Finish-ground super-hard sand wheel for micro drilling and manufacturing method thereof

A fine grinding and micro-drilling technology, used in bonded grinding wheels, grinding/polishing equipment, abrasives, etc., can solve the problems of low bonding force between the abrasive layer and the substrate, inability to fine-grinding micro-drilling tips, and low grinding wheel toughness. , to achieve the effect of reducing the trimming frequency, improving the yield and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

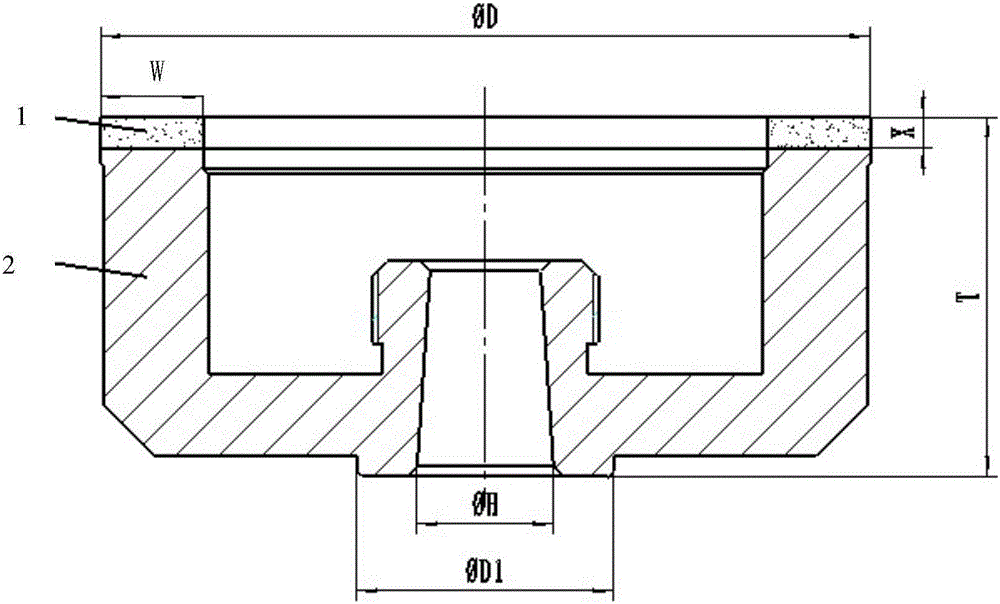

[0034] Such as figure 1 As shown, the fine grinding superhard grinding wheel for micro-drilling in this embodiment includes a base 2 and an abrasive layer 1. The base is aluminum, and the abrasive layer is composed of the following components by weight: 30.15g polyamide PA1012, 30.15g polyimide, The polyimide uses the thermosetting polyimide resin powder shown in Table 1, 44g diamond with a particle size of M4 / 8, 80g silicon carbide with a particle size of M1 / 2, and 6g polytetrafluoroethylene with a particle size of ≤10μm (PTFE), 56g of cerium oxide with particle size ≤10μm.

[0035] The preparation method of the fine grinding super-hard grinding wheel for micro-drilling includes the following steps:

[0036] 1) Weigh the binder thermoplastic polyamide resin powder PA1012 and thermosetting polyimide resin powder, abrasive diamond powder, silicon carbide powder, and cerium oxide powder according to the above weight; mix the weighed raw materials, stir and grind and mix for 30 minute...

Embodiment 2

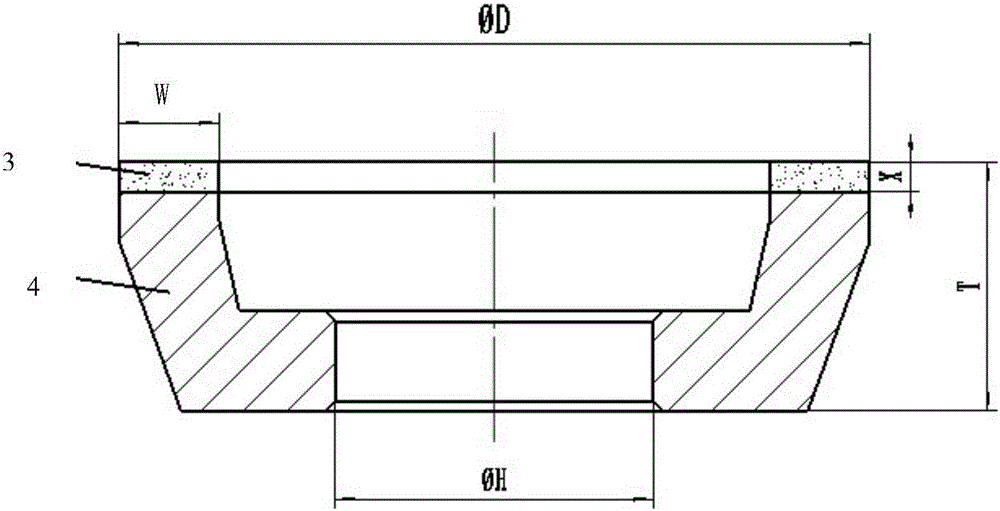

[0042] Such as figure 2 As shown, the fine grinding superhard grinding wheel for micro-drilling in this embodiment includes a base 4 and an abrasive layer 3. The base is aluminum, and the abrasive layer is composed of the following components by weight: 29.3g polyamide PA1012, 58.6g polyimide, The polyimide uses the thermosetting polyimide resin powder shown in Table 1, 88g diamond with a particle size of M2 / 4, 51.2g silicon carbide with a particle size of M0 / 1, 4.8g with a particle size of ≤10μm Polytetrafluoroethylene (PTFE), 44.8g of cerium oxide with a particle size ≤ 10μm.

[0043] The preparation method of the fine grinding super-hard grinding wheel for micro-drilling includes the following steps:

[0044] 1) Weigh the binder thermoplastic polyamide resin powder PA1012 and thermosetting polyimide resin powder, abrasive diamond powder, silicon carbide powder, and cerium oxide powder according to the above weight; mix the weighed raw materials, stir and grind and mix for 40 m...

Embodiment 3

[0050] The fine grinding super-hard grinding wheel for micro-drilling in this embodiment includes a substrate and an abrasive layer, the substrate is aluminum, and the abrasive layer is composed of the following components by weight: 15.2g polyamide PA1012, 45.6g polyimide, the polyimide Using the thermosetting polyimide resin powder shown in Table 1, 66g diamond with a particle size of M1 / 2, 67.2g silicon carbide with a particle size of M0 / 1, 4.8g polytetrafluoroethylene (PTFE) with a particle size ≤10μm, 33.6g of cerium oxide with particle size ≤10μm.

[0051] The preparation method of the fine grinding super-hard grinding wheel for micro-drilling includes the following steps:

[0052] 1) Weigh the binder thermoplastic polyamide resin powder PA1012 and thermosetting polyimide resin powder, abrasive diamond powder, silicon carbide powder, and cerium oxide powder according to the above weight; mix the weighed raw materials, stir evenly, and grind and mix for 35 minutes. Then sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com