Automatic micro-drill processing center

A technology of automatic processing and micro-drilling, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low precision and low degree of automation, and achieve the effect of high degree of automation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Attached below figure 1 to attach Figure 8 The present invention is described further:

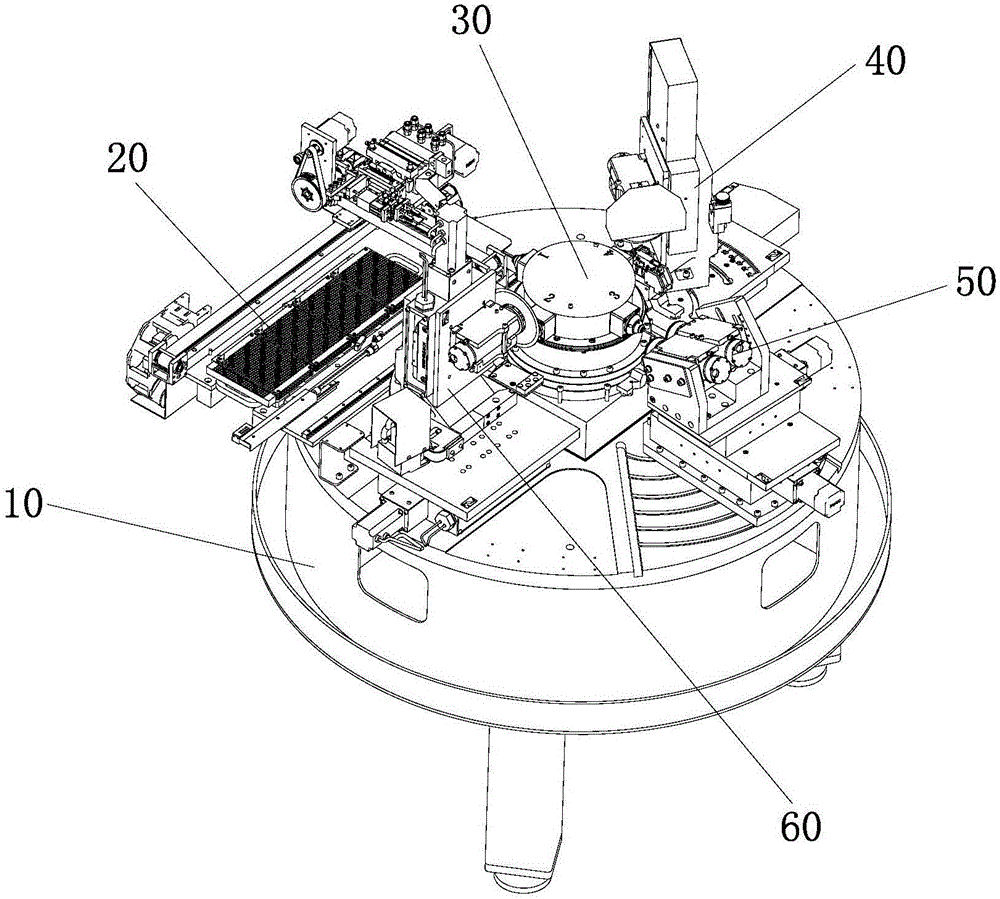

[0027] Such as figure 1 A micro-drilling automatic machining center shown includes a workbench 10, the workbench 10 is circular, and the workbench 10 is equipped with a feeding mechanism 20, a clamping mechanism 30, a slotting mechanism 40, a sharpening mechanism 50 and a shovel The back mechanism 60, the feeding mechanism 20, the slotting mechanism 40, the sharpening mechanism 50 and the shovel back mechanism 60 surround the clamping mechanism 30. In this embodiment, the clamping mechanism 30 is fixedly installed on the front of the workbench 10. In the middle, the feeding mechanism 20 , the slotting mechanism 40 , the sharpening mechanism 50 and the shoveling mechanism 60 are evenly distributed around the clamping mechanism 30 in a clockwise direction.

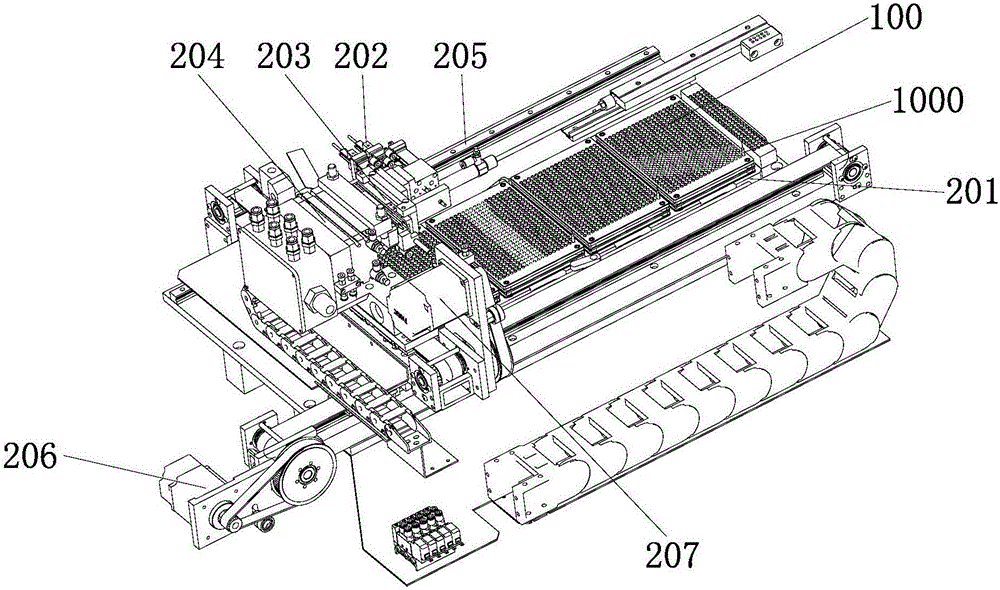

[0028] Such as figure 2 As shown, the feeding mechanism 20 includes a material platform 201 , air claws 202 , sliding tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com