Low-carbon and environment-friendly feeding system

A low-carbon, environmentally friendly, feeding device technology, applied in fish farming, applications, animal husbandry, etc., can solve the problems of easy damage to mechanical equipment, high cost, and increased fish farming costs, saving packaging costs, small weather effects, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

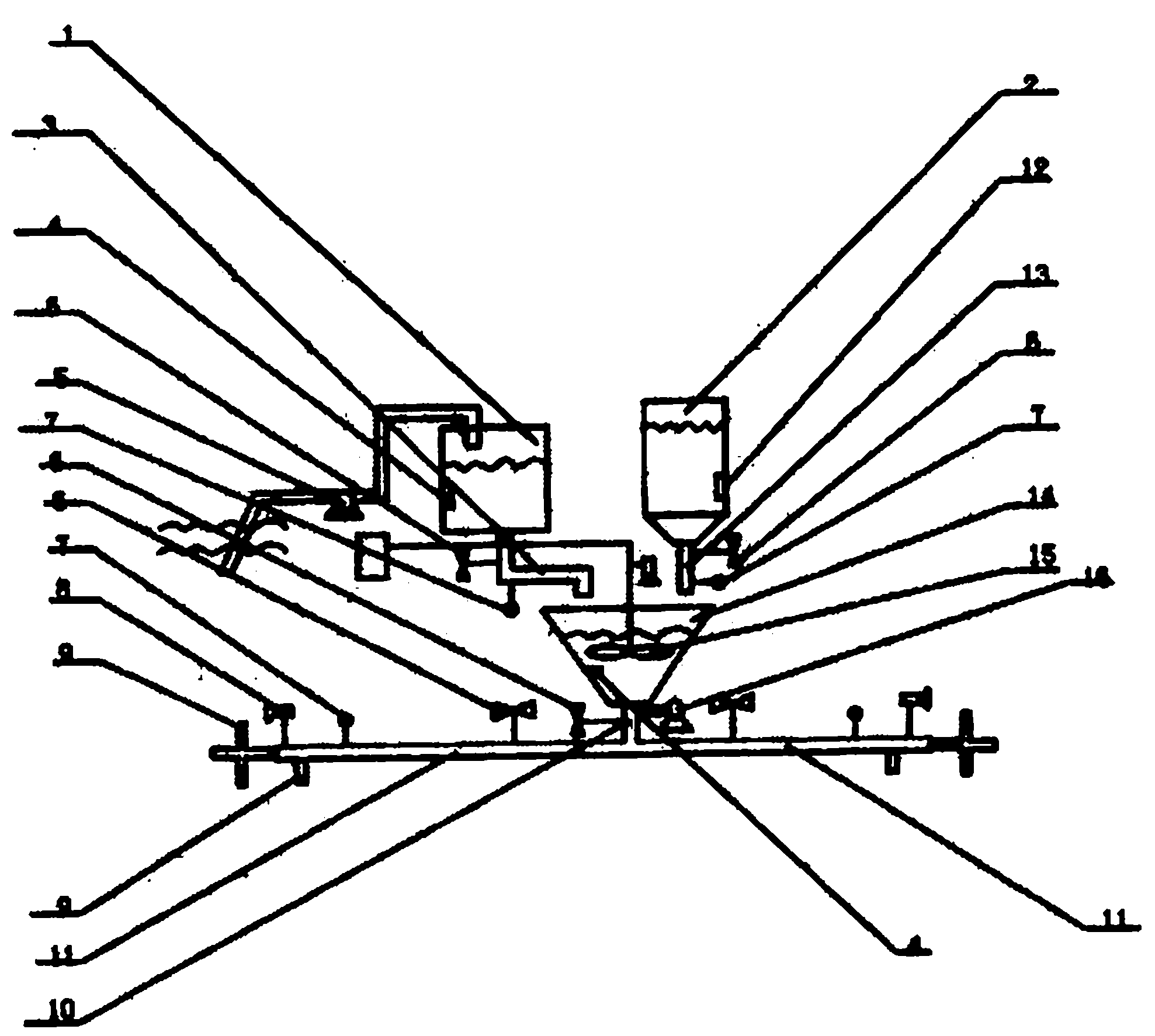

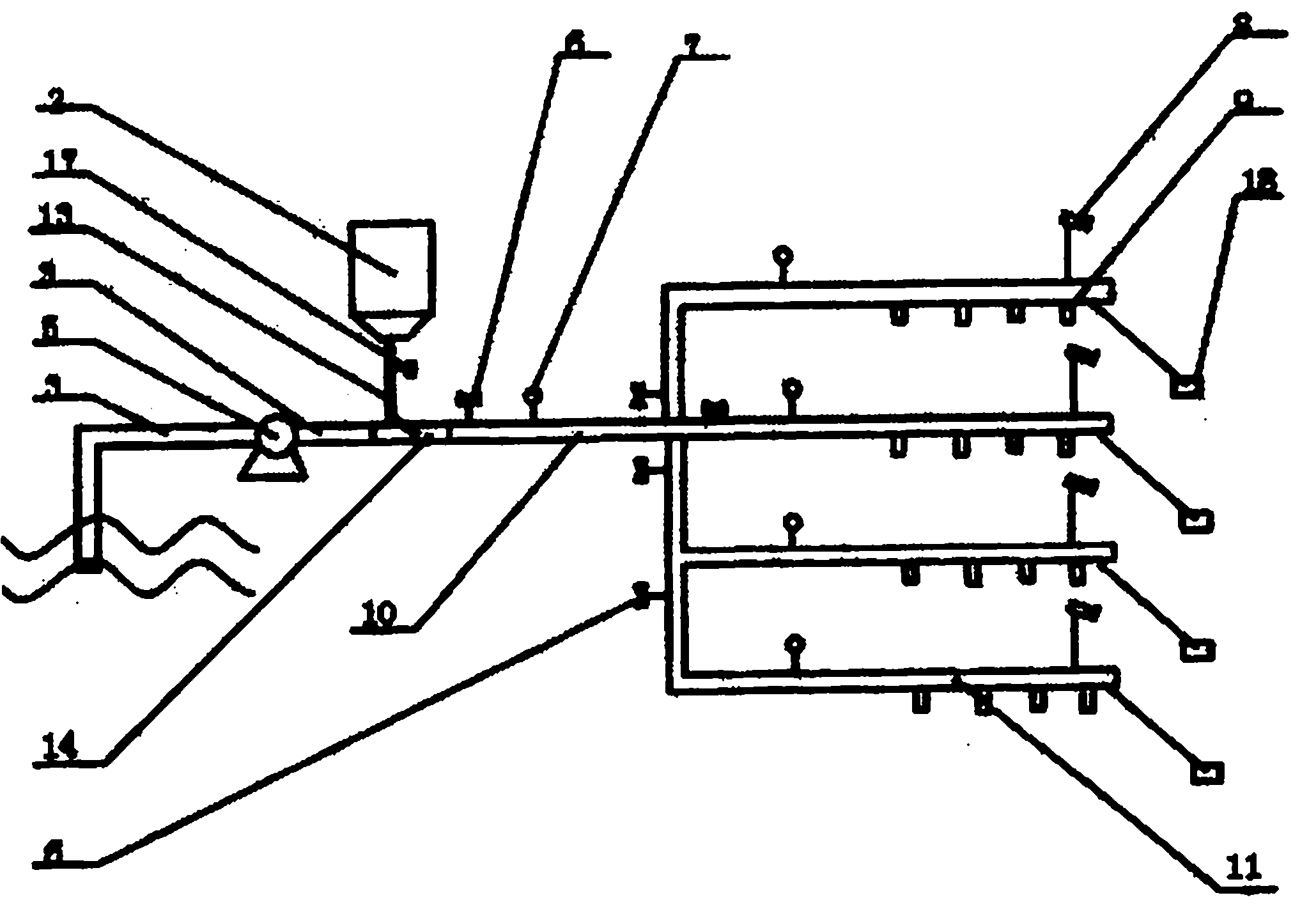

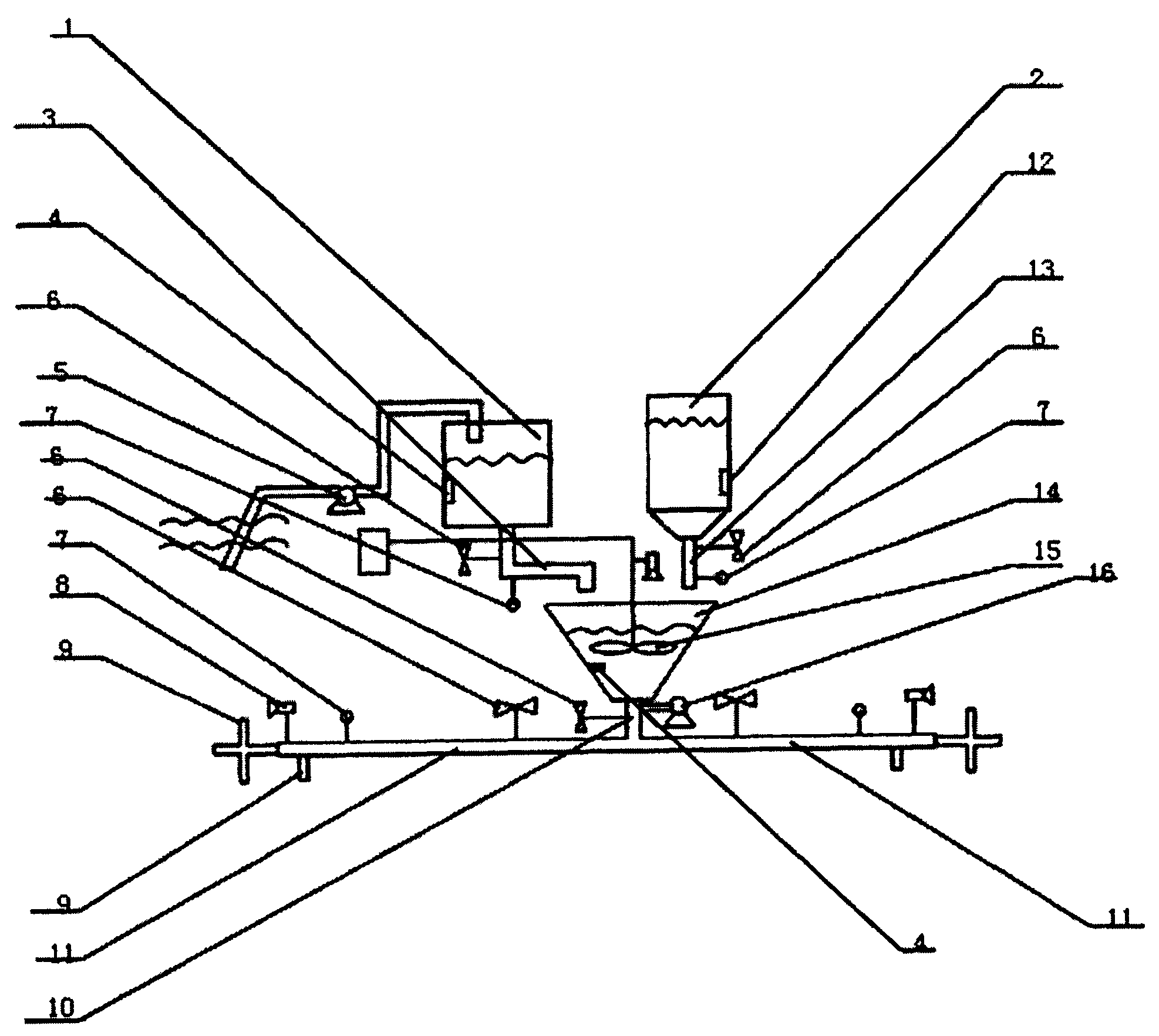

[0023] As shown in the figure, 1 is the water tank, 2 is the material storage device, 3 is the water inlet pipe, 4 is the water level sensor, 5 is the water pump, 6 is the adjustment device, 7 is the flow meter, 8 is the monitoring camera, 9 is the feeding device, 10 is the material mixing main pipe, 11 is the material mixing branch pipe, 12 is the feed sensor, 13 is the feeding pipe, 14 is the mixing device, 15 is the agitator, 16 is the pressurizing device, 17 is the electric control feeding valve, 18 is the water temperature and dissolved oxygen detectors.

[0024] figure 1 As an embodiment of the present invention, the water in the water tank 1 and the feed in the storage device 2 are mixed in the mixing device 14, then flow through the material mixing main pipe 10 to the material mixing branch pipe 11, and finally pass through the feeding device connected to the branch pipe 9. Feed it on the water surface of the fish pond. Among them, it should be noted that after the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com