Electronic levelling staff with levelling indication

An electronic level and ruler technology, which is applied in the direction of measuring rulers, movable marks, measuring point marks, etc., can solve the problems of discoloration of the marking edge, easy to accumulate dirt, high cost, etc., achieve high definition, solve processing technology problems, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

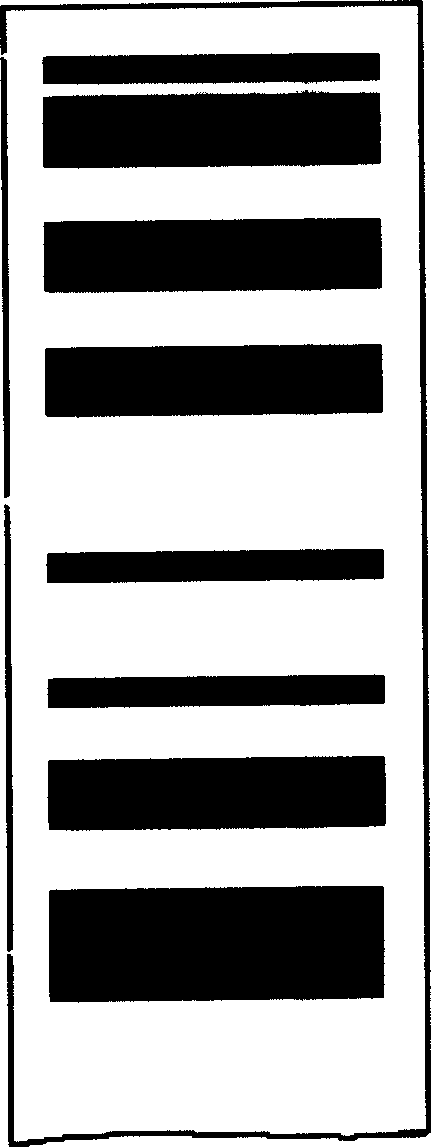

[0024] detailed description: figure 1 A schematic diagram of the leveling staff used by the electronic level is given. The barcode on the scale is designed as black and white or yellow and black stripes, and all stripes are integer multiples of the thinnest stripe.

[0025] Such as figure 2 As shown, in order to realize the production by spraying process figure 1 An electronic level gauge, which at least includes processing a strip 1 with a length and width similar to the scale to be processed, and the strip 1 is wider than the leveling scale pattern part, figure 2 Band 1 that fits the fabrication template is given.

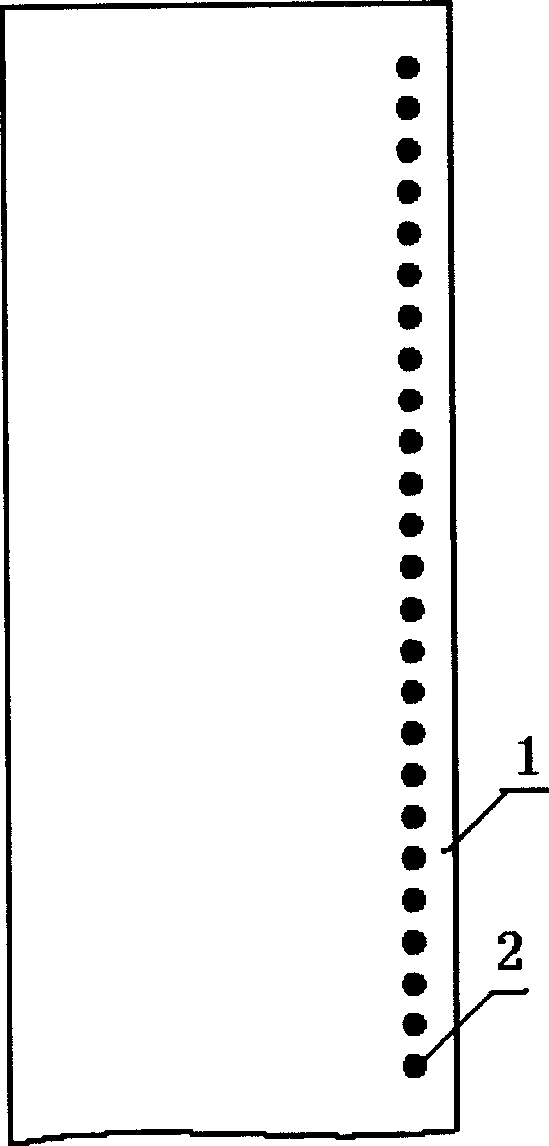

[0026] image 3 On the strip 1, the positioning marks 2 are firstly arranged at a certain period, and the positioning marks 2 can be discs or square discs, which play a positioning role. The center distance between two positioning marks is 2.025mm. Then the positioning mark 2 is drilled to form a positioning hole 4, as shown in FIG. 4 .

[0027] Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com