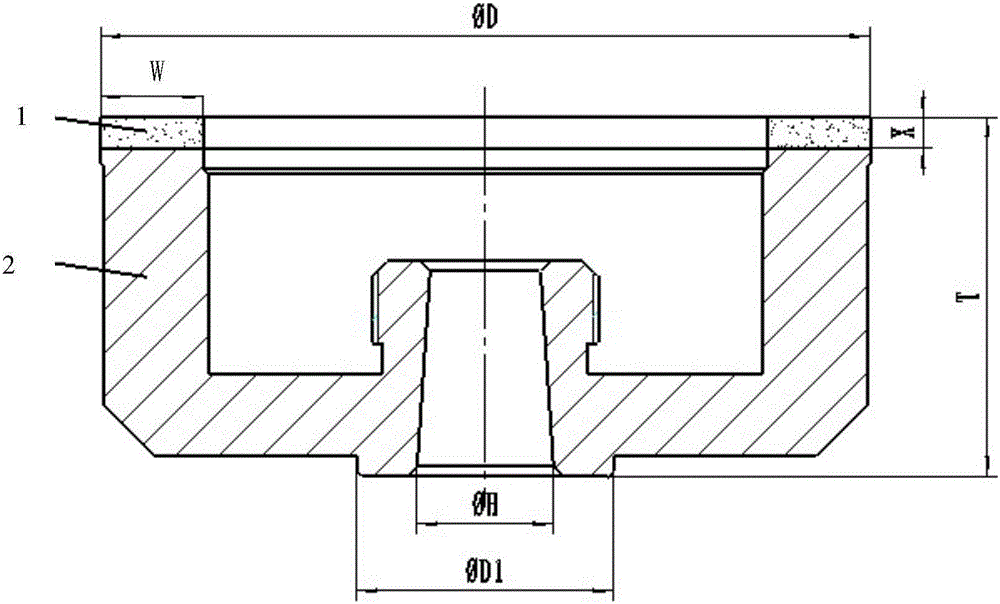

Diamond micro-drilling grinding tool

ActiveCN104723184AExtended service lifeImprove blockageRevolution surface grinding machinesMaterials scienceMicro drilling

A diamond micro-drilling grinding tool comprises a base body and a grinding layer. The grinding layer is a diamond particle layer and is arranged on the surface of the base body in an electroplated mode, and the thickness of the grinding layer ranges from 0.04 mm-0.08 mm. The top end of the base body is arranged to be a grinding head, the top end face of the grinding head is a plane and is provided with a cross-shaped semicircular groove, and a center hole used for eliminating a low-speed grinding area is formed in the axial center of the grinding head. A step-shaped base is arranged between the grinding head and the base body and comprises a primary chambering step on the grinding side and a secondary chambering step on the base body side. The diamond micro-drilling grinding tool is mainly used for drilling and grinding micro holes of crisp and hard materials, a vertical tool feeding mode can be achieved and makes tool setting and machining program compiling easier compared with a traditional spiral tool feeding mode, and the machining period is effectively shortened. The phenomena that a micro grinding head is blocked and a grinding layer is abraded are effectively improved, the quality and size uniformity of the micro holes is improved, and the service life of the grinding tool is prolonged.

Owner:NORTHEASTERN UNIV

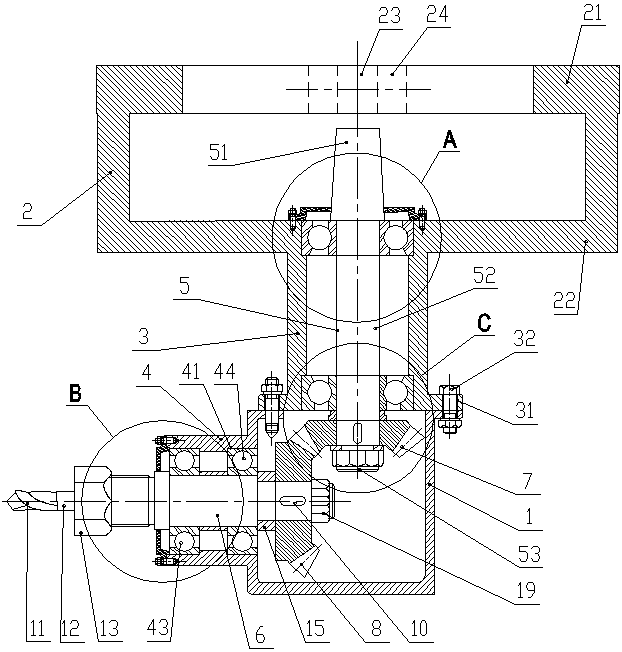

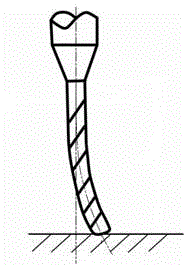

Steerable micro drilling and milling device used for workpiece inner and outer cavity processing

ActiveCN107914173AExpand the range of processingSmall sizeOther manufacturing equipments/toolsDriving apparatusDrive shaftEngineering

The invention discloses a steerable micro drilling and milling device used for workpiece inner and outer cavity processing. The steerable micro drilling and milling device comprises a connecting frame, a gearbox, a transmission mechanism and a detachable tool structure, wherein the connecting frame comprises an upper double-layer ring body connected with a vertical type milling machine main shafthousing and a lower cylinder; the transmission mechanism is arranged in the gearbox; the transmission mechanism comprises a transmission shaft, an output shaft, a drive bevel gear and a driven bevel gear; a tapered shaft section of the transmission shaft extends out of the cylinder and is mounted on the main shaft of the vertical type milling machine; the drive bevel gear is in transmission connection on the transmission shaft through a key; a tool mounting section of the output shaft leftwards extends out of an output shaft mounting barrel; the detachable tool structure is mounted on the toolmounting section of the output shaft; and the driven bevel gear is in transmission connection on the output shaft through a key. The steerable micro drilling and milling device can be assembled ontothe vertical type milling machine to complete processing processes of drilling holes, milling small steps, milling inner molded surfaces and the like for workpiece inner and outer cavities, is compactin structure, is convenient to dismount, expands the processing range of the vertical type milling machine, and improves processing efficiency and processing precision.

