Machining technological method of steel wire cutter

A processing technology and wire cutter technology, which is applied in metal processing and other directions to achieve the effects of high processing accuracy, strong practicability, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments of the accompanying drawings.

[0025] Such as Figure 1-7 Shown, a kind of processing technology method of steel wire cutter, comprises the following steps:

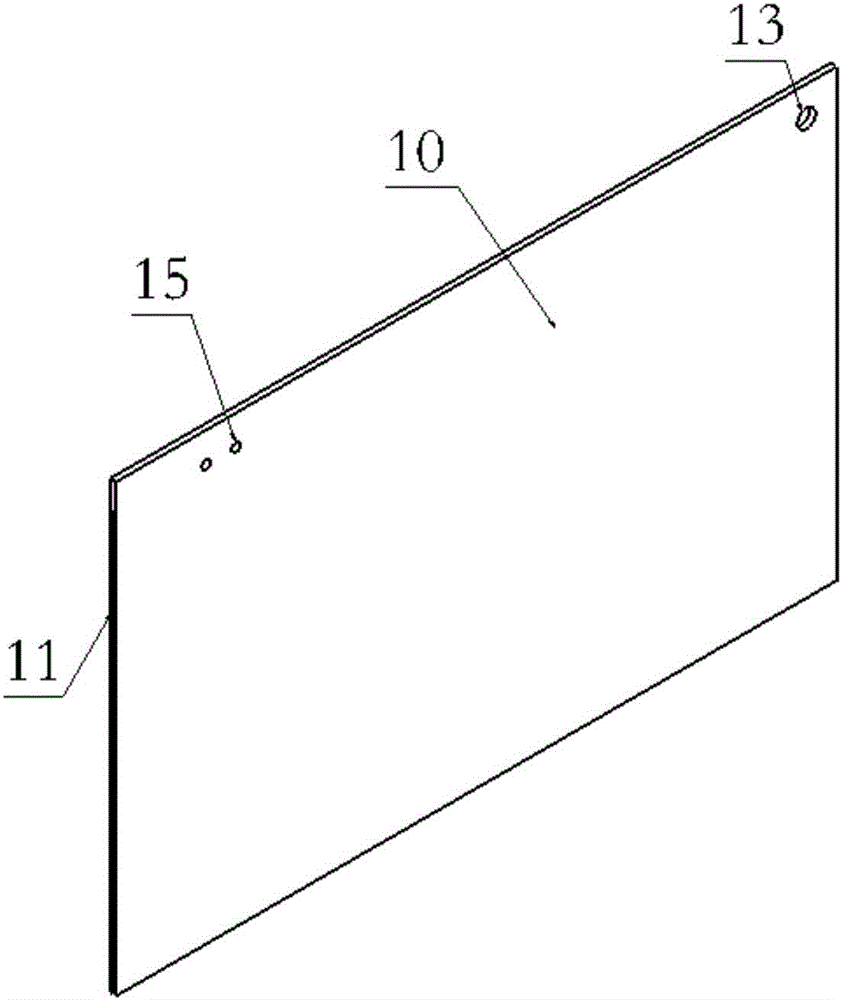

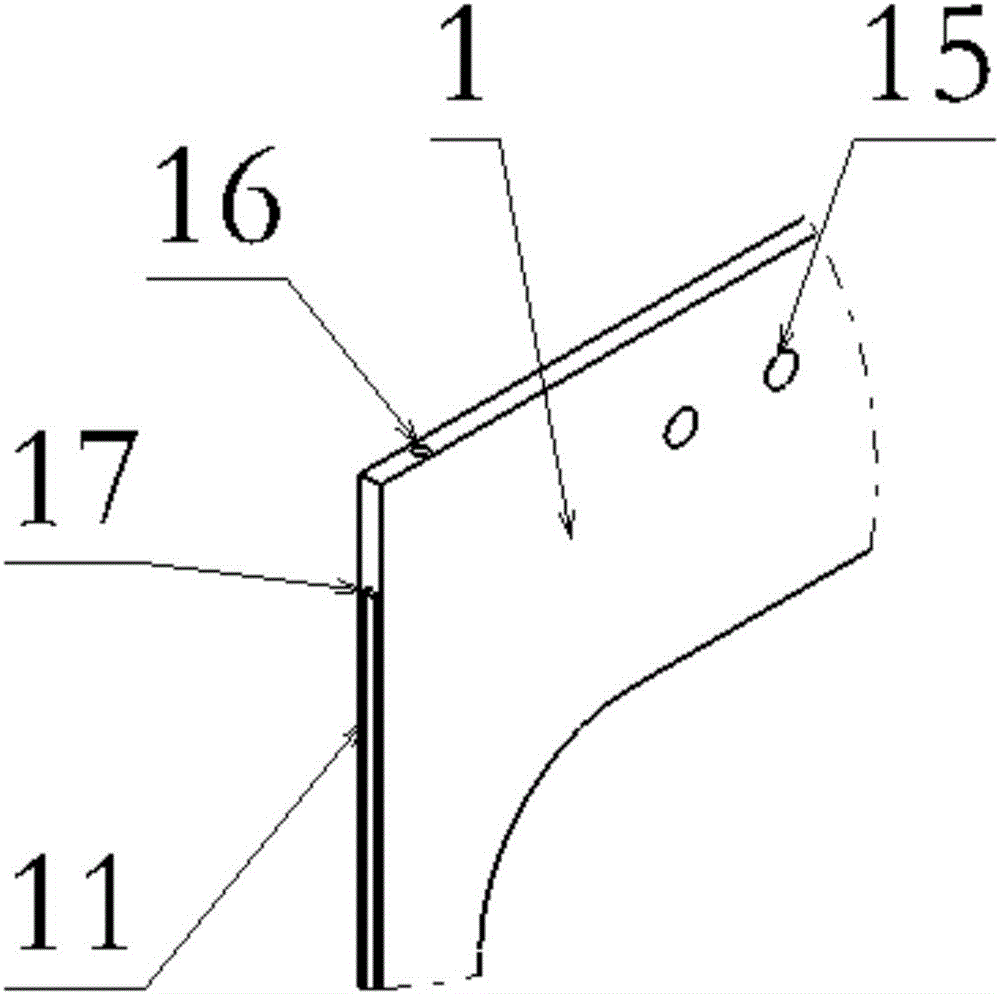

[0026] S1) Perform quenching and tempering treatment on the rectangular blank 10, and drill a hole 13 on the side of the blank 10 close to the upper end after cooling, and drill a hole 15 on the other side of the blank 10 close to the upper end;

[0027] S2) Grooving the two sides of the blank 10 and the ground with a V-shaped grinding wheel, the side wire groove 11 is obtained on the side surface, and the bottom wire groove 12 is obtained on the bottom surface;

[0028] S3) EDM machining the thread-stopping hole 18 on the keyhole 13;

[0029] S4) The vertical threading hole 16 on the upper bottom surface and the horizontal threading hole 17 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com