Micro-drilling method for flexible circuit board

A flexible circuit board and micro-drilling technology, used in printed circuits, boring/drilling, printed circuit manufacturing, etc., can solve the problem that the drilling parameters cannot reach the parameter accuracy range, the quality of the circuit board is difficult to guarantee, and the circuit is reduced. Board reliability and other issues, to achieve the effect of improving effectiveness, improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

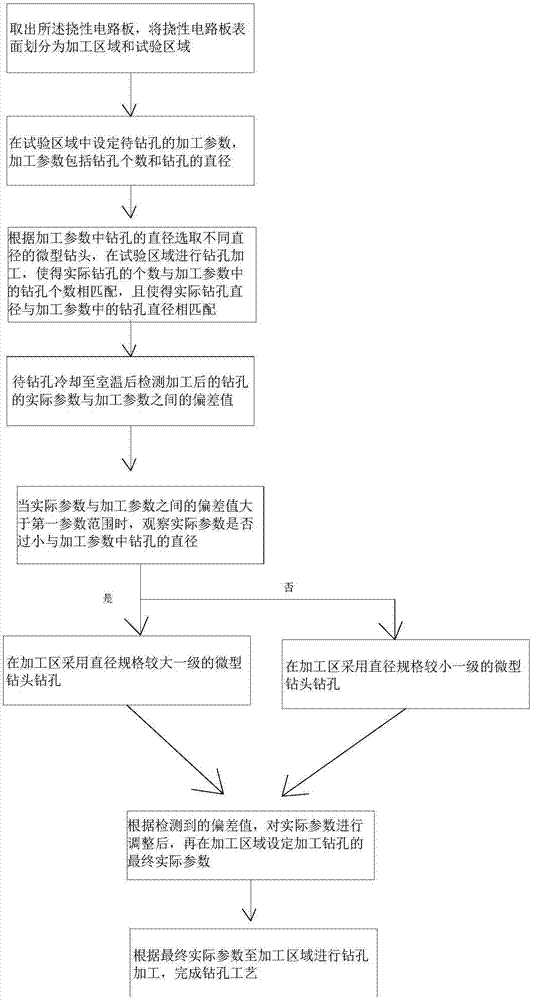

[0022] Example: A micro-drilling method for a flexible circuit board

[0023] Such as figure 1 , prepare the following materials and tools in advance, the material includes a flexible circuit board, the tool uses a micro-drill, the micro-drill includes a drill head, a drill body and a drill tail, the drill head has a first spiral groove, so The drill body part has a second helical groove, the helical direction of the first helical groove and the second helical groove are the same, and the helical angle of the first helical groove is smaller than the helical angle of the second helical groove.

[0024] Follow the steps below.

[0025] In the first step, the flexible circuit board is taken out, and the surface of the flexible circuit board is divided into a processing area and a test area.

[0026] In the second step, the processing parameters of holes to be drilled are set in the test area, and the processing parameters include the number of drilled holes and the diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com