Owner:HENAN POLYTECHNIC UNIV

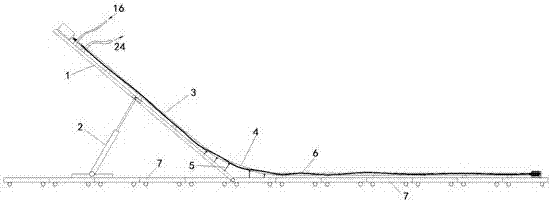

Rotary drilling large-scale experimental bench with adjustable well deviation and vertical-depth ratio

The invention relates to a rotary drilling large-scale experimental bench with adjustable well deviation and vertical-depth ratio which is used to conduct simulation drilling on highly-deviated wells, directional wells and horizontal wells. The experimental bench includes a power end system, a wellbore system, a well bottom micro drilling system, and a data acquisition system. A hydraulic lifting device, a telescopic slide rail frame and a detachable mobile slide rail frame constitute a base of the whole experimental bench. The power end system is composed of a hydraulic servo mechanism, an adjustable-speed motor, a fluid inlet cavity, and a quick adapter. The wellbore system is composed of a PVC pipe, a glass pipe, and a steel wire hose. The well bottom micro drilling system is composed of a micro drill, a rock box, a rock mounting guide rail, and a rock box guide rail. Experimental study of the drilling kinetic parameters, friction torque and whirling and buckling behavior of a rotary drill string can be conducted under various fluid circulation mediums, various drilling conditions and various wellbore structures. The experimental bench is simple to operate, and has complete functions.

Owner:SOUTHWEST PETROLEUM UNIV

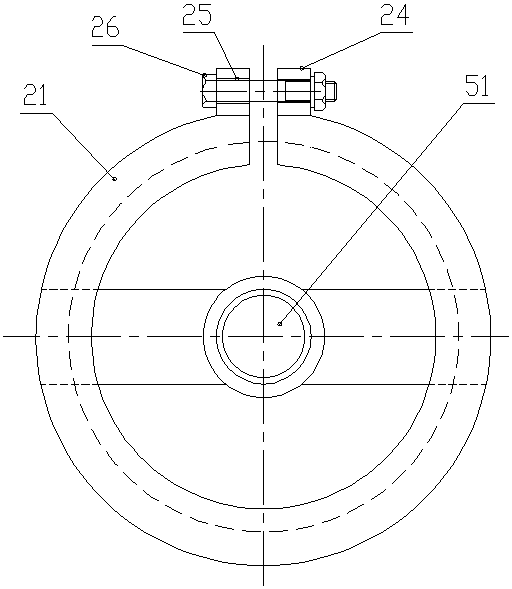

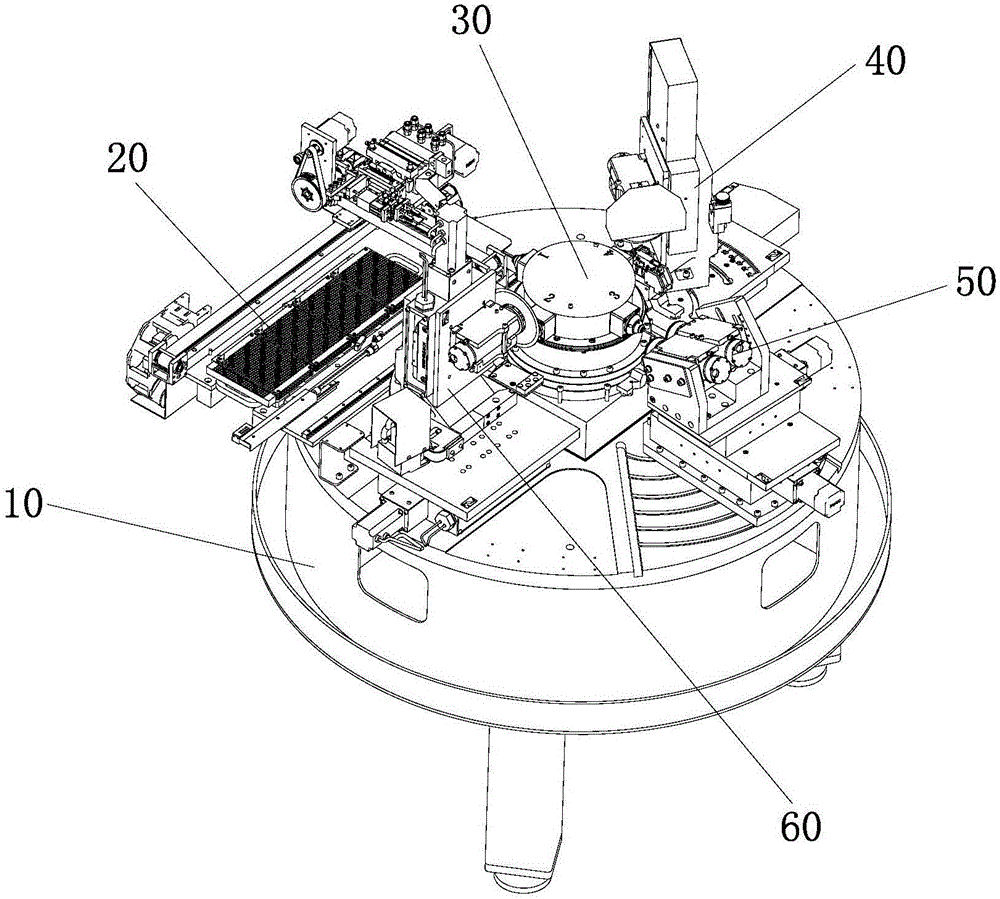

Automatic micro-drill processing center

ActiveCN105108496AHigh degree of automationImprove efficiencyOther manufacturing equipments/toolsEngineeringDrill

The invention relates to the technical field of processing equipment, in particular to an automatic micro-drill processing center. The automatic micro-drill processing center comprises a working platform, wherein the working platform is circular; a feed mechanism, a clamping mechanism, a grooving mechanism, a point grinding mechanism and a back-off mechanism are mounted on the working platform; and the feed mechanism, the grooving mechanism, the point grinding mechanism and the back-off mechanism surround the clamping mechanism. With the adoption of the feed mechanism, the clamping mechanism, the grooving mechanism, the point grinding mechanism and the back-off mechanism, procedures such as grooving, point grinding and back-off on a micro-drill can be sequentially realized simply after an operator puts a material box, where a micro-drill to be processed is contained, onto a designated position of the feed mechanism and starts the automatic micro-drill processing center. Compared with the traditional processing equipment, the automatic micro-drill processing center is high in automation degree and efficiency.

Owner:东莞市升宏智能科技有限公司 +1

Coating micro-drilling knife for printed circuit board machining and preparation method thereof

InactiveCN107881468AStrong membrane bindingImprove performanceVacuum evaporation coatingSputtering coatingWear resistantFilm base

The invention discloses a coating micro-drilling knife for printed circuit board machining. The coating micro-drilling knife comprises a micro-drilling knife base body, wherein a metallurgical bondinglayer, a transition layer, a main wear-resistant layer and a self-lubricating layer are sequentially attached to the micro-drilling knife base body from inside to outside; and the metallurgical bonding layer is a pure metal Cr layer, the transition layer is a nano multilayer formed by alternating Cr and Vn, the main wear-resistant layer is a nano multilayer formed by alternating DLC and VN, and the self-lubricating layer is a Cr-doped DLC layer. According to the coating structure, on one hand, the composite coating has relatively high performance; and on the other hand, the coating and the base body can have good adhesive force; and meanwhile, operability is simple and feasible. The coating micro-drilling knife has good film-base binding force, high hardness (greater than 20 GPa) and lowfriction coefficient (less than 0.3).

