Modular inline micro-drilling re-grinding device

A micro-drill, modular technology, applied in drilling accessories, drilling/drilling equipment, grinding machine parts, etc., can solve the problems of waste of resources, reduce production efficiency, affect price competitiveness, etc., to reduce labor Cost, time saving, labor cost reduction and space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

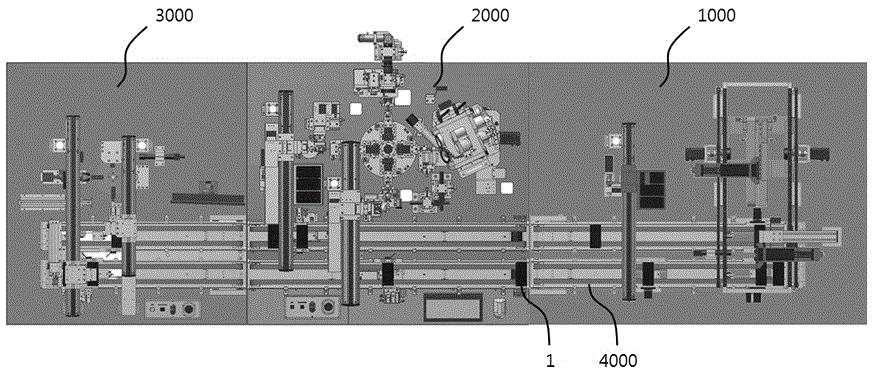

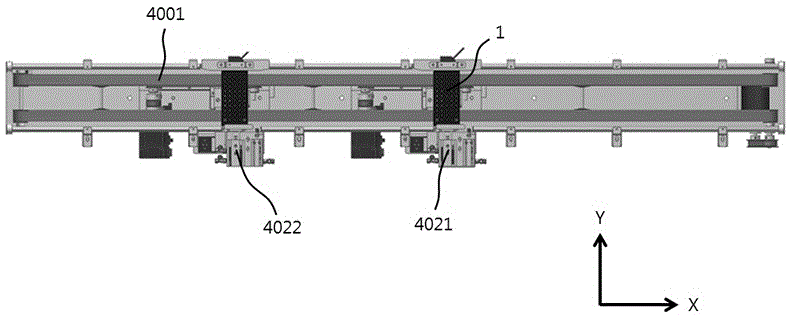

[0048] figure 2 It is a structural schematic diagram of the modular inline micro-drill regrinding device of the present invention. The modular inline micro-drill regrinding device includes a cleaning module 1000 that sprays high-pressure cleaning water to the used micro-drill for cleaning and then sprays dry air to remove the cleaning water remaining on the micro-drill; The micro-drill grinding module 2000 is a micro-drill grinding module 2000 that checks the grinding quality and classifies inferior micro-drills after regrinding one by one; according to the length of the cutting edge of the re-grinded micro-drill, it is combined with the micro-drill outer peripheral surface of the re-ground A collar installation module 3000 at the collar position; a plurality of trays 1 for loading a plurality of micro drills; a delivery module 4000 for transporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com