Owner:ZHOUKOU NORMAL UNIV

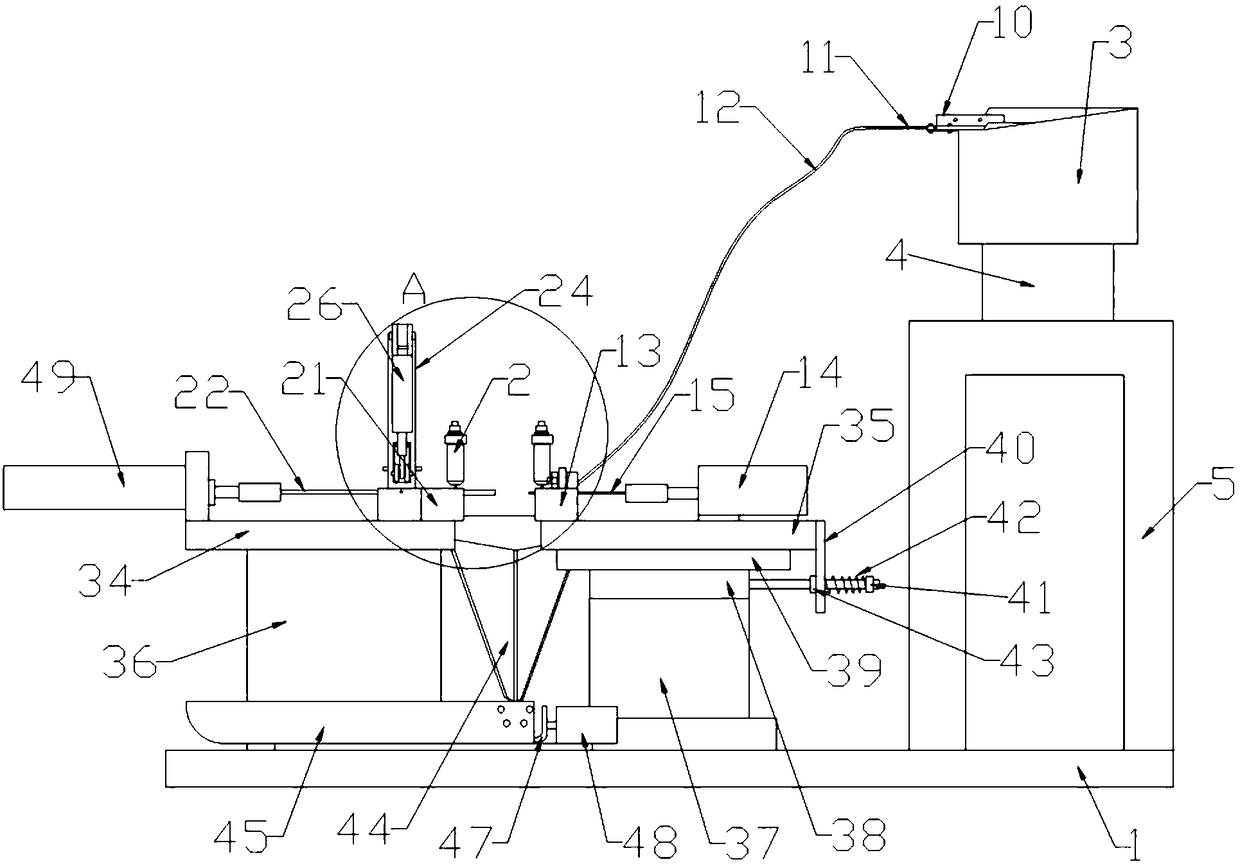

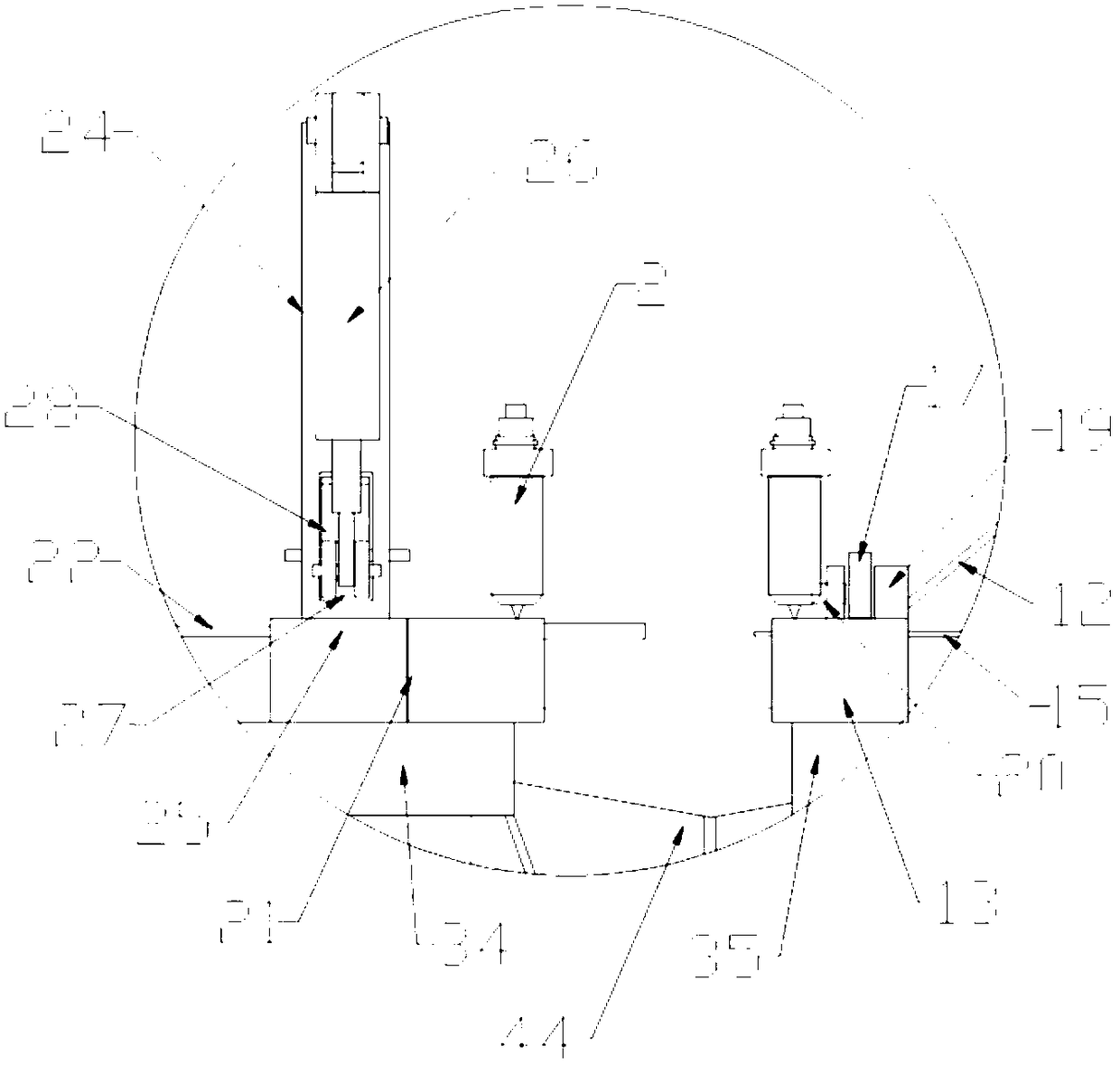

Novel micro-drill automatic welding device and welding method

PendingCN109332865AAutomatic welding fastFast Streamlined OperationResistance welding apparatusWater flowSmall footprint

The invention provides a novel micro-drill automatic welding device and a welding method. The welding device comprises a base. The upper end of the base is provided with a telescopic workbench. The left side and the right side of the upper end of the telescopic workbench are oppositely provided with a drillstock feeding mechanism for automatic and sequential feeding, and a drill bit feeding mechanism for automatic and sequential feeding. Electrodes for welding are arranged above the discharging end of the drillstock feeding mechanism and the discharging end of the drill bit feeding mechanism correspondingly. The electrodes are connected with a pressing mechanism. A drill bit conveying mechanism is arranged above the drill bit feeding mechanism. The drill bit conveying mechanism is connected with the drill bit feeding mechanism through a conveying assembly. The device is compact in structure and small in occupied area, fast water flow operation of micro-drill automatic welding is achieved, and micro-drilling welding efficiency and quality are improved.

Owner:HUILIAN XINXIANG ELECTRONICS TECH CO LTD

A downhole torque self-balancing cabled drilling tool system

ActiveCN106761480BRealize disturbance drillingDisturbance reachesSurveyDrill bitsWinchLogging while drilling

The invention relates to a downhole torque self-balancing cabled drilling tool system, which belongs to the technical field of drilling engineering equipment. The inner and outer double drill bits rotate reversely to crush the rock to achieve micro-disturbance drilling of the surrounding rock; the stator group and the rotor group of the power motor are used to drive the outer drill bit and the inner drill bit respectively. Torque action; the present invention integrates the power source, mud circulation system and well logging system into the drilling tool, and the ground only needs to use the drawworks equipment for lifting the drilling tool to realize normal drilling, tripping and logging while drilling, etc. Operation: When the drill is stuck, the winch lifts the drilling tool, and the drill bit rotates forward and reverse alternately to release the stuck rock particles to realize the stuck release.

Owner:JILIN UNIV

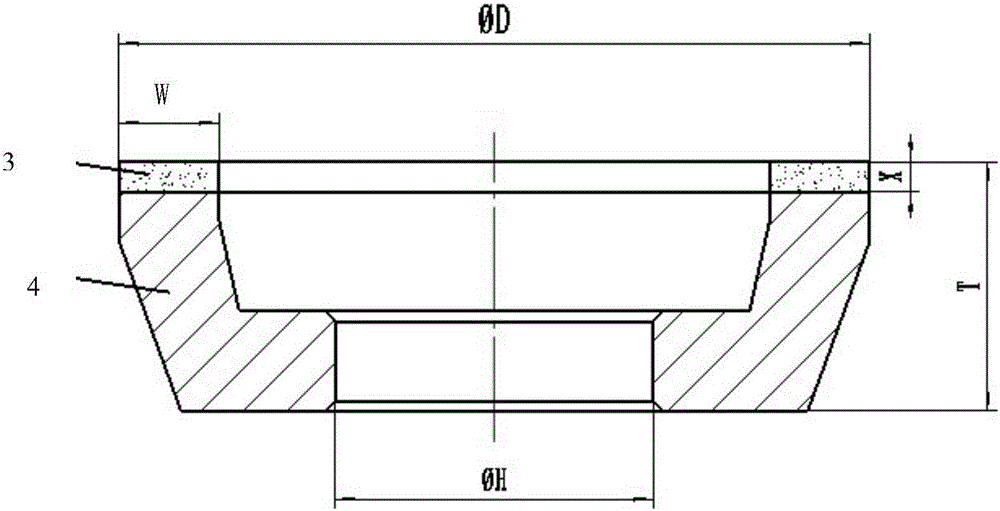

Finish-ground super-hard sand wheel for micro drilling and manufacturing method thereof

ActiveCN105856081AImprove toughnessImprove wear resistanceBonded abrasive wheelsGrinding devicesSuperhard materialShock resistance

The invention relates to a finish-ground super-hard sand wheel for micro drilling and a manufacturing method thereof, and belongs to the technical field of super-hard materials and products. The finish-ground super-hard sand wheel for micro drillingcomprises a matrix and an abrasive layer. The abrasive layer comprises, by weight, 44-88 parts of abrasives, 60.3-87.9 parts of bonding agents and 100.8-142 parts of filler, wherein the bonding agents are composed of polyamide resin and polyimide resin with the weight ratio being 1:1-3; and the filler is made of silicon carbide, polytetrafluoroethylene and cerium oxide. The toughness and abrasion resistance of the finish-ground super-hard sand wheel for micro drillingare improved, the shock resistance and shock absorption properties of the sand wheel are improved in the workpiece machining process, and the workpiece quality is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

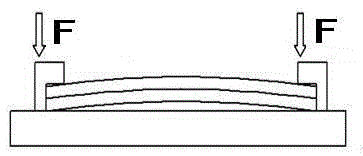

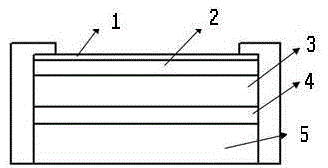

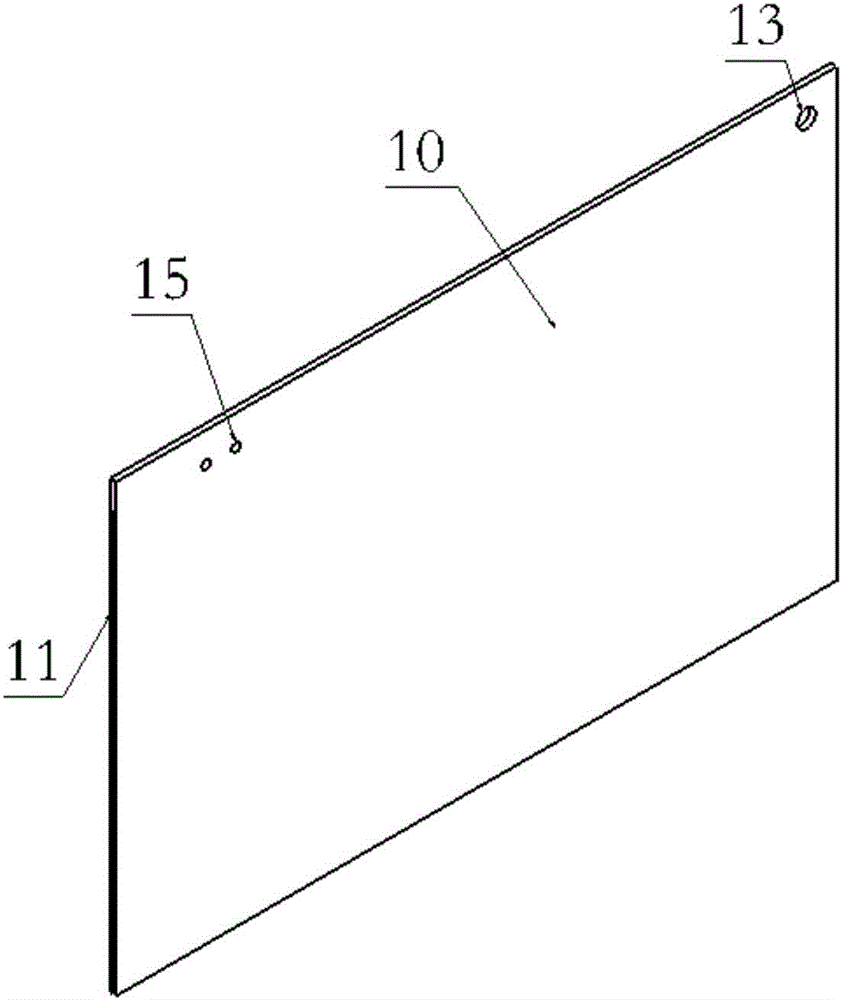

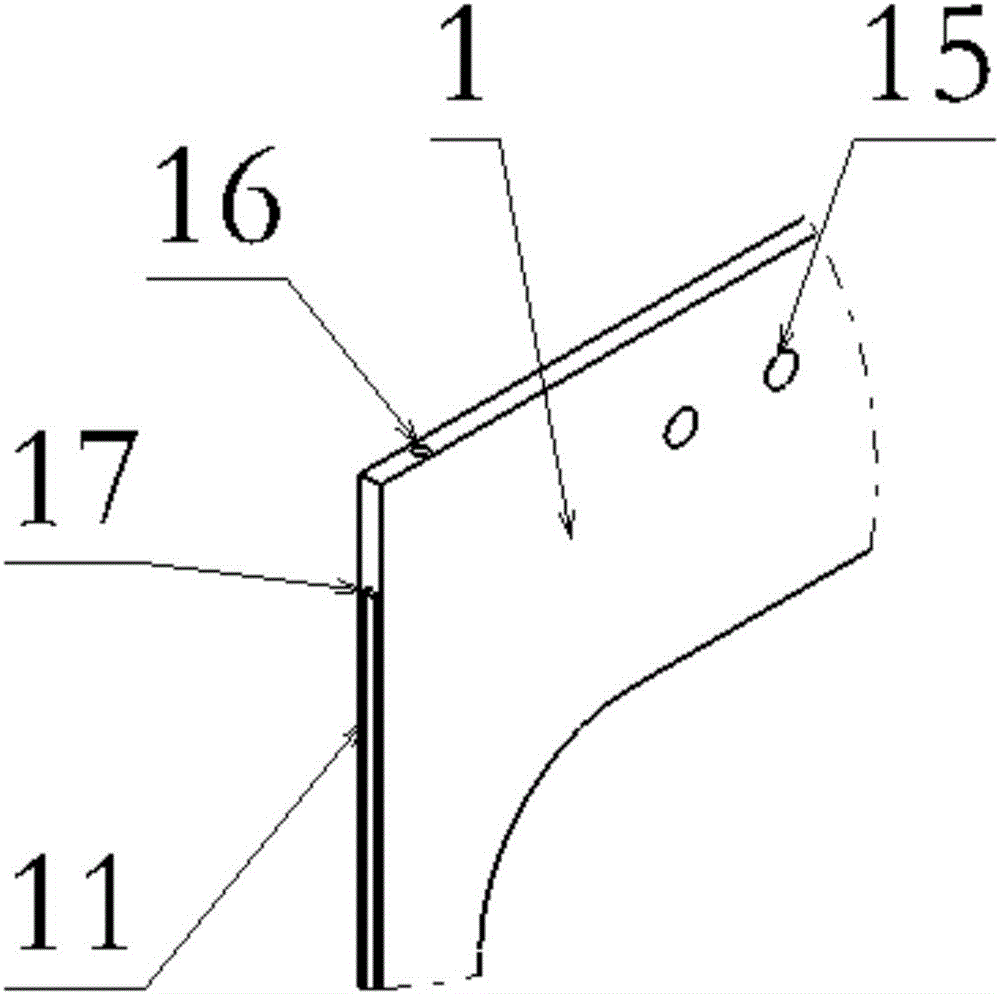

Multi-layer structured cover plate for improving drilling position precision of flexible PCB (printed circuit board)

ActiveCN104552415AReduce wearReduce gapMetal working apparatusPrinted circuit boardHigh speed drilling

The invention relates to a multi-layer structured cover plate for improving the drilling position precision of a flexible PCB. The multi-layer structured cover plate comprises a drill-in guide layer and a hard cover plate, wherein the drill-in guide plate is arranged on the top surface of the hard cover plate and attached to a substrate to form a soft cover plate layer. The multi-layer structured cover plate for improving drilling position precision of the flexible PCB can improve the micro-drilling-in drilling position precision, reduce high-speed drilling temperature as well as wearing of tools, improve the machining efficiency and reduce the cost.

Owner:DONGGUAN HUANGJIANG DASHUN ELECTRONICS

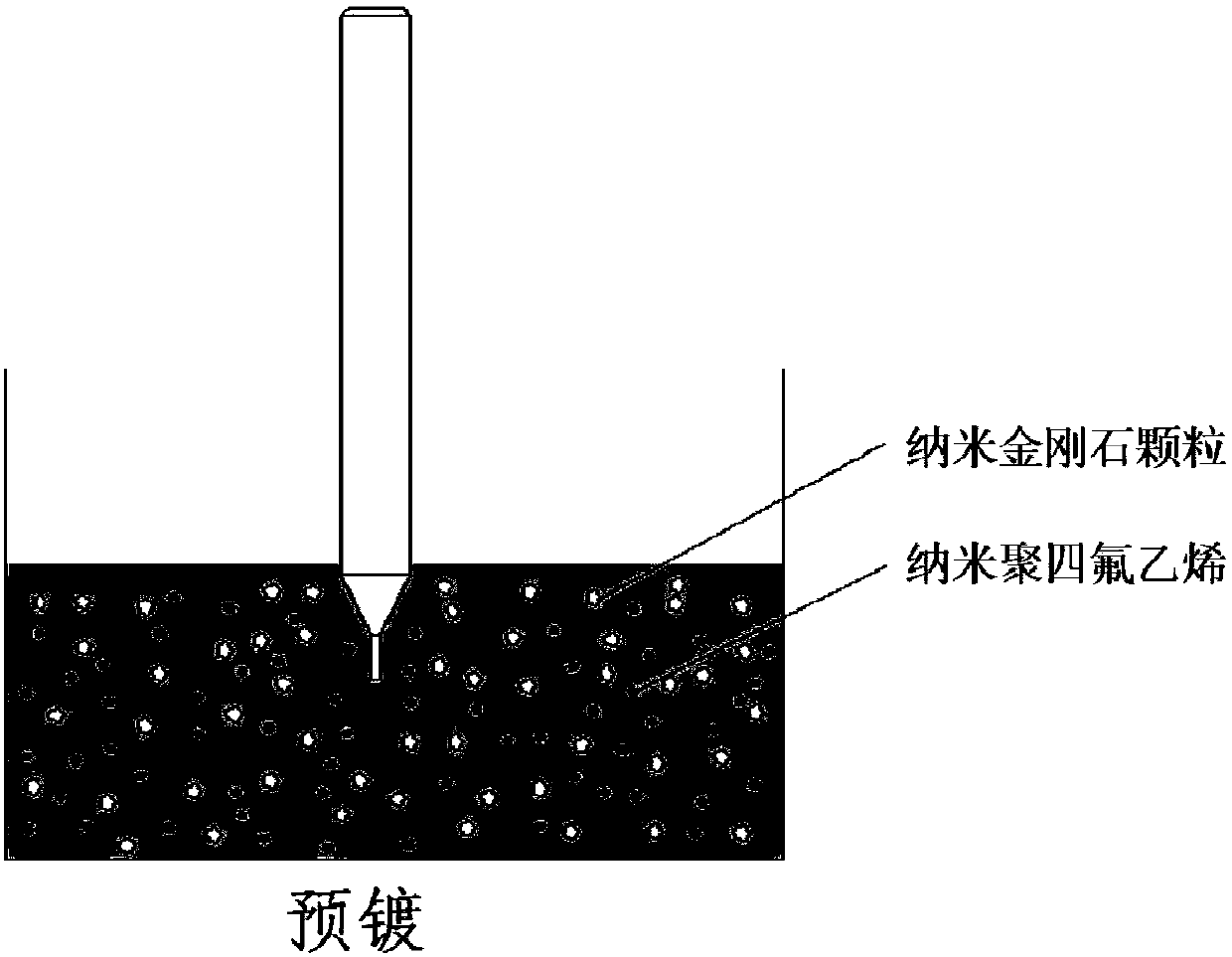

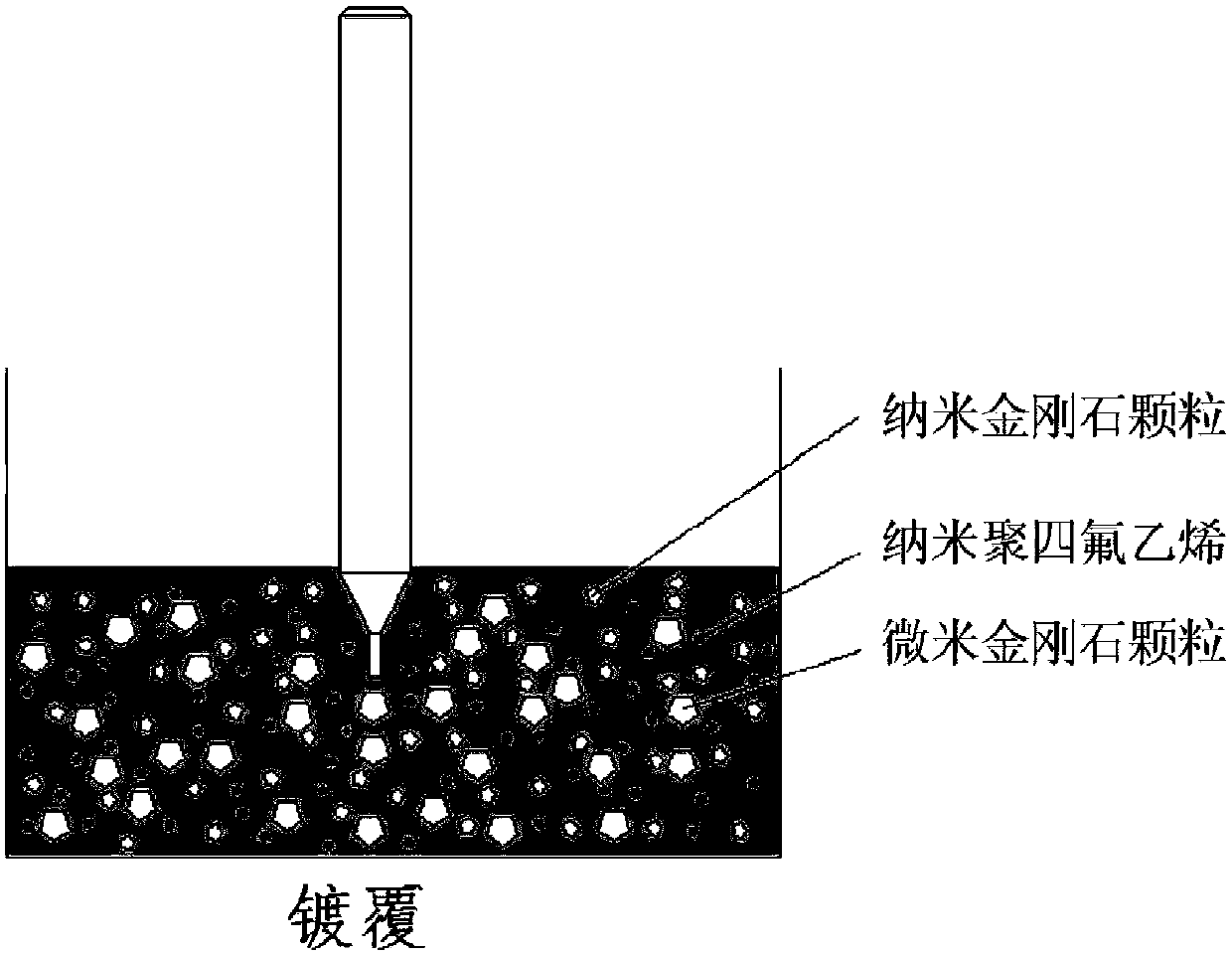

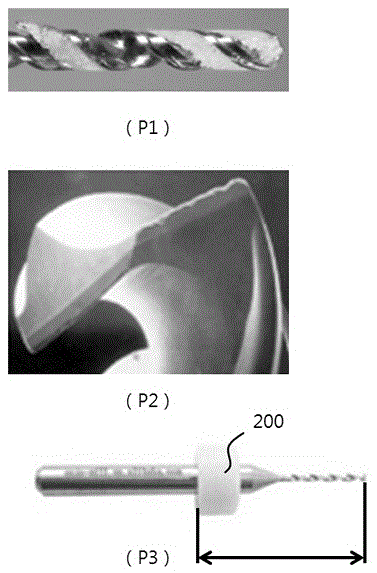

Diamond micro drilling tool and machining method thereof

ActiveCN107675147ASimple processLow costAbrasion apparatusLiquid/solution decomposition chemical coatingChemical platingHardness

The invention discloses a diamond micro drilling tool and a machining method thereof. A grinding layer is plated on the surface of the micro drilling tool, and comprises a fixed grain composite plating layer and micron diamonds; and the fixed grain composite plating layer comprises nanometer diamonds and nanometer polytetrafluoroethylene. Meanwhile, the invention further discloses the machining method of the diamond micro drilling tool. A chemical composite plating method is adopted to prepare a micro drill containing diamonds; and the micro drill is prepared by using a chemical plating method, and has the characteristics of simple process, low cost and good wear resistance. The fixed grain composite plating layer in the grinding layer comprises the nanometer diamonds and a polytetrafluoroethylene composite plating layer; the nanometer diamonds are added to achieve higher hardness of the composite plating layer and better wear resistance; the wear resistance of the plating layer and the holding force of a fixed grain layer to diamond abrasive grains are improved; and nanometer polytetrafluoroethylene particles can reduce friction between the plating layer and a hole wall, reduce the wear of the fixed grain layer, and prolong the service life of the micro drill.

Owner:GUANGDONG UNIV OF TECH

Modular inline micro-drilling re-grinding device

InactiveCN105234753ASave labor costsReduce excess spaceGrinding machine componentsDrilling toolsPoor qualityMicro drilling

The present invention relates to a modular inline micro drill regrinding device, and more particularly to the use of a washing module after cleaning micro drill used to remove impurities and its pressurized, fixed and re-grinding, through the collar installation module so that binds to the outer peripheral surface of a micro drill collar can automatically adjust its position according to the length of the micro drill after regrinding modular inline micro drill regrinding devices. The present invention is a modular inline micro drill comprises a carrier to be throwaway throwaway micro drill tray; conveyance for conveying the tray portion; rotating portion fixed to be milled and the throwaway micro drill predetermined rotation angle; for heavy grinding throwaway be fixed to any one of micro drill grinding portion; applying pressure from the side facing the micro drill and a fixed blade, thereby preventing the generation of poor quality due to jitter grinding micro drill by regrinding is performed when the abrasive portion holding portion.

Owner:INSTERN

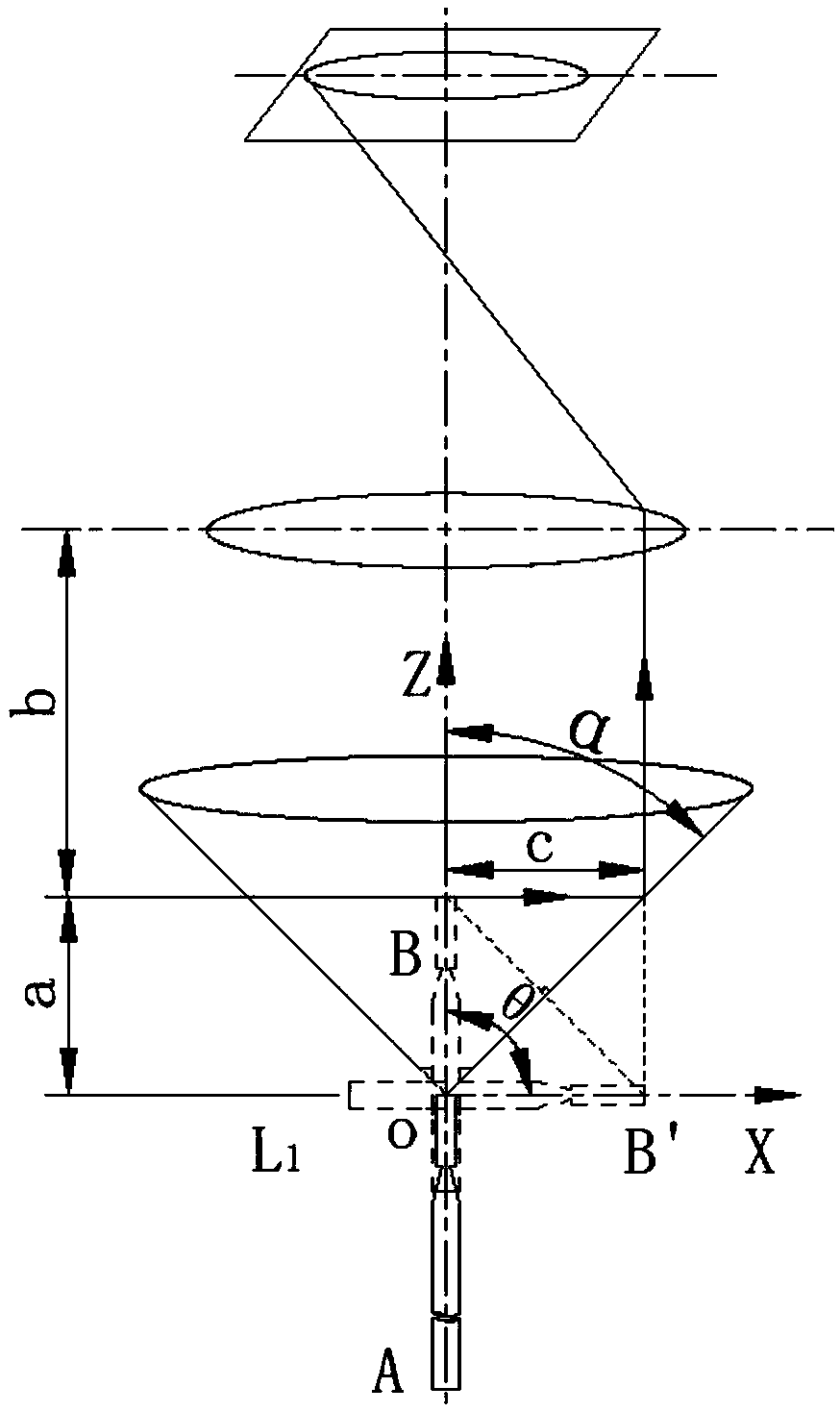

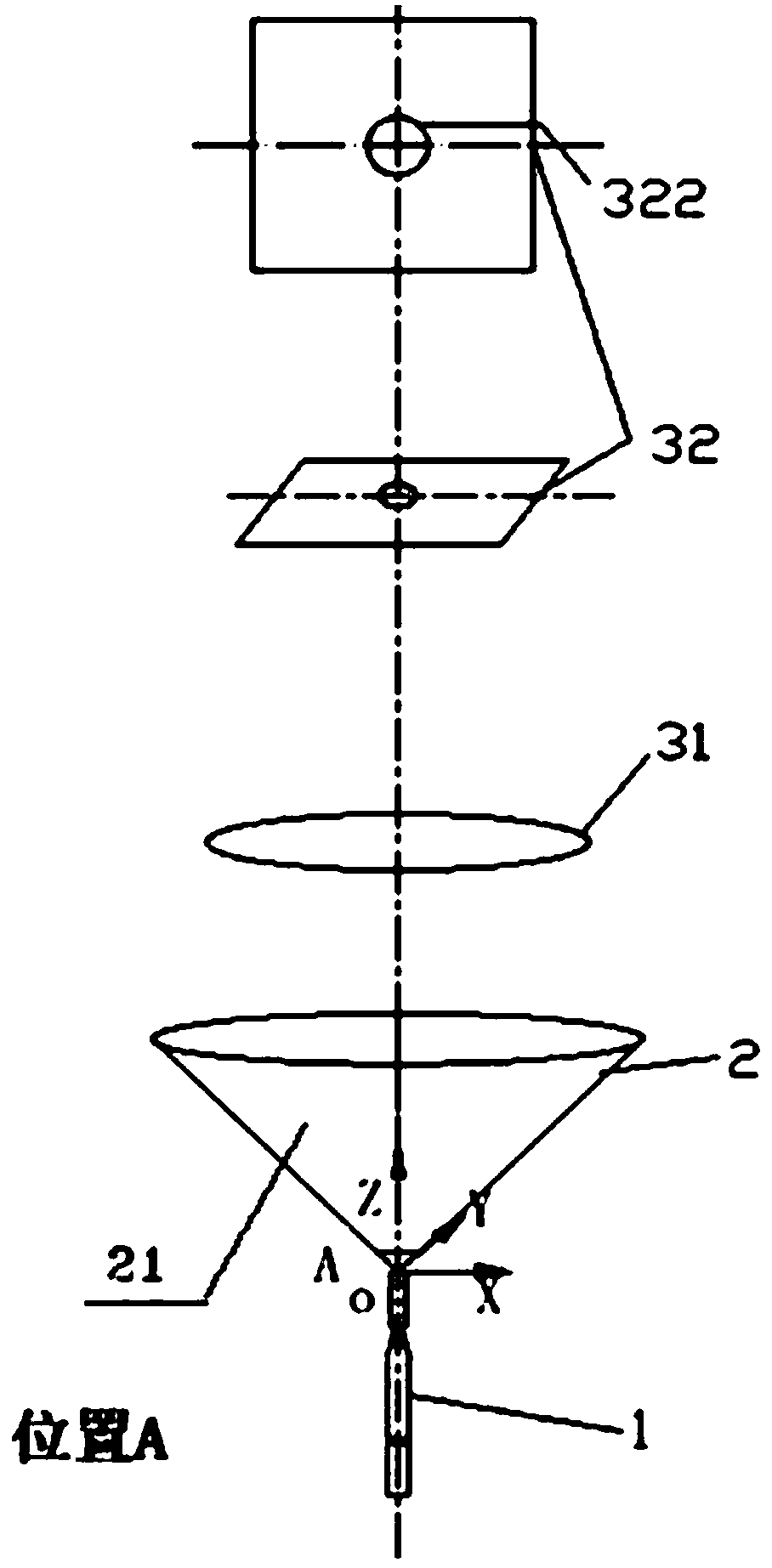

Micro-drilling visual detection method and device based on inner-cone mirror surface scanning panoramic imaging

ActiveCN109343303AOvercome costsOvercoming cumbersome working stepsPanoramic photographyVisual perceptionAngle of view

The invention belongs to the technical field of micro-drilling visual quality detection, and discloses a micro-drilling visual detection method based on inner-cone mirror surface scanning panoramic imaging. The method simultaneously adopts a device with an inner cone mirror surface annular local imaging device, an image acquisition and processing unit and a digital motion unit; firstly, an image with a clear end edge is shot and obtained, and if the end edge is judged to be qualified, continuous shooting is performed to obtain a plurality of side edge images, the side edge images are unfoldedto extract image clear bands, and then a final clear and complete side edge image is obtained through splicing. The invention further provides a micro-drilling visual detection system using the method. According to the invention, in a one-time motion process, the clear, complete and all-around side edge images can be obtained without converting a shooting view angle of a camera, so that the problems that the current micro-drilling detection technology is high in cost, has the detection dead angle, is unstable in detection quality and the like are overcome, the detection efficiency and precision of the micro-drill are greatly improved, and the requirements of batch production and detection are met.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Machining technological method of steel wire cutter

InactiveCN106392519ASolve processing technology problemsImprove machining accuracyMetal working apparatusWire cuttingEngineering

The invention discloses a machining technological method of a steel wire cutter. The machining technological method comprises the following steps: S1) tempering a rectangular blank, drilling one side, close to the upper end, of the blank to obtain a locking hole after the blank is cooled, and drilling the other side, close to the upper end, of the blank to obtain a connection hole; S2) slotting two side edges of the blank and the ground by adopting a V-shaped sand wheel to obtain side wire slots in the sides and a bottom wire slot in the bottom surface; S3) machining a wire stop hole in the locking hole by means of electric sparks; S4) performing micro drilling machining to obtain a perpendicular wire passing hole in the upper bottom surface and a horizontal wire passing hole in the side surface of one side of the connection hole; and S5) performing cutting machining on the blank along the contour by a wire cutting process to obtain a ''C-shaped'' cutter body. The machining technological method of the steel wire cutter successfully solves the problems of a machining process of a steel wire cutter body. The method is high in machining precision, high in practicability and convenient to popularize.

Owner:SